Energy saving system and method for clean burning of layer burning boiler

A clean combustion and energy-saving system technology, applied in the field of boiler combustion system, can solve the problems of low thermal efficiency of boilers, achieve the effect of increasing chemical reaction rate, accelerating combustion speed, and reducing Ringelmann blackness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

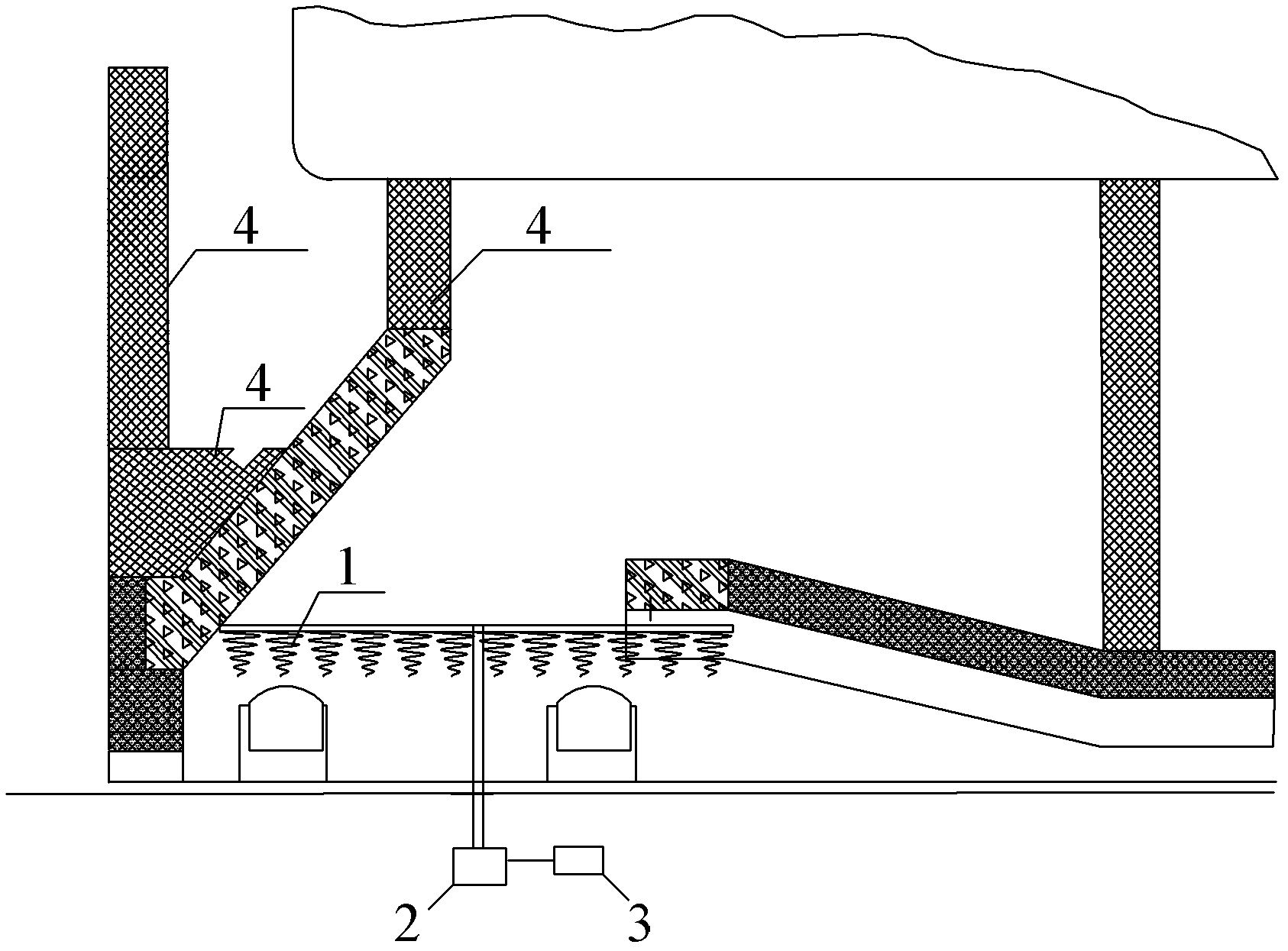

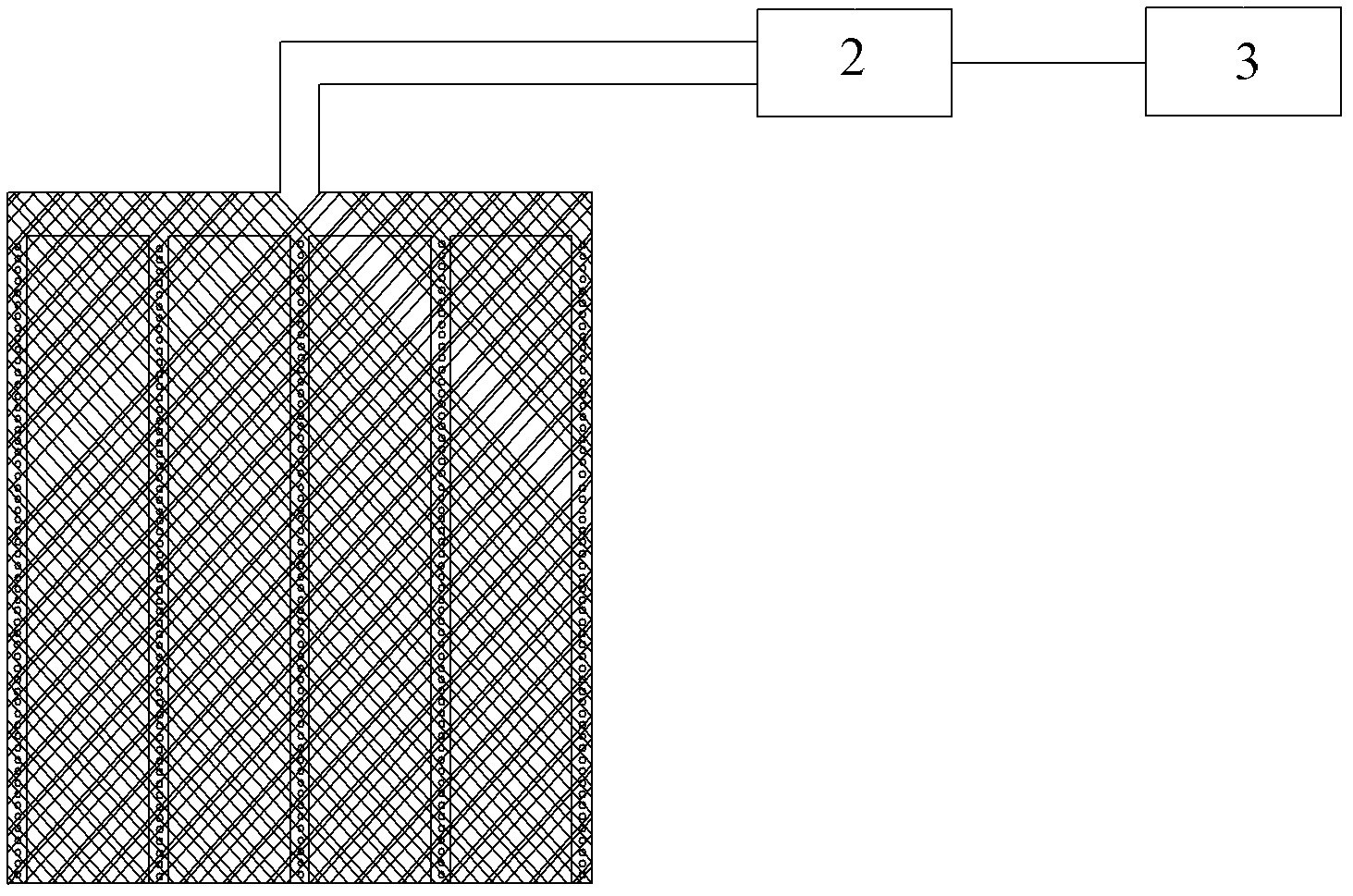

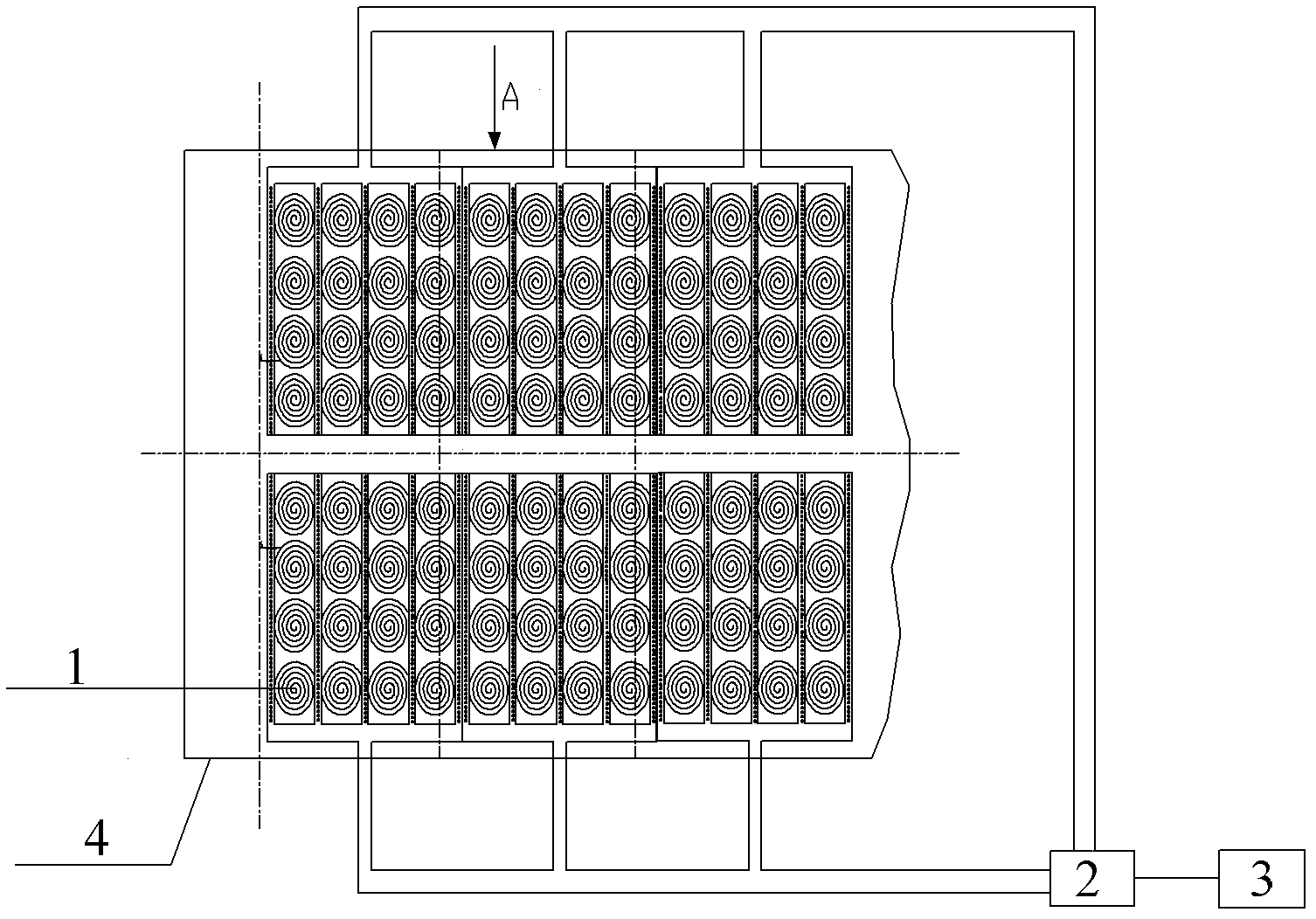

[0024] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0025] The invention cracks low-temperature water vapor through the metal catalyst, and when the alloy material is higher than 850°C, the water vapor can be adsorbed on the metal surface, reducing the activation energy of water cracking, increasing the reaction speed, and cracking into a large amount of O, H and OH, etc. Active ions accelerate the reaction speed of a large amount of carbon monoxide, hydrogen, gaseous hydrocarbons and phenolic aldehydes in the flue gas through air flow disturbance and make them burn more fully, reducing the heat loss Q4 of incomplete combustion of solids and Q3 of heat loss of incomplete combustion of gases , thereby improving the thermal efficiency and furnace temperature of the boil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com