Beneficiation method of recovering sulfur from copper sulfide ore flotation tailings

A technology for flotation tailings and ore dressing methods, applied in flotation, solid separation, etc., can solve the problems of low recovery rate of polluted sulfur, achieve stable process flow, reduce the amount of sulfuric acid, and reduce the amount of sulfuric acid.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

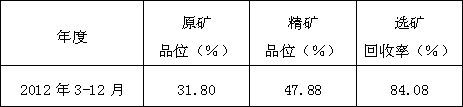

[0016] The production capacity of Jiangxi Copper Company's Dexing Copper Mine Dashan Concentrator is 92,000 t / d. Copper flotation tailings are used for sulfur separation, and hydrocyclones are used for sulfur separation operations. The output and concentrate grade cannot meet the needs of acid production.

[0017] 1. Equipment configuration of flotation sulfur separation system: 10 sets of 70m 3 Inflatable flotation machine for sulfur selection. Select 2 sets of φ420mm×10 cyclone grading equipment. Three 12 / 10ST-AH slurry pumps are selected and one φ45m thickener is used.

[0018] 2. Flotation process: The tailings separated from copper and sulfur use a thickener to remove the drug and dewater. After the underflow enters the cyclone for classification, the sand enters the flotation sulfur separation system, and the overflow can also enter the thickener after washing and removing the drug. The flotation sulfur separation system obtains the final sulfur concentrate after one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com