Constructional ceramic prepared from copper-molybdenum tailings and preparation method thereof

A technology of building ceramics and tailings, applied in the field of mineral processing, to achieve the effects of simple process, mitigation of environmental pollution, and shortening of sintering time

- Summary

- Abstract

- Description

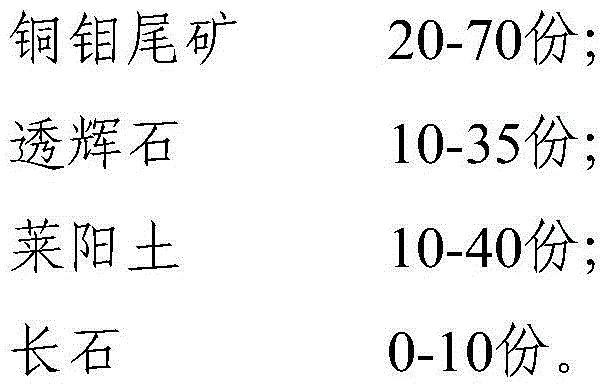

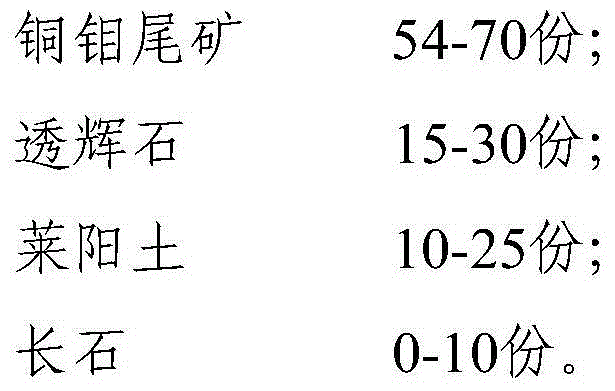

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

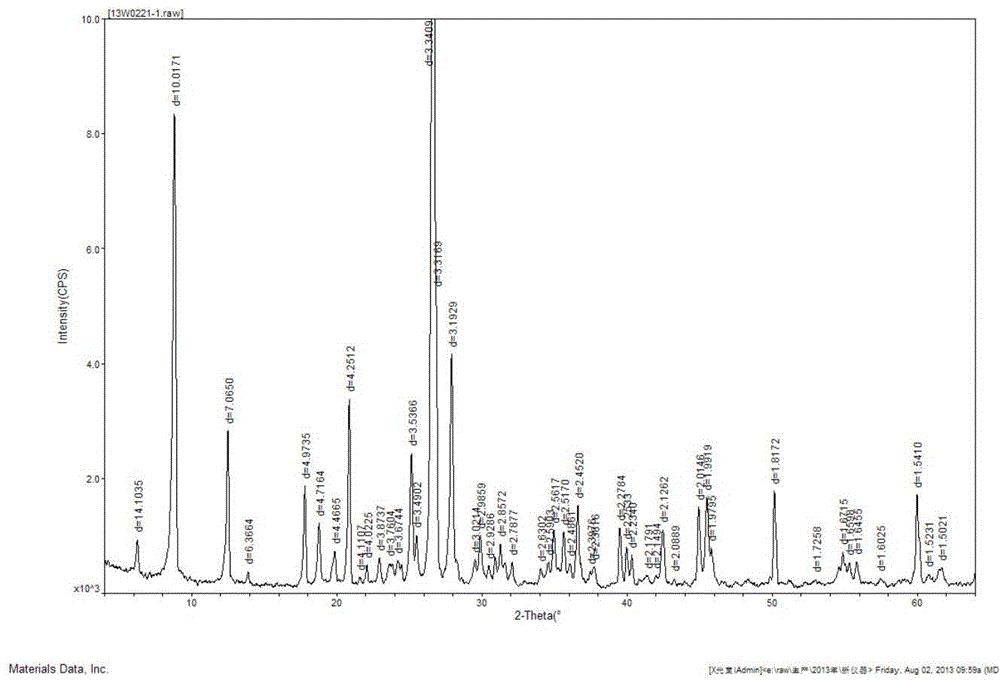

Image

Examples

Embodiment 1

[0046] The preparation of embodiment 1 ceramic floor tile

[0047] 1) Mixing of raw materials

[0048] Proportion by mass: 55% copper-molybdenum tailings, 29% diopside, 6% feldspar, 10% Laiyang, put the mixed raw materials into a ball mill, and add 0.8% of the mass of copper-molybdenum tailings CaCO 3 Mix with water until the raw material concentration is 40%, grind to 4% remaining on the million-hole sieve, spray dry, and set aside;

[0049] 2) Dry the above materials to a moisture content of 7%;

[0050] 3) Using an automatic hydraulic molding machine to press the material obtained in step 2) with a strength of 25 MPa to obtain an embryo body;

[0051] 4) The embryo body obtained in step 3) is dried in a roller-type drying kiln at 110±5°C and then glazed, and then sintered in a roller-type kiln at 1160°C×23min to obtain ceramic floor tiles.

[0052] It has been determined that the flexural strength of ceramic floor tiles is 1402.6N, the modulus of rupture is 44.45MP, and ...

Embodiment 2

[0053] The preparation of embodiment 2 ceramic floor tiles

[0054] 1) Mixing of raw materials

[0055] Proportion by mass: copper-molybdenum tailings 65%, diopside 16%, feldspar 7%, Laiyang soil 12%, put the mixed raw materials into a ball mill, add 0.8% of the mass of copper-molybdenum tailings CaCO 3 Mix with water until the concentration of the raw material is 35%, grind to 5% remaining on a multi-hole sieve, spray dry, and set aside;

[0056] 2) Dry the above materials to a water content of 6%;

[0057] 3) Using an automatic hydraulic molding machine to press the material obtained in step 2) with a strength of 20 MPa to obtain an embryo body;

[0058] 4) The embryo body obtained in step 3) is dried in a roller-type drying kiln at 110±5°C and then glazed, and then sintered in a roller-type kiln at 1160°C×23min to obtain ceramic floor tiles.

[0059]It has been determined that the flexural strength of ceramic floor tiles is 978N, the modulus of rupture is 42.45MP, and th...

Embodiment 3

[0060] The preparation of embodiment 3 ceramic floor tiles

[0061] 1) Mixing of raw materials

[0062] Proportion by mass: copper-molybdenum tailings 70%, diopside 15%, feldspar 3%, Laiyang 12%; put the mixed raw materials into a ball mill, add 0.8% of the mass of copper-molybdenum tailings CaCO 3 Mix with water until the concentration of the raw material is 45%, grind to 5% remaining on a multi-hole sieve, spray dry, and set aside;

[0063] 2) Dry the above materials to a water content of 8%;

[0064] 3) Using an automatic hydraulic molding machine to press the material obtained in step 2) with a strength of 30 MPa to obtain an embryo body;

[0065] 4) The embryo body obtained in step 3) is dried in a roller-type drying kiln at 110±5°C and then glazed, and then sintered in a roller-type kiln at 1160°C×23min to obtain ceramic floor tiles.

[0066] It has been determined that the flexural strength of ceramic floor tiles reaches 951N, the modulus of rupture is 41.45MP, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com