Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

102results about How to "Eliminate the risk of explosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Unitary solid chlorine dioxide sustained-release generating agent and preparation method thereof

ActiveCN101999405AAvoid harmImprove the bactericidal effectBiocideDisinfectantsChlorine dioxideAdhesive

The invention discloses a unitary solid chlorine dioxide sustained-release generating agent and a preparation method thereof. The generating agent does not contain solid acid; potassium hydrogen persulfate composite salt is reacted with stable acidic chlorite in a solution system under the synergy of synergist to generate chlorine dioxide; the generating agent consists of the chlorite, the potassium hydrogen persulfate composite salt, the synergist, stabilizer, forming agent, dryer, adhesive and effervescing agent; and the preparation method comprises the following steps of: drying the chlorite and the potassium hydrogen persulfate composite salt respectively, mixing the dried chlorite, the dried potassium hydrogen persulfate composite salt and the other materials uniformly according to acertain proportion, and preparing the mixture into tablets of different specifications under certain environmental humidity and pressure. The composite tables dissolved to water can sustainedly release the chlorine dioxide gas and have the characteristics of long effect, sustained release, environment friendliness, safety and the like.

Owner:定州市荣鼎水环境生化技术有限公司

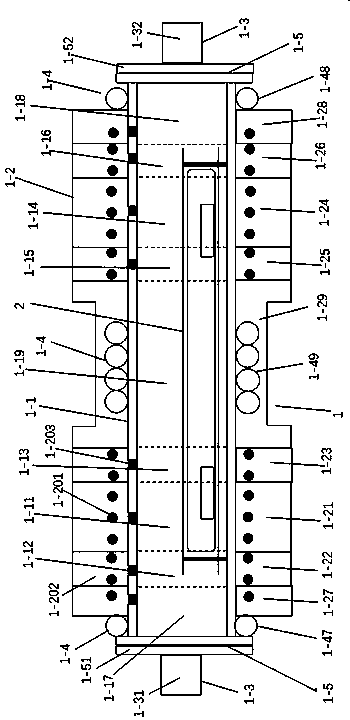

Direct current breaker bridge type module

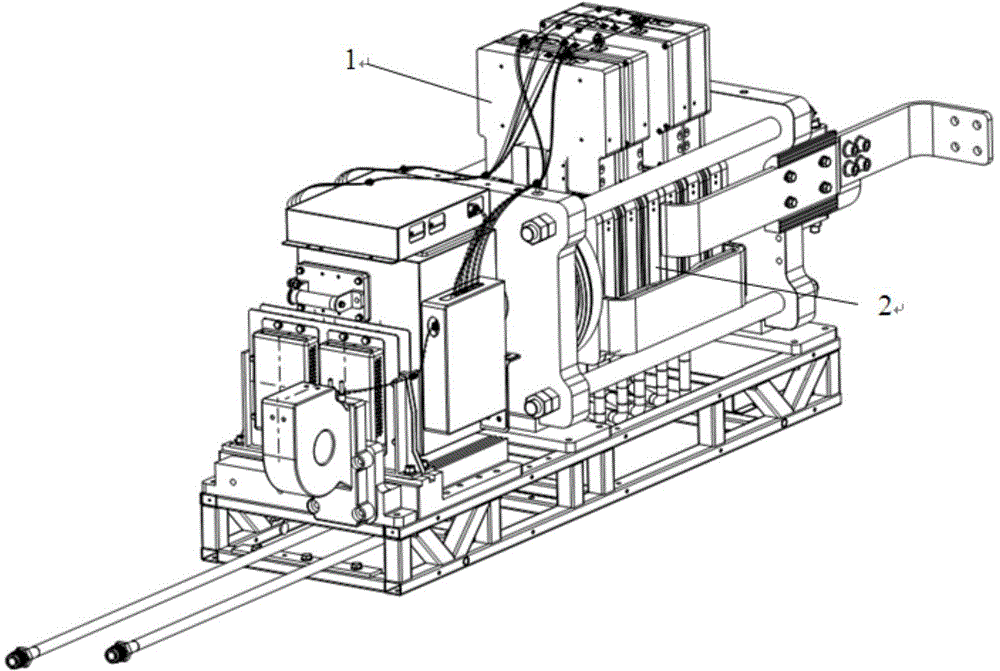

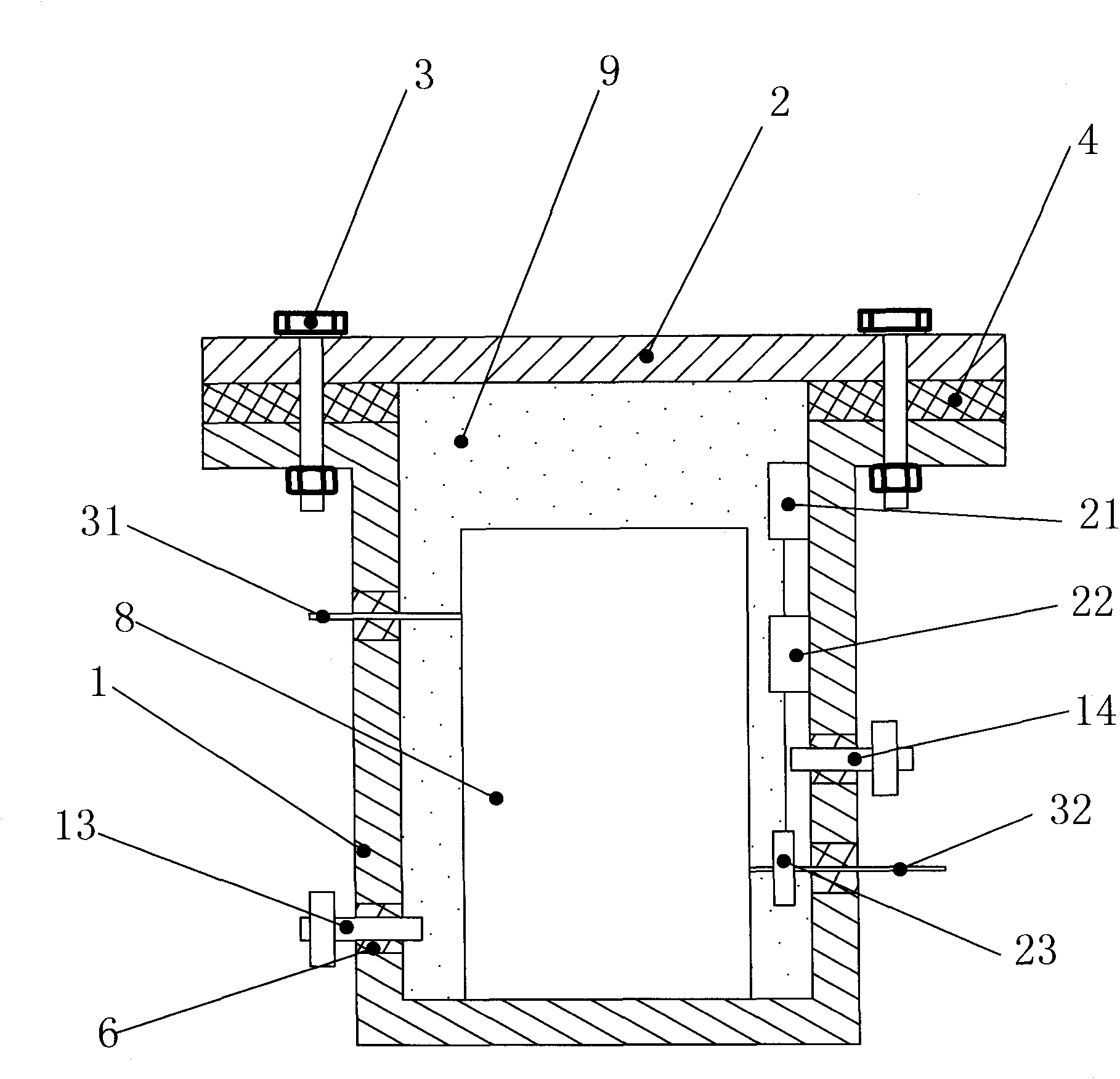

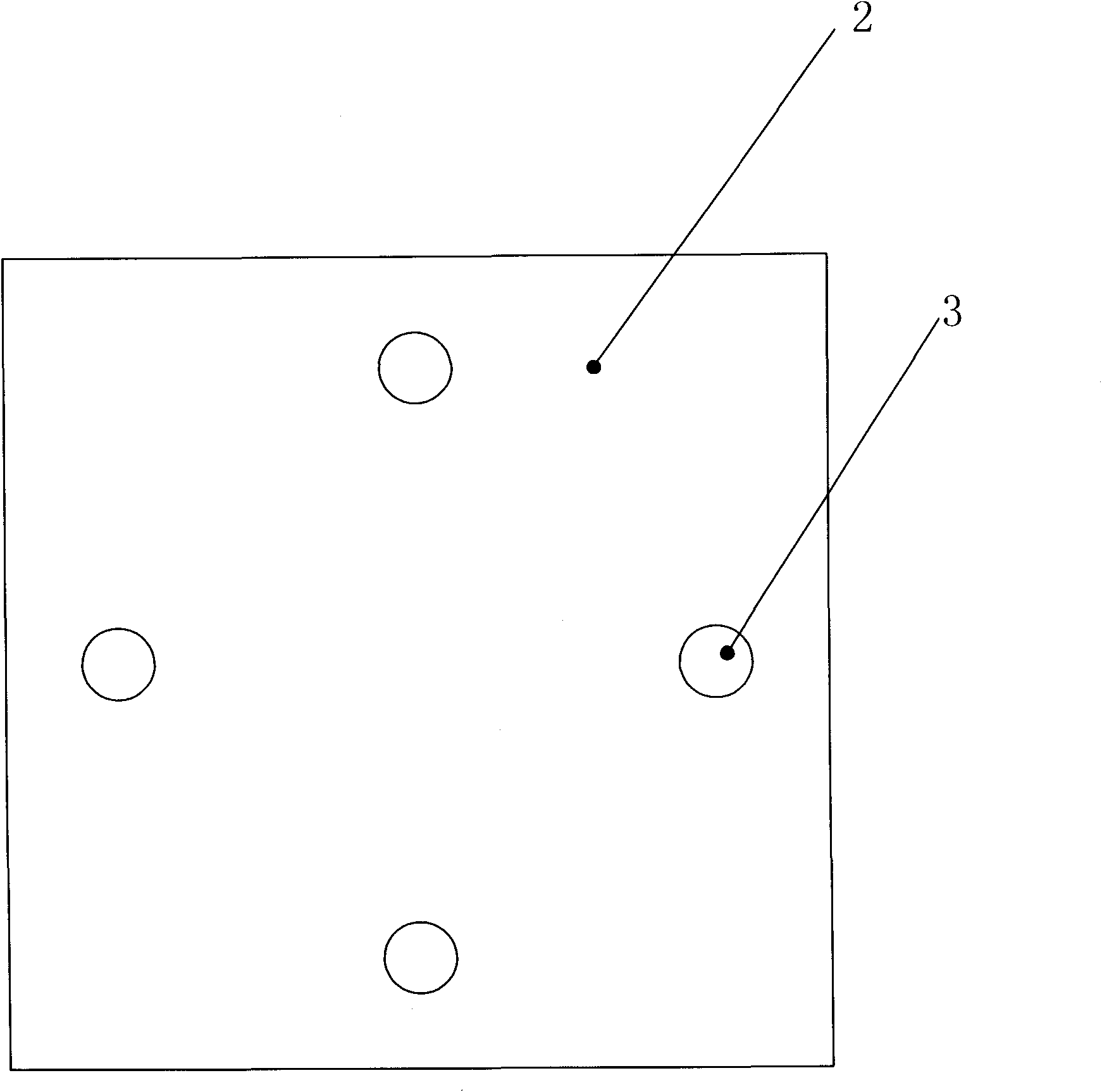

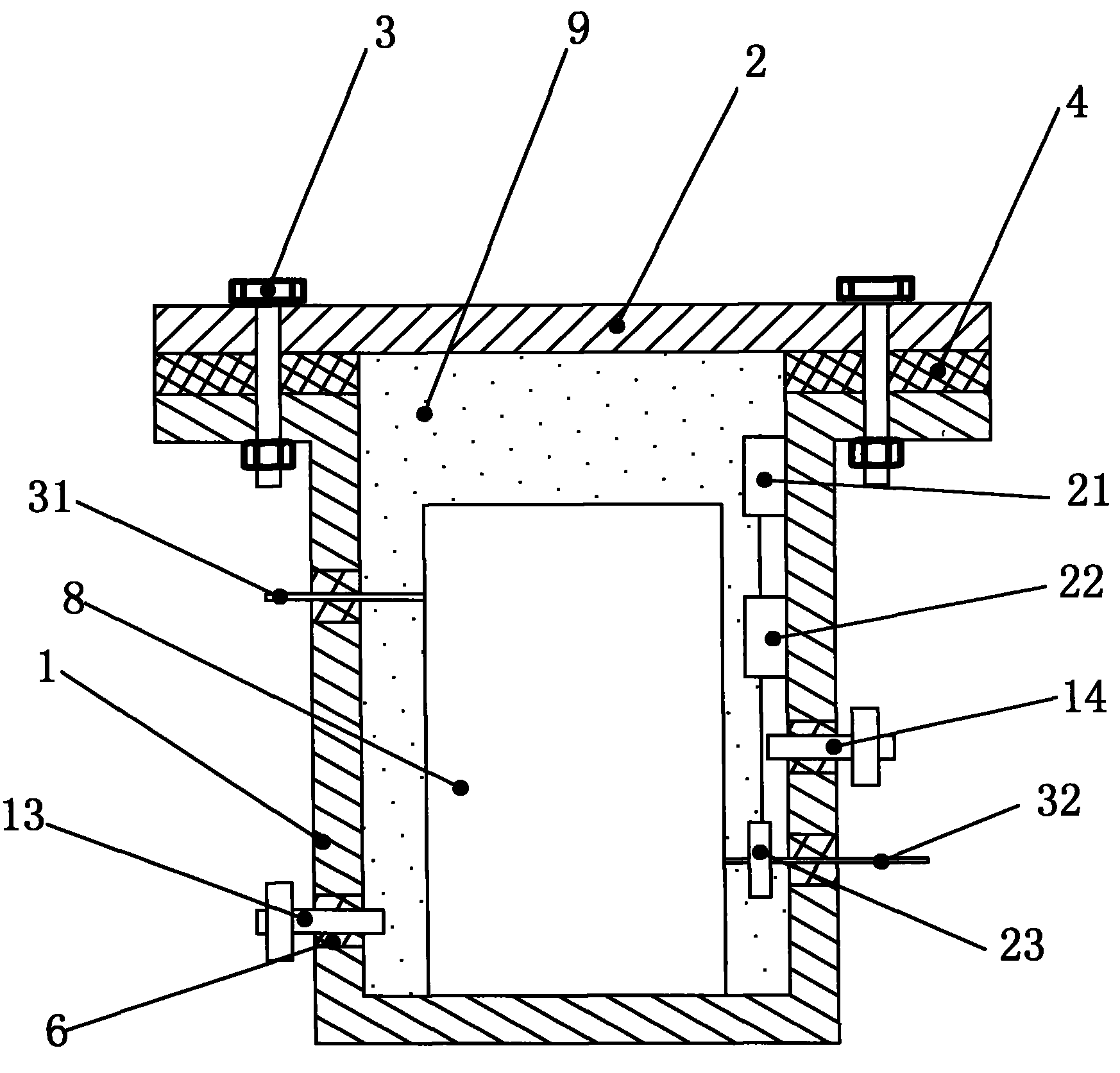

ActiveCN104701096AEliminate the risk of explosionHighly integratedProtective switch detailsElectric switchesBridge typeDc circuit breaker

The invention discloses a direct current breaker bridge type module. The direct current breaker bridge type module comprises an IGBT (insulated gate bipolar translator) press fitting unit, a capacitor bank, a stack bus bar, a control unit, an energy supply unit and a support frame, wherein the capacitor bank is electrically connected with the IGBT press fitting unit through the stack bus bar, the capacitor bank is connected with the control unit and the energy supply unit, and the IGBT press fitting unit, the capacitor bank, the stack bus bar, the control unit and the energy supply unit are located on the support frame. By adopting the technical scheme, bursting hidden dangers of a traditional welded module under a failure state are eliminated, the integration level of the direct current breaker bridge type module is greatly improved, the overall size of the direct current breaker bridge type module is reduced, a voltage peak of the direct current breaker bridge type module is effectively reduced when a large current is cut off, and simultaneously a large heat radiating area is further provided to the control unit.

Owner:STATE GRID CORP OF CHINA +2

Explosion-proof tank for electric appliance

InactiveCN101778546AReduce weightEasy to carryHermetically-sealed casingsElectric sparkWaste management

The invention relates to an explosion-proof tank for an electric appliance, which comprises a sealed tank body, wherein the electric appliance needing explosion prevention is arranged in the tank body, and safety gas is filled into the tank body. In the explosion-proof tank for an electric appliance, the electric appliance in the tank body is arranged in a safety environment without causing explosion for electric sparks because the safety gas is filled into the tank body, and the explosion-proof effect can be achieved without very high mechanical strength of the material of the tank body, so that various light materials can be adopted as the tank body, and the processing difficulty is smaller. Compared with the traditional technical scheme, the explosion-proof tank for an electric appliance has the advantages of light weight, convenient transportation, low manufacturing cost and the like.

Owner:赵幼敏

Safe and slow release chlorine dioxide disinfectant and preparation method thereof

InactiveCN108991007AStrong water absorptionImprove water retentionBiocideDisinfectantsHydrogen SulfateDisinfectant

The invention provides a safe and slow release chlorine dioxide disinfectant and relates to the technical field of daily disinfectants. The disinfectant is prepared from 50-60 parts by weight of a slow-release passivation stabilizer, 10-20 parts by weight of anhydrous sodium chlorite, 10-18 parts by weight of anhydrous sodium hydrogen sulfate, 7-12 parts by weight of anhydrous magnesium sulfate and 0-13 parts by weight of povidone K. The nano-attapulgite in the nanometer formula has the function of passivating a strong oxidizing substance, and the special multi-channel structure can effectively adsorb and control the moisture content so that the risk of ignition or explosion of a chlorine dioxide disinfectant product in the preparation and trial processes are significantly reduced or avoided and the slow release effect is obtained. The safe and slow release chlorine dioxide disinfectant has the ability to stably produce a low concentration of chlorine dioxide gas for six months and isespecially suitable for household disinfection and cleaning of daily necessities.

Owner:QINGDAO UNIV

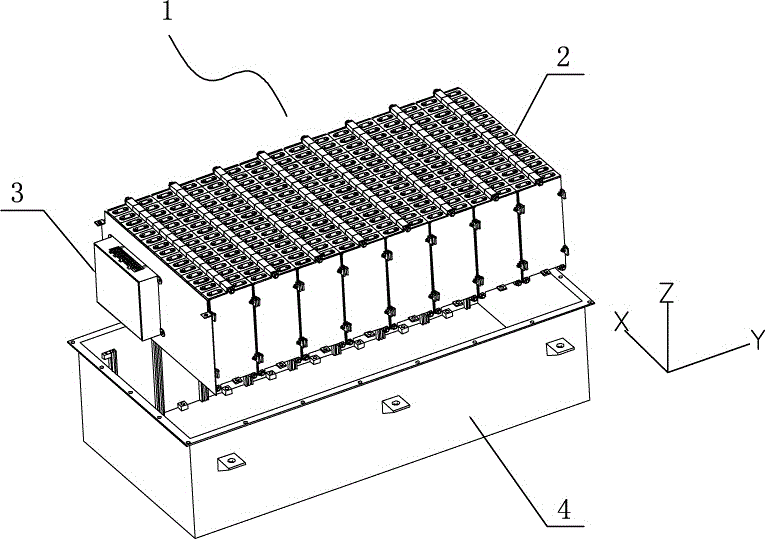

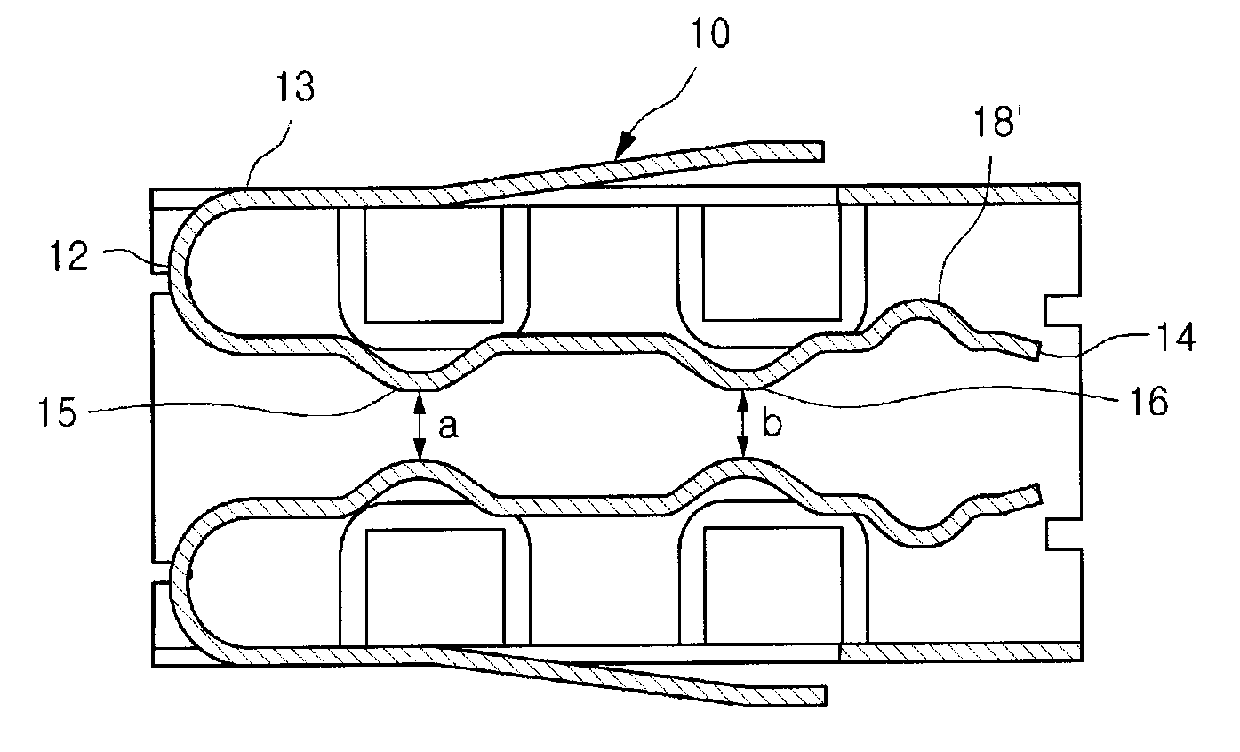

Lithium ion battery pack

ActiveCN106058110AGood vibration resistanceGood thermal conductivity and confluence performanceSecondary cellsCell component detailsElectrical batteryCell expansion

The invention discloses a lithium ion battery pack. The lithium ion battery pack comprises a battery box, a battery module and a battery pack electronic part are arranged in the battery box and are fixed in the battery box in the three-dimensional direction, the battery module comprises a plurality of square single cells which are superposed in a lamination manner, pressure plates positioned at two ends of the battery module, insulating plates for separating the single cells from the pressure plates, and pull bars and pull strips which are used for fixing the pressure plates and the single cells, and every single cell is fixed in the battery module in the three-dimensional direction through a corresponding single cell assembling frame. The lithium ion battery pack has the advantages of overcoming of defects existing in the prior art, strong vibration and impact resistance, no displacement problem caused by cell expansion in the use process, good heat conduction and conflux performances, simple structure, convenience in assembling and operating, realization of modular design and assembling, strong applicability and low production cost.

Owner:辽宁比科新能源股份有限公司

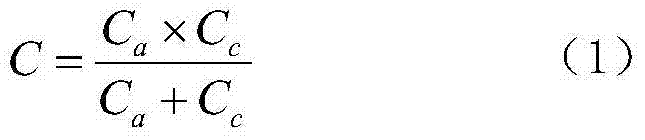

High-specific-volume low-voltage aluminum electrolytic capacitor and manufacturing method thereof

InactiveCN103680978AEasy to prepareLarge specific surface areaLiquid electrolytic capacitorsTio2 nanotubeLow voltage

The invention discloses a high-specific-volume low-voltage aluminum electrolytic capacitor and a manufacturing method thereof. A titanium oxide nanotube array film is used as a cathode which replaces a corrosion aluminum foil cathode of a traditional aluminum electrolytic capacitor, and the capacitor is manufactured with the adoption of the production technology, a working electrolyte and the burn-in technology similar to those of the traditional aluminum electrolytic capacitor. Due to the fact that the titanium oxide cathode is high in strength, small in thickness and high in specific volume, under the circumstance that the volumes are the same, the area of an anode aluminum foil can be increased, and the specific volume of the capacitor is improved. According to the manufacturing method, the specific volume of the low-voltage aluminum electrolytic capacitor can be improved by more than 50%; in addition, the titanium oxide cathode is directly formed on a titanium foil substrate through anodic oxidation, the binding force between the titanium oxide cathode and the titanium foil substrate is high, and no titanium oxide film falls off from the substrate.

Owner:NANJING UNIV OF SCI & TECH

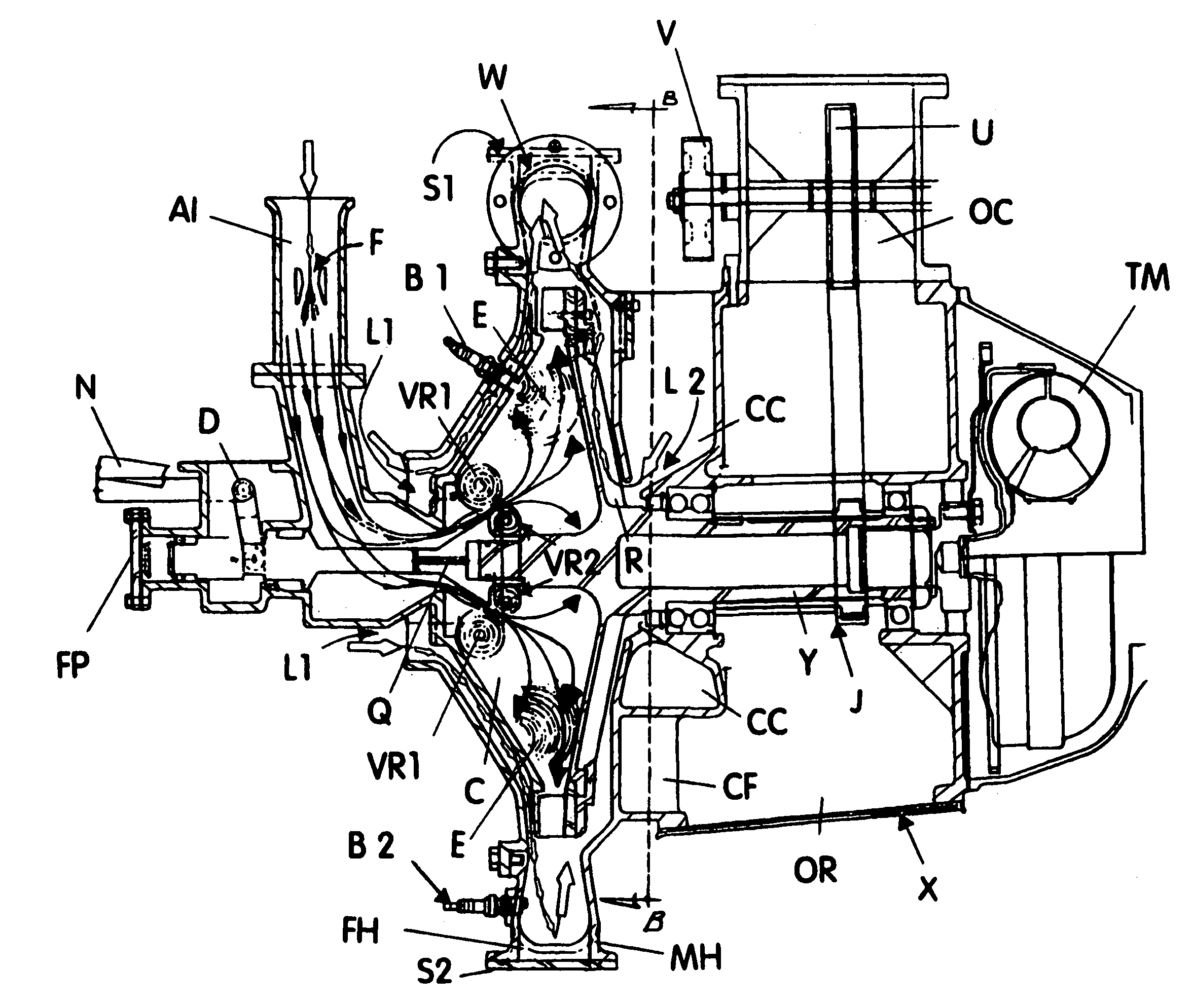

Thermodynamic pressure generator

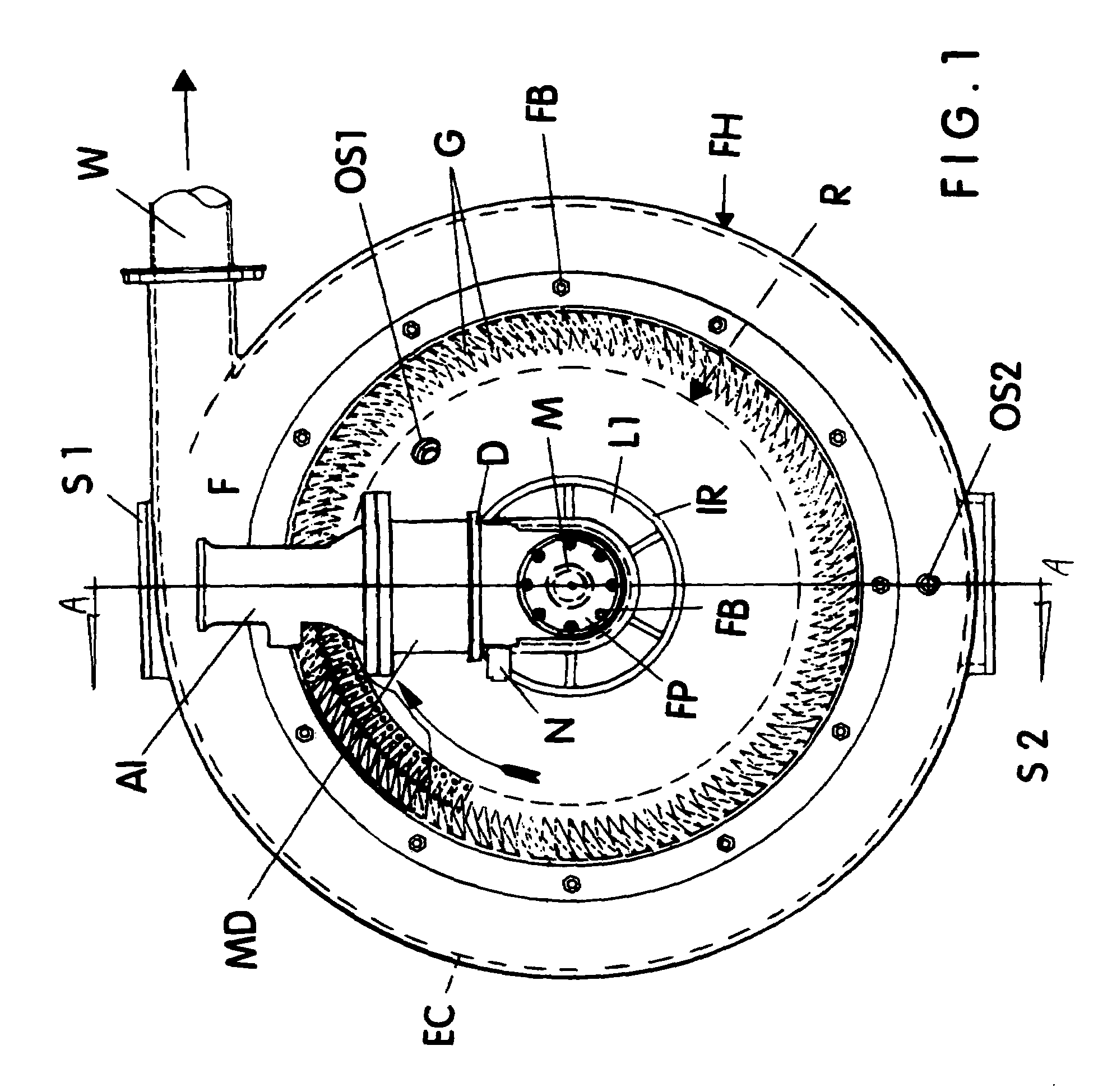

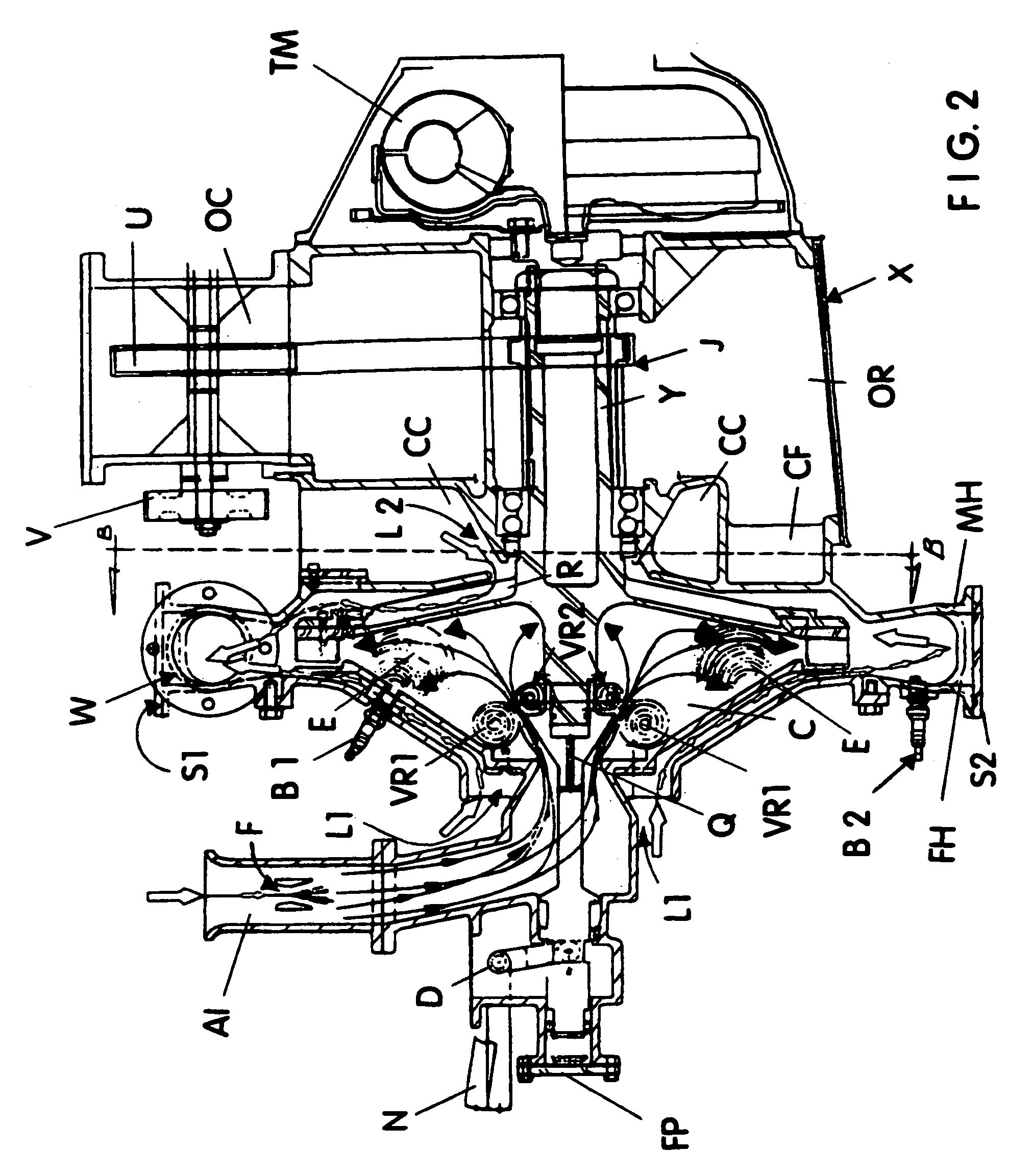

InactiveUS6983604B1High horsepowerGreat torqueGas turbine plantsHot gas positive displacement engine plantsExhaust gasPropeller

A thermodynamic pressure generator having an oscillating valve that allows premixed fuel to enter a combustion chamber in turbulence, until it comes into contact with an annular spoiler, which converts a portion of the fuel into a Karmon vortex ring for delayed ignition. A continuous spark then ignites the remaining fuel with rapid pressure rise that kills the vortex. The fuel in the vortex goes from laminar to turbulence, adding fuel to the already burning charge, super charging it and permitting total ignition. Thus, present invention exhaust contains no polluting by-products and only sensible heat is released into the environment. Exhaust gases are released radially through turbine vanes having a shape that permits a relatively low rotational speed, with sufficient peripheral speed to create torque of considerable degree. Applications include, but are not limited to, land transportation vehicles, propeller-driven airplanes, and marine vessels.

Owner:TAFOYA SAMUEL BARRAN

Stable chlorine dioxide effervescent and preparation method thereof

InactiveCN110558318AEliminate the risk of explosionDisintegrates quicklyBiocideDisinfectantsChlorine dioxideDecomposition

The invention discloses a stable chlorine dioxide effervescent and a preparation method thereof. The stable chlorine dioxide effervescent is prepared by mixing sodium chlorate, anhydrous sodium bisulfite, anhydrous sodium bisulfate, anhydrous sodium sulfate, anhydrous copper sulfate and anhydrous sodium carbonate according to a mass ratio of (5-20):(3-8):(5-12):(25-40):(1-3):1. The preparation method comprises the following steps: a, uniformly mixing the sodium chlorate, anhydrous sodium sulfate and anhydrous sodium carbonate according to a corresponding mass ratio, and carrying out vacuum drying at 45-60 DEG C for 6-12 h to obtain a material A; b, uniformly mixing the anhydrous sodium bisulfite, anhydrous sodium bisulfate and anhydrous copper sulfate according to a corresponding mass ratio, and performing vacuum drying at 45-60 DEG C for 6-12 h to obtain a material B; and c, fully and uniformly mixing the material A prepared in step a with the material B prepared in step b in a powdermixer, performing seal packaging, and storing the obtained product in a dry and shady environment. The effective content of chlorine dioxide in the product is 8-12%, and the chlorine dioxide effervescent provided by the invention is safe and stable, has no decomposition or explosion risks, and has a long sterilization and disinfection duration and a high killing rate.

Owner:HENAN CHEM IND RES INST

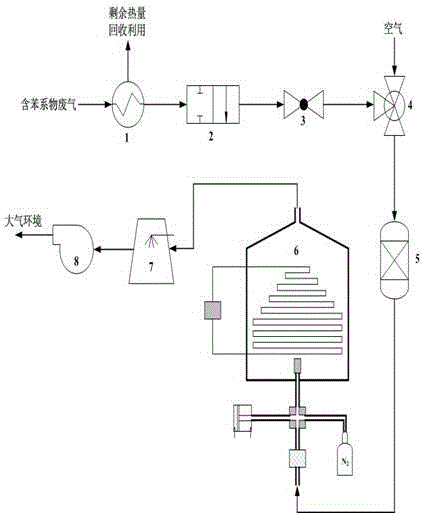

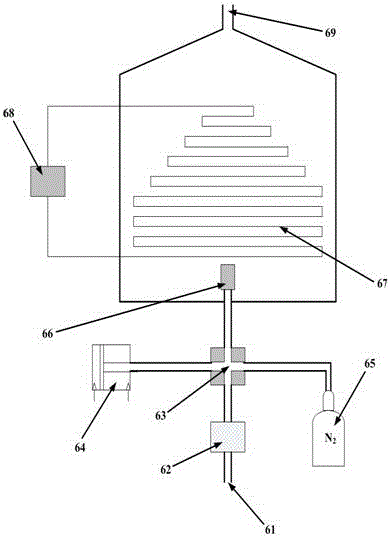

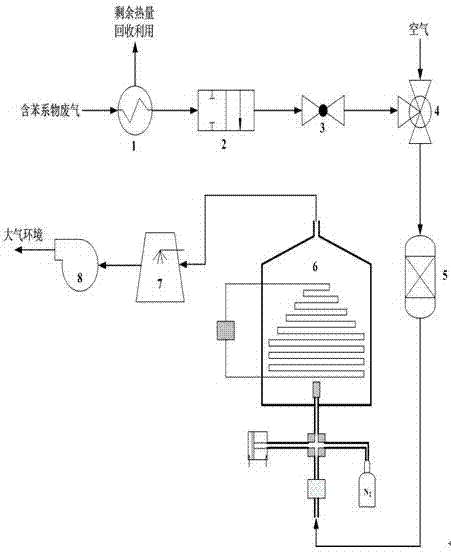

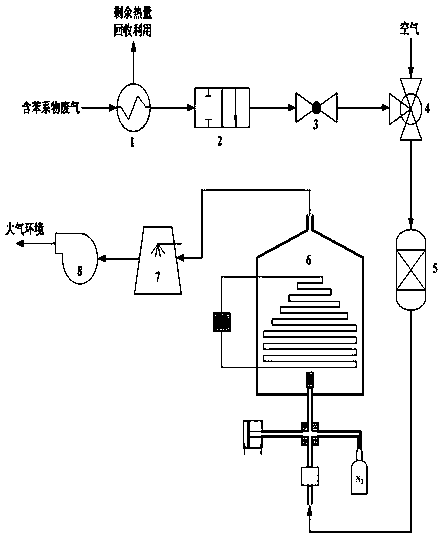

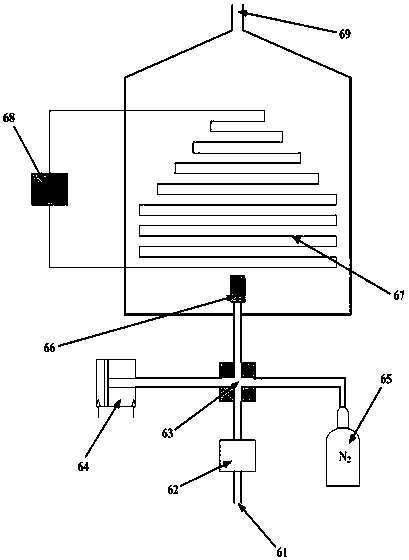

Treatment system for removing benzenes in petrochemical industry waste gas

ActiveCN106110809AOxidative decomposition is goodLow costCombination devicesGas treatmentIncandescencePetrochemical

The invention discloses a treatment system for removing benzenes in petrochemical industry waste gas. The system comprises a waste heat exchanger, a gas overheating protection device, a thermal type gas mass flow meter, a mixed gas flow control valve, a bag type dust collector, a tungsten coil surface activation-ozone oxidation treatment device, a smoke washing purifying tower, a draught fan and the like. According to the system, the unique surface activation property of ozone on the surfaces of some metal elementary substances is creatively utilized; when a tungsten metal coil is in an electrified incandescence state, ozone can rapidly release activated oxygen atoms on the surface of the tungsten metal coil, and a strong oxidation environment can be generated on the surface of tungsten metal; when molecules, containing C-C bonds with the conjugation effect, of benzenes and the like are in the strong oxidation environment, the conjugated C-C bonds of the molecules can be broken by the activated oxygen atoms, the molecules of benzenes can be decomposed into H2O, CO2 and other inorganic molecules finally under oxygenolysis, and thus the purpose of removing benzenes in waste gas is achieved.

Owner:广东吉之准检测有限公司

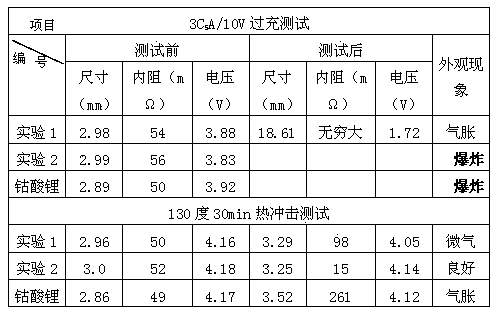

High safety anti-overcharging lithium ion battery positive electrode paste formula and production method of positive plate

InactiveCN104377348AEliminate the risk of explosionImprove safety performanceCell electrodesEngineeringLithium electrode

The invention relates to a high safety anti-overcharging lithium ion battery positive electrode paste formula and a production method of a positive plate, and lithium manganate is contained in the formula and the production method, thus overcoming the limitations of cobalt acid lithium in performance in a traditional battery and playing a role in reducing cost and improving the performance of the battery.

Owner:刘广源

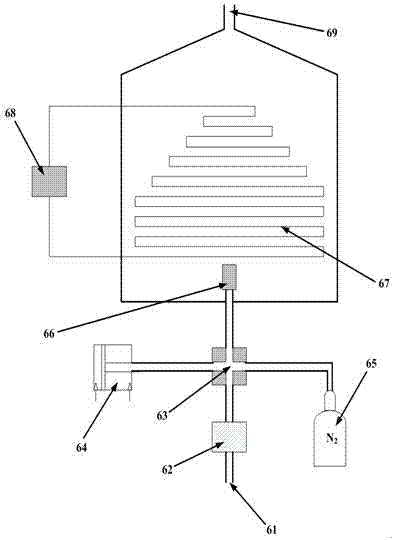

Nitrogen injection fireproofing method for adjacent goafs during tunneling along empty roadway

InactiveCN106499431AEliminate the risk of explosionAvoid self-heatingDust removalFire preventionSpontaneous combustionKerosene

The invention particularly relates to a nitrogen injection fireproofing method for adjacent goafs during tunneling along empty roadways, and solves the problem of difficult fire prevention in the goafs during tunneling. The nitrogen injection fireproofing method for adjacent goafs during tunneling along empty roadways comprises the following steps: determining nitrogen injection flow in the goafs and the time of the nitrogen injection, and starting the nitrogen injection if the following conditions meet anyone of the conditions including the temperature of the goafs over 26 DEG C or daily temperature rise of 1 DEG C; the water temperature of the goafs exceeding 26 DEG C; local parts of the workplace giving signs of fire, such as tar or kerosene odor; preburying nitrogen injection pipelines using a cross bedding method, with the step distance of 40 m, and cycling until the workplace is tunneled. The method applies the nitrogen injection fireproofing method to the fire prevention and control of the goafs during tunneling, not only eliminates the danger of gas explosion, reduces the effect of air leakage, plays the role of cooling, but prevents the self-heating and the spontaneous combustion of coal and reduces burning strength.

Owner:DATONG COAL MINE GRP

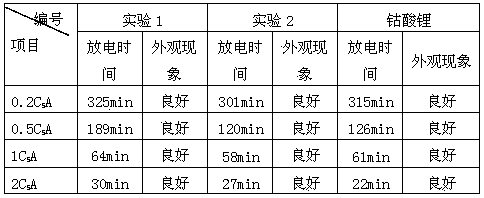

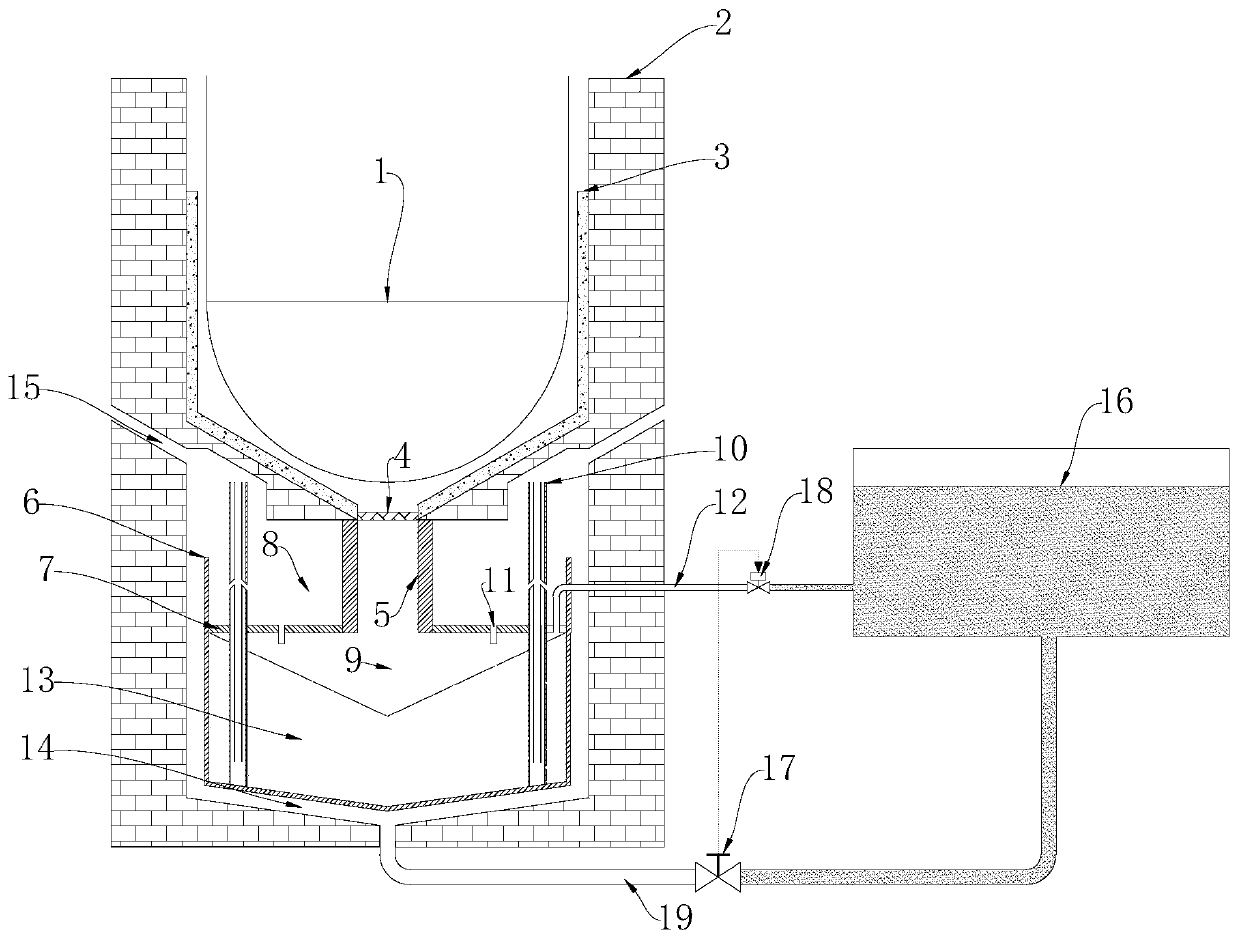

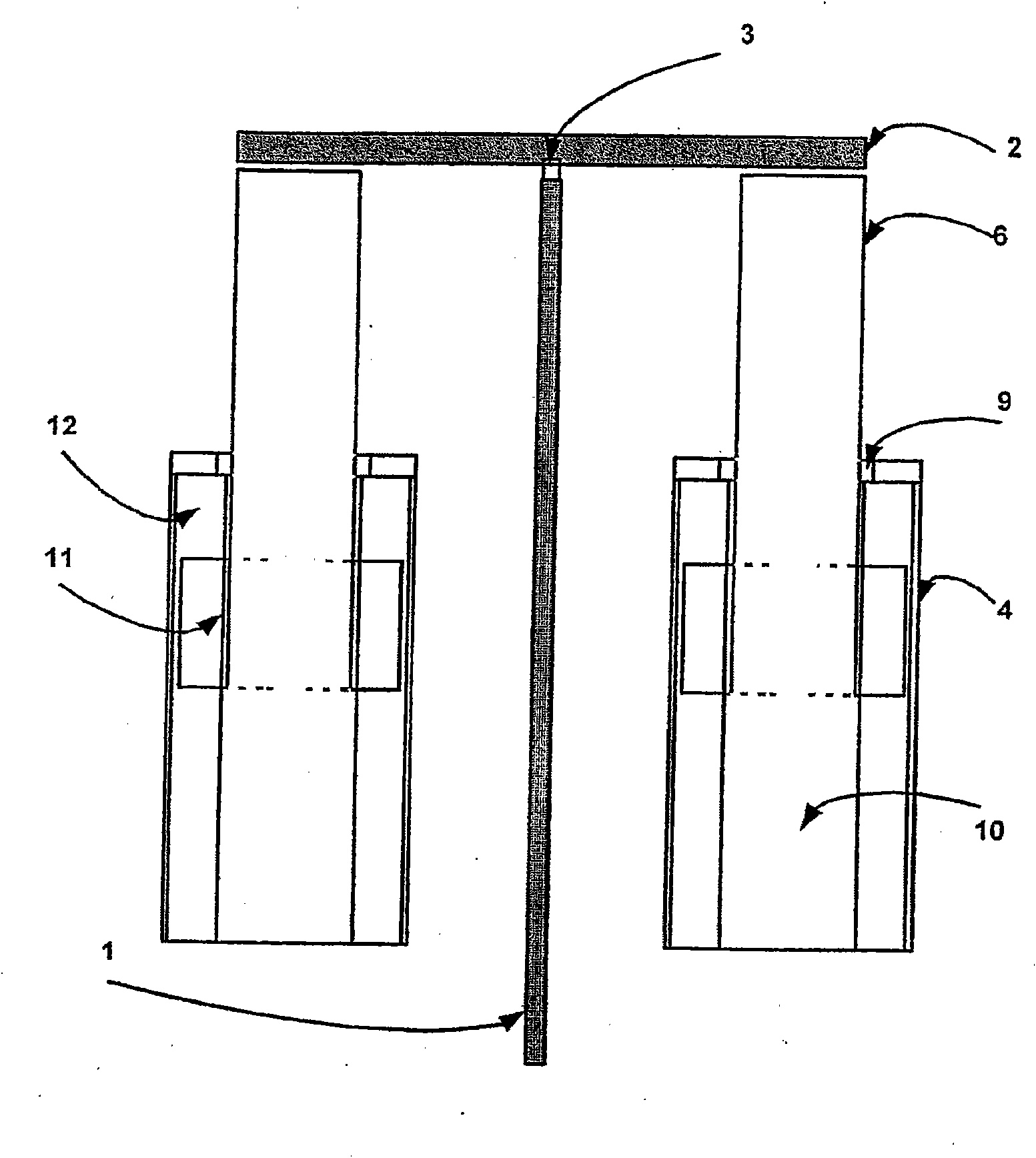

Partitioned crucible melt out-of-pile catcher

PendingCN110391030AAvoid direct contactEliminates the risk of steam explosionsNuclear energy generationEmergency protection arrangementsPower densityWater tanks

The invention relates to a partitioned crucible melt out-of-pile catcher. The partitioned crucible melt out-of-pile catcher comprises a melt transferring channel, a melt collection crucible and a cooling water tank, wherein a refractory material is laid on the inner wall surface of the bottom part of a reactor pit; the melt transferring channel is connected with the reactor pit and the melt collection crucible, and also comprises a melt plug used for plugging the reactor pit; and the melt collection crucible is connected with the cooling water tank. The partitioned crucible melt out-of-pile catcher provided by the invention has the following beneficial effects: (1) through the specially-designed melt collection crucible, direct contact between an early-stage reactor core melt and cooling water is completely eradicated, so the risk of steam explosion is eliminated; (2) through introduction of a plurality of specially-designed cooling pipes, the heat exchange area of melts is increased,and the heat exchange capacity of the melts is further reinforced; and (3) through filling of the melt collection crucible with a sacrificial material, the melts are guaranteed to fully react with thesacrificial material before contacting with trap structural membranes (i.e., the cooling pipes and the wall surface of a container), so the temperature, melting point and volumetric power density ofthe melts are reduced.

Owner:CHINA NUCLEAR POWER ENG CO LTD

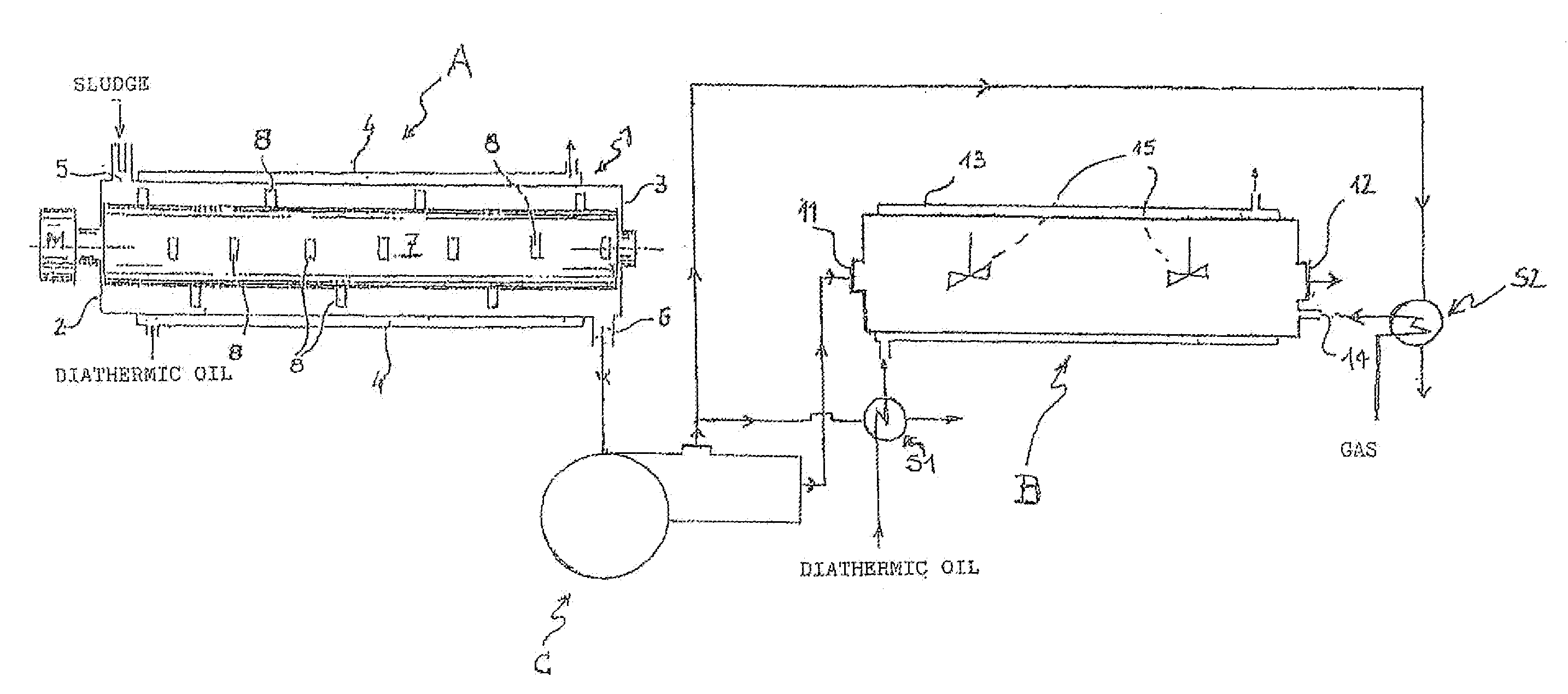

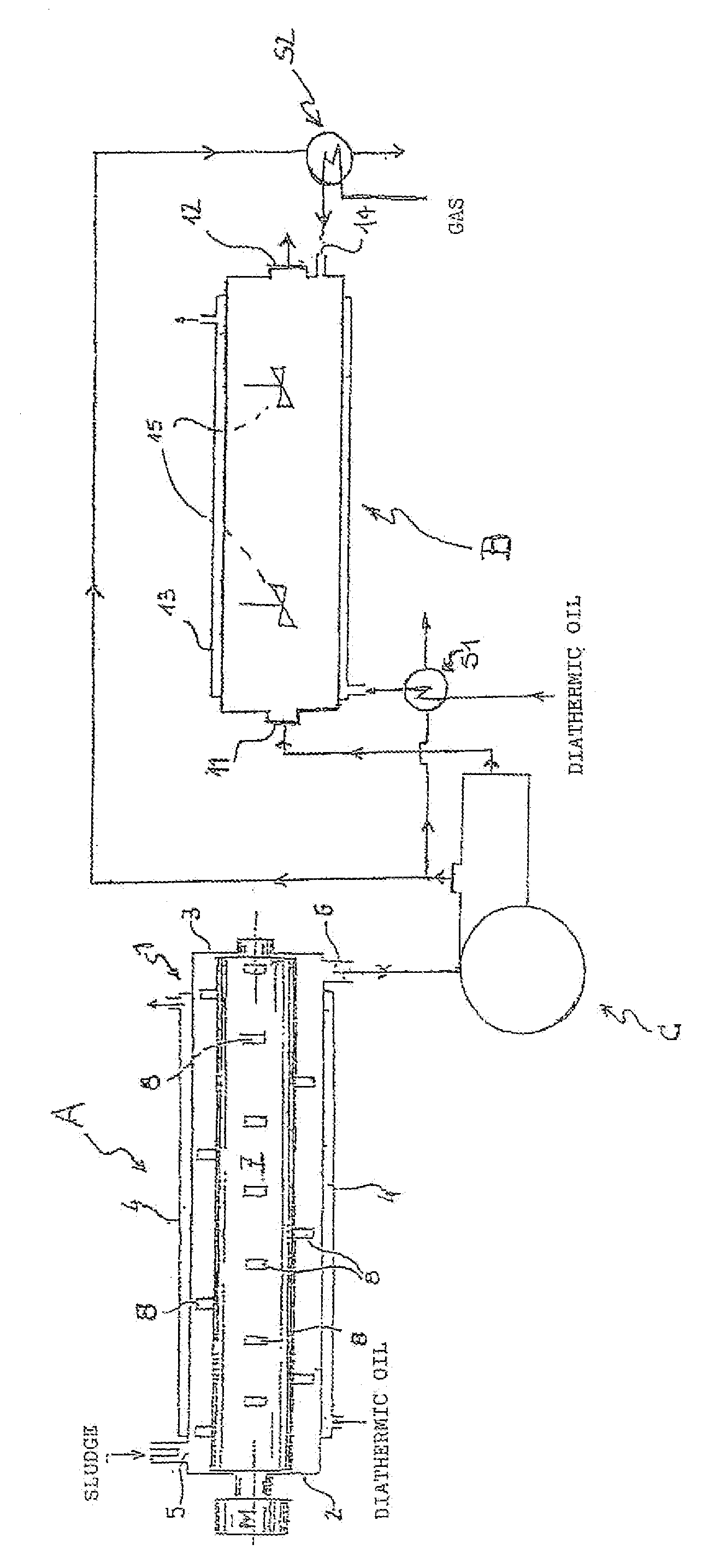

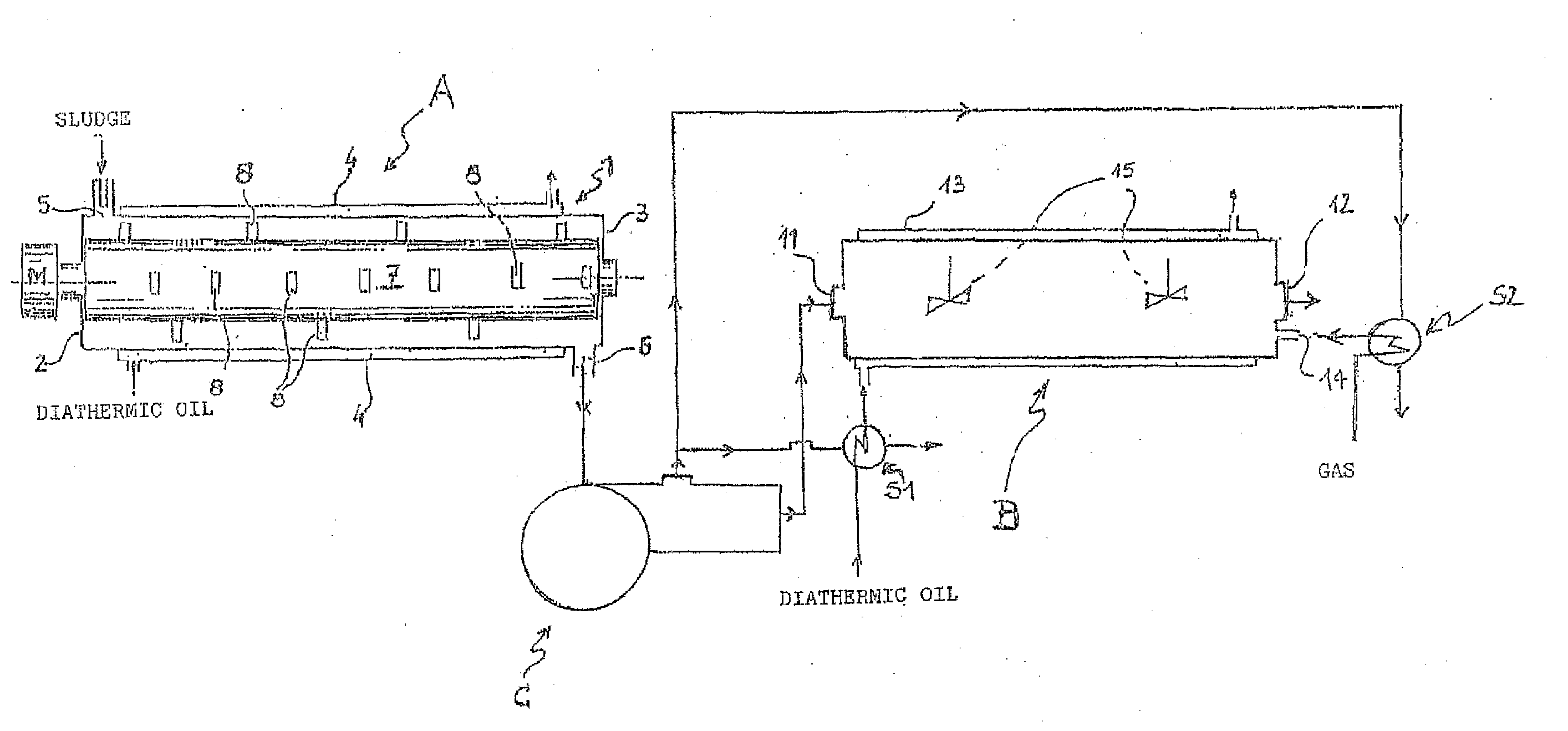

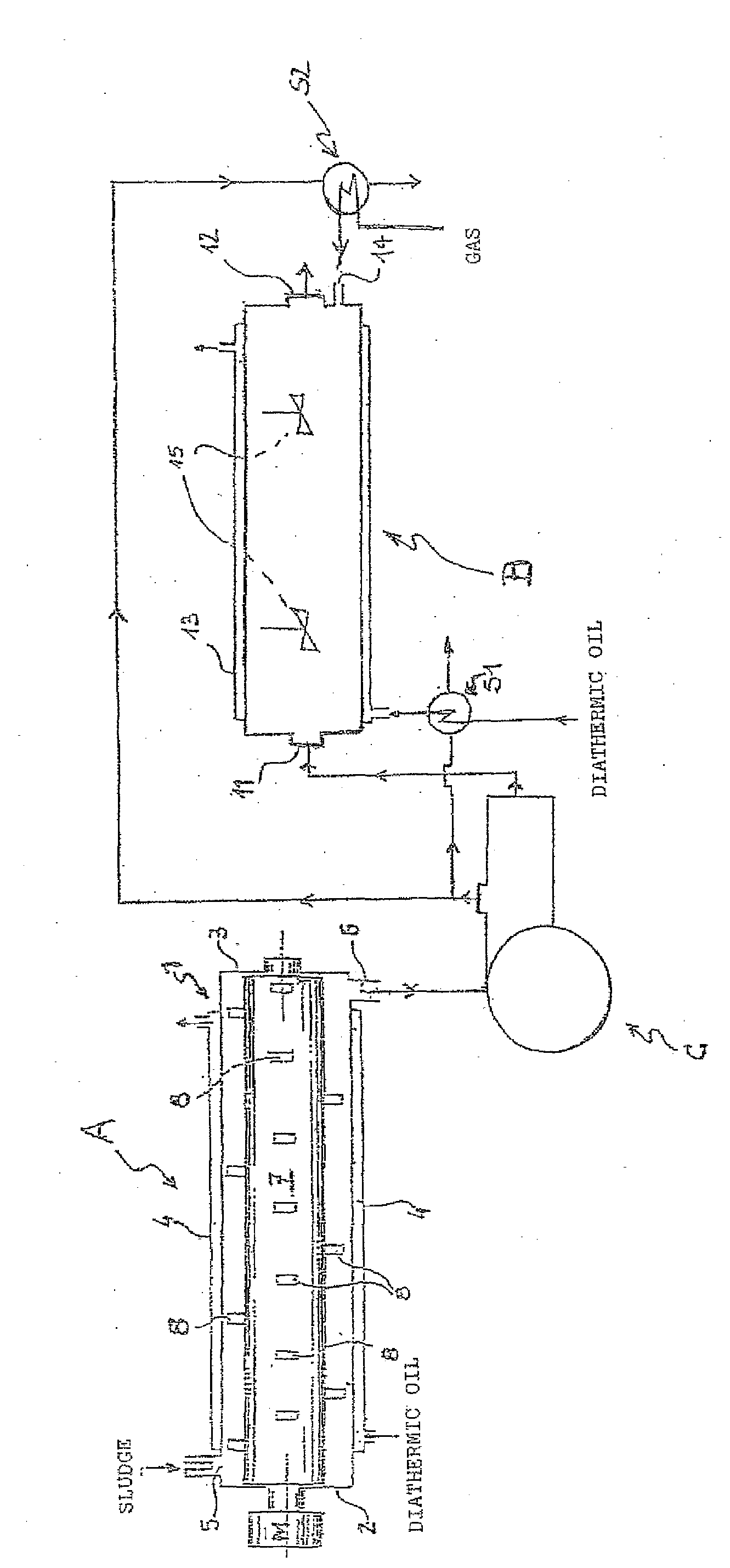

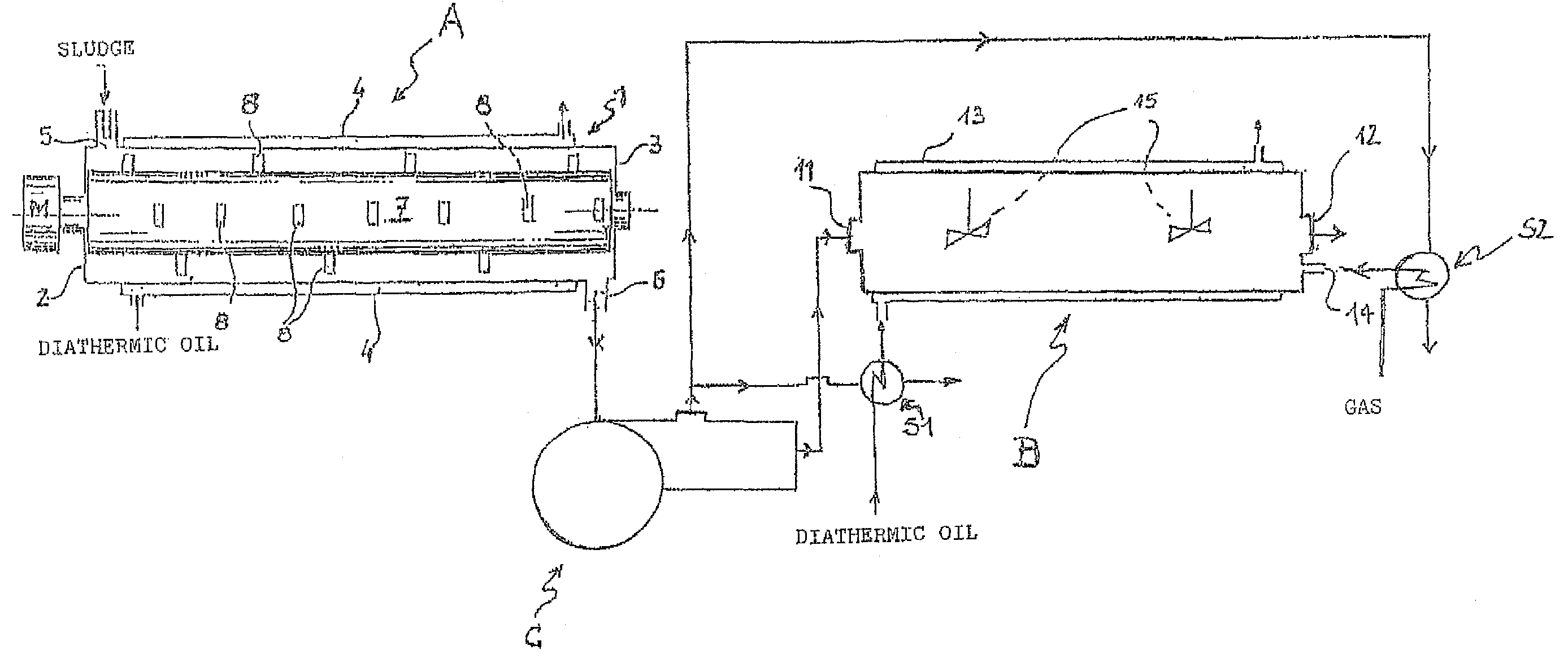

System for making plants for drying solid organic substances in aqueous phase capable of causing explosive reactions safe and process for drying said substances

InactiveUS20110232121A1Eliminate the risk of explosionLow costSludge dryingDrying machines with non-progressive movementsAmount of substanceChemistry

Owner:GEOLINE S R L ROZZANO

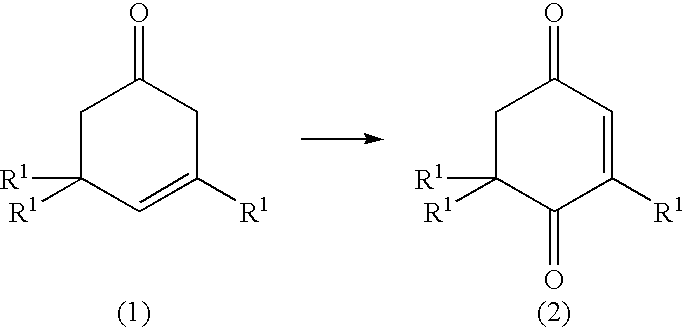

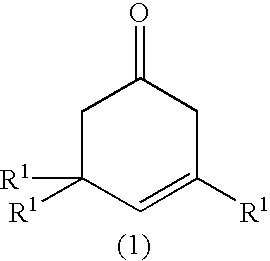

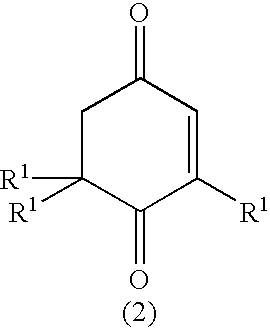

Process for the production of ketoisophorone derivatives and equipment therefor

InactiveUS6410797B1Efficient removalEfficiently oxidizedOrganic compound preparationOrganic chemistry methodsIsophoroneSolvent

In the presence of an oxidizing catalyst, a beta-isophorone derivative of the following formula (1) is oxidized in a solvent substantially from acid components (organic carboxylic acids) to form a ketoisophorone derivative of the following formula (2). The amount of the acid component in the solvent is 0 to 4,000 ppm (weight basis). The oxidizing catalyst is a complex salt of a transition metal and an N,N'-disalicylidenediamine. In the reaction, a cyclic base may further be employed as a co-catalyst. The solvent separated from the reaction mixture may be recycled to the oxidation reaction after removal of the acid component contained therein.

Owner:DAICEL CHEM IND LTD

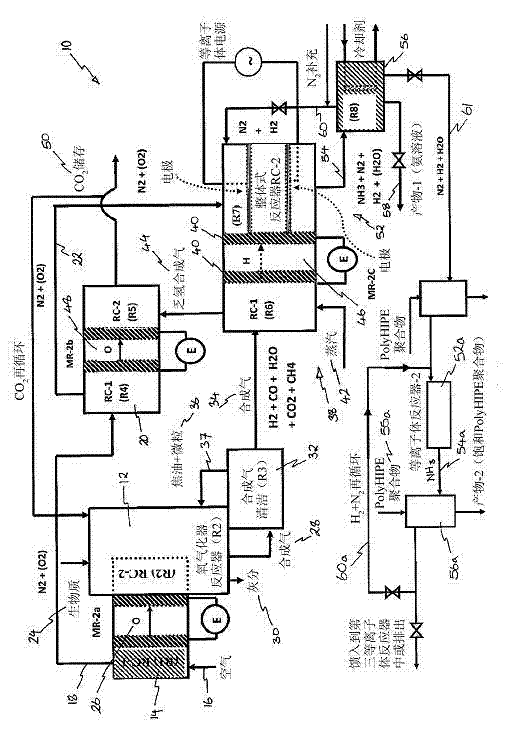

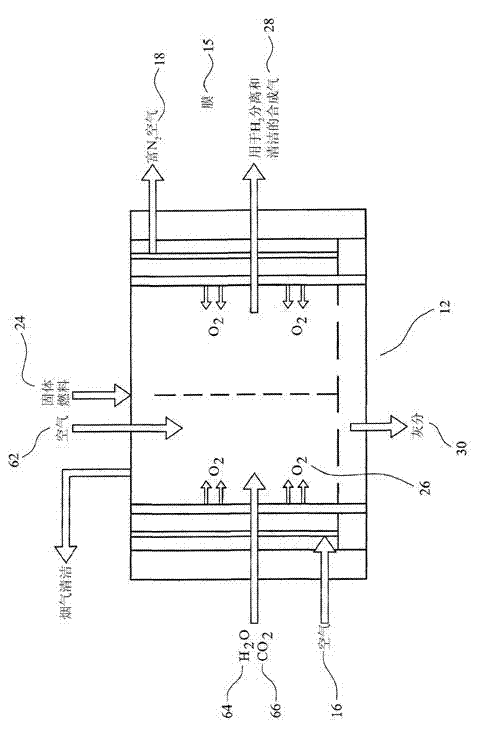

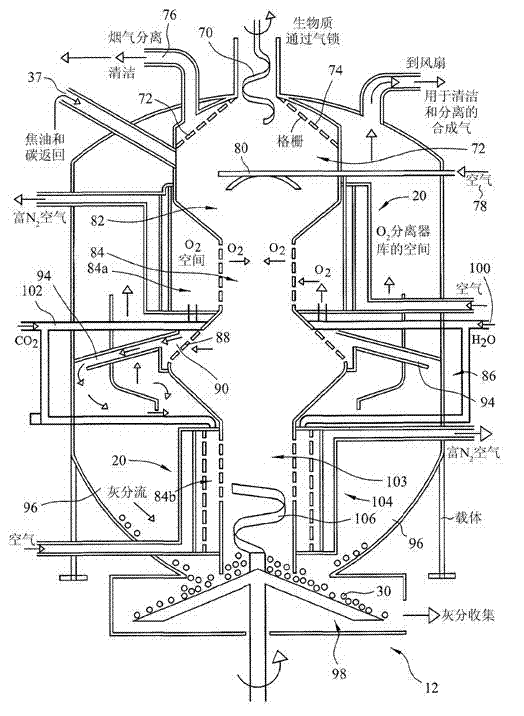

Ammonia production by integrated intensified processes

An ammonia production process is disclosed. The process uses gasification of biomass waste and the like to produce syngas which, using an integrated system including using nitrogen enriched air and a porous coated catalyst, produces ammonia in a plasma reactor. The ammonia is finally recovered using sulphonated PolyHIPE Polymer which can be used as a fertilizer after neutralisation.

Owner:NEWCASTLE UNIV

System for making plants for drying solid organic substances in aqueous phase capable of causing explosive reactions safe and process for drying said substances

ActiveUS20090113754A1Eliminate the risk of explosionHigh degreeDrying solid materials with heatDrying solid materials without heatHorizontal axisContinuous flow

The present invention refers to a process for drying solid organic substances in aqueous phase including the steps of:feeding a continuous flow of such organic substances having a water content=50% by weight into a turbodrier having a cylindrical tubular body with horizontal axis, equipped with inlet and outlet openings, a heating jacket for bring the inner wall of the tubular body to a predetermined temperature, a bladed rotor extending inside the cylindrical tubular body (1) where it is made to rotate at speeds between 15 and 40 m / s, so as to disperse the continuous flow of organic substances into a flow of particles of organic substances;centrifuging the particles of organic substances against the inner wall of the turbodrier heated to a temperature above 130° C., with formation of a thin, dynamic, highly turbulent tubular fluid layer, which advances substantially in contact with the inner wall of the turbodrier towards the outlet opening;continuously discharging, from the turbodrier, a flow of organic substances in disgregated wet solid form having a water content=45% by weight;continuously feeding the flow of disgregated wet solid into an drier operating at a temperature lower than or equal to 160° C.;continuously discharging a flow of dry product having a water content=20% by weight from the drier.

Owner:GEOLINE

Treatment system for removing benzene series in petrochemical industrial waste gas

ActiveCN107441904AOxidative decomposition is goodLow costCombination devicesGas treatmentBiological activationMixed gas

The invention discloses a treatment system for removing benzene series in petrochemical industrial waste gas. The system comprises a waste heat exchanger, a gas overheating protection device, a thermal gas mass flowmeter, a mixed gas flow regulating valve, a cloth bag type dust remover, a tungsten coil surface activation-ozonation treatment device, a smoke water-washing purification tower, an induced draft fan and the like. According to the system, the specific surface activation character of ozone on the surfaces of certain metal elementary substances is creatively used, when a tungsten metal coil is in an electrified fervidity state, the ozone can quickly release activated oxygen atoms on the surface of the tungsten metal coil, a strong oxidation environment can be generated on the surface of tungsten metal, when molecules containing a C-C bond with conjugative effect, of the benzene series and the like are in the strong oxidation environment, the conjugated C-C bond can be broken by the activated oxygen atoms, and the benzene series molecules are finally oxidized and decomposed into inorganic modecules such as H2O and CO2, so that the purpose of removing the benzene series in the waste gas is realized.

Owner:南京宇清环境科技有限公司

Treatment system for removing benzene series in petrochemical industrial waste gas

ActiveCN107441905AOxidative decomposition is goodLow costCombination devicesGas treatmentBiological activationToxic industrial waste

The invention discloses a treatment system for removing benzene series in petrochemical industrial waste gas. The system comprises a waste heat exchanger, a gas overheating protection device, a thermal gas mass flowmeter, a mixed gas flow regulating valve, a cloth bag type dust remover, a tungsten coil surface activation-ozonation treatment device, a smoke water-washing purification tower, an induced draft fan and the like. According to the system, the specific surface activation character of ozone on the surfaces of certain metal elementary substances is creatively used, when a tungsten metal coil is in an electrified fervidity state, the ozone can quickly release activated oxygen atoms on the surface of the tungsten metal coil, a strong oxidation environment can be generated on the surface of tungsten metal, when molecules, containing a C-C bond with a conjugative effect, of the benzene series and the like are in the strong oxidation environment, the conjugated C-C bond can be broken by the activated oxygen atoms, and the benzene series molecules are finally oxidized and decomposed into inorganic modecules such as H2O and CO2, so that the purpose of removing the benzene series in the waste gas is realized.

Owner:FUYANG HESHI CHEM FIBER AUX CO LTD

Treatment system for removing benzene series in petrochemical waste gas

ActiveCN107441911AOxidative decomposition is goodLow costCombination devicesGas treatmentPetrochemicalBiological activation

The invention discloses a treatment system for removing benzene series in petrochemical industrial waste gas. The system comprises a waste heat exchanger, a gas overheating protection device, a thermal gas mass flowmeter, a mixed gas flow regulating valve, a cloth bag type dust remover, a tungsten coil surface activation-ozonation treatment device, a smoke water-washing purification tower, an induced draft fan and the like. According to the system, the specific surface activation character of ozone on the surfaces of certain metal elementary substances is creatively used, when a tungsten metal coil is in an electrified fervidity state, the ozone can quickly release activated oxygen atoms on the surface of the tungsten metal coil, a strong oxidation environment can be generated on the surface of tungsten metal, when molecules, containing a C-C bond with a conjugative effect, of the benzene series and the like are in the strong oxidation environment, the conjugated C-C bond can be broken by the activated oxygen atoms, and the benzene series molecules are finally oxidized and decomposed into inorganic modecules such as H2O and CO2, so that the purpose of removing the benzene series in the waste gas is realized.

Owner:JIANGSU ENVIFRP ANTISEPSIS EQUIP

Method for producing epoxy chloropropane

The invention relates to a method for producing epoxy chloropropane which is produced by using with 3-chloropropene as a raw material, phosphotungstic acid quaternary ammonium salt as a catalyst, hydrogen peroxide as an oxidizing agent and chloroform as a solvent by utilizing a phase transfer method. The method comprises the following steps of: adding the chloroform, the 3-chloropropene and the phosphotungstic acid quaternary ammonium salt into a reactor; stirring and raising temperature to a reaction temperature; adding the hydrogen peroxide to react at a bubble point temperature; and condensing, reflowing and taking away reaction heat in the reaction process through organic vapor. The oxygen concentration of reactor gas phase is controlled in the range of 0-6%; and the reaction temperature is the bubble point temperature, and the starting reaction temperature is 52-54 DEG C. Because the hydrogen peroxide decomposes in the reaction process, a blasting mixture is easily formed by the generated oxygen in the reactor gas phase and the organic vapor. The method is characterized in that the mixed gas in the reactor does not blast in the range, therefore, the blasting danger of the reactor gas is effectively eliminated.

Owner:CHINA PETROLEUM & CHEM CORP +1

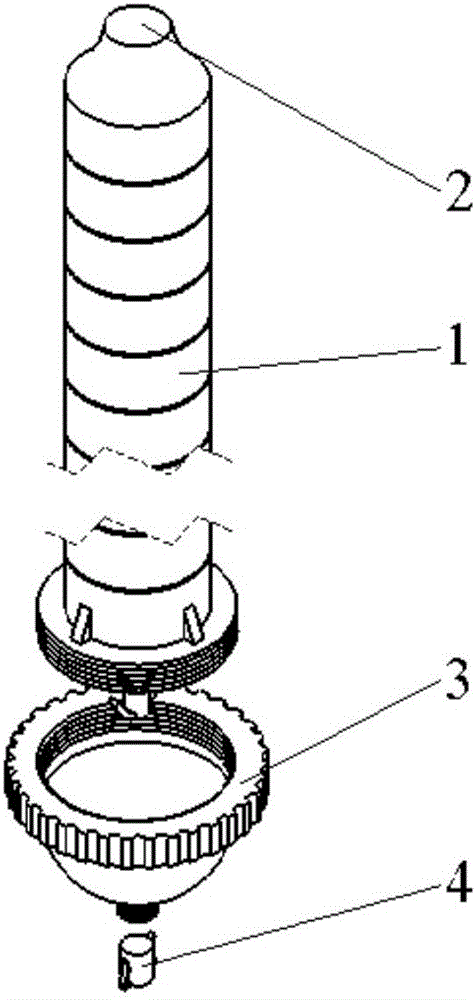

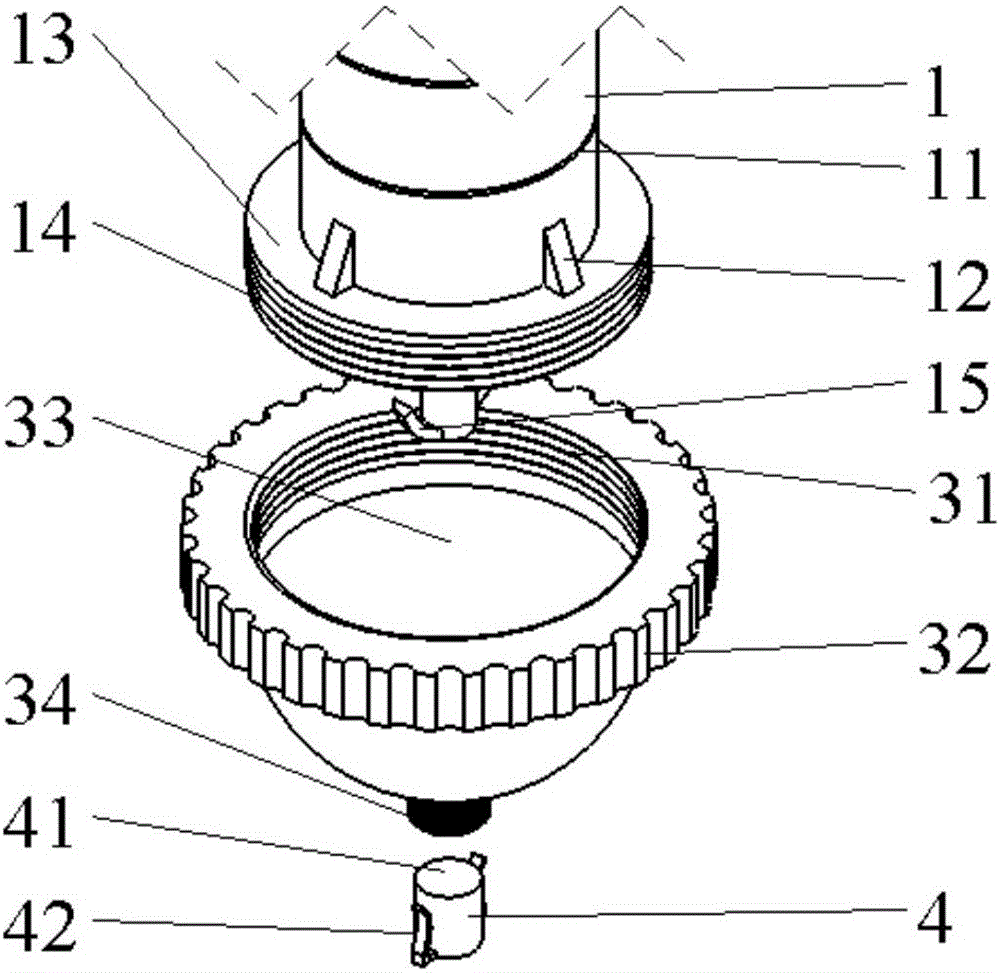

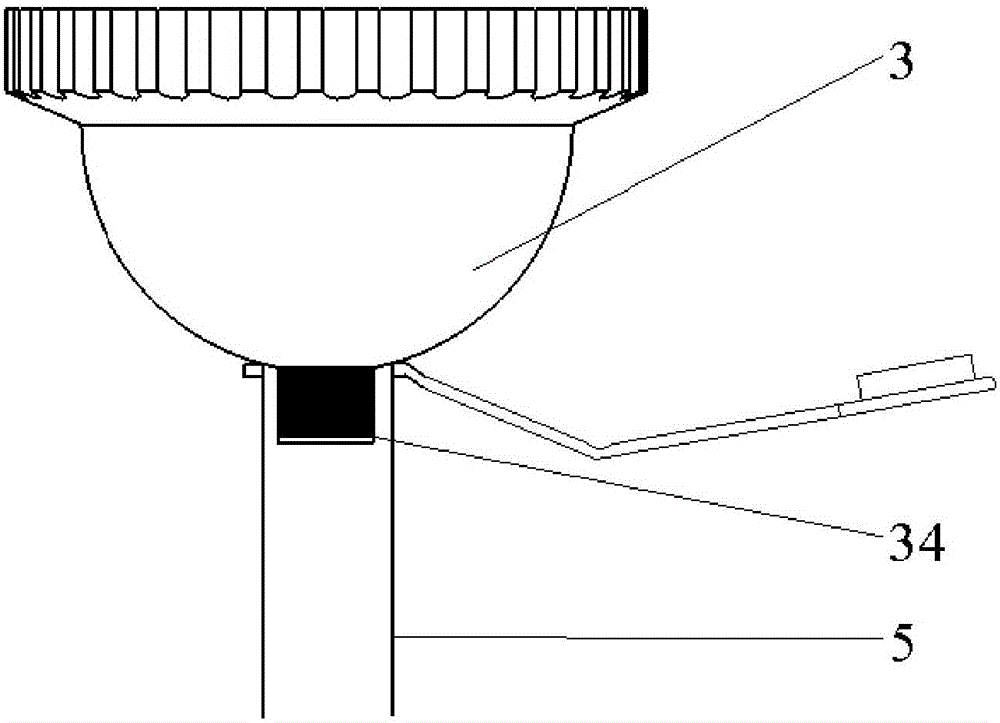

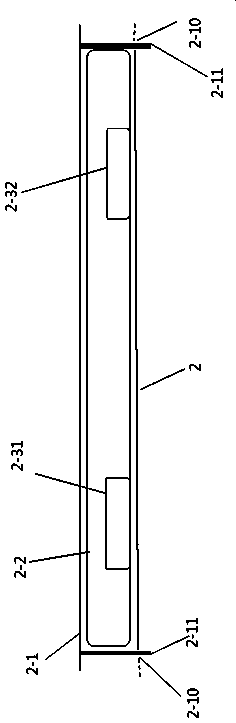

Sample grinder for tissue sample grinding

ActiveCN105728145AAvoid wasting timeAvoid human deficienciesPreparing sample for investigationGrain treatmentsTissue sampleEngineering

The invention belongs to the field of biotechnology instruments, and particularly relates to a sample grinder for plant or animal tissue. The sample grinder is composed of a hanging mill (1), a linkage line (2), a funnel (3) and a funnel plug (4). The hanging mill (1) is connected with a motor through the linkage line (2). A base plate (13) below the hanging mill (1) is matched with the funnel (3) in a threaded manner. Vertical grain (32) is arranged on the outer side of the upper portion of the funnel (3). An inner spherical surface (33) of the funnel (3) is smooth. A funnel opening (34) is arranged at the outer bottom of the funnel (3), and cross grain is arranged on the outer side of the funnel opening (34). The upper surface of the funnel plug (4) is a spherical surface, and spring pieces (42) are arranged on the side face of the funnel plug (4). The funnel plug (4) is buckled and plugged into the funnel opening (34) at the bottom of the funnel (3), and the upper spherical surface (41) of the funnel plug (4) coincides with the inner spherical surface (33) of the funnel (3). According to the sample grinder, sample grinding is thorough, time is short, samples and liquid nitrogen are saved, the probability of cross contamination is lowered, and the risk that a sample pipe explodes is eliminated.

Owner:广西作物遗传改良生物技术重点开放实验室

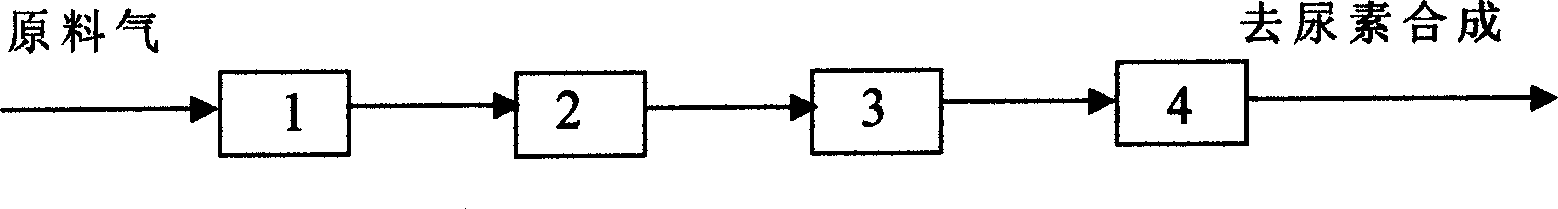

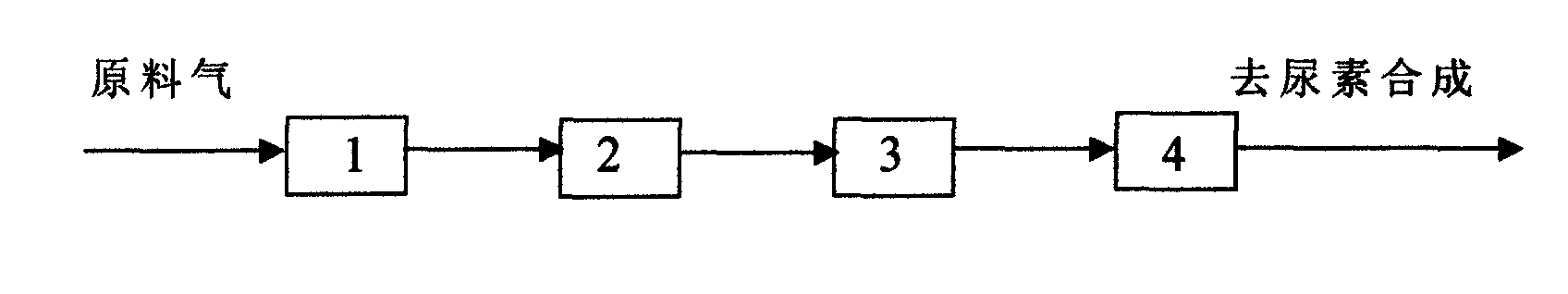

Dehydrogenation method of CO2 raw material gas for synthesizing urea

InactiveCN1367134ASimple processEliminate explosionUrea derivatives preparationCarbon compoundsActivated carbonUrea

A dehydrogenation method of CO2 charge gas for synthesizing urea includes the following steps: firstly, using active carbon or iron oxide normal-temp. desulfurizer to remover H2S from CO2 charge gas,then using the normal-temp. hydrolyst to hydrolyze orgnaic sulfur at 40-100 deg.C, then using active carbon or iron oxide refined desulfurizer to make desulfurization up to total sulfur content in the gas be less than 0.5 ppm, then using dehydrogenation catalyst containing Pt-Pd dual noble metals or TH-3 type rare earth metal element-contained Pt-Pd dual noble metals dehydrogenation catalyst to mare dehydrogenation, removing H2 from CO2 charge gas and making H2 content be less than 300 ppm under the conditions of that its inlet temp. is 120-250 deg.C and pressure is les sthan 20 MPa. The saidmethod is applicable to urea plant using coal or heavy oil to produce gas, can eliminate the hazard due to accumulation of H2, and can prolong catalyst life to about 5 years.

Owner:HAISO TECH

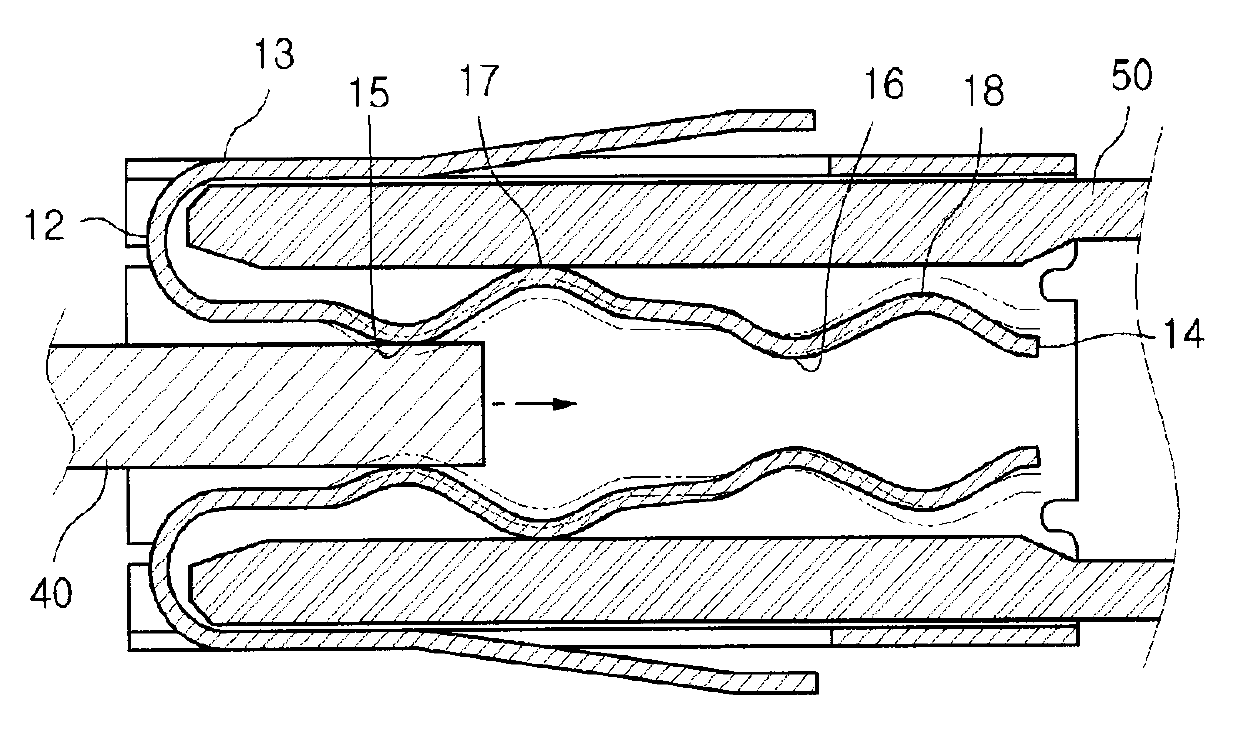

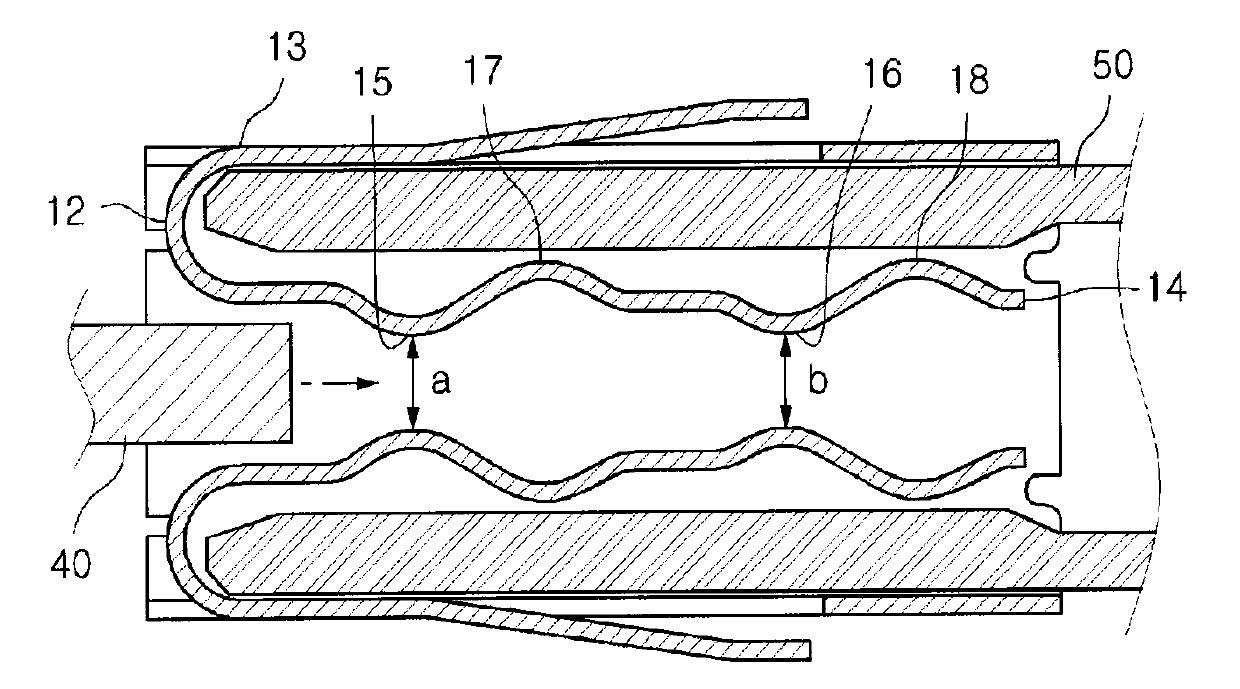

Connector terminal

ActiveCN102668265AAvoid sparksEliminate explosionElectric/fluid circuitMulticonductor cable end piecesEngineeringTerminal unit

Disclosed herein is a connector terminal. The connector terminal has a coupling terminal unit including upper and lower coupling terminal parts each of which contacts a connection terminal unit and a connection body terminal unit at two or more contact points, respectively. The two or more contact points include at least two inside contact points formed at each of the upper and lower coupling terminal parts of the coupling terminal unit such that the at least two inside contact points protrude inward of the coupling terminal unit and at least two outside contact points formed at each of the upper and lower coupling terminal parts of the coupling terminal unit such that the at least two outside contact points protrude outward of the coupling terminal unit.

Owner:TYCO ELECTRONICS AMP KOREA

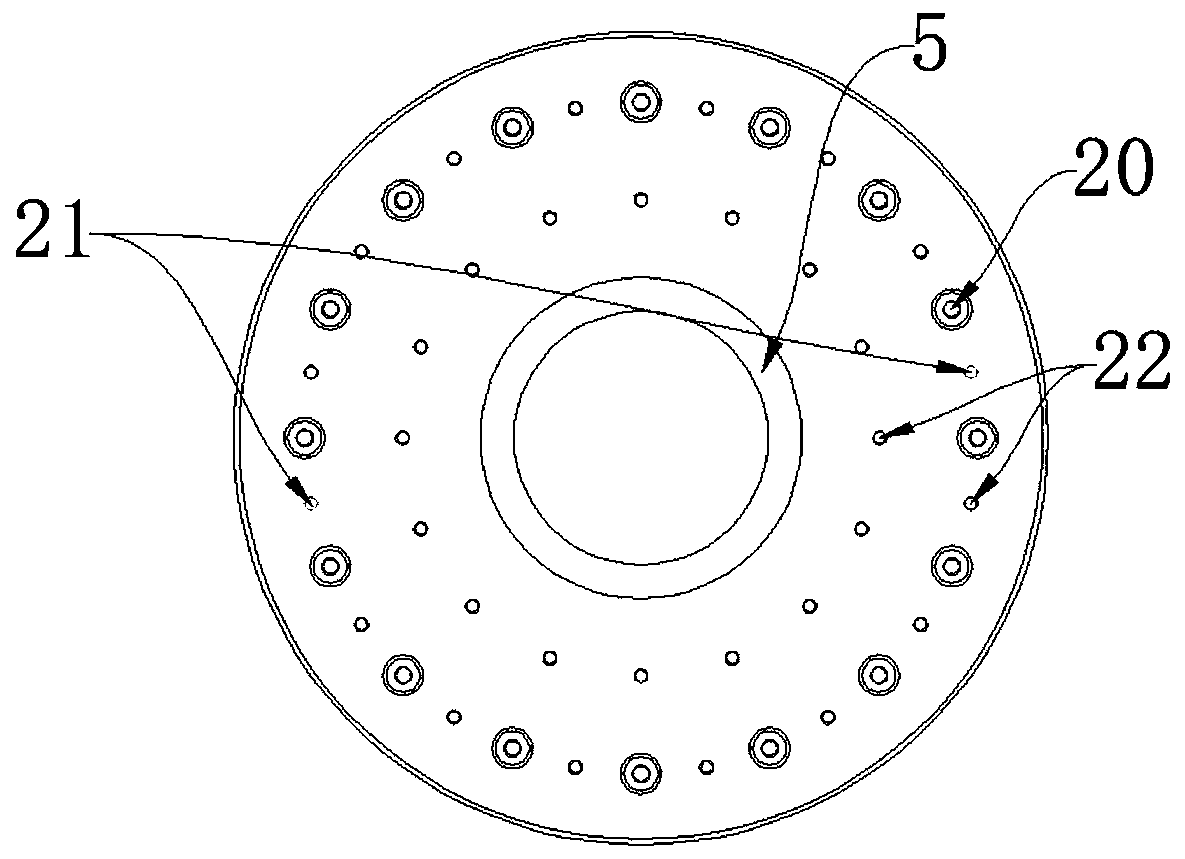

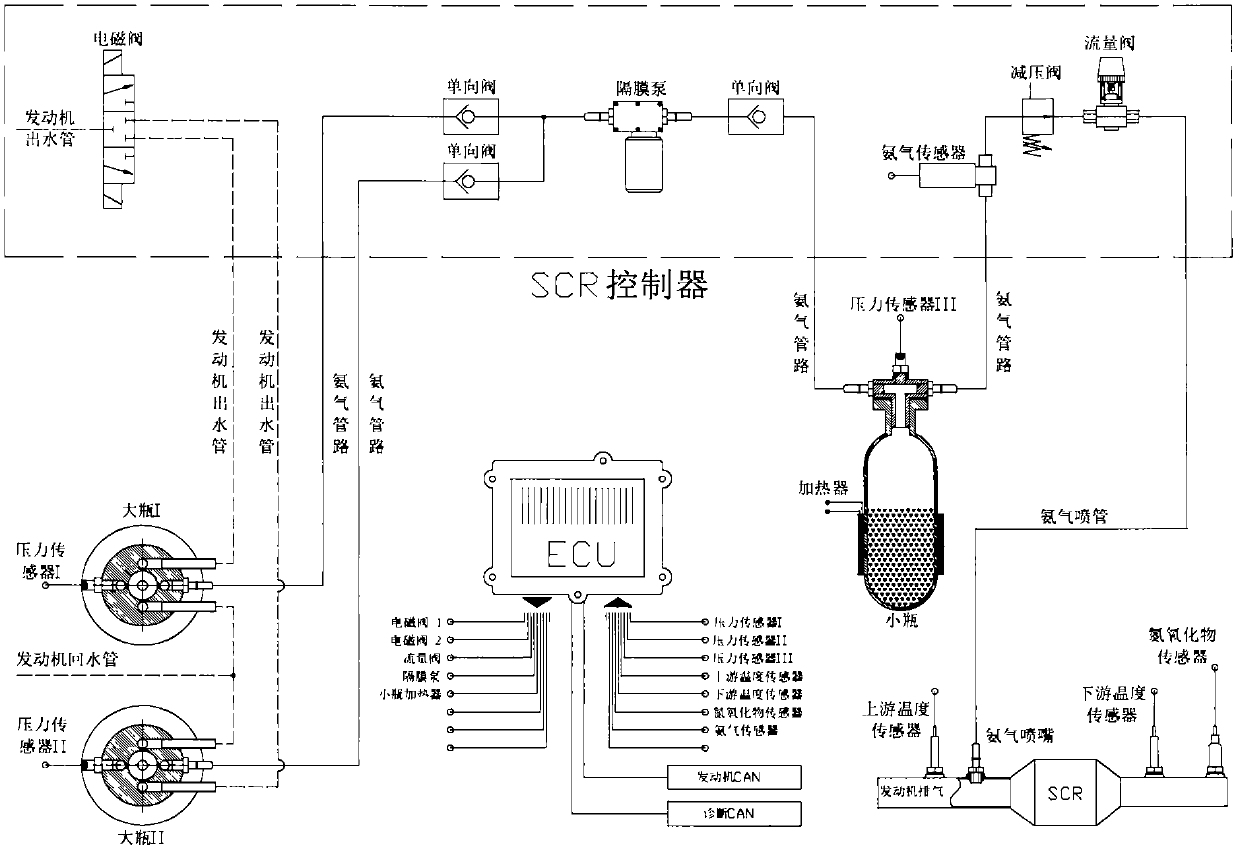

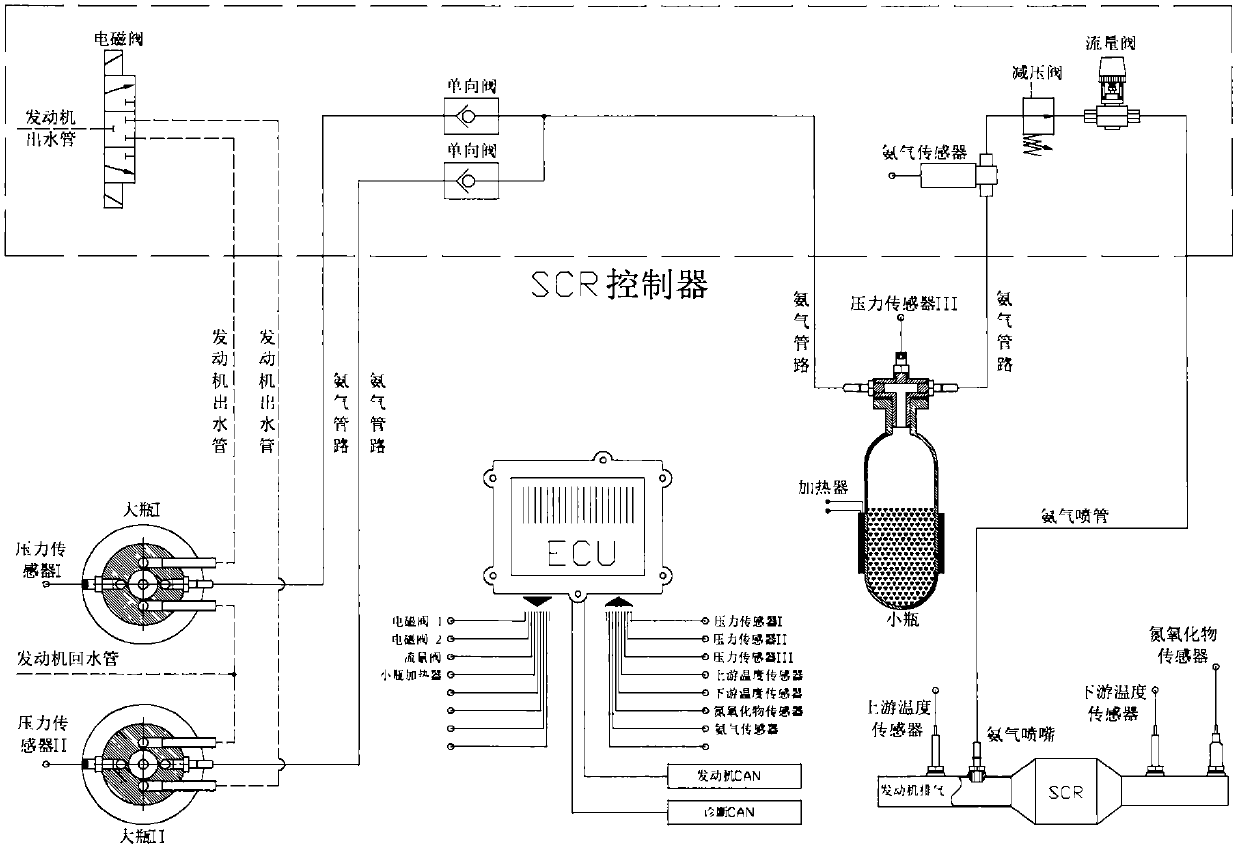

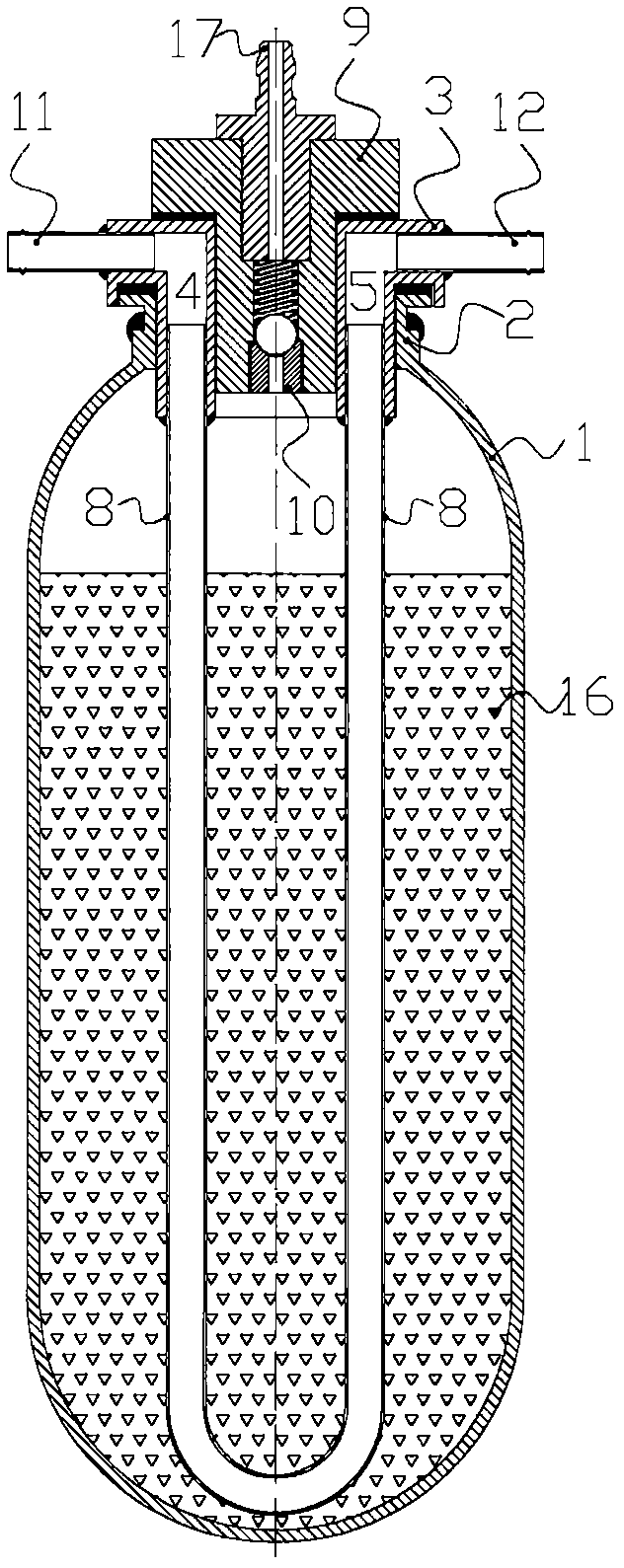

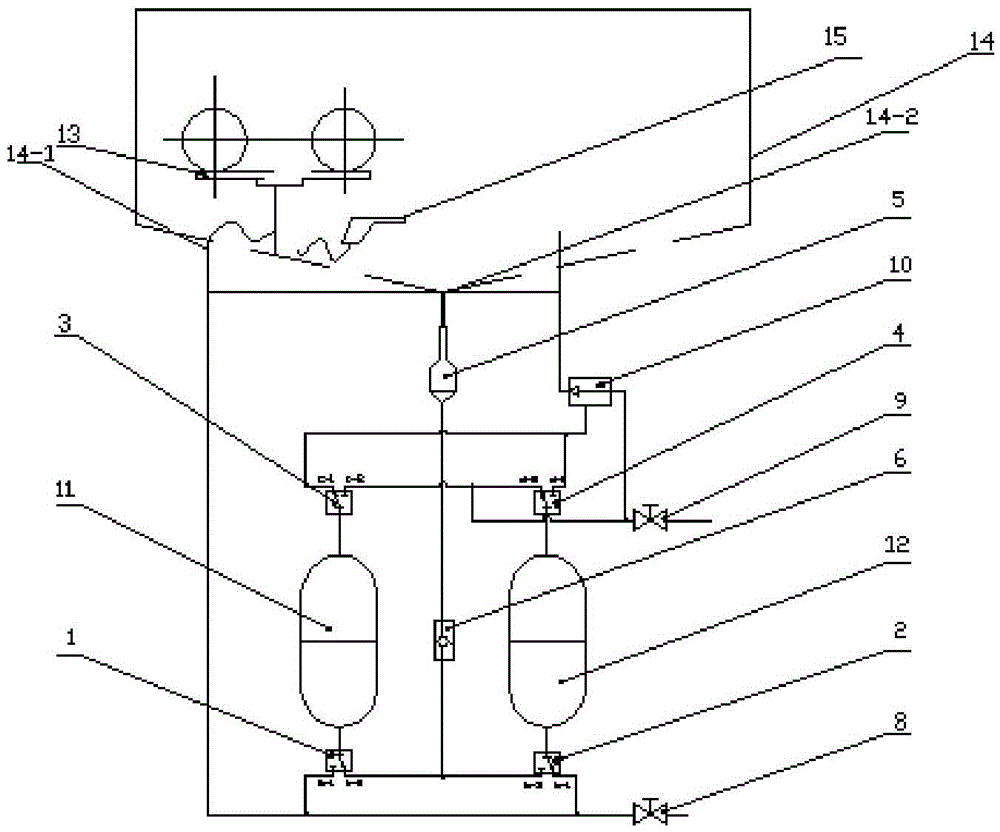

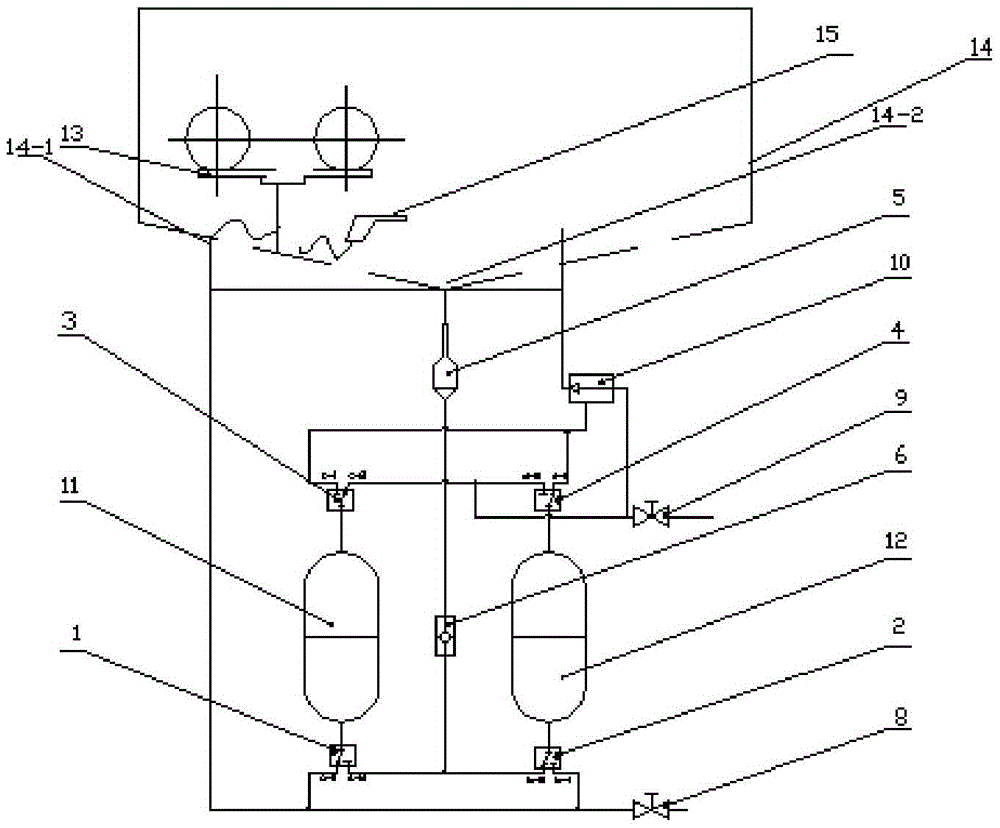

Diesel engine tail gas aftertreatment SCR ammonium bicarbonate injection system

InactiveCN110500162AAvoid pollutionAvoid mixingInternal combustion piston enginesExhaust apparatusWater vaporVehicle miles of travel

The invention discloses a diesel engine tail gas aftertreatment SCR ammonium bicarbonate injection system. The diesel engine tail gas aftertreatment SCR ammonium bicarbonate injection system is characterized in that ammonium bicarbonate replaces a traditional urea solution to serve as matter for providing an SCR reducing agent ammonia gas; the solid ammonium bicarbonate is heated with hot water ofan engine and is pyrolyzed to generate ammonia gas, carbon dioxide and water, the three kinds of matter are all gaseous, and a mixture of the ammonia gas, the carbon dioxide and the water is sprayedinto a diesel engine exhaust pipe through an SCR controller; and the ammonia gas and NOx are subjected to a reducing reaction to generate harmless nitrogen gas and water, and therefore the aim of eliminating NOx in diesel engine tail gas is achieved. The ammonium bicarbonate replaces the urea solution, the problem of urea crystallization is solved firstly, and the problem that NOx cannot be treated with urea when the exhaust temperature is lower than 160 DEG C is solved secondly; and the ammonia content of the solid ammonium bicarbonate and the ammonia content of the urea solution are fundamental equivalent, the vehicle-miles of travel is equivalent when the ammonium bicarbonate is injected once and the urea solution is injected once, and the cost of the solid ammonium bicarbonate is lower.

Owner:梁天宇

Treatment method for removing benzene series in petrochemical industrial waste gas

ActiveCN105944494AOxidative decomposition is goodLow costCombination devicesGas treatmentBiological activationMixed gas

The invention discloses a treatment method for removing benzene series in petrochemical industrial waste gas. The waste gas sequentially passes through a waste heat exchanger, a gas overtemperature protection device, a thermal type gas mass flow meter, a mixed gas flow control valve, a bag filter, a tungsten coil surface activation-ozonation treatment device, a flue gas washing and purifying tower and an induced draft fan to be treated. Specific surface activation characteristics of ozone on the surface of metal elementary substance is creatively used, when a tungsten coil is in a power-on hot state, ozone can fast release activated oxygen atoms on the surface of the tungsten coil to generate a strong oxidization environment on the tungsten surface, when the benzene series and other molecules containing a conjugative effect C-C bond are in the strong oxidization environment, the conjugative C-C bond will be broken by the activated oxygen atoms, benzene series molecules are finally oxidized and decomposed into H2O, CO2 and other inorganic molecules, and the purpose of removing the benzene series in the waste gas is achieved.

Owner:东营国安化工有限公司

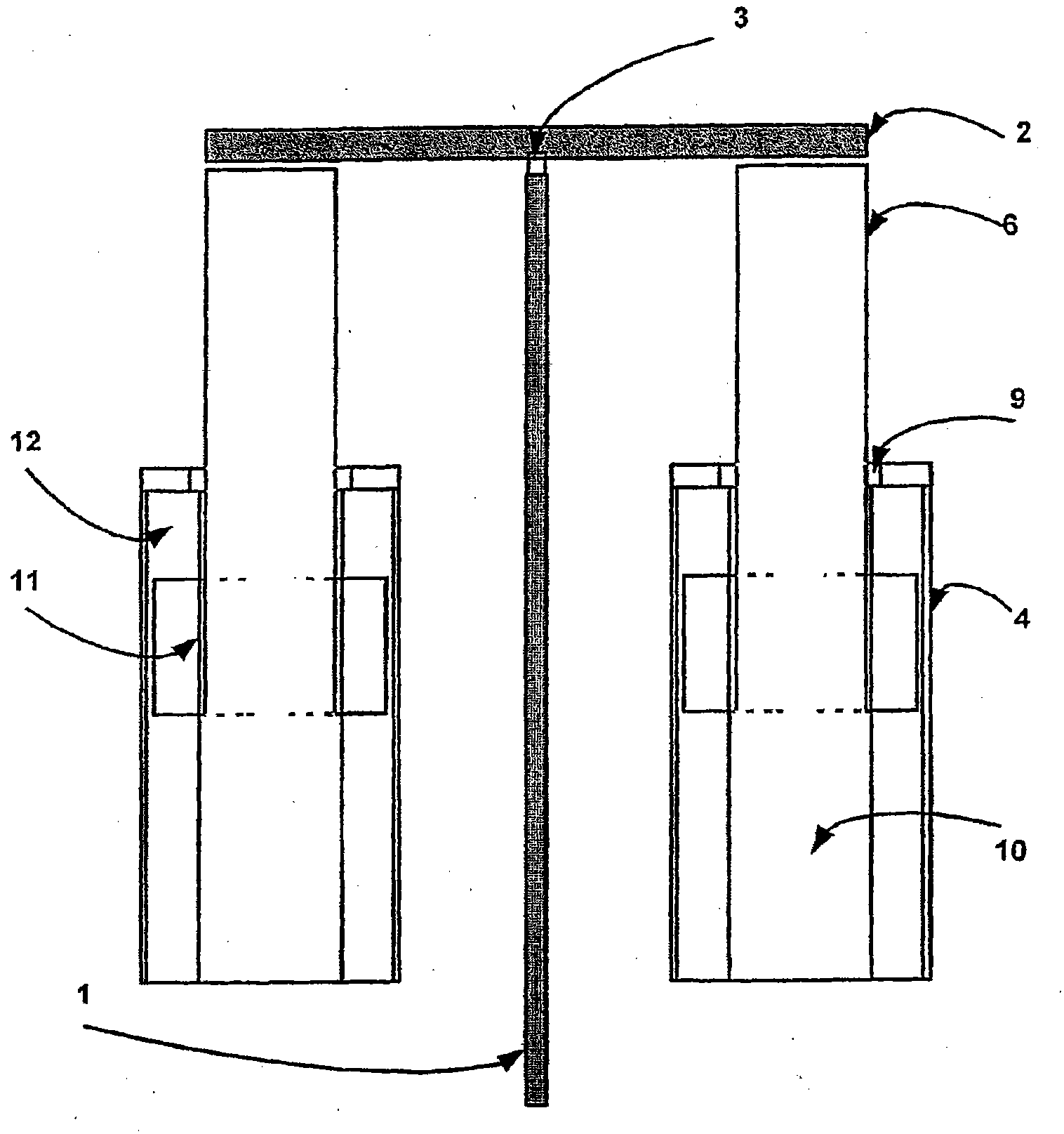

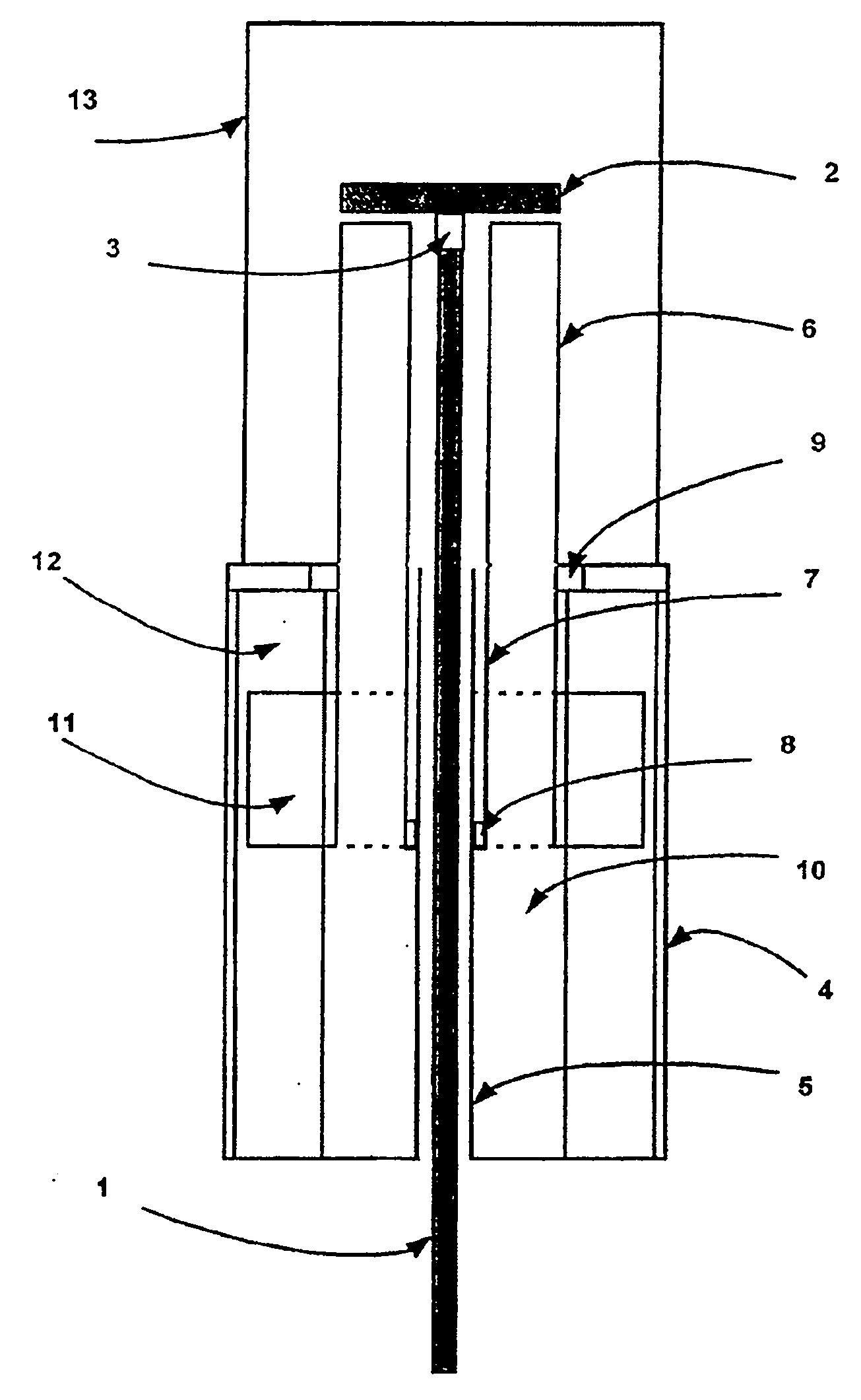

System for making plants for drying solid organic substances in aqueous phase capable of causing explosive reactions safe and process for drying said substances

ActiveUS7877896B2Eliminate the risk of explosionLow costDrying solid materials with heatDrying solid materials without heatHorizontal axisContinuous flow

The present invention refers to a process for drying solid organic substances in aqueous phase including the steps of:feeding a continuous flow of such organic substances having a water content=50% by weight into a turbodrier having a cylindrical tubular body with horizontal axis, equipped with inlet and outlet openings, a heating jacket for bring the inner wall of the tubular body to a predetermined temperature, a bladed rotor extending inside the cylindrical tubular body (1) where it is made to rotate at speeds between 15 and 40 m / s, so as to disperse the continuous flow of organic substances into a flow of particles of organic substances;centrifuging the particles of organic substances against the inner wall of the turbodrier heated to a temperature above 130° C., with formation of a thin, dynamic, highly turbulent tubular fluid layer, which advances substantially in contact with the inner wall of the turbodrier towards the outlet opening;continuously discharging, from the turbodrier, a flow of organic substances in disgregated wet solid form having a water content=45% by weight;continuously feeding the flow of disgregated wet solid into an drier operating at a temperature lower than or equal to 160° C.;continuously discharging a flow of dry product having a water content=20% by weight from the drier.

Owner:GEOLINE

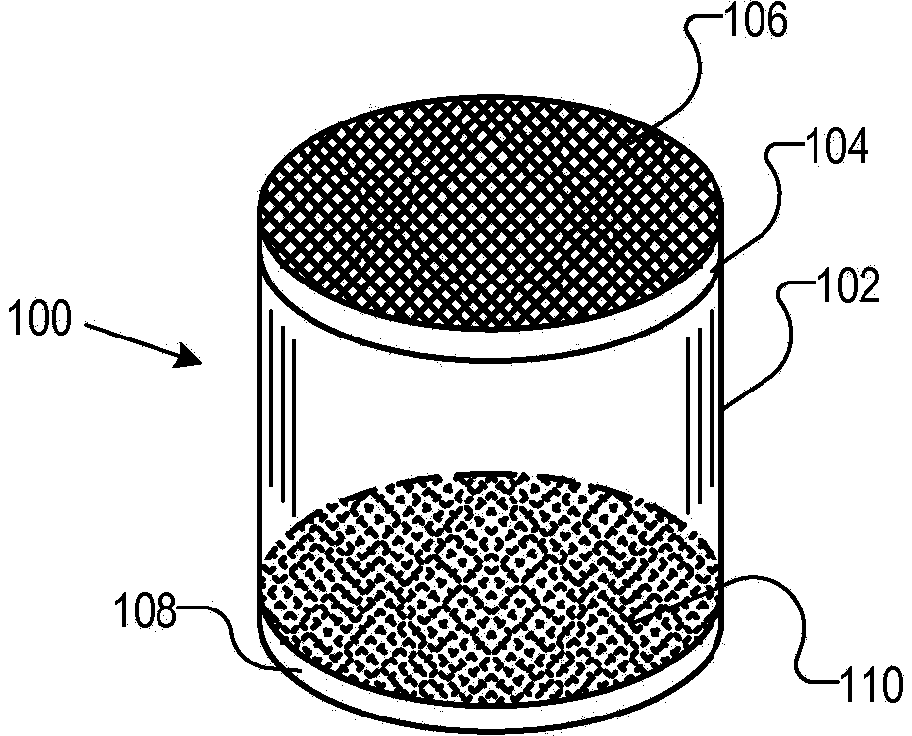

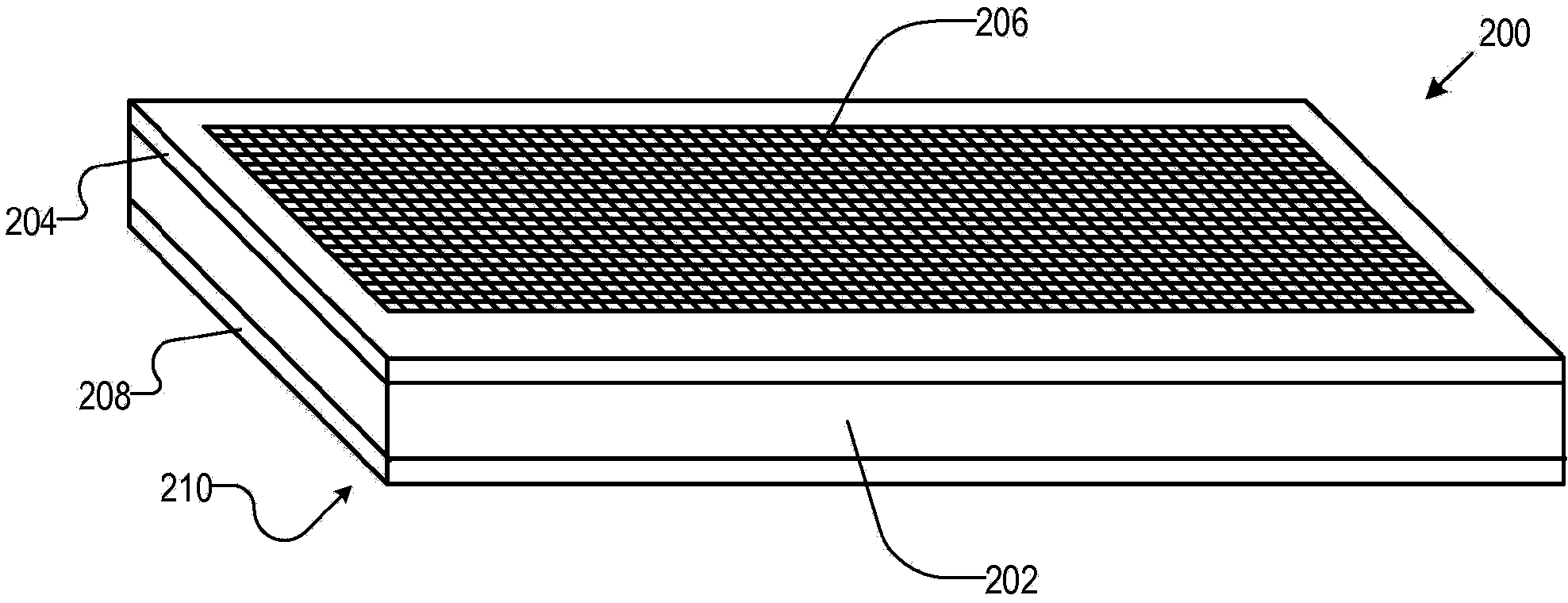

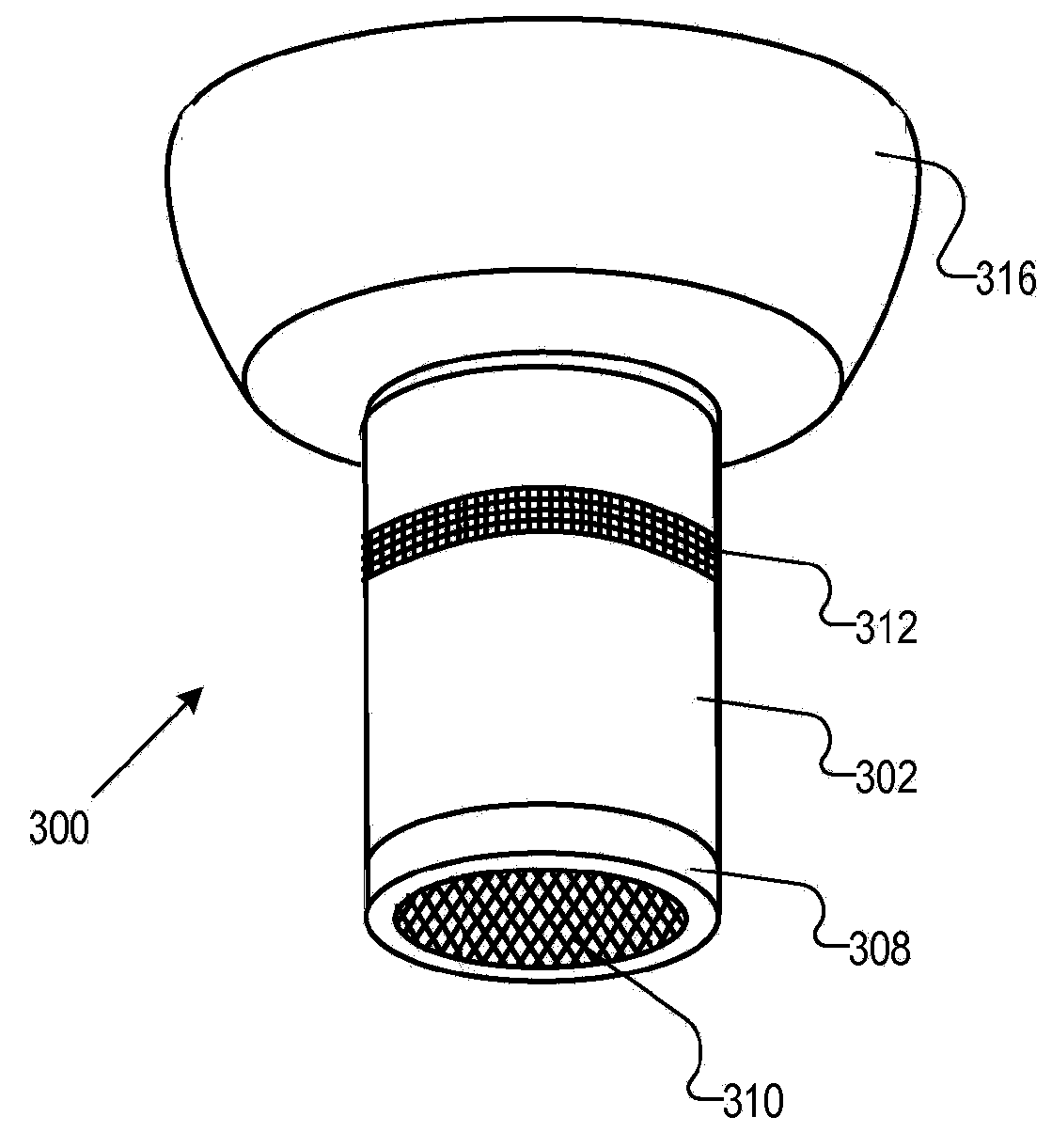

System and method for generating chlorine dioxide

ActiveCN102811946BAvoid accumulationEliminate the risk of explosionChlorine dioxideChlorine dioxideSuper absorbent

Some systems for generating chlorine dioxide include a chlorine-dioxide generating composition comprising an alkali chlorite salt, acid, cellulose, a super absorbent, and optionally a surfactant. Systems disclosed herein are able to generate chlorine-dioxide gas, chlorine-dioxide solution, and chlorine-dioxide solution with surfactants. Some systems for generating chlorine dioxide include a canister containing a chlorine-dioxide generating composition. The canister includes at least one porous region that places an exterior of the canister in fluidic communication with an interior of the canister. The porous region, which in some embodiments, is realized as a mesh, is characterized by a size in a range of about 20 mesh to about 325 mesh.

Owner:SIPKA

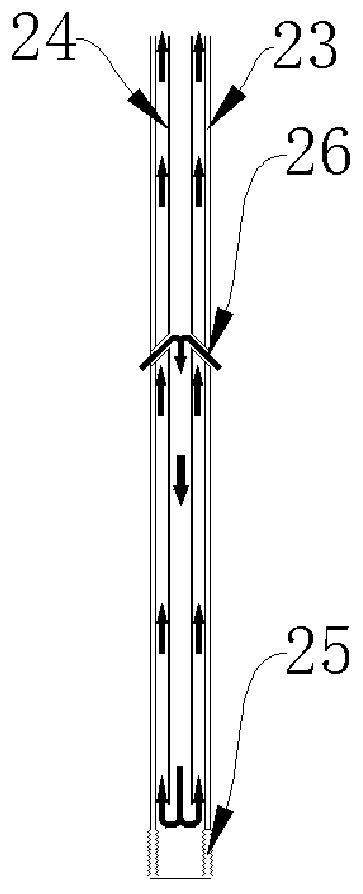

Artificial lift mechanisms

InactiveCN101815871AAvoid contactEliminate fire riskConstructionsFlexible member pumpsGas springEngineering

Owner:CROSTEK MANAGEMENT CORP

Phosphorus-germanium-zinc polycrystal pressurized synthesis device and synthesis method

PendingCN111424316AEasy to adjustReduce the pressure difference inside and outside the quartz ampoulePolycrystalline material growthSingle crystal growth detailsSynthesis methodsCrucible

The invention relates to a phosphorus-germanium-zinc polycrystal pressurized synthesis device and synthesis method, wherein the device comprises a main body furnace body and an ampoule; the main bodyfurnace body comprises an inner furnace body, an outer-layer heating device, air pressure control devices, cooling devices and a sealing flange; the interior of the inner furnace body is divided intonine temperature zones in the axial direction, the cooling devices and the outer-layer heating device wrap the periphery of the inner furnace body in a surrounding mode and are arranged at the corresponding positions of the temperature zones of the inner furnace body, and the air pressure control devices are arranged at the two ends of the inner furnace body. The ampoule comprises a protection container, a synthesis container and a crucible; the ampoule is placed in the inner furnace body by taking a limiting spacer as a support; when the device is used for synthesizing phosphorus-germanium-zinc polycrystal, the internal and external pressure difference of the quartz ampoule in the synthesis process is reduced, the explosion risk caused by out-of-control phosphorus saturated vapor pressureis eliminated, and large-batch synthesis can be carried out at a time; the ampoule protection container can limit the position of the synthesis container, the limiting spacer can also play a role ofa supporting frame, and free adjustment can be conducted according to the sizes of different ampoules and the positions of temperature zones.

Owner:CHINA ELECTRONICS TECH GRP NO 46 RES INST

Compressed air type mechanical part cleaning machine and use method thereof

ActiveCN105057263ASpeed up filteringNo high temperatureCleaning using liquidsMechanical componentsMachine parts

The invention relates to the field of production and manufacturing, and particularly relates to a compressed air type mechanical part cleaning machine, and the invention further provides a use method of the compressed air type mechanical part cleaning machine. The compressed air type mechanical part cleaning machine comprises a cleaning chamber and a cleaning liquid circulating system, wherein the cleaning chamber is provided with a workbench, a spray gun, a cleaning chamber inflow opening and a cleaning chamber outflow opening, and the cleaning chamber inflow opening and the cleaning chamber outflow opening are connected with the spray gun; the cleaning liquid circulating system comprises a cleaning liquid filter, a check valve, a pressure vessel and a liquid storage tank; through the conversion of four three-way valves, the pressure vessel and the liquid storage tank alternately realize the functions of a cleaning tank and the liquid storage tank by utilizing a vacuum generator and compressed air. The cleaning machine is not provided with an electric control system, so that the risk of sparks is avoided; a driving component is not arranged in the whole cleaning machine, so that high temperature of the cleaning machine cannot happen, thereby avoiding the risks of burning and explosion of a common small cleaning machine, and the effects of safety and no hidden danger are really achieved.

Owner:ZHEJIANG SIEKON PRECISION MACHINERY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com