Combined SBR-Carrousel oxidation ditch high-efficiency denitrification process

An oxidation ditch and composite technology, applied in the field of high-efficiency denitrification process and denitrification process, can solve the problems that the stability of sludge is not as good as that of anaerobic digestion, the effect of denitrification and phosphorus removal is not too high, and the requirements for self-control are high, so as to achieve nitrification Enhanced denitrification effect, saving pipes, and enhanced denitrification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

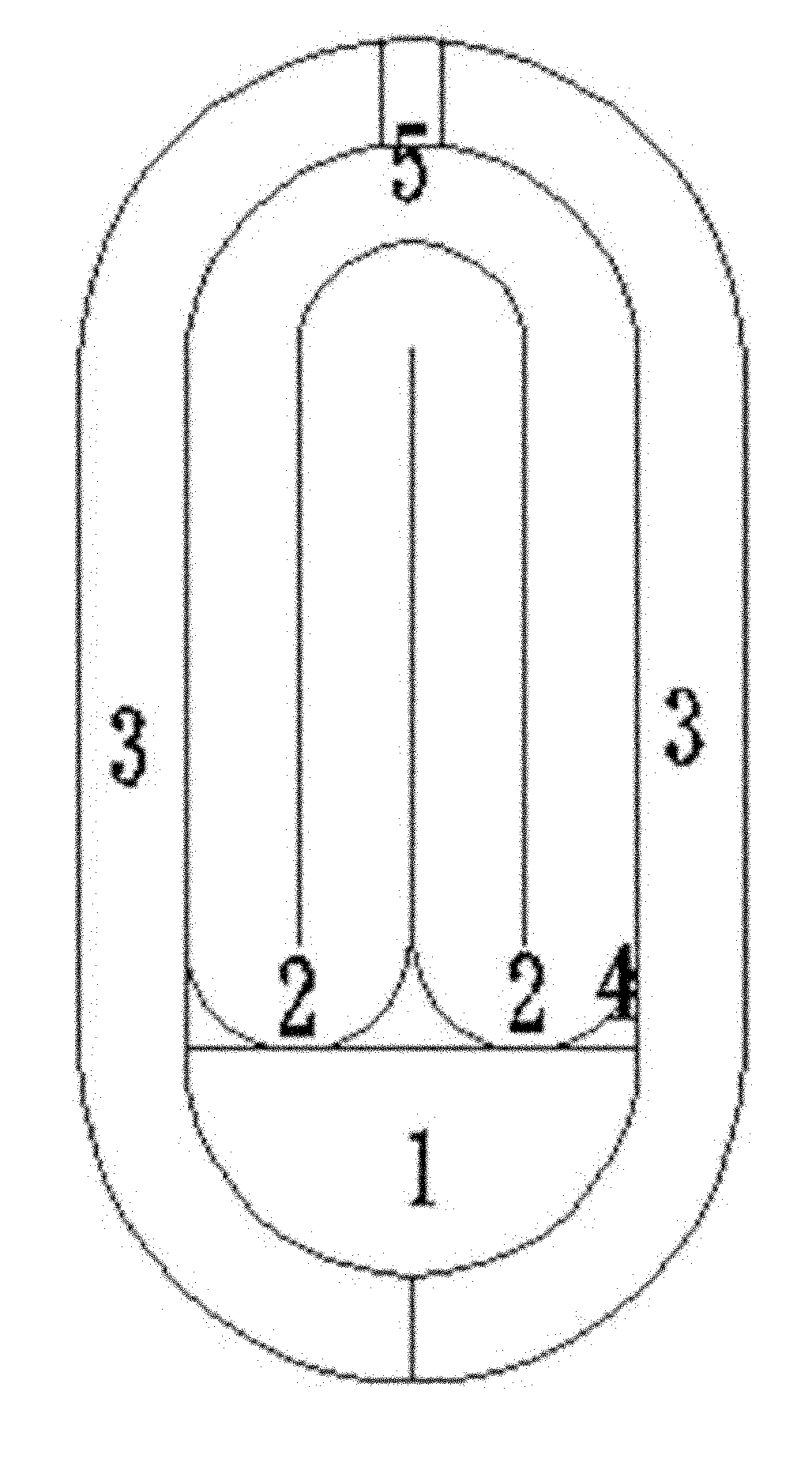

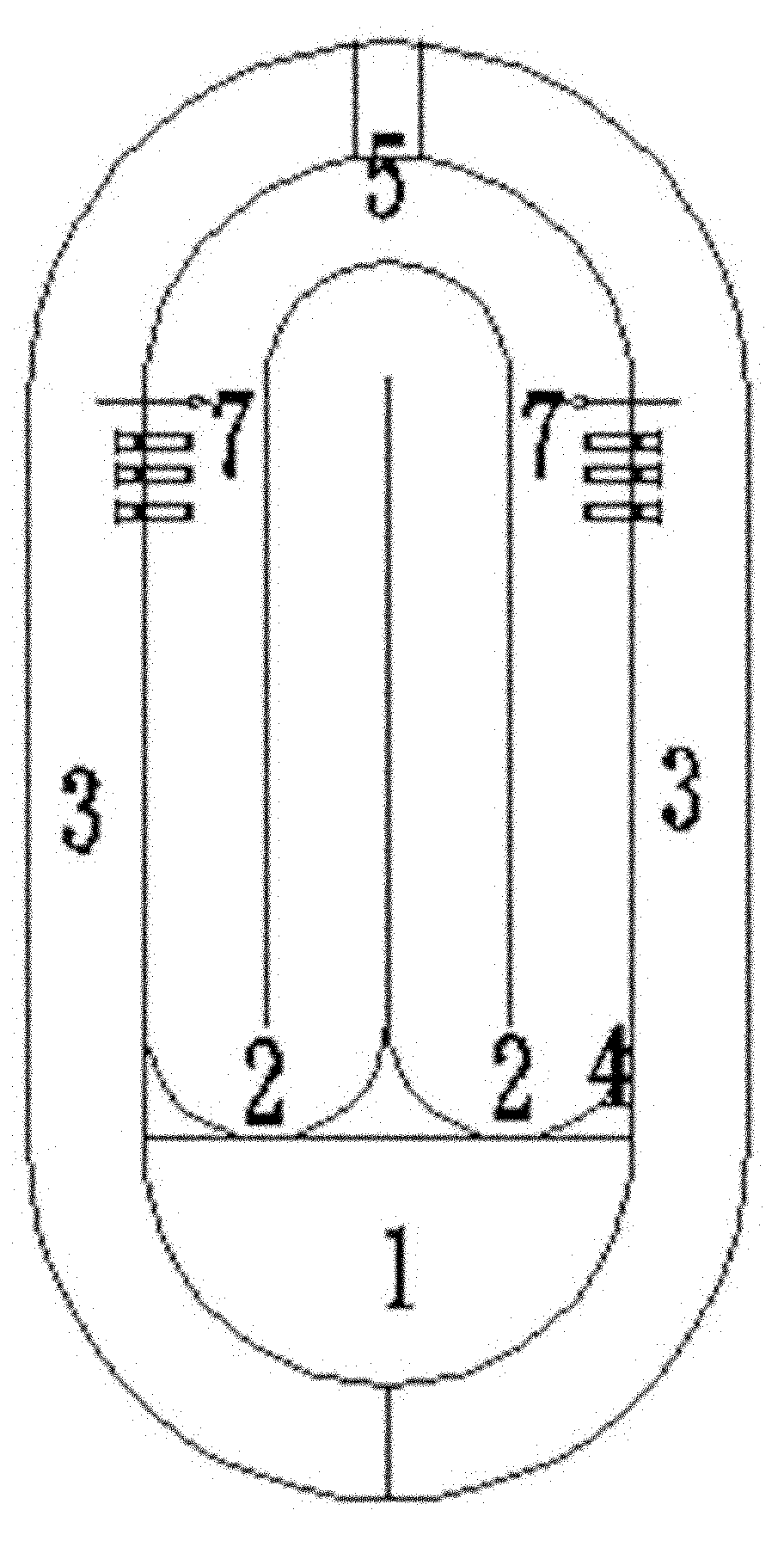

[0023] The main innovation of the present invention is that the Carrousel oxidation ditch and SBR are organically combined, which not only utilizes their respective denitrification functions, strengthens the denitrification effect, but also utilizes the characteristics of SBR that does not require a secondary sedimentation tank, saving civil engineering and reducing occupation. land area. The specific implementation method is as follows: the composite SBR-Carrousel oxidation ditch high-efficiency denitrification process includes an oval Carrousel oxidation ditch and an SBR pool, and an anoxic zone is set at the top of the Carrousel oxidation ditch aerobic zone. Make full use of the tank volume; two SBR tanks are respectively set on both sides of the Carrousel oxidation ditch, and share the outer tank wall with them; the two SBR tanks operate alternately, which can not only achieve enhanced denitrification, but also realize mud-water separation, as a secondary sedimentation tank...

Embodiment 1

[0026] Example 1, the composite SBR-Carrousel oxidation ditch high-efficiency denitrification process, including the Carrousel oxidation ditch (including anoxic zone 1 and aerobic zone 2) and SBR pool 3, the Carrousel oxidation ditch oval One end of the shaped pool body is the anoxic zone 1, and the other part is divided into two corridors, an elliptical aerobic zone 2, and the SBR pool 3 shares the outer walls of the anoxic zone 1 and the aerobic zone 2 of the Carrousel oxidation ditch, and is set as Symmetrical two sets of SBR pools3. A regulating gate 4 is set between the anoxic pool and the aerobic pool in the Carrousel oxidation ditch to form an internal backflow, and the backflow is controlled by the opening degree of the regulating gate. A regulating weir gate 5 is set between the Carrousel oxidation ditch and the SBR tank.

Embodiment 2

[0027] Example 2, composite SBR-Carrousel oxidation ditch high-efficiency denitrification process, including Carrousel oxidation ditch (including anoxic zone 1 and aerobic zone 2) and SBR pool 3, Carrousel oxidation ditch oval One end of the shaped pool body is the anoxic zone 1, and the other part is divided into two corridors, an elliptical aerobic zone 2, and the SBR pool 3 shares the outer walls of the anoxic zone 1 and the aerobic zone 2 of the Carrousel oxidation ditch, and is set as Symmetrical two sets of SBR pools3. A regulating gate 4 is set between the anoxic pool and the aerobic pool in the Carrousel oxidation ditch to form an internal backflow, and the backflow is controlled by the opening degree of the regulating gate. A regulating weir gate 5 is set between the Carrousel oxidation ditch and the SBR tank. The underwater pusher 6 is set in the aerobic zone of the Carrousel oxidation ditch.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com