Processing method of water-proof carbonization wood board

A processing method and water-repellent technology, which is applied to wood processing equipment, wood treatment, impregnated wood, etc., can solve the problems of insufficient carbonization and high cost, and achieve the effects of improving waterproof performance, short time consumption, and strong cohesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

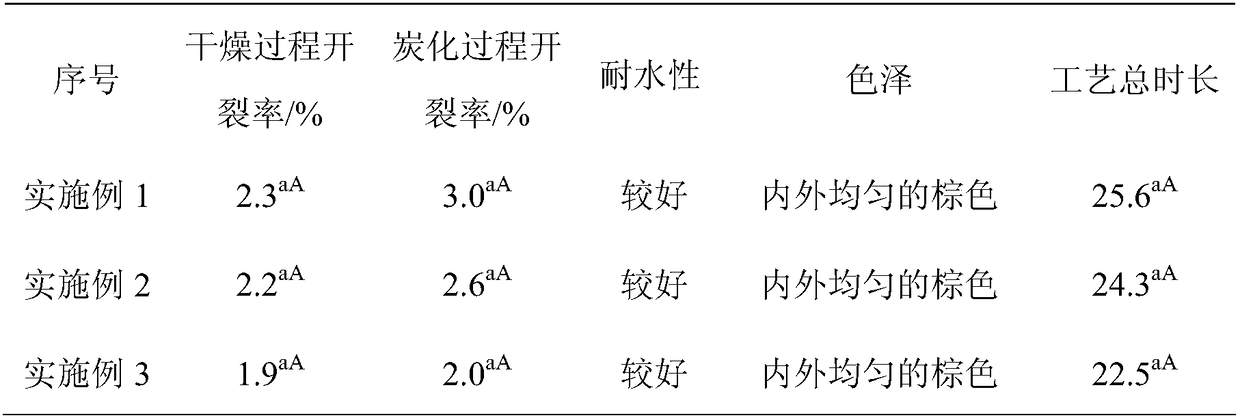

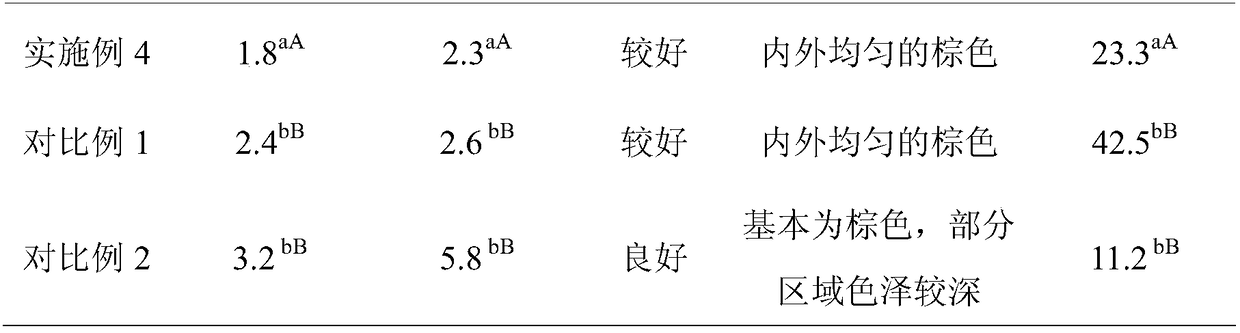

Examples

Embodiment 1

[0024] A processing method of waterproof carbonized wood board, comprising the following steps:

[0025] (1) Preparation of treatment liquid: 1) raw materials of treatment liquid: 20 parts of EVA resin, 15 parts of rosin resin, 1 part of copper sulfate, 1.5 parts of ferrous sulfate, 2.5 parts of molybdenum oxide, 5 parts of nano titanium dioxide, 10 parts of polyethylene wax , 4 parts of monoglyceride diacetyl tartrate, 1 part of polyoxypropylene oxide glyceryl ether and 100 parts of water;

[0026] 2) Preparation method of treatment liquid: dissolve 1 part of copper sulfate, 1.5 parts of ferrous sulfate and 2.5 parts of molybdenum oxide in 100 parts of water, mix well under stirring, then add 4 parts of diacetyl tartrate monoglyceride and polyoxypropylene 1 part of oxyethylene glyceryl ether is made into an emulsion, and other components are added in turn, mixed evenly, and the product is obtained;

[0027] (2) Cutting and cleaning: cut the wood into planks with a length of ...

Embodiment 2

[0033] A processing method of waterproof carbonized wood board, comprising the following steps:

[0034] (1) Preparation of treatment liquid: 1) raw materials of treatment liquid: 25 parts of EVA resin, 20 parts of rosin resin, 1.6 parts of copper sulfate, 2.4 parts of ferrous sulfate, 4 parts of molybdenum oxide, 8 parts of nano titanium dioxide, 12 parts of polyethylene wax , 5 parts of monoglyceride diacetyl tartrate, 2 parts of polyoxypropylene oxide glyceryl ether and 105 parts of water;

[0035] 2) Preparation method of treatment liquid: dissolve 1.6 parts of copper sulfate, 2.4 parts of ferrous sulfate and 4 parts of molybdenum oxide in 105 parts of water, mix well under stirring, then add 5 parts of diacetyl tartrate monoglyceride and polyoxypropylene 2 parts of oxyethylene glyceryl ether to make an emulsion, add other components in turn, mix well, and get it;

[0036] (2) Cutting and cleaning: cut the wood into planks with a length of 0.5m and a thickness of 4cm, spr...

Embodiment 3

[0042] A processing method of waterproof carbonized wood board, comprising the following steps:

[0043] (1) Preparation of treatment liquid: 1) raw materials of treatment liquid: 30 parts of EVA resin, 25 parts of rosin resin, 1.6 parts of copper sulfate, 2.4 parts of ferrous sulfate, 4 parts of molybdenum oxide, 12 parts of nano titanium dioxide, 16 parts of polyethylene wax , 5 parts of monoglyceride diacetyl tartrate, 2.5 parts of polyoxypropylene oxide glyceryl ether and 112 parts of water;

[0044] 2) Preparation method of treatment solution: dissolve 1.6 parts of copper sulfate, 2.4 parts of ferrous sulfate and 4 parts of molybdenum oxide in 112 parts of water, mix well under stirring, then add 5 parts of diacetyl tartrate monoglyceride and polyoxypropylene 2.5 parts of oxyethylene glyceryl ether, make an emulsion, add other components in turn, mix well, and get it;

[0045] (2) Cutting and cleaning: cut the wood into planks with a length of 0.8m and a thickness of 8cm, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com