Cathode material

A cathode material and emitter technology, which is applied in the manufacture of thermionic cathodes, electrical components, discharge lamps, etc., can solve the problems of uneven distribution of emitter materials and unstable arc, and achieve stable shape, less evaporation, and low blackness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

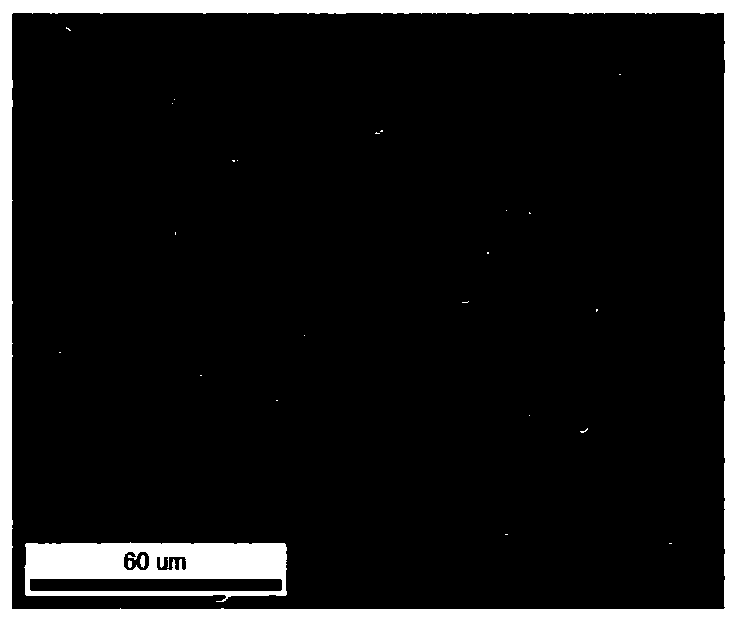

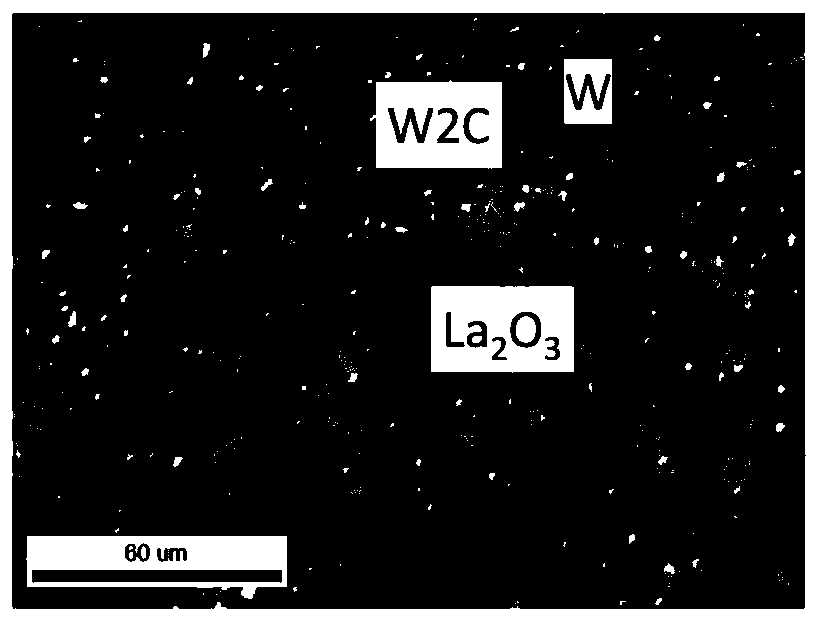

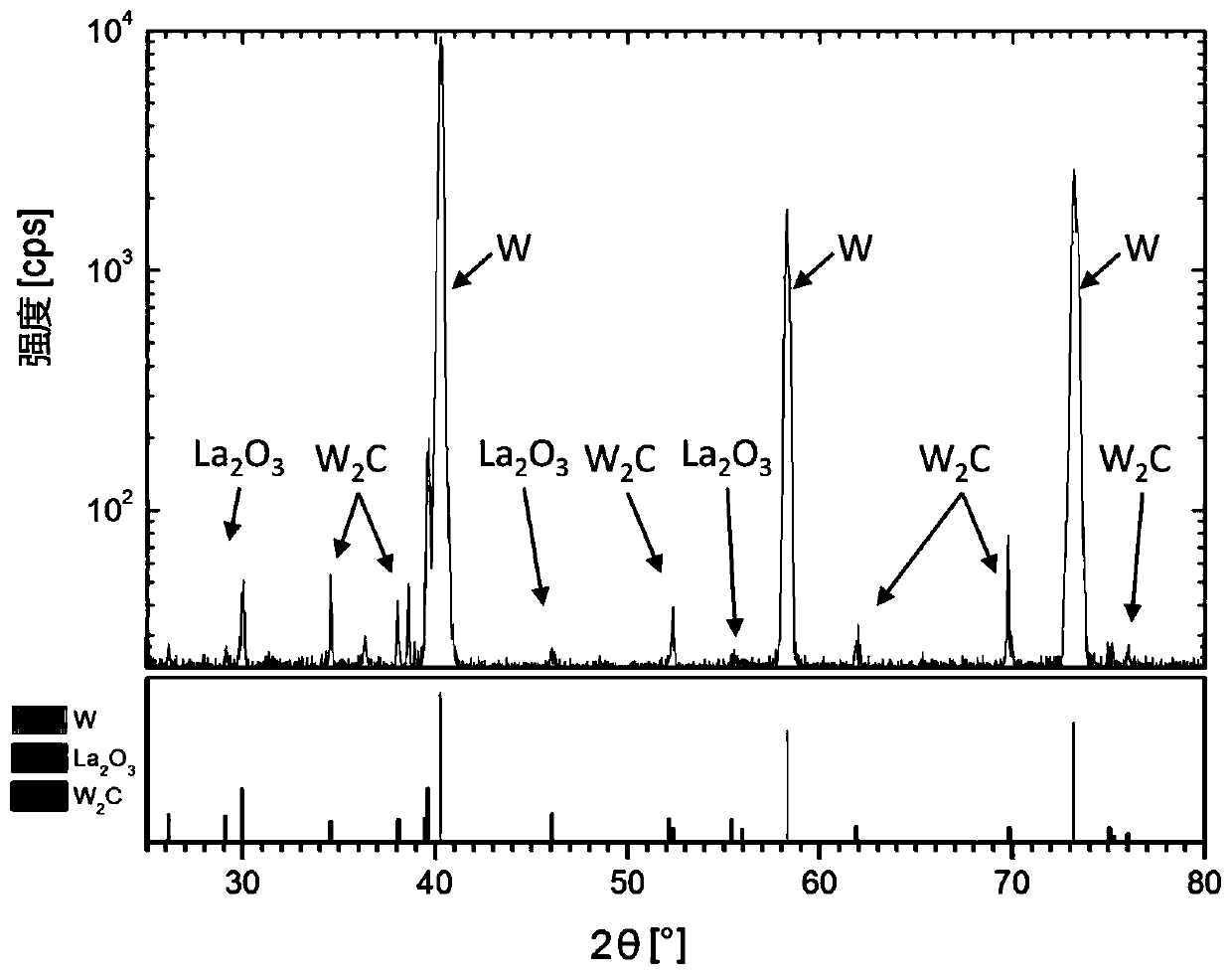

[0078] Figure 1a Containing W, 2% by weight La is shown 2 o 3 and 800 μg / g C cathode material secondary electron scanning electron microscope (SEM). Figure 1b The phase diagram corresponding to electron backscatter diffraction (EBSD) is shown.

[0079] Lanthanum is therefore chosen as the emitter element in this embodiment of the cathode material. Figure 1b The dark gray phase in is the tungsten matrix, and the light gray phase is W 2 C, the white phase is La 2 o 3 .

[0080] It can be seen that most of the lanthanum oxide particles are removed in preparation for the EBSD method. The phase diagram shows that the material not only consists of a W (tungsten) matrix and lanthanum oxide particles, but also at least a carbide phase (W 2 C) Composition.

[0081] According to the analysis of 5 images, W 2 The average area ratio of the C phase was 0.5%. Assuming no preferred orientation of the grains, the volume ratio is equal to the area ratio. The area ratio is 0.5% of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com