Industrial treatment method of sintering red mud

A technology of calcification treatment and carbonization treatment is applied in the field of industrialized treatment of sintered red mud to achieve the effect of saving water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

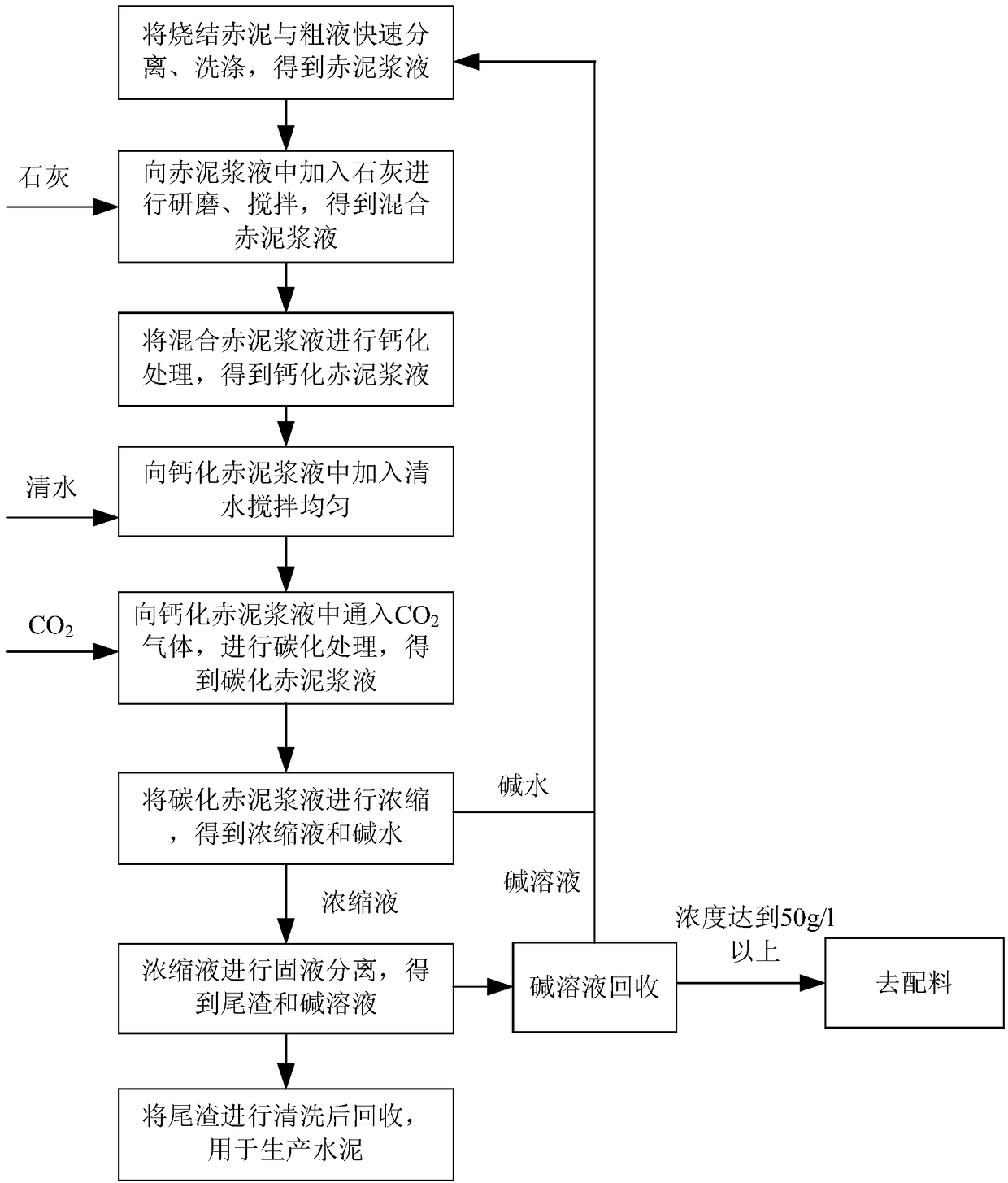

[0023] Such as figure 1 As shown, the method for industrially treating sintered red mud of the present invention includes the following steps:

[0024] (1) Separation and washing: the sintered red mud and the crude liquid are quickly separated and washed to obtain the red mud slurry. The sintered red mud produced in the process of alumina production is mixed with the crude liquid, which is an alkaline aqueous solution. When the sintered red mud is processed, the sintered red mud needs to be washed and mixed with the crude liquid. Separate.

[0025] (2) Mixing: The red mud slurry is fed into the mill, and lime is added to the red mud slurry for grinding and mixing uniformly to obtain a mixed red mud slurry. Specifically, the mass concentration of the mixed red mud slurry is 40%, the ratio of the calcium oxide content in the added lime to the sodium oxide content in the red mud slurry is 2, and the particle size of the red mud after grinding is 120 mesh, so The mass concentration ...

Embodiment 2

[0033] The industrialized method for processing sintered red mud of the present invention includes the following steps:

[0034] (1) Separation and washing: the sintered red mud and the crude liquid are quickly separated and washed to obtain the red mud slurry. The sintered red mud produced in the process of alumina production is mixed with the crude liquid, which is an alkaline aqueous solution. When the sintered red mud is processed, the sintered red mud needs to be washed and mixed with the crude liquid. Separate.

[0035] (2) Mixing: The red mud slurry is fed into the mill, and lime is added to the red mud slurry for grinding and mixing uniformly to obtain a mixed red mud slurry. Specifically, the mass concentration of the mixed red mud slurry is 40%, the ratio of the calcium oxide content in the added lime to the sodium oxide content in the red mud slurry is 2.5, and the particle size of the red mud after grinding is 160 mesh, so The mass concentration of sodium oxide in the...

Embodiment 3

[0043] The industrialized method for processing sintered red mud of the present invention includes the following steps:

[0044] (1) Separation and washing: the sintered red mud and the crude liquid are quickly separated and washed to obtain the red mud slurry. The sintered red mud produced in the process of alumina production is mixed with the crude liquid, which is an alkaline aqueous solution. When the sintered red mud is processed, the sintered red mud needs to be washed and mixed with the crude liquid. Separate.

[0045] (2) Mixing: The red mud slurry is fed into the mill, and lime is added to the red mud slurry for grinding and mixing uniformly to obtain a mixed red mud slurry. Specifically, the mass concentration of the mixed red mud slurry is 43%, the ratio of the calcium oxide content in the added lime to the sodium oxide content in the red mud slurry is 3, and the particle size of the red mud after grinding is 200 mesh, so The mass concentration of sodium oxide in the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com