Black ceramic pigment and preparation method thereof

A technology for black ceramics and pigments, applied in the field of black ceramic pigments and their preparation, can solve the problems of restricting the development of black ceramic products, high cobalt oxide prices, secondary pollutant discharge, etc., achieving good coloring performance and shortening production time. , the effect of eliminating environmental hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A black ceramic pigment and a preparation method thereof. Its preparation method is:

[0022] 1) Mix the dust removal dust from electric furnace smelting stainless steel with chromium trioxide, nickel monoxide and manganese monoxide in a molar ratio of Fe:Cr:Ni:Mn=1:0.8:1.1:1.0 to obtain a mixed material;

[0023] 2) Place the mixed material in a microwave field, heat it for 15 minutes in an air atmosphere and a microwave power of 1.5kw, and keep it warm for 15 minutes when the temperature of the mixed material rises to 1100°C; then take the material out of the microwave field and cool it to room temperature in air , to obtain black ceramic pigments.

Embodiment 2

[0025] A black ceramic pigment and a preparation method thereof. Its preparation method is:

[0026] 1) Mix the dust removal dust from electric furnace smelting stainless steel with chromium trioxide, nickel monoxide and manganese monoxide in a molar ratio of Fe:Cr:Ni:Mn=1:1:0.5:1.2 to obtain a mixed material;

[0027] 2) Put the mixed material in the microwave field, heat it for 12 minutes under the condition of air atmosphere and microwave power of 2.4kw, when the temperature of the mixed material rises to 1075°C, keep it warm for 13 minutes; then take the material out of the microwave field, and air cool to room temperature , to obtain black ceramic pigments.

Embodiment 3

[0029] A black ceramic pigment and a preparation method thereof. Its preparation method is:

[0030] 1) Mix the dust removal dust from electric furnace smelting stainless steel with chromium trioxide, nickel monoxide and manganese monoxide in a molar ratio of Fe:Cr:Ni:Mn=1:1.3:0.7:0.7 to obtain a mixed material;

[0031] 2) Put the mixed material in the microwave field, heat it for 8 minutes under the condition of air atmosphere and microwave power of 3kw, when the temperature of the mixed material rises to 1150°C, keep it warm for 20 minutes; then take the material out of the microwave field, air cool to room temperature, A black ceramic pigment is obtained.

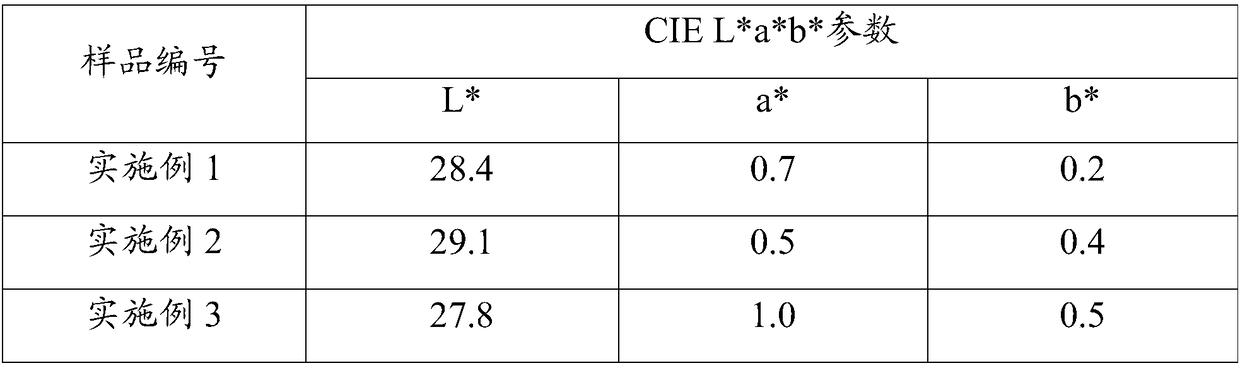

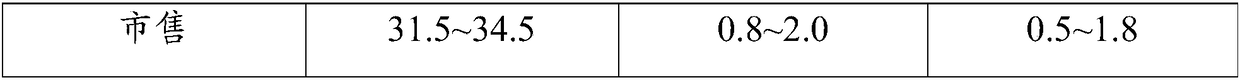

[0032] The black ceramic pigments prepared in Examples 1-3 and the commercially available cobalt-containing black ceramic pigment chromaticity CIE parameters are shown in Table 1

[0033] The prepared black ceramic pigment and commercially available cobalt-containing black ceramic pigment chromaticity CIE parameter in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com