Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

51results about How to "Reduce blackness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

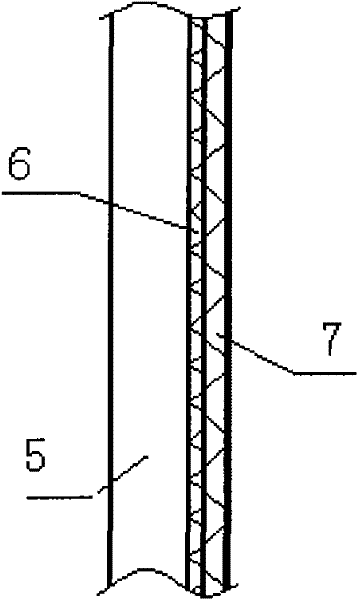

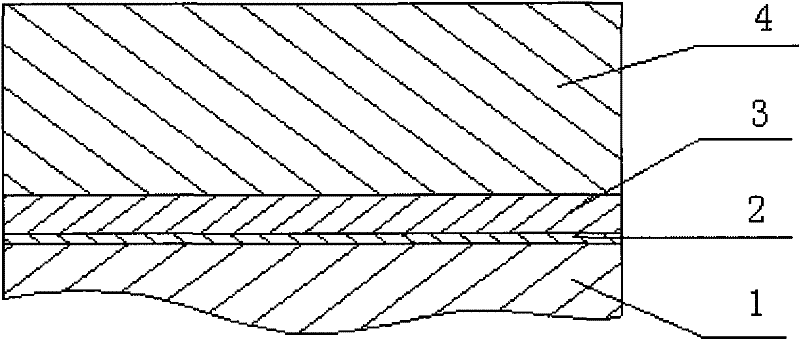

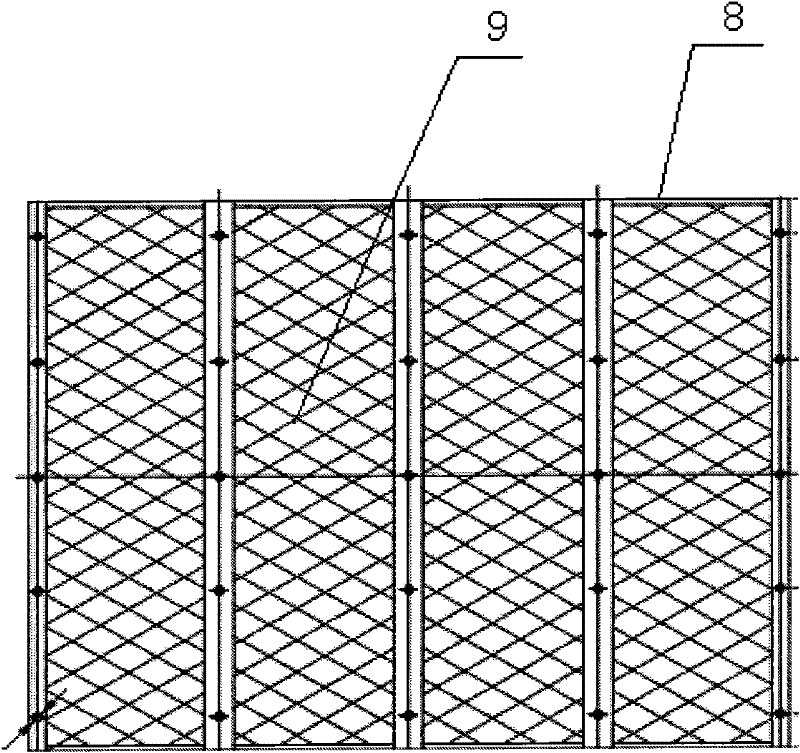

A kind of composite lead dioxide electrode plate and its manufacturing method

ActiveCN102280626AGuaranteed cleanlinessReduce blacknessElectrode carriers/collectorsLead-acid accumulator electrodesLead dioxideTitanium

The invention discloses a composite lead dioxide electrode plate, which comprises a composite lead dioxide anode plate and a protective net covering the periphery of the composite lead dioxide anode plate, wherein the composite lead dioxide anode plate is arranged in a framework and comprises a plurality of small anode plates spliced and connected with one another; and each small anode plate comprises a titanium substrate, a transition layer coated on the titanium substrate, an alpha-PbO2 interlayer coated on the transition layer and a beta-PbO2 active layer coated on the alpha-PbO2 interlayer; and the transition layer comprises at least one component of Pt, IrO2, Ta and Ta2O5. Correspondingly, the invention also provides a method for manufacturing the composite lead dioxide electrode plate. The composite lead dioxide electrode plate prepared by the method has long service life, the passivation process is stable, and an excellent implementation effect is achieved.

Owner:BAOSHAN IRON & STEEL CO LTD

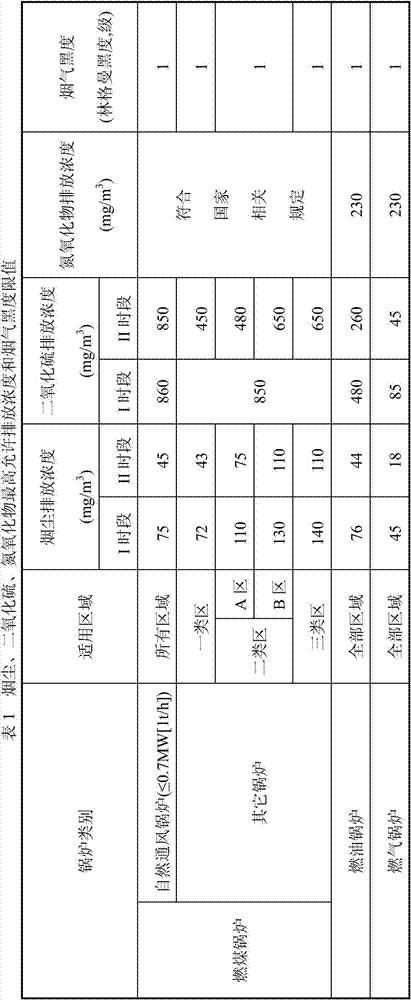

Combustion-supporting, desulfurization and coal-saving additive used for boiler fire coal

InactiveCN101230301AHigh thermal efficiencyPrevent coking accidentsSolid fuelsFuel additivesCombustionPotassium dichromate

The invention provides a combustion-supporting desulfurating coal-saving additive which is used in the burning coal in boiler, the preparation of which is composed of 24-35 percent combustion improvers of methanol, aether, tween-80; 32-38 percent oxidants of potassium permanganate, potassium chlorate and potassium dichromate; 4-28 percent desulfurizer in which quicklime, potassium permanganate, potassium chlorate and potassium dichromate take part in; 18-22 percent anti-coking agent which contains potassium dichromate and quicklime; the rest is water, which complement the total volume of the additive to be 100 percent. The additive is prepared by adding water in the quicklime to produce lime cream; heating the water for acting as solution, after potassium permanganate, potassium chlorate and potassium dichromate are added into the solution and are stirred evenly; adding and mixing the methanol and tween-80 into the solution evenly, and then adding and mixing the lime cream into the solution evenly; finally adding and mixing the aether into the solution evenly; and preserving the heat for 1 hour. The invention can improve the desulfurization rate by 40 percent, improve the coal saving rate by 25 percent, and improve the thermal efficiency of the boiler by up to 5-10 percent; and can prevent the occurrence of boiler coking accident.

Owner:周兴泽

High-performance energy-saving rare earth deashing and delayed action activator for boiler, and its manufacturing method

InactiveCN1730630APromote sheddingAvoid generatingLighting and heating apparatusFuel additivesCongruent meltingNitrate

The invention provides a rare earth high-performance energy-saving boiler deashing and decoking agent and its manufacture process, which comprises selecting and weighing nitrates, cerium oxide, neodymium oxide, tinkalite, sodium carbonate, sodium chloride, calcium carbonate, magnesium oxide, agitating and mixing, congruent melting, drying, granulating and inspecting.

Owner:金余兴

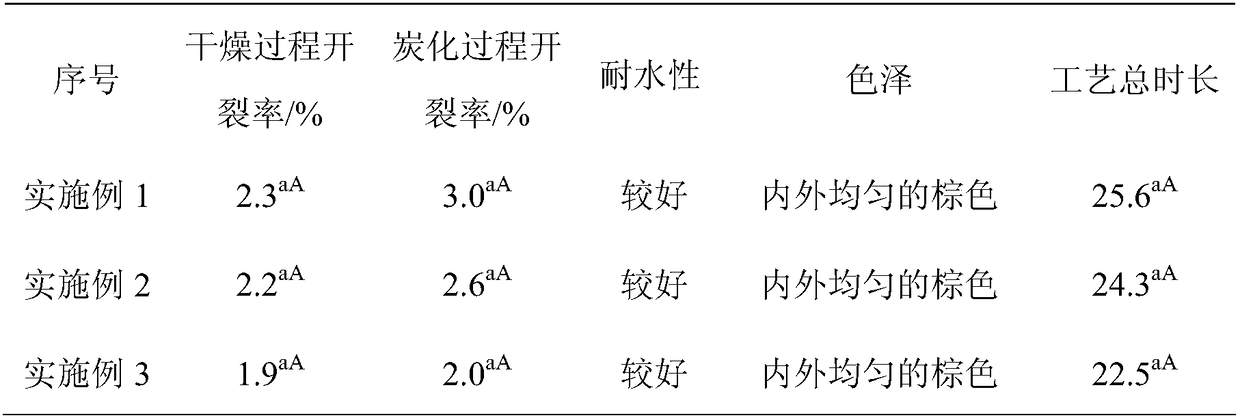

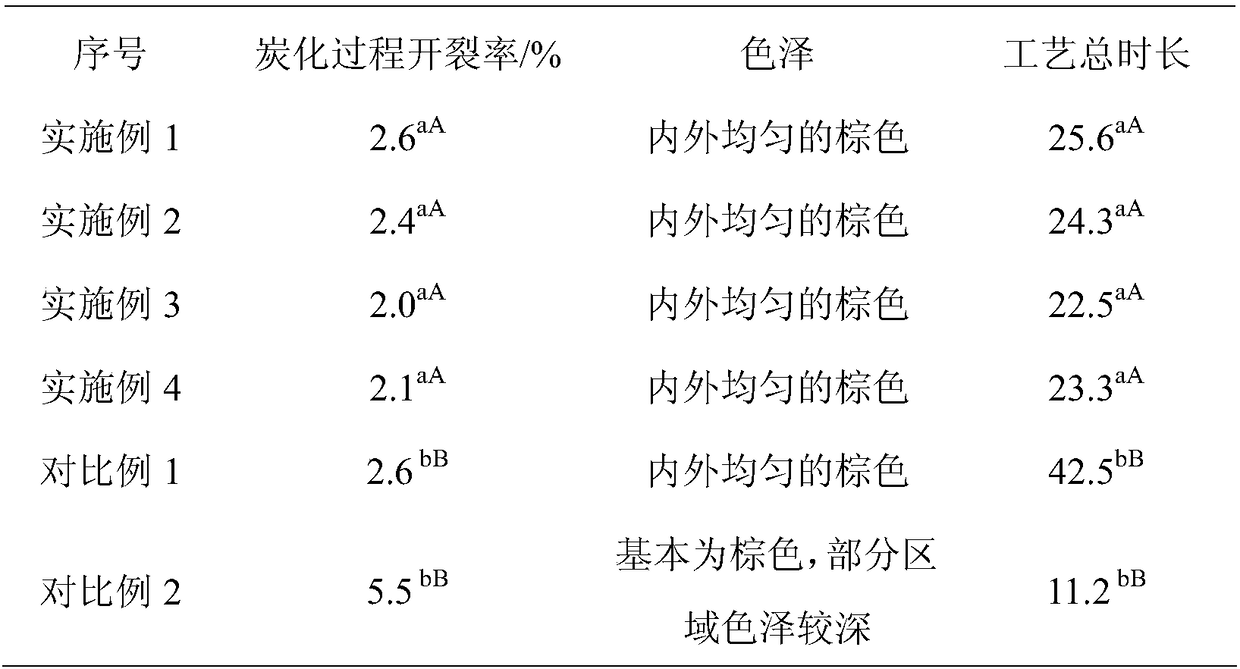

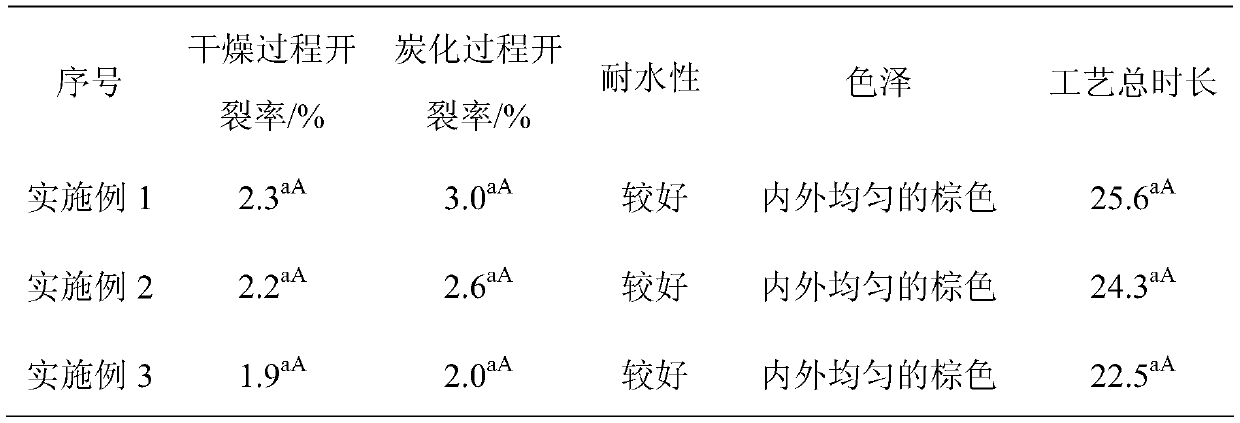

Processing method of water-proof carbonization wood board

ActiveCN108189184AStrong connectionShort timeWood treatment detailsCoating impregnationSurface finishingCarbonization

The invention belongs to the field of wood, and discloses a processing method of a water-proof carbonization wood board. The processing method comprises the five steps of cutting and cleaning, drying,surface treating, carbonization and shaping. The invention provides a processing method of a water-proof carbonization wood board, less time is consumed, and the carbonization is even.

Owner:台州中知英健机械自动化有限公司

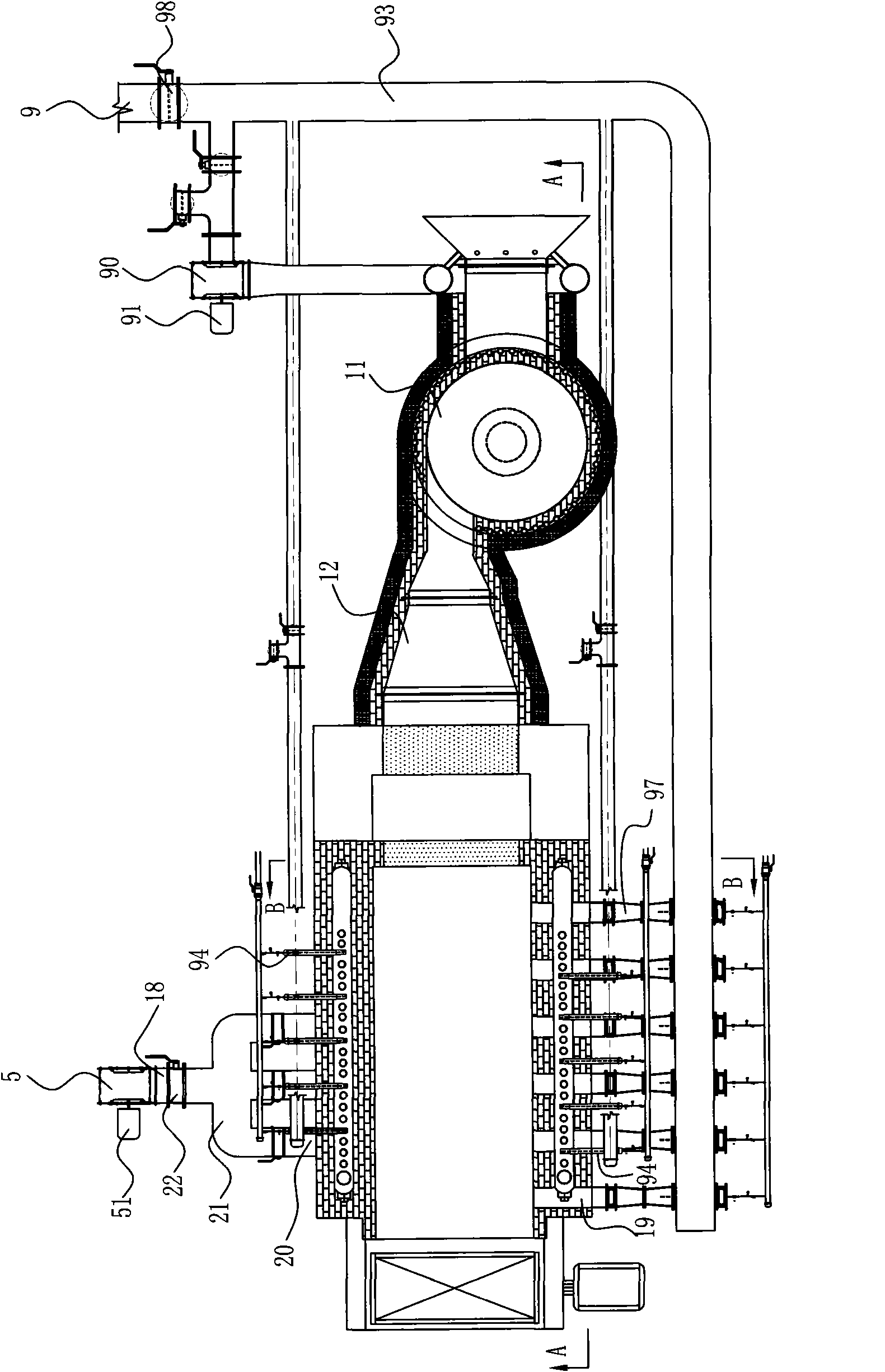

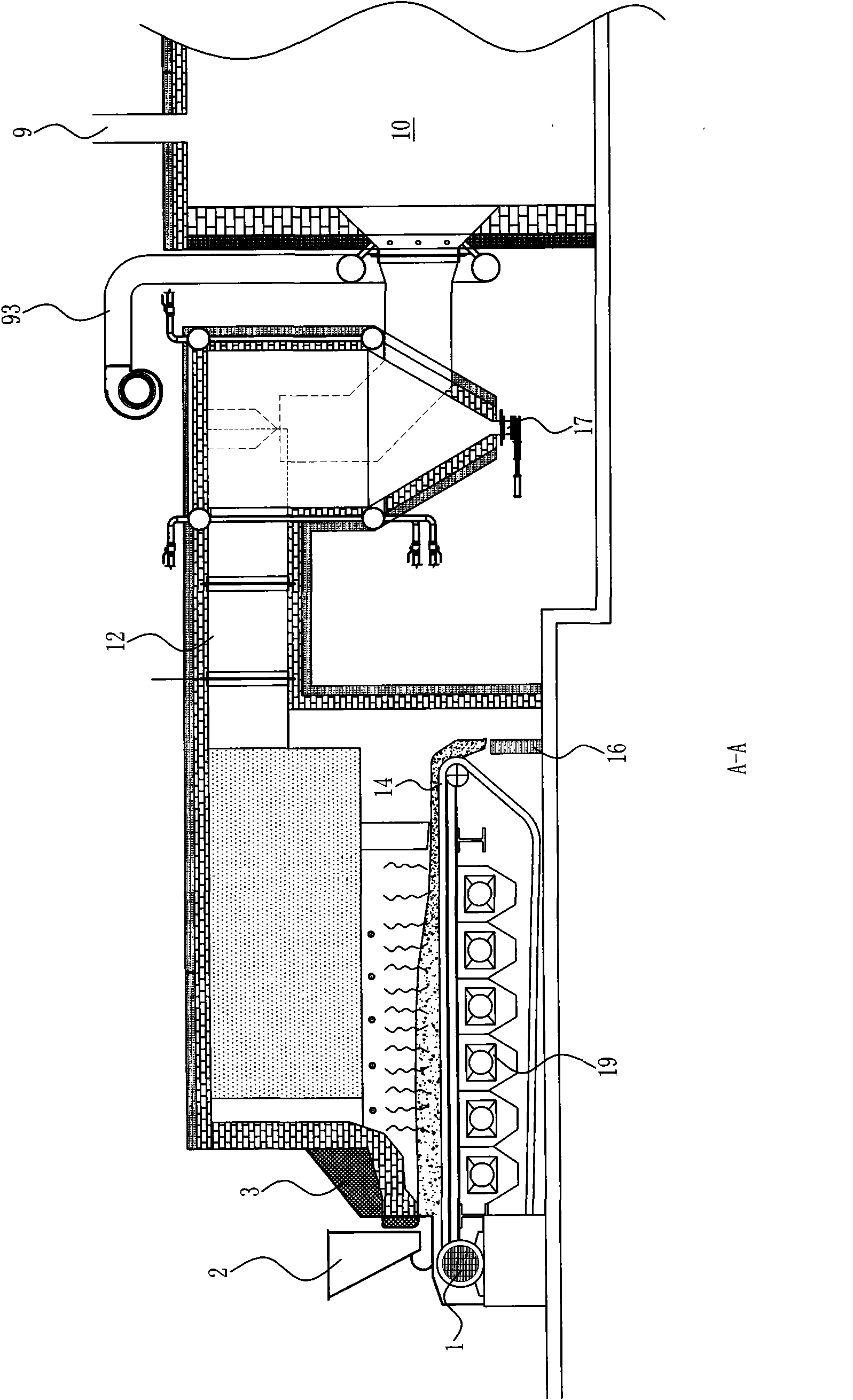

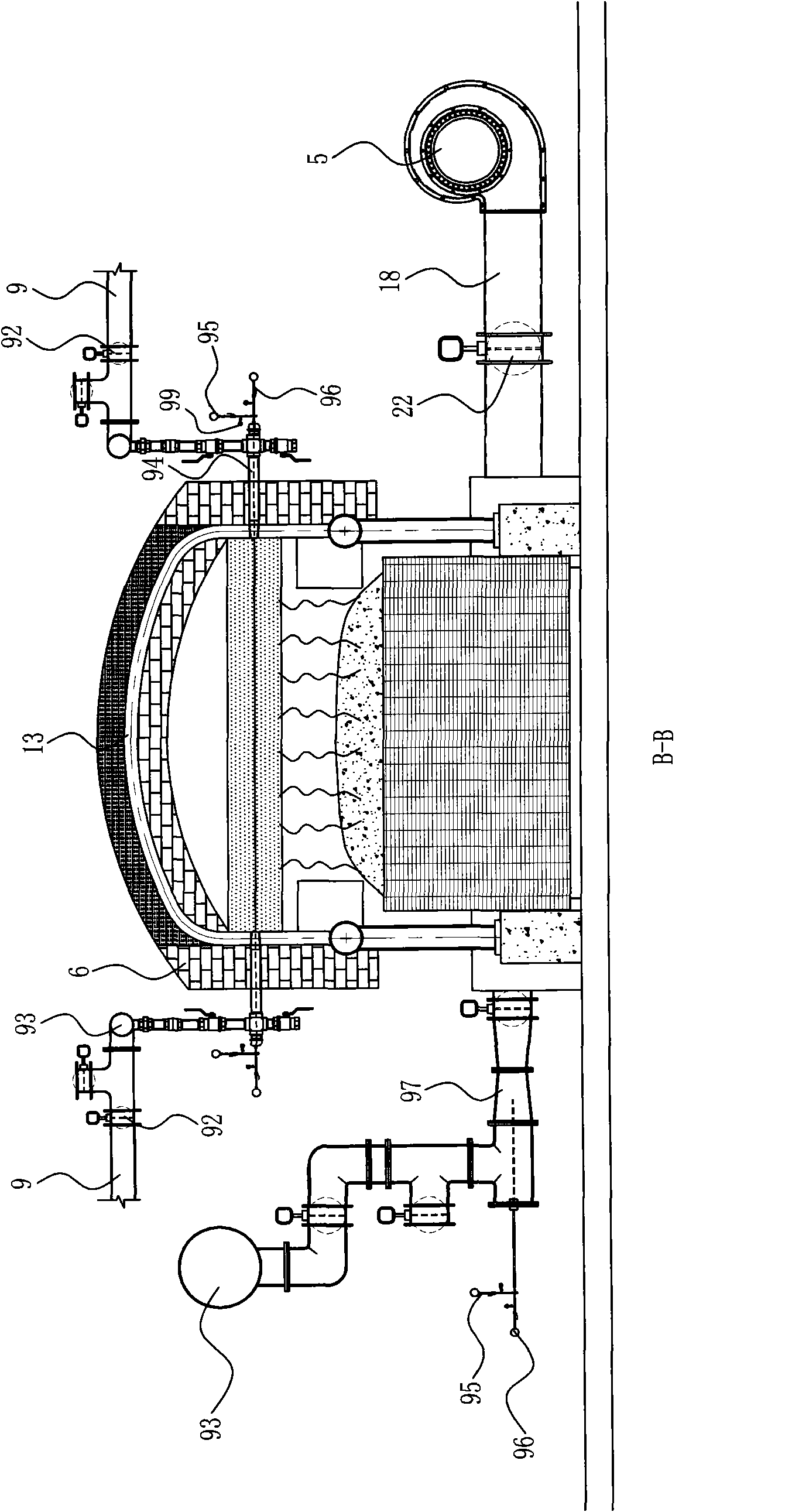

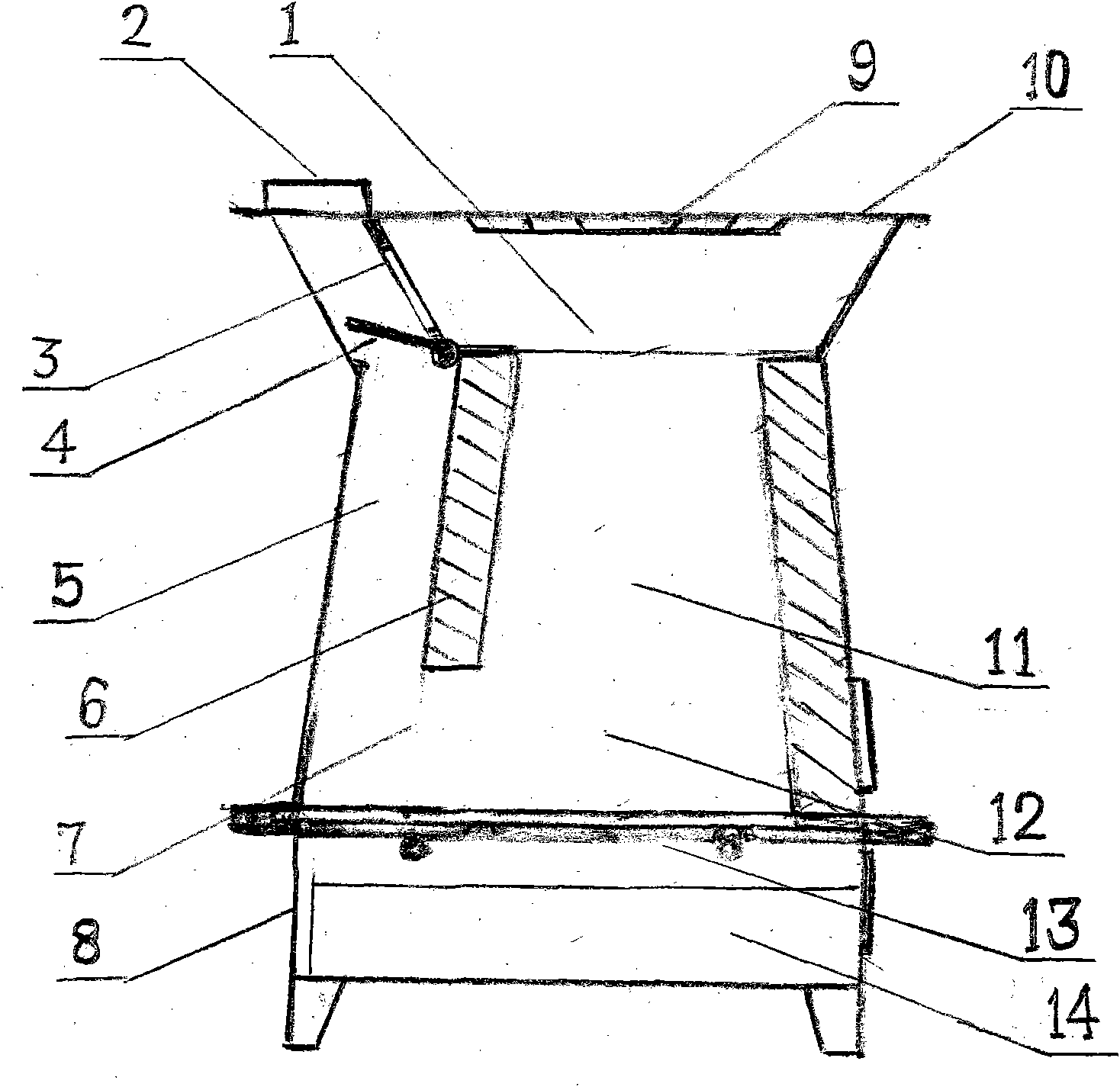

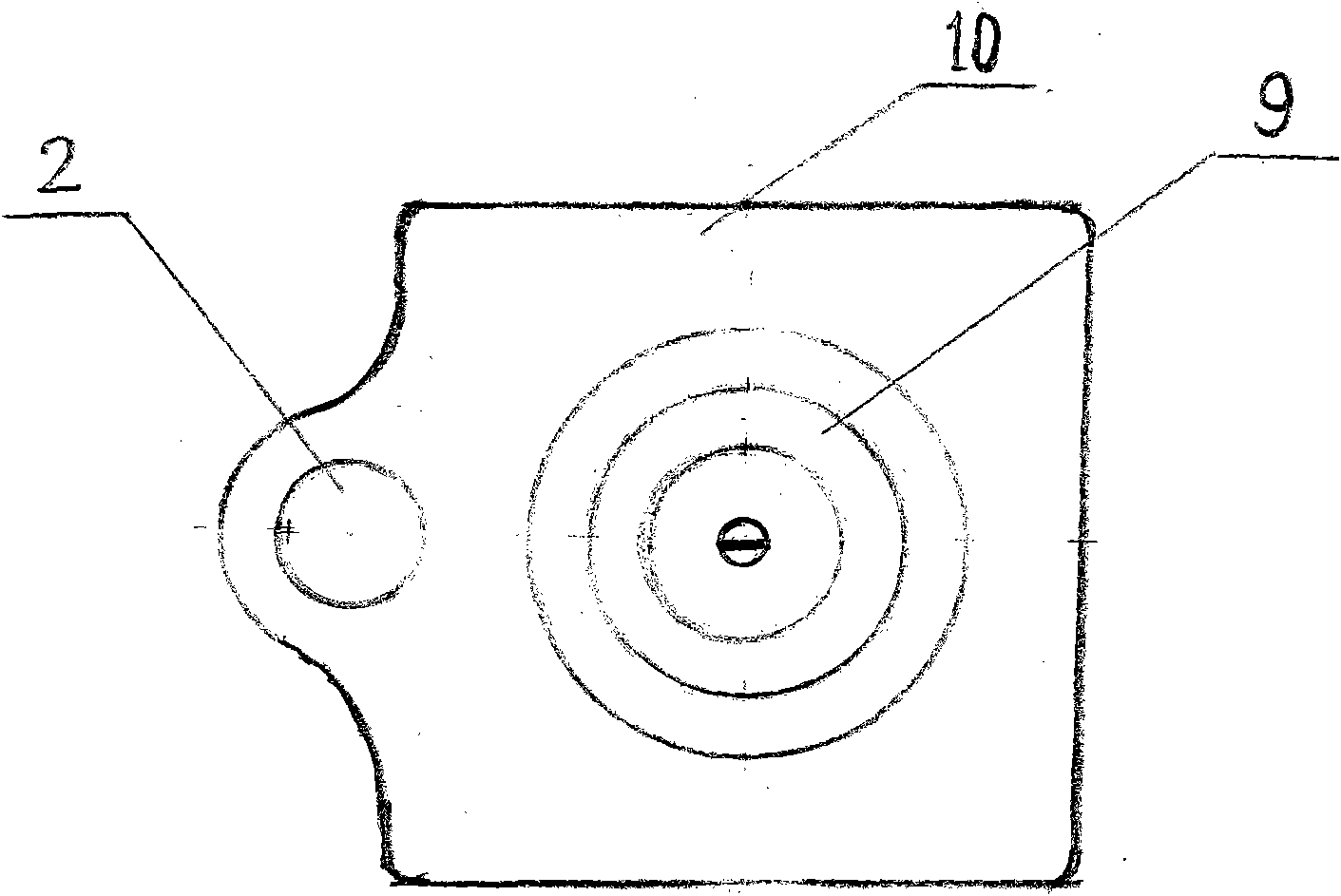

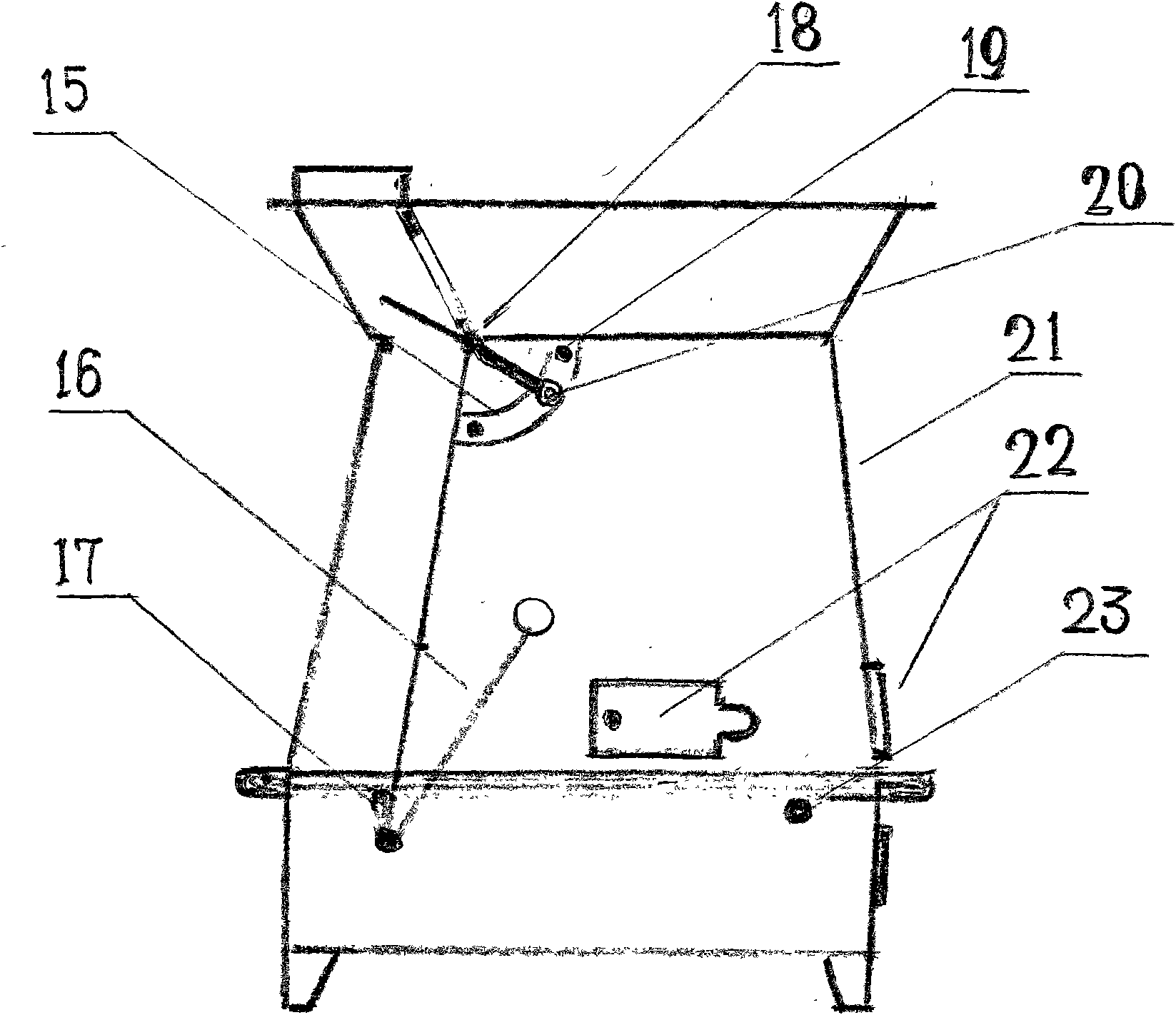

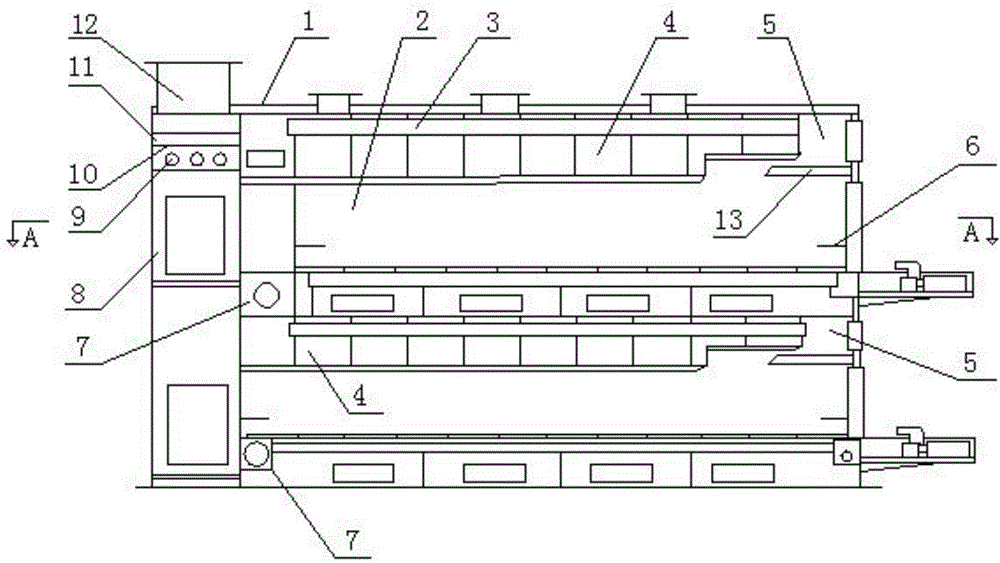

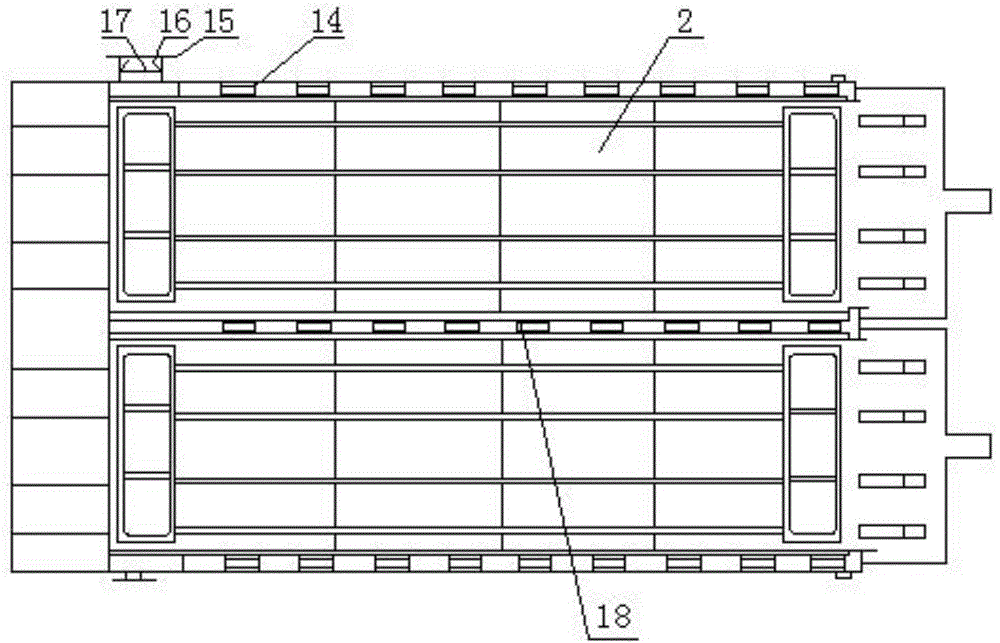

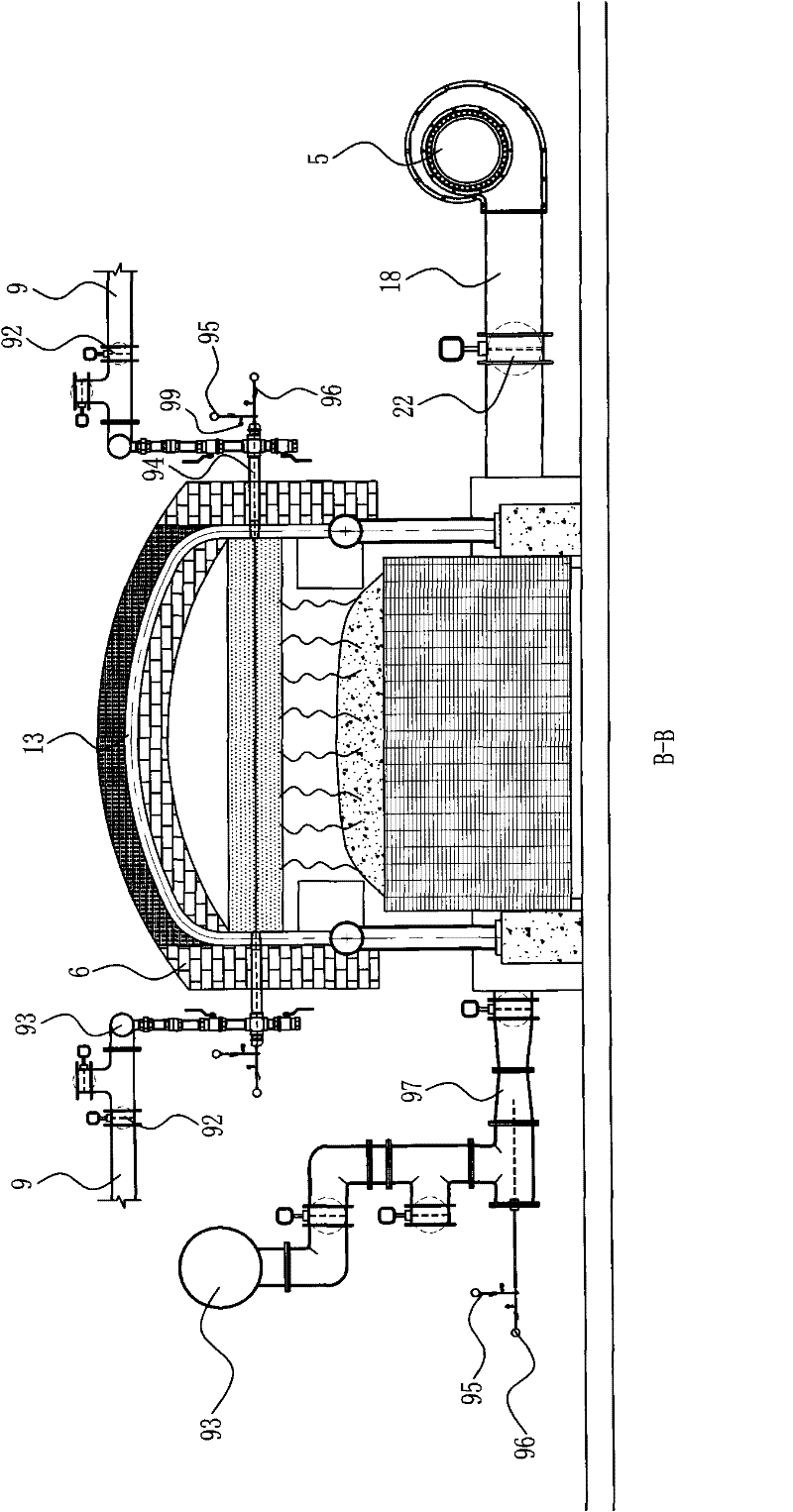

Horizontal mobile grate gasifier

InactiveCN101776260AEmission reductionImprove protectionCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorFlue gas

The invention relates to a horizontal mobile grate gasifier, which comprises a furnace body with a grate and an air supply device. The air supply device consists of a primary air supply pipe and an upper-layer air supply pipe, the primary air supply pipe is connected with a plurality of air chambers and is arranged below the grate, the upper-layer air supply pipe is arranged on the two sidewalls of the furnace body and is communicated with the inner chamber of the furnace body, the rear part of the furnace body is provided with a flue gas channel, the rear end of the flue gas channel is connected with the combustor of a boiler, a flue gas circulating pipe which is connected with the rear part of the combustor communicates circulating flue gas and the upper-layer air supply pipe to form a mixed gas channel, the mixed gas channel and a steam pipe respectively extend into the air chamber and the cavity of the furnace body through a primary air Venturi pipe and a secondary air Venturi pipe; and mixed gas can flow to the front side of the combustor of the boiler through a gas mixing fan. The invention has the advantages of reducing Ringelman black and smoke emission, allowing the use of coal raw materials which are each to be coked, expanding the flexibility of the boiler use and the diversity of operating modes, and realizing the online real-time control and adjustment of parameters of steam output variables, grate operation and gasification dosage, thereby achieving the best operating conditions.

Owner:NINGBO YINUO ENERGY TECH

Environment friendly energy-saving smokeless stove

InactiveCN101566355ASimple structureEasy to manufactureDomestic stoves or rangesLighting and heating apparatusProcess engineeringHeating furnace

The invention relates to heating furnace for town and country families, particularly an environment friendly energy-saving smokeless stove. The furnace is provided with a taper fire resistant burner band such as a counter heating area and a hand-operated movable fire grate with a reasonable gap, thus facilitating burning, heating and cooking. The furnace can burn industrial refuse and domestic garbage so as to purify the environment and convert the heat energy.

Owner:王世俊

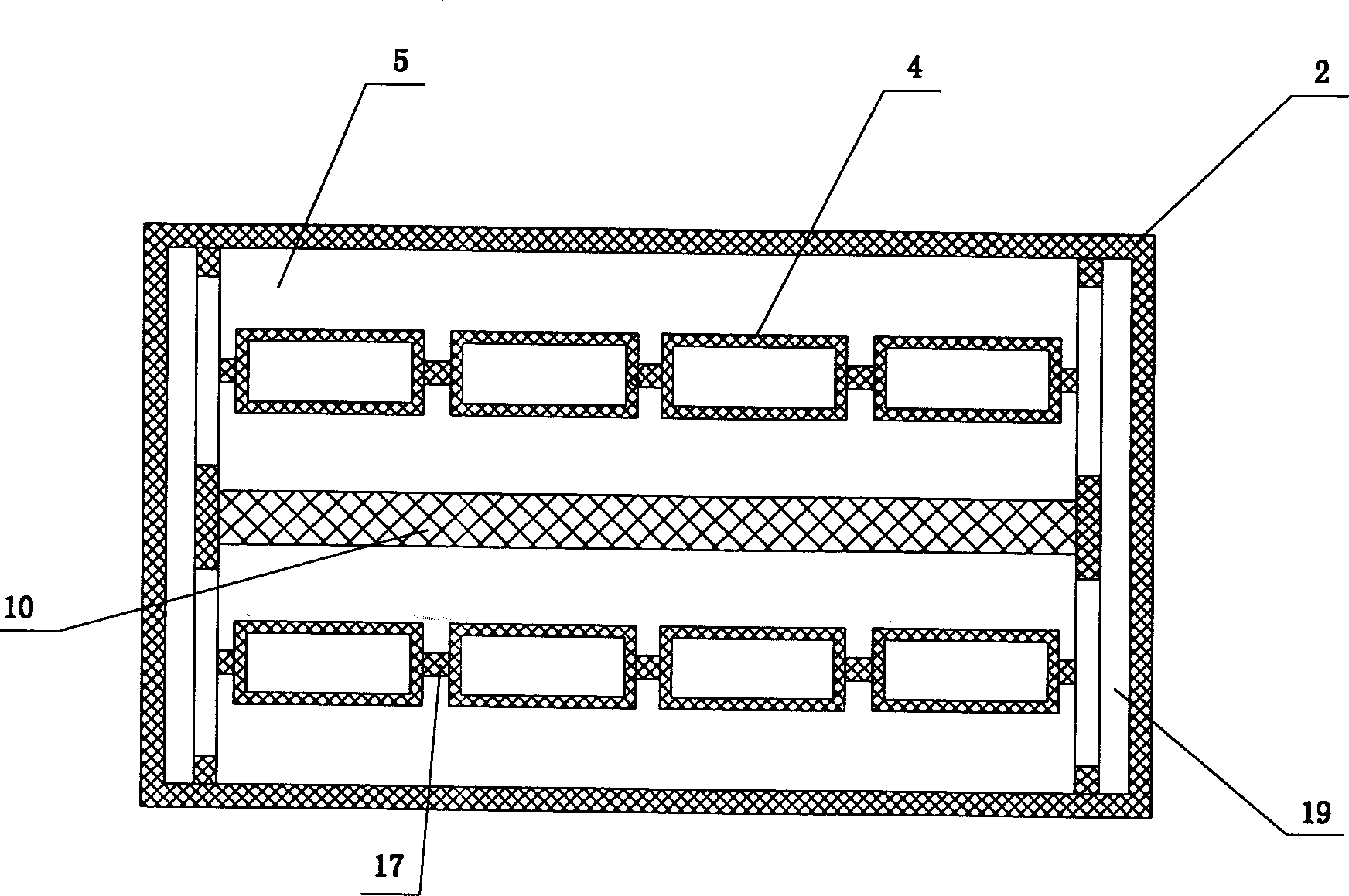

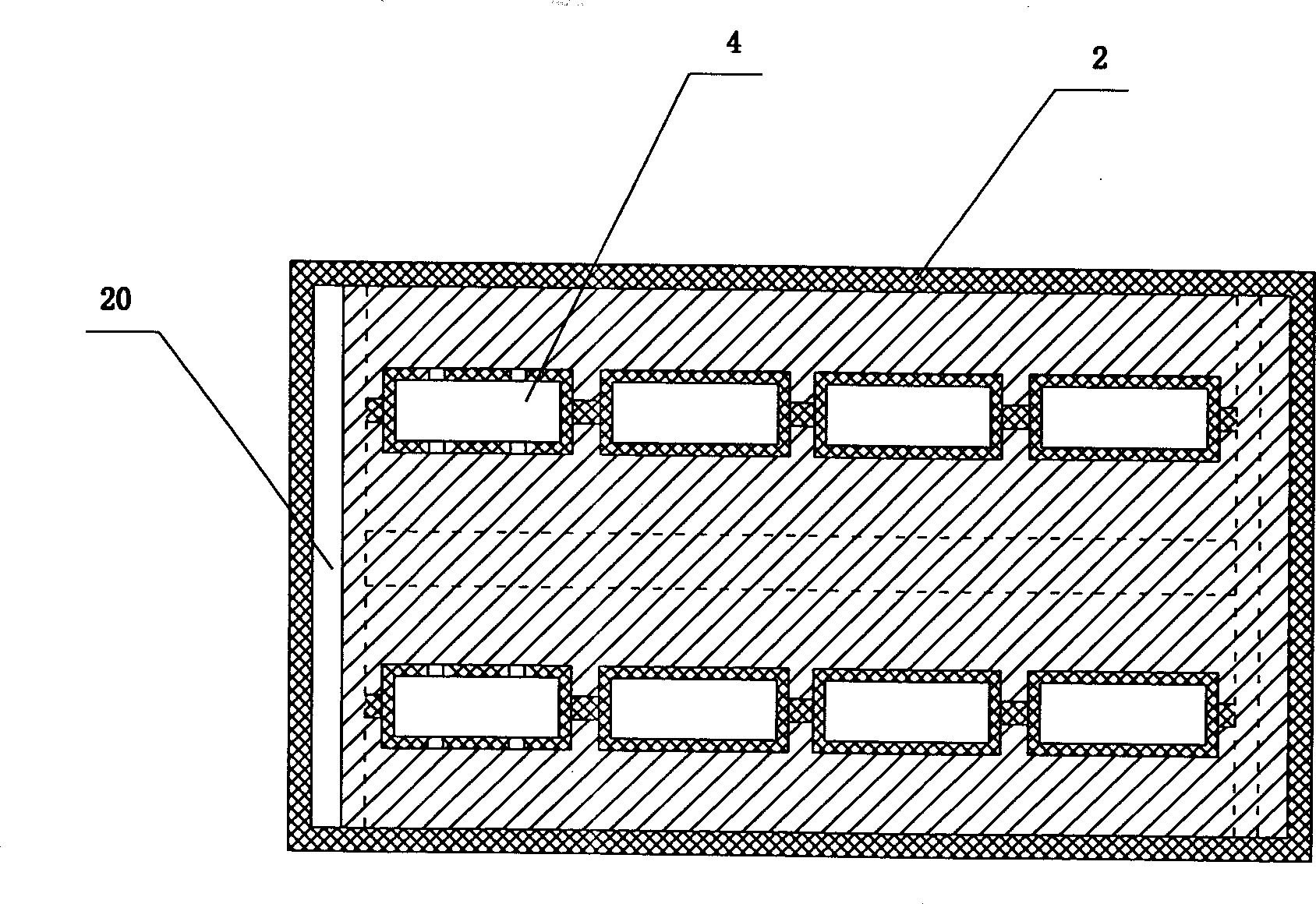

8-box 9-layer high-temp calciner

InactiveCN1363816AAvoid overhaul in less than three yearsUniform temperatureMuffle furnacesRetort furnacesEngineeringCoal

A 8-chamber 9-layer high-temp calciner is composed of 8 coal calcining chambers in two rows, heating fire channel surrounding them, flue and chimney. The material feeding hopper and discharging hopper are respectively on the top and bottom of said calcining chambers. Its advantages are long service life, and high temp (1200-1300 deg.C).

Owner:李令杰

Coal additive

ActiveCN103320195APlay a catalytic roleLower the ignition temperatureSolid fuelsRare-earth elementCombustion

The invention provides a coal additive. The coal additive comprises an emulsifier, a dispersant, a corrosion inhibitor and a penetrant. The coal additive contains O, Mg, Al, Si, S, Ca, Ba and Mn. The coal additive has the advantages that the emulsifier, the dispersant, the corrosion inhibitor and the penetrant are used and the rare earth elements improve catalyst activity so that a traditional exterior-to-interior combustion mode is changed into an interior-exterior synchronous combustion mode and thus a coal complete-combustion degree is improved and a heat loss caused by chemical incomplete combustion and mechanical incomplete combustion of coal in a furnace is reduced; and through composite carriers having mesoporous structures, catalyst activity is improved, a hydrodesulfurization process is finished and discharge amounts of flue dust and harmful gas in exhaust gas are reduced so that coal saving and sulfur fixation are realized.

Owner:甘肃泰聚环保科技有限公司

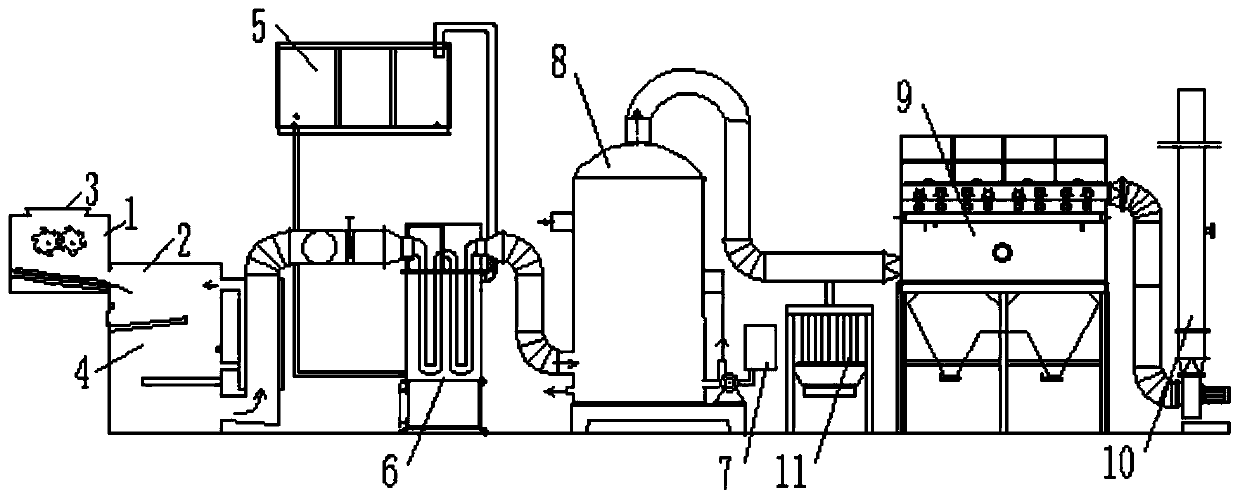

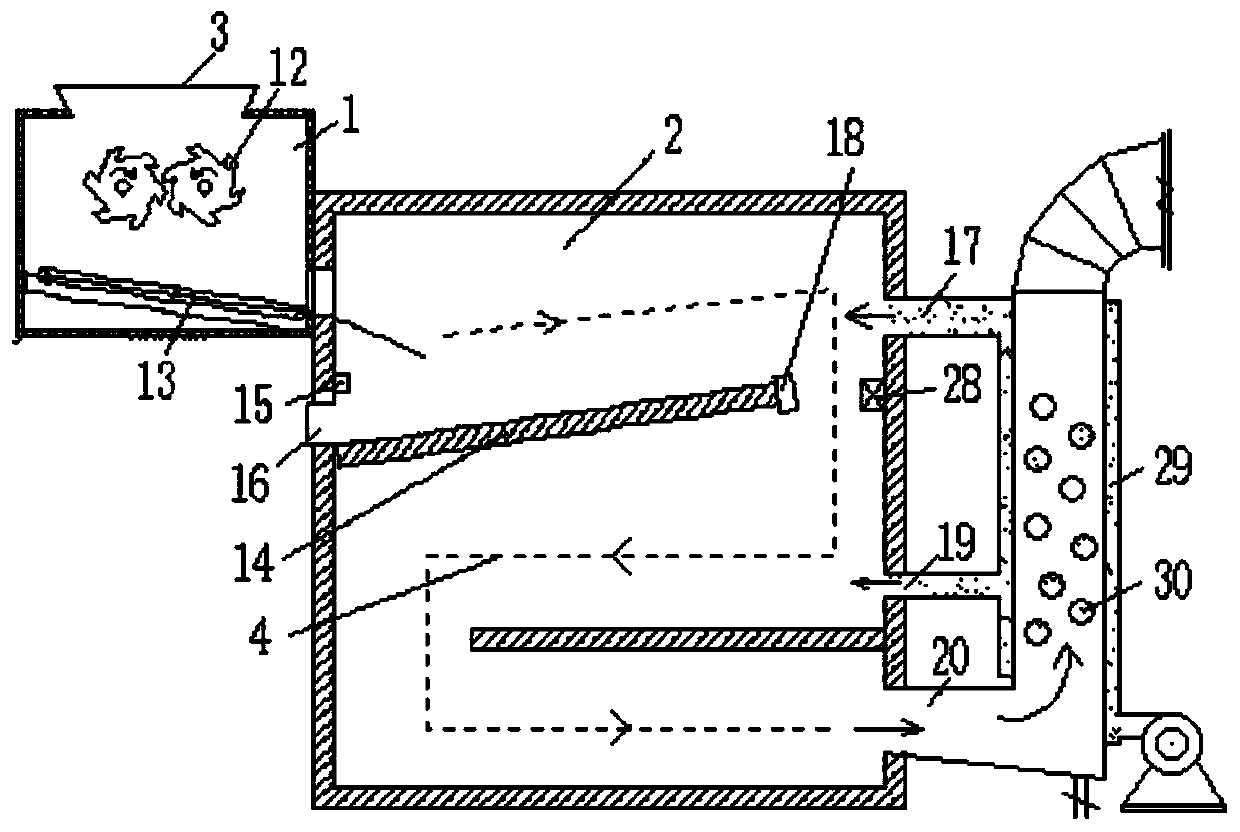

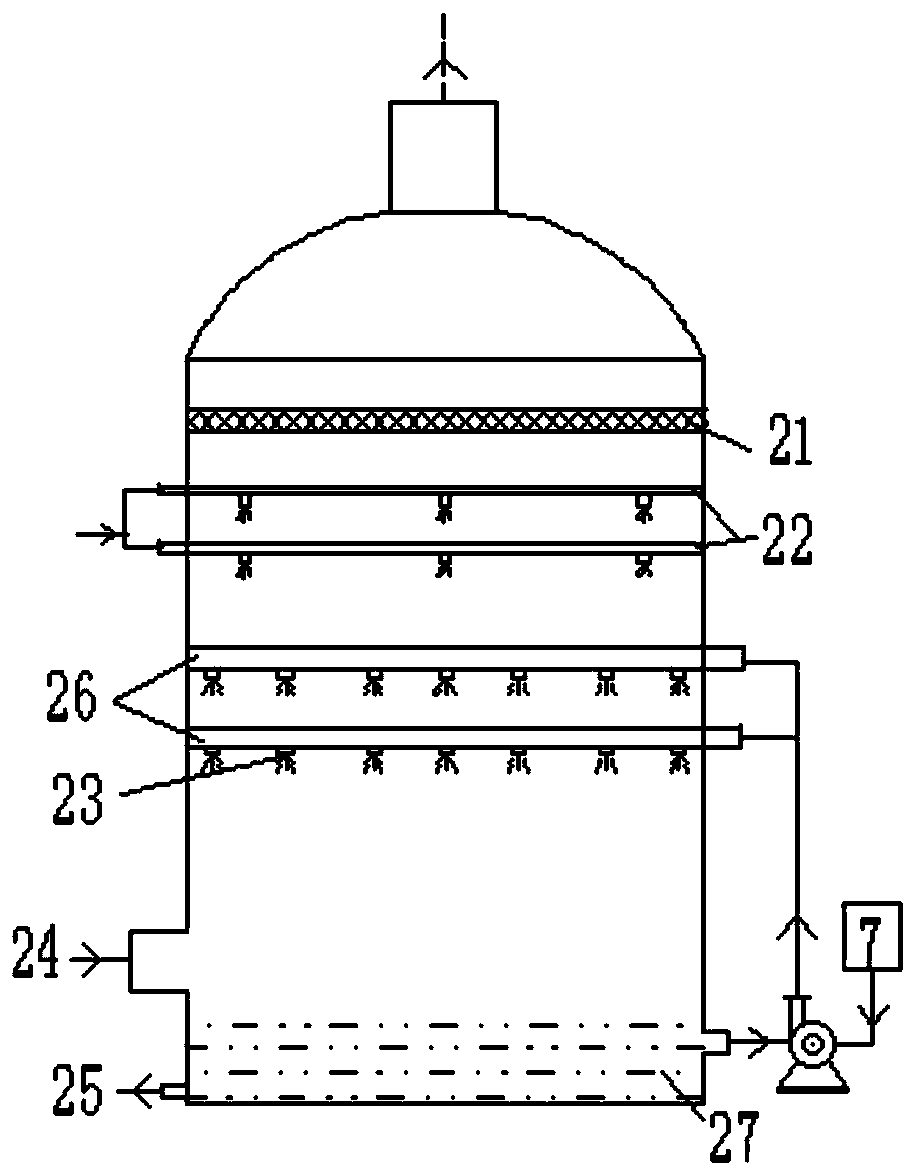

Sacrificial offering incinerator provided with smoke cleaning system

PendingCN109751607AExtend discharge timeImprove combustionCombination devicesIncinerator apparatusCombustion chamberCombustor

A sacrificial offering incinerator provided with a smoke cleaning system comprises a crushing bin, an incinerator body, a quenching tower, a spraying tower, a cloth bag dust remover and a chimney which are sequentially connected through pipelines, wherein the incinerator body comprises a main combustion chamber, a re-combustion chamber and a board baffle; the board baffle is arranged between the main combustion chamber and the re-combustion chamber; a combustor and an air inlet are arranged on the inner wall of the main combustion chamber; sacrificial offerings are crushed through the crushingbin and then are fed into the incinerator body; air is supplied through the air inlet, and fuel is injected through the combustor; the sacrificial offerings are fully combusted in the main combustionchamber; smoke enters the re-combustion chamber for further combusting and is completely decomposed; the combusted smoke is cooled through the quenching tower and then enters the spraying tower for depickling and washing; the smoke is subjected to dust removing by the cloth bag dust remover; and the cleaned gas is exhausted into atmosphere through the chimney. The sacrificial offering incineratoris capable of performing multi-stage cleaning treatment, including dust removing, smell removing, and harmful substance removing; and the sacrificial offering incinerator has the characteristics of being high in combustion efficiency, and good in cleaning effect.

Owner:民政部一零一研究所 +1

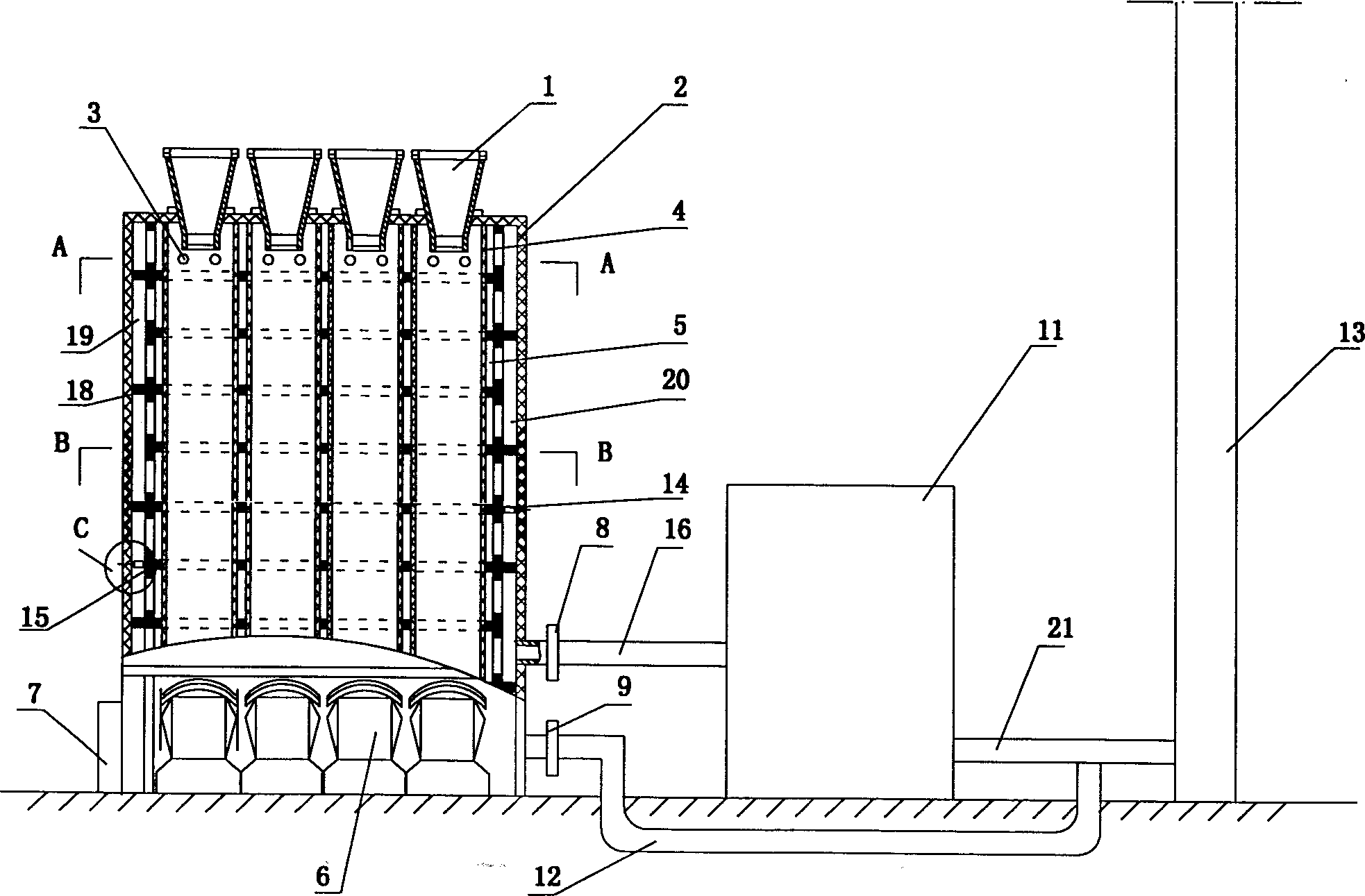

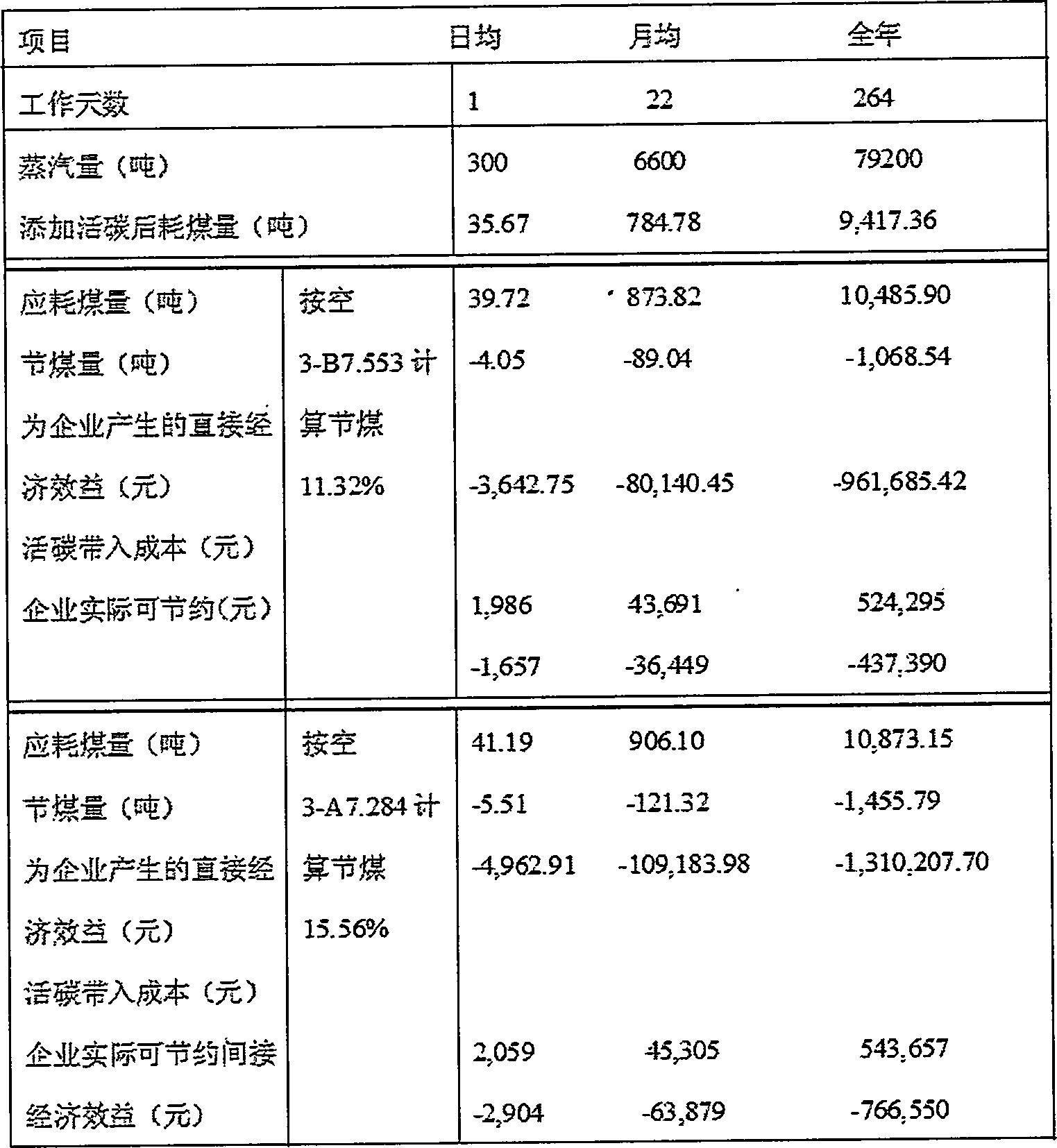

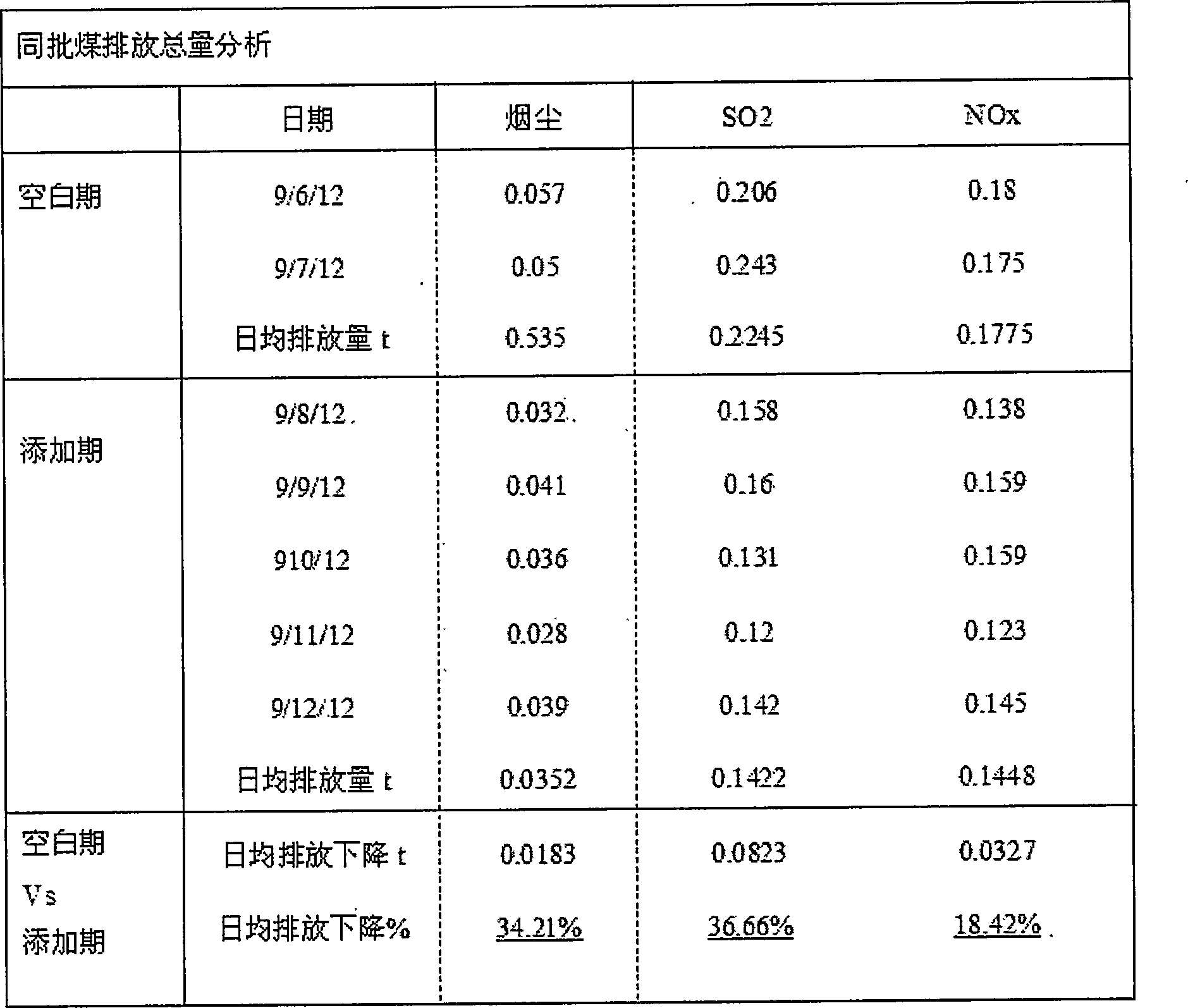

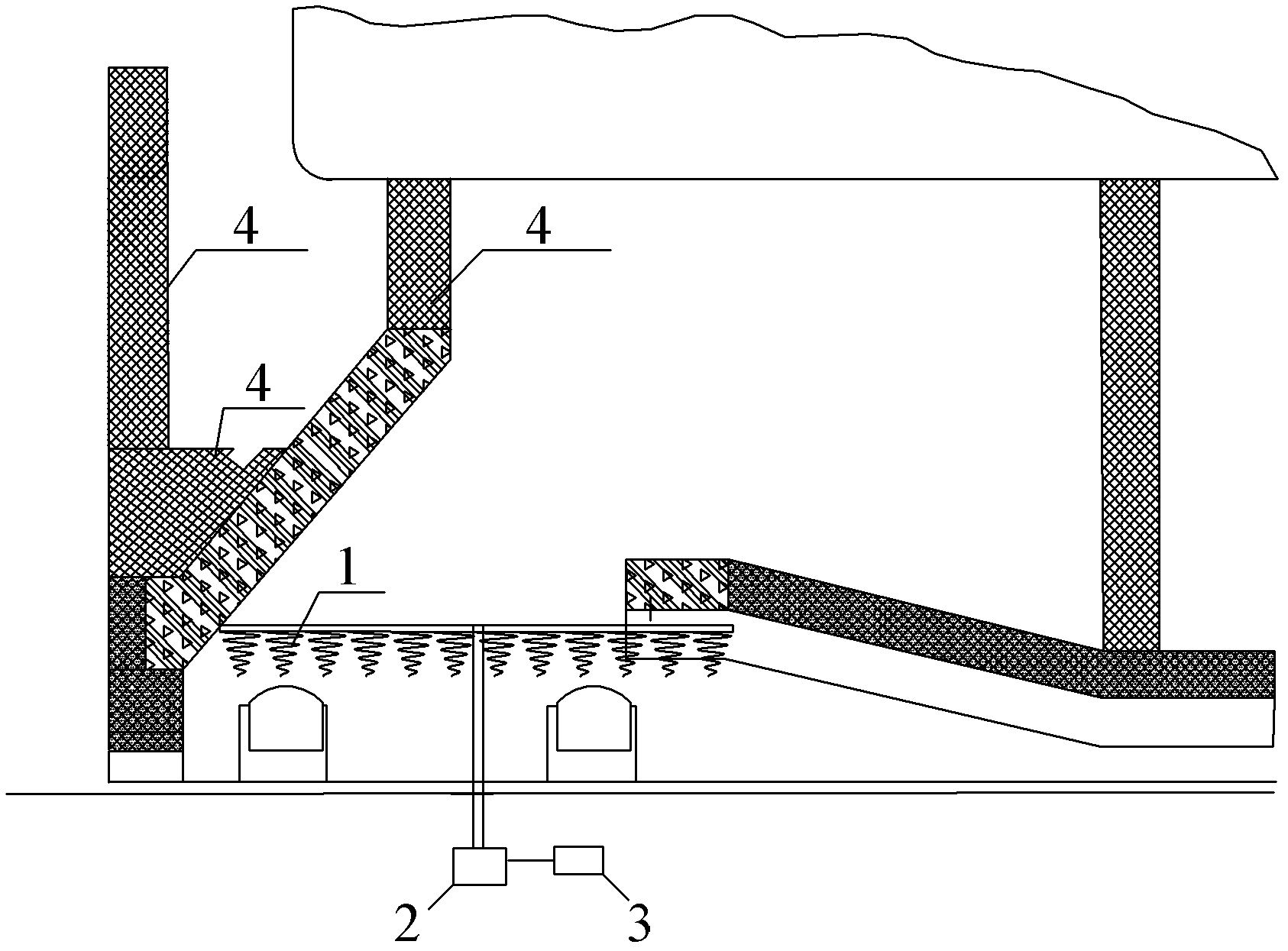

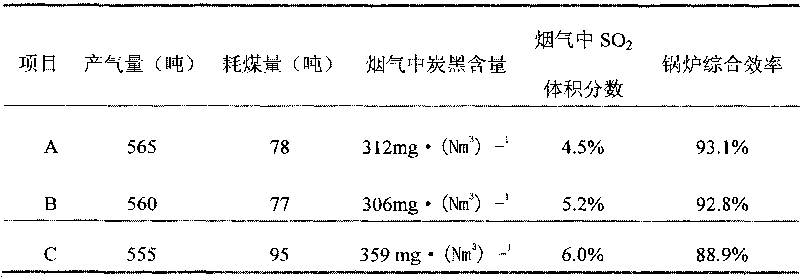

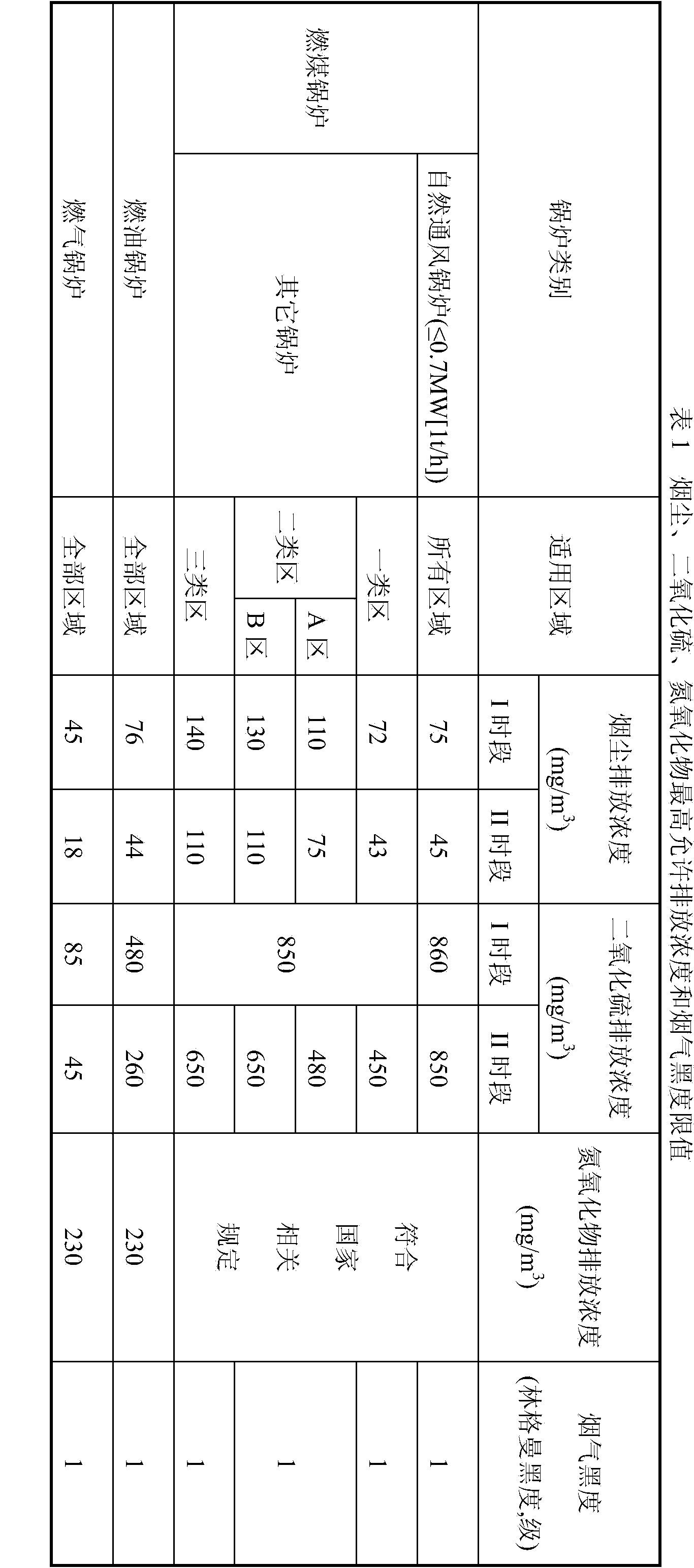

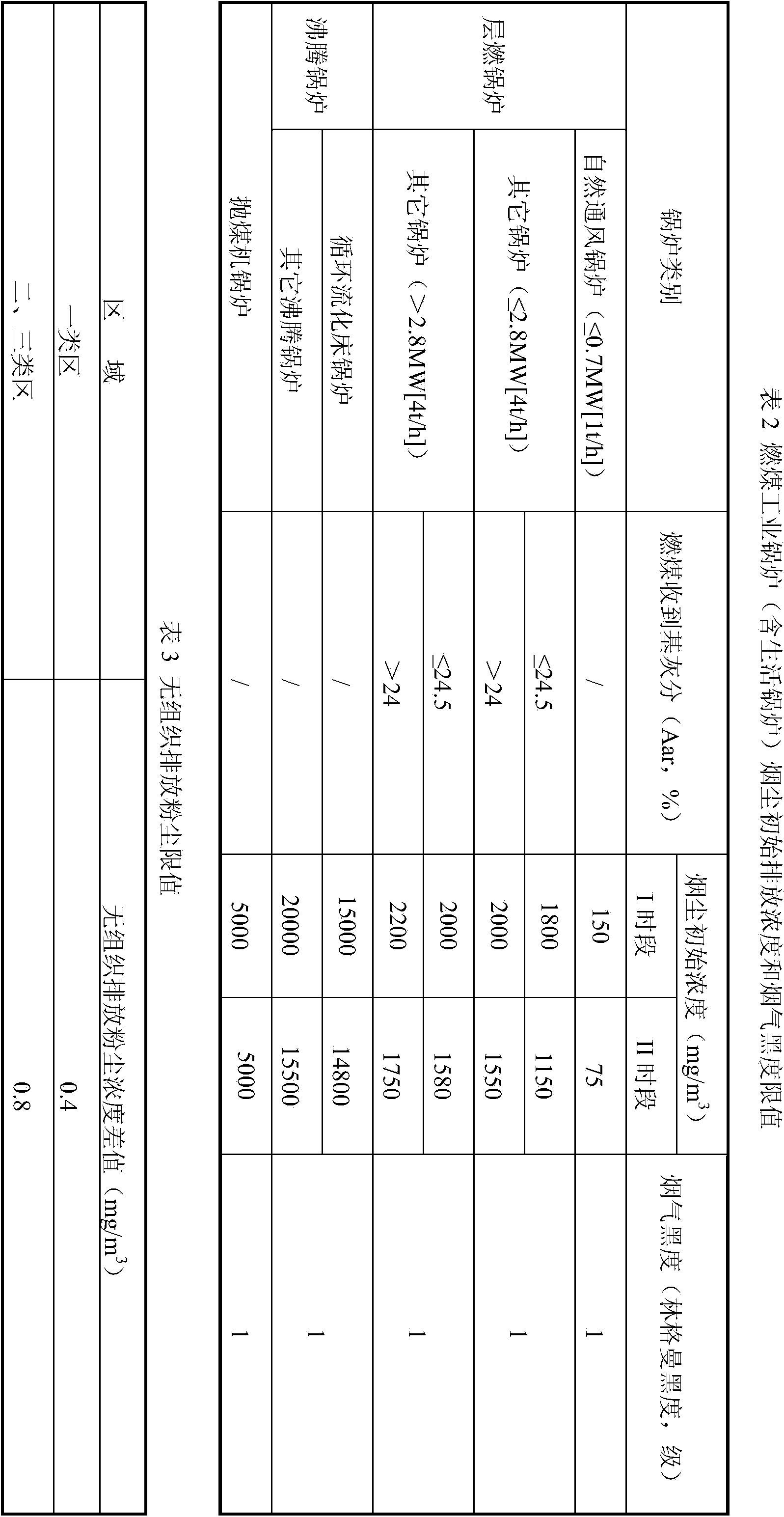

Energy saving system and method for clean burning of layer burning boiler

InactiveCN102620283AChange disturbanceHigh thermal efficiencySolid fuel combustionNon-combustible gases/liquids supplyChemical reactionReaction rate

The invention relates to an energy saving system and method for the clean burning of a layer burning boiler. The energy saving system for the clean burning of the layer burning boiler comprises the layer burning boiler, a metal catalyst unit arranged inside the hearth of the layer burning boiler, a vapor generating unit arranged outside the layer burning boiler and a control unit connected to the vapor generating unit, wherein the metal catalyst unit is arranged in a space between the upside of a coal bed and a smoke outlet; and the metal catalyst unit is connected with the vapor generating unit through a vapor conveying pipeline used for conveying vapor generated by the vapor generating unit to the inside of the hearth. The thermal efficiency of the boiler is increased through changing the burning way in the boiler, and vapor can be decomposed into a great deal of O, H, OH and other active ions under the action of a metal catalyst with the temperature of about 900 DEG C, so that the chemical reaction rate is increased, a favorable wet chain reaction condition is provided for combustible materials in smoke, the burning speed is increased, and the Ringelman emittance is lowered.

Owner:北京中煤神州节能环保技术开发有限公司

Combustion improver for boiler and preparation method and application thereof

The invention provides a combustion improver for a boiler. The combustion improver is prepared from the following raw materials in parts by weight: 4 parts of sulfuric acid, 4 parts of hydrochloric acid, 4 parts of iron oxide, 4 parts of zinc oxide, 4 parts of copper oxide, 4 parts of calcium oxide, 4 parts of magnesium oxide, 4 parts of aluminum oxide, 16 parts of selenium dioxide, 16 parts of strontium oxide, 16 parts of difluorine monoxide, 16 parts of No. 97 gasoline, 16 parts of No. -20 diesel oil, 16 parts of ethanol, 16 parts of kerosene, 10 parts of paraffin, 10 parts of n-octane, 10 parts of nonane, 10 parts of decane, 10 parts of undecane, 10 parts of dodecane, 10 parts of eicosane, 10 parts of triacontane and 10 parts of tetracontane. The combustion improver provided by the invention can reduce pollution, improve combustion efficiency and prolong the service life of the boiler. The invention further provides a preparation method and application of the combustion improver.

Owner:上海悦和科技有限公司

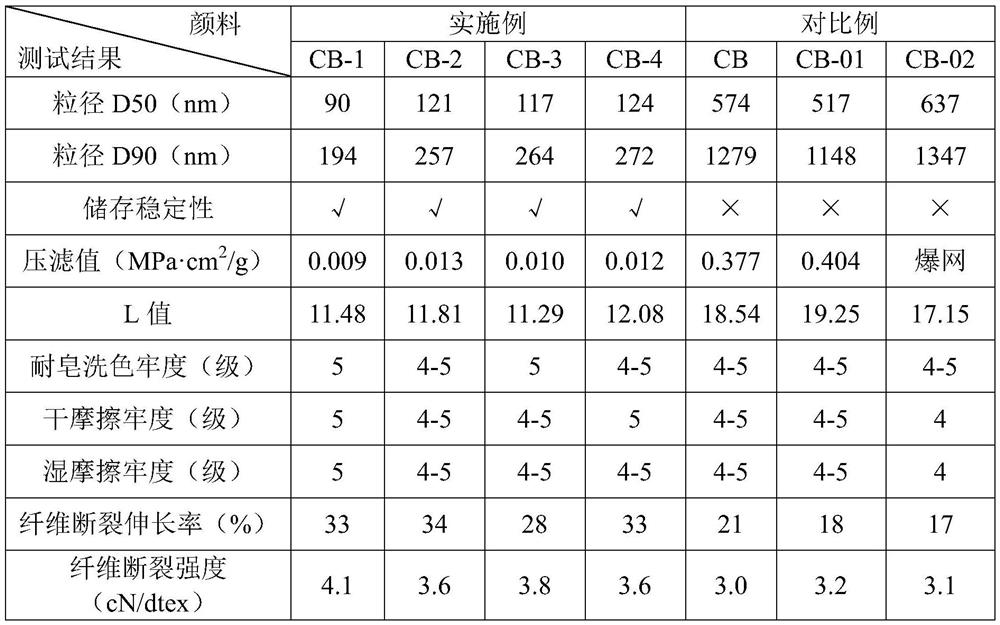

Modified carbon black as well as preparation method and application thereof

ActiveCN114045048AGood dispersionImprove stabilityTextile/flexible product manufacturePigment addition to spinning solutionPolyesterSulfonyl chloride

The invention discloses modified carbon black as well as a preparation method and application thereof. The modified carbon black is prepared by grafting a phthalocyanine derivative to carbon black of which the surface contains hydroxyl. The preparation method of the modified carbon black comprises the following steps: adding phthalocyanine into chlorosulfonic acid to carry out sulfonation reaction, then adding thionyl chloride to carry out chlorination reaction, and after the reaction, carrying out cooling suction filtration and washing to be neutral to obtain phthalocyanine sulfonyl chloride; then, adding the obtained phthalocyanine sulfonyl chloride into ice water, uniformly dispersing, adjusting the pH value, adding a modified additive containing a polyether chain and pyridine, reacting the mixture, and filtering and drying the reaction product to obtain a phthalocyanine derivative; finally, adding a phthalocyanine derivative and carbon black of which the surface contains hydroxyl into a pyridine-containing solvent, and reacting the system to obtain the modified carbon black. The modified carbon black is small in particle size, good in storage stability and good in self-dispersity, and after the modified carbon black is applied to polyester fiber stock solution coloring, the blackness of polyester fibers can be improved, and therefore, it is guaranteed that the polyester fibers have good mechanical and color fastness performance.

Owner:SUZHOU SUNMUN TECH CO LTD

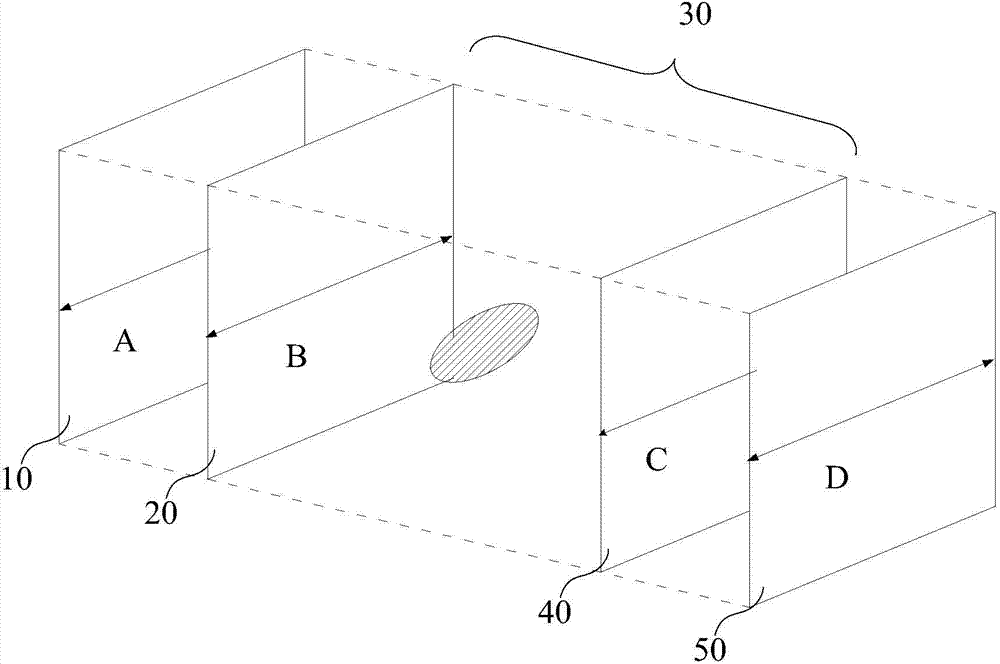

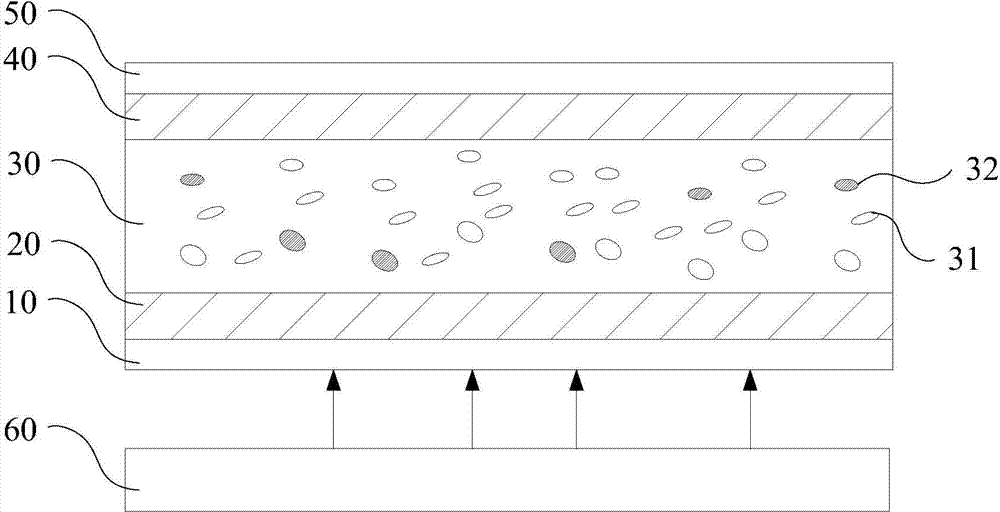

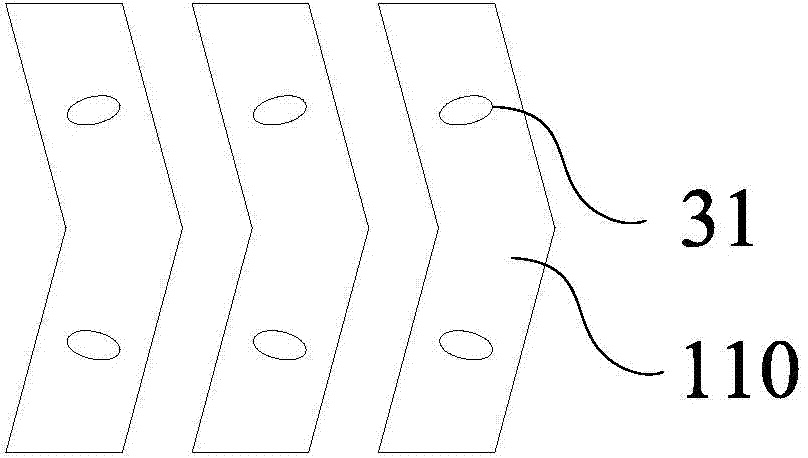

Liquid crystal display

InactiveCN104503167AReduce blacknessSmall color differenceNon-linear opticsLiquid-crystal displayOptical density

The invention discloses a liquid crystal display. The liquid crystal display comprises a first polarizing film, a first substrate, a liquid crystal layer, a second substrate and a second polarizing film, and the first polarizing film has a first transmission axis; the first substrate has a first orientation parallel to the first transmission axis; the second substrate has a second orientation parallel to the first transmission axis; the second polarizing film has a second transmission axis vertical to the first transmission axis; incidence light from a backlight unit passes through the first polarizing film, first substrate, liquid crystal layer, second substrate and second polarizing film in sequence; the first substrate and second substrate comprise a plurality of dual-domain pixel electrodes. The optical density of the liquid crystal display is reduced without voltage, the visual angle is broad, the color difference is small, and the imaged picture is bright-colored.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

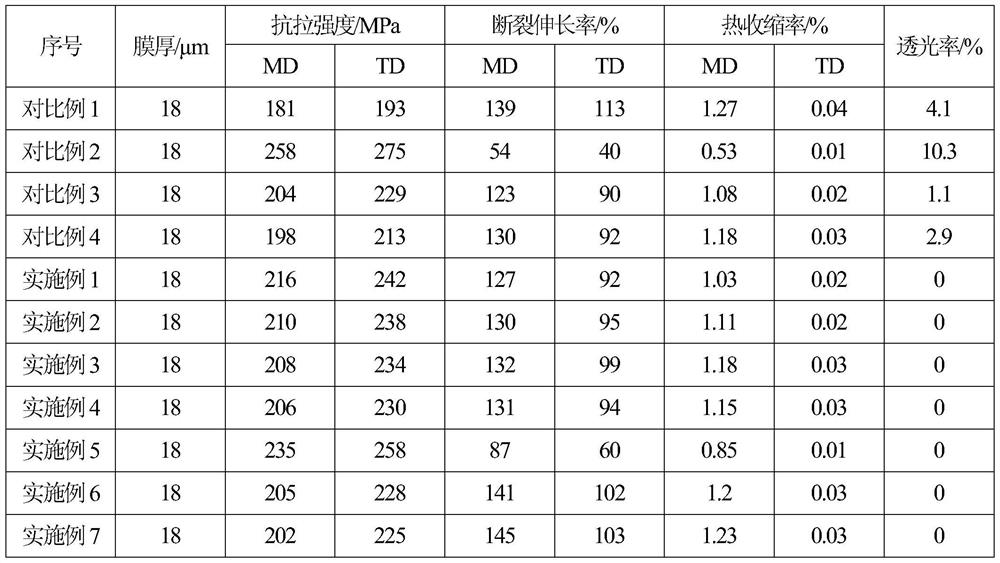

Black light shielding master batch, black light shielding polyester film and preparation method

The invention relates to the technical field of high polymer materials, and discloses a black light shielding master batch, a black light shielding polyester film and a preparation method thereof. Theblack light shielding master batch is prepared from, by mass, 60%-80% of polyester and 20%-40% of modified black additive; the modified black additive is prepared from the following raw material components, by mass: 84.9-94.92% of carbon black, 5-15% of carbon fiber, and 0.08%-0.1% of a coupling agent; master batch is obtained through melt blending, and then black light shielding polyester film is prepared through polyester melt blending, die head casting, longitudinal drawing, transverse drawing and winding forming; the black light shielding polyester film with uniform optical performance, high tensile strength and good dimensional stability is obtained by utilizing the synergistic effect of the carbon black, the carbon fibers and the coupling agent, and the preparation method is simpleto operate and easy to control. The production efficiency is high; and the black light shielding master batch is suitable for industrial production.

Owner:HANGZHOU NORMAL UNIVERSITY +1

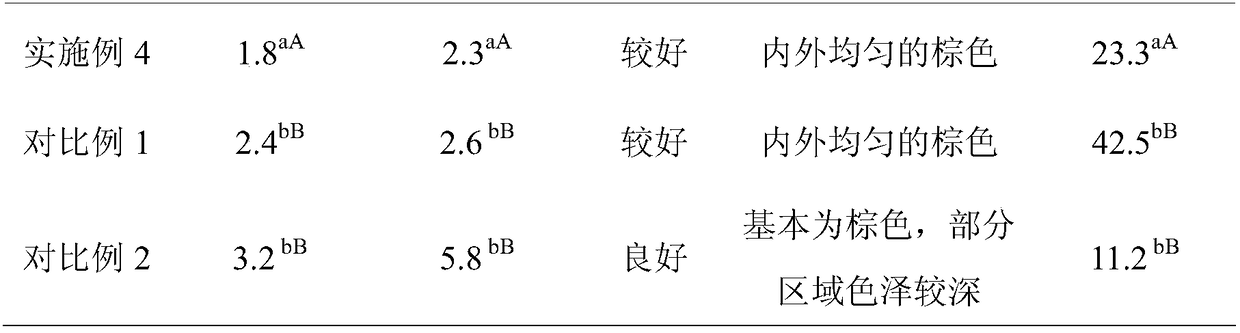

Preparation method of charred boards

ActiveCN108393993AImprove cell activityReduce risk of damageWood treatment detailsWood charring/burningWood plankChemistry

The invention belongs to the field of wood, and discloses a preparation method of charred boards. The preparation method comprises five steps of cutting and washing, drying, surface treatment, charring and shaping. The preparation method of the charred boards is short in consumed time and uniform in charring.

Owner:贵港沃斯顿科技有限公司

Method for preparing black cobalt-based ceramic pigment by utilizing tannery sludge

PendingCN111499353AIncrease profitGood economic and social benefitsPigmenting treatmentCeramic materials productionCobalt oxideBrown iron oxide

The invention discloses a method for preparing cobalt-based black ceramic pigment by utilizing tannery sludge. Leather industrial waste is employed and comprises the following components, by weight: 40-60% of tannery sludge, 20-30% of iron oxide red, 5% of nickel oxide and 15-20% of cobalt oxide. The tannery sludge is calcined and sieved in a non-oxidizing atmosphere for later use, and then the processed tannery sludge and other components are blended, mixed, calcined and crushed to obtain a product. The invention also discloses black ceramic pigment prepared by the preparation method. The method can be used for preparing the ceramic pigment for the black glaze, wherein the pigment is high in blackness, pure in color and stable.

Owner:QILU UNIV OF TECH

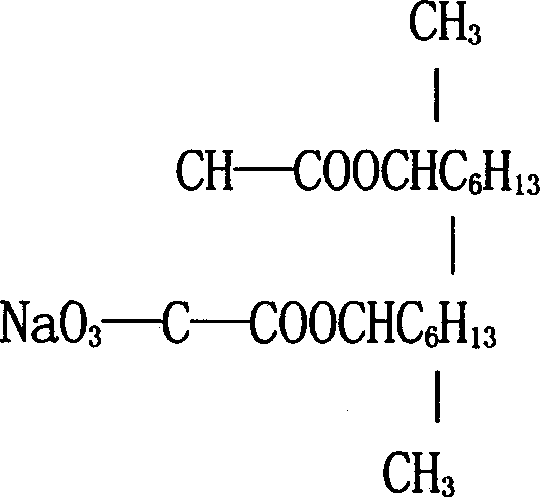

Environmental-protection type coal-saving surface-removing dust-reducing emulsion and its preparing method

InactiveCN1743437AImprove combustion efficiencyEmission reductionSolid fuelsChemical reactionSodium chlorate

This invention relates to an environmental protection coal-saved sulphur-remove and dust-reducing emulsion. Taking the weight percentage as one unit, 25%-75% weight portion of distilled water is added into a reaction kettle to be mixed and heated to 60-80deg.C then 0.1-1.5% weight portion of a malcate and 0.1~5.5% of light hydrocarbon are added and mixed at high speed for 15-35min to keep the temperature, then 0.1-0.5% portion of sodium tetraborate, 0.1~20% of sodium nitrate, 0.1~5% of sodium chlorate, 0.1~2.5% of sodium dioxide, 0.1~5% heavy sodium chromate and 0.1~3.5% ammonium perchlorate are added into the kettle to carry out chemical reaction and mix for 15-30min then enters into a high speed jet crushing machine to cut them repeatedly for 3-5times.

Owner:北京洲际荣源投资有限公司

Combustion improver for boiler as well as preparation method and application of combustion improver

The invention provides a combustion improver for a boiler. The combustion improver is prepared from the following ingredients in parts by weight: 4 parts of manganese dioxide, 4 parts of molybdenum oxide, 4 parts of ferric oxide, 4 parts of zinc oxide, 4 parts of copper oxide, 4 parts of calcium oxide, 4 parts of magnesium oxide, 4 parts of potassium oxide, 4 parts of sodium oxide, 4 parts of aluminum oxide, 16 parts of selenium dioxide, 16 parts of strontium oxide, 16 parts of oxygen difluoride, 16 parts of No.97 gasoline, 16 parts of No.20 diesel, 16 parts of ethyl alcohol, 16 parts of kerosene, 10 parts of paraffin, 10 parts of normal octane, 10 parts of nonane, 10 parts of decane, 10 parts of undecane, 10 parts of dodecane, 10 parts of eicosane, 10 parts of triacontane and 10 parts of tetracontane. The combustion improver provided by the invention has the advantages that the pollution can be reduced, the combustion efficiency is improved, and the service life of the boiler is prolonged. The invention also provides a preparation method and application of the combustion improver.

Owner:上海悦和科技有限公司

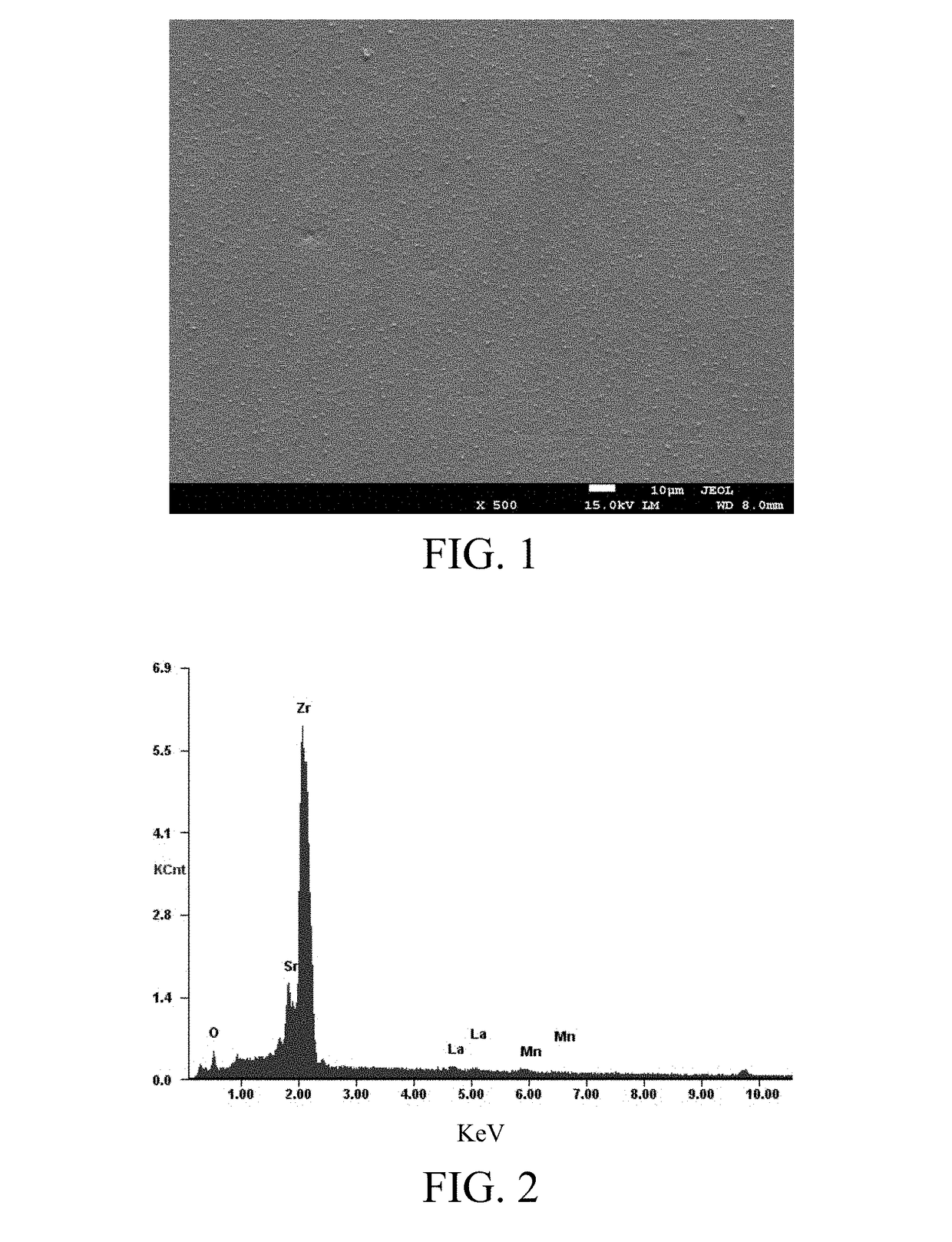

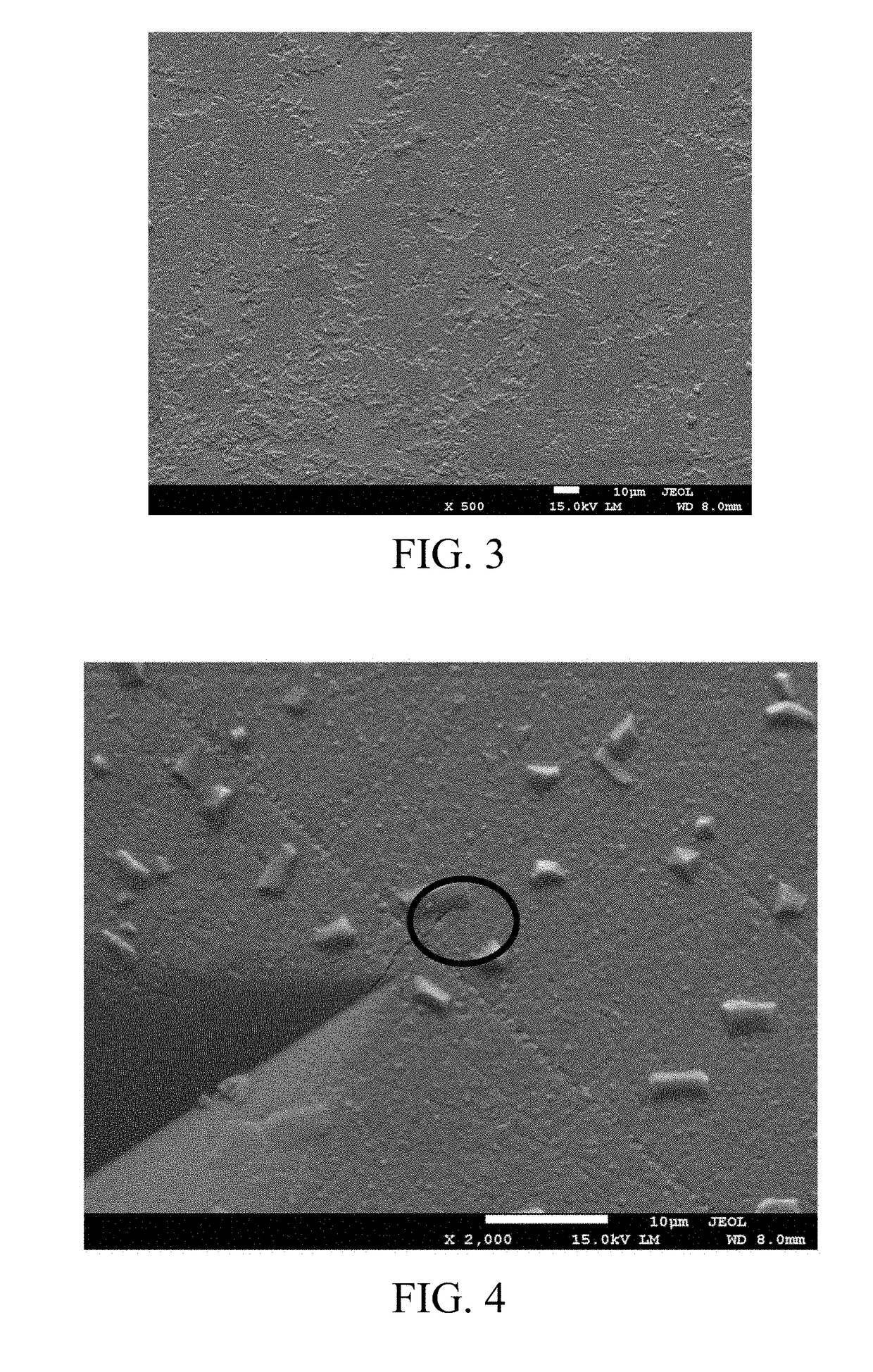

Ceramic and preparation method therefor

A ceramic and a preparation method therefor are provided. The ceramic includes a zirconia matrix, and an additive dispersed inside and on an outer surface of the zirconia matrix. The additive is an oxide including elements A and B, where A is selected from at least one of Ca, Sr, Ba, Y, and La, and B is selected from at least one of Cr, Mn, Fe, Co, and Ni.

Owner:BYD CO LTD

Horizontal boiler

A technical scheme of a horizontal boiler comprises a boiler body, a combustion chamber disposed in the boiler body, a collection box arranged under the combustion chamber and a water jacket arranged over the combustion chamber, wherein the collection box is connected under the water jacket via a water path; a firework pipe is disposed in the water jacket; one end of the firework pipe is provided with a front smoke case and the other end is provided with a back smoke case; a smoke outlet is formed in the back smoke case; an inlet of the water jacket is provided with a filter; the filter is provided with a handle; the water jacket is longitudinally distributed and a wet back type square water jacket; one end of the wet back type water jacket is connected with a plate case water jacket; the lower part of the plate case water jacket is connected with a water supplying box; the firework pipe is longitudinally distributed; a detachable smoke filter is disposed in the back smoke case; and the smoke filter comprises a filter net and active carbon. The horizontal boiler has large heating area and is uneasy to form scales; and the water tanks up and down possess great circulating effect, so temperature can quickly rise.

Owner:凤城市百利锅炉制造有限公司

Crop straw blending coal

The invention discloses a crop straw composite coal, which is composed of 10-40% straw and 60-90% coal, wherein the calorific value of hay is 4300kilocalorie / kg (18003kj / kg); the calorific value of dried leaf and dried branch is 3900kilocalorie / kg (16328kj / kg), which is higher than soy straw and cotton straw.

Owner:HENAN UNIVERSITY

Four-time inflation and combustion method for coal burning boiler

The invention discloses a four-time inflation and combustion method for a coal burning boiler and belongs to the technical field of combustion in a coal burning boiler. The processing steps are as follows: supplying air for the first time, supplying fire coal at a uniform speed through a mechanical coal feeding device according to the fire coal quantity needed for combustion in the boiler, so that the coal can be naturally gasified, coked and burned to generate a large amount of carbon monoxide and other combustible substances; supplying air for the second time 8-10 minutes after supplying air for the first time, and carrying out mixed burning on the air supplied at the second time and carbon monoxide, thereby further increasing the boiler temperature; supplying air for the third time, and enabling the coal to be sufficiently burned inside; and finally mixing fume, and oxygen forcibly inflated by a fourth-time air-supplying burner at the fire outlet of a hearth, so that the combustible substances in exhaust gas are sufficiently burned in a high-temperature and high-oxygen condition. The four-time inflation and combustion method for the coal burning boiler has the beneficial effects of energy conservation, high thermal efficiency, stable combustion, high adaptability to various coals, low flue dust concentration and flue gas blackness, and good environmental friendliness.

Owner:毛玉兰

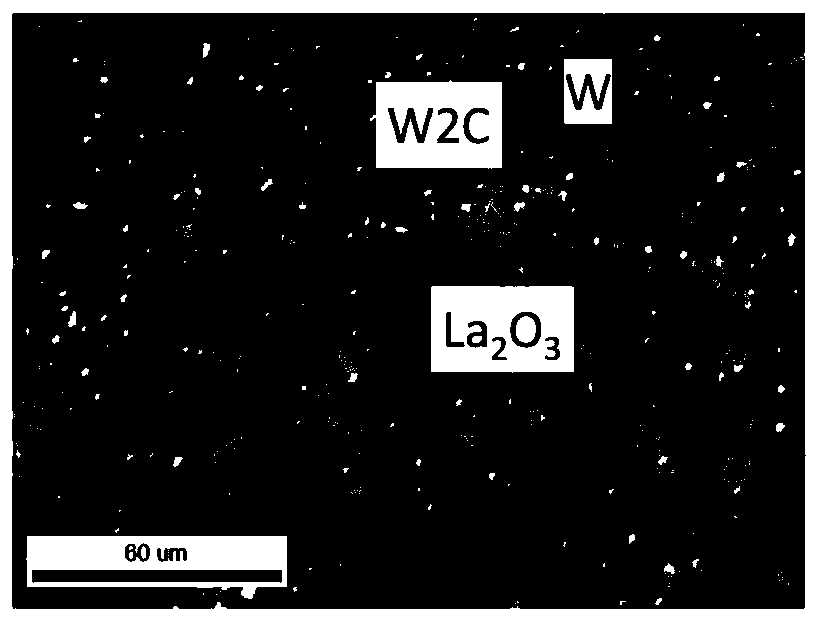

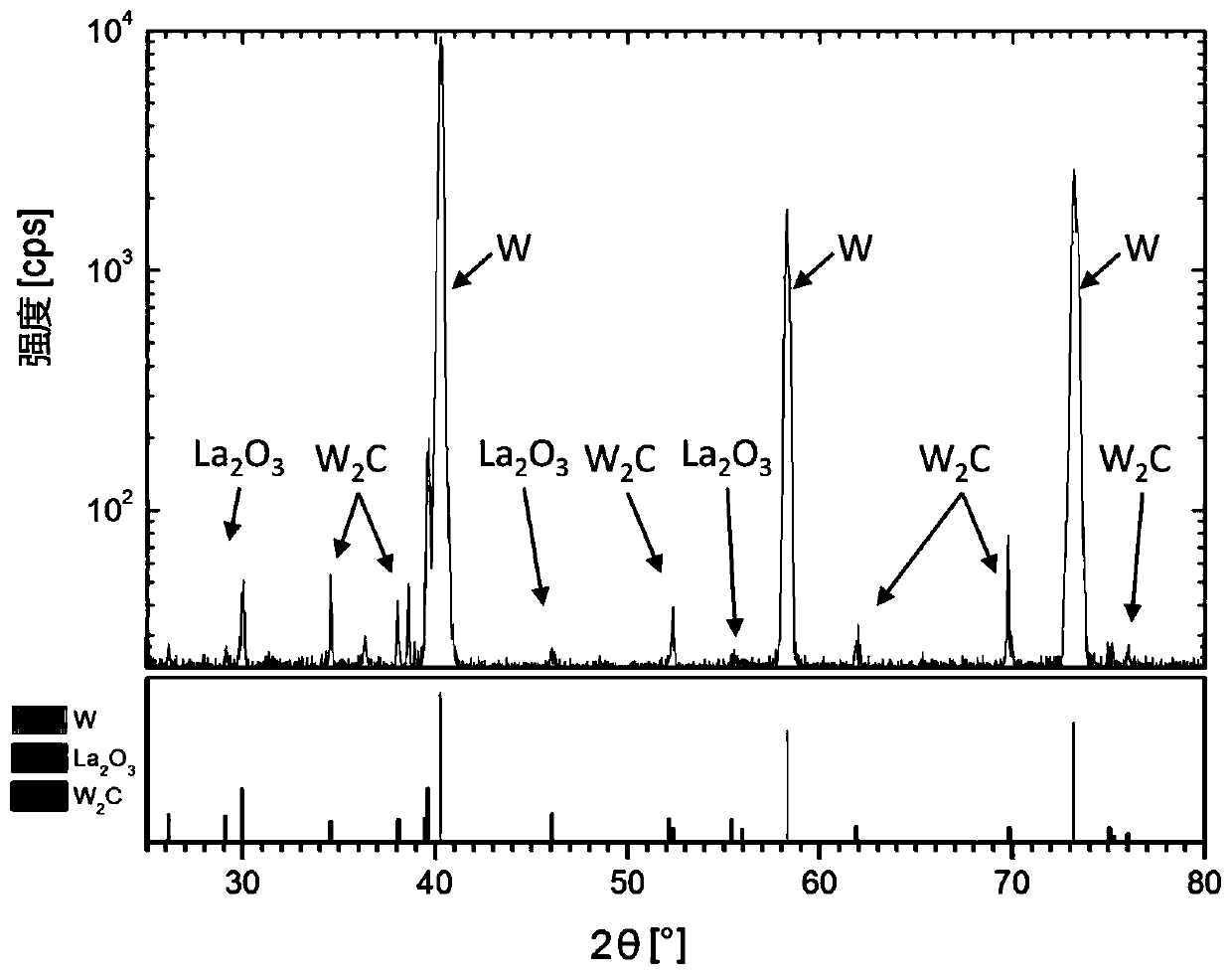

Cathode material

ActiveCN110753987AReduce evaporationReduce blacknessGas discharge lampsThermionic cathode manufactureMischmetalCarbide

The invention relates to a cathode material for use in a high intensity discharge lamp, said material containing at least the following elements: a matrix based on tungsten having a tungsten content of more than or equal to 95 wt.%; tungsten carbide; oxides and or predominantly oxidic phases of one or more emitter elements from the group consisting of (rare earth metals, Hf Zr), wherein the cathode material contains predominantly carbide phases from one or more emitter elements from the group (rare earth metals, Hr, Zr). The invention relates to a high intensity discharge lamp which comprisesa cathode made from the claimed cathode material and to a method for producing a cathode material.

Owner:PLANSEE SE +1

Highly effective environment protectional catalytic agent for coal saving , its preparation method and uses

InactiveCN1326980CReduce carbon contentImprove protectionSolid fuelsAlkaline earth metalPolyethylene oxide

Disclosed is a highly effective environmental protection catalysts coal-saving agent, which comprises 20-30 weight parts of puffing agent composing of mixture of lignin sulfonate and alkylbenzene sulfonate, 30-40 weight parts of emulsifying agent composing alkylphenol polyoxyethylene, 8-15 weight parts of purifying agent composing polyethylene oxide, 15-25 weight parts of catalyst composing the mixture of palladium metal salts, titanium metal salts and cerium metal salts, 3-10 weight parts of catalyst promoter composing cobalt metal salts, 3-10 weight parts of modifier composing alkaline metal and / or alkaline metal hydrates. The invention also discloses the process for preparing the coal-saving agent and its use.

Owner:张冰青

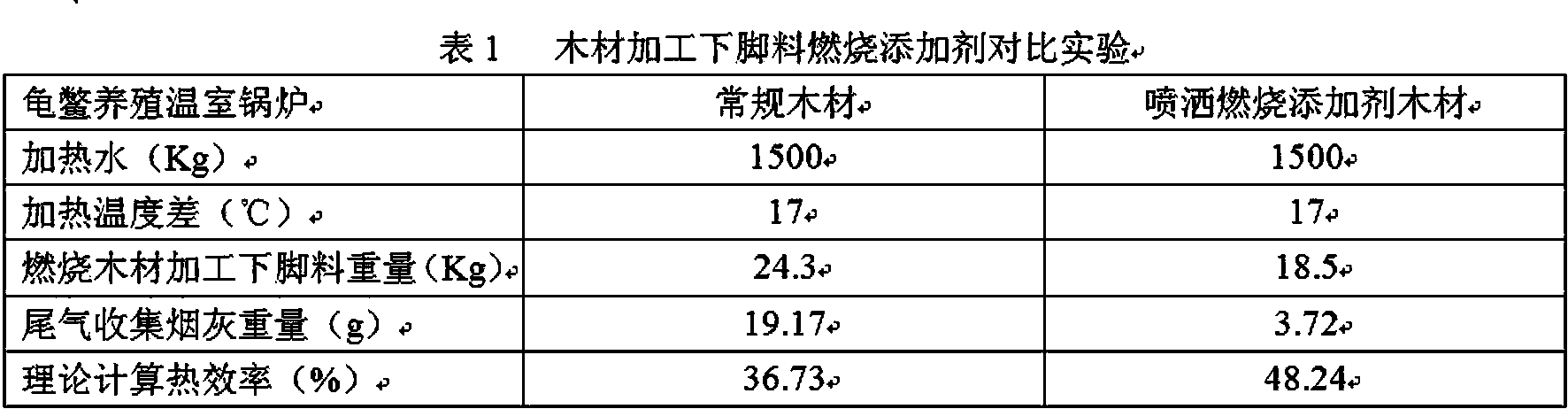

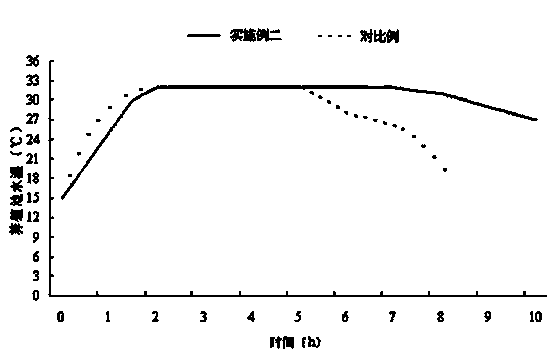

Wood processing offal additive for testudinate greenhouse cultivation combustion and using method thereof

InactiveCN103448115AImprove Burning StaminaReduce the generation of black smokeWood charring/burningWood impregnation detailsCombustionWood processing

The invention relates to a combustion additive, in particular to a wood processing offal additive for testudinate greenhouse cultivation combustion and a using method of the additive. The wood processing offal additive comprises 9-10 of Fe203, 55-60 of MgO, 8-10 of KCl, 16-18 of NaCl and 9-12 of KMnO4. According to the wood processing offal additive for testudinate greenhouse cultivation combustion, after the combustion additive is adjusted by an inventor, a novel using method is matched, the technical problems to be solved, like how to improve the combustion endurance of wood processing offal and how to reduce black smoke can be solved, due to the fact that the KCl, the NaCl and the KMnO4 in the additive can be dissolved in water, the KCl, the NaCl and the KMnO4 can be absorbed by wood so as to play a role in the later period, and the Fe203 and the MgO can not be dissolved in water and play a role in the earlier period of combustion.

Owner:ZHEJIANG INST OF FRESH WATER FISHERIES

A kind of processing method of waterproof carbonized wood board

ActiveCN108189184BReduce risk of damageReduce moistureWood treatment detailsCoating impregnationCarbonizationPulp and paper industry

The invention belongs to the field of wood, and discloses a processing method of a water-proof carbonization wood board. The processing method comprises the five steps of cutting and cleaning, drying,surface treating, carbonization and shaping. The invention provides a processing method of a water-proof carbonization wood board, less time is consumed, and the carbonization is even.

Owner:贵港沃斯顿科技有限公司

Method for producing high calorific value coal based fuel by using low calorific value coal

InactiveCN101705134AImprove flammabilityIncrease fuel calorific valueSolid fuelsPotassium hydroxideCoal

The invention discloses a method for producing a high calorific value coal based fuel by using low calorific value coal, which comprises the following steps: taking 3 to 5 parts of potassium permanganate, 3 to 5 parts of potassium chlorate, 3 to 6 parts of calcined lime, 1 to 3 parts of potassium hydroxide and 1 to 3 parts of calcium chloride at the normal temperature and under normal pressure, and crushing the materials into granules of 80 to 150 meshes; and adding 5 to 10 parts of residual oil and 65 to 85 parts of low calorific value coal into the granules, and blending the mixture in a stirrer evenly. The method can effectively save the coal, improve the utilization rate of energy sources, reduce the emission of smoke dust and sulfur dioxide, and reduce environment pollution.

Owner:JINAN DEV ZONE XINGHUO SCI & TECH RES INST

Combustion improver for boiler and preparation method and application thereof

The invention provides a combustion improver for a boiler. The combustion improver is prepared from the following raw materials in parts by weight: 4 parts of sodium carbonate, 4 parts of coal powder, 4 parts of iron oxide, 4 parts of zinc oxide, 4 parts of copper oxide, 4 parts of calcium oxide, 4 parts of magnesium oxide, 4 parts of aluminum oxide, 16 parts of selenium dioxide, 16 parts of strontium oxide, 16 parts of difluorine monoxide, 16 parts of No. 97 gasoline, 16 parts of No. -20 diesel oil, 16 parts of ethanol, 16 parts of kerosene, 10 parts of paraffin, 10 parts of n-octane, 10 parts of nonane, 10 parts of decane, 10 parts of undecane, 10 parts of dodecane, 10 parts of eicosane, 10 parts of triacontane and 10 parts of tetracontane. The combustion improver provided by the invention can reduce pollution, improve combustion efficiency and prolong the service life of the boiler. The invention further provides a preparation method and application of the combustion improver.

Owner:上海悦和科技有限公司

Horizontal mobile grate gasifier

InactiveCN101776260BReduce exhaust temperatureRealize the purpose of zone controlled gasificationCombustion using gaseous and pulverulent fuelGasifier feeding meansCombustorFlue gas

The invention relates to a horizontal mobile grate gasifier, which comprises a furnace body with a grate and an air supply device. The air supply device consists of a primary air supply pipe and an upper-layer air supply pipe, the primary air supply pipe is connected with a plurality of air chambers and is arranged below the grate, the upper-layer air supply pipe is arranged on the two sidewalls of the furnace body and is communicated with the inner chamber of the furnace body, the rear part of the furnace body is provided with a flue gas channel, the rear end of the flue gas channel is connected with the combustor of a boiler, a flue gas circulating pipe which is connected with the rear part of the combustor communicates circulating flue gas and the upper-layer air supply pipe to form a mixed gas channel, the mixed gas channel and a steam pipe respectively extend into the air chamber and the cavity of the furnace body through a primary air Venturi pipe and a secondary air Venturi pipe; and mixed gas can flow to the front side of the combustor of the boiler through a gas mixing fan. The invention has the advantages of reducing Ringelman black and smoke emission, allowing the use of coal raw materials which are each to be coked, expanding the flexibility of the boiler use and the diversity of operating modes, and realizing the online real-time control and adjustment of parameters of steam output variables, grate operation and gasification dosage, thereby achieving the best operating conditions.

Owner:NINGBO YINUO ENERGY TECH

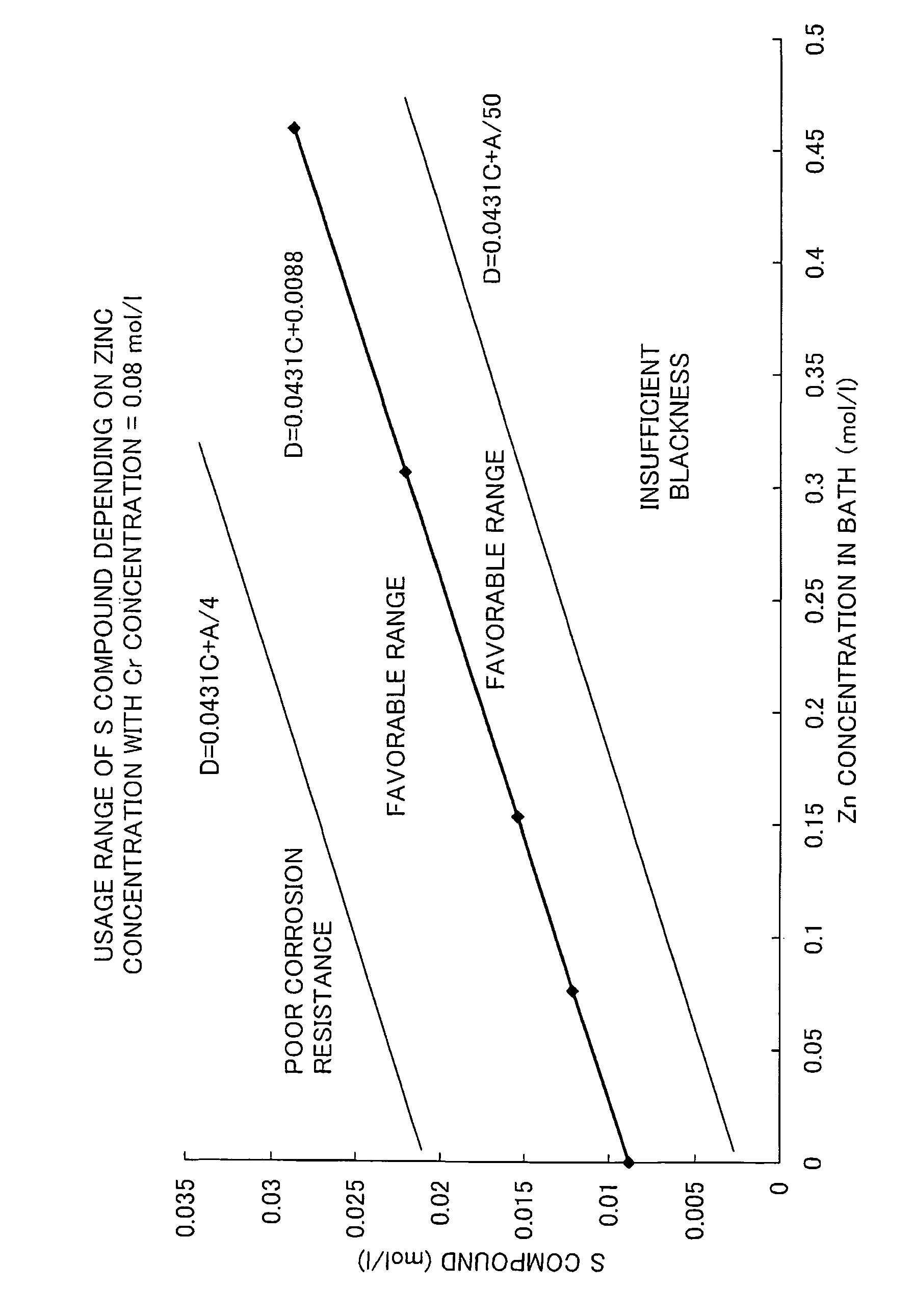

Aqueous treating solution for forming black trivalent-chromium chemical conversion coating on zinc or zinc alloy and method of forming black trivalent-chromium chemical conversion coating

InactiveUS9157154B2Reduce blacknessSolution to short lifeMetallic material coating processesWelding/cutting media/materialsChemical treatmentPhosphoric Acid Esters

A treating solution for forming on a surface of either zinc or a zinc alloy a hexavalent-chromium-free trivalent-chromium chemical conversion coating which has an even black appearance and satisfactory corrosion resistance. The treating solution has a long treating-bath life. Also provided is a method of forming a black trivalent-chromium chemical conversion coating. The aqueous treating solution, which is for forming a black trivalent-chromium chemical conversion coating on zinc or a zinc alloy, contains trivalent chromium ions, a phosphoric ester and / or phosphorous ester, and a sulfur compound. The method is a method of chemically treating zinc or a zinc alloy which comprises using the aqueous treating solution to chemically treat the zinc or zinc alloy at a solution temperature of 10-60° C., whereby a black trivalent-chromium chemical conversion coating is formed on the zinc or zinc alloy. Furthermore provided is a coated zinc or zinc alloy metal which comprises zinc or a zinc alloy and, formed thereon, a black trivalent-chromium chemical conversion coating formed by a chemical treatment with the aqueous treating solution.

Owner:DISPOL CHEMICALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com