Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

94results about How to "Realize harmless use" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Four-phase solid-liquid separation method for well drilling wastes

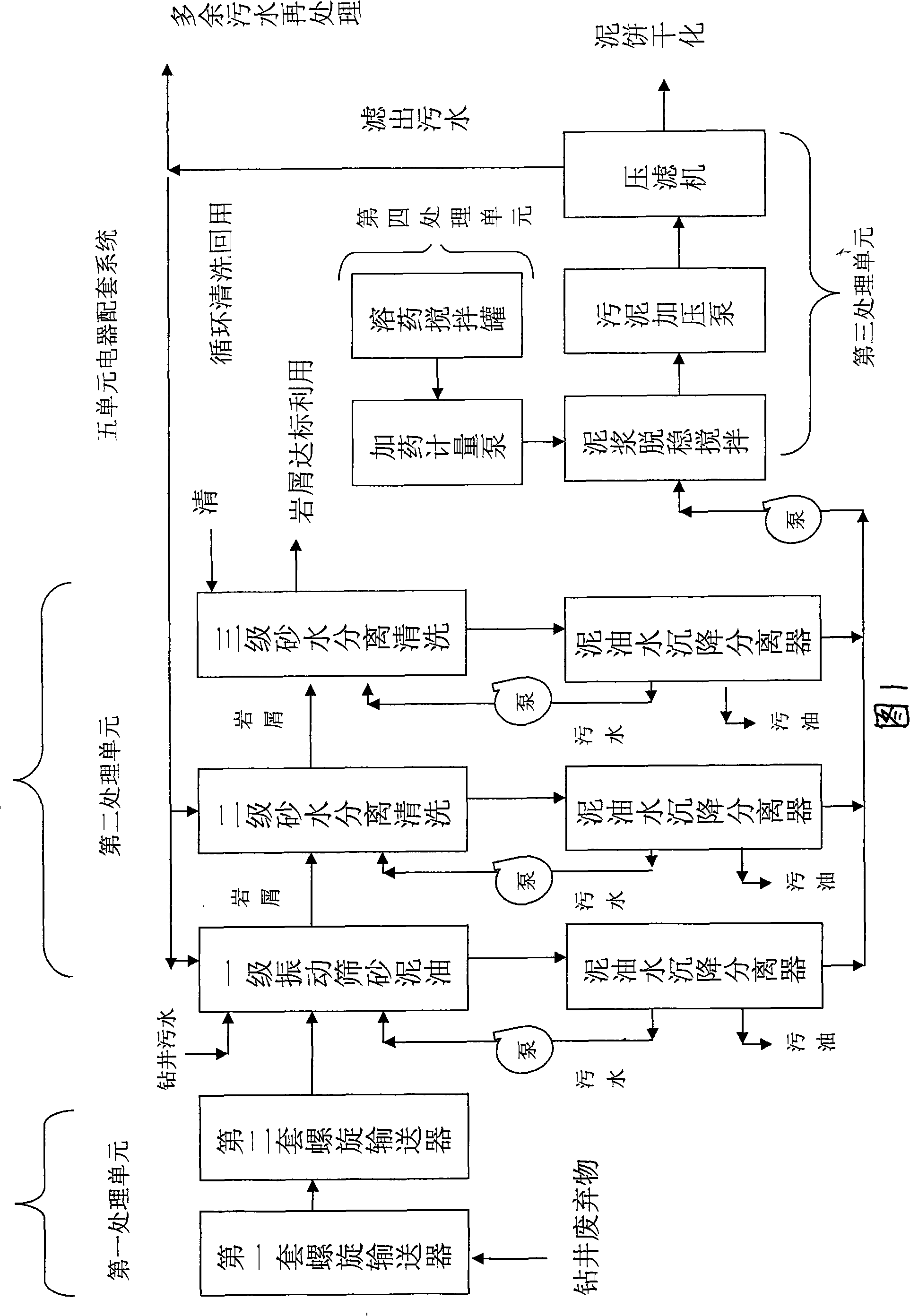

Disclosed is a technique method for the solid-liquid four-phase separation of well drilling wastes, which is a technique for realizing the four-phase separation of well drilling detritus, well drilling mud, well drilling sewage and dirty oil in the well drilling wastes, and the technique has the goal that the wastes do not fall to the ground while drilling when equipping the well drilling scene and in treatment, and has the technique principles that: detritus are separated out by washing, settled sludge is pressed into mud cakes, filtrate forms sewage and dirty oil floats upward and is discharged by automatic overflow sequentially according to different particle sizes and properties of particles of the well drilling wastes, then the four phases are separated for providing conditions for classification, retreatment and comprehensive utilization, thereby realizing the demand of environmental protection that the well drilling wastes do not fall to the ground.

Owner:PUYANG TIANDIREN ENVIRONMENTAL PROTECTION TECH CO LTD

Phosphogypsum purification and neutralization apparatus

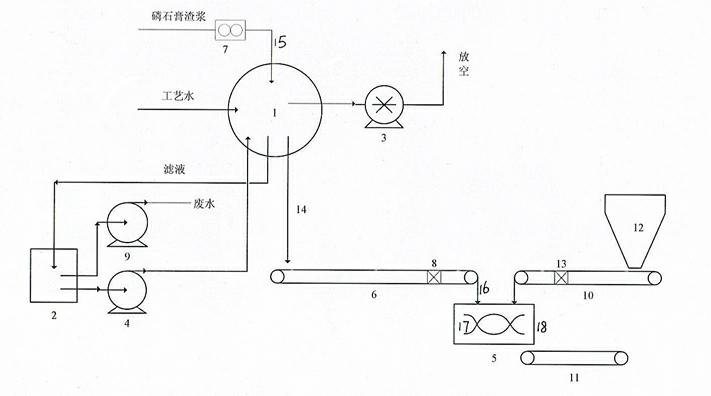

The present invention discloses a phosphogypsum purification and neutralization apparatus. The phosphogypsum purification and neutralization apparatus comprises a purification device and a neutralization device. The purification device comprises a phosphogypsum feeding pipeline (15), a turntable filter (1), a washing and cycling water tank (2), a vacuum pump (3), a wastewater conveying pump (9), a filter cloth regenerating and washing pump (4) and a material placing chute (14). The neutralization device comprises a material feeding chute (16), a drive device (17), a neutralizing and mixing stirrer (5) and a cylinder (18). The neutralizing and mixing stirrer (5) is connected with a lime bin (12) through a lime conveying belt, and is connected with the material placing chute (14) through a phosphogypsum material conveying belt (6). An outlet of the neutralizing and mixing stirrer (5) is connected with a phosphogypsum product conveying belt (11). With the present invention, the phosphogypsum produced through a wet-process phosphoric acid apparatus can be recovered and utilized so as to provide great economic benefits.

Owner:WENGFU (GRP) CO LTD

Iron tailing soil improvement agent and iron tailing soil improvement method

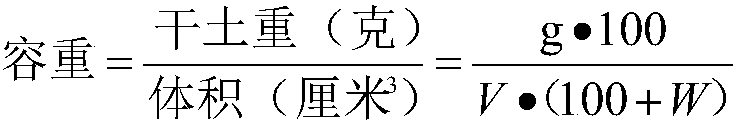

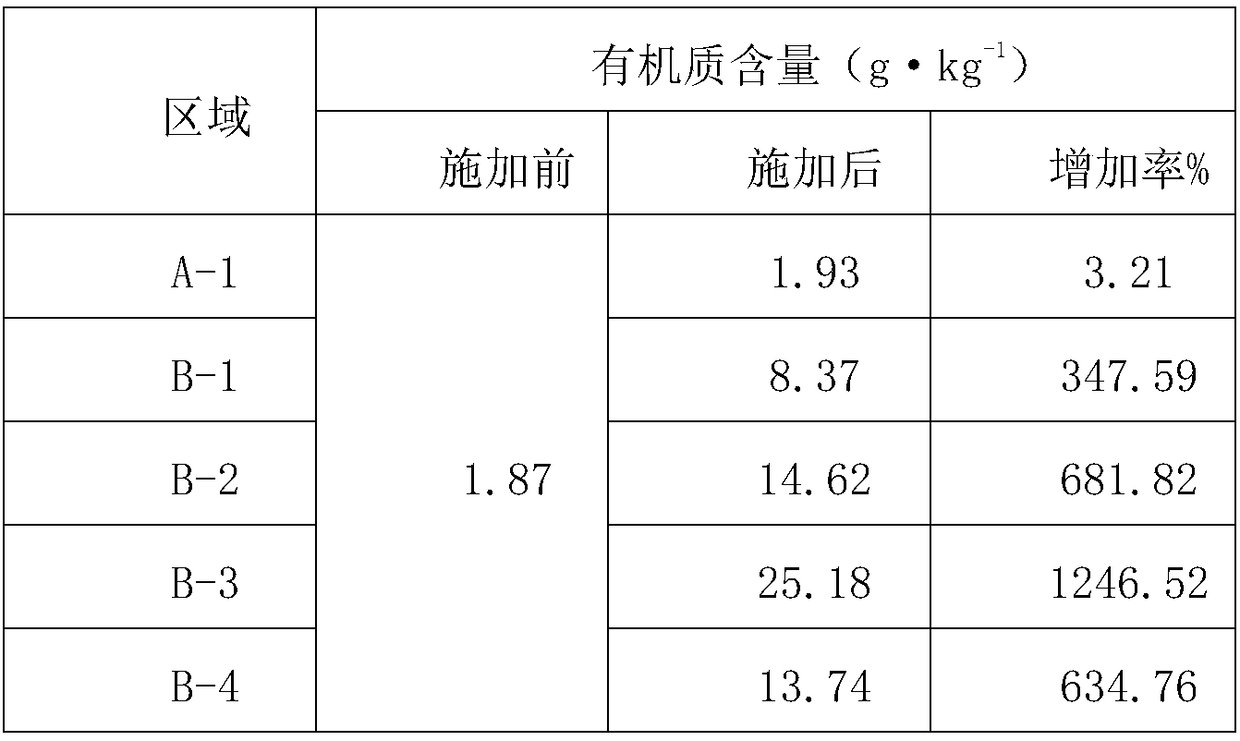

ActiveCN108795440AAdjustable pHMaintain pHAgriculture tools and machinesContaminated soil reclamationLoss ratePorosity

The invention relates to an iron tailing soil improvement agent and an iron tailing soil improvement method. The iron tailing soil improvement agent comprises biochar, rice husks, ceramsite, organic fertilizers, attapulgite powder and planting soil. A mass ratio of the biochar to the rice husks to the ceramsite to the organic fertilizers to the attapulgite powder to the planting soil is (0.5-3):(0.2-1):(0.5-1.5):(1-4):(1-2.5):(1.0-2.2). The iron tailing soil improvement agent and the iron tailing soil improvement method have the advantages that the particle size of soil can be improved by theaid of the iron tailing soil improvement agent, the loss rate of water in the soil can be eased, the water retention capacity can be enhanced, organic matters can be quickly and effectively supplemented, the content of organic matters in tailing can be effectively increased, and suitable environments can be provided for plant growth; the rice husks and the ceramsite are matched with one another, the porosity of iron tailing soil can be improved, the hardening degree of the soil can be lowered, the tailing soil can keep in excellent gas-permeable and soft states for a long term, accordingly, the iron tailing soil improvement agent and the iron tailing soil improvement method are favorable for respiration of animals and plants in the soil, and the survival rate can be increased.

Owner:SHANDONG UNIV

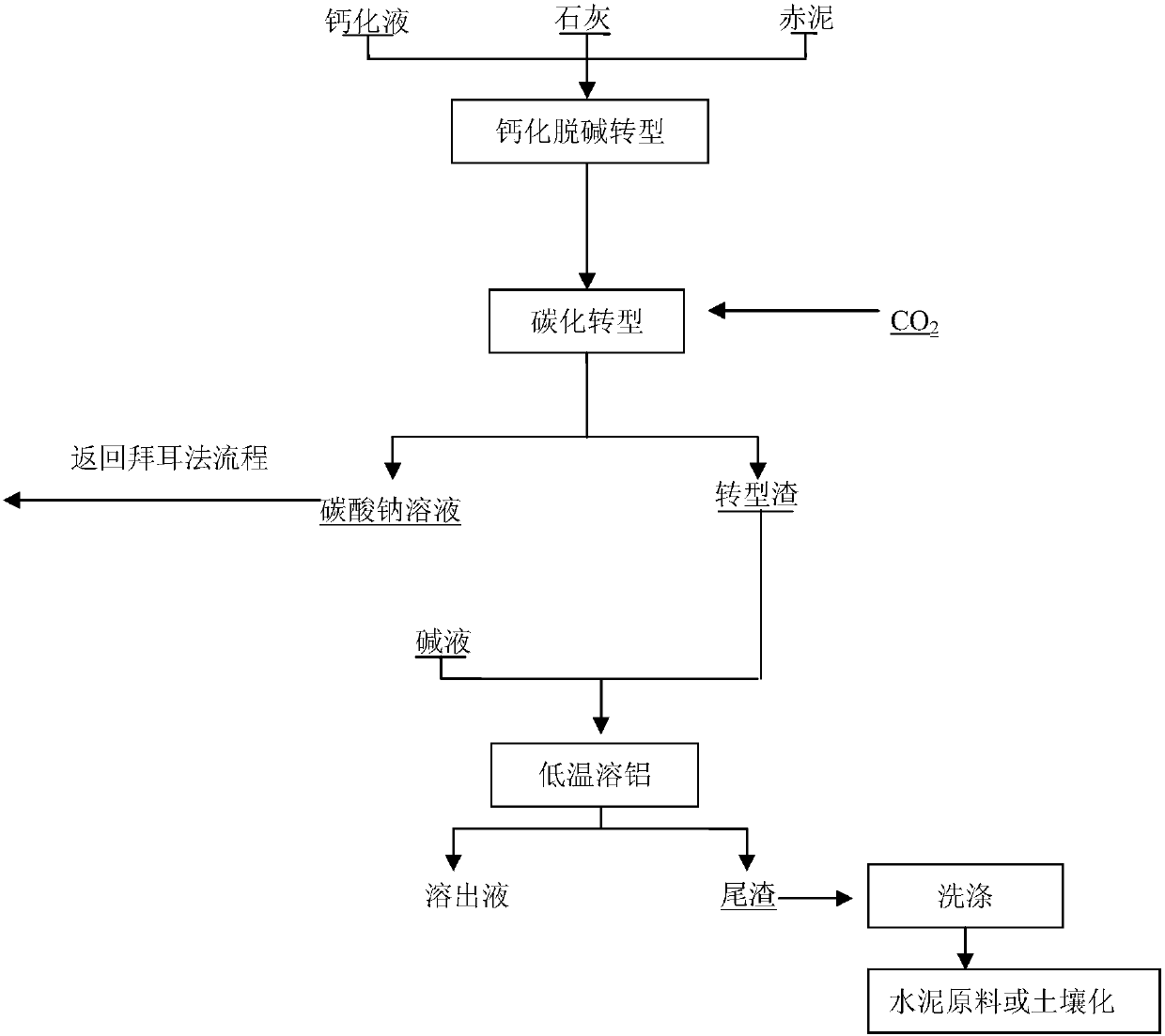

Method for recycling alkali and aluminum in process of treating bayer red mud by calcification-carbonization method

ActiveCN103934258APromote incomeReduce energy consumptionSolid waste disposalContaminated soil reclamationHigh concentrationRecovery method

The invention relates to the field of environment protection, and in particular relates to a method for recycling alkali and aluminum in a process of treating bayer red mud by a calcification-carbonization method. The method comprises the steps of mixing the bayer red mud with calcium aluminate or lime and the calcium aluminate to obtain a mixture, performing calcification dealkalization transformation on the mixture in high-concentration alkali liquid with the caustic alkali concentration being 100-300g / L, totally converting silicon-containing phases in the red mud into calcified slag generated in a dealkalization process in the form of hydrate garnet, carbonizing the calcified slag to obtain carbonized slag, then o carrying out low-temperature aluminum smelting and aluminum precipitation to obtain a calcium aluminate product, and recycling the calcium aluminate product in the red mud calcification dealkalization transformation process. Part of alkali and aluminum-containing liquid phases subjected to calcification dealkalization transformation can be reused as supplement alkali in a bayer production process. The method disclosed by the invention can realize recycling of alkali and aluminum in the red mud and harmless treatment of the bayer red mud, and is an energy-saving and environment-friendly red mud utilization method.

Owner:DONGDA NONFERROUS SOLID WASTE TECH RES INST LIAOLING CO LTD

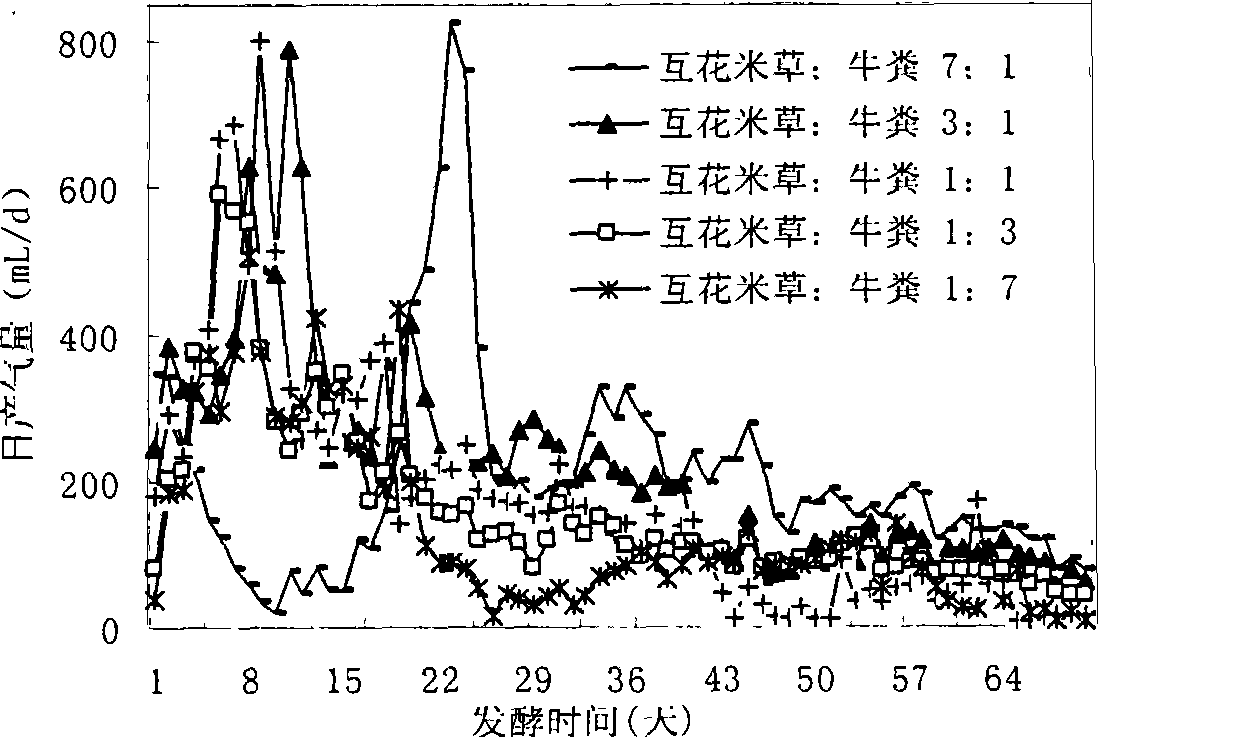

Method for producing methane from smooth cord-grass and cattle manure

InactiveCN101413015ASimple processStrong maneuverabilityWaste based fuelFermentationBiogasRenewable energy

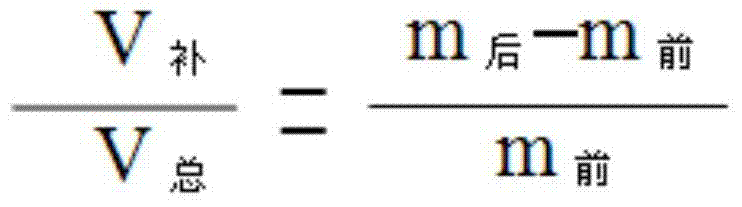

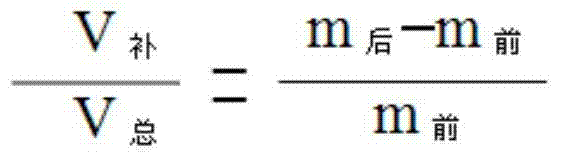

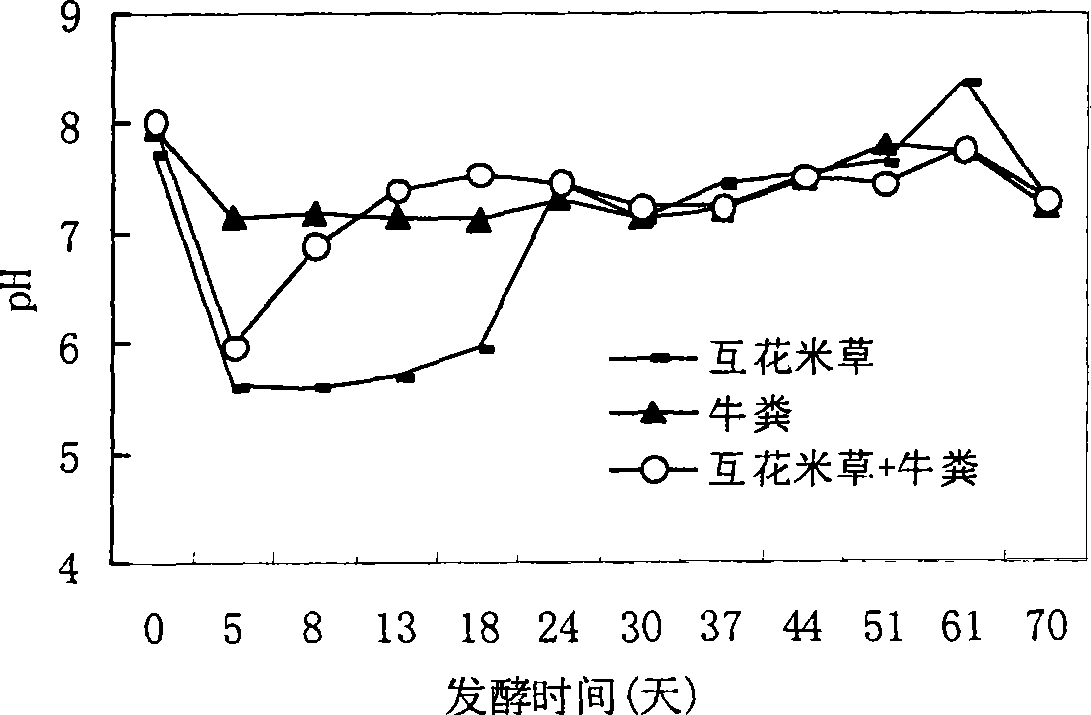

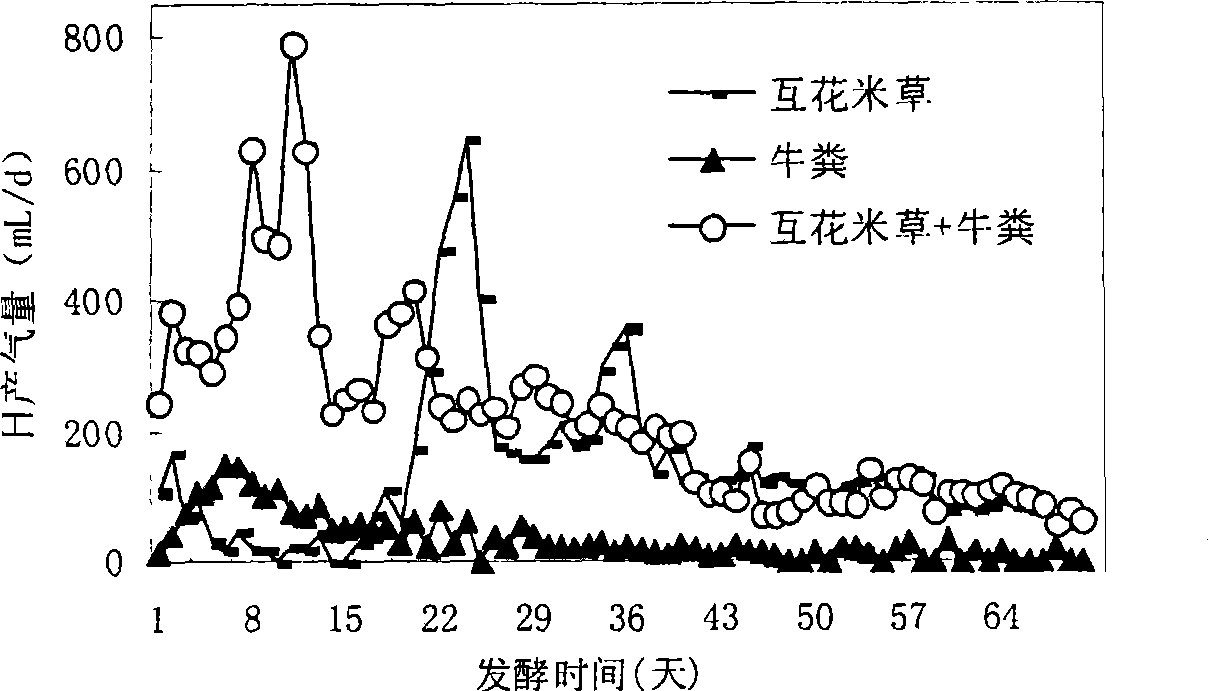

The invention belongs to the field of development and utilization of renewable energy sources and environmental protection, and discloses a method for producing biogas by utilizing the fermentation of smooth cord-grass and cattle dung. The method comprises the following steps: the smooth cord-grass and the cattle dung are mixed evenly according to the proper proportion and are grafted for anaerobic fermentation, and an inoculum is one or various of biogas residues of old biogas tanks, putrid river mud or anaerobic digestion sludge of city sewage treatment plants; and the temperature of an anaerobic fermentation reaction is controlled to 35+-2 DEG C, fermented objects are stirred during the fermentation process, and the biogas can be produced within 24 hours of the fermentation. The method has the advantages that the method has simple process and strong maneuverability, adopts mixed anaerobic digestion to produce the biogas, not only synchronously treats two kinds of organic solid wastes, but also improves the biological transformation rate of the smooth cord-grass, ensures that the biogas yield of unit smooth cord-grass can improve 31.60 percent at best, and realizes the resourceful, quantitative and innoxious utilization of the smooth cord-grass and the cattle dung.

Owner:NANJING UNIV

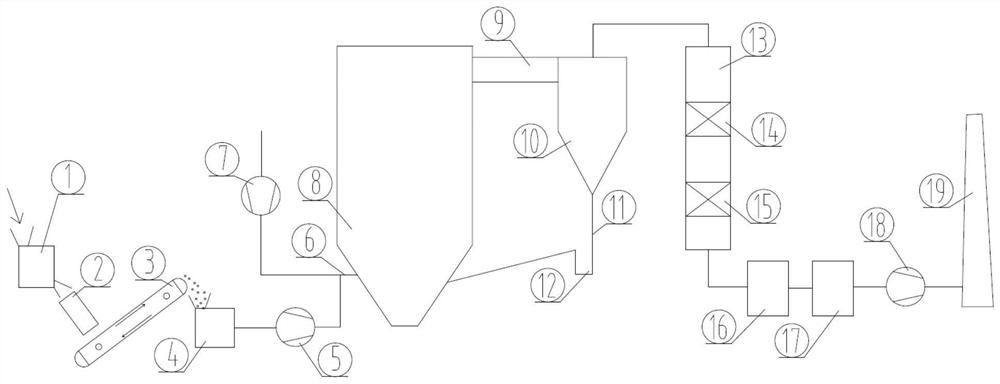

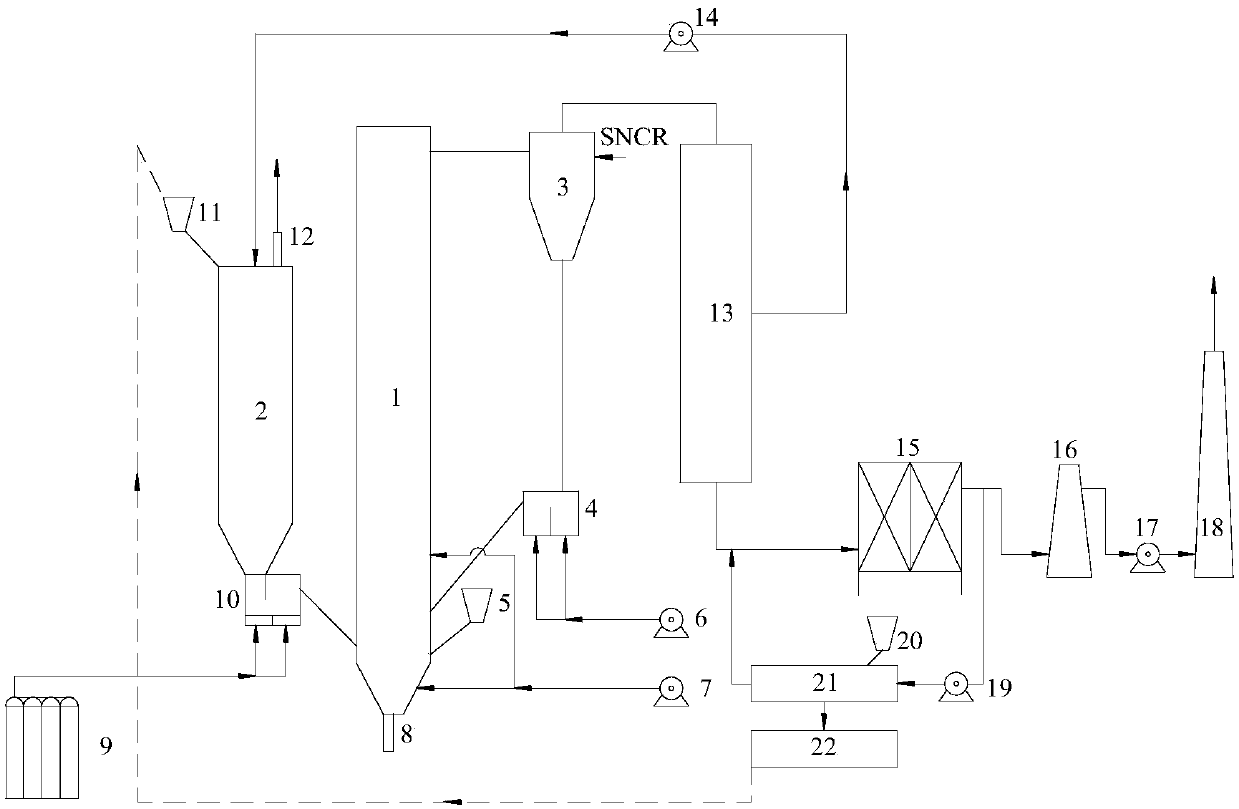

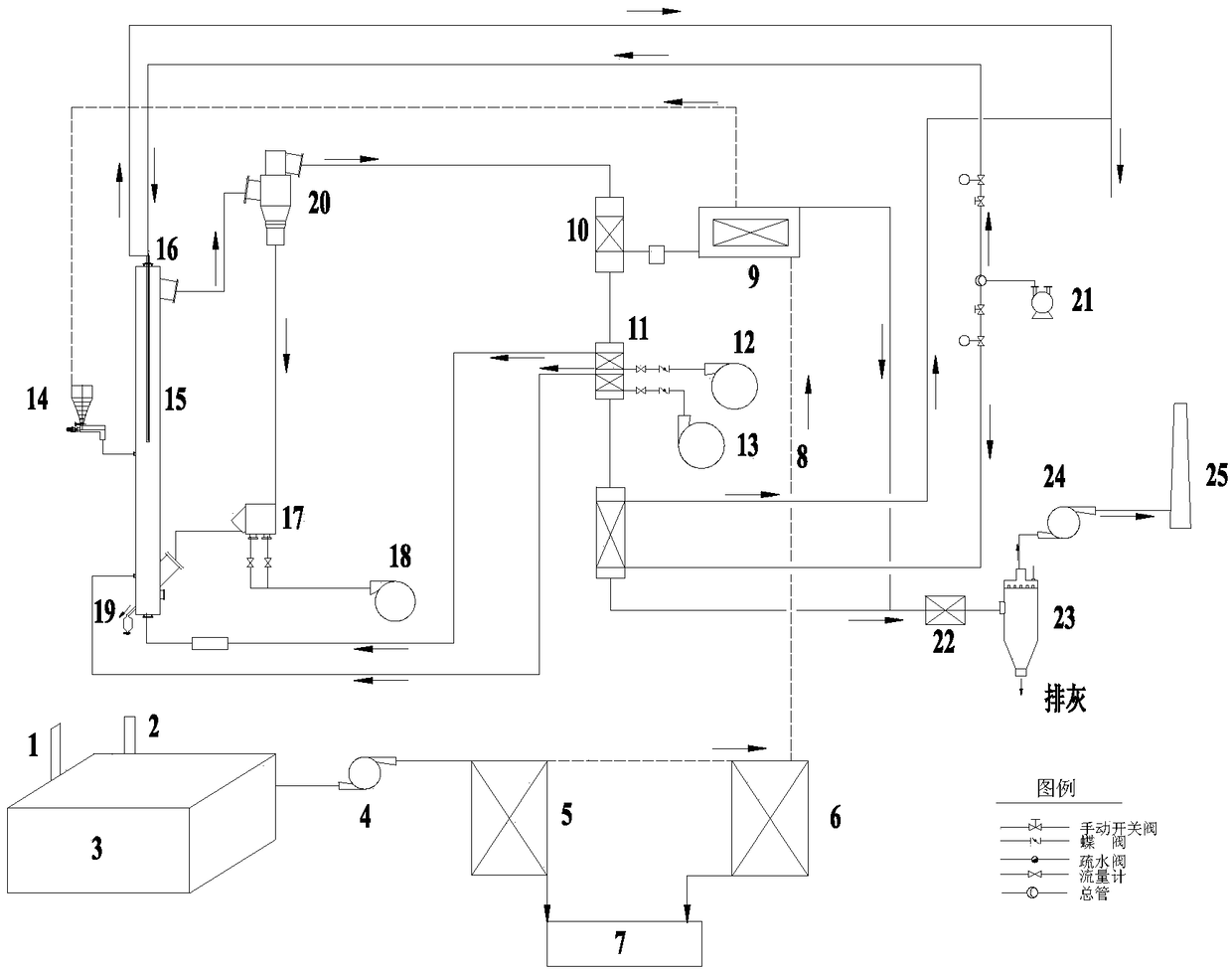

Circulating fluidized bed boiler system for incinerating waste blades and working method thereof

PendingCN112268284AImplement resourcesRealize harmless useIncinerator apparatusCombined combustion mitigationFlue gasFluidized bed

The invention discloses a circulating fluidized bed boiler system for incinerating waste blades and a working method thereof, and belongs to the technical field of fluidized bed boilers. A secondary air port of a circulating fluidized bed boiler is connected with a secondary fan through a secondary air pipeline; a crushing device is connected with an iron removing device, the iron removing deviceis connected with a conveying device, the conveying device is connected with a crushing device, the crushing device is connected with the secondary air pipeline through a conveying pipeline, and a first induced draft fan is arranged on the conveying pipeline; a flue gas outlet of the circulating fluidized bed boiler is connected with an inlet of a cyclone separator through a horizontal flue, and an upper end outlet of the cyclone separator is connected with a flue gas tail gas treatment system; and a bottom outlet of the cyclone separator is connected with a material returning system through avertical pipe, and the material returning system is connected with a material returning inlet of the circulating fluidized bed boiler. The system is reasonable in structure, the change of an originalCFB boiler system is small, the heat value of the waste blades is fully utilized, and centralized, harmless and resource treatment of the waste blades is realized.

Owner:HUANENG CLEAN ENERGY RES INST +1

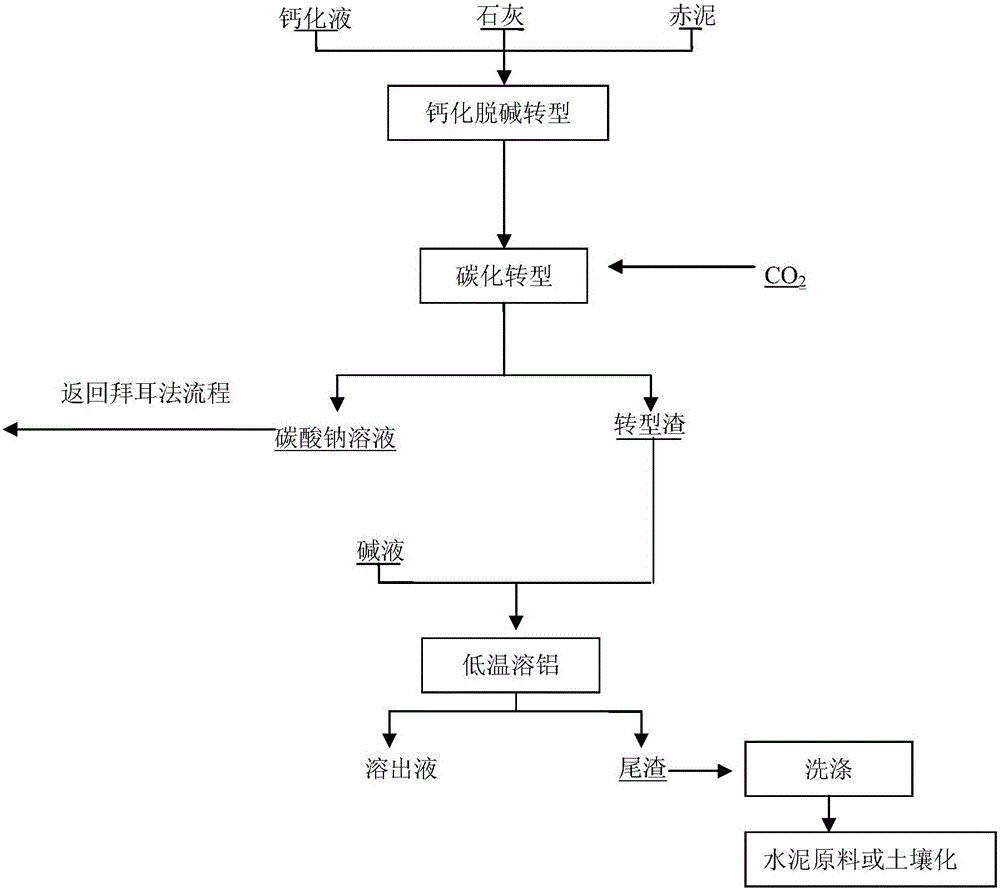

Method for processing Bayer process red mud through calcification-carbonization one-step method

ActiveCN106006688AReduce production energy consumptionReduce energy consumption and operating costsCement productionAluminium oxides/hydroxidesChemistryBayer process

The invention relates to a method for processing Bayer process red mud through a calcification-carbonization one-step method and belongs to the field of environmental protection. The method comprises the steps of first mixing Bayer process red mud, lime and transition liquid, causing the transition liquid to be clear water or a solution with the mass concentration of Na2O not larger than 40 g / L, and calcifying the mixed pulp; causing the pulp after the transition not to undergo solid-liquid separation, directly adding pressurized gas containing a CO2 component into a reaction system, and performing a carbonization transition reaction; causing the pulp having undergone the carbonization transition to undergo solid-liquid separation, obtaining tailings and a liquid phase, causing the tailings to undergo aluminum hydroxide extraction through soluble aluminum mother liquid and then serve as a cement industry raw material or soil, and causing the liquid phase to return a Bayer process system. According to the method, red mud no-alkalinization and aluminum oxide recycling can be achieved through calcification-carbonization one-step transition processing, and the method is an energy-saving environment-friendly Bayer process red mud short process processing method.

Owner:NORTHEASTERN UNIV

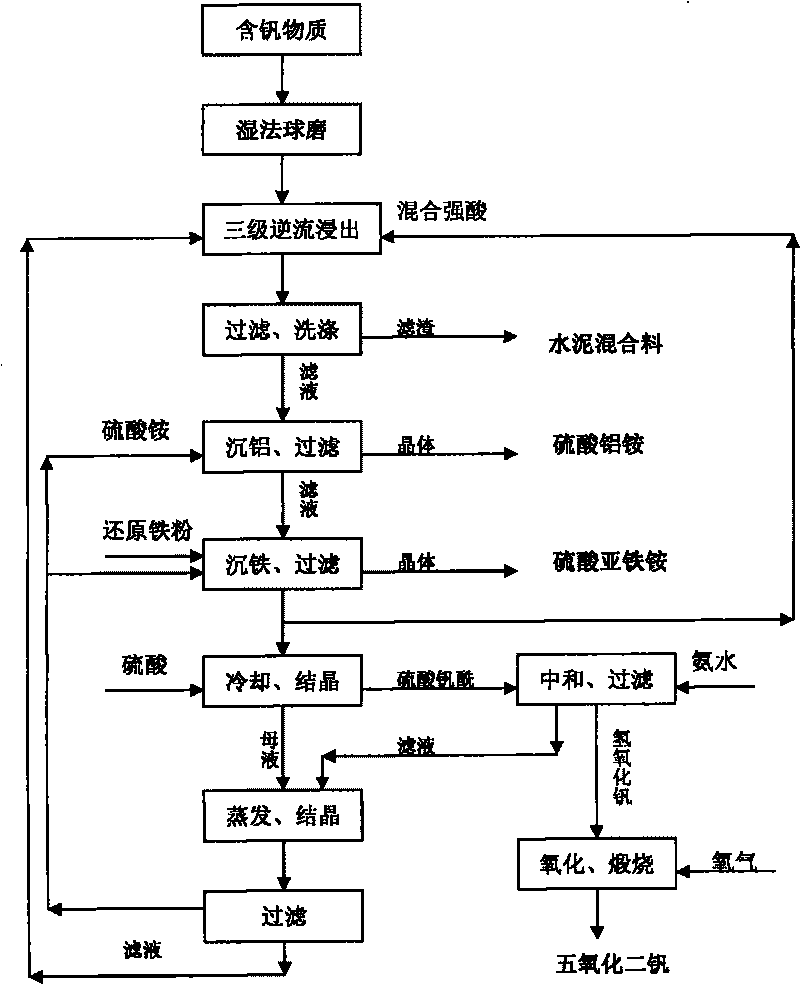

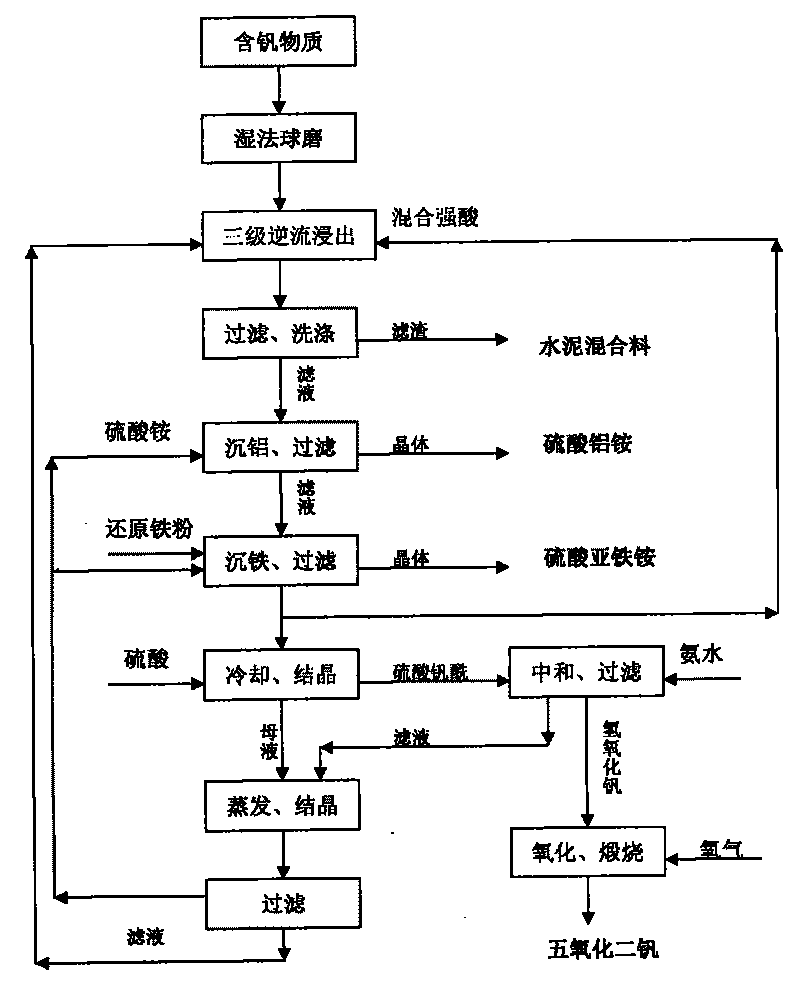

Method for cleanly extracting vanadium pentexide from vanadium containing material

ActiveCN101723458AHigh yieldRealize comprehensive utilizationVanadium oxidesPhosphateAluminum ammonium sulfate

The invention relates to a method for cleanly extracting vanadium pentexide from a vanadium containing material. The method is characterized in that: the vanadium containing material is milled by the wet method, and then mixed with a certain weight amount of sulfuric acid, vanadic acid, water, sulfuric acid or phosphoric acid salt having certain association; under conditions of set temperature and set time, performing three-stage reflux leaching reaction of the mixture; adding ammonia sulfate and reducing iron powder to reaction leach solution in sequence to obtain aluminum ammonium sulfate crystals and ammonium ferrous sulfate crystals respectively; adding sulfuric acid to the solution in which aluminum and iron are separated out, cooling the solution for crystallization to obtain vanadium sulfate acyl crystals, and returning the mother liquor to extract vanadium ores; performing the neutralization reaction of the vanadium sulfate acyl crystals and ammonia water to obtain a precipitate of vanadium hydroxide, and returning the solution of ammonia sulfate to precipitate the aluminum and iron; and calcining the vanadium hydroxide and oxygen gas at a high temperature of over 300 DEG C to obtain the vanadium pentexide. The method has the advantages of short process flow, less energy consumption, high vanadium yield, low production cost, environmental protection, and comprehensive utilization of valuable metallic elements in ores.

Owner:河南龙宇钒业有限公司

Method for generating biogas by anaerobic fermentation of vegetable straws with high content of lignocellulose

ActiveCN104357489AAchieve reductionRealize harmless useWaste based fuelFermentationCelluloseResource utilization

The invention relates to a method for generating biogas by anaerobic fermentation of vegetable straws with high content of lignocellulose. The method comprises the following steps: after crushing vegetable straws, adding catalysts A and B for pretreatment; mixing the pretreated vegetable straws with fresh cow manure and / or pig manure; adding active sludge as an inoculum; adjusting the pH value to 7.2-8.0; putting into an anaerobic reactor; and carrying out anaerobic fermentation at 30-37 DEG C. Reductive and harmless utilization of vegetable straw wastes can be effectively achieved by resource utilization of the vegetable straws and cow manure, so that the environmental damage is greatly reduced, and meanwhile, the generated biogas, biogas residues and biogas slurry are of relatively high economic values. The method is higher in fermentation starting speed, is hardly acidified in system and is more stable in fermentation process. Compared with single raw material fermentation of cow manure, the gas yielding hold time is lasting, the total gas yield is high, and the comprehensive cost is low.

Owner:INST OF AGRI RESOURCES & ENVIRONMENT SHANDONG ACADEMY OF AGRI SCI

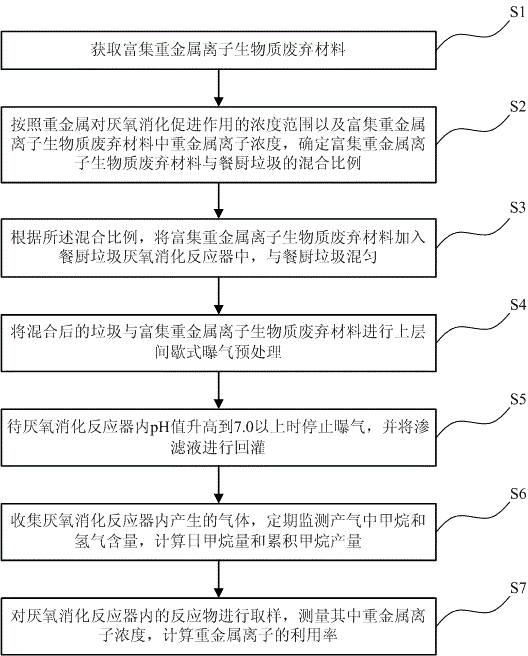

Method for carrying out anaerobic digestion by using heavy metal ions-rich biomass waste materials

InactiveCN106591378AAchieve reductionRealize harmless useTransportation and packagingSolid waste disposalAerobic digestionHydrolysis

Owner:PEKING UNIV SHENZHEN GRADUATE SCHOOL

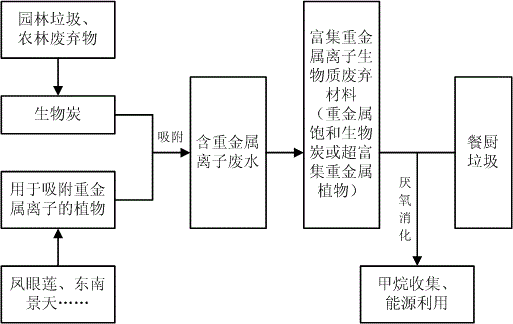

Processing method of applying waste desulfurizing agents to sintering

ActiveCN108715930ASintering is safe and reliableReduce processing costsGas treatmentDispersed particle separationActivated carbonResource utilization

The invention discloses a processing method of applying waste desulfurizing agents to sintering. The processing method includes the following steps that the waste desulfurizing agents are crushed intoparticles with the granularity smaller than 8 mm accounting for 100%, and with the granularity smaller than 1 mm accounting for 10%; evenly mixed powder is obtained by evenly mixing the crushed wastedesulfurizing agents and iron ore powder; evenly mixed ore powder is obtained by burying the evenly mixed powder in an iron ore powder pile; evenly mixed sintering powder is obtained by mixing the evenly mixed ore powder, iron ore powder, solid fuel, fluxing agents and return fines; water is added to the evenly mixed sintering powder to be subject to mixing and pelletizing to form evenly mixed sintering powder; sintered ore and sintering flue gas are obtained by sintering the pelletized materials; and the sintering flue gas is exhausted into the atmosphere after being subjected to desulfurization and denitrification. According to the processing method, the waste desulfurizing agents are crushed and then matched with the iron ore powder for sintering, the sintered ore is obtained for blastfurnace ironmaking, and iron, calcium and magnesium are recycled. Activated carbon absorbing sulfur dioxide can be used for desorbing the sulfur dioxide and making acid so as to recover sulfur. Thus,harmless disposal of the waste desulfurizing agents is carried out, and resource utilization of the waste desulfurizing agents is achieved.

Owner:CENT SOUTH UNIV

Method for recovering glucomannan and protein in konjac flying powder by enzyme process

InactiveCN102020856AImplement resourcesRealize harmless useFood processingAnimal feeding stuffAmylaseNutrition

The invention relates to a method for recovering glucomannan and protein in konjac flying powder by the enzyme process, which comprises the following process steps: (1) liquification: adding alpha-amylase into water solution of the konjac flying powder and liquifying till starch is fully degraded; (2) saccharification: adding amyloglucosidase into solution in the step (1) for saccharification; (3) centrifugation: regulating the pH of the solution in the step (2) to 3.5-5.0, centrifugating and getting precipitate; (4) acid washing: adding water into the precipitate in the step (3), regulating the pH of the solution to acidic condition, stirring, centrifugating, and getting the precipitate; and (5) drying: regulating the pH of the precipitate after the acid washing of the step (4) to be neutral, drying and finally getting a final extract. The process flow is simple, the operation is easy, the content of the glucomannan and crude protein in the got extract is high, and the extract can be used as a high-quality feed or a protein raw material and the like; and a stinking matter of trimethylamine and an antinutritional factor of tannin can be effectively removed.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

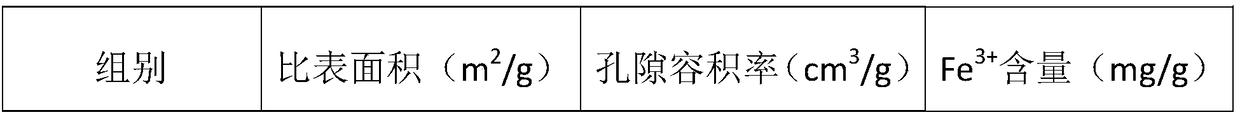

Fe<3+> antibiotic fungi residue activated carbon as well as preparation method and application thereof

InactiveCN109012599AEasy to operateRealize harmless useGas treatmentOther chemical processesActivated carbonChemistry

The invention relates to Fe<3+> antibiotic fungi residue activated carbon as well as a preparation method and application thereof. The preparation method comprises the following steps: drying and grinding antibiotic fungi residues; dipping the ground fungi residues in a Fe<3+> salt solution, oscillating and filtering; drying the filtered fungi residues; baking the dried fungi residues, cooling, washing and drying to obtain the activated carbon. The preparation method is simple to operate, and can realize harmless utilization of the antibiotic fungi residues; in addition, the preparation methodcan be used for increasing the loading capacity of Fe<3+>, and also can increase the internal micropore amount of the activated carbon; the Fe<3+> antibiotic fungi residue activated carbon prepared by the method has the characteristics of being large in specific surface area, dense in internal micropores and high in porosity and content of the loaded Fe<3+>.

Owner:BEIJING GUANLAN TECH

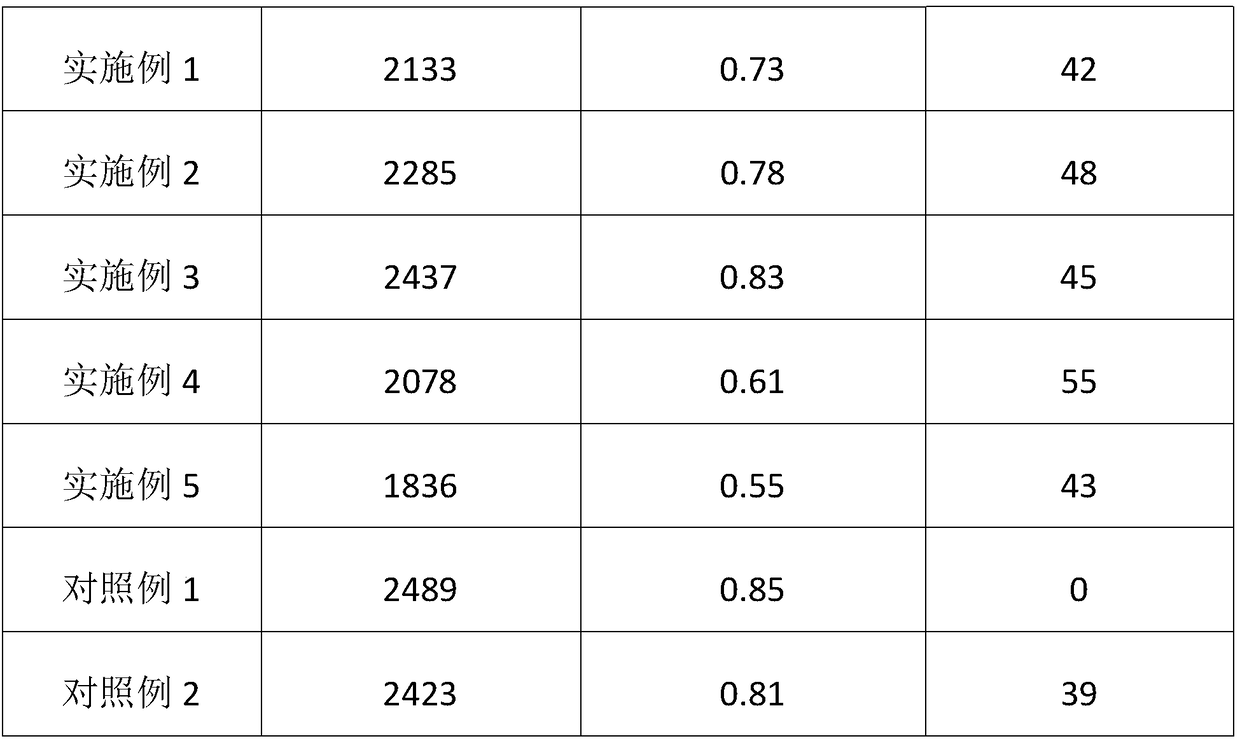

Method for preparing biogas by dry-fermenting sugarcane leaves as raw materials

InactiveCN101575618AImplement resourcesRealize harmless useEfficient propulsion technologiesWaste based fuelReaction temperaturePre treatment

The invention discloses a method for preparing biogas by dry-fermenting sugarcane leaves as raw materials, which is characterized in that the method comprises the following concrete steps: pretreating the sugarcane leaves as the raw materials by cutting harvested sugarcane leaves into small pieces or grinding the sugarcane leaves and adding water to wet the obtained product for a period of time; directing stacking and soaking the obtained product or adding 0.5 to 1 percent of Lujieling, stirring the two and evenly stacking and soaking the obtained product and holding stacking-soaking temperature up to above 50 DEG C for more than three days; mixing the obtained mixture and inoculum well for inoculation; obtaining and putting a fermentation raw material into a fermentation device; sealing the fermentation device; controlling reaction temperature between 35 and 38 DEG C; performing fermentation for gas production; and producing biogas, namely a target product after 1 to 2 days. The method has the advantages of greatly easing current energy shortage problem in China, helping to save energy and protect environment and returning biogas residue to fields in order to improve soil, reduce fertilizer consumption and then reduce production cost of sugarcane.

Owner:AGRI MACHINERY INST CHINESE TROPICAL ACAD OF SCI

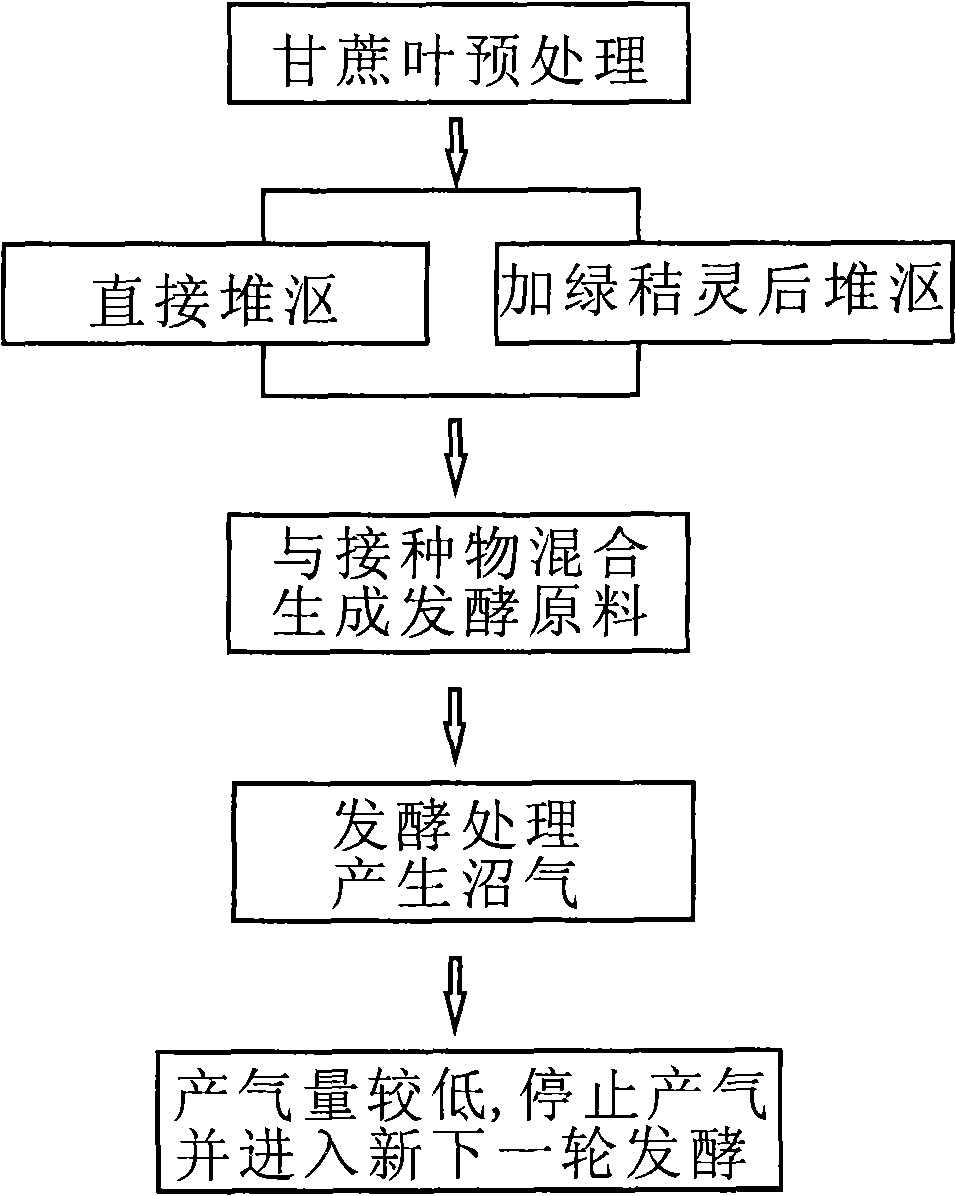

Thermal insulation mortar containing papermaking sludge ash and preparation method thereof

The invention discloses a thermal insulation mortar containing papermaking sludge ash; the thermal insulation mortar is composed of sulfoaluminate cement, the papermaking sludge ash, polyphenyl particles, vitrified micro-beads, cellulose ether, an air-entraining agent, a polycarboxylic acid water reducing agent, alkali-resistant glass fiber and water. The invention also provides a preparation method of the thermal insulation mortar. With use of the papermaking sludge ash instead of partial cement, the thermal insulation mortar has the advantages of good compactness and waterproof performance, stable product physical properties, no cracking, aging resistance, long service life and good thermal insulation performance, not only realizes the papermaking sludge harmless utilization and protects the environment, but also can save resources, turns waste into wealth, reduces the amount of the cement, reduces the cost, and has good economic and social benefits. The preparation method is simple, can be completed according to a conventional technology process, and is low in production cost.

Owner:UNIV OF JINAN

Thermal insulation mortar for building external walls and preparation method thereof

The invention discloses a thermal insulation mortar for building external walls. The thermal insulation mortar consists of sulfate aluminium cement, papermaking sewage sludge ash, polystyrene granules, glazed hollow beads, cellulose ether, an air-entraining agent, a polycarboxylate superplasticizer, alkali-resistant glass fibers and water, and further discloses a preparation method of the thermal insulation mortar. As paper mill sludge ash replaces part of cement, the compactness and the water resistance are very good, the thermal insulation mortar is stable in physical property, free of cracks, ageing-resistant, long in service life and excellent in thermal insulation performance. Not only is harmless utilization of paper mill sludge ash realized to protect the environment, but also resources are saved, waste is changed into valuable, the consumption of cement is reduced, the cost is lowered, and favorable economic and social benefits are achieved. The preparation method is simple, can be completed according to the conventional technology and is low in production cost.

Owner:东莞市欧瑞建筑有限公司

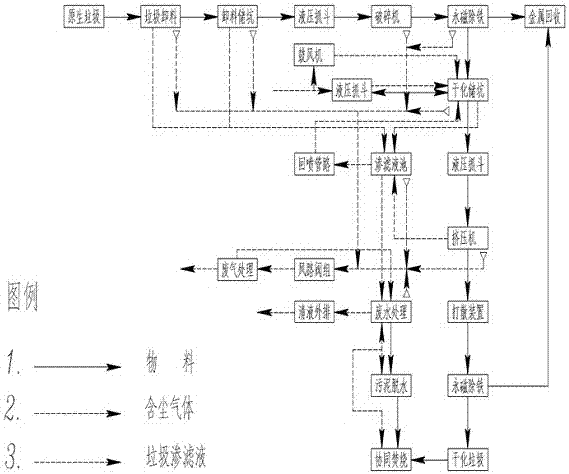

Method for pretreating urban and rural domestic refuse by means of mechanical-biological method

InactiveCN107335676AImprove qualityHarmlessSolid waste disposalEnvironmental engineeringPre treatment

The invention discloses a method for pretreating urban and rural domestic refuse by means of a mechanical-biological method, and relates to the technical field of environmental protection. According to the technological process, the method is prominently characterized in that primary crushing and mechanical retransfer are adopted, and then a pore texture beneficial for bio-drying is formed; and free transfer of moisture of domestic refuse is achieved in the bio-drying process, and then water on the surface of the domestic refuse is removed in a mechanical squeezing manner, and therefore effective solid-liquid separation of the domestic refuse is achieved. Products produced through mechanical-biological method pretreatment are suitable for cement kiln collaborative incineration disposal or grate furnace incineration disposal. According to the method for pretreating the urban and rural domestic refuse by means of the mechanical-biological method, by means of organic linking with an incineration system, harmlessness and cleanliness of the pretreatment process can be achieved, improving of the domestic refuse quality is completed, and recycling, reducing and harmless utilization is achieved.

Owner:蓝天众成环保工程有限公司 +2

Calcium silicate board with paper mill sludge ash and preparation method thereof

ActiveCN105016663ARealize harmless useReduce dosageSolid waste managementCalcium silicateMoisture resistance

The invention discloses a calcium silicate board with paper mill sludge ash and a preparation method thereof. The calcium silicate board is composed of, by weight, 20-40% of cement, 10-31% of the paper mill sludge ash, 21-40% of quartz sand, 1-10% of wood pulp, 1-5% of asbestos fiber and 6-15% of sanding waste. The paper mill sludge ash is used for replacing some cement, so that the calcium silicate board has the good shock resistance and humidity resistance performance, the bulking factor is smaller than or equal to 0.25%, the hot-shrinkage rate is smaller than or equal to 0.5%, and the calcium silicate board completely conforms with the regulations of JC / T564-2000 Fiber-Reinforced Calcium Silicate Board standards. According to the invention,harmless utilization of paper mill sludge can be achieved, the environment is protected, resources are saved, waste is turned into wealth, the cement and quartz sand use amount is reduced, the cost is lowered, and the calcium silicate board has the good economic and social benefits. The preparation method of the calcium silicate board is easy and convenient to implement and is low in production cost.

Owner:UNIV OF JINAN

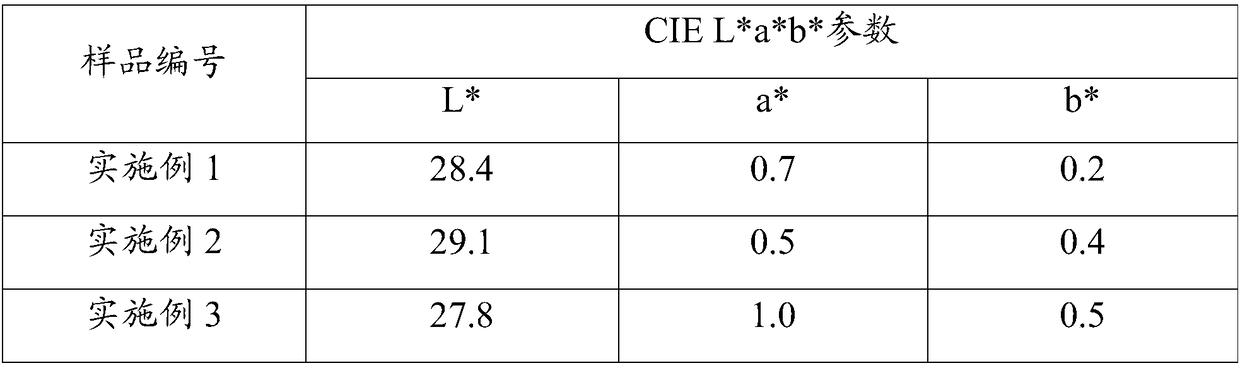

Black ceramic pigment and preparation method thereof

ActiveCN109456617ALow firing temperatureOptimizing crystal form compositionPigmenting treatmentAir atmosphereNickel Monoxide

The invention provides a preparation method for a black ceramic pigment. The preparation method comprises the following steps: 1) uniformly mixing electric furnace smelting stainless steel fly ash containing an iron element with chromic oxide, nickel monoxide and manganese monoxide according to a molar ratio of Fe to Cr to Ni to Mn being equal to1:(0.8-1.3):(0.5-1.1):(0.7-1.2), so as to obtain a mixture material; and 2) placing the mixture material in a microwave field, microwave-heating in an air atmosphere, while a temperature of the mixture material rises to 1050-1200 DEG C, preserving heatfor 10-20 min, taking out the roasted material from the microwave field, and cooling to room temperature, so as to prepare the black ceramic pigment. The method uses the industrial solid waste electric furnace smelting stainless steel fly ash as a raw material, so that while transition metal elements richly contained in the fly ash are greatly used, the effect on the environment by emission thereof is eliminated, and defects that sintering time is long, a needed temperature is high and energy consumption is high caused by of preparing the black ceramic pigment by using an industrial solid waste currently. The prepared black ceramic pigment has the characteristics of high blackness, pure color generation and good coloring property.

Owner:WUHAN UNIV OF SCI & TECH

A kind of calcification-carbonization one-step processing method for Bayer process red mud

ActiveCN106006688BRealize harmless useReduce production energy consumptionCement productionAluminium oxides/hydroxidesRed mudCalcification

The invention relates to a one-step calcification-carbonization method for treating Bayer process red mud, and belongs to the field of environmental protection. This method first mixes Bayer process red mud, lime and transformation liquid phase, in which the transformation liquid phase is clean water or a solution with Na2O mass concentration ≤ 40g / L, and the mixed slurry is calcified; the transformation slurry is directly processed without solid-liquid separation. Add pressurized gas containing CO2 components to the reaction system to perform the carbonization transformation reaction; the slurry after carbonization transformation is separated from liquid and solid to obtain tailings and liquid phase, and the tailings are extracted with aluminum hydroxide through aluminum-dissolving mother liquor The liquid phase is returned to the Bayer process system as raw material for the cement industry or for soil formation. This technology can achieve alkalinization of red mud and recovery of alumina through a one-step transformation process of calcification-carbonization. It is an energy-saving and environmentally friendly short-process treatment method of Bayer red mud.

Owner:NORTHEASTERN UNIV LIAONING

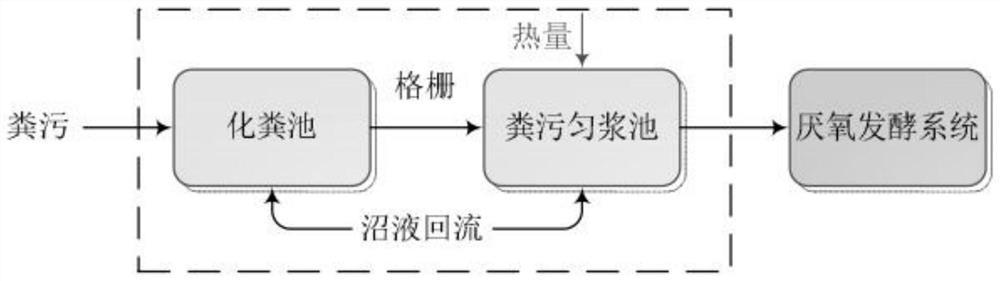

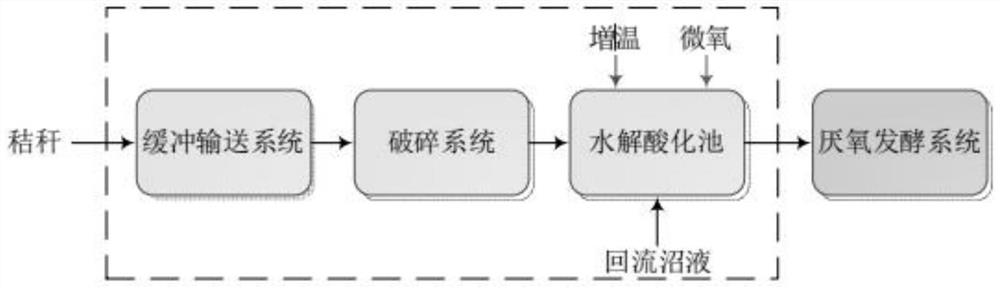

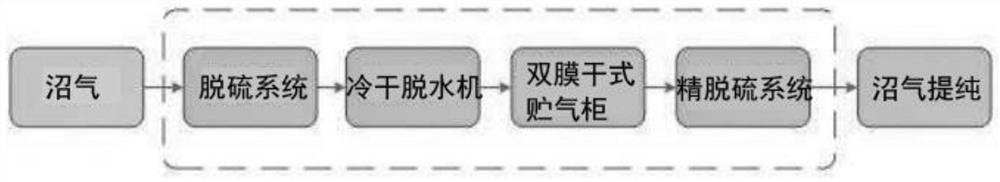

Poly-generation method employing coupling of biomass with livestock and poultry manure

InactiveCN112830821AReduce energy consumptionIncrease soil volatile organic carbon contentCarbon compoundsDrying solid materials without heatBiogasBiomass

The invention belongs to the technical field of comprehensive utilization of biomass and livestock and poultry manure, and particularly relates to a poly-generation method employing coupling of biomass with livestock and poultry manure. The poly-generation method comprises the following steps: burning straws to generate power so as to provide heat, pretreating the straws and the livestock and poultry manure, respectively hydrolyzing and acidifying the straws and livestock and poultry manure, feeding the straws and livestock and poultry manure having been hydrolyzed and acidified into a CSTR anaerobic fermentation tank, allowing the hydrolyzed and acidified straw and livestock and poultry manure to undergo medium-temperature anaerobic fermentation in the CSTR anaerobic fermentation tank so as to obtain biogas and biogas slurry, subjecting the biogas slurry to solid-liquid separation before preparation of an organic fertilizer from the biogas slurry, and subjecting the biogas to drying, gas-water separation, desulfurization and filtration before preparation of natural gas from the biogas. According to the invention, the straw and the livestock and poultry manure are coupled and recycled to generate electricity, heat, cold, biogas and organic fertilizer, so harmless utilization of resources is realized.

Owner:国能生物发电集团有限公司

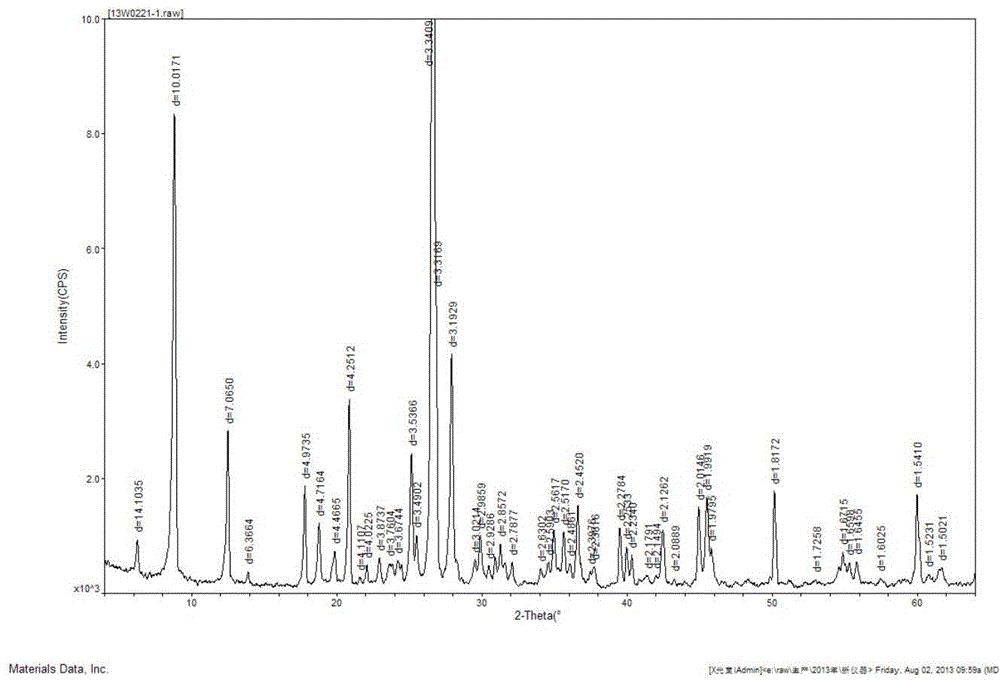

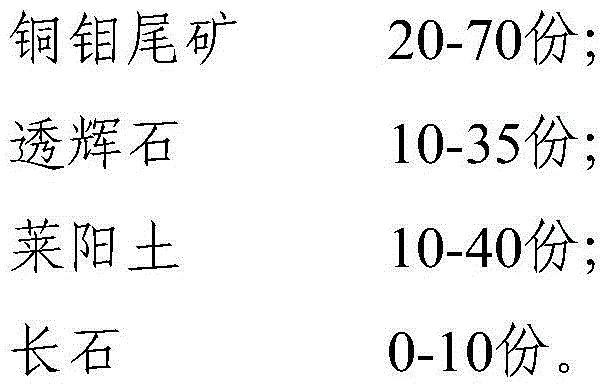

Constructional ceramic prepared from copper-molybdenum tailings and preparation method thereof

InactiveCN104926283ARealize harmless useReduce pollutionCeramic materials productionClaywaresCopperPollution

The invention relates to a constructional ceramic prepared from copper-molybdenum tailings. The ceramic is composed of the following components in parts by weight: 20 to 70 parts of copper-molybdenum tailings, 10 to 35 parts of diopside, 10 to 40 parts of Laiyang soil, and 0 to 10 parts of feldspar. The added tailing can account for 70% of the weight of ceramic wall tile and ceramic floor tile, the tailing is converted into valuable resources, the environment pollution is avoided, the environment is protected, the ceramic raw material shortage is relieved, and the production cost for the ceramic industry is reduced.

Owner:中条山有色金属集团有限公司 +1

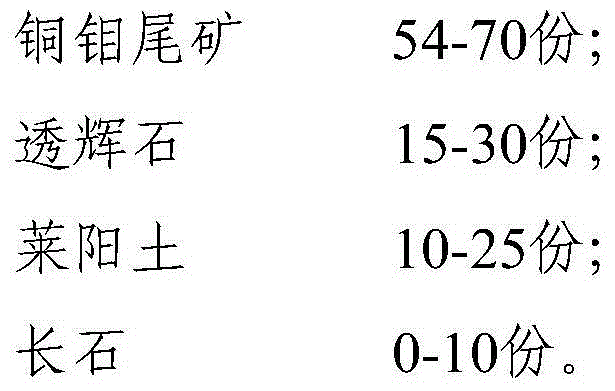

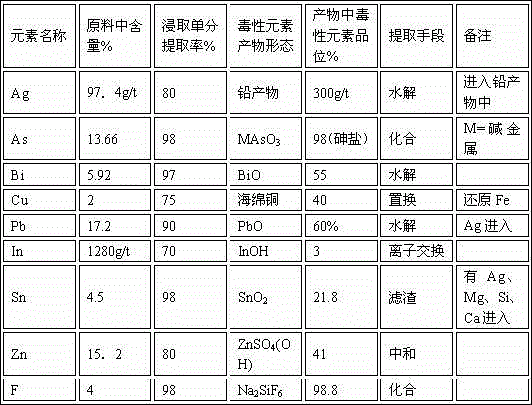

Method for normal temperature and pressure whole-wet leaching of toxic elements in mining and metallurgical solid waste

The invention relates to a method for normal temperature and pressure whole-wet leaching of toxic elements in mining and metallurgical solid waste, wherein the solid waste at least contains one of toxic elements comprising Hg, Cd, Ge, Te, Cr, Ga, Li, In, Sn, Pb, Ni, Tl, As, Sb, Be, F, Co, Bi, Cu and Ag. The method comprises the steps: crushing the solid waste, then adding water, and blending into a mine slurry; adding sulfuric acid and a leaching aid polyol sulfone halogen into the mine slurry, and carrying out first-stage leaching; filtering the last-step leached liquid, carrying out itemized extraction of the toxic elements contained in the filtrate, carrying out second-stage leaching on a filter residue with sodium chloride added with the leaching aid, and carrying out hydrolysis or ion exchange of the leached liquid to obtain corresponding metal enriched products. With adopting of the novel leaching aid polyol sulfone halogen, the acid leaching process of the toxic elements in the solid waste is fundamentally changed, not only is the efficiency improved but also all the toxic elements can be leached, then itemized separation and extraction is carried out, the post liquid after the toxic elements are extracted can be purified into pure water for reuse, and elements in the leached residue have no toxicity, so that the mining and metallurgical solid waste raw material can be treated with low cost and high efficiency, the waste is turned into treasure, and solid waste resource and innocuous utilization are achieved.

Owner:徐强富

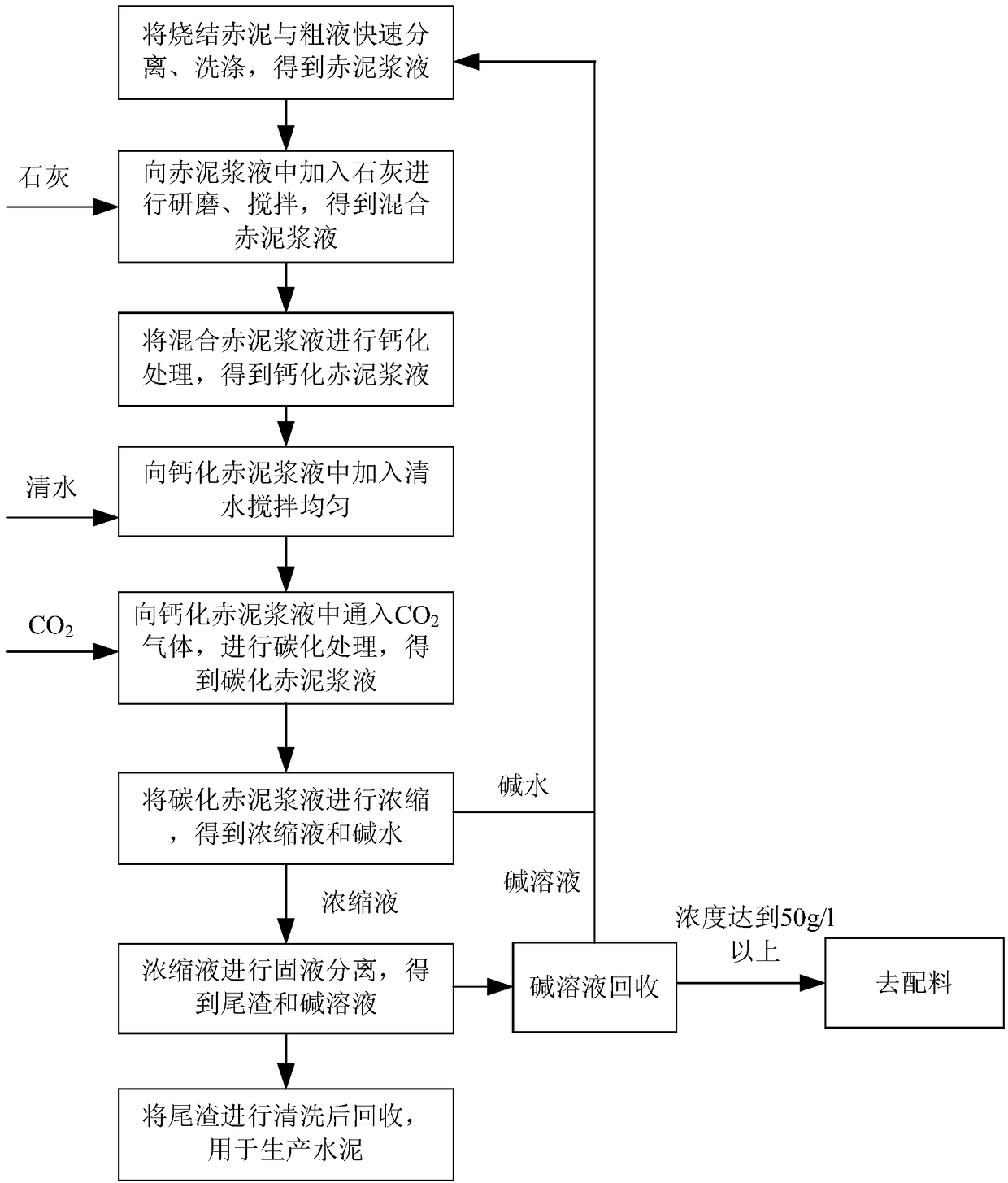

Industrial treatment method of sintering red mud

InactiveCN108296267ARealize harmless useMeet environmental protection requirementsSolid waste disposalCalcium silicateSoil treatment

The invention discloses an industrial treatment method for sintering red mud. The industrial treatment method of the sintering red mud is characterized by comprising the following steps of (1) conducting separation and washing, wherein the sintering red mud is rapidly separated from raw liquor and washed, and red mud slurry is obtained; (2) conducting mixing, lime is added to the red mud slurry, grinding and stirring are conducted, and then the red mud slurry mixture is obtained; (3) conducting calcification, wherein the red mud slurry mixture is calcified, and then calcified red mud slurry isobtained and the like. The main ingredients of tailings obtained after the sintering red mud is treated are calcium silicate and calcium carbonate, the tailings can be directly used for the cement industry and can also be used for soil treatment, and therefore harmless utilization of the red mud in the aluminum oxide production process is achieved. The content of Na2O in the tailings generated after the sintering red mud is treated is below 1%, and the environment-friendly requirement is met.

Owner:BEIJING HUASUO TECH

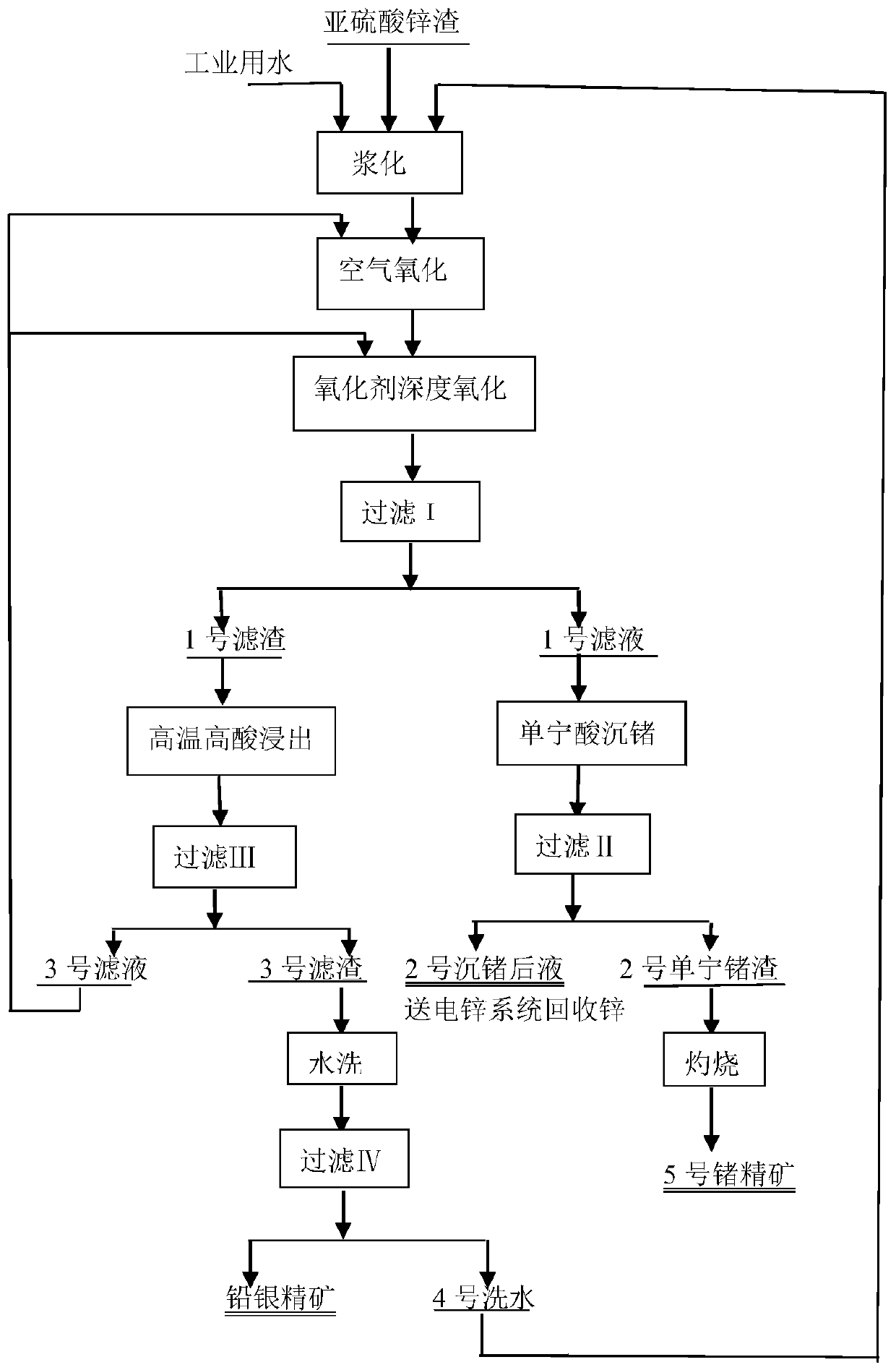

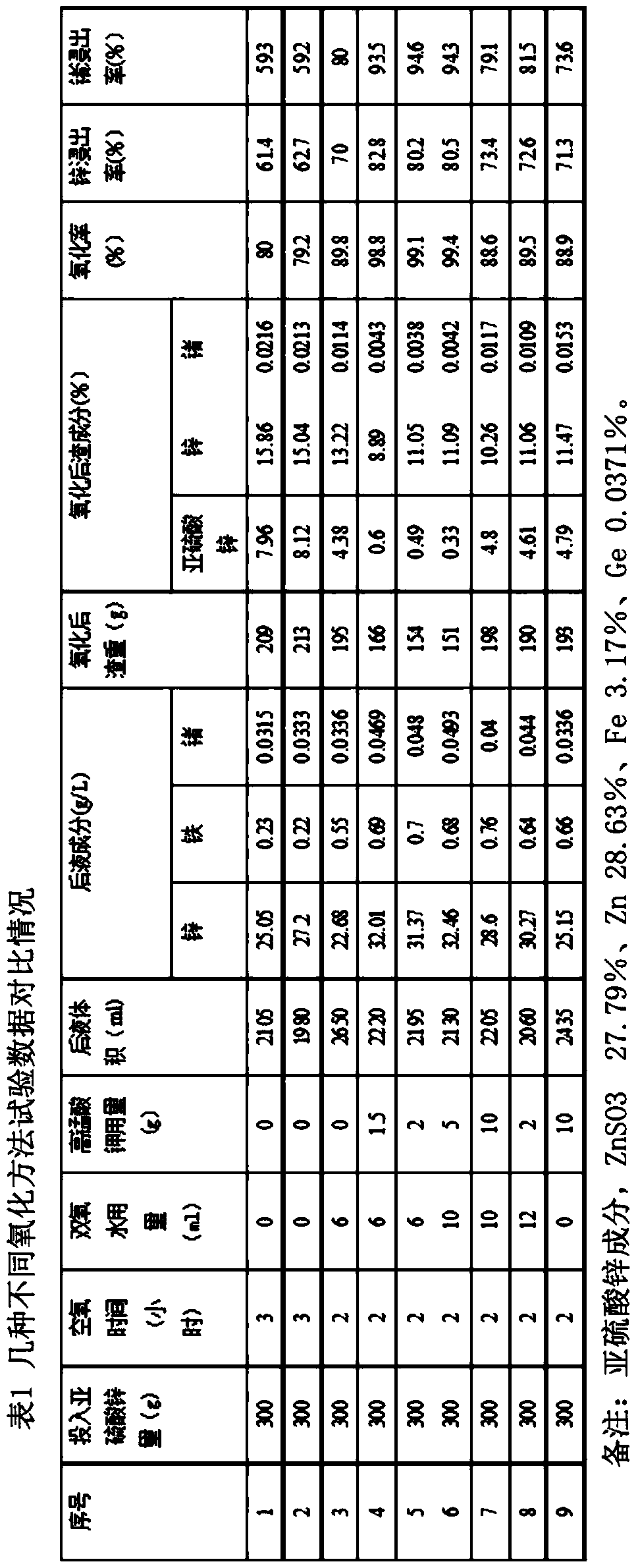

Method for deep oxidation and harmless treatment of zinc sulfite slag for comprehensive recovery of valuable metal

PendingCN111235392AAir Oxidation Process BriefOxidation Process BriefProcess efficiency improvementSlagHydrometallurgy

The invention discloses a method for deep oxidation and harmless comprehensive recovery processing of zinc sulfite slag. The method comprises the following steps: zinc oxide powder produced by a zincvolatilizezing kiln is directly pulpified to absorb low-concentration sulfur dioxide flue gas generated by the zinc volatilizezing kiln to obtain zinc sulfite slag as the raw material, the zinc sulfite slag is first pulpified and then subjected to air oxidation, then, a mixing oxidizing agent is added for deep oxidation, heating and warming are carried out, finally filtering is carried out to obtain germanium-containing zinc sulfate solution and zinc oxide slag, germanium-containing zinc sulfate solution and zinc oxide slag are the raw materials of zinc hydrometallurgy, wherein zinc sulfate solution contains high content of germanium and low contents of zinc and ferric iron, germanium can be directly recycled to obtain high-grade germanium concentrate, acid leaching is carried out on zincoxide slag to recycle zinc and produce lead and silver concentrate to recycle lead and silver.

Owner:YUNNAN LUOPING ZINC & ELECTRICITY

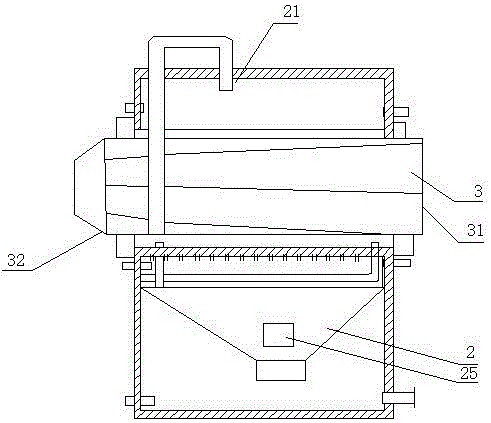

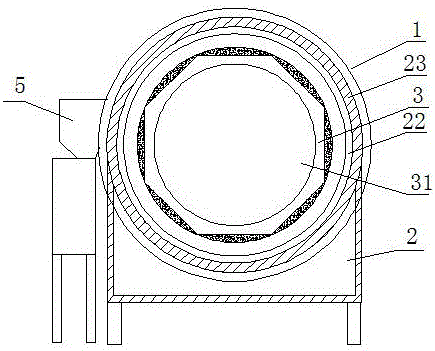

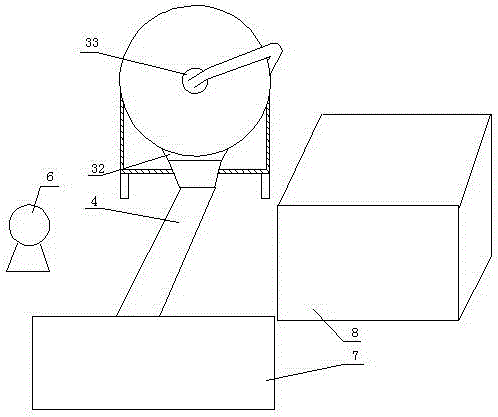

Drying furnace for household garbage and drying method

InactiveCN105823056AReduce moisture contentAchieve reductionDrying gas arrangementsIncinerator apparatusLitterResource utilization

The invention discloses a drying furnace for household garbage and a drying method. The drying method includes the following steps that firstly, the household garbage is preprocessed so that loose and uniform to-be-processed garbage can be obtained; secondly, the to-be-processed garbage is placed in the drying furnace to be dried, the drying temperature is 100 DEG C to 140 DEG C, the machine speed is 15 r / min to 20 r / min, the drying time is 3 min to 8 min, and the to-be-processed garbage is blown into a suspended state in the drying process; and thirdly, air separation is performed, wherein the dried garbage is subjected to air separation so that small-specific-gravity garbage and large-specific-gravity garbage can be obtained, and the small-specific-gravity garbage and the large-specific-gravity garbage are packaged and subjected to resource utilization. The drying furnace for the household garbage is further included in the invention. By means of the drying furnace for the household garbage and the drying method, firstly, secondary pollution in the processing process can be effectively eliminated; secondly, the processing cost can be greatly reduced, the processing efficiency is improved, and reduction, reclamation and harmlessness of the household garbage are efficiently and fast achieved.

Owner:龚亚强 +1

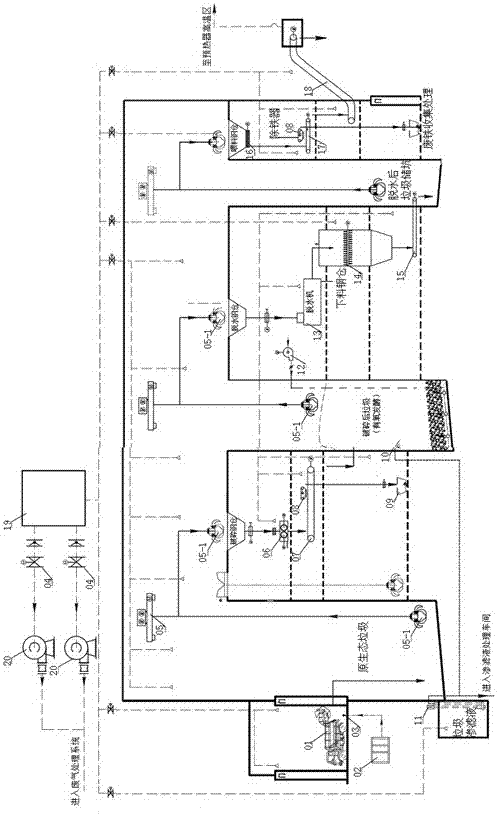

Oil-contained sludge pyrolysis-combustion coupled double-bed integrated treatment process system

InactiveCN109974001AAchieve reductionRealize resourcesIncinerator apparatusProcess systemsCirculating fluidized bed boiler

The invention discloses an oil-contained sludge pyrolysis-combustion coupled double-bed treatment process. A process system comprises an oil-contained sludge drying system, a combustion system and a fluidized bed incineration system, wherein the drying system comprises a feeding machine, a drying unit, a storage tank and the like, the combustion system comprises a combustion furnace, a nitrogen gas cylinder set, a re-circulating fan, a refeeder, a belt conveyor, a dried oil-contained sludge feeding machine, a pyrolysis gas outlet and the like, and the fluidized bed incineration system comprises a circulating fluidized bed boiler, an auxiliary fuel feeding machine, a cyclone separator, a refeeder, a flue, a dust remover, a desulfurization tower, a chimney, an air supply machine, a high-pressure fluidization fan and the like. Oil-contained sludge enters the combustion furnace to be combusted after being dried, hot flue gas enters a pyrolysis furnace to provide heat required by pyrolysis,pyrolyzed oil-contained sludge coke is returned to a combustion chamber to be incinerated under the action of fluidization air provided by the nitrogen gas cylinder set, the incinerated flue gas is purified and then discharged through the chimney, and through the process, reduction, recycling and harmless comprehensive utilization of the oil-contained sludge is realized.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

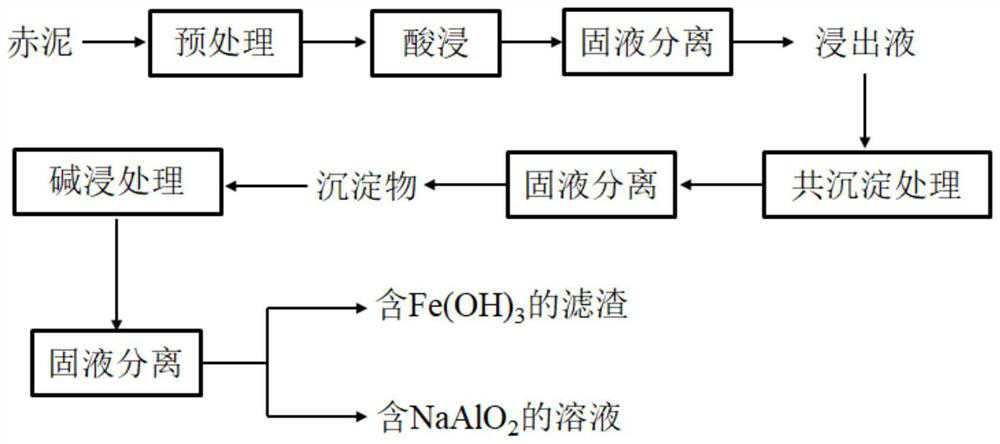

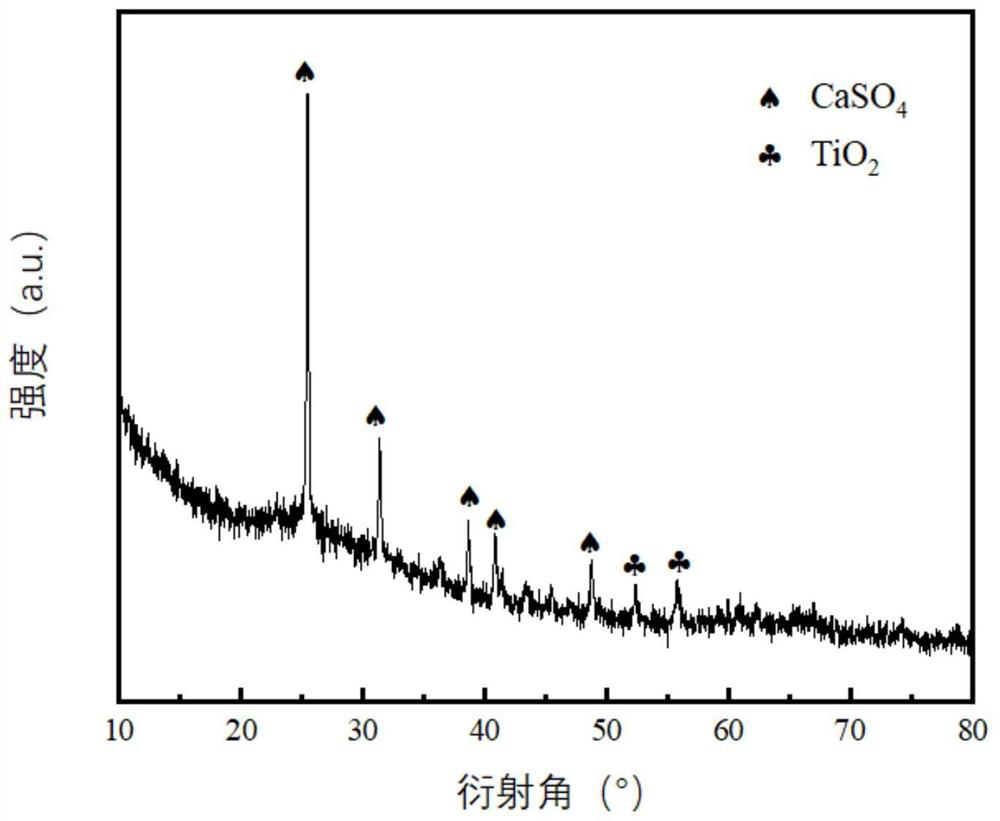

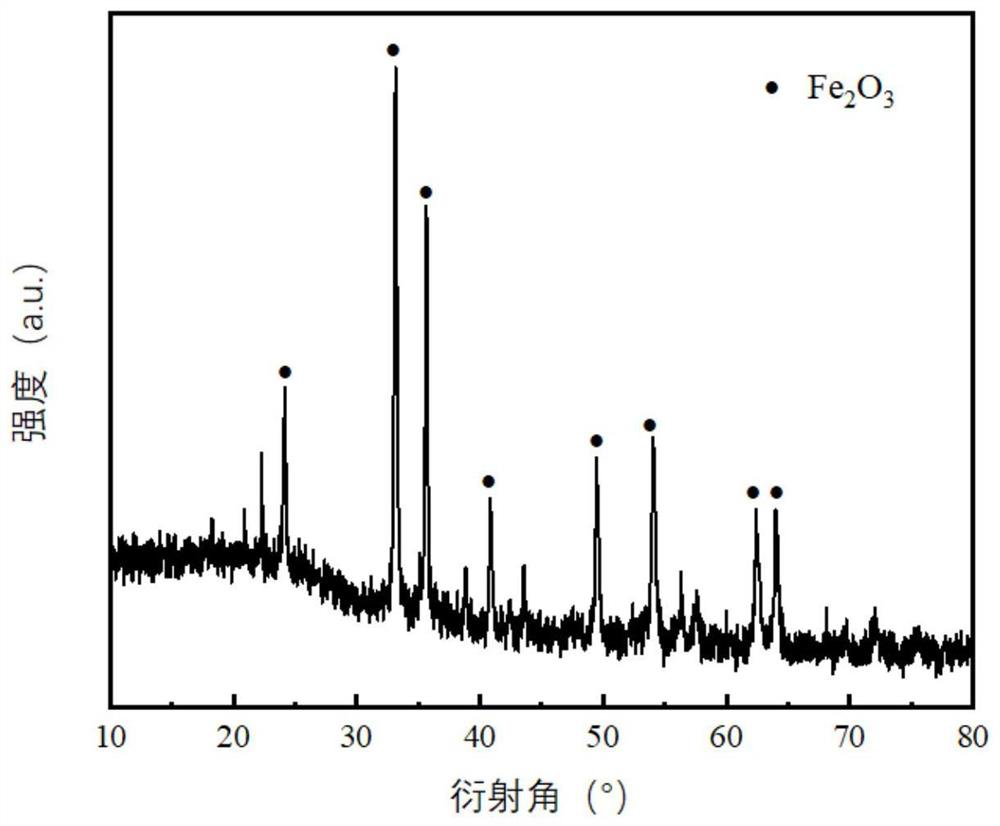

Method for separating iron and aluminum in red mud

The invention relates to a method for separating iron and aluminum from red mud, which comprises the following steps: (1) sequentially carrying out pretreatment, acid leaching and solid-liquid separation on the red mud to obtain a leaching solution; (2) carrying out coprecipitation treatment on the leachate obtained in the step (1), and then carrying out solid-liquid separation to obtain a precipitate; and (3) carrying out alkaline leaching treatment on the precipitate obtained in the step (2), and then carrying out solid-liquid separation to obtain a solution containing NaAlO2 and filter residues containing Fe (OH) 3. The method for separating the iron and the aluminum in the red mud can be connected in series with the aluminum oxide industry and the iron and steel industry, effective separation and recovery of the iron and the aluminum are achieved, the treatment cost is low, and secondary pollution is avoided.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Oily sludge extraction-separation-drying-incineration integral process system

InactiveCN108644787ARealize capacity reductionImplement resourcesSludge treatment by de-watering/drying/thickeningLiquid hydrocarbon mixture productionCycloneProcess systems

The invention relates to an oily sludge extraction-separation-drying-incineration integral process system. An extraction system comprises a dosing port, a water filling port and a pressure-resistant stirring tank. A separation system comprises a first-stage separator, a second-stage separator, an oil-water separator and the like. A drying system comprises a drying heat exchanger, an oily sludge conveyor belt and the like. An incineration system comprises a fluidized bed incinerator, a feeder, a first-stage cyclone separator, a return feeder, a primary draught fan, a secondary draught fan, a fluidized air blower, a second-stage cyclone separator, a bag-type dust collector, an induced draft fan, a chimney, a gas-gas heat exchanger and the like. Oily sludge is subjected to high-temperature and high-pressure extraction and separation to obtain an oil product which can serve as a secondary energy source. Oily sludge residues obtained through separation and coal are mixed and sufficiently burned under the action of combustion air so as to provide energy for industrial production. Burned flue gas is subjected to cooling and denitration treatment to achieve harmful discharging. Through theprocess, reduction, recycling and harmless comprehensive utilization of the oily sludge are achieved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Method for preparing exterior wall paint by utilizing paper mill sludge

InactiveCN106010035AReduce utilization costSimple preparation processCoatingsRevolutions per minuteSodium carboxymethylcellulose

The invention provides a method for preparing exterior wall paint by utilizing paper mill sludge. The exterior wall paint is prepared from the following components in a paint dispersion machine: 2.5 to 3.5 parts of a polyacrylate emulsion with the solid content being 50%, 55 to 65 parts of a sodium carboxymethyl cellulose aqueous solution with the solid content being 2%, paper mill sludge with the dry component being 25 to 30 parts, 2.5 to 3.5 parts of pigment, 0.2 part of a defoaming agent, and 1 part of a preservative; the preparation process of the exterior wall paint in the paint dispersion machine is that the sodium carboxymethyl cellulose solution is added into the paint dispersion machine, and the paper mill sludge, the pigment, the defoaming agent and the preservative are added in sequence at the revolving speed of 1000 to 2000 rpm (revolutions per minute), and stirred for 30 to 5o minutes; then the polyacrylate emulsion is added, and stirred for 15 to 20 minutes to obtain the exterior wall paint. The preparation method of the paint provided by the invention has the characteristics that the operation is simple and easy operation and the quality and performance of the paint are excellent, thereby providing an effective way for resource utilization of paper mill sludge waste.

Owner:SHAANXI UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com