Oily sludge extraction-separation-drying-incineration integral process system

The technology of a process system and separation system is applied in the field of oily sludge extraction-separation-drying-incineration integrated process system, which can solve the problems of environmental pollution, waste of petroleum resources, and oily sludge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The equipment and method provided by the present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited thereto.

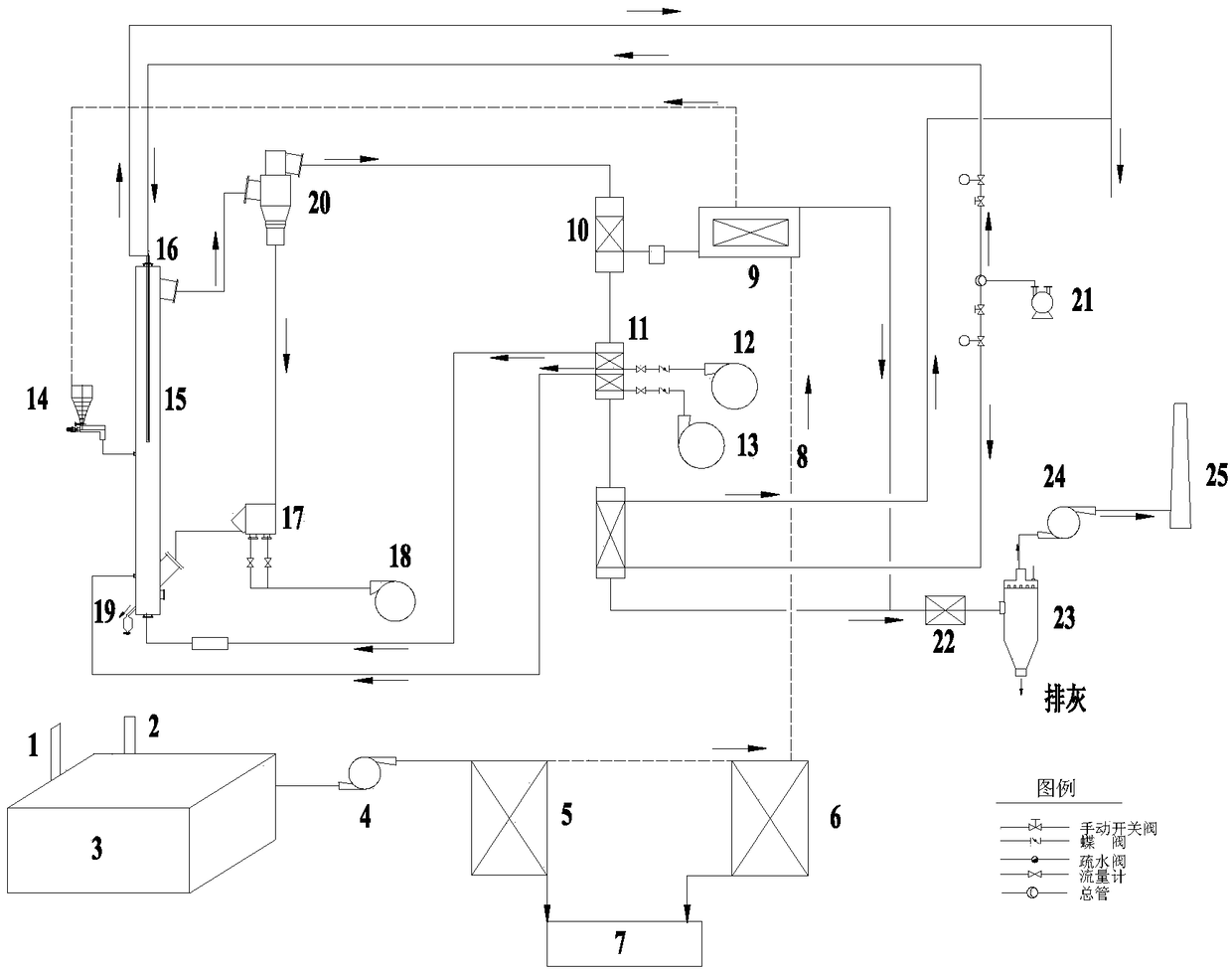

[0025] figure 1 It is a schematic diagram of the oily sludge extraction-separation-drying-incineration integrated process system of the present invention.

[0026] Such as figure 1As shown, the oily sludge extraction-separation-drying-incineration integrated process system includes an oily sludge extraction system, a separation system, a drying system and an incineration system. Among them, the oily sludge extraction system includes a chemical feed port 1, a water feed port 2, and a pressure-resistant stirring tank 3; the separation system includes a slurry pump 4, a primary separator 5, a secondary separator 6, and an oil-water separator 7; the drying system Including drying heat exchanger 9, oily sludge conveyor belt 8, flue gas heat exchanger 10, etc.; incineration system includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com