Multi-section spiral moving bed pyrolysis gasification device

A technology of pyrolysis gasification and moving bed, which is applied in the direction of spiral gasifier, horizontal gasifier, gasification process, etc., which can solve the problem of complicated system operation control and detection methods, uneven biomass reaction and easy coking , The pyrolysis process is not easy to be controlled by humans, etc., to achieve the effect of taking into account economy and system operation reliability, not easy to local over-temperature and coking, and ensuring availability and selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0036] In the present invention, the reactors in the drying section, the reactors in the pyrolysis section and the reactors in the gasification section are sequentially connected in series to form multiple independent reaction sections, so as to ensure the independent and continuous operation of each section of bellows, and realize the precise control of the material pyrolysis and gasification process. The structure of the present invention will be described in detail below using specific implementation methods.

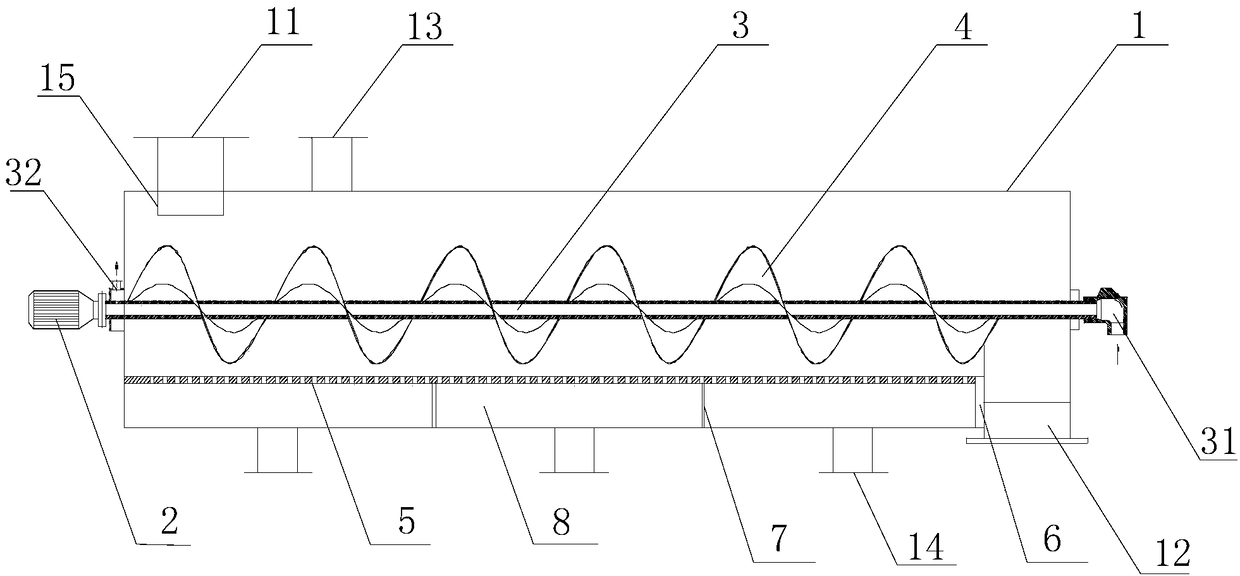

[0037] Please refer to Figure 1 to Figure 5 , a multi-stage spiral moving bed pyrolysis gasification device, including a drying section reaction 100, a pyrolysis section reactor 200 and a gasification section reactor 300, the drying section reactor 100 is used to dry materials, and the pyrolysis section The reactor 200 is used to perform pyrolysis treatment on the material, and the reactor 300 in the gasification section is used to perform gasification treatment on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com