Method for extracting precious metal from auto-exhaust catalyst by hydrometallurgy and pyrometallurgy complex process

A precious metal and catalyst technology, which is applied in the field of effective recovery of platinum group metals, can solve the problem of low recovery rate of precious metals, and achieve the effect of good environmental friendliness, easy realization, and high recovery rate of precious metals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

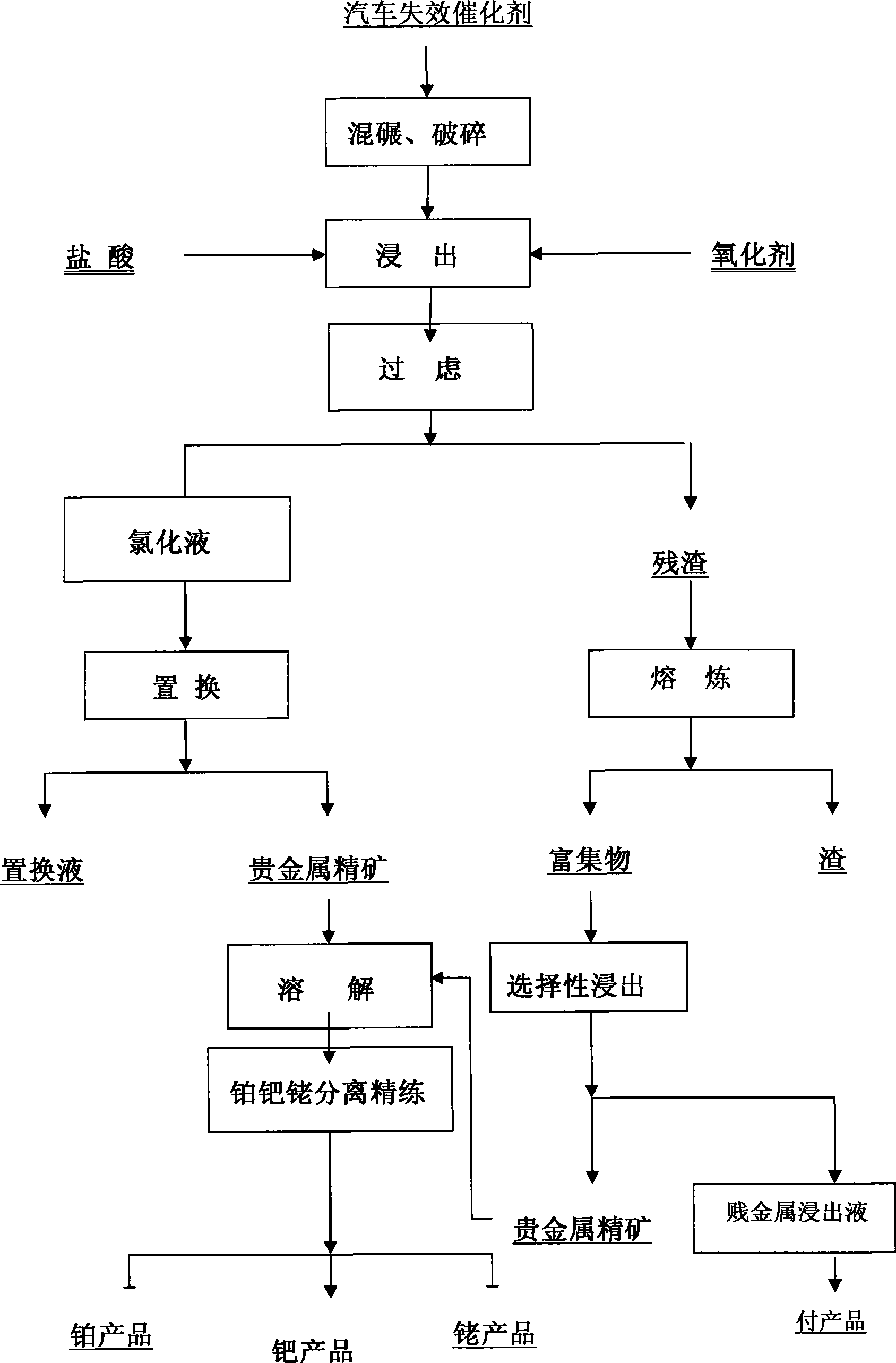

Method used

Image

Examples

Embodiment Construction

[0021] 1. Leaching

[0022] The exhausted automobile catalyst is first crushed and powdered, and 200g is taken each time and added to the hydrochloric acid solution, the temperature is raised to about 80°C, chlorine gas is introduced, stirred and leached, filtered,

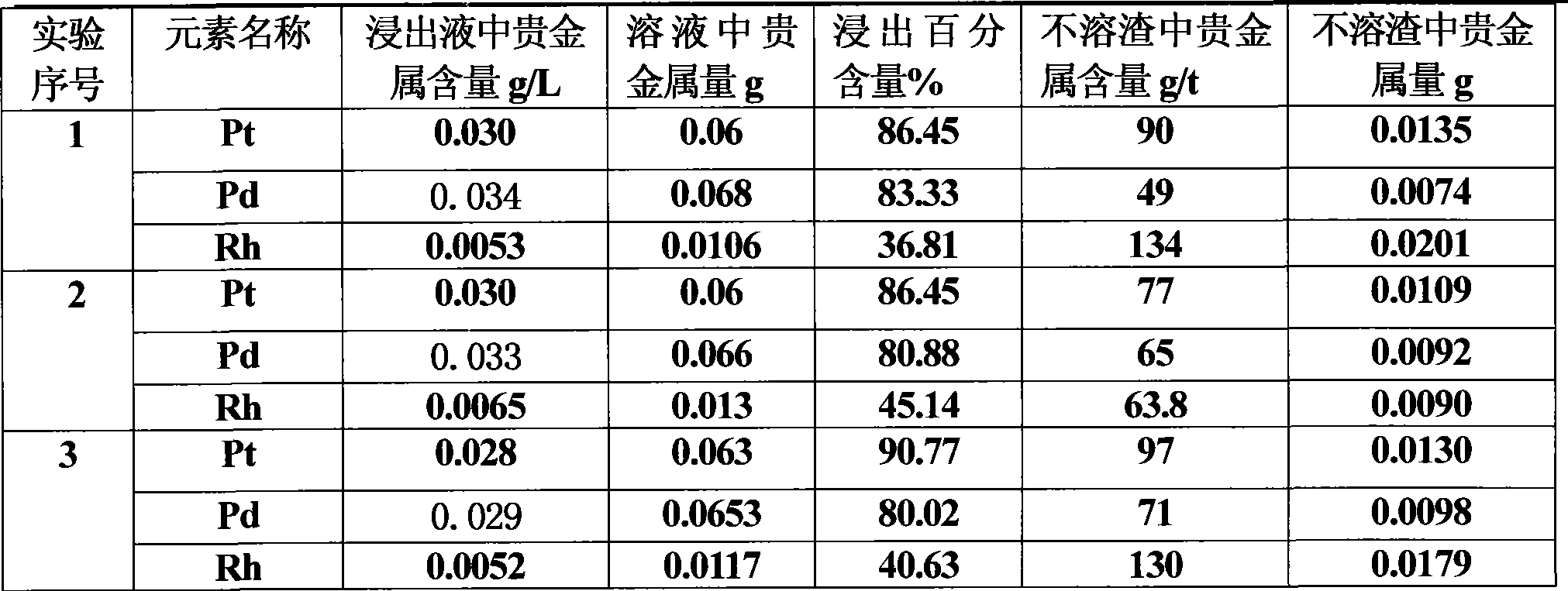

[0023] The leaching results are as follows:

[0024]

[0025] 2. Replacement

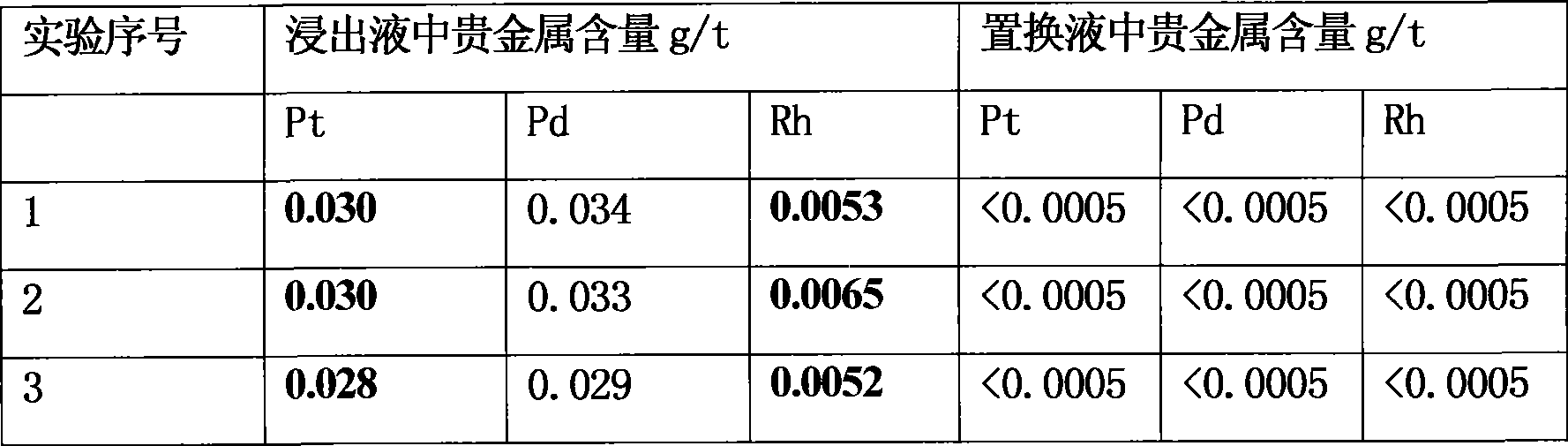

[0026] Put the leaching solution in a beaker, first add iron powder for replacement, then add zinc powder for replacement, precipitate the precious metal in it, and obtain precious metal concentrate. The replacement results are as follows:

[0027]

[0028] 3. Melting

[0029] Take the leaching residue of the exhausted automobile catalyst, add the trapping agent, slagging agent and reducing agent, mix it evenly with a mixer, put it into a clay graphite crucible, place it in a high temperature resistance furnace, keep the temperature at 1400°C for 0.5 hours, and the melting is completed Then take it out, cool to room temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com