A method for preparing biological flocculant by using biological iron-calcium slag in biological heap leaching

A bio-flocculant and bio-iron technology, which is applied in separation methods, chemical instruments and methods, flocculation/sedimentation water/sewage treatment, etc., can solve the problems of failure to meet the standards of bio-flocculants, reduced leaching speed and leaching rate, and difficult microbial Problems such as survival and reproduction can be achieved to reduce environmental risks and pressures, reduce the amount of sulfuric acid, and destroy stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

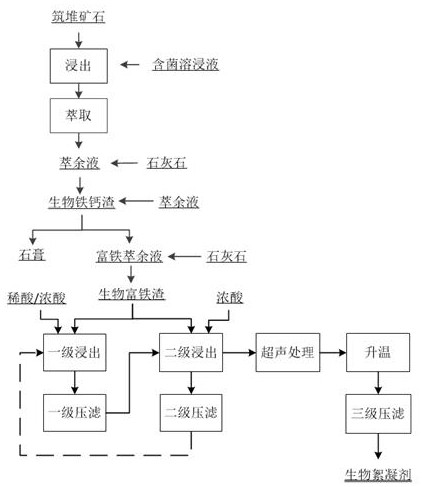

Image

Examples

Embodiment 1

[0028] In this example, the raw material is biological iron-calcium slag from a mining company in Fujian. The biological iron-calcium slag contains 5.4% iron, 10.1% calcium, 64.4% moisture, and a mass ratio of iron to calcium of 1:1.87. The leaching process and leaching effect as follows:

[0029] (1) Iron-calcium pre-separation: Stir the biological iron-calcium slag and raffinate at a solid-to-liquid ratio of 1:1 (kg: liter), at a speed of 60 r / min, and for a stirring time of 120 minutes, to obtain gypsum slag and rich Iron raffinate. Limestone is added to the iron-rich raffinate for neutralization to obtain gypsum slag and biological iron-rich slag. The water content in the biological iron-rich slag is 66%, the iron content is 10%, the calcium content is 4.5%, and the mass ratio of iron to calcium is 2.2:1.

[0030] (2) Leaching pretreatment: dry and pulverize the biological iron-rich slag, and then perform primary leaching.

[0031] (3) Primary leaching: put biological i...

Embodiment 2

[0035] In this example, the raw material is biological iron-calcium slag from a mining company in Jiangxi. The biological iron-calcium slag contains 3.7% iron, 10.8% calcium, 68.1% water content, and a mass ratio of iron to calcium of 1:2.91. The leaching process and leaching effect as follows:

[0036](1) Pre-separation of iron-calcium: Stir the biological iron-calcium slag and raffinate at a solid-to-liquid ratio of 1:1 (kg: liter), at a rotation speed of 80 r / min, for a stirring time of 160 minutes, and obtain gypsum slag and rich Iron raffinate. Limestone is added to the iron-rich raffinate for neutralization to obtain gypsum slag and biological iron-rich slag. The moisture content in the biological iron-rich slag is 61%, the iron content is 8.1%, the calcium content is 6.8%, and the mass ratio of iron to calcium is 1.19:1.

[0037] (2) Leaching pretreatment: dry and pulverize the biological iron-rich slag, and then add it to the leaching tank 1.

[0038] (3), primary l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com