Vinegar-dreg (or vinasse)-burning hearth structure of fluidized-bed boiler

A technology of fluidized bed boiler and furnace structure, which is applied in the direction of fluidized bed combustion equipment, fuel for combustion in molten state, combustion method, etc., can solve problems such as difficulty in popularization, complex composition structure, and difficult control, and achieve cost reduction, The effect of improving system economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

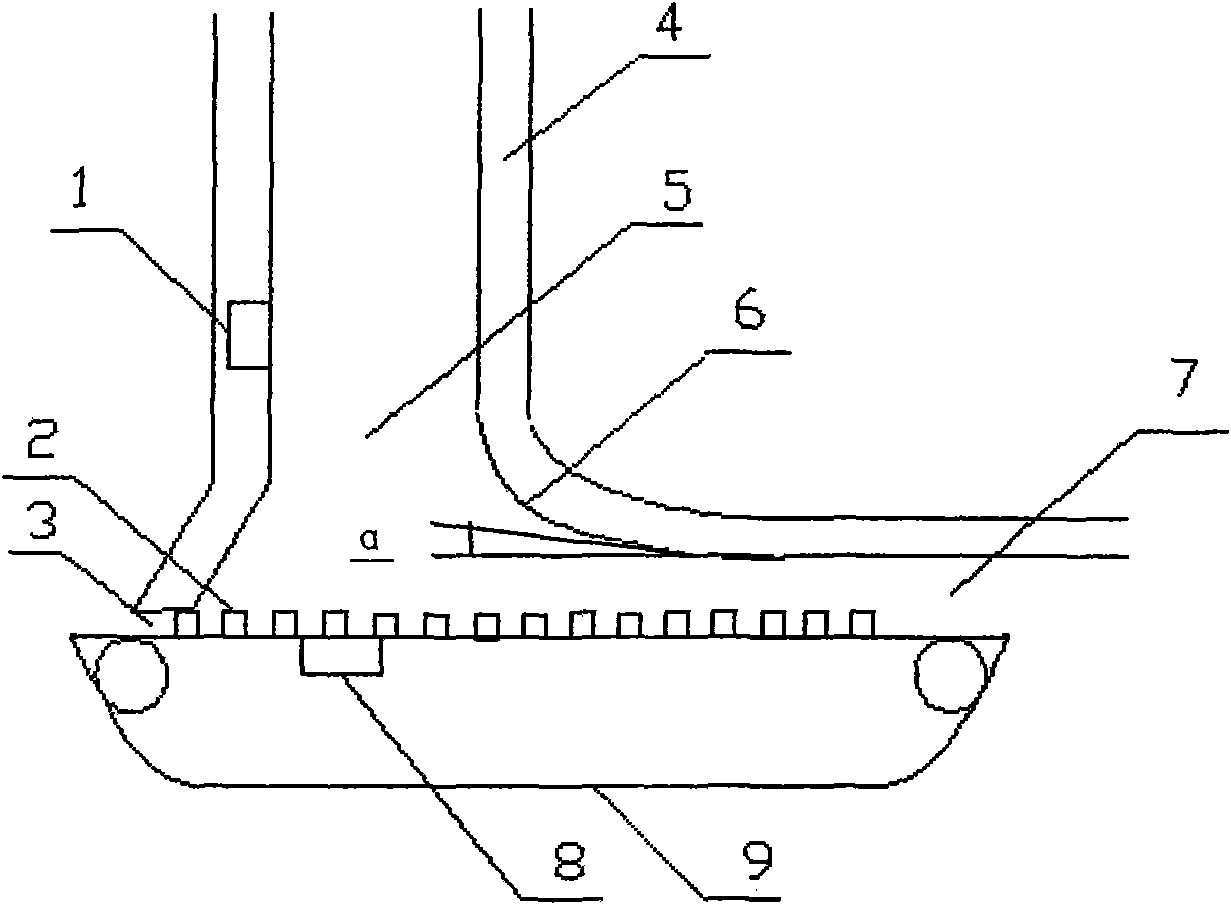

[0014] As shown in Figure 1, it is a fluidized bed boiler burning distiller's grains, and the humidity of distiller's grains is 15%. The key technology of the furnace structure is to organically combine the upper tuyere 1, the lower tuyere 8, and the heat storage layer 6 to achieve the purpose of maximizing the use of heat. The fuel delivery device 9 is at the lowermost end of the furnace body, passes through the bottom of the combustion chamber 5, and extends from the feed port 3 to the discharge port 7. For boilers with an evaporation capacity of 4-40t / h, the length ranges from 3.65 to 8.18 m. The downwind port 8 is located at the bottom of the combustion chamber 5, near the end of the feeding port 3. The upper tuyere 1 is on the furnace wall 4 on one side of the feed port 3 of the furnace body, and the distance between the upper tuyere 1 and the bottom of the combustion chamber 5 is 1.5-3m. The height of the furnace wall 4 is greater than the maximum rising height of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Inclination | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com