Method for deep oxidation and harmless treatment of zinc sulfite slag for comprehensive recovery of valuable metal

A zinc sulfite, deep oxidation technology, applied in the direction of improving process efficiency, can solve the problems of lowering grade, high energy consumption, difficult to control uniformity, etc., to reduce production safety and environmental protection pressure, reduce safety and environmental protection pressure, reduce The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

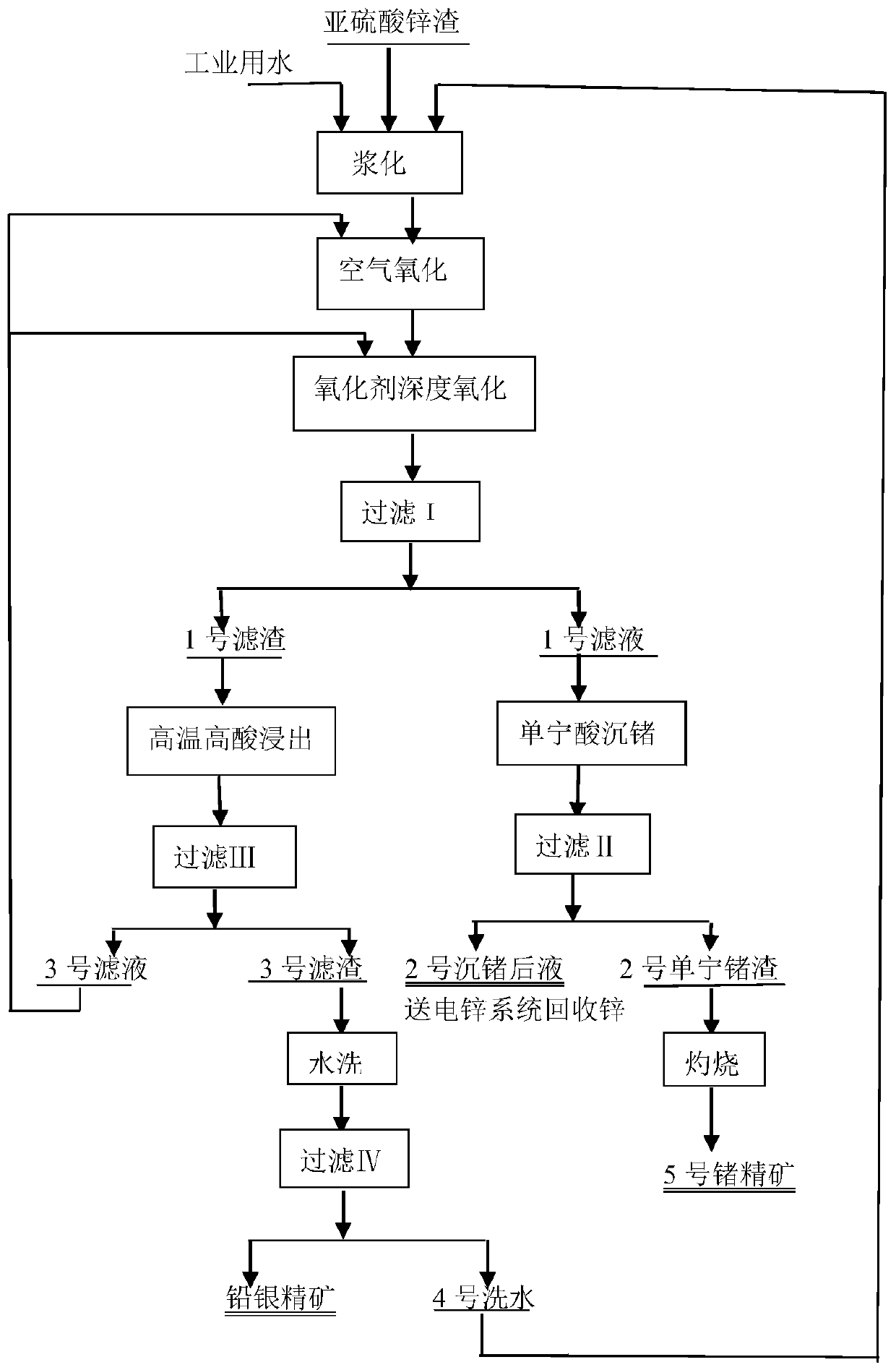

Method used

Image

Examples

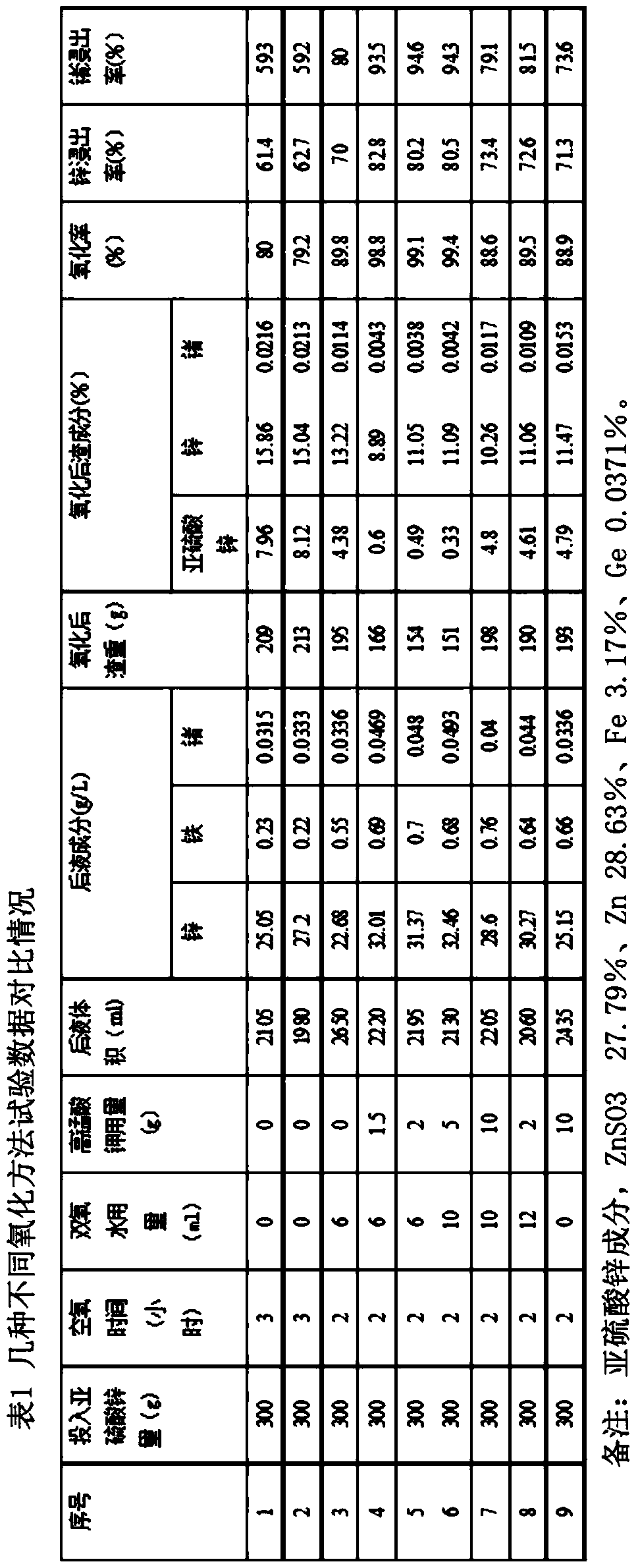

Embodiment 1

[0039] Get 15,000 grams of zinc sulfite slag produced by our company and dry it for use. The zinc sulfite slag contains 24.63wt% of zinc, 22.79wt% of zinc sulfite, 2.17wt% of iron, 0.0299wt% of germanium, 1.95wt% of lead, and 0.0056% of silver. wt%, moisture 9.5wt%.

[0040] 1) Slurrying of zinc sulfite slag: take 60 liters of industrial water, add 10,000 grams of zinc sulfite slag for slurrying, the slurrying time is 10 minutes, stir and slurry evenly before use.

[0041] 2) Oxidation of pulped pulp by air: the pulp after stirring and pulping is fed with compressed air in reverse, and the acidity is adjusted with 150g / l-200g / l sulfuric acid or acid-containing filtrate during the process, and the process pH is kept at 3.5-4.0 at room temperature Stirring, air oxidation for 2.0-2.5 hours. Obtain air oxidation liquid.

[0042] 3) Deep oxidation of oxidizing agent: After air oxidation, add 200 grams of hydrogen peroxide and 50 grams of potassium permanganate to the middle liqui...

Embodiment 2

[0052] Get 15,000 grams of zinc sulfite slag produced by our company and dry it for use by calculation. Silver 0.0026wt%, moisture 8.8wt%.

[0053] 1) Slurrying of zinc sulfite slag: take 65 liters of industrial water, add 10,000 grams of zinc sulfite slag for slurrying, the slurrying time is 10 minutes, stir and slurry evenly before use.

[0054] 2) Oxidation of pulped pulp by air: the pulp after stirring and pulping is fed with compressed air in reverse, and the acidity is adjusted with 150g / l-200g / l sulfuric acid or acid-containing filtrate during the process, and the process pH is kept at 3.5-4.0 at room temperature Stirring, air oxidation for 2.0-2.5 hours. Obtain air oxidation liquid.

[0055] 3) Deep oxidation of oxidant: add 300 grams of hydrogen peroxide and 70 grams of potassium permanganate to the liquid after air oxidation, adjust the acidity with 150 grams per liter of sulfuric acid or acid-containing filtrate, keep the process pH = 2.0-3.0, and then carry out d...

Embodiment 3

[0065] Get 15,000 grams of zinc sulfite slag produced by our company and dry it for later use. The zinc sulfite slag contains 32.56wt% of zinc, 29.89wt% of zinc sulfite, 4.35wt% of iron, 0.0338wt% of germanium, 3.35wt% of lead, and 0.0047wt% of silver. wt%, moisture 8.5wt%.

[0066] 1) Slurrying of zinc sulfite slag: take 70 liters of industrial water, add 10,000 grams of zinc sulfite slag for slurrying, the slurrying time is 10 minutes, stir and slurry evenly before use.

[0067] 2) Oxidation of pulped pulp by air: the pulp after stirring and pulping is fed with compressed air in reverse, and the acidity is adjusted with 150g / l-200g / l sulfuric acid or acid-containing filtrate during the process, and the process pH is kept at 3.5-4.0 at room temperature Stirring, air oxidation for 2.0-2.5 hours. Obtain air oxidation liquid.

[0068] 3) Deep oxidation of oxidant: add 400 grams of hydrogen peroxide and 100 grams of potassium permanganate to the liquid after air oxidation, adju...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxidation rate | aaaaa | aaaaa |

| oxidation rate | aaaaa | aaaaa |

| oxidation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com