A kind of alcohol production method based on comprehensive utilization of waste water

A production method and alcohol technology, applied in chemical instruments and methods, water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problem of high conductivity of mixing water, scaling of pipes and production equipment, and high osmotic pressure of alcohol. Yeast and other problems, to achieve the effect of eliminating bacterial pollution, environmental protection and economic benefits, and reducing the amount of addition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

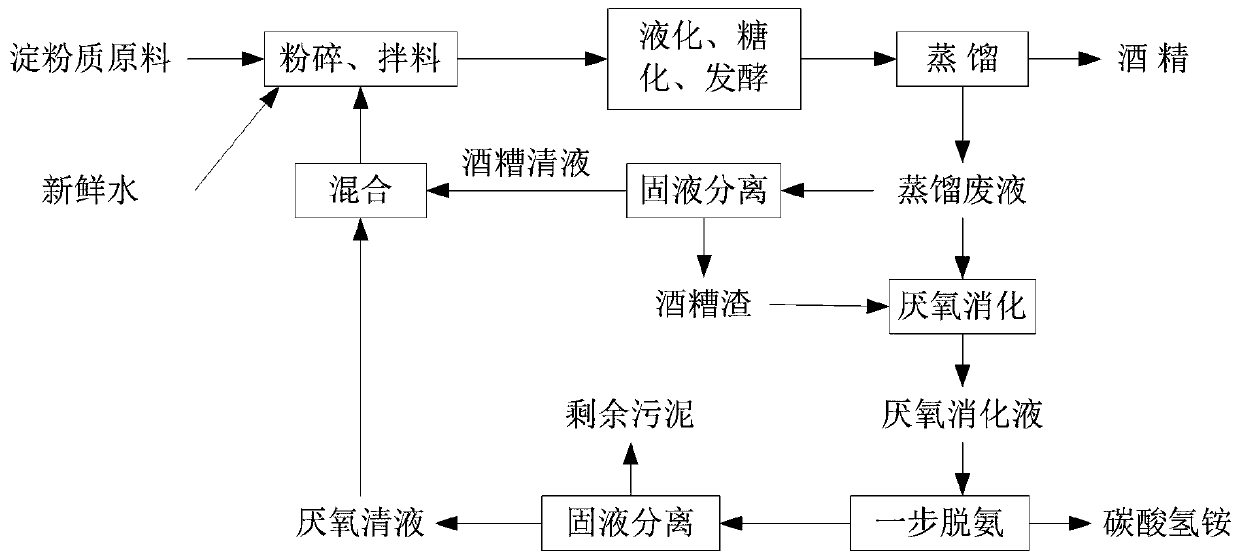

Method used

Image

Examples

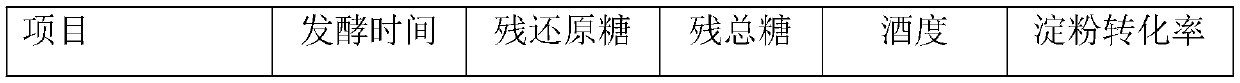

Embodiment 1

[0039] Using cassava as raw material, 80% anaerobic clear liquid and 20% vinasse clear liquid are mixed as mixing water, the ratio of material to water is 1:3, the ammonia nitrogen concentration after mixing is 240mg / L, and the pH of the slurry after mixing is 5.6; Add 10U / g starch commercial liquefaction enzyme to the powder slurry, increase the heating temperature to 95℃ and maintain 100min; after liquefaction, cool down to 60℃, add 150U / g starch commercial saccharification enzyme, saccharify 15min, then cool to 30℃ ; 15% yeast seed liquid is added to the cooled saccharification liquid to start fermentation, and the fermentation time is 48 hours; after the fermentation is completed, the finished alcohol and distillation waste liquid are obtained through distillation; part of the distillation waste liquid is centrifuged to obtain the vinasse clear liquid And back to step (1), the vinasse discharged from the centrifuge is incorporated into the remaining distillation waste liquid...

Embodiment 2

[0046] Using corn as raw material, 60% anaerobic clear liquid and 40% vinasse clear liquid are mixed and used as mixing water. After mixing, the ammonia nitrogen concentration is 100mg / L, and the pH of the slurry after mixing is 5.0; adding 20U / to the slurry g starch liquefaction enzyme, heated to 105°C and liquefaction for 60min; after liquefaction, the temperature is reduced to 58°C, 200U / g starch commercial saccharification enzyme is added, and then the temperature is lowered to 28°C; the saccharification solution is inserted into the saccharification solution volume 8% yeast The seed liquor begins to ferment; after the fermentation, alcohol and distillation waste liquid are obtained through distillation; part of the distillation waste liquid is filtered through plate and frame to obtain vinasse clear liquid and return to step (1), the vinasse and remaining residues discharged from the plate and frame filter press Distillation waste liquid enters anaerobic digestion treatmen...

Embodiment 3

[0052] Using cassava and corn mixture as raw materials, 99% anaerobic clear liquid and 1% vinasse clear liquid are mixed as the mixing water, and the ammonia nitrogen concentration after mixing is 400mg / L; after mixing, a small amount of sulfuric acid is added to adjust the pH of the slurry to 6.0 , Then add 5U / g starch liquefaction enzyme and liquefy at 80°C for 120min; quickly cool the liquefied mash to 65°C, then add 80U / g starch saccharification enzyme, saccharify for 60 minutes, and cool to 32°C after saccharification; add 22% of the saccharification solution volume The yeast seed liquid starts fermentation. After fermentation, alcohol and distillation waste liquid are obtained through distillation; part of the distillation waste liquid is filtered through plate and frame to obtain vinasse clear liquid and returns to step (1). The remaining distillation waste liquid and the distiller’s dregs obtained by plate and frame pressure filter all enter the waste Oxygen digestion t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical oxygen demand (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com