Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

42results about "Horizontal gasifiers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for producing negative carbon fuel

ActiveUS20130025190A1Improve thermal conductivityBio-organic fraction processingCarbon compoundsCarbon creditCarbon offset

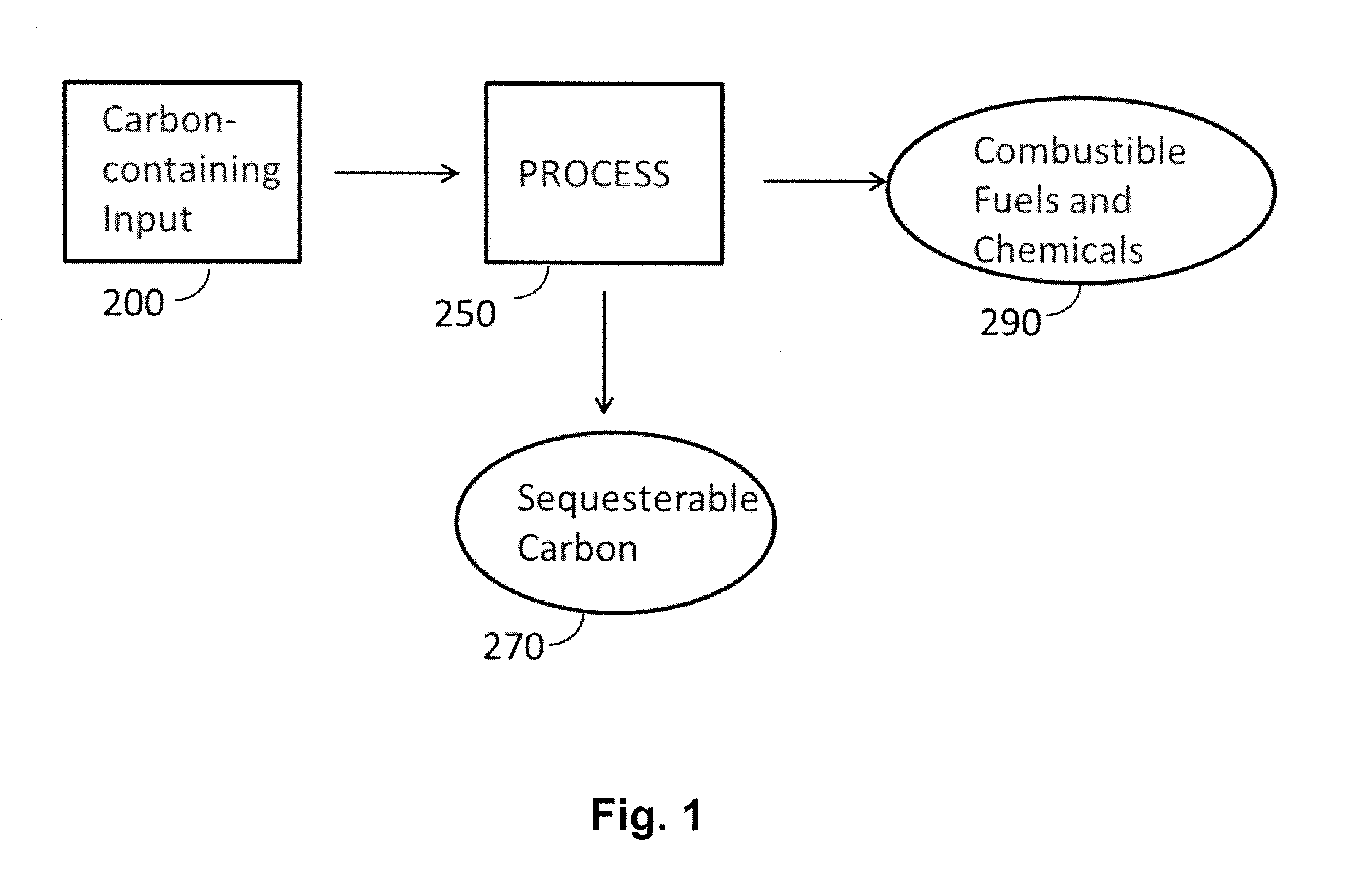

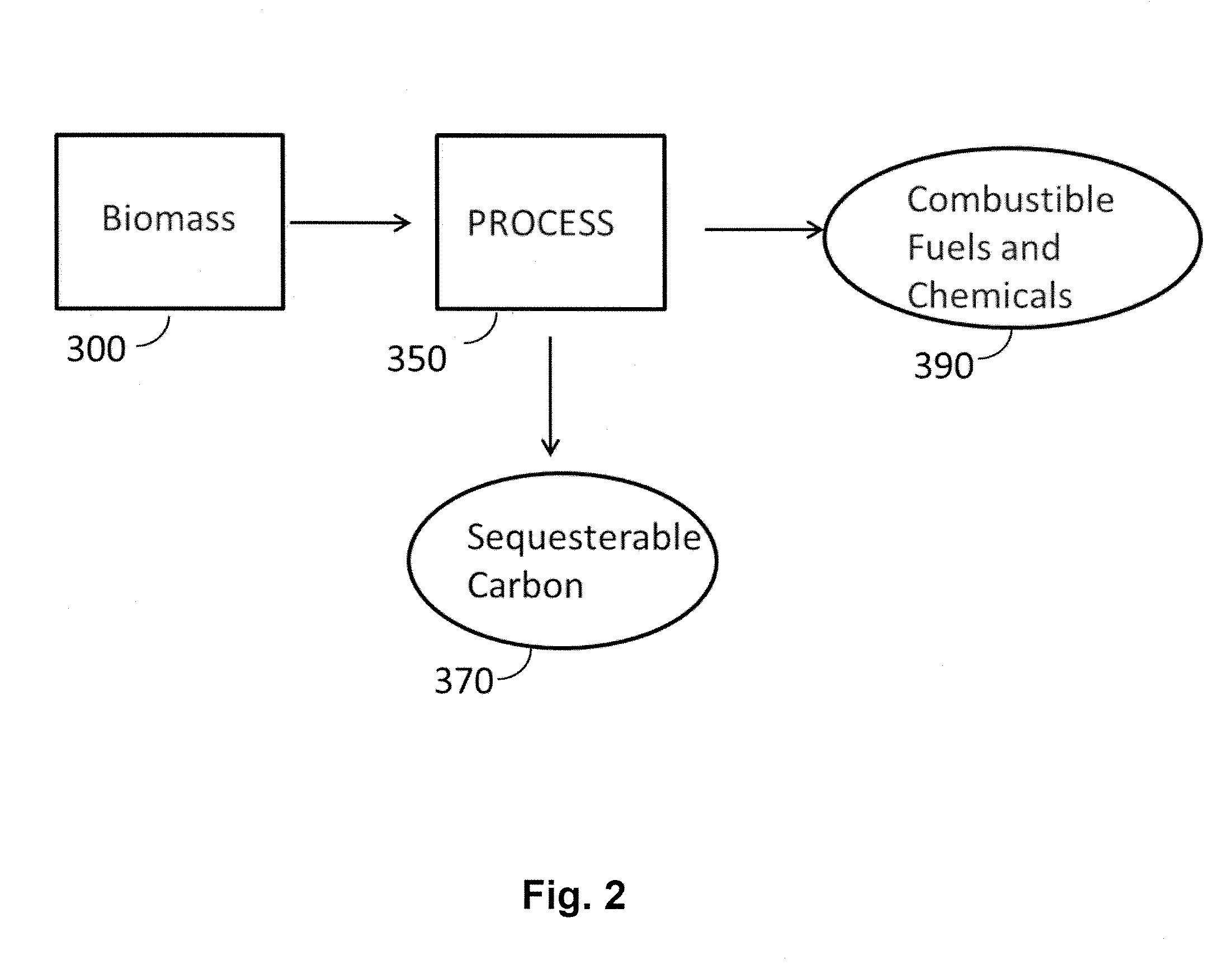

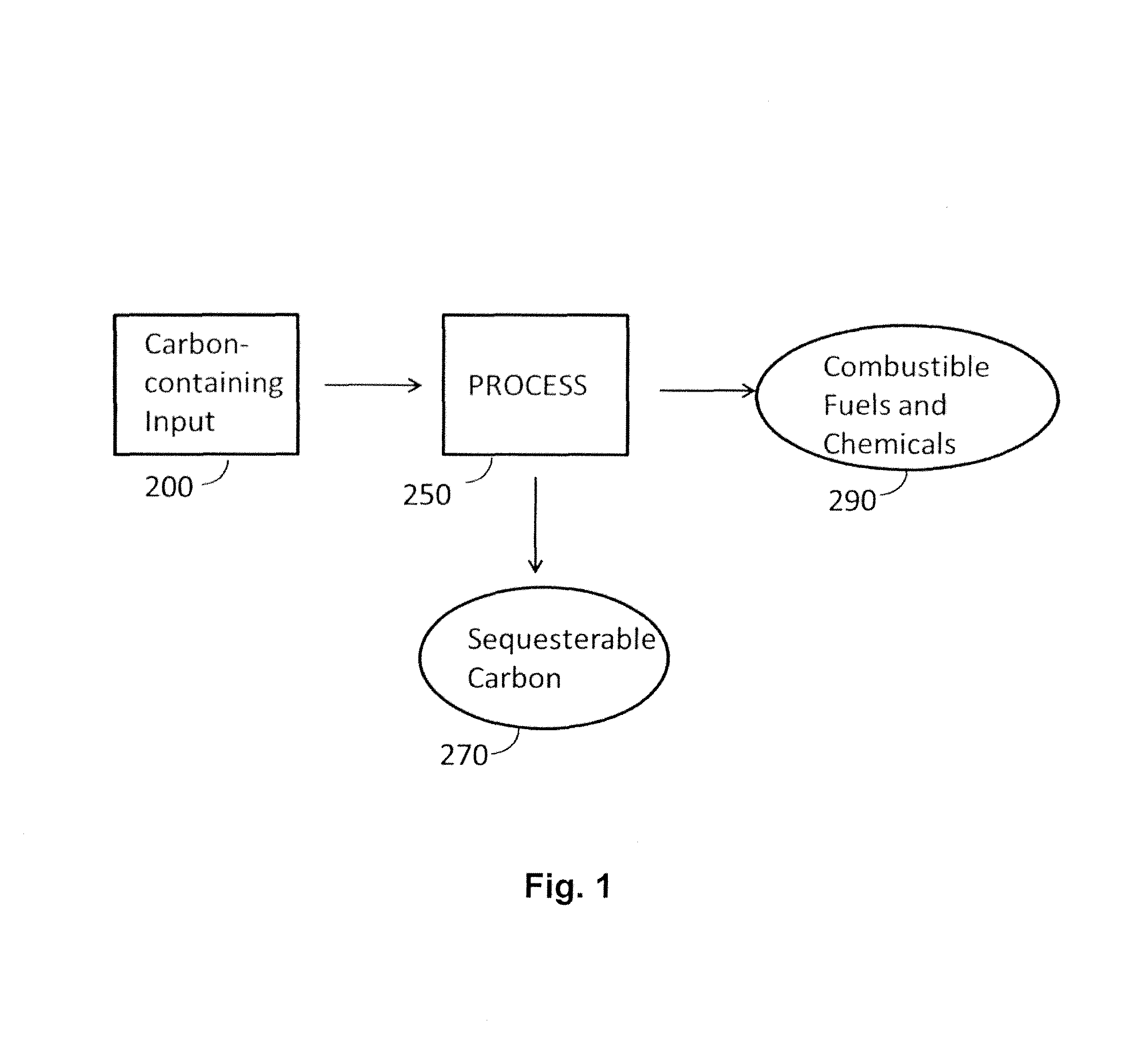

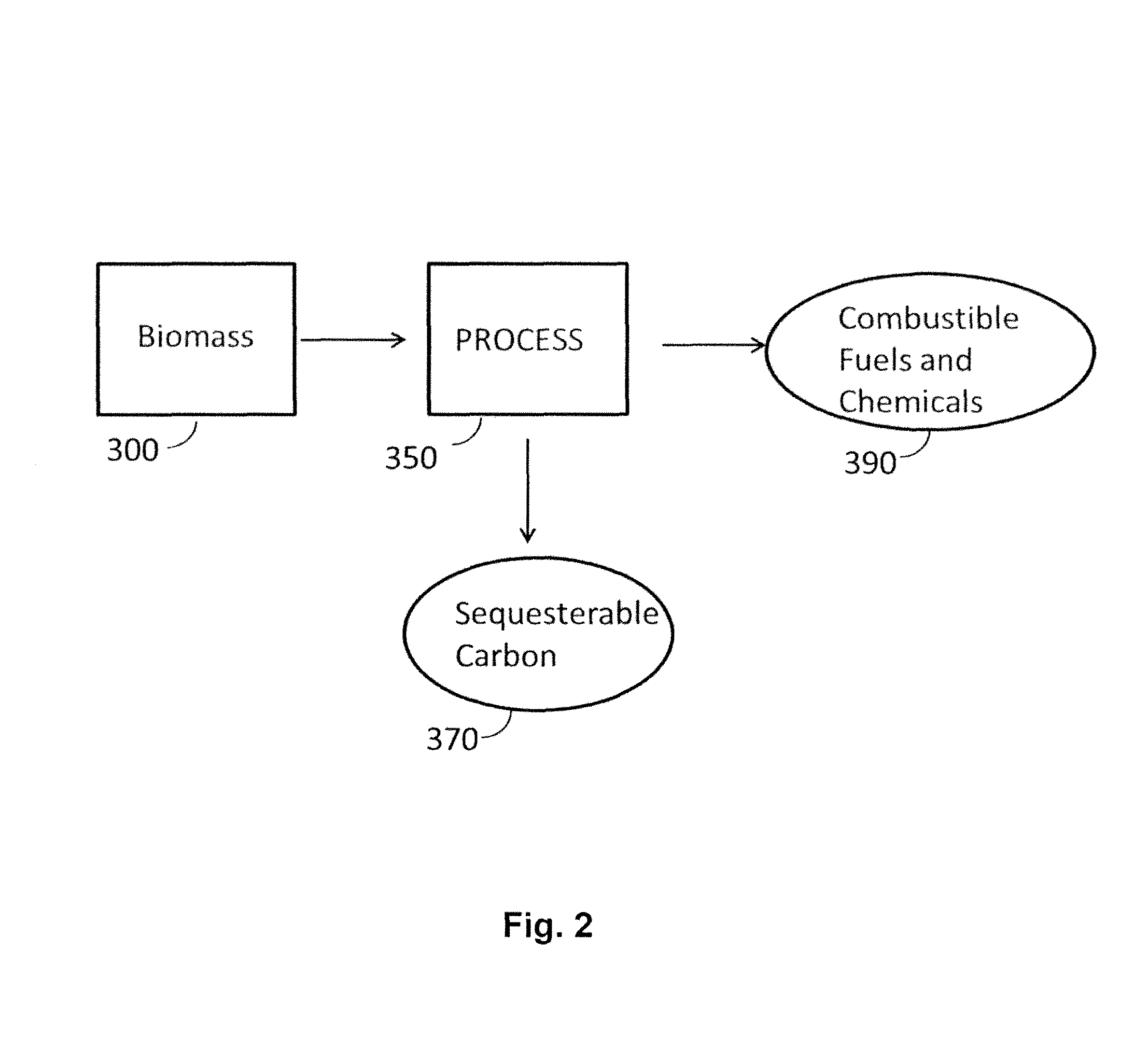

A method and process is described for producing negative carbon fuel. In its broadest form, a carbon-containing input is converted to combustible fuels, refinery feedstock, or chemicals and a carbonaceous solid concurrently in separate and substantially uncontaminated form. In an embodiment of the invention, biomass is converted via discrete increasing temperatures under pressure to blendable combustible fuels and a carbonaceous solid. The carbonaceous solid may be reacted to synthesis gas, sold as charcoal product, carbon credits, used for carbon offsets, or sequestered.

Owner:COOL PLANET ENERGY SYST

Method for producing negative carbon fuel

A method and process is described for producing negative carbon fuel. In its broadest form, a carbon-containing input is converted to combustible fuels, refinery feedstock, or chemicals and a carbonaceous solid concurrently in separate and substantially uncontaminated form. In an embodiment of the invention, biomass is converted via discrete increasing temperatures under pressure to blendable combustible fuels and a carbonaceous solid. The carbonaceous solid may be reacted to synthesis gas, sold as charcoal product, carbon credits, used for carbon offsets, or sequestered.

Owner:COOL PLANET ENERGY SYST

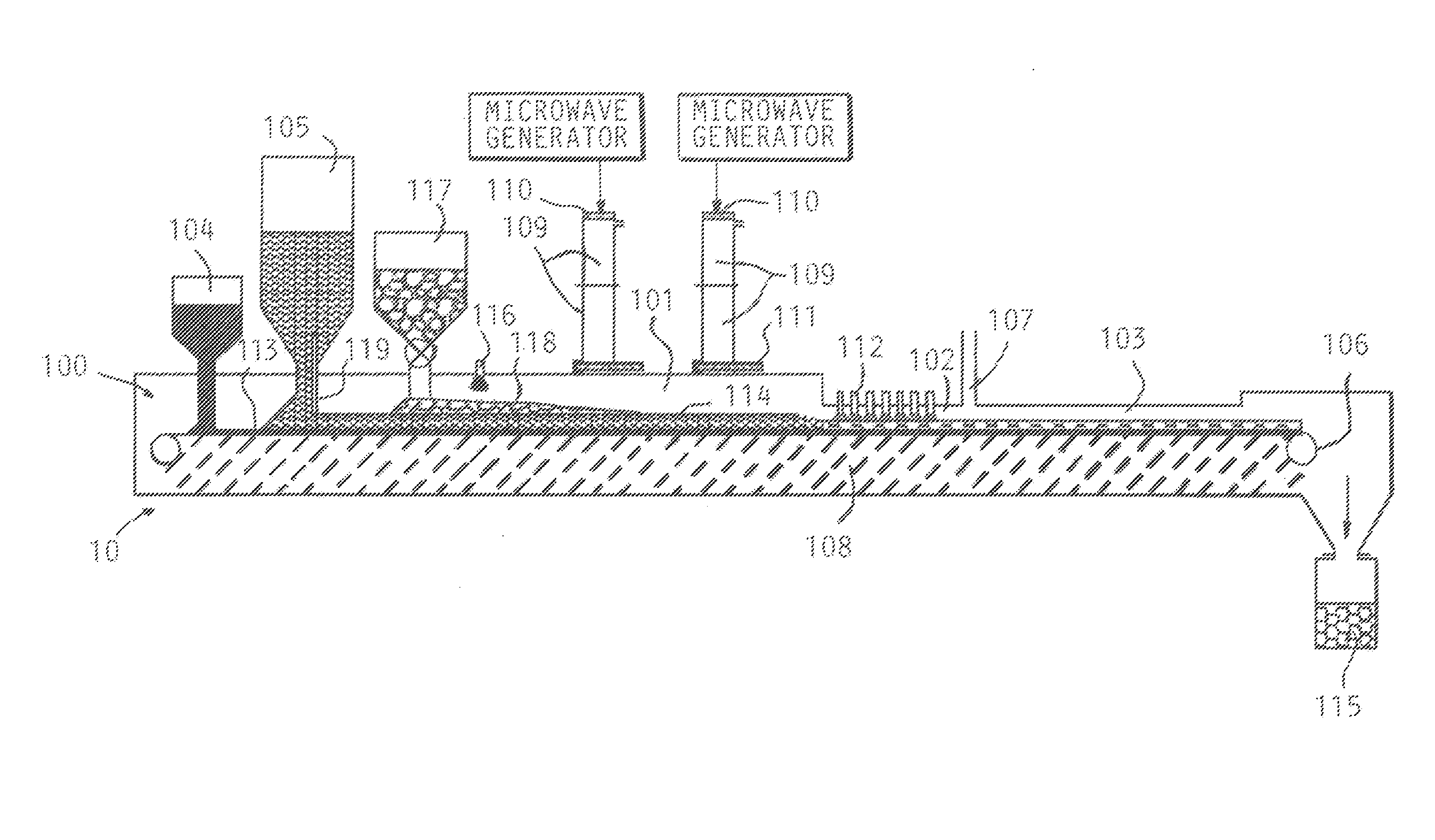

Method and Apparatus For Coproduction of Pig Iron and High Quality Syngas

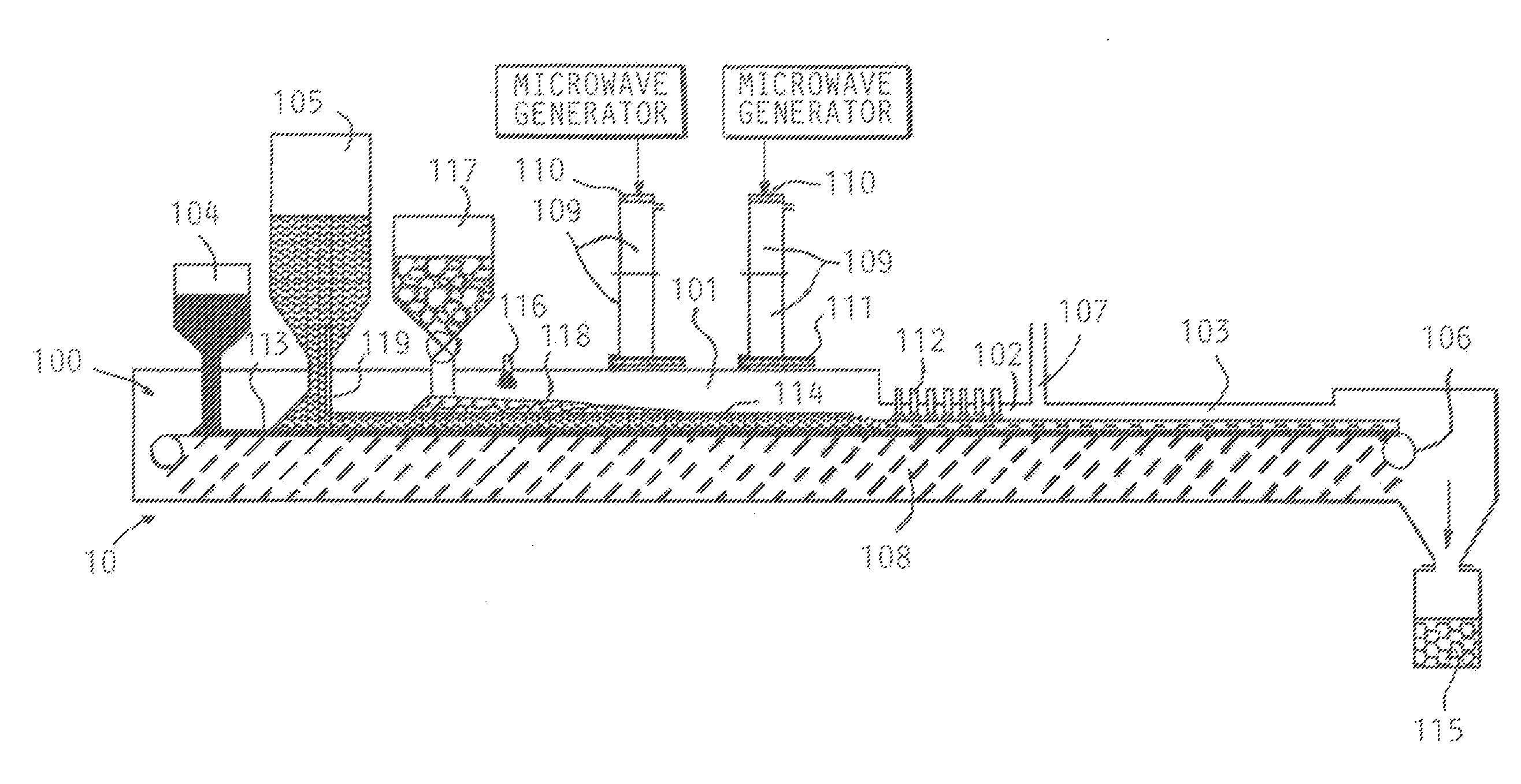

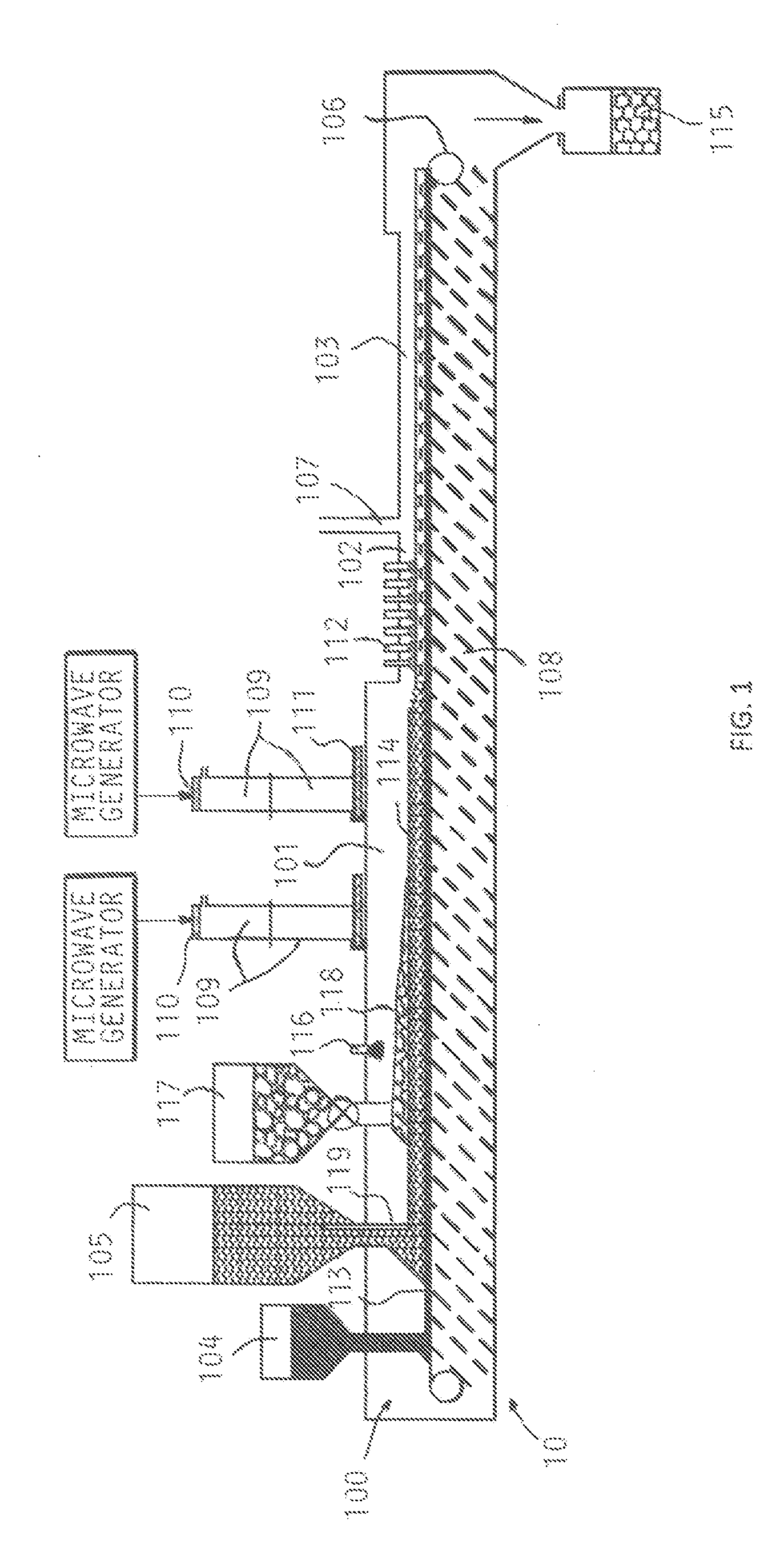

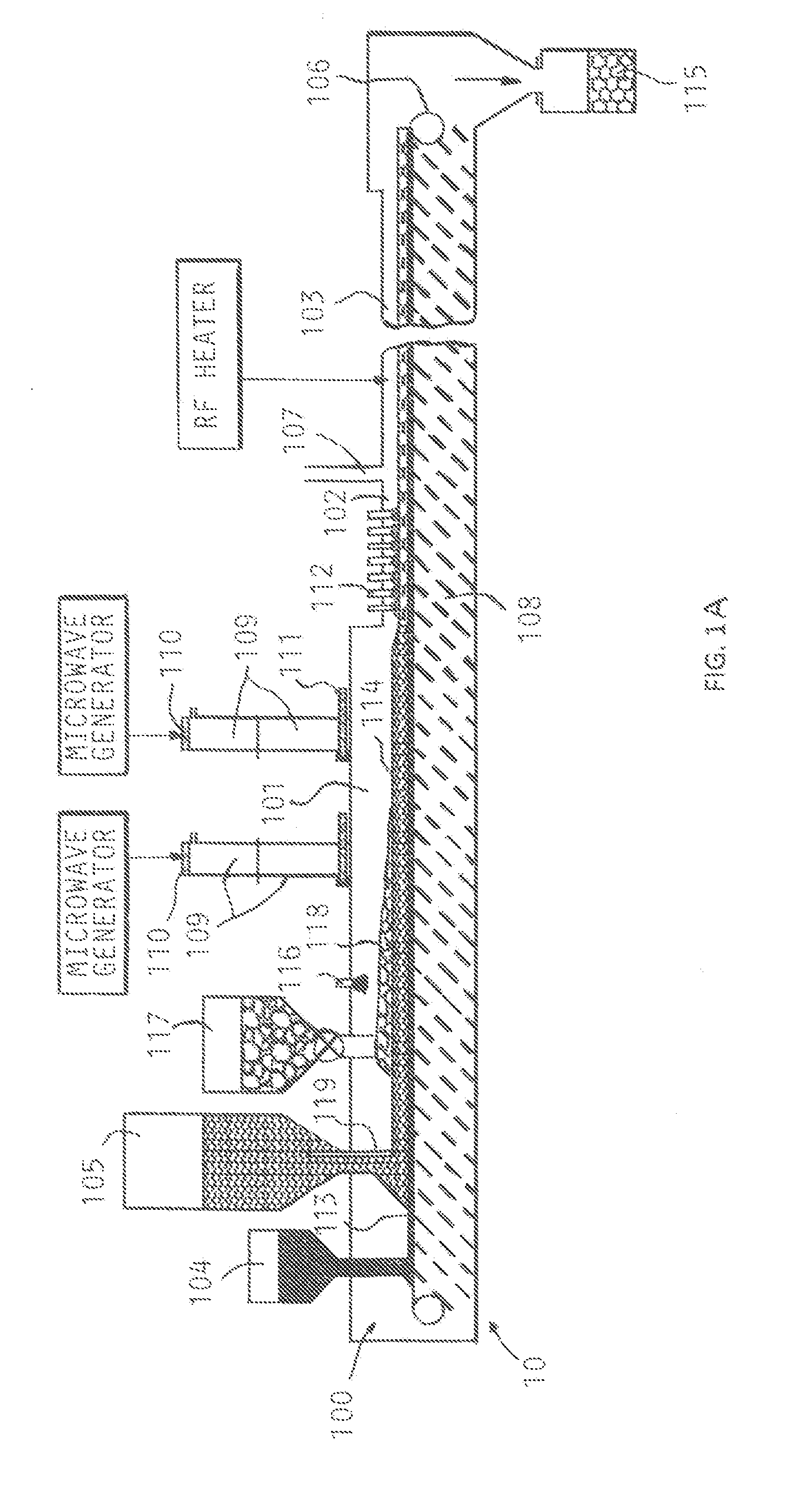

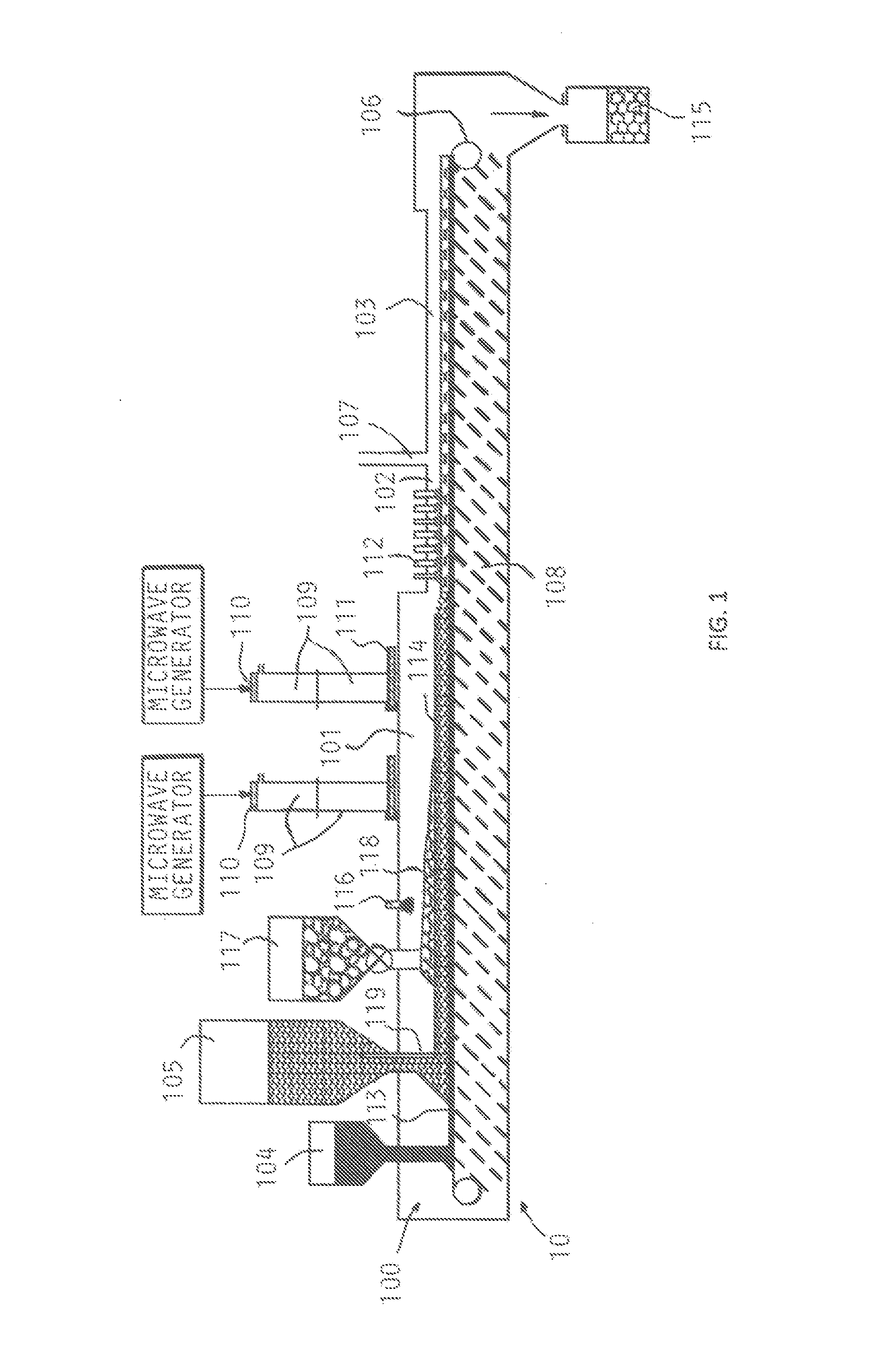

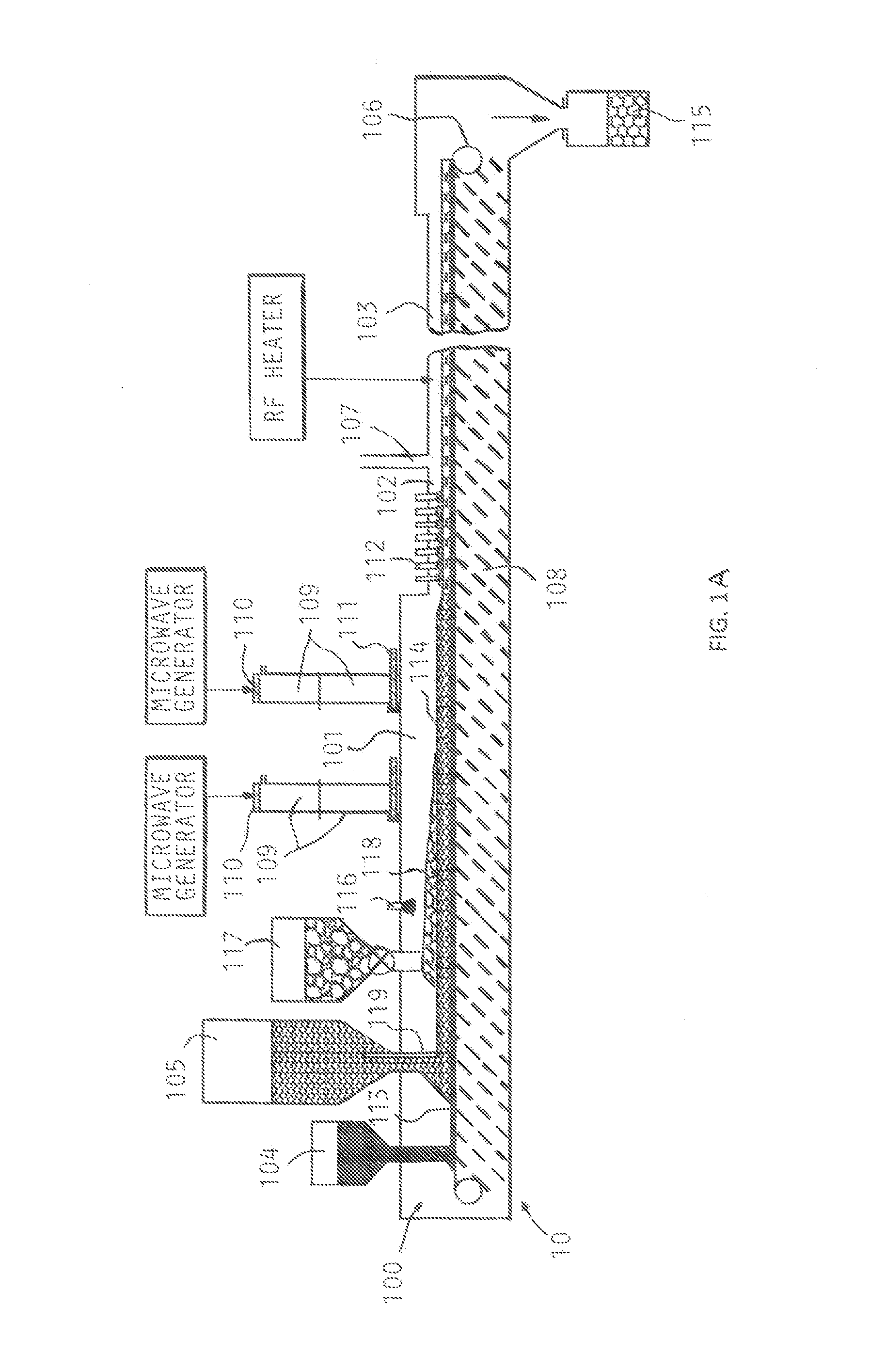

ActiveUS20120031232A1Improve microwave absorption performanceHeating up fastBlast furnace detailsCharge manipulationSludgeLiquid fuel

Combined microwave heating and plasma / electric arc heating is utilized in several processes and apparatus which involve co-production of pig iron and high quality syngas, biomass to liquid fuel production, coal to liquid fuel production, co-gasification of biomass and coal, municipal solid waste treatment, waste-to-energy (agriculture waste, ASR and PEF), EAF dust and BOF sludge treatment to recover zinc and iron, hazardous bottom ash vitrification, and bromine, chlorine and sulfur removal / recycling.

Owner:HUANG XIAODI +1

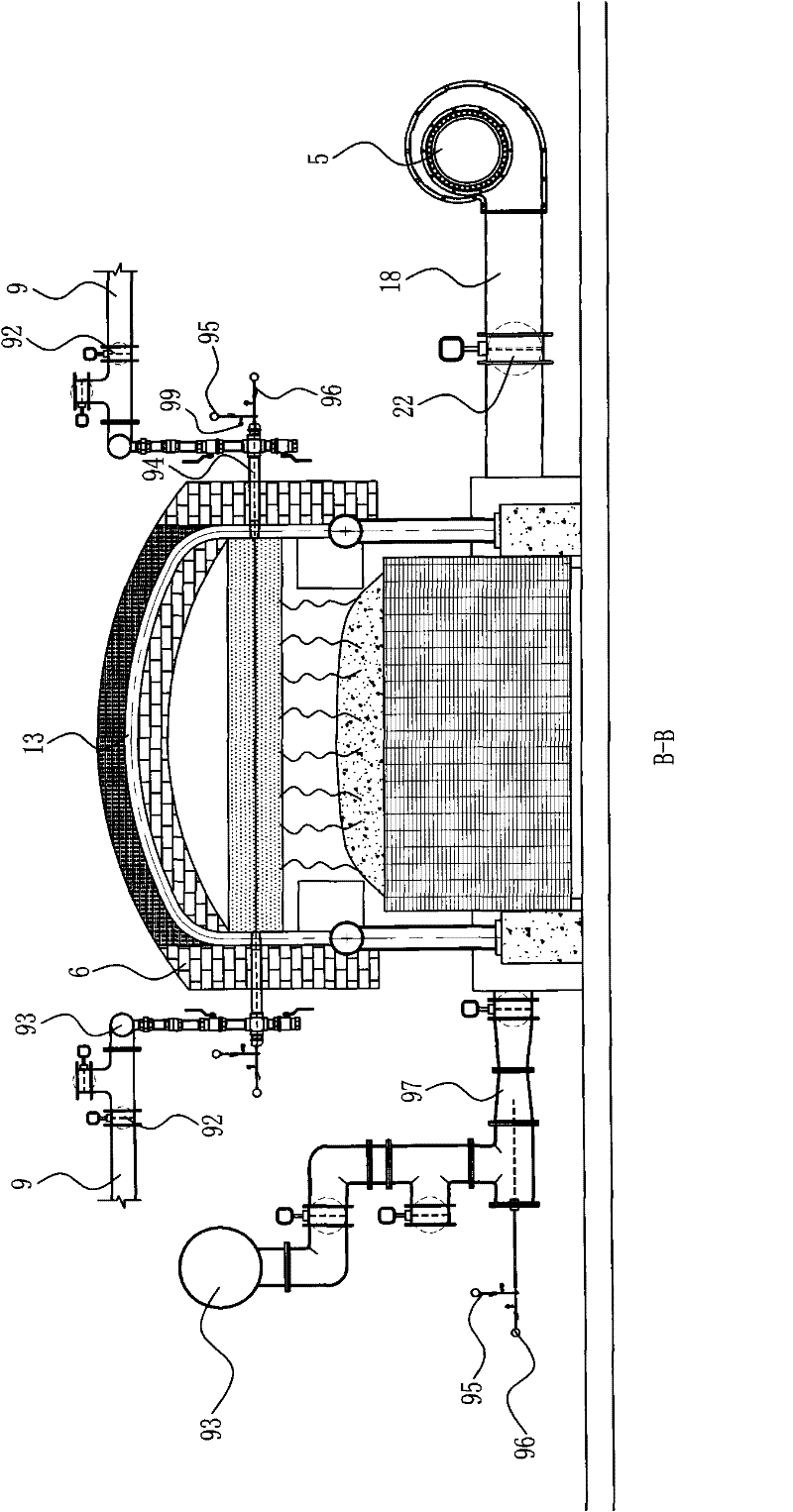

Heat Recycling System for Use with a Gasifier

InactiveUS20070284453A1Improve efficiencyMinimize energy consumptionGasifier mechanical detailsEnergy inputWorking fluidControl system

The present invention provides a system that recycles heat recovered from hot products of a carbonaceous feedstock gasification process back into the gasification process. The hot gaseous products are used to heat working fluids such as air and water to produce hot air, hot water or steam. The heated fluids are used to return heat back to the gasification process. The system also comprises a control system to optimize the efficiency of a gasification process by minimizing energy consumption of the process, while also maximizing energy production.

Owner:PLASCO ENERGY GROUP INC

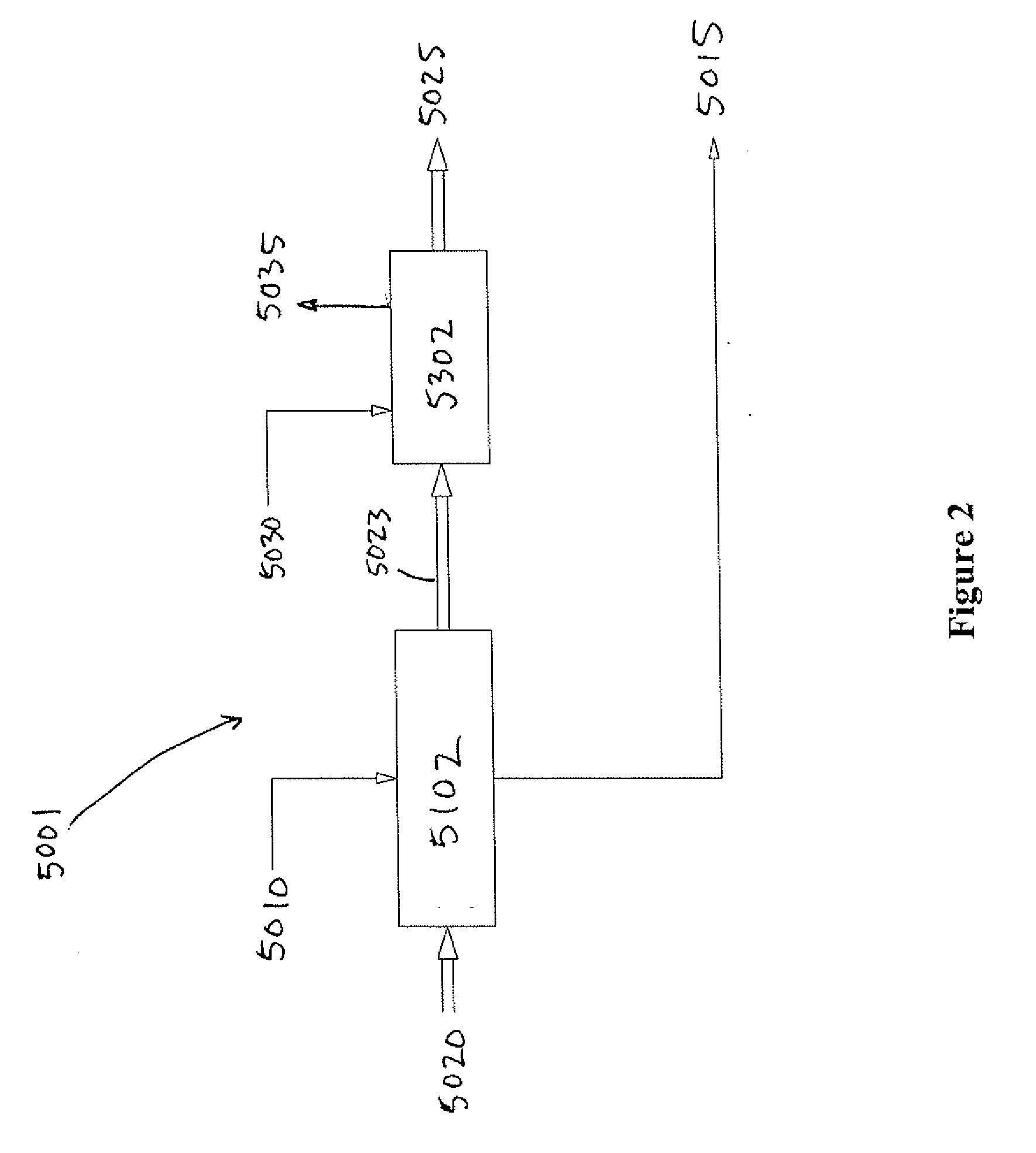

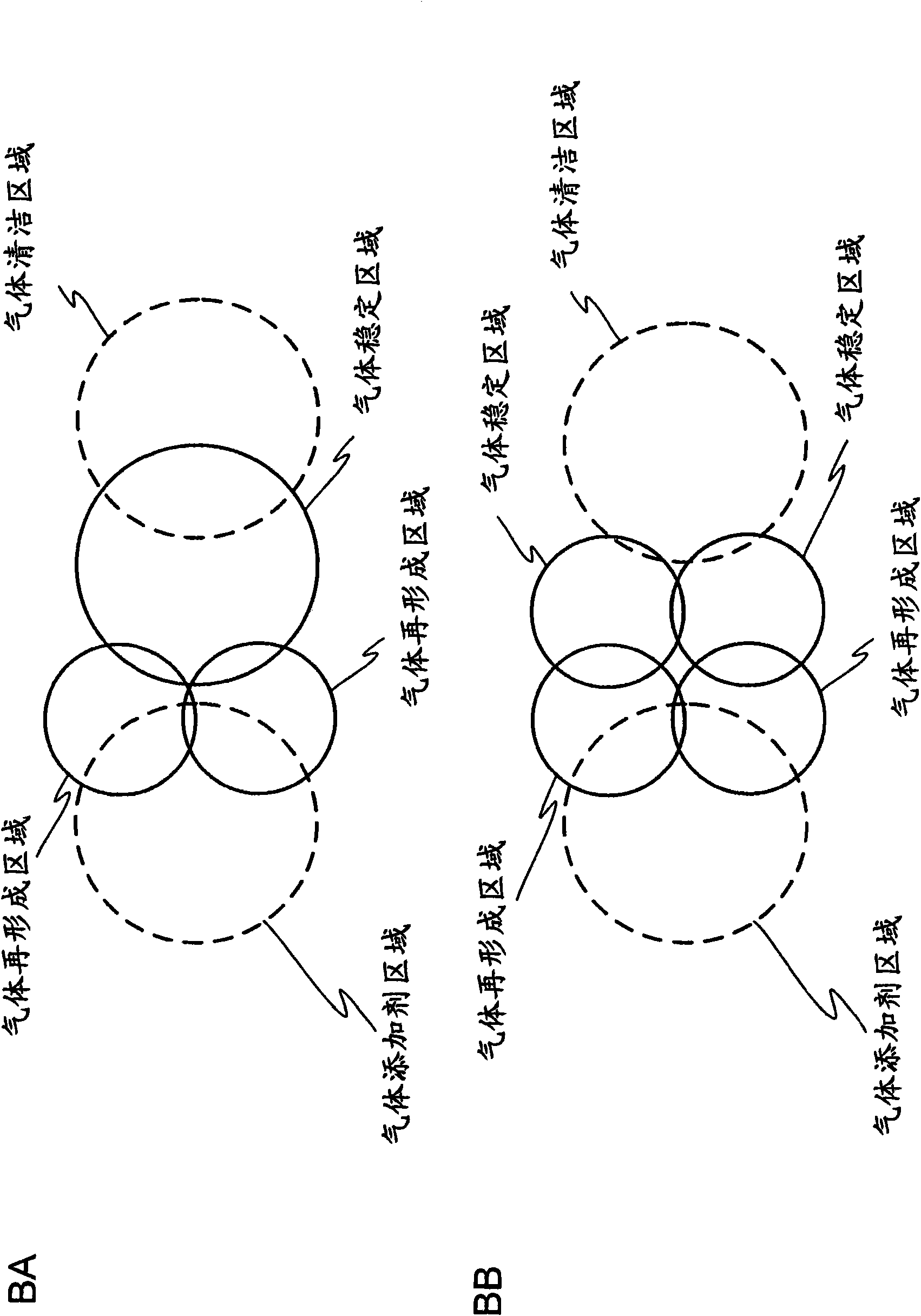

A gas reformulation system comprising means to optimize the effectiveness of gas conversion

This invention provides a system and method for efficient reformulation of an initial gas with associated characteristics into an output gas with desired characteristic parameters, within a substantially sealed, contained, and controlled environment. The gas reformulating system uses a gas energizing field to disassociate the initial gas molecules and molecules of injected process additives of appropriate types and amounts, into their constituents that then recombine to form the output gas with the desired parameters. The gas reformulating system further comprises a control system that regulates the process and thereby enables the process to be optimized. The gas energizing field may be provided at least partly by hydrogen burners or plasma torches.

Owner:PLASCO CONVERSION TECH INC

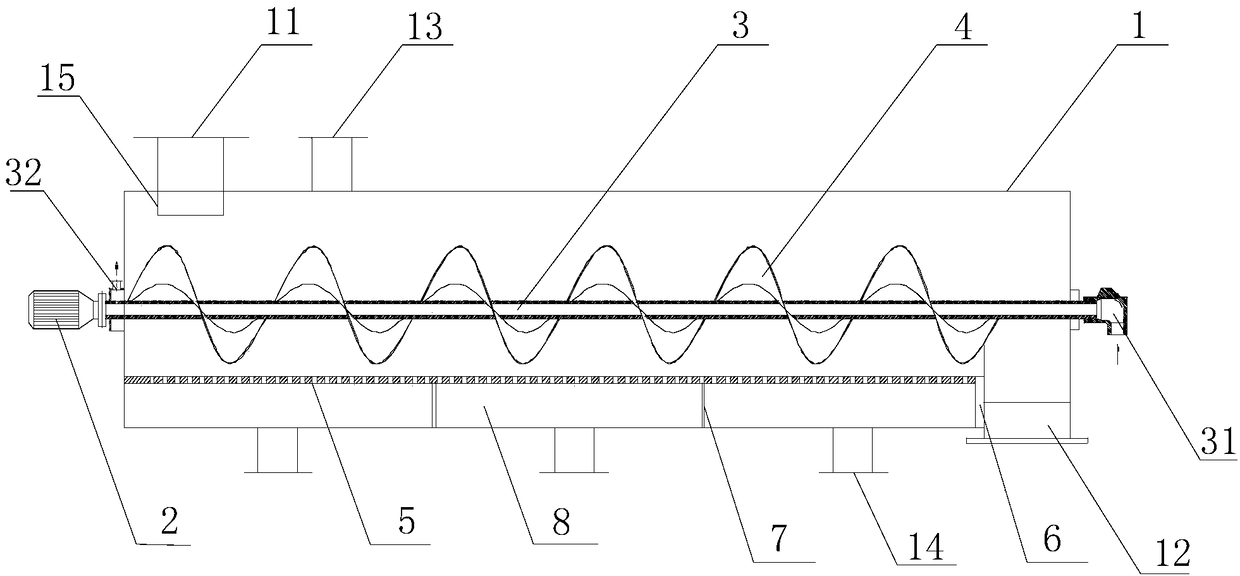

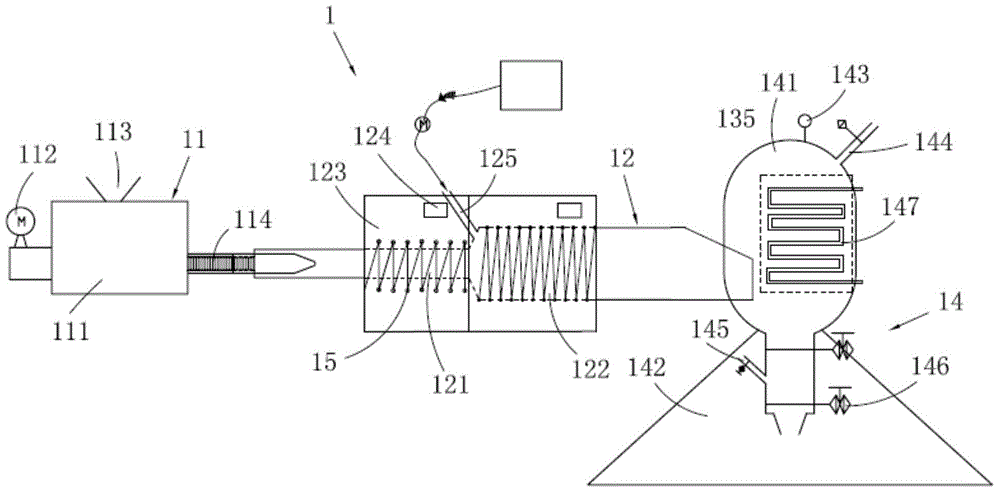

Multi-section spiral moving bed pyrolysis gasification device

PendingCN108148627AAvoid enteringGuaranteed availabilityDirect heating destructive distillationGasification processes detailsProcess engineeringMoving bed

The invention discloses a multi-section spiral moving bed pyrolysis gasification device which comprises a dry-section reactor, a pyrolysis-section reactor and a gasification-section reactor. The dry-section reactor is used for drying materials, the pyrolysis-section reactor is used for pyrolyzing the materials, the gasification-section reactor is used for gasifying the materials, the dry-section reactor, the pyrolysis-section reactor and the gasification-section reactor are provided with feeding ports and discharging ports, the discharging port of the dry-section reactor is connected with thefeeding port of the pyrolysis-section reactor, and the discharging port of the pyrolysis-section reactor is connected with the feeding port of the gasification-section reactor. The device has the advantages that the standing time of the materials is controlled by adjusting the rotating speed of a motor, and matching amount of gasifying agents and the materials is manually and accurately controlledby combining the sectioned air supply speed of an air-distribution plate, so that physical and chemical properties of target products can be controlled.

Owner:广东国能中林实业有限公司

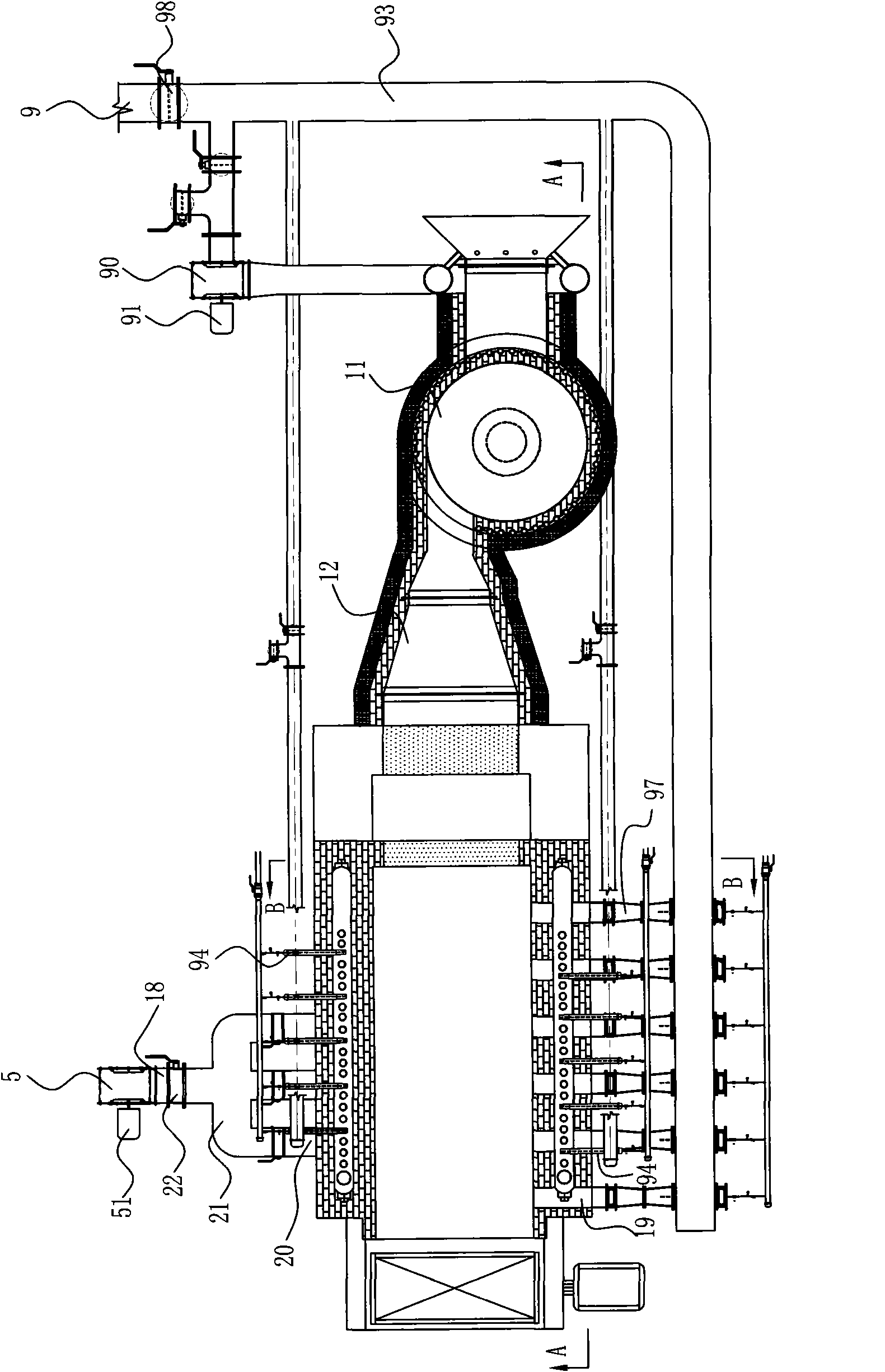

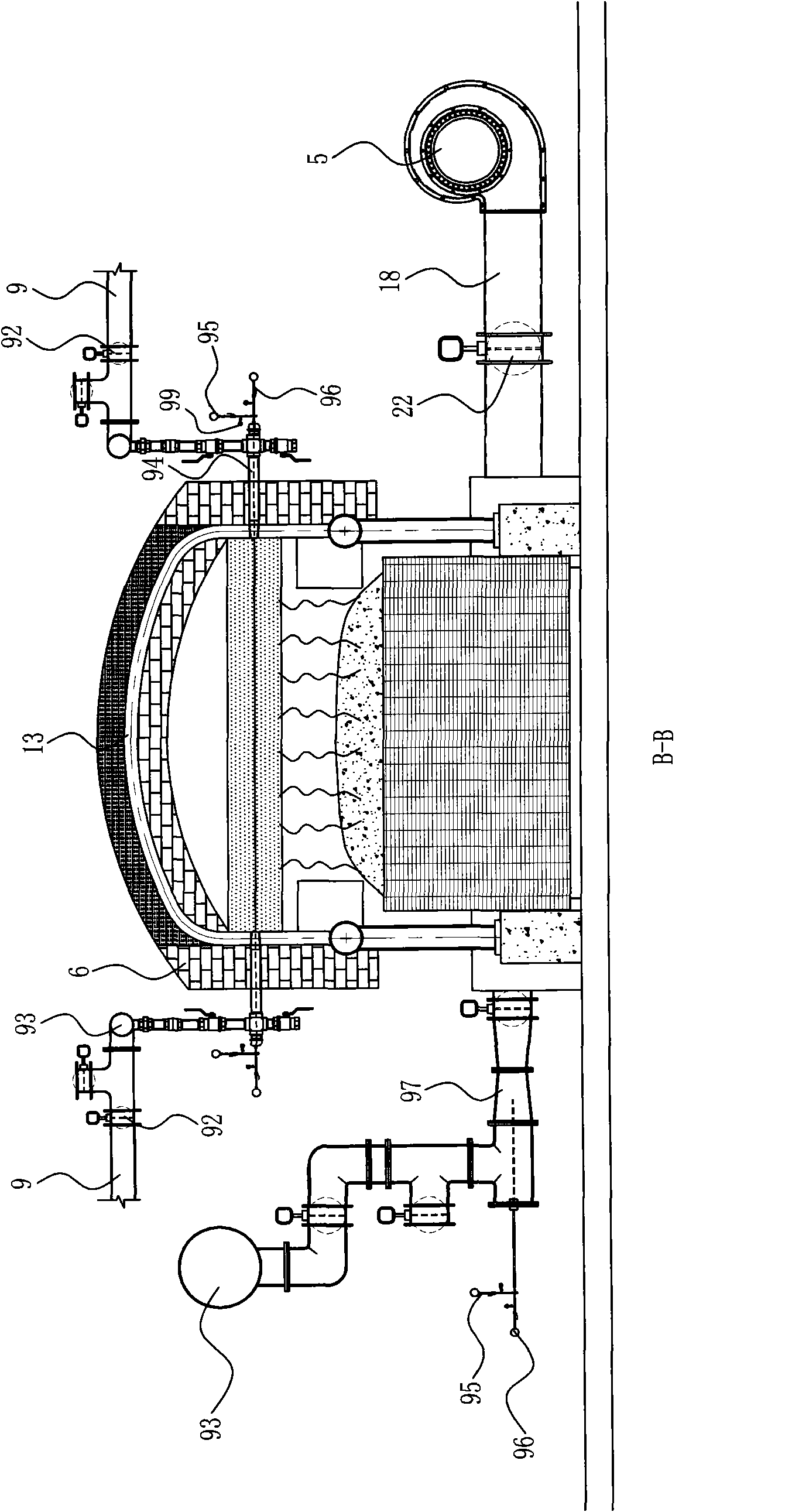

Horizontal mobile grate gasifier

InactiveCN101776260AEmission reductionImprove protectionCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorFlue gas

The invention relates to a horizontal mobile grate gasifier, which comprises a furnace body with a grate and an air supply device. The air supply device consists of a primary air supply pipe and an upper-layer air supply pipe, the primary air supply pipe is connected with a plurality of air chambers and is arranged below the grate, the upper-layer air supply pipe is arranged on the two sidewalls of the furnace body and is communicated with the inner chamber of the furnace body, the rear part of the furnace body is provided with a flue gas channel, the rear end of the flue gas channel is connected with the combustor of a boiler, a flue gas circulating pipe which is connected with the rear part of the combustor communicates circulating flue gas and the upper-layer air supply pipe to form a mixed gas channel, the mixed gas channel and a steam pipe respectively extend into the air chamber and the cavity of the furnace body through a primary air Venturi pipe and a secondary air Venturi pipe; and mixed gas can flow to the front side of the combustor of the boiler through a gas mixing fan. The invention has the advantages of reducing Ringelman black and smoke emission, allowing the use of coal raw materials which are each to be coked, expanding the flexibility of the boiler use and the diversity of operating modes, and realizing the online real-time control and adjustment of parameters of steam output variables, grate operation and gasification dosage, thereby achieving the best operating conditions.

Owner:NINGBO YINUO ENERGY TECH

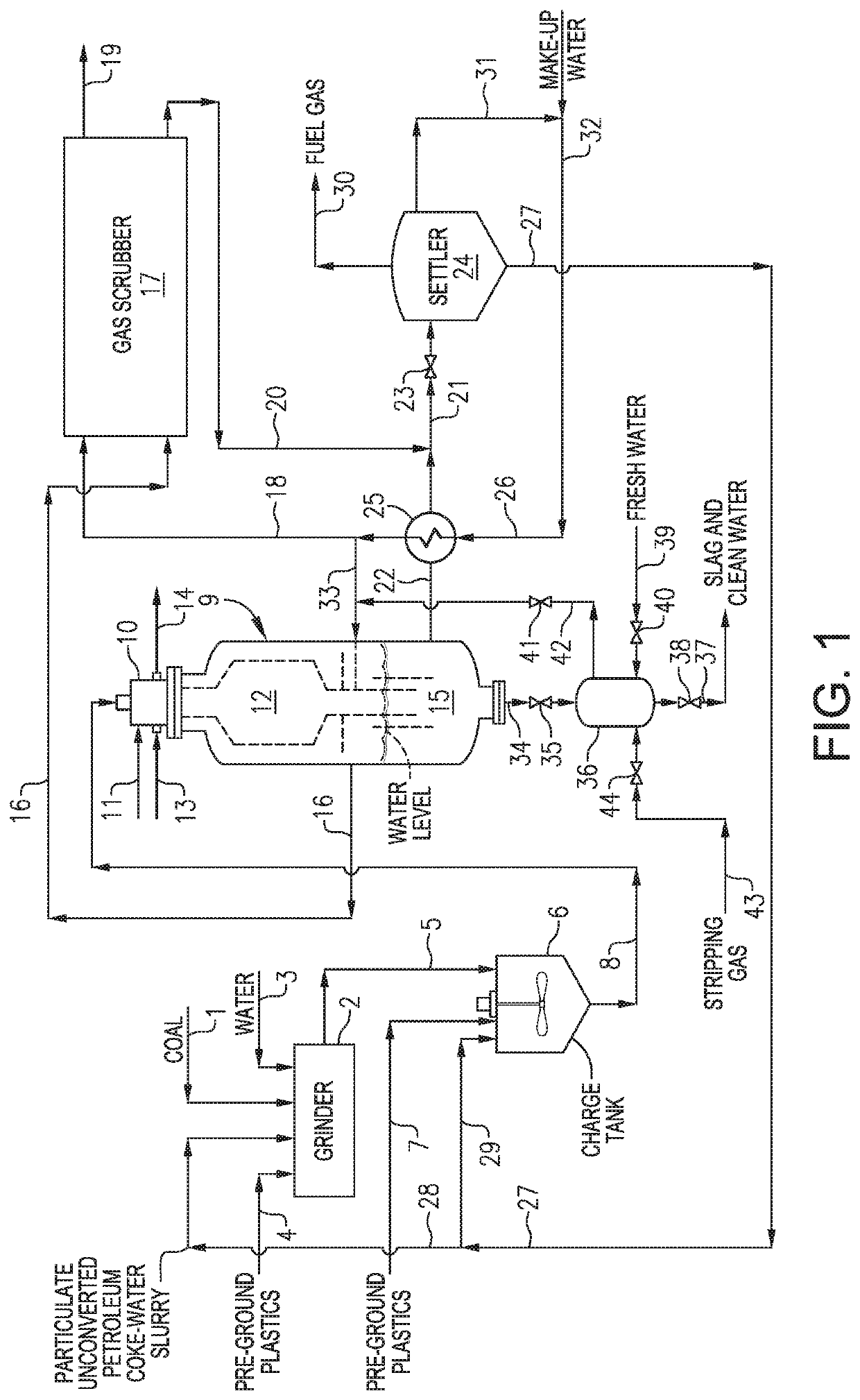

Gasification of plastics and solid fossil fuels to produce organic compounds

Pre-ground plastics of small particle size not more than 2 mm are co-fed into a solid fossil fuel fed entrained flow partial oxidation gasifier. High solids concentrations in the feedstock stream can be obtained without significant impact on the feedstock stream stability and pumpability. A consistent quality of syngas can be continuously produced, including generation of carbon dioxide and a carbon monoxide / hydrogen ratio while stably operating the gasifier and avoiding the high tar generation of fluidized bed or fixed bed waste gasifiers and without impacting the operations of the gasifier. The subsequent syngas produced from this material can be used to produce a wide range of chemicals.

Owner:EASTMAN CHEM CO

Feed location for gasification of plastics and solid fossil fuels

Pre-ground plastics of small particle size not more than 2 mm are co-fed into a solid fossil fuel fed entrained flow partial oxidation gasifier. A syngas composition can be made by charging an oxidant and a feedstock composition comprising recycle plastics and a solid fossil fuel to a gasification zone within a gasifier; gasifying the feedstock composition together with the oxidant in said gasification zone to produce said syngas composition; and discharging at least a portion of said syngas composition from said gasifier; wherein the recycled plastics are added to a feed point comprising a solid fossil fuel belt feeding a grinder after the solid fossil fuel is loaded on the belt, a solid fossil fuel belt feeding a grinder before the solid fossil fuel is loaded onto the belt, or a solid fossil fuel slurry storage tank containing a slurry of said solid fossil fuel ground to a size as the size fed to the gasification zone.

Owner:EASTMAN CHEM CO

Method and apparatus for coproduction of pig iron and high quality syngas

Combined microwave heating and plasma / electric arc heating is utilized in several processes and apparatus which involve co-production of pig iron and high quality syngas, biomass to liquid fuel production, coal to liquid fuel production, co-gasification of biomass and coal, municipal solid waste treatment, waste-to-energy (agriculture waste, ASR and PEF), EAF dust and BOF sludge treatment to recover zinc and iron, hazardous bottom ash vitrification, and bromine, chlorine and sulfur removal / recycling.

Owner:HUANG XIAODI +1

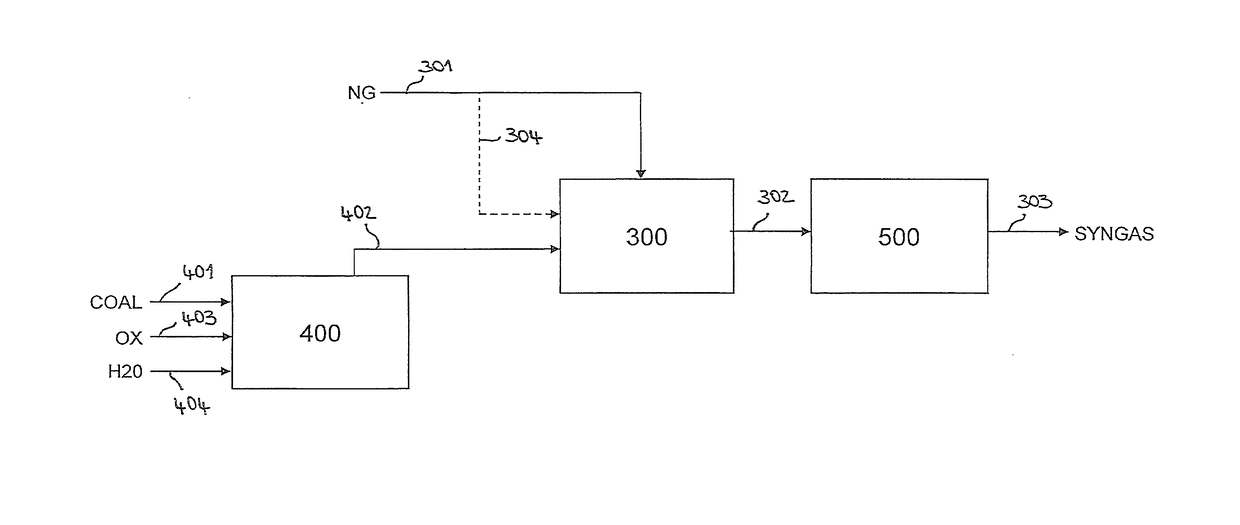

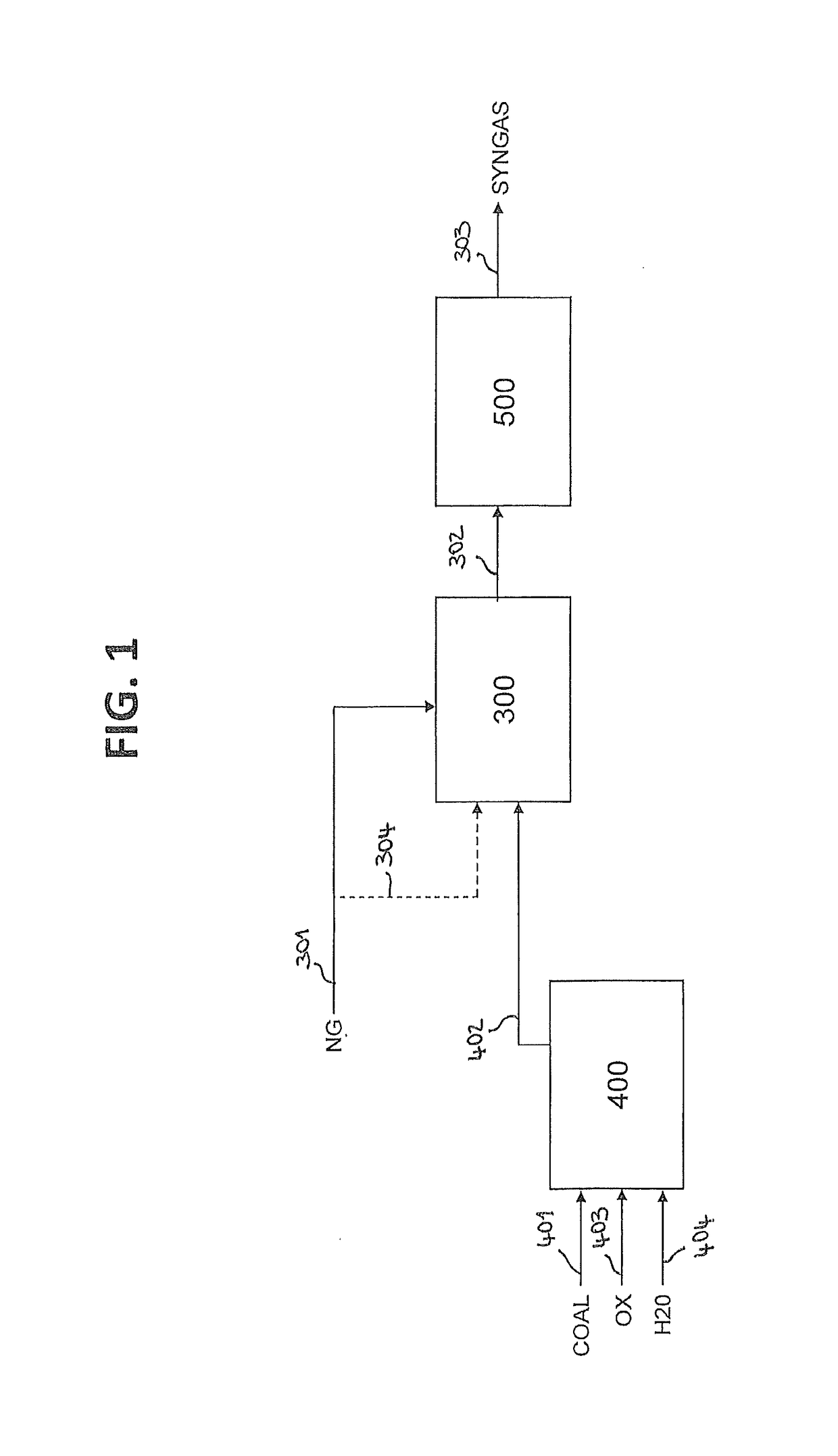

Process for producing a synthesis gas

ActiveUS20170349435A1Simplified sulphur removal techniqueSimple and cheap sulphur separationSolidificationLiquefactionCombustionHydrogen

Process for manufacturing a hydrogen-containing synthesis gas from a natural gas feedstock, comprising the conversion of said natural gas into a raw product gas and purification of said product gas, the process having a heat input provided by combustion of a fuel; said process comprises a step of conversion of a carbonaceous feedstock, and at least a portion of said fuel is a gaseous fuel obtained by said step of conversion of said carbonaceous feedstock.

Owner:CASALE SA

Gasification combustion system

ActiveCN104981658ASolid waste disposalGasification processes detailsCombustion systemProcess engineering

A two stage refuse gasification combustion system for processing refuse is disclosed. The system may contain features such as an advancer, a first and second gasifier, a gas regulator, and a post combustor. Additionally, methods for regulating gas and advancing refuse through a two stage refuse gasification combustion system are disclosed.

Owner:COVANTA ENERGY CORPORATION

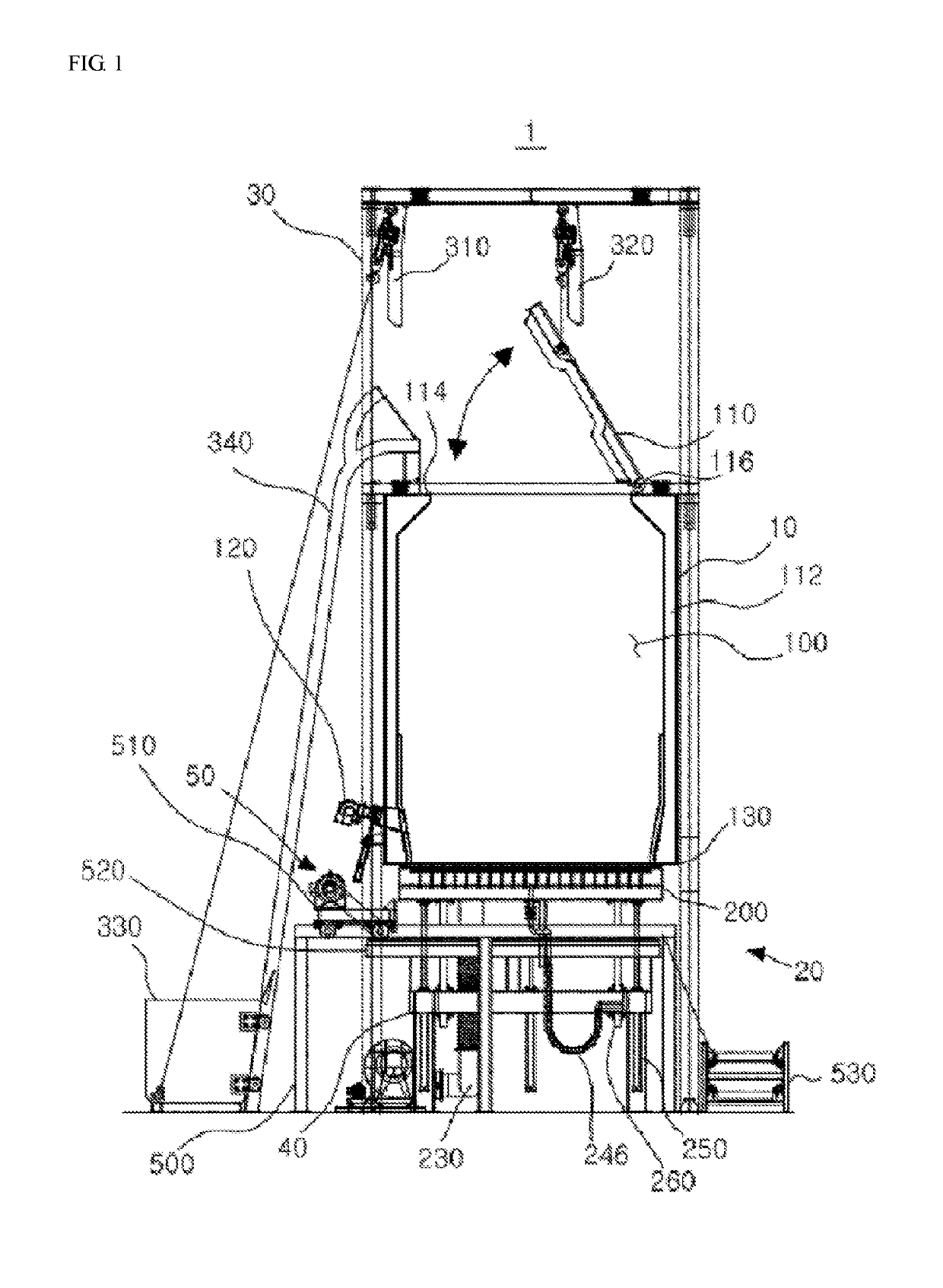

Pyrolysis gasifier comprising automatic ash processor

ActiveUS20190292472A1Shorten the timeImprove processing efficiencyGasifier mechanical detailsGasifier moving partsMechanical engineeringPyrolysis

A pyrolysis gasifier includes a tubular body configured to receive and pyrolyze a combustible waste, a bottom door disposed below the tubular body to selectively seal the tubular body, a main frame supporting the tubular body, a base frame supporting the bottom door, an automatic ash processor configured to, while traveling in one direction, push and remove ash remaining on the bottom door after pyrolysis of the combustible waste, and a guide frame supporting the automatic ash processor and configured to guide the travel of the automatic ash processor.

Owner:LIM YUNG TAEK +1

Methods for gasification of carbonaceous materials

The present disclosure is generally directed to process of gasification of carbonaceous materials to produce synthesis gas or syngas. The present disclosure provides improved methods of gasification comprising adding a molecular oxygen- containing gas and optionally adding water into said gasifier. This disclosure is also directed to process of production of one or more alcohols from said syngas via fermentation or digestion in the presence of at least one microorganism.

Owner:INEOS USA LLC

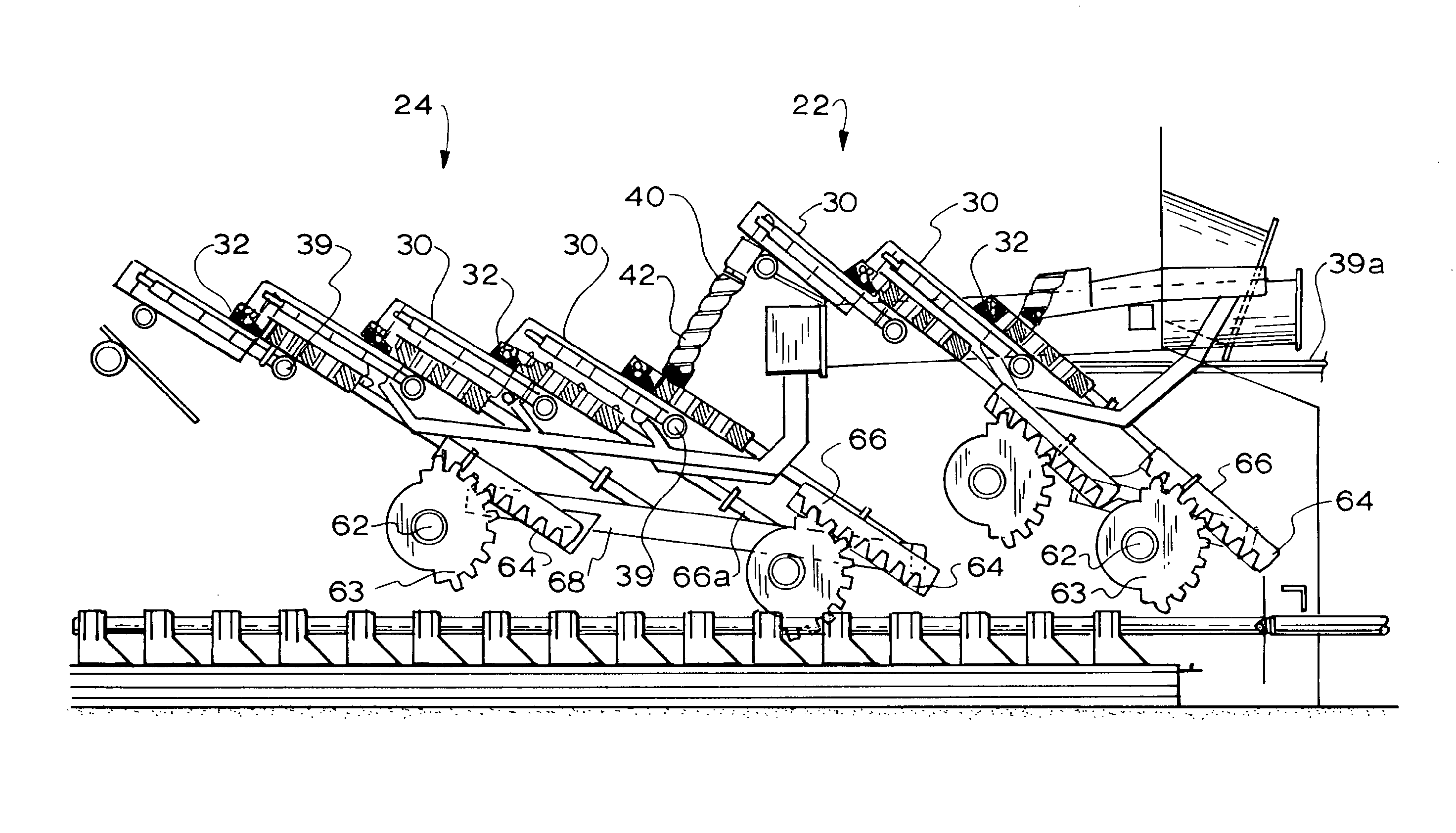

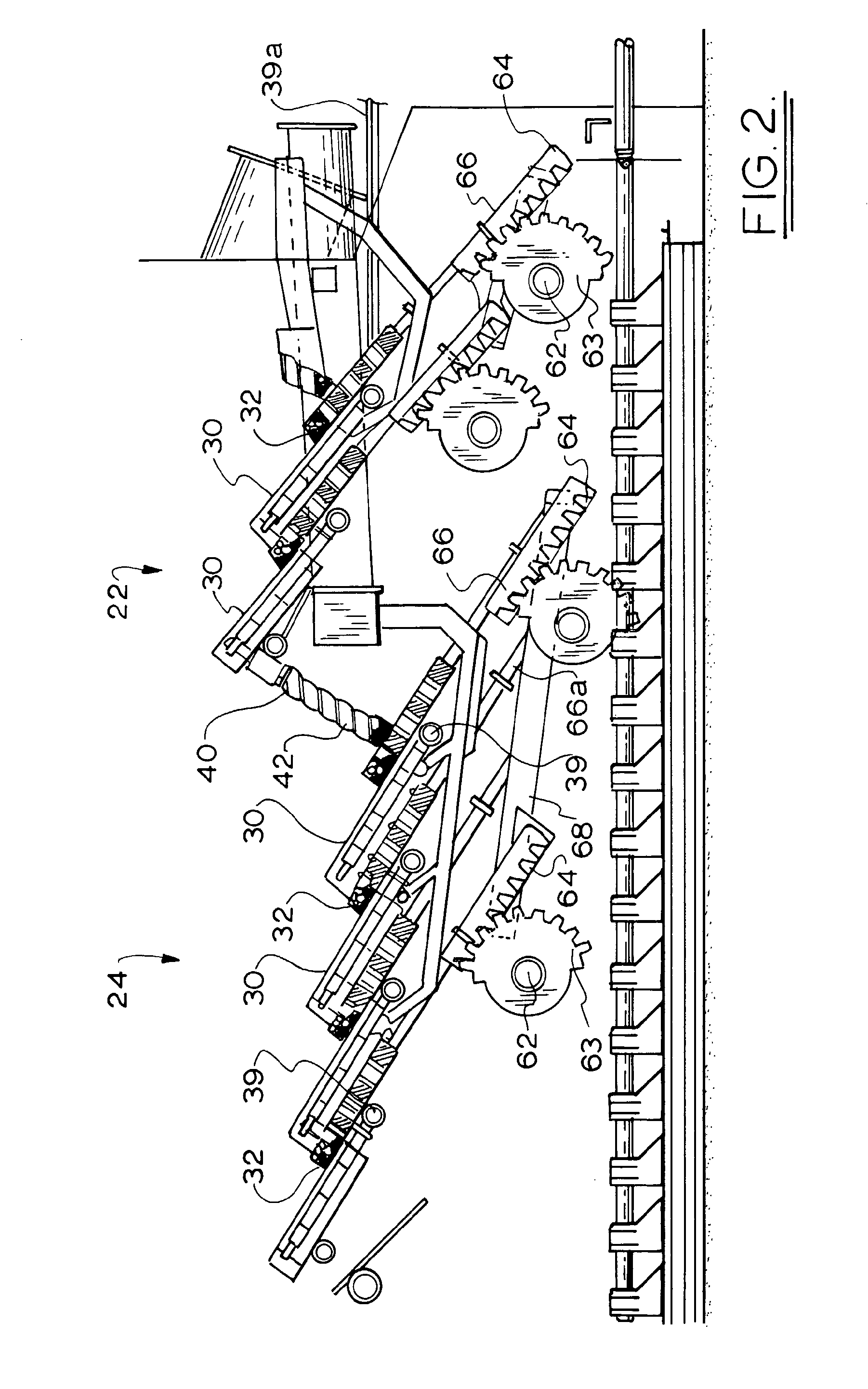

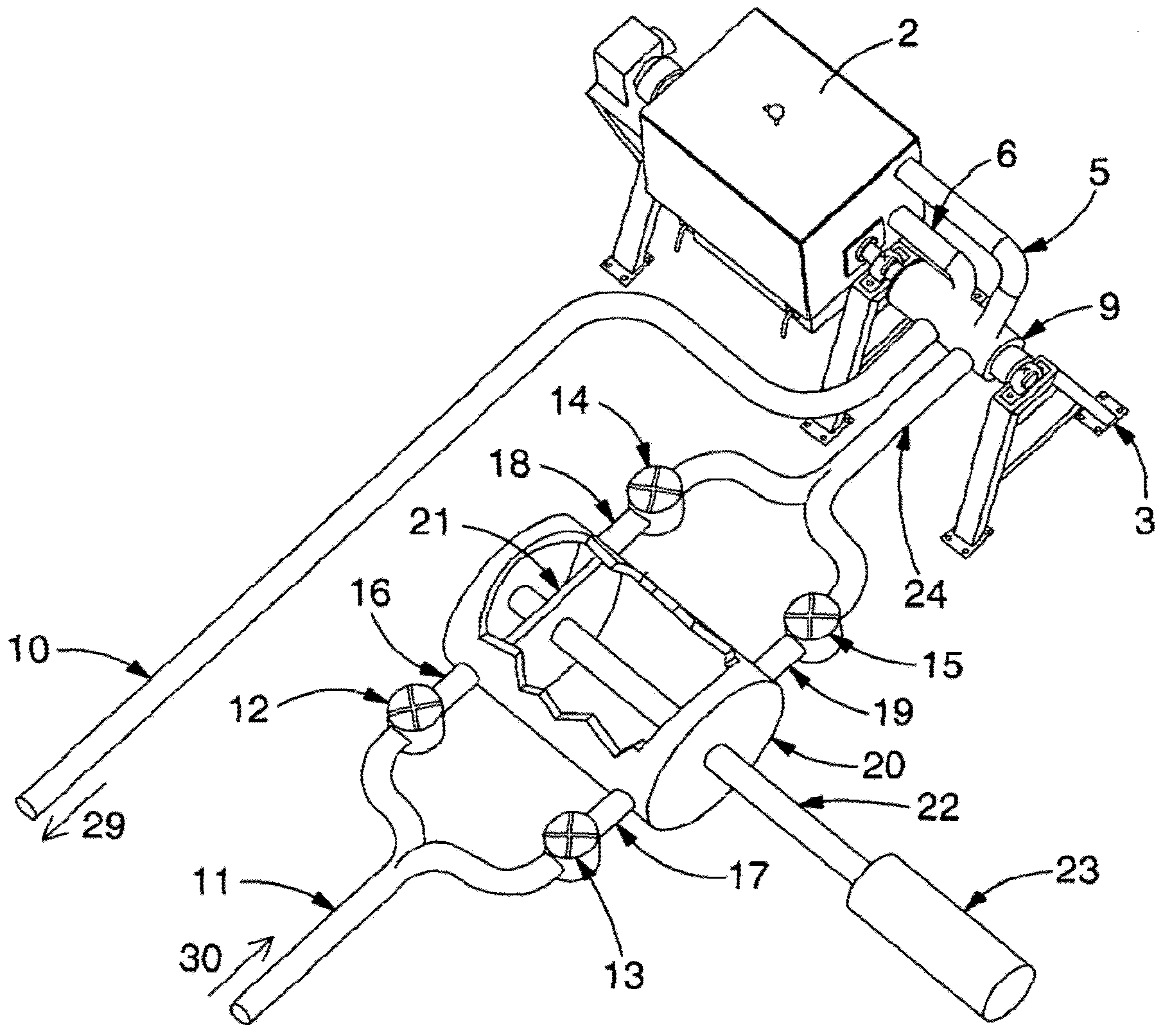

Grate Structure for Solid Fuel Burners

InactiveUS20080006187A1Promote combustionSteadily and slowly stroke or conveySolid bar grateEnergy inputCombustorReciprocating motion

In one aspect, a grate segment for a burner, comprises a substantially rigid body (30) having a dispersed array of cavities (38) filled with a refractory material. In another aspect, a solid fuel gasifier includes a housing (12) defining a gasifier chamber (14), and a solid fuel inlet (21), grate structure (22, 24) in the gasifier chamber. The grate structure includes base means, a plurality of agitator segments (32) positioned relative to the base means for reciprocating movement to agitate a fuel load in the gasifier, and means to support the base means and the agitator segments so that the latter reciprocate in a direction at a substantial inclination to both horizontal and vertical. In use of the gasifier a deep burden of fuel accumulates on the grate structure and the outward stroke of the reciprocation of the agitator elements is in the overall direction of flow of the fuel burden or generally oppositely thereto.

Owner:SALINAS ENERGY

Gasification of plastics and solid fossil fuels to produce organic compounds

Pre-ground plastics of small particle size not more than 2 mm are co-fed into a solid fossil fuel fed entrained flow partial oxidation gasifier. High solids concentrations in the feedstock stream can be obtained without significant impact on the feedstock stream stability and pumpability. A consistent quality of syngas can be continuously produced, including generation of carbon dioxide and a carbon monoxide / hydrogen ratio while stably operating the gasifier and avoiding the high tar generation of fluidized bed or fixed bed waste gasifiers and without impacting the operations of the gasifier. The subsequent syngas produced from this material can be used to produce a wide range of chemicals.

Owner:EASTMAN CHEM CO

Grate structure for solid fuel burners

InactiveUS7284491B2Promote combustionEfficiently agitatedSolid bar grateEnergy inputCombustorReciprocating motion

In one aspect, a grate segment for a burner, comprises a substantially rigid body (30) having a dispersed array of cavities (38) filled with a refractory material. In another aspect, a solid fuel gasifier includes a housing (12) defining a gasifier chamber (14), and a solid fuel inlet (21), grate structure (22, 24) in the gasifier chamber. The grate structure includes base means, a plurality of agitator segments (32) positioned relative to the base means for reciprocating movement to agitate a fuel load in the gasifier, and means to support the base means and the agitator segments so that the latter reciprocate in a direction at a substantial inclination to both horizontal and vertical. In use of the gasifier a deep burden of fuel accumulates on the grate structure and the outward stroke of the reciprocation of the agitator elements is in the overall direction of flow of the fuel burden or generally oppositely thereto.

Owner:SALINAS ENERGY

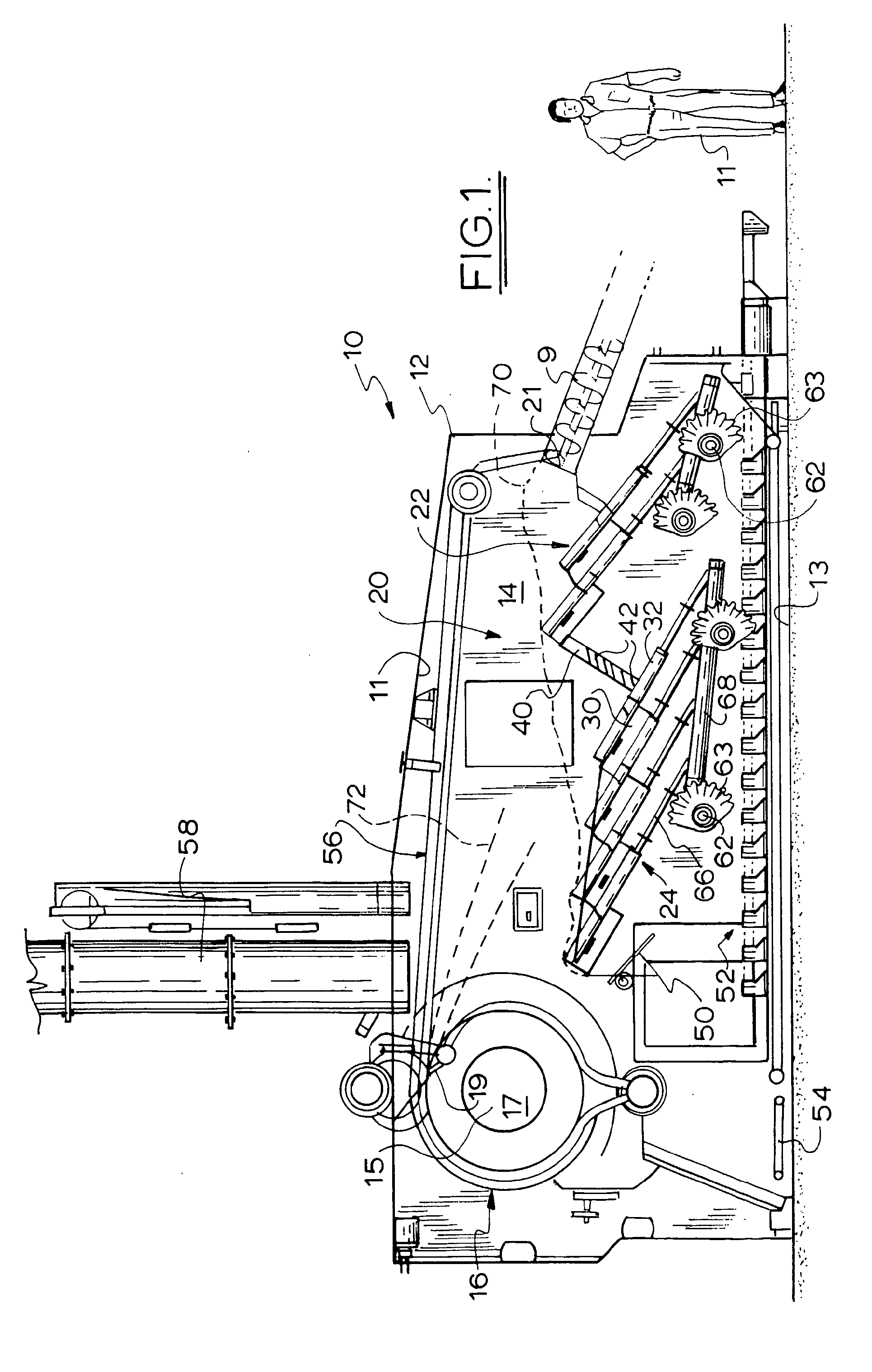

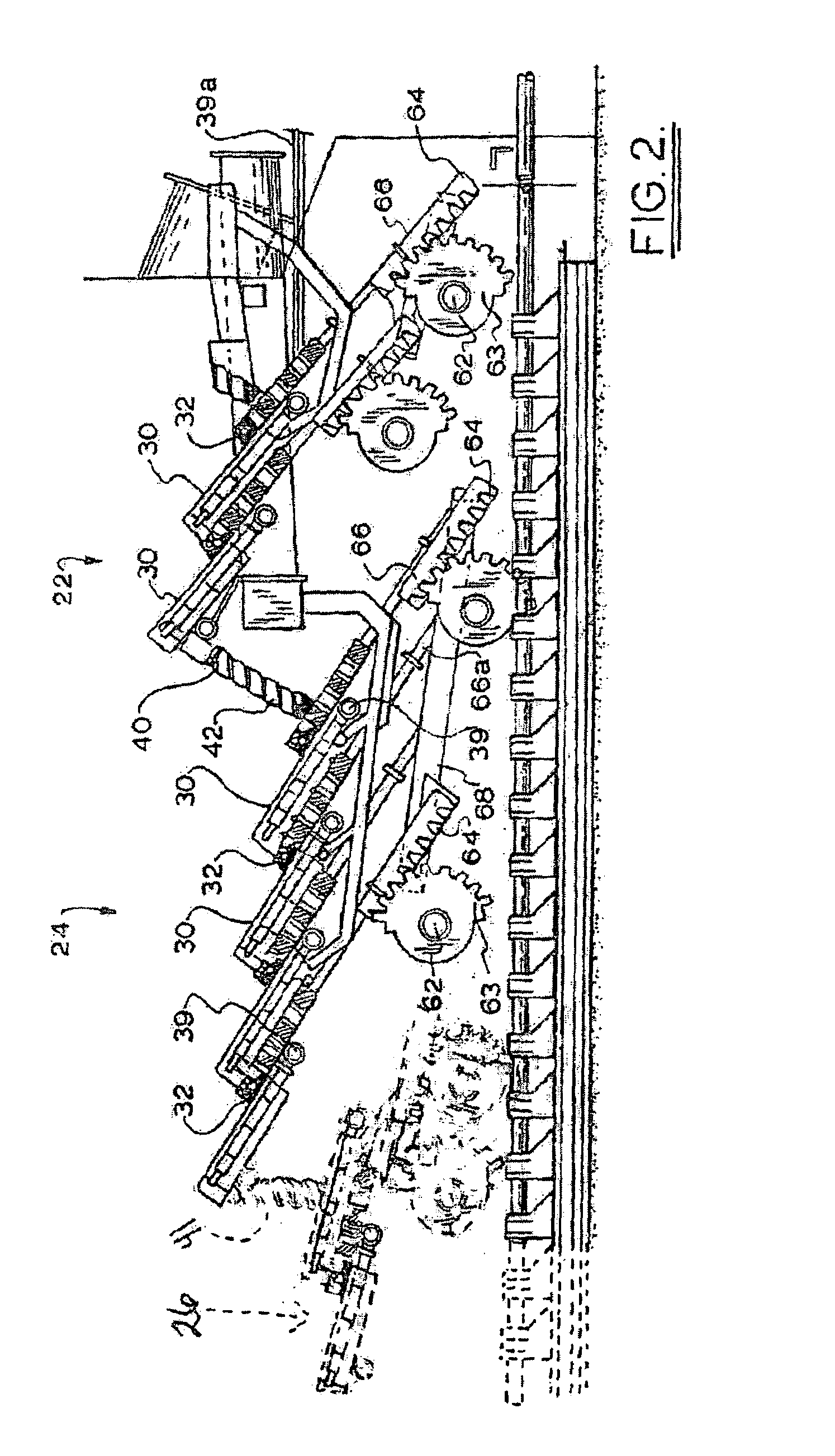

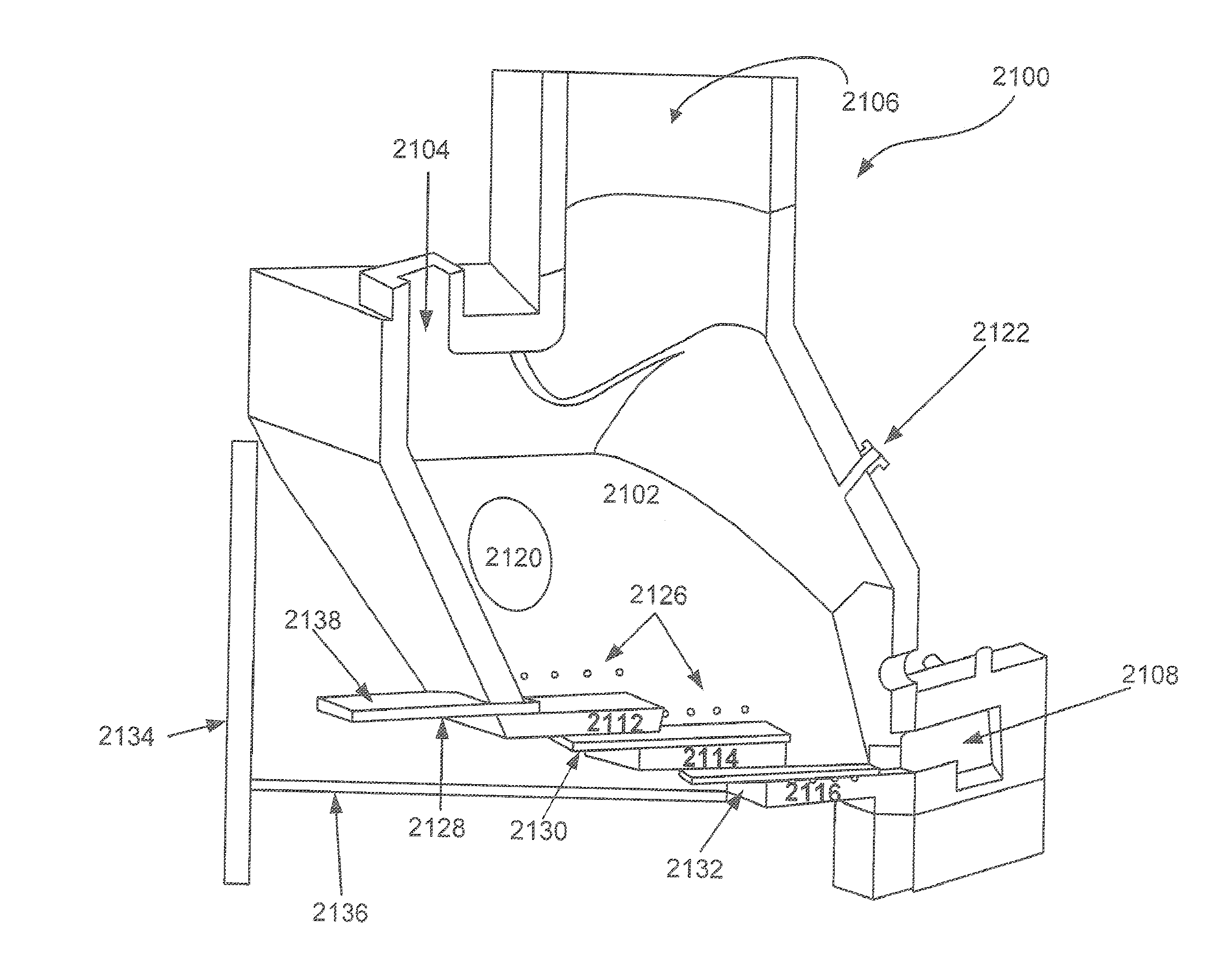

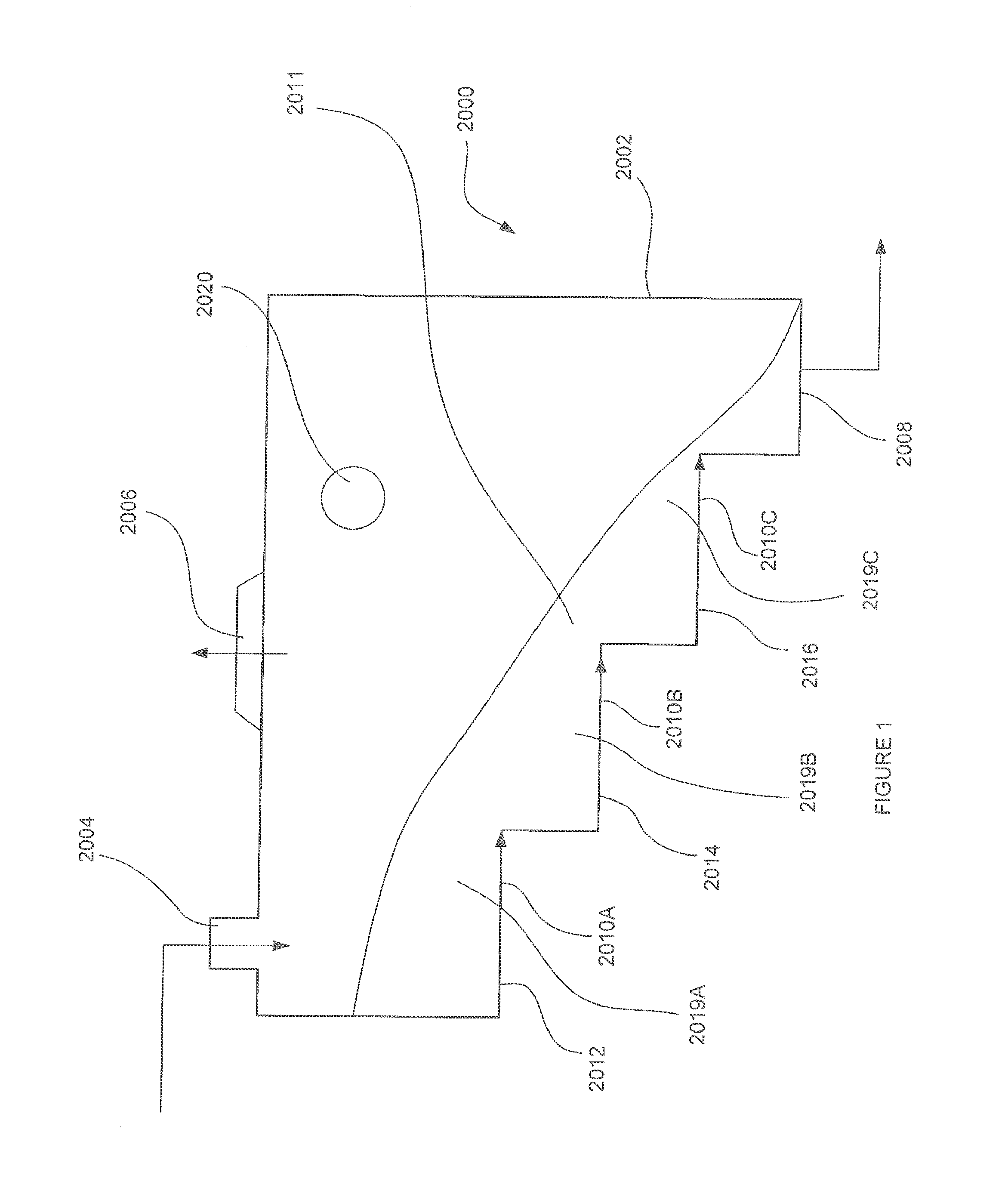

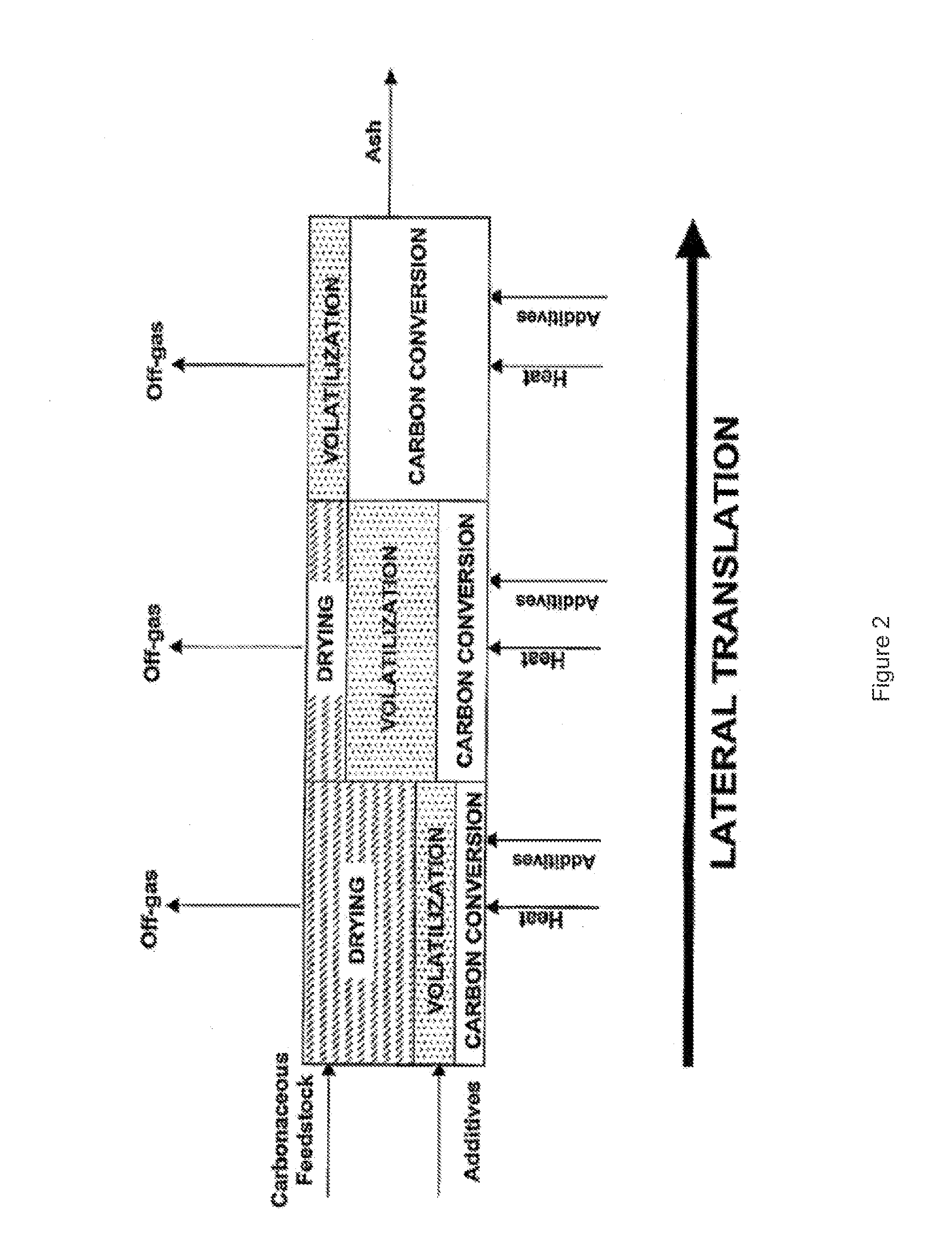

Horizontally-oriented gasifier with lateral transfer system

A method and apparatus is described for the efficient conversion of carbonaceous feedstock including municipal solid waste into a product gas through gasification. More specifically, a horizontally-oriented gasifier having one or more lateral transfer system for moving material through the gasifier is provided thereby allowing for the horizontal expansion of the gasification process such that there is sequential promotion of feedstock drying, volatization and char-to-ash conversions.

Owner:PLASCO ENERGY GROUP INC

Method and apparatus for treating combustible substance

PendingUS20220235933A1Eliminate the risk of explosionIncrease volumeNitrous oxide captureGas treatmentSludgeCement kiln

A treatment method and apparatus is provided to effectively use a combustible waste such as waste plastic, waste tires, rice husk, wood shavings, PKS, RDF and sludge while maintaining stable operation; to improve the combustion efficiency of a fossil fuel such as coal and coke; and furthermore to reduce the NOx concentration in a cement kiln exhaust gas. An apparatus 1 for treating a combustible, the apparatus comprising: a mixer 3 for mixing a combustible C with a preheated raw material R2, which has a temperature of 600° C. or higher and 900° C. or lower and which is drawn from a preheater cyclone of a cement burning device 10, to gasify the combustible; and a feeder 5 for feeding the gasified combustible and the preheated raw material (mixed raw material M) to a region from an inlet end 13a of the cement burning device to a calciner 12. When the combustible and the preheated raw material are mixed, moisture may be added to cause water gas shift reaction, and the resultant water gas and the preheated raw material may be introduced to the region from the inlet end of the cement burning device to the calciner.

Owner:TAIHEIYO ENG

Refractory wall structure and damper device

InactiveUS6854403B2Gasification processes detailsPulverulent fuel combustion burnersCombustorSolid fuel

This invention relates generally to high temperature burners such as a solid fuel burner of the type commonly referred to as a gasifier or gasifier combustor. The invention includes a refractory wall structure having an array of tubular members. Refractory material is arranged about the tubular members so that the tubular members protrude from a wall defined by the refractory material by a distance smaller than the diameter of the tubular members.

Owner:SALINAS ENERGY

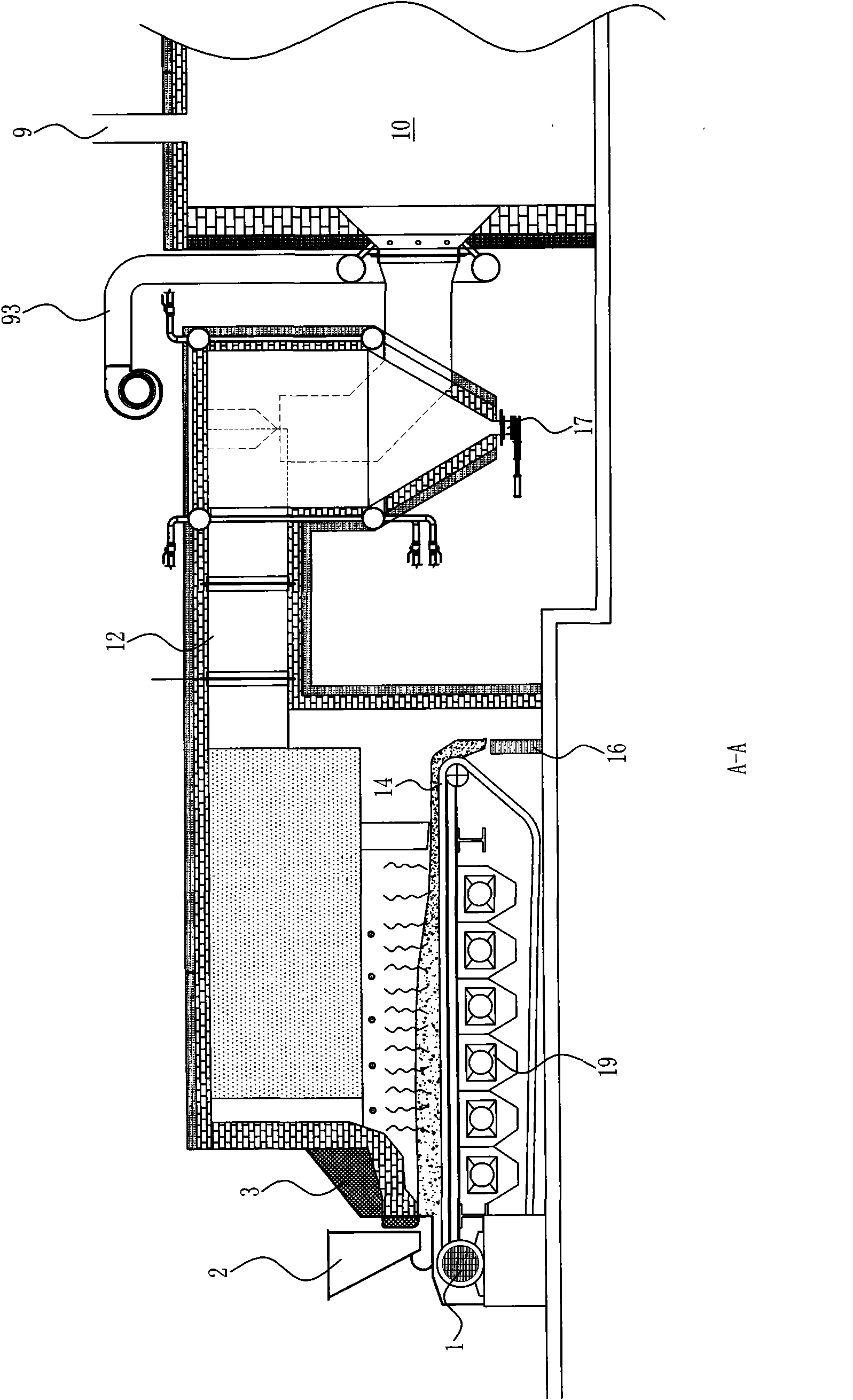

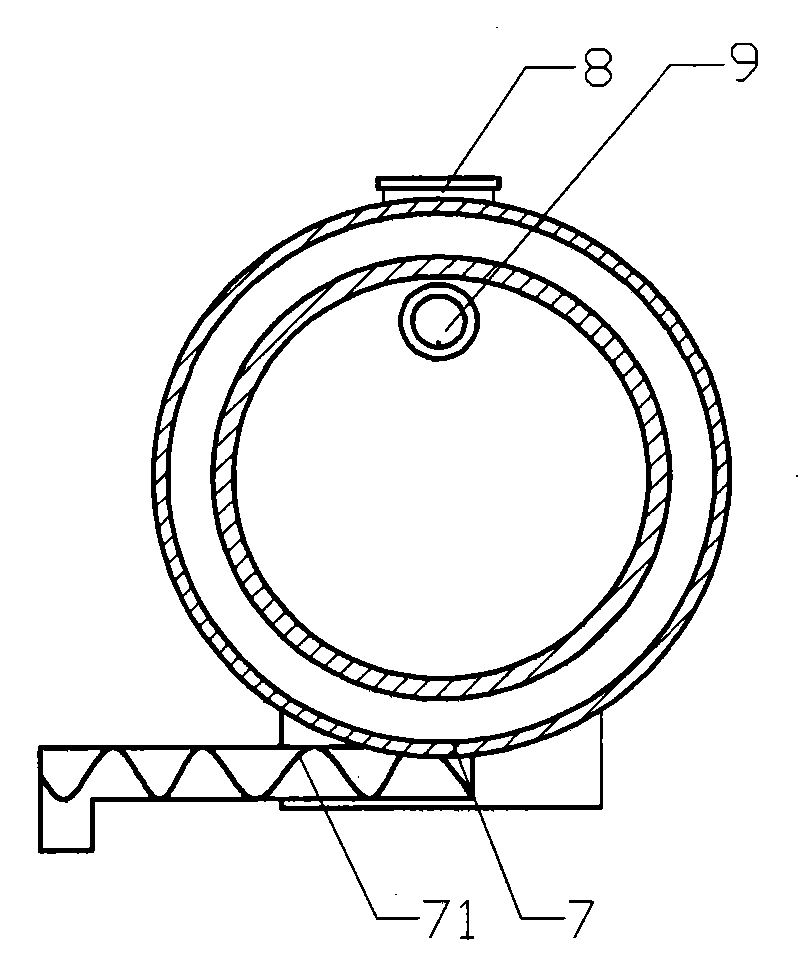

Biomass horizontal pyrolysis gasifier

ActiveCN104560200AGuaranteed uptimeGasifier feeding meansGasification processes detailsCold airEngineering

The invention discloses a biomass horizontal pyrolysis gasifier. The structure of the biomass horizontal pyrolysis gasifier comprises a furnace body (1), a feed inlet (8), a gas nozzle (9), an air inlet (5) and an ash discharge opening (7). The feed inlet is arranged at the rear end of the furnace body. The furnace body (1) is a sandwich structure, wherein an inner cavity of the sandwich structure is a gasifying chamber (11), and the middle part of the sandwich structure is an air inlet chamber (12). The feed inlet (8) and the gas nozzle (9) are communicated with the gasifying chamber. The air inlet (5) is communicated with the air inlet chamber (12). The bottom of the furnace body is provided with a feed delivery mechanism (4). The gasifying chamber (11) and the air inlet chamber (12) are communicated with each other at the position of the feed delivery mechanism. According to the biomass horizontal pyrolysis gasifier, by introducing cold air into the air inlet of the sandwich structure, the furnace wall and a reciprocating grate are cooled, and heat-absorbed hot air also can flow upwards from the bottom of a feed layer through the reciprocating grate. By an up-to-bottom counter-burning mode, the feed layer will not be overlapped or mixed during operation of the reciprocating grate, multiple tower-type feed layers are formed to undergo continuous pyrogasification, and safe and stable operation can be carried out on the grate.

Owner:JIANGMEN WANGDE CLEAN ENERGY

Feed location for gasification of plastics and solid fossil fuels

Pre-ground plastics of small particle size not more than 2 mm are co-fed into a solid fossil fuel fed entrained flow partial oxidation gasifier. A syngas composition can be made by charging an oxidant and a feedstock composition comprising recycle plastics and a solid fossil fuel to a gasification zone within a gasifier; gasifying the feedstock composition together with the oxidant in said gasification zone to produce said syngas composition; and discharging at least a portion of said syngas composition from said gasifier; wherein the recycled plastics are added to a feed point comprising a solid fossil fuel belt feeding a grinder after the solid fossil fuel is loaded on the belt, a solid fossil fuel belt feeding a grinder before the solid fossil fuel is loaded onto the belt, or a solid fossil fuel slurry storage tank containing a slurry of said solid fossil fuel ground to a size as the size fed to the gasification zone.

Owner:EASTMAN CHEM CO

Horizontal gas gasifier and gasification method thereof

PendingCN113583713AReduce the overall heightLower the altitudeGasification processes detailsHorizontal gasifiersCombustionMolten slag

The invention discloses a horizontal coal gas gasifier and a gasification method thereof, and relates to the field of clean coal gasification. According to the horizontal gas gasifier and the gasification method thereof, the horizontal gasifier comprises a gasification reaction chamber, a gas-slag separation section and a slag pool which are sequentially arranged from top to bottom, burner channels are symmetrically arranged on the two sides of the gasification reaction chamber, pulverized coal is introduced into the burner channels for incomplete combustion, and high-temperature coal gas and slag generated by gasification reaction enter the gas-slag separation section from a slag discharging opening; a membrane type water cooling wall is vertically arranged in the middle of the gas-slag separation section, low-temperature coal gas enters the gas-slag separation section from a chilling ring arranged on the upper portion of the membrane type water cooling wall, the temperature of the high-temperature coal gas is reduced to be below the ash melting point of slag, the slag is solidified into solid slag, the coal gas and the solid slag are subjected to gas-slag separation at the bottom, the slag falls into the slag pool, coal gas enters a subsequent system from the coal gas outlet in the upper portion, the horizontally-arranged gasification reaction chamber and the membrane type water cooling wall are adopted to play a baffling role, and then the overall height of the gasifier is greatly reduced.

Owner:KEDA MAS CLEAN ENERGY

Separated chambers pyrolysis furnace

InactiveUS20200048559A1Easy to produceLow powerGasification processes detailsIndirect heating destructive distillationCombustion chamberOrganic fuel

The present invention is directed to an apparatus for domestic hot water and electricity production by the use of a natural organic fuel, the apparatus comprising a separated chambers pyrolysis furnace comprising: a) a pyrolysis chamber wherein the fuel is heated, substantially in the absence of oxygen at a temperature capable of causing pyrolysis of fuel; b) a combustion chamber of the pyrolyzed fuel, wherein the pyrolyzed fuel is burned in the presence of an air flux. The invention is also directed to an apparatus for the production of domestic hot water and electricity, which apparatus comprises: the above defined furnace; b) a heat exchanger connected to the exit of the exhausted gas, wherein domestic water is heated; c) a power generator connected with the exit of syngas, wherein syngas produced in the pyrolysis chamber is used as a fuel.

Owner:PYRO&TECH SRLS

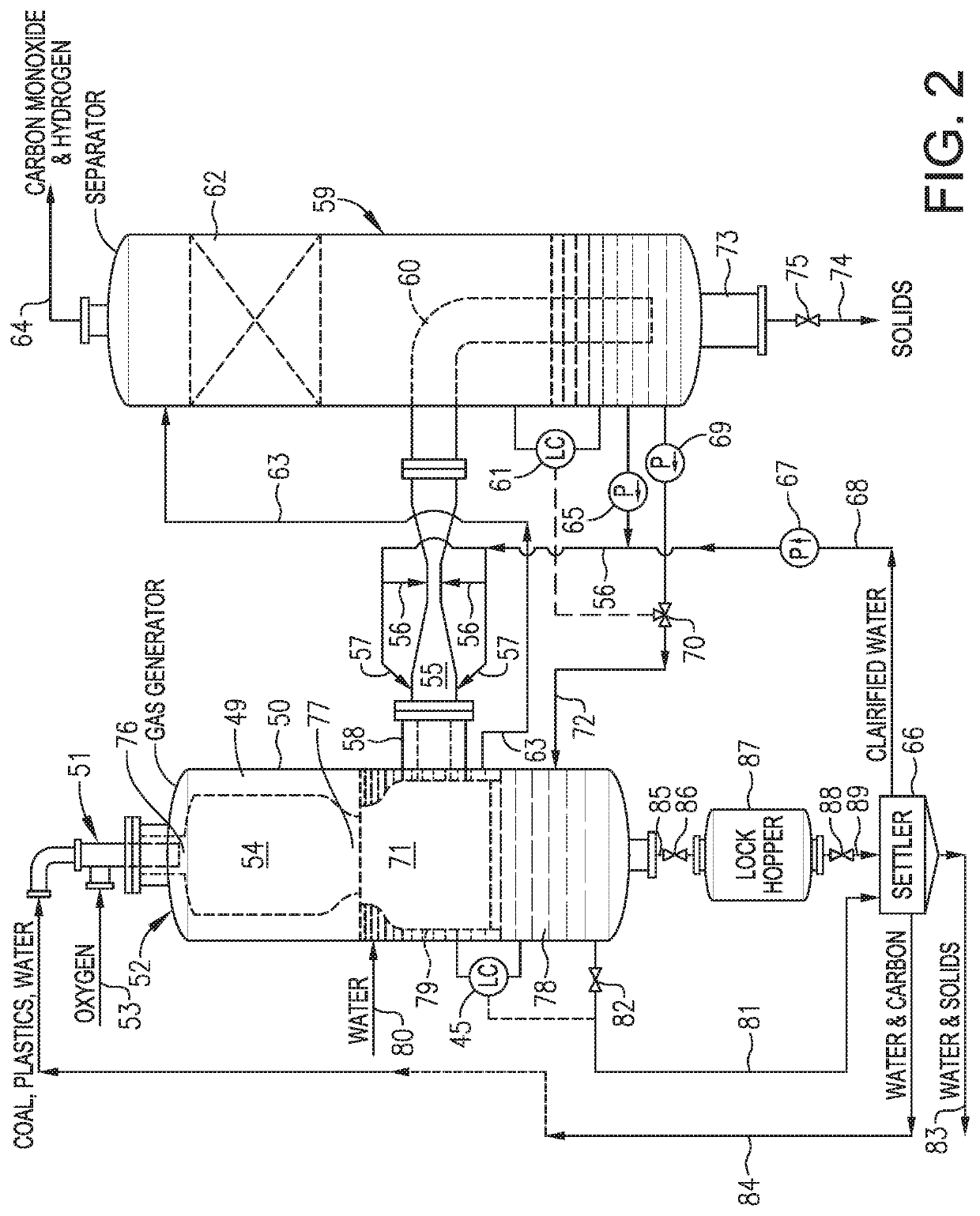

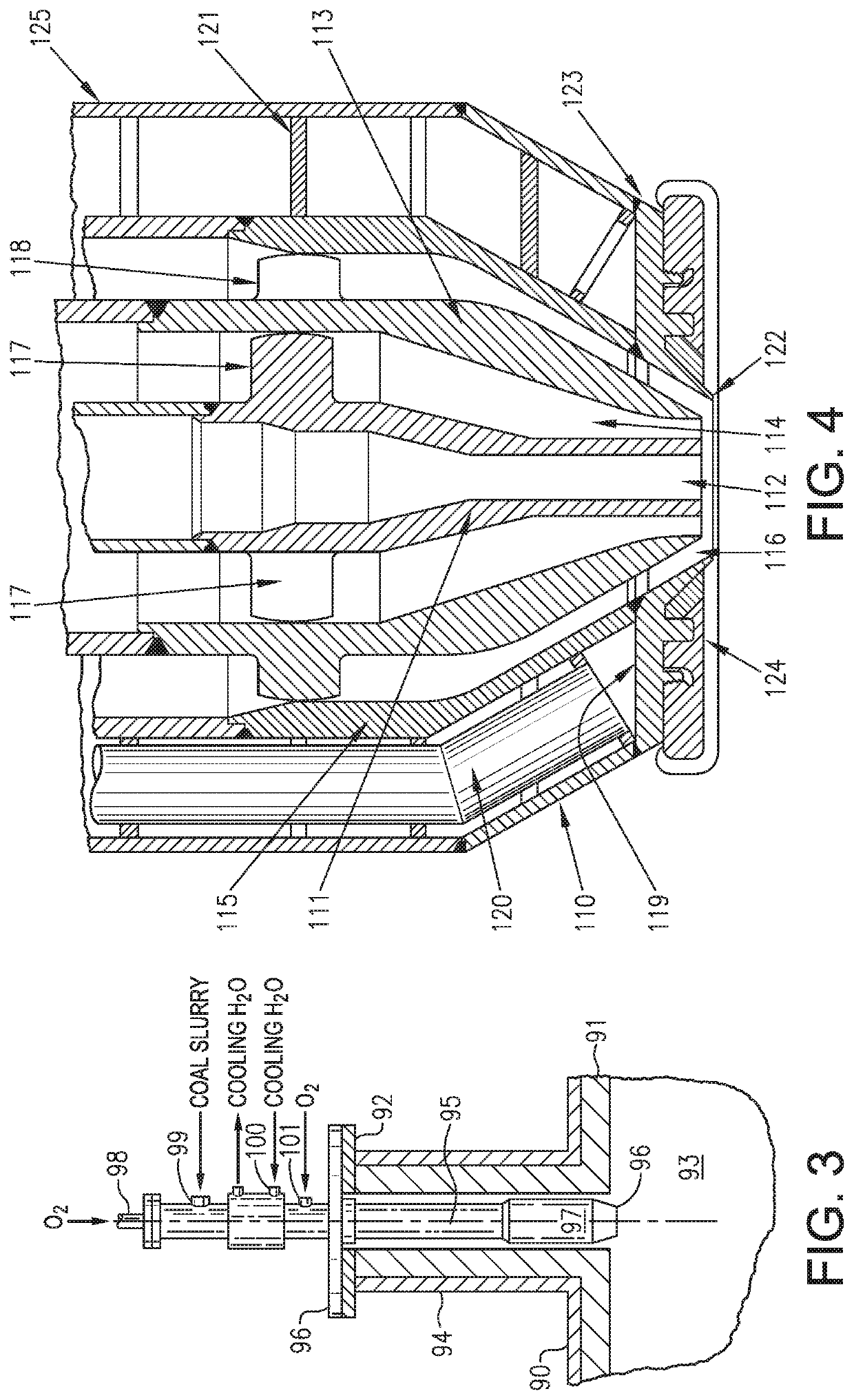

Gasification system and process

ActiveUS10760017B2Gasifier mechanical detailsGasification processes detailsPartial oxidationProcess engineering

A gasification system for the partial oxidation of a carbonaceous feedstock to at least provide a synthesis gas, comprising: a reactor chamber for receiving and partially oxidizing the carbonaceous feedstock; a quench chamber below the floor of the reactor chamber for holding a bath of liquid coolant; an intermediate section at said reactor chamber floor, the intermediate section having a reactor outlet opening through which the reactor chamber communicates with the quench chamber to conduct the synthesis gas from the reactor chamber into the bath of the quench chamber; at least one layer of refractory bricks arranged on and supported by the reactor chamber floor, the lower end section of the refractory bricks enclosing the reactor outlet opening and defining the inner diameter thereof; and a dip tube extending from the reactor outlet opening to the bath of the quench chamber, the dip tube having a widened top section.

Owner:AIR PROD & CHEM INC

Horizontal mobile grate gasifier

InactiveCN101776260BReduce exhaust temperatureRealize the purpose of zone controlled gasificationCombustion using gaseous and pulverulent fuelGasifier feeding meansCombustorFlue gas

The invention relates to a horizontal mobile grate gasifier, which comprises a furnace body with a grate and an air supply device. The air supply device consists of a primary air supply pipe and an upper-layer air supply pipe, the primary air supply pipe is connected with a plurality of air chambers and is arranged below the grate, the upper-layer air supply pipe is arranged on the two sidewalls of the furnace body and is communicated with the inner chamber of the furnace body, the rear part of the furnace body is provided with a flue gas channel, the rear end of the flue gas channel is connected with the combustor of a boiler, a flue gas circulating pipe which is connected with the rear part of the combustor communicates circulating flue gas and the upper-layer air supply pipe to form a mixed gas channel, the mixed gas channel and a steam pipe respectively extend into the air chamber and the cavity of the furnace body through a primary air Venturi pipe and a secondary air Venturi pipe; and mixed gas can flow to the front side of the combustor of the boiler through a gas mixing fan. The invention has the advantages of reducing Ringelman black and smoke emission, allowing the use of coal raw materials which are each to be coked, expanding the flexibility of the boiler use and the diversity of operating modes, and realizing the online real-time control and adjustment of parameters of steam output variables, grate operation and gasification dosage, thereby achieving the best operating conditions.

Owner:NINGBO YINUO ENERGY TECH

Horizontally-Oriented Gasifier with Lateral Transfer System

InactiveUS20130228445A1Mechanical conveying coke ovensGasifier feeding meansTransfer systemProcess engineering

A method and apparatus is described for the efficient conversion of carbonaceous feedstock including municipal solid waste into a product gas through gasification. More specifically, a horizontally-oriented gasifier having one or more lateral transfer system for moving material through the gasifier is provided thereby allowing for the horizontal expansion of the gasification process such that there is sequential promotion of feedstock drying, volatization and char-to-ash conversions.

Owner:PLASCO ENERGY GROUP INC

Waste motor vehicle crushing residue fuelization treatment device and method thereof

The invention relates to a waste motor vehicle crushing residue fuelization treatment device and a method thereof, the waste motor vehicle crushing residue fuelization treatment device is characterized in that a waste vehicle is preliminarily decomposed into recyclable and unrecyclable wastes, and the unrecyclable wastes are crushed, screened and torn to form ASR raw material; the ASR raw materialis subjected to screening, magnetic substance separation and non-ferrous metal separation to remove inorganic substances such as sandy soil, magnetic substances and non-ferrous metals in the ASR rawmaterial, is homogenized by homogenization equipment, and is fed into pyrolysis gasification equipment to be subjected to pyrolysis gasification treatment in an anoxic environment, so that synthesis gas which can be used as fuel and used for power generation is generated. Flue gas containing the synthesis gas serving as fuel gas is fed into secondary combustion equipment to be combusted, harmful substances are removed, heat energy is generated, the combusted gas is fed into heat energy recovery equipment to collect combustion heat energy, and the collected heat energy is supplied into the energy conversion equipment to generate available energy. After the available energy is recovered, the residual flue gas is purified and then discharged to the outside through the exhaust equipment.

Owner:陈俊宇 +4

Direct gasification method and apparatus for charcoal and carbon compound

InactiveCN104789265AAvoid pollutionReduce energy consumptionGasification processes detailsHorizontal gasifiersHigh pressureOxygen

The invention relates to the technical field of gasification of charcoal and discloses a direct gasification method for charcoal and a carbon compound. According to the method, the charcoal and the carbon compound are placed in the front section of an enclosed cavity and mixed with water or hydrogen; then the obtained mixture is heated to more than 800 DEG C, and high temperature and high pressure are formed in the cavity; the charcoal and the carbon compound become a variety of elemental atoms or micro-molecules through pyrolysis, and the elemental atoms or micro-molecules recombine with hydrogen atoms and oxygen atoms produced after pyrolysis of water or hydrogen atoms produced after pyrolysis of hydrogen to form high-calorific-value gases (mainly including methane and carbon monoxide) which are mainly low molecules (also called as small molecules); and a recovery chamber is arranged at the rear section of the enclosed cavity for collecting the high-calorific-value gases and a plurality of solids. The whole gasification process is carried out in the enclosed cavity, and the high-calorific-value gases and a plurality of solids are eventually recovered by the recovery chamber communicated with the front section, which enables air pollution to be completely prevented. In the gasification process, energy release and absorption in the process of pyrolysis of the charcoal, the carbon compound and water or hydrogen into elemental atoms or micro-molecules and in the process of atom recombination are directly utilized, so minimum energy consumption is realized and good economic benefits are obtained; moreover, the method is simple and can realize streamline production in a completely enclosed production line in actual production.

Owner:杜峰

Improvements in gasification and/or pyrolysis

The present invention provides a method and apparatus for gasifying / pyrolysing material containing organic matter including introducing the material into a treatment chamber (2) and heating the material by passing a flow of hot gas (30) containing less than 8% oxygen through the chamber (2) so as to cause the material therein to gasify or pyrolyse. In a first mode of operation the gas (30) is passed through the chamber (2) at a first velocity. The apparatus comprises a means (20, 21) for temporarily increasing the velocity of the hot gas (30) such that in a second mode of operation the velocity of the gas (30) exiting the means (20, 21) is temporarily increased.

Owner:CHINOOK END STAGE RECYCLING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com