Horizontal mobile grate gasifier

A mobile grate and gasifier technology, applied to horizontal gasifiers, gasification processes, fixed bed gasification, etc., can solve the problems of impact, no introduction of circulating flue gas, etc., to reduce SO2 emissions, Effects of reducing Ringelmann blackness, smoke emission and lowering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

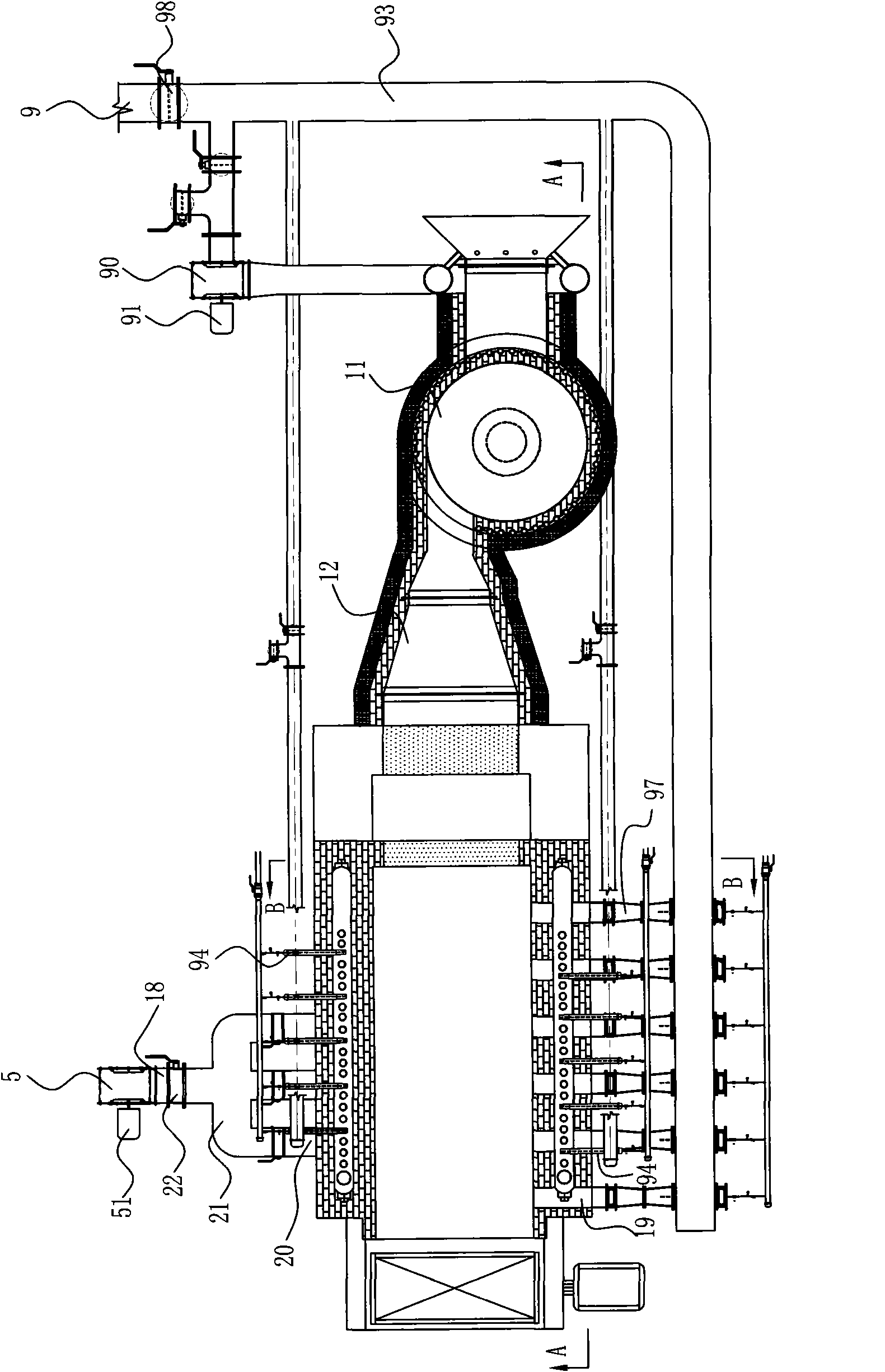

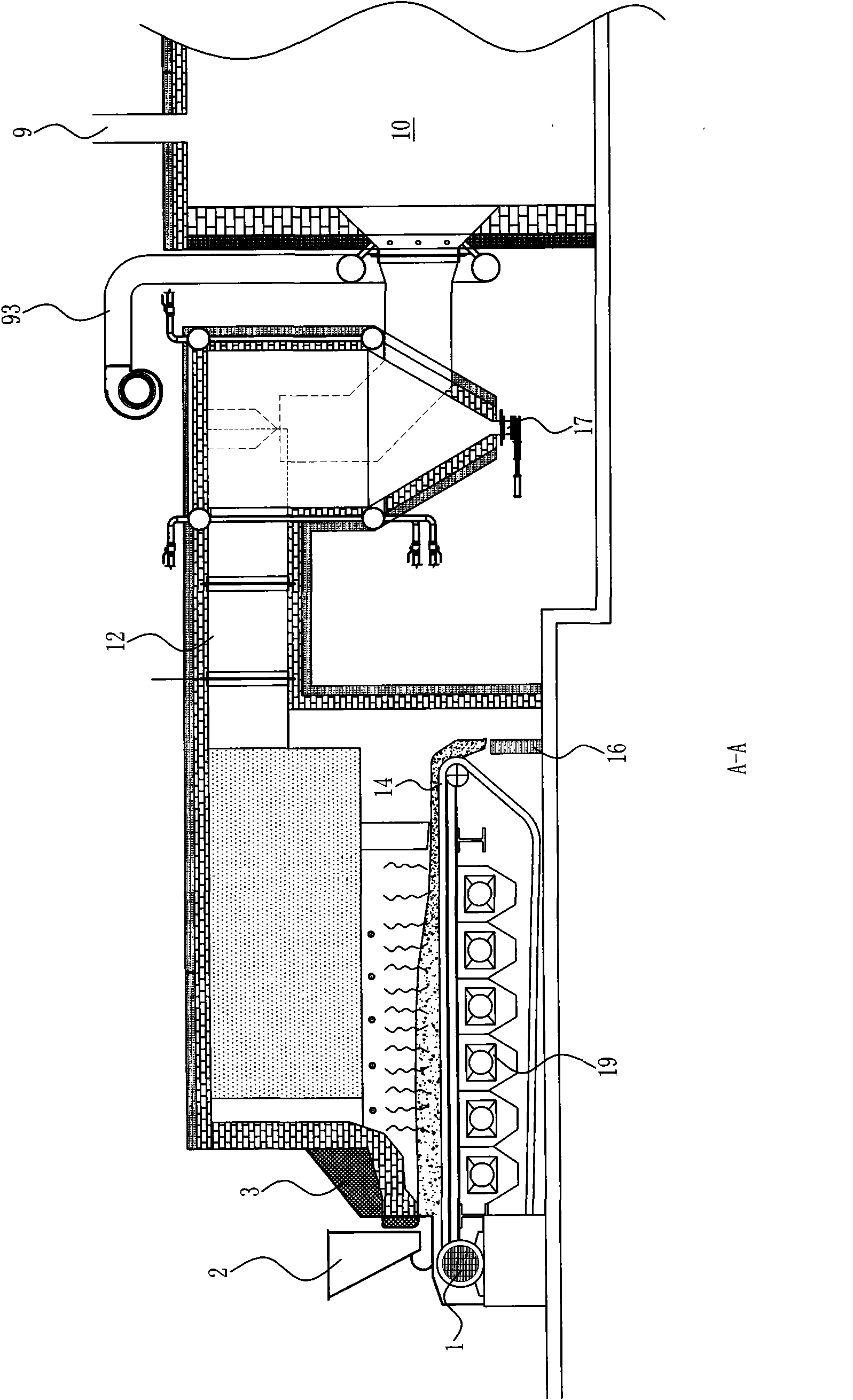

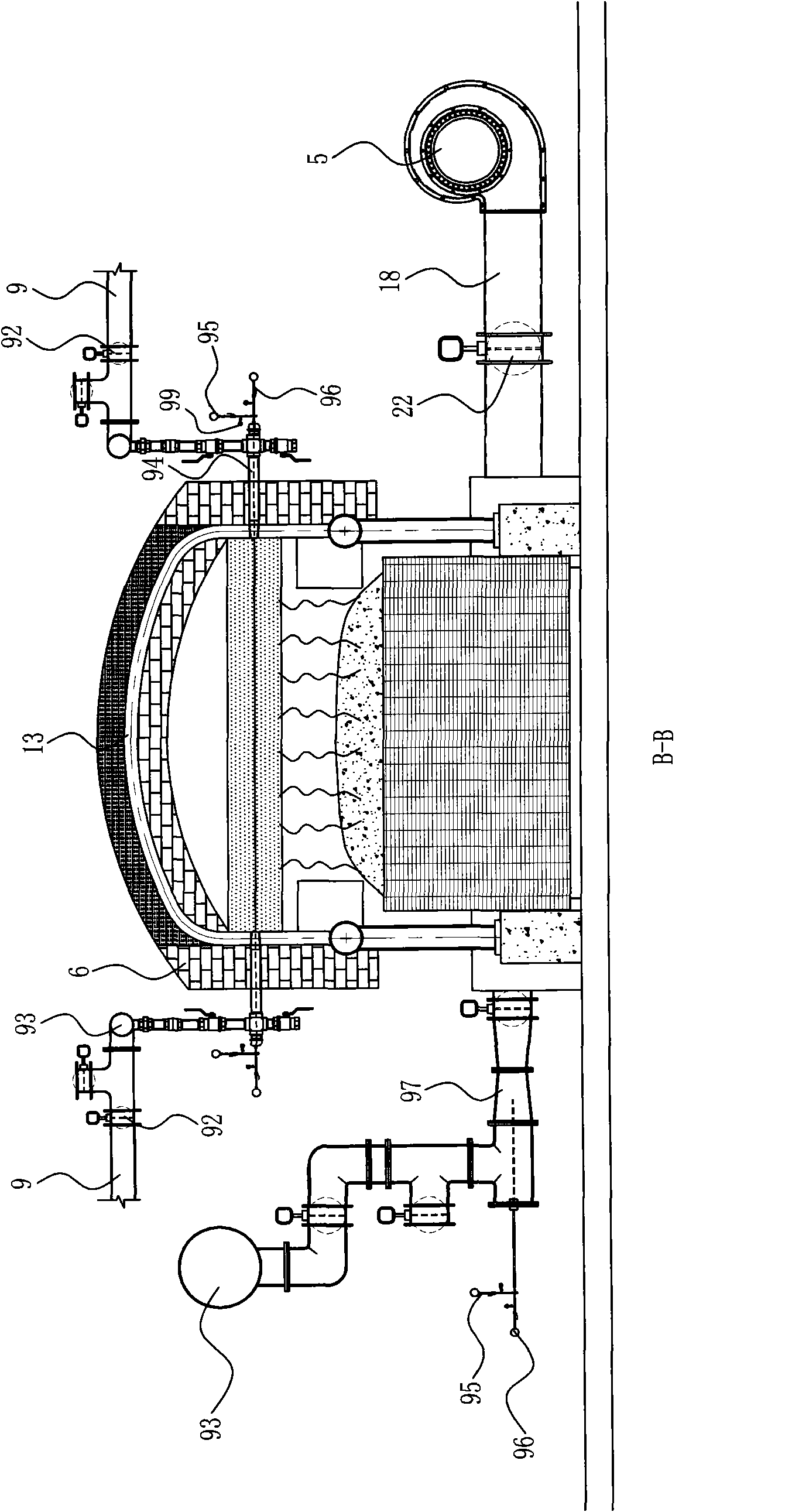

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0026] Figure 1 to Figure 4 An embodiment of the present invention is shown, including a furnace body 6, a front furnace arch 3 and an air supply device, and a water jacket 13 is arranged around the furnace body and on the top, and the water jacket can reduce the usage of thermal insulation materials to save costs; at the same time , the steam generated by the water jacket can be reused as a gasification agent.

[0027] The air supply device is composed of blower 5 and connected primary air supply pipe 18 and upper air supply pipe; the bottom of the furnace body 6 is provided with a fire grate 14 with a transmission device, and the primary air supply pipe 18 is connected with a plurality of air chambers 19 and Arranged below the fire grate, the upper air supply pipe is arranged above the fire grate, the upper air supply pipe is arranged on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com