Vinegar-dreg (or vinasse)-burning hearth structure of fluidized-bed boiler

A fluidized bed boiler and furnace structure technology, which is applied to fluidized bed combustion equipment, fuels burned in a molten state, combustion methods, etc., can solve the problems of complex composition, difficult popularization, and difficult control, and improve system economy. performance, cost reduction

Inactive Publication Date: 2011-01-05

JIANGSU UNIV

View PDF3 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

But the deficiency of this patent is: in the structure such as material ram, slag drop pool, tower type water spray dust collector, water tank type soot collector of burning rice husk boiler, water must be used.

However, the disadvantages of this patent are: the composition structure is very complicated, the control of the upper temperature of the furnace and the outlet steam temperature of the tail heating surface is not easy to realize, the cost is high, and it is difficult to popularize

However, the disadvantage of this patent is that the composition structure is complex, which will inevitably lead to high cost, and it is impractical to use it in a large area in rice-producing areas.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

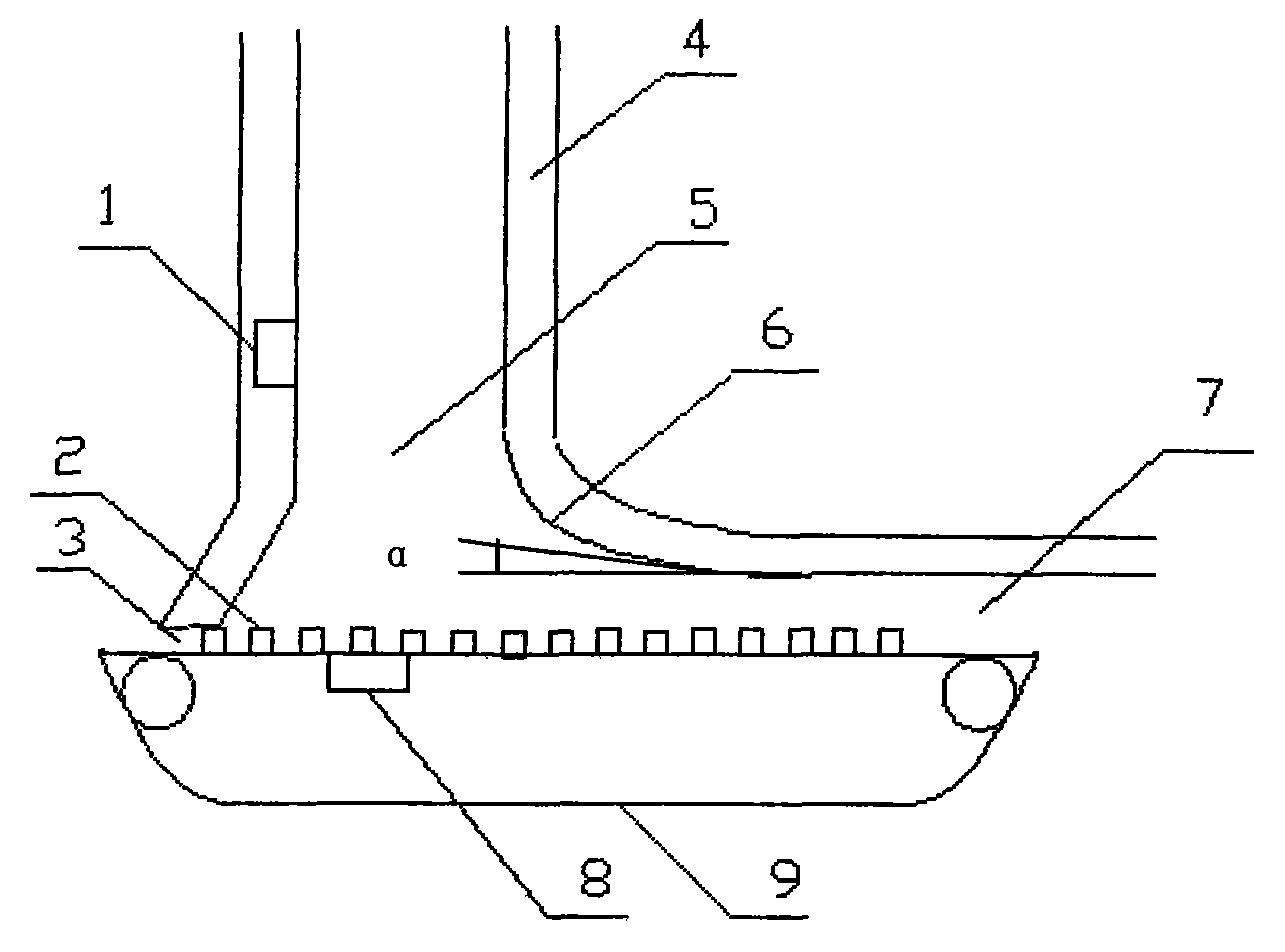

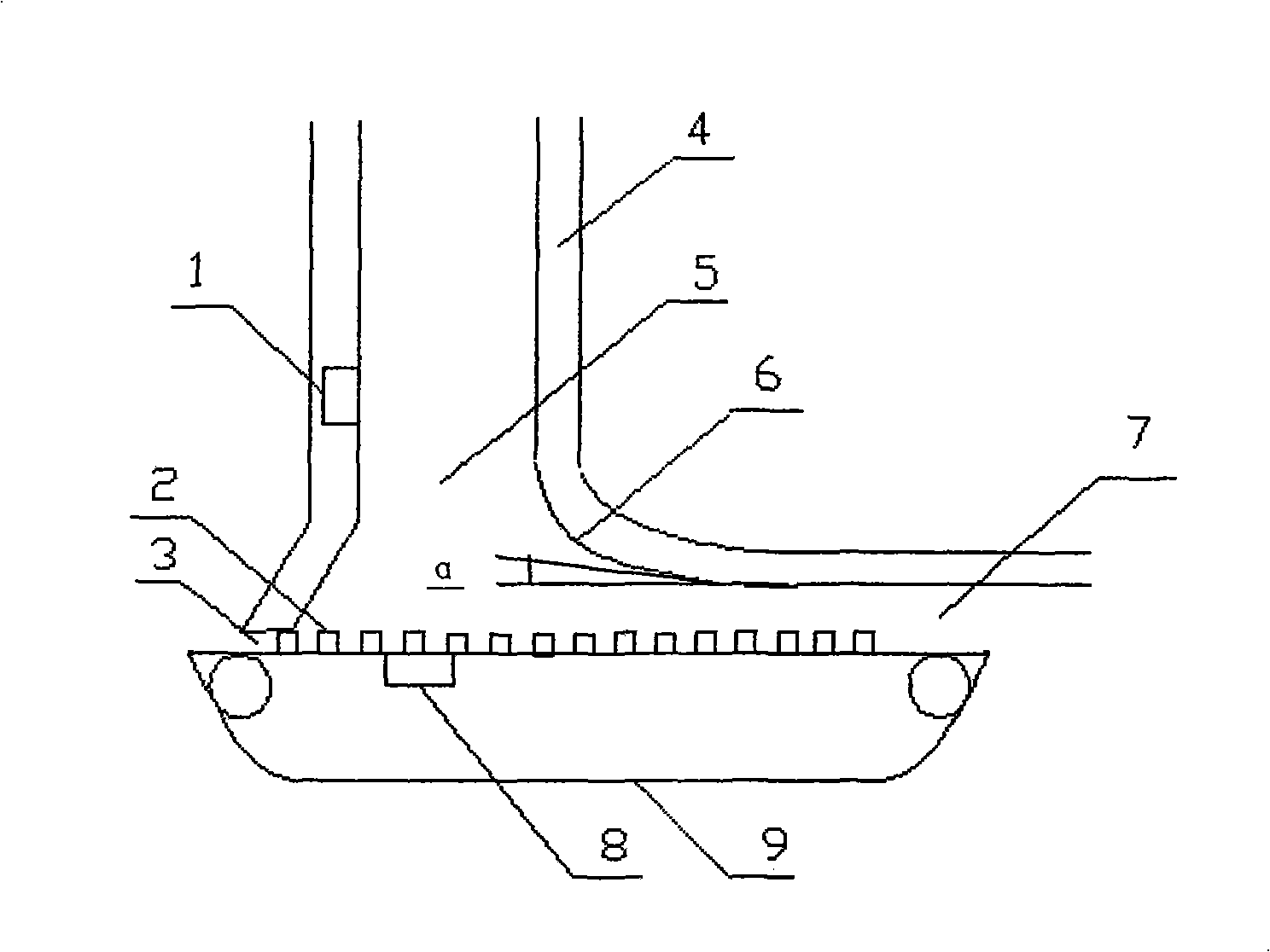

The invention relates to the filed of boiler apparatuses, in particular to a vinegar-dreg (or vinasse)-burning hearth structure of a fluidized-bed boiler. The hearth structure comprises an air opening, a feeding opening, a boiler body, a burning chamber, a heat accumulating layer, a discharge opening, an air discharge opening and a fuel conveying device. Vinegar dregs (or vinasse) are conveyed bythe fuel conveying device to enter the feeding opening and finally pass through the discharge opening. A boiler wall and the fuel conveying device are both made of high-temperature-resisting materials. The temperature in the burning chamber is high. Within a primary heating, the majority of the ash carried in the vinegar dregs (or vinasse) is burned. After a secondary heating, the vinegar dregs (or vinasse) releases the majority of heat, and meanwhile, the vinegar dregs (or vinasse) are completely burned out. The hearth structure realizes large-scale quantity-reduction, volume-reduction and non-harmful utilization of the vinegar dreg (or vinasse) resource, and better solves the social, environmental and energy problems caused by the vinegar dregs (or vinasse).

Description

Furnace structure of a fluidized bed boiler for burning vinegar or distiller's grains technical field The invention relates to the field of boiler equipment, in particular to a fluidized bed boiler furnace structure for burning vinegar (wine) grains, which can be widely used in various engineering companies, large-scale vinegar factories, wineries, paper mills and garbage treatment plants. Background technique Vinegar (wine) grains are residual waste in the vinegar (wine) industry. In the vinegar (wine) industry, the amount of vinegar (wine) lees produced every day is large, and has low calorific value, high moisture content, high salinity, a large amount of odor, takes up a lot of space and resources, and is slow to dissolve naturally. Characteristics such as serious pollution are produced to the environment, because these characteristics, the processing of vinegar (wine) grains is quite difficult. At present, vinegar (wine) grains are processed, and some studies are use...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): F23C10/18

Inventor 施爱平叶丽华

Owner JIANGSU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com