Circulating graded leaching method of stone coal acid-leaching vanadium extraction sulfuric acid

A stone coal acid and leaching technology, which is applied in the direction of improving process efficiency, can solve problems such as increasing costs, and achieve the effect of reducing the amount of sulfuric acid and reducing the concentration of residual acid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

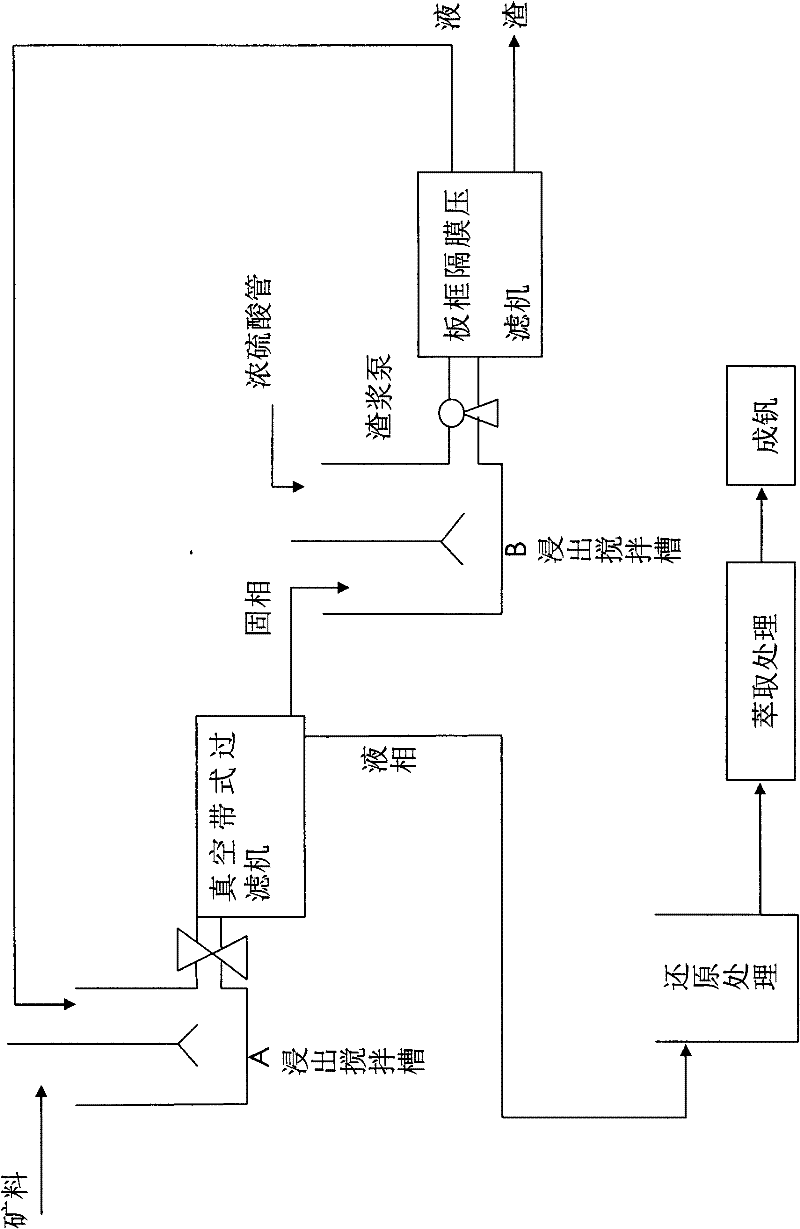

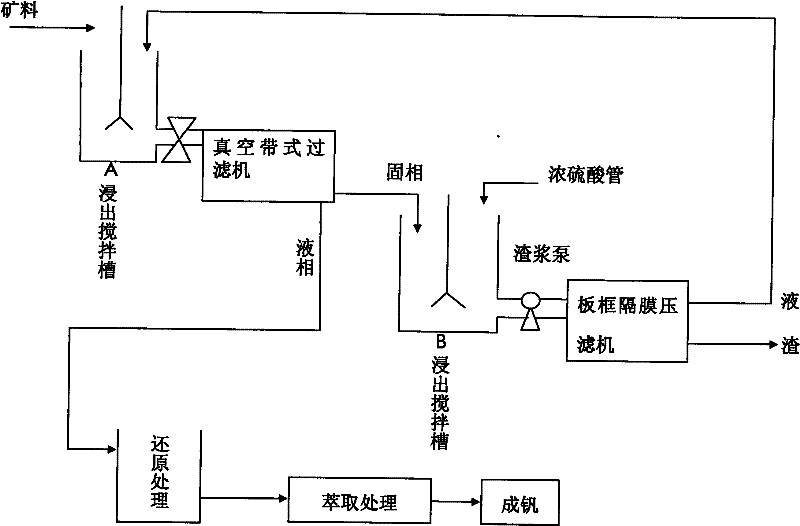

[0007] Minerals are heated to 90-120°C with a vanadium-containing sulfuric acid solution of 1.3-1.5 molar concentration at a liquid-solid ratio of 0.35:0.65 in A leaching stirring tank, and soaked for 8-12 hours. The occurrence of sulfuric acid and minerals is shallow , Higher valence vanadium oxide reacts to generate tetravalent vanadium oxide, sulfate and water, tetravalent vanadium dissolves into the acid solution, at the same time, the hydrogen ion in the solution is greatly reduced, and the acidity of the solution is reduced to 0.2 moles. When the pH value is 2.5, the solid-liquid separation is carried out by a vacuum belt filter, and the liquid phase (also known as A leachate) is directly sent to the subsequent process for reduction and extraction; the solid phase enters the B leaching stirring tank, and the liquid-solid ratio is 0.35:0.65. The concentrated sulfuric acid solution with 3 molar concentration is heated to 90-120°C and soaked for 24-44 hours. More than 90% of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com