Method for pretreating ethyl alcohol produced from corn straws

A corn stalk and pretreatment technology, which is applied in the direction of biofuel and fermentation, can solve the problems of long microbial fermentation cycle, low efficiency, and inability to industrial production, and achieve high pretreatment effect, reduce production cost, and increase sugar production rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Raw material selection: the corn stalk used in the present invention is taken from the northeast region of my country.

[0026] 1. Instrument:

[0027] Plant grinder, precision electronic balance, muffle furnace, water bath, blast drying oven, circulating water vacuum pump, rapid moisture analyzer, electric heating plate, DR5000 spectrophotometer, Soxhlet extractor.

[0028] 2 Raw materials and processing:

[0029] Corn stalks are taken from Changchun, Jilin Province, my country, representative raw materials are randomly selected, mechanically crushed to 3-5 cm, and air-dried in a natural state until the moisture content is less than 10%. It is stored in a plastic bag under normal temperature and dry environment to balance the moisture, and is used for subsequent determination and analysis of the chemical composition of bagasse and pretreatment.

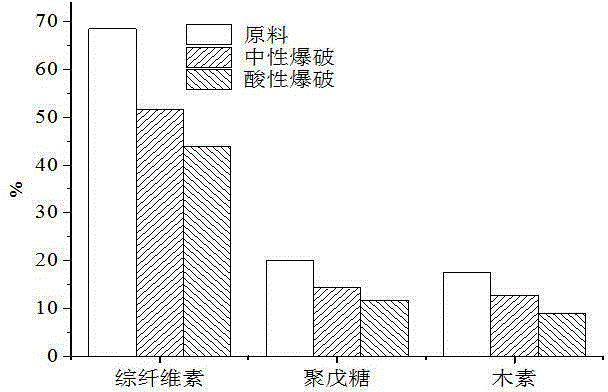

[0030] 3. Results:

[0031] The chemical composition analysis results of the corn stover of the variety are listed in Table 1 below.

...

Embodiment 2

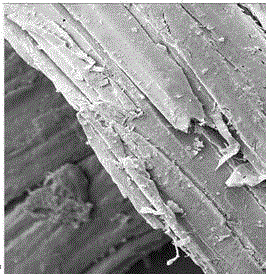

[0038] Neutral steam explosion pretreatment of corn stover

[0039] 1. Instrument:

[0040] Steam explosion device; Olympus BX51 biological microscope; Carl Zeiss EVO18 scanning electron microscope; IC 5000 ion chromatograph; Metso FS-300 automatic fiber analyzer; Micro Meritics ASAP2020 automatic specific surface area pore analyzer.

[0041] 2. Raw materials and processing:

[0042] The corn stalk powder obtained in Example 1 was balanced with moisture and subjected to neutral steam explosion pretreatment. After the hydrolysis reaction, the explosion sample and the hydrolysate were centrifuged, and the samples and hydrolysate were collected separately for subsequent analysis (see Table 2 for specific parameters) ); After processing, the blasted sample and the hydrolysate are centrifuged, the filtrate is used for the analysis of sugar components, and the substrate is placed in a sealed plastic bag to balance the moisture, and then used for the analysis yield. Then take a representati...

Embodiment 3

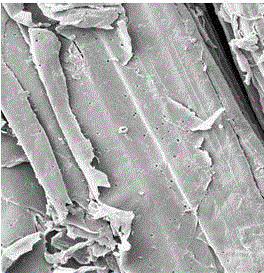

[0060] Pretreatment of Corn Stalk by Weak Acidic Medium Pressure Steam Explosion

[0061] 1. Instrument:

[0062] Steam explosion device; Olympus BX51 biological microscope; Carl Zeiss EVO18 scanning electron microscope; IC 5000 ion chromatograph; Metso FS-300 automatic fiber analyzer; Micro Meritics ASAP2020 automatic specific surface area pore analyzer.

[0063] 2. Raw material pretreatment:

[0064] The corn stalk powder obtained in Example 1 was balanced with moisture, water and acid were added, and the weak acid medium pressure steam explosion pretreatment was performed. After the hydrolysis reaction, the explosion sample and the hydrolysate were centrifuged to separate the samples and the hydrolysate for subsequent use For analysis (see Table 5 for parameters); after processing, centrifuge the blasted sample and the hydrolysate. The filtrate is used for the analysis of carbohydrate components, and the substrate is put into a sealed plastic bag to balance the moisture for analysi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com