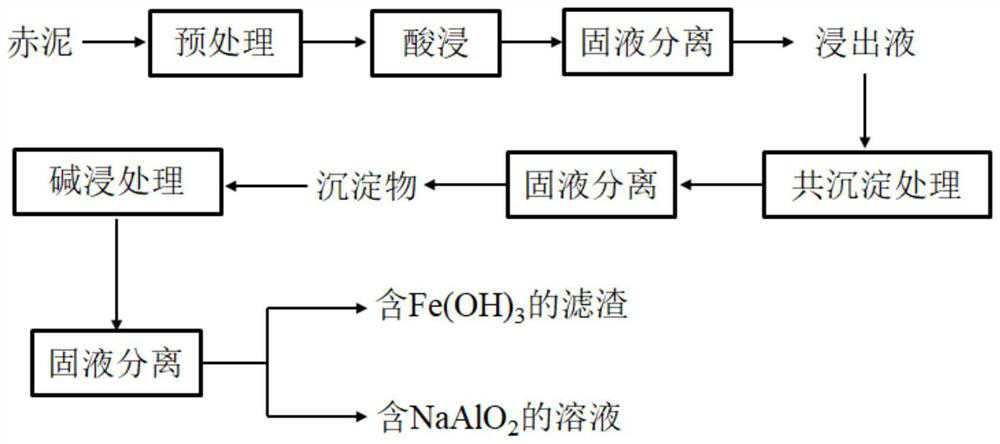

Method for separating iron and aluminum in red mud

A red mud, iron and aluminum technology, applied in the field of solid waste recycling, can solve the problems of low added value, high processing cost, low comprehensive recovery rate, etc., to achieve no secondary pollution, effective separation and recycling, and low processing cost cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

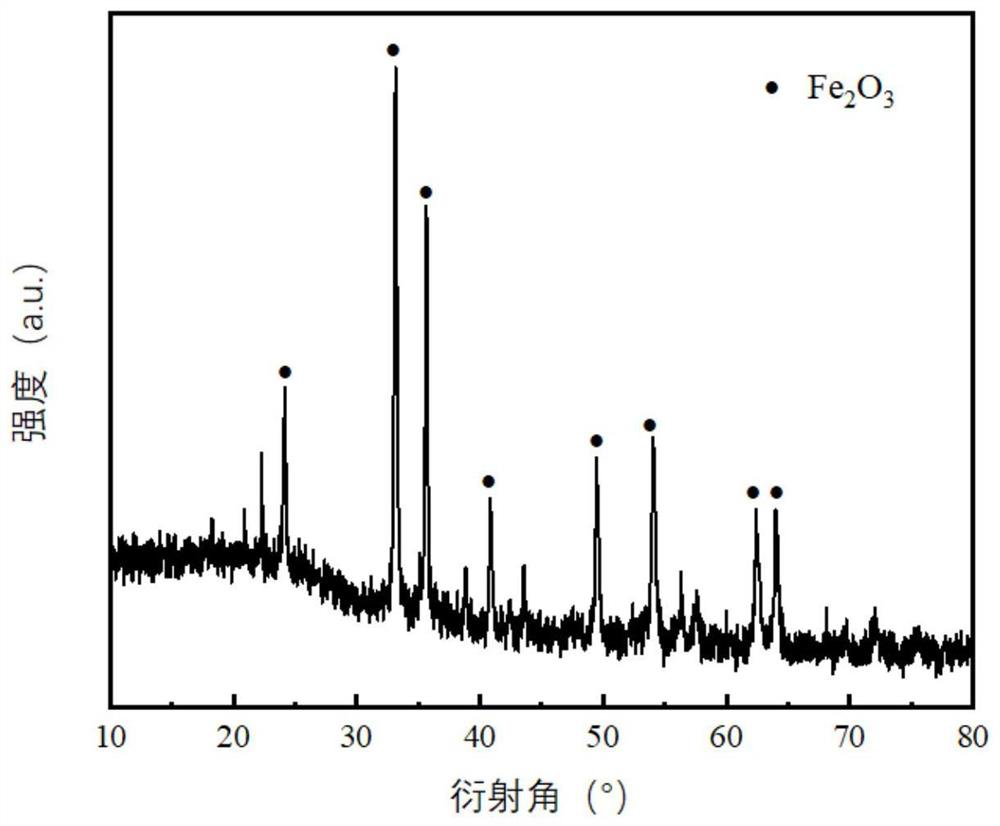

[0055] The present embodiment provides a method for separating iron and aluminum in red mud, and the method comprises the following steps:

[0056] (1) The red mud is crushed and ground successively, and the average particle size after grinding is 180 μm, then mixed with concentrated sulfuric acid, red mud and deionized water, the mass percentage of the concentrated sulfuric acid is 98%, and carried out at 85° C. Acid leaching for 3h to obtain a first mixed solution, the liquid-solid ratio of the concentrated sulfuric acid and red mud is 8:1mL / g, the liquid-solid ratio of the first mixed solution is 30:1mL / g, and then filtered to obtain Leachate, and also obtain leaching residue;

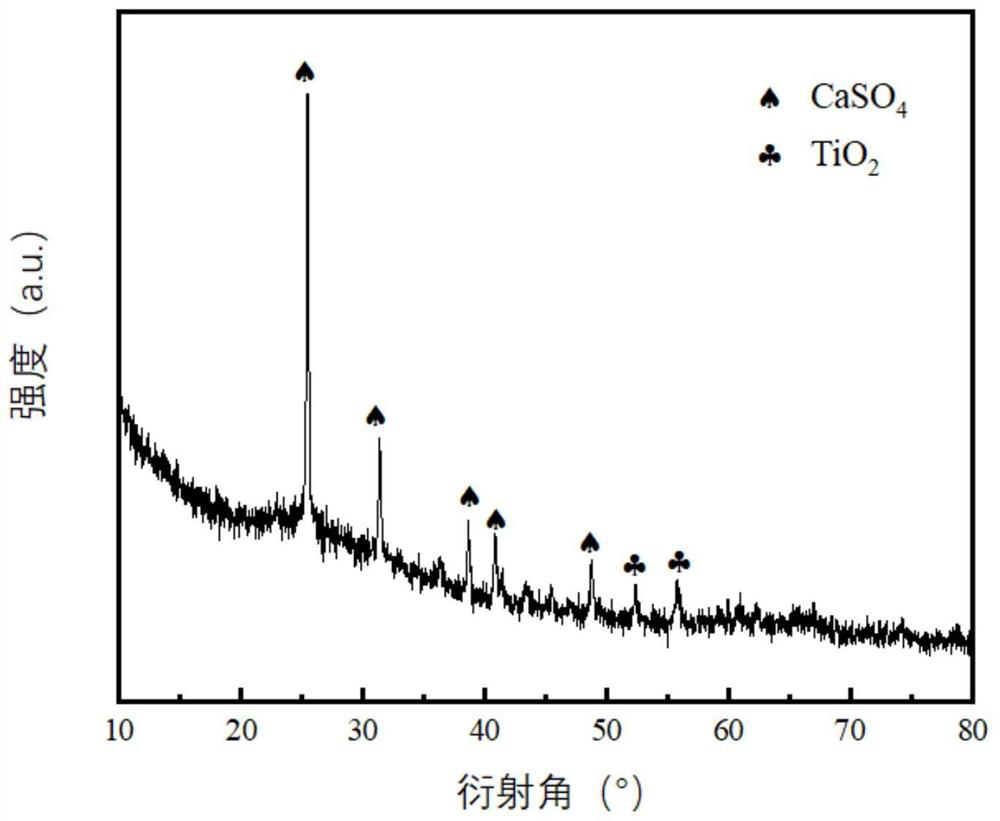

[0057] (2) mixing the leaching solution obtained in step (1) with the first alkaline agent, and carrying out co-precipitation treatment at 55° C., the first alkaline agent is ammonia water, and the pH value of the leaching solution after the co-precipitation treatment is 5.0 , and then filtered to ...

Embodiment 2

[0064] The present embodiment provides a method for separating iron and aluminum in red mud, and the method comprises the following steps:

[0065] (1) The red mud is crushed and ground in turn, and the average particle size after grinding is 150 μm, then mixed with concentrated sulfuric acid, red mud and deionized water, the mass percentage of the concentrated sulfuric acid is 98%, and carried out at 95 ° C. Acid leaching for 1h to obtain a first mixed solution, the liquid-solid ratio of the concentrated sulfuric acid and the red mud is 10:1mL / g, and the liquid-solid ratio of the first mixed solution is 10:1mL / g, and then filtered to obtain Leachate;

[0066] (2) mixing the leaching solution obtained in step (1) with the first alkali agent, and performing co-precipitation treatment at 20° C., the first alkali agent is sodium hydroxide, and the pH value of the leaching solution after the co-precipitation treatment is 4.7, and then filtered to obtain a precipitate;

[0067] (...

Embodiment 3

[0071] The present embodiment provides a method for separating iron and aluminum in red mud, and the method comprises the following steps:

[0072] (1) The red mud is crushed and ground successively, and the average particle size after grinding is 270 μm, then mixed with concentrated sulfuric acid, red mud and deionized water, the mass percentage of the concentrated sulfuric acid is 98%, and carried out at 55 ° C. Acid leaching for 6h to obtain a first mixed solution, the liquid-solid ratio of the concentrated sulfuric acid and red mud is 6:1mL / g, and the liquid-solid ratio of the first mixed solution is 50:1mL / g, and then filtered to obtain Leachate;

[0073] (2) mixing the leaching solution obtained in step (1) with the first alkali agent, and performing co-precipitation treatment at 60° C., the first alkali agent is sodium hydroxide, and the pH value of the leaching solution after the co-precipitation treatment is 8.4, and then filtered to obtain a precipitate;

[0074](3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com