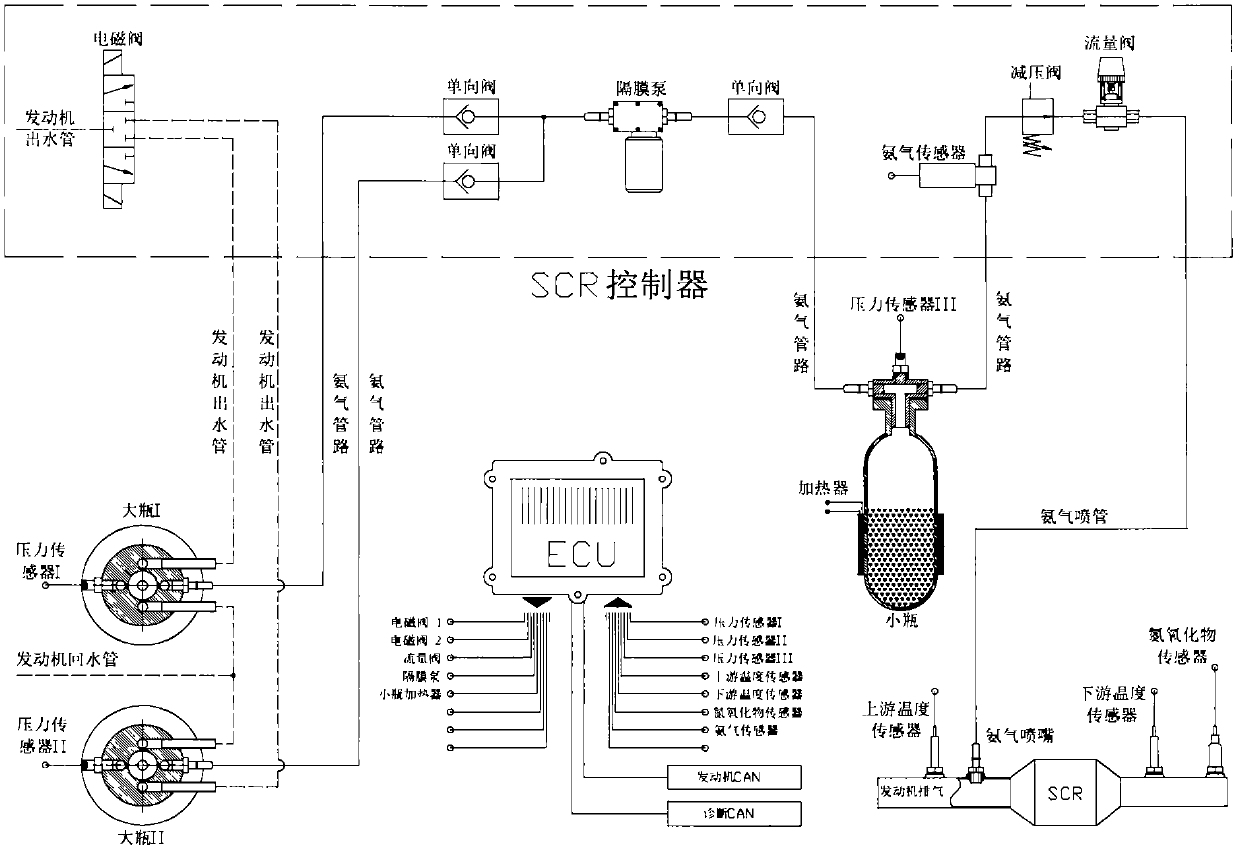

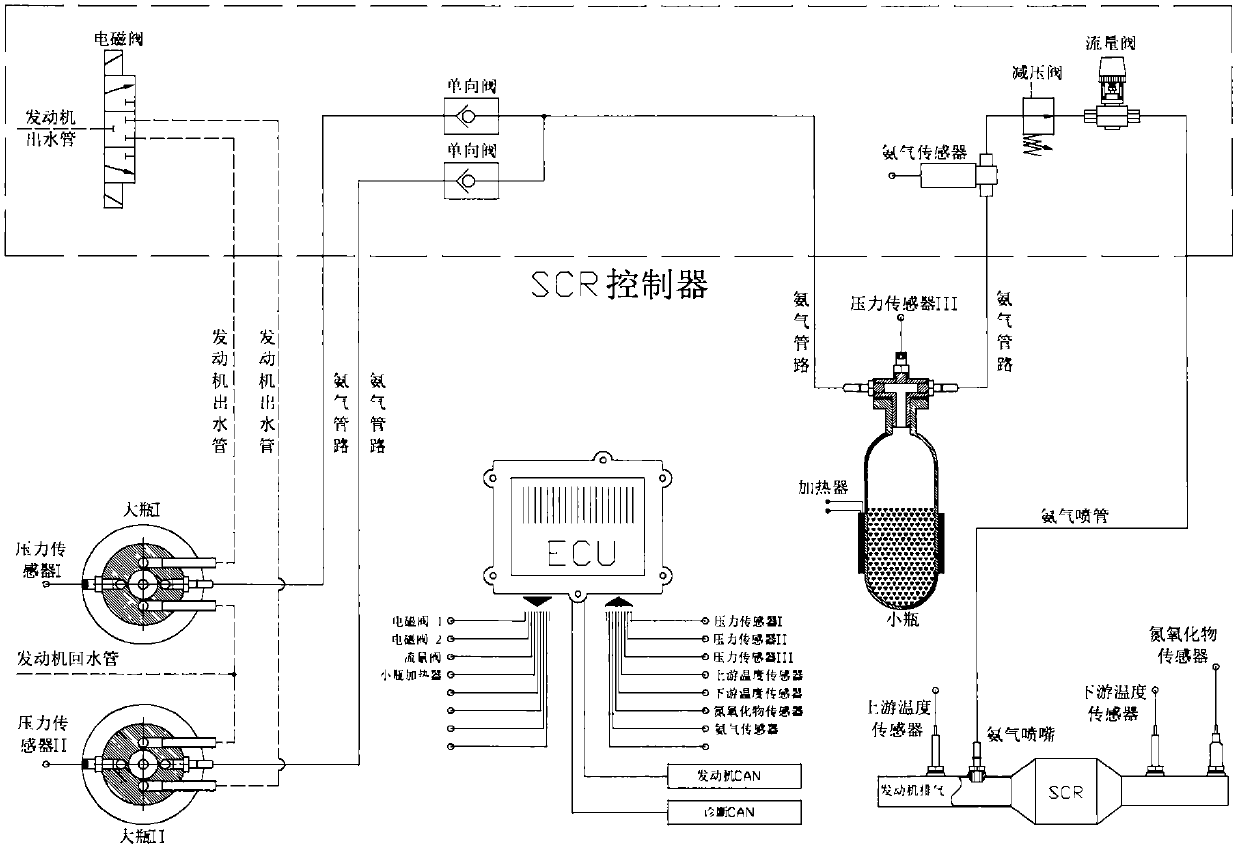

Diesel engine tail gas aftertreatment SCR ammonium bicarbonate injection system

A tail gas post-treatment and ammonium bicarbonate technology, which is applied in exhaust gas treatment, mechanical equipment, exhaust devices, etc., can solve the problems of immature technology, reduction, and unsound supporting facilities, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

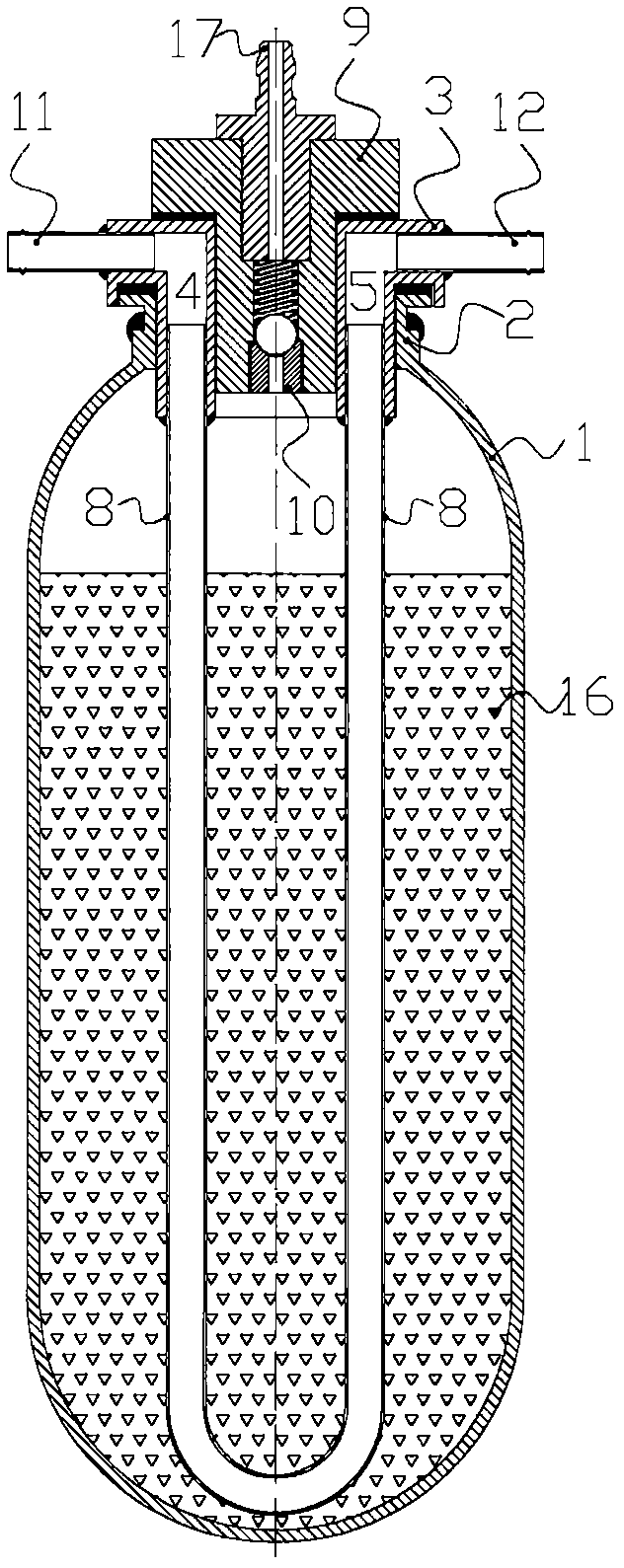

[0024] Cold start stage: the SCR ammonium bicarbonate injection system first heats the vial, and the heater is energized by the ECU through the car power supply. In a short period of time, generally less than 2 minutes, the vial will generate ammonia gas and reach a certain pressure, which is controlled by the ECU. The flow valve is opened, and the high-pressure gas in the small bottle passes through the flow valve, passes through the ammonia nozzle and the ammonia nozzle, and is sprayed into the exhaust pipe of the car to clean up the NOx in the exhaust. The large bottle does not work during the cold start stage.

[0025] Normal driving stage: When the water temperature rises to a certain temperature, at least 60 degrees, the engine ECU will turn off the heater, and the ECU will control the solenoid valve to supply hot water to the large bottle I or large bottle II, and heat one of the large bottles, ammonium bicarbonate Pyrolysis produces ammonia, carbon dioxide and water, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com