Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

54results about "Screw type gasifiers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

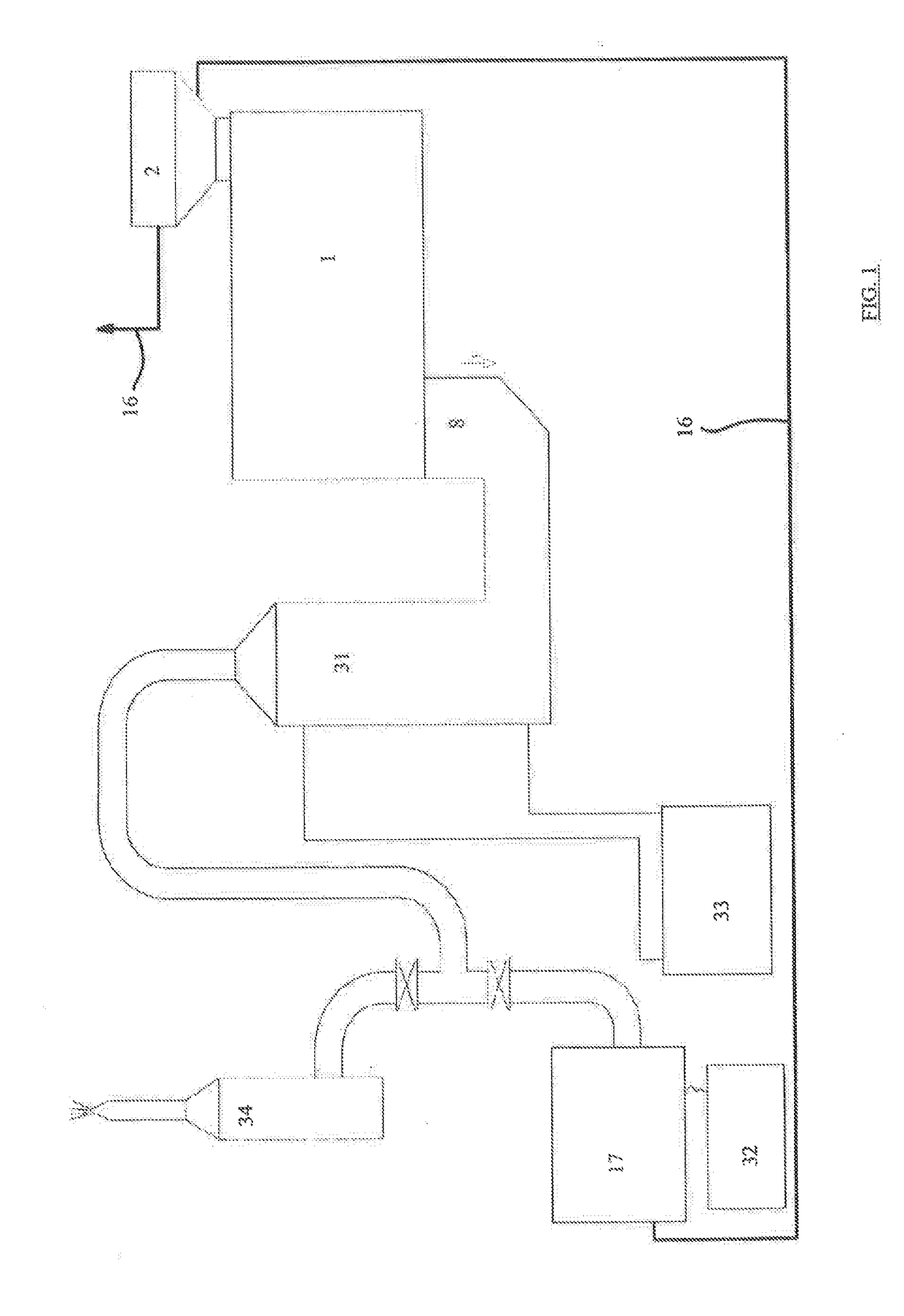

Process and system for converting carbonaceous feedstocks into energy without greenhouse gas emissions

ActiveUS20070099038A1High hydrogen contentFuel cells groupingHydrogen separation using solid contactPetroleum cokePetroleum

The process of the invention converts carbonaceous feedstock such as coal, hydrocarbon oil, natural gas, petroleum coke, oil shale, carbonaceous-containing waste oil, carbonaceous-containing medical waste, carbonaceous-containing military waste, carbonaceous-containing industrial waste, carbonaceous-containing medical waste, carbonaceous-containing sewage sludge and municipal solid waste, carbonaceous-containing agricultural waste, carbonaceous-containing biomass, biological and biochemical waste, and mixtures thereof into electrical energy without the production of unwanted greenhouse emissions. The process uses a steam / CO2 reformer operating in the exit range of at least 700° to about 1600° C. (1300-2900°0 F.) to convert the carbonaceous feedstock and a greenhouse gas stream into a synthesis gas comprising mostly carbon monoxide and hydrogen that contains poisons and the compounds that poison fuel cells. The syngas is sent to an interface zone to remove these poisons and other fouling compounds that are electrochemically oxidized in an electricity-producing fuel cell into an exit gas comprising carbon dioxide and water.

Owner:RAVEN SR INC

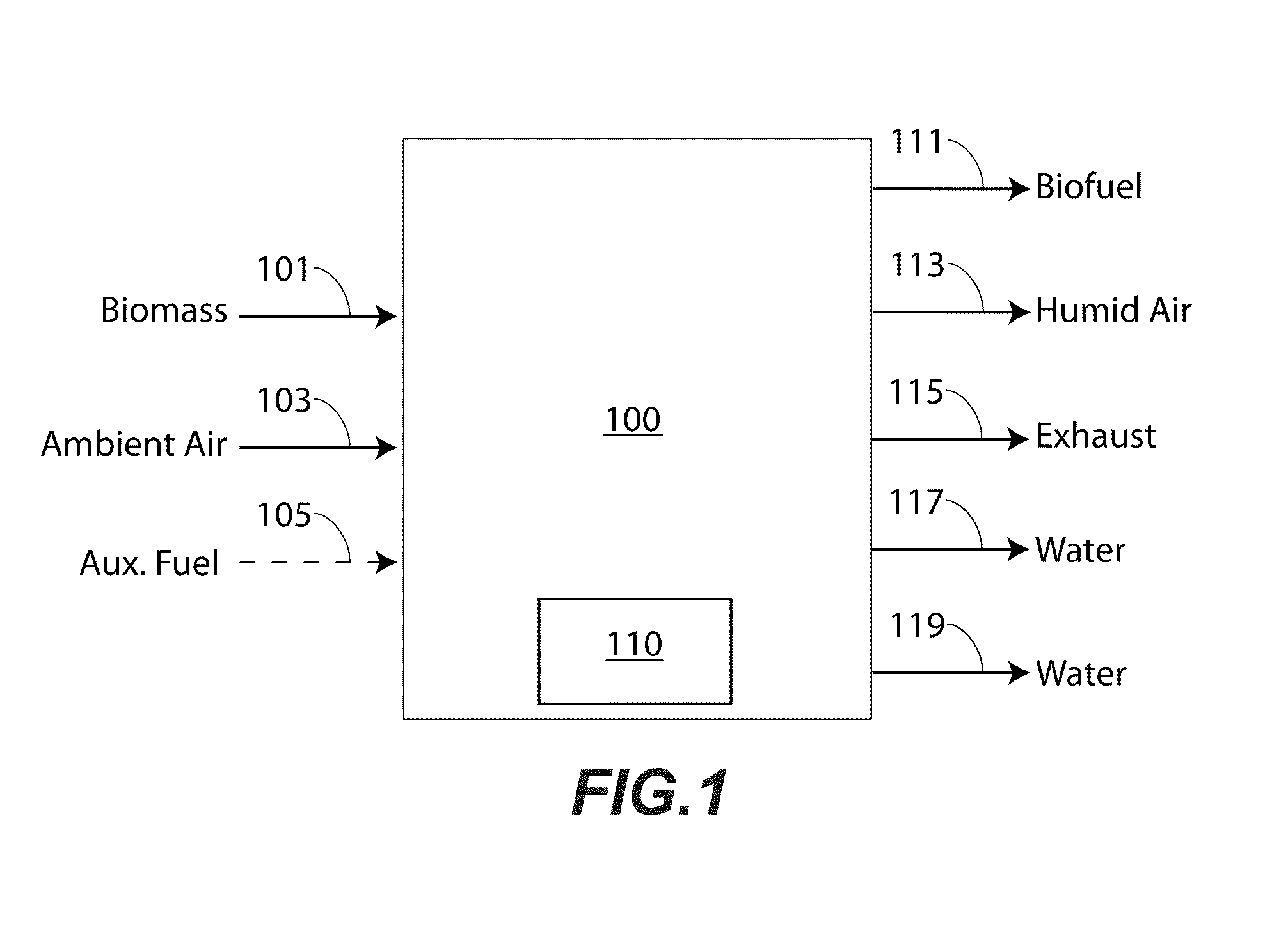

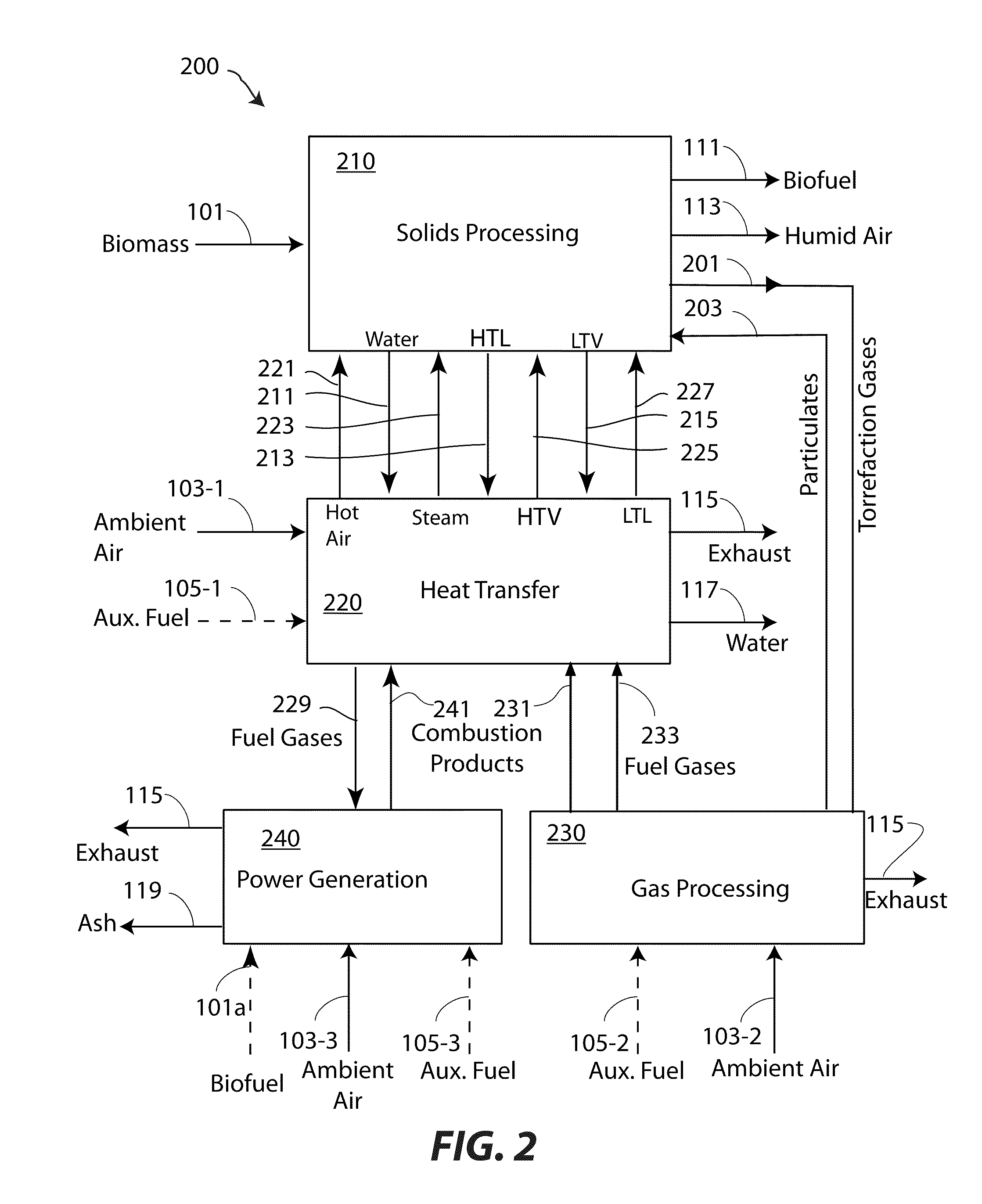

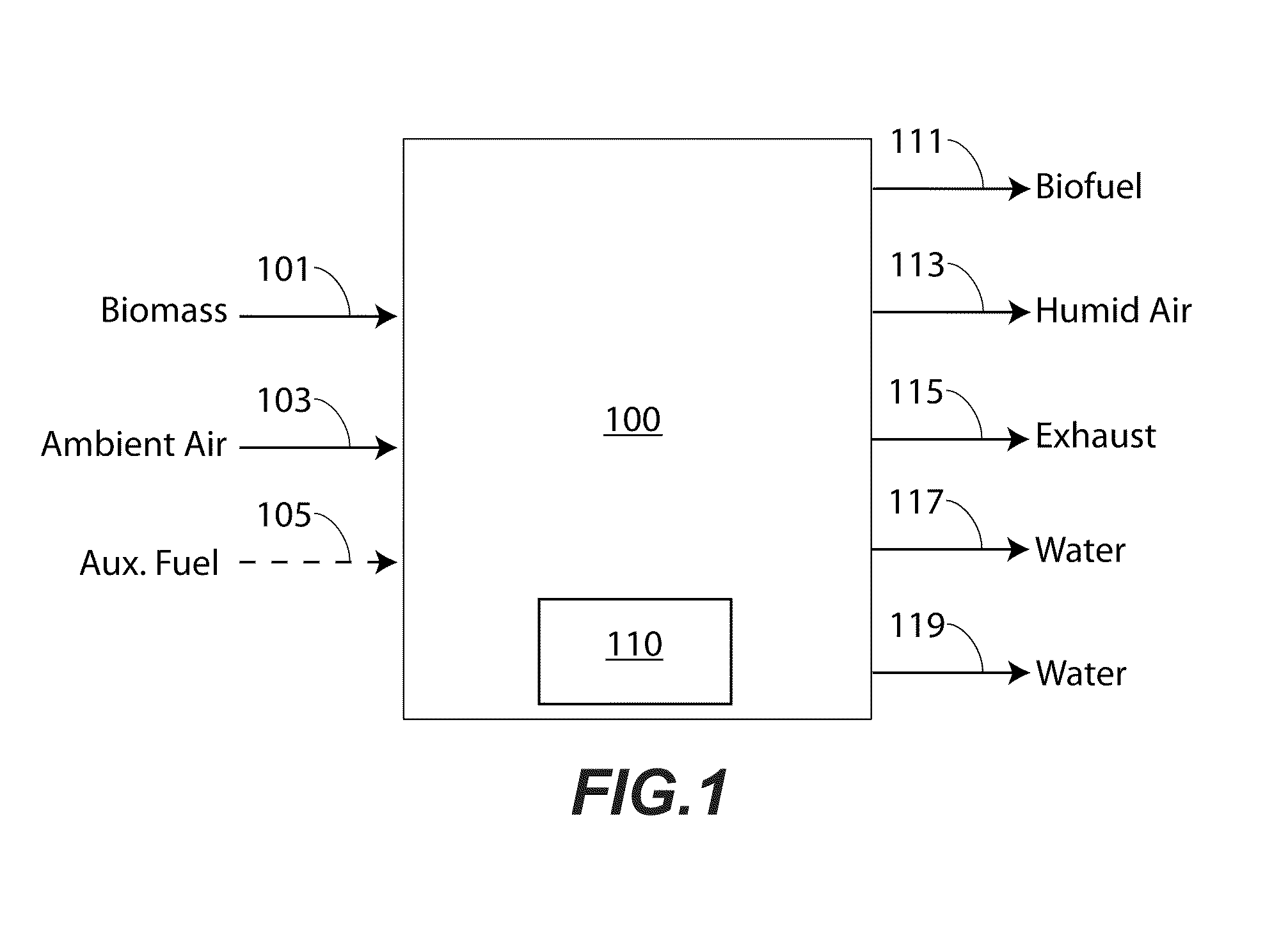

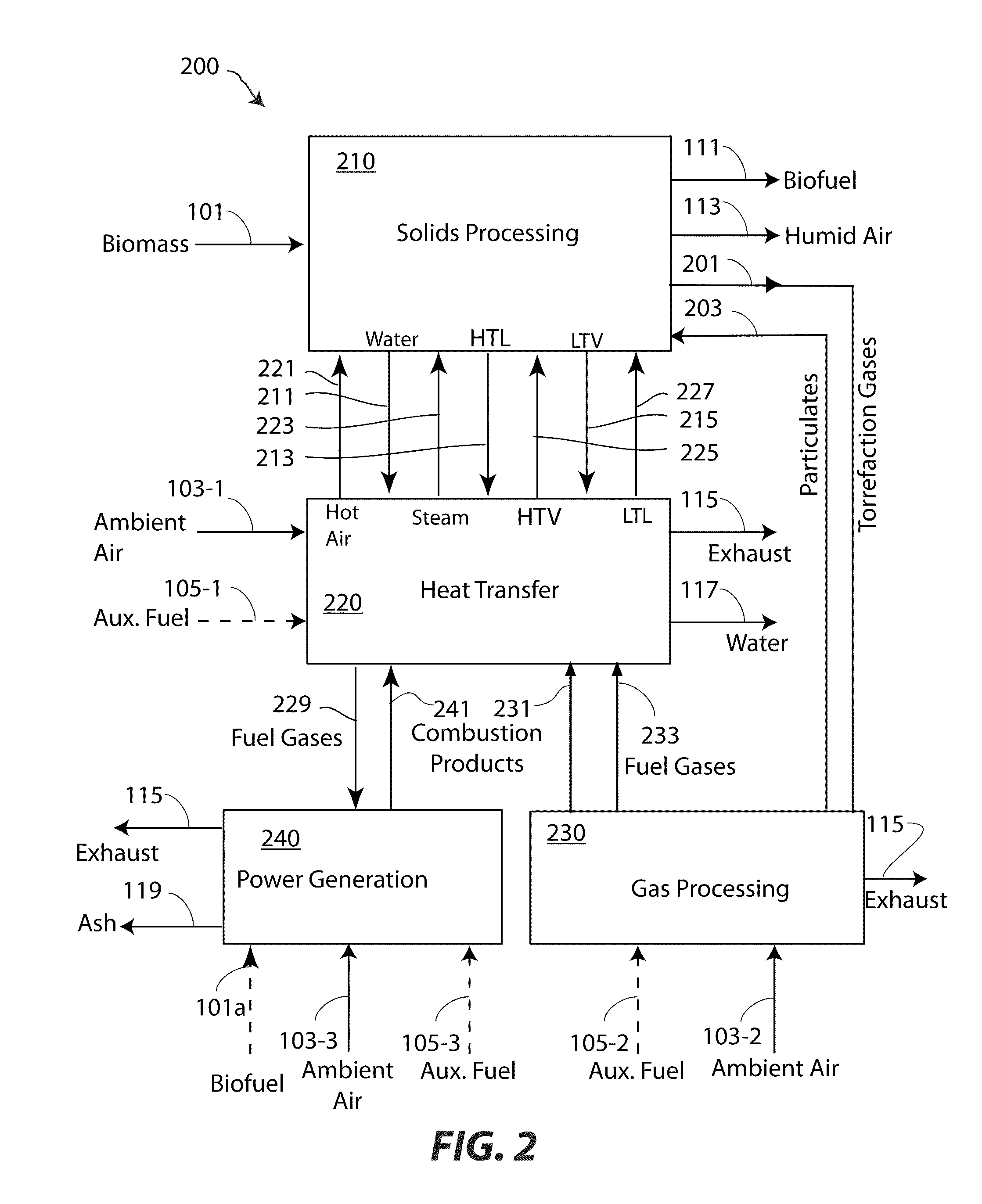

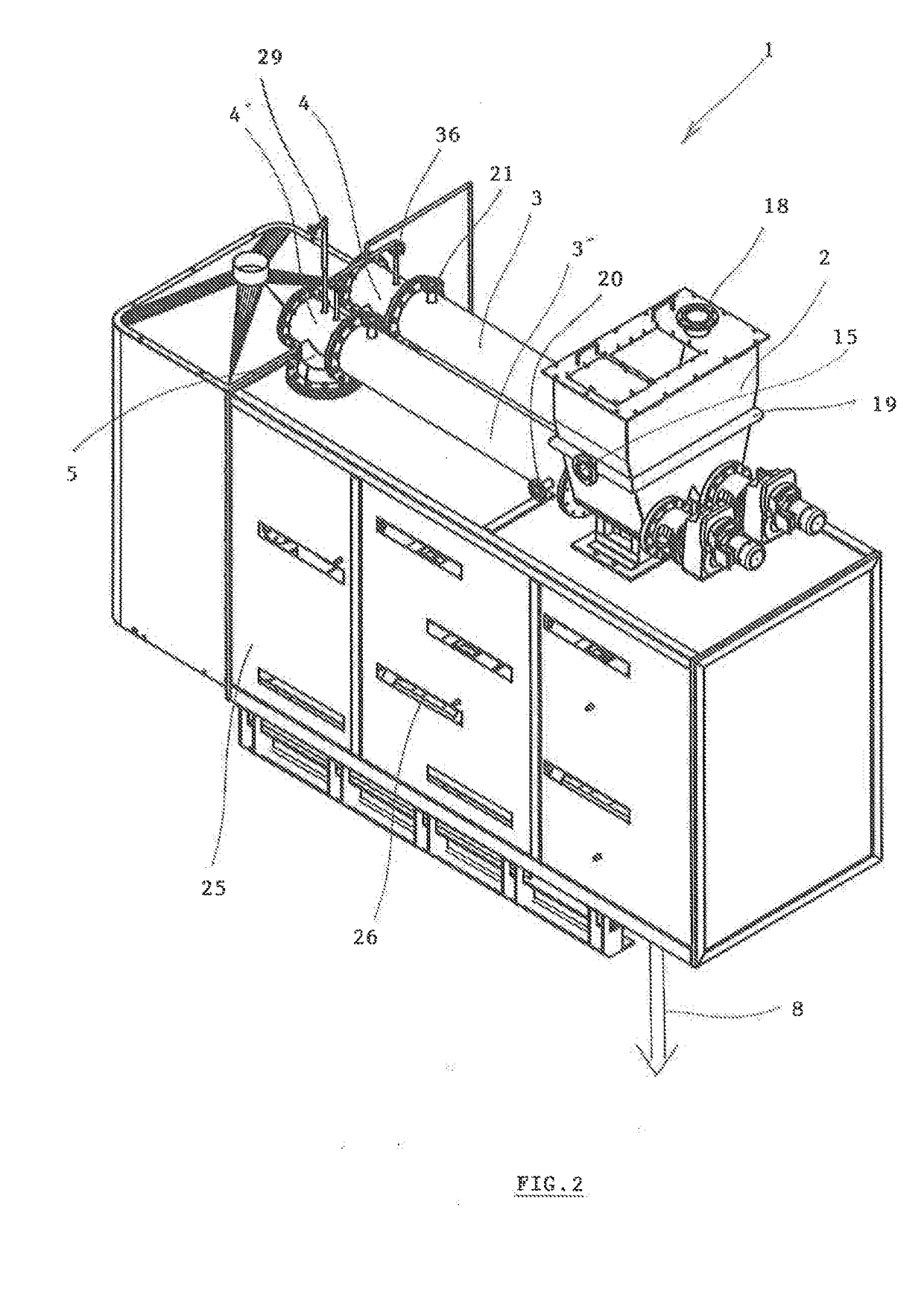

Device and method for conversion of biomass to biofuel

Embodiments presented herein describe an apparatus and method to convert carbonaceous materials, particularly biomass and those biomass resources which are remotely located, into a high performance solid fuel. This method, and the apparatus described as the means to accomplish this method, provides a continuous process which can be completely powered by the energy contained in the biomass. The heat, mechanical power and electrical power are provided from the energy in the biomass, through the methods described. In this way, the apparatus is free to operate in remote locations, where no power or auxiliary fuel sources are available.

Owner:RENEWABLE FUEL TECH

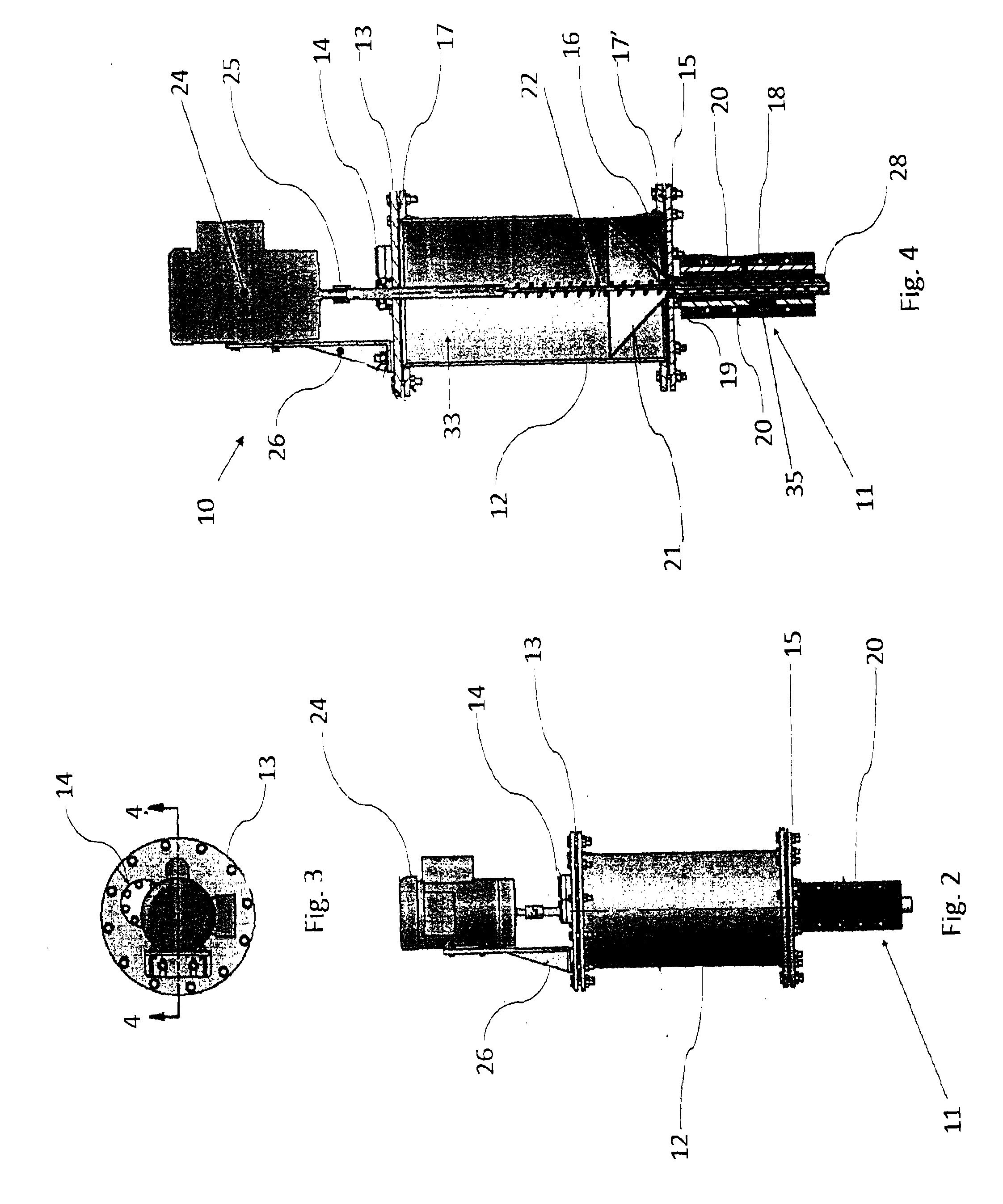

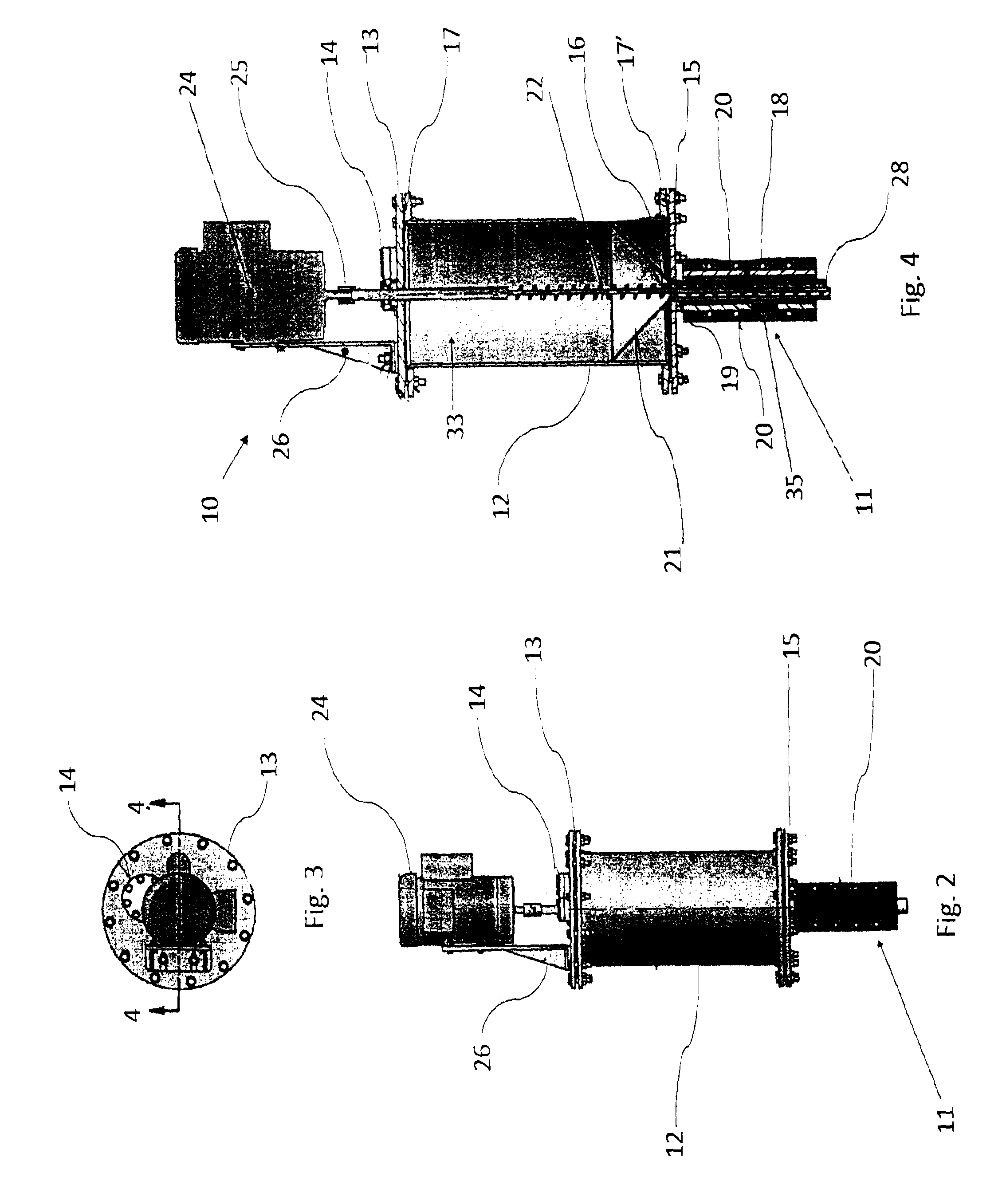

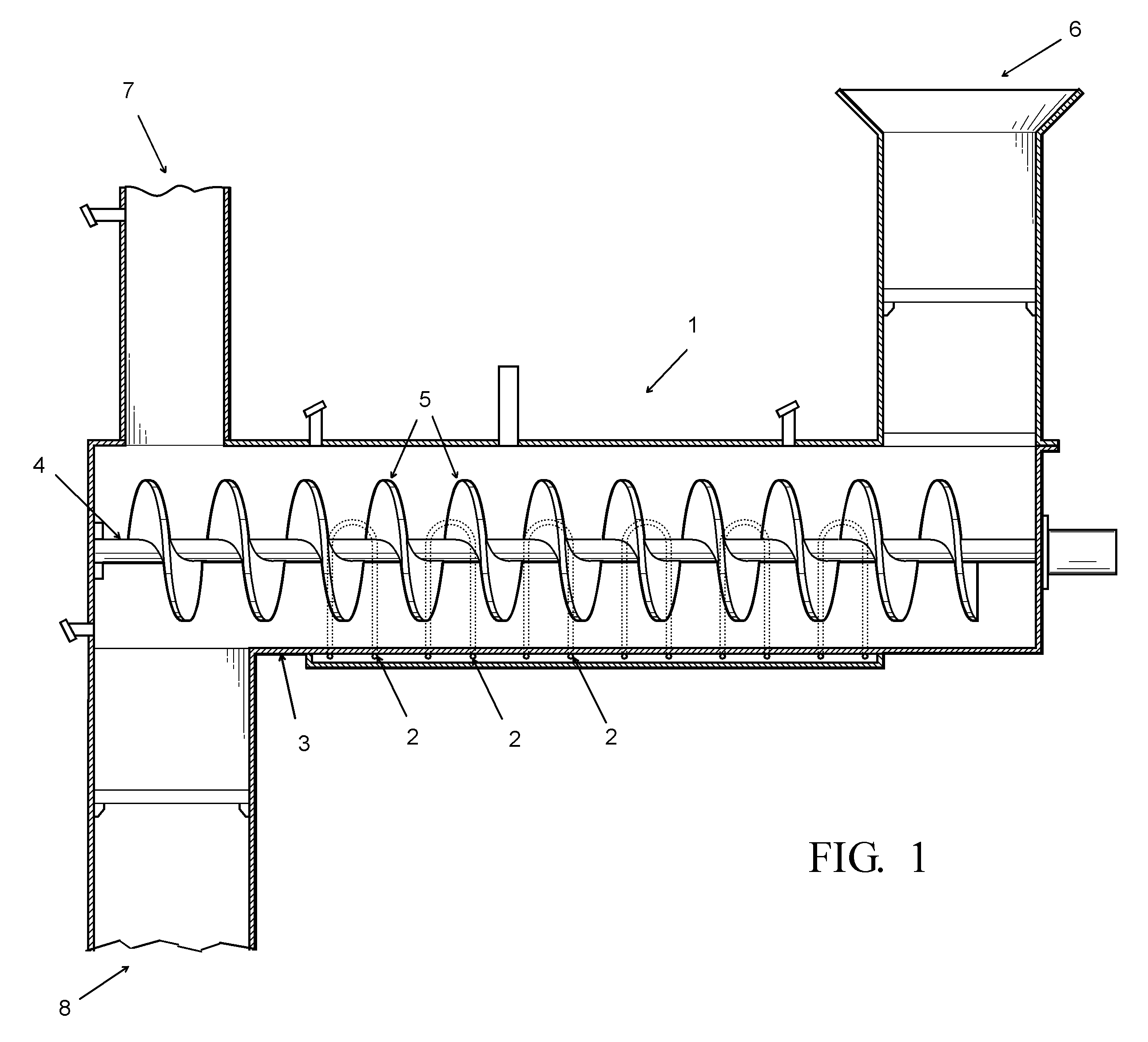

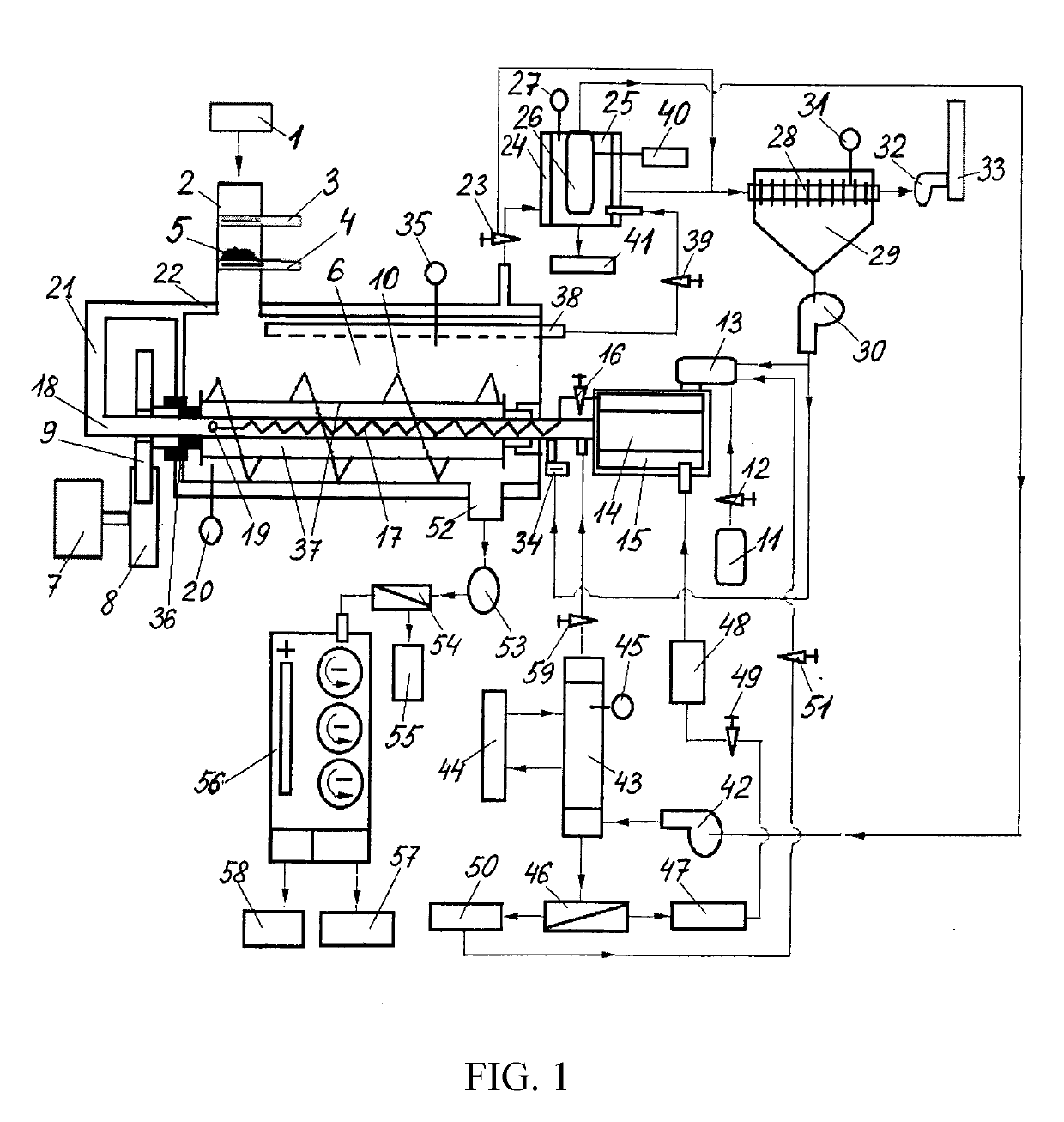

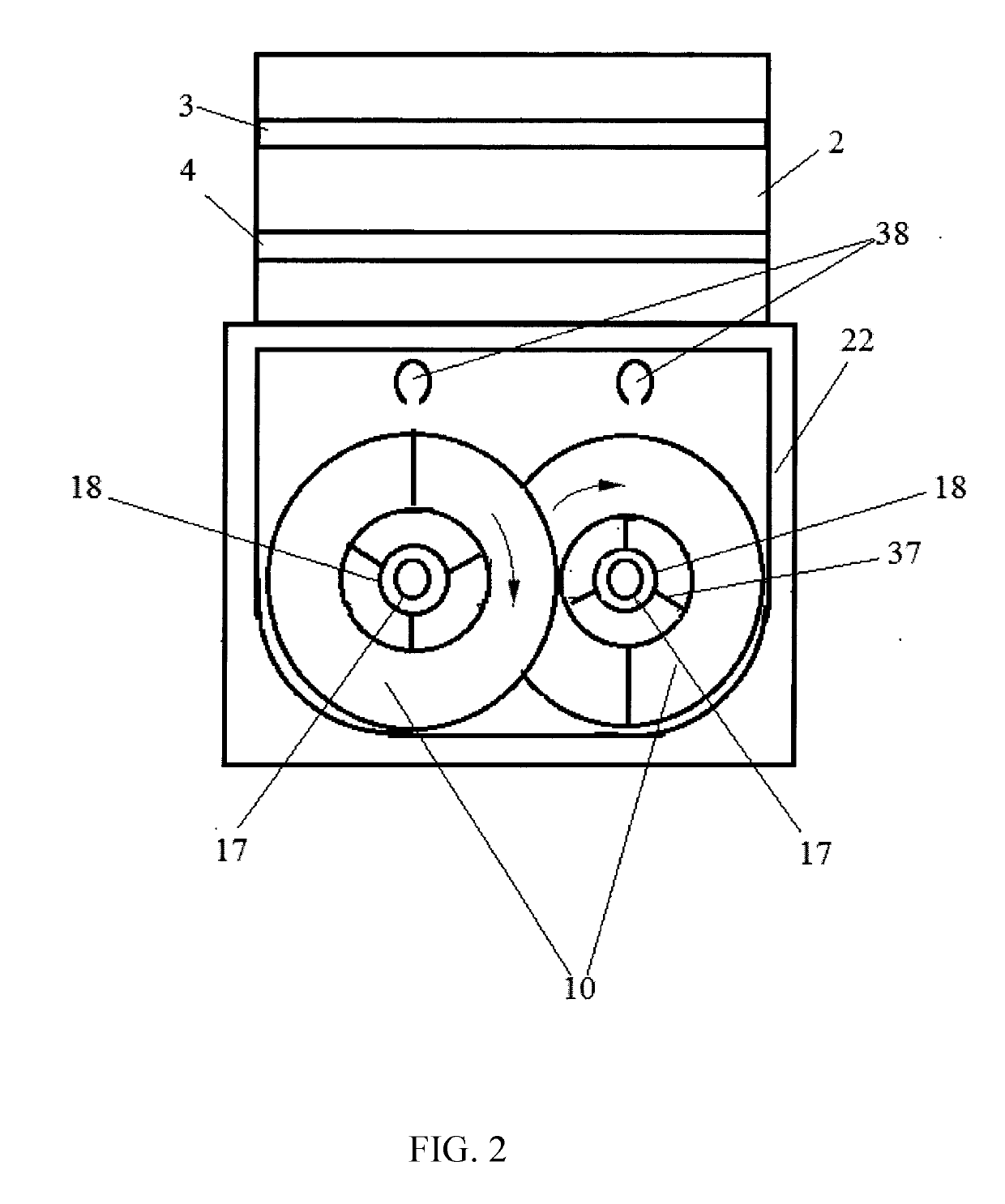

Pyrolyzer furnace apparatus and method for operation thereof

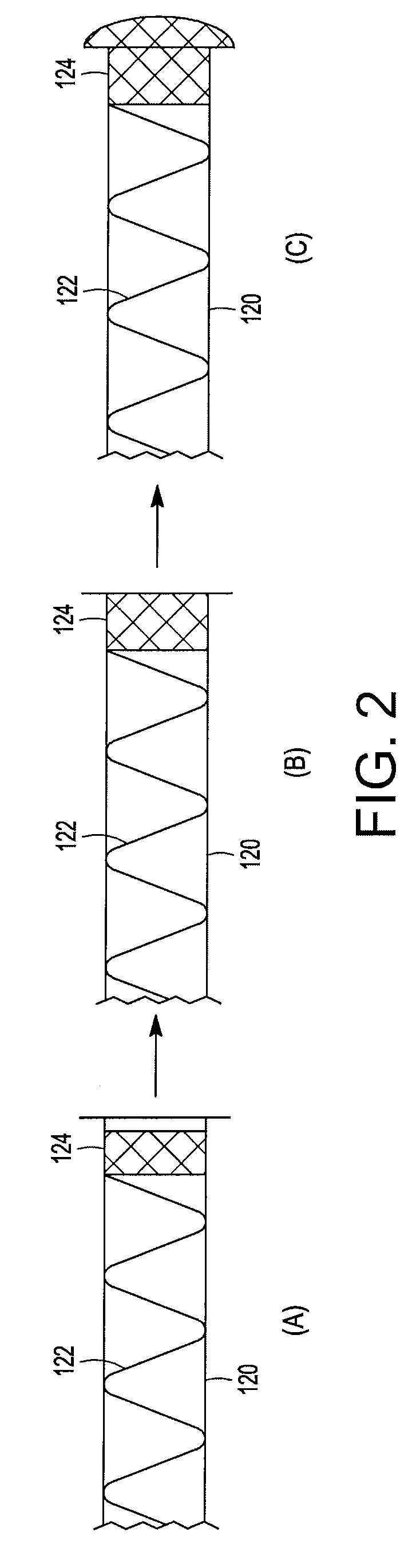

InactiveUS20080149471A1Weaken energyLower Level RequirementsMechanical conveying coke ovensDirect heating destructive distillationCombustion chamberDrive shaft

A pyrolyzer and method is provided for devolatizing coal and other volatile materials. The pyrolyzer has a pyrolyzer furnace housing having at least two screws laterally positioned adjacent and overlapping rotatably mounted within the furnace for moving volatile material through the pyrolyzer furnace housing. The screws have hollow drive shafts with a diverter inside for converging heated fluid to heat the volatile material moving through the pyrolyzer furnace housing. A combustion chamber combusts fuel to create heated exhaust gas for directing through the hollow drive shafts to heat the volatile material. The pyrolyzer furnace housing may have a double wall with a cavity between, capable of receiving heated fluid for further heating of volatile material moving through the pyrolyzer furnace housing.

Owner:NUCOR CORP

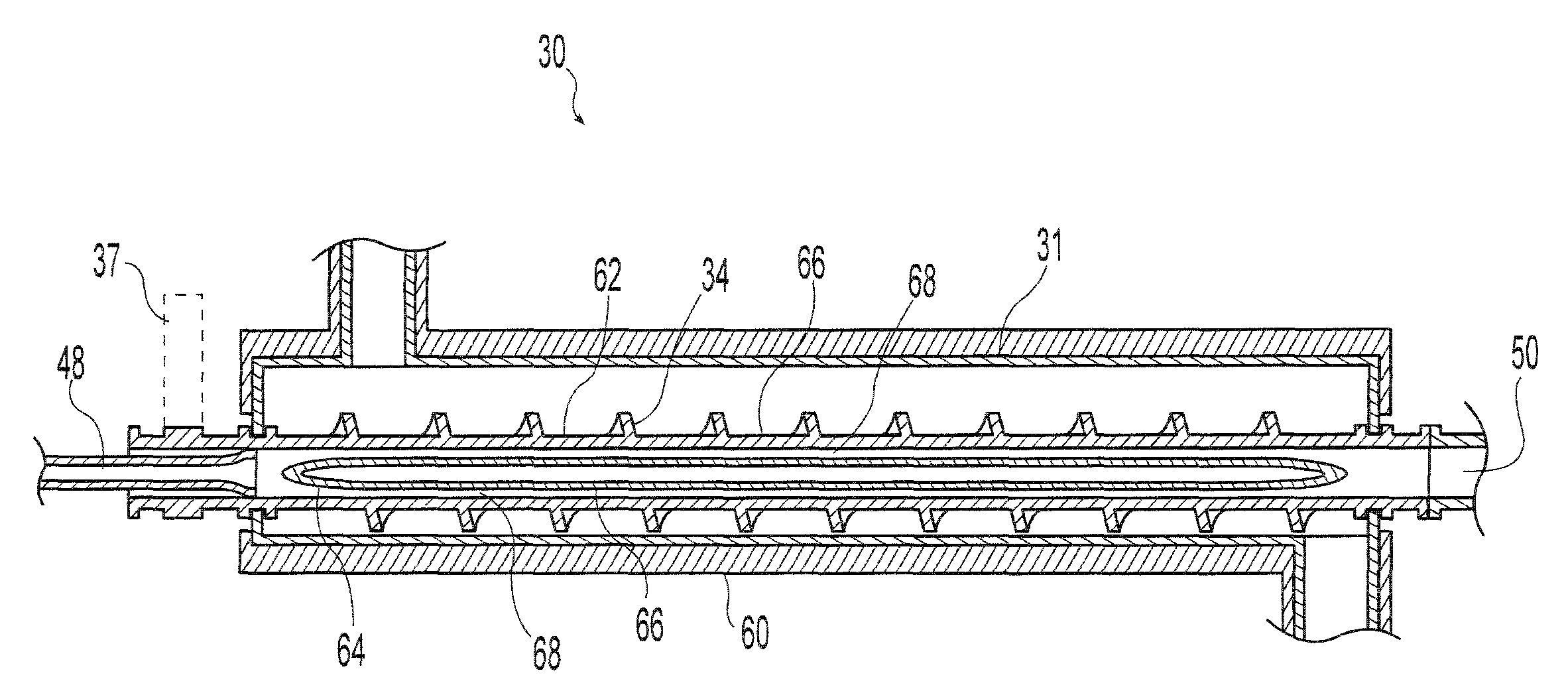

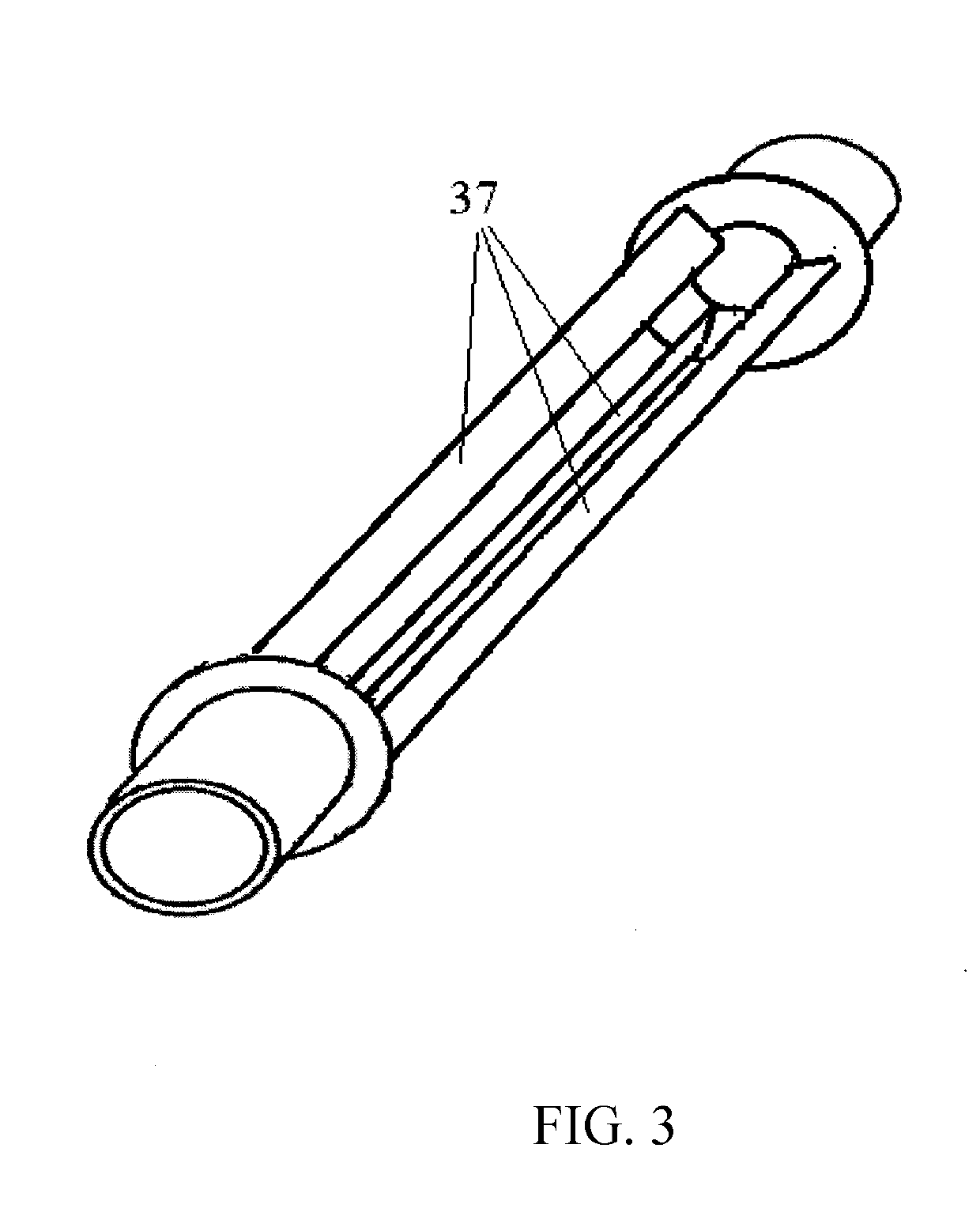

Pyrolyzer furnace apparatus and method for operation thereof

InactiveUS20130240343A1Reduce the cross-sectional areaWeaken energyCombustible gas coke oven heatingCoal charges mechanical treatmentCombustion chamberMechanical engineering

A char making apparatus comprises a longitudinal pyrolyzer furnace housing wherein coal-bearing material may be heated to a temperature to fluidize volatile materials therein and plasticize coal in the coal-bearing material. At least two rotatable drive screws are laterally positioned and interleaved within the longitudinal furnace housing and capable of conveying coal-bearing materials through the pyrolyzer furnace housing, each drive screw having a hollow drive shaft and a diverter positioned within the drive shaft to provide heating to the coal-bearing material. A heating jacket about the longitudinal furnace housing provides additional heating to the coal-bearing material. Multiple combustion chambers adjacent the heating jacket and hollow drive shaft burn fluidized volatile materials and exhaust combustion fluids through the jacket and shaft.

Owner:NUCOR CORP

Pyrolyzer furnace apparatus and method for operation thereof

InactiveUS9045693B2Weaken energyLower Level RequirementsCombustible gas coke oven heatingCoal charges mechanical treatmentCombustion chamberDrive shaft

A char making apparatus comprises a longitudinal pyrolyzer furnace housing wherein coal-bearing material may be heated to a temperature to fluidize volatile materials therein and plasticize coal in the coal-bearing material. At least two rotatable drive screws are laterally positioned and interleaved within the longitudinal furnace housing and capable of conveying coal-bearing materials through the pyrolyzer furnace housing, each drive screw having a hollow drive shaft and a diverter positioned within the drive shaft to provide heating to the coal-bearing material. A heating jacket about the longitudinal furnace housing provides additional heating to the coal-bearing material. Multiple combustion chambers adjacent the heating jacket and hollow drive shaft burn fluidized volatile materials and exhaust combustion fluids through the jacket and shaft.

Owner:NUCOR CORP

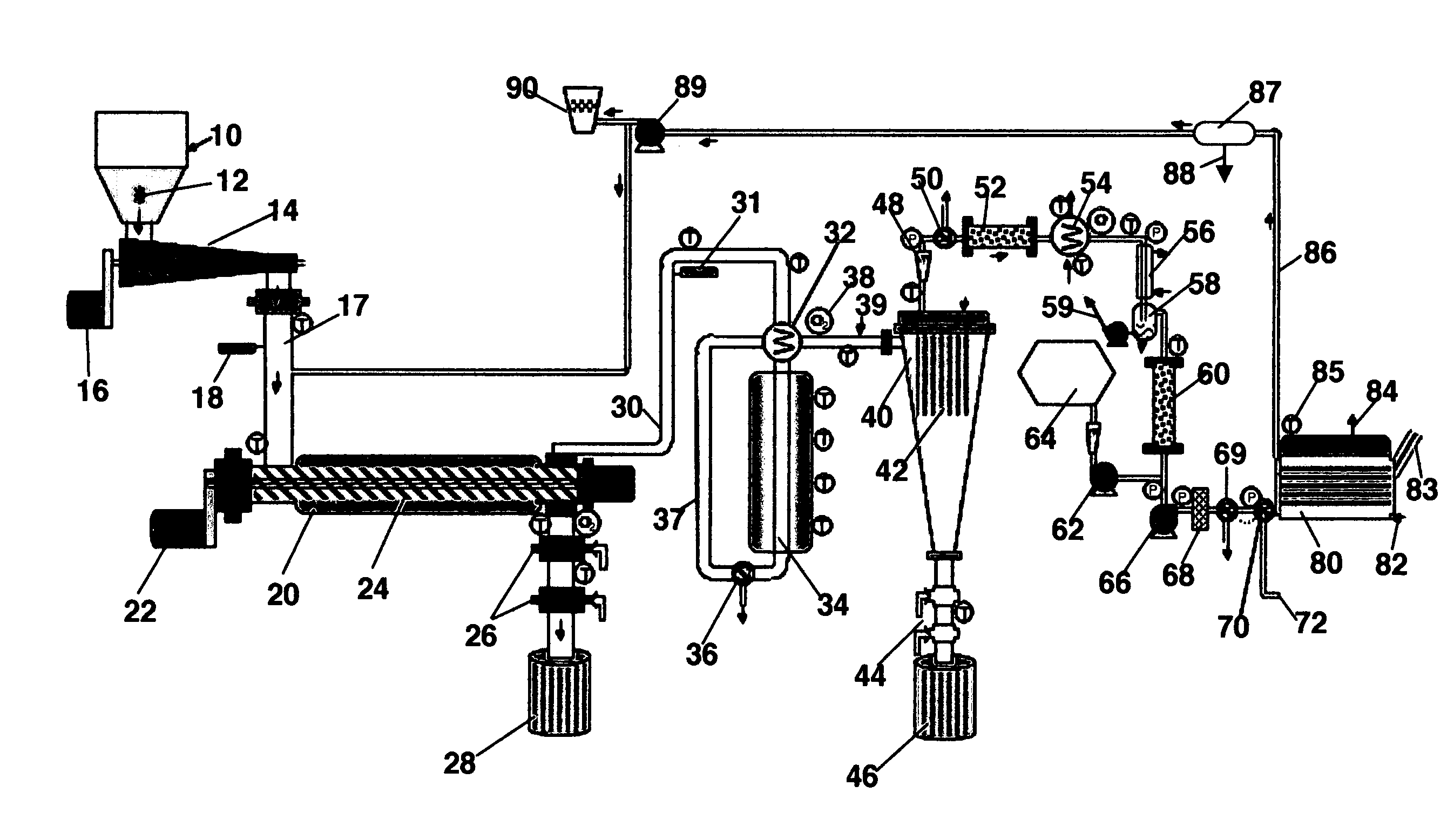

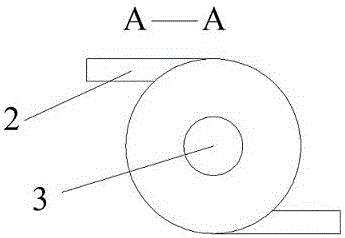

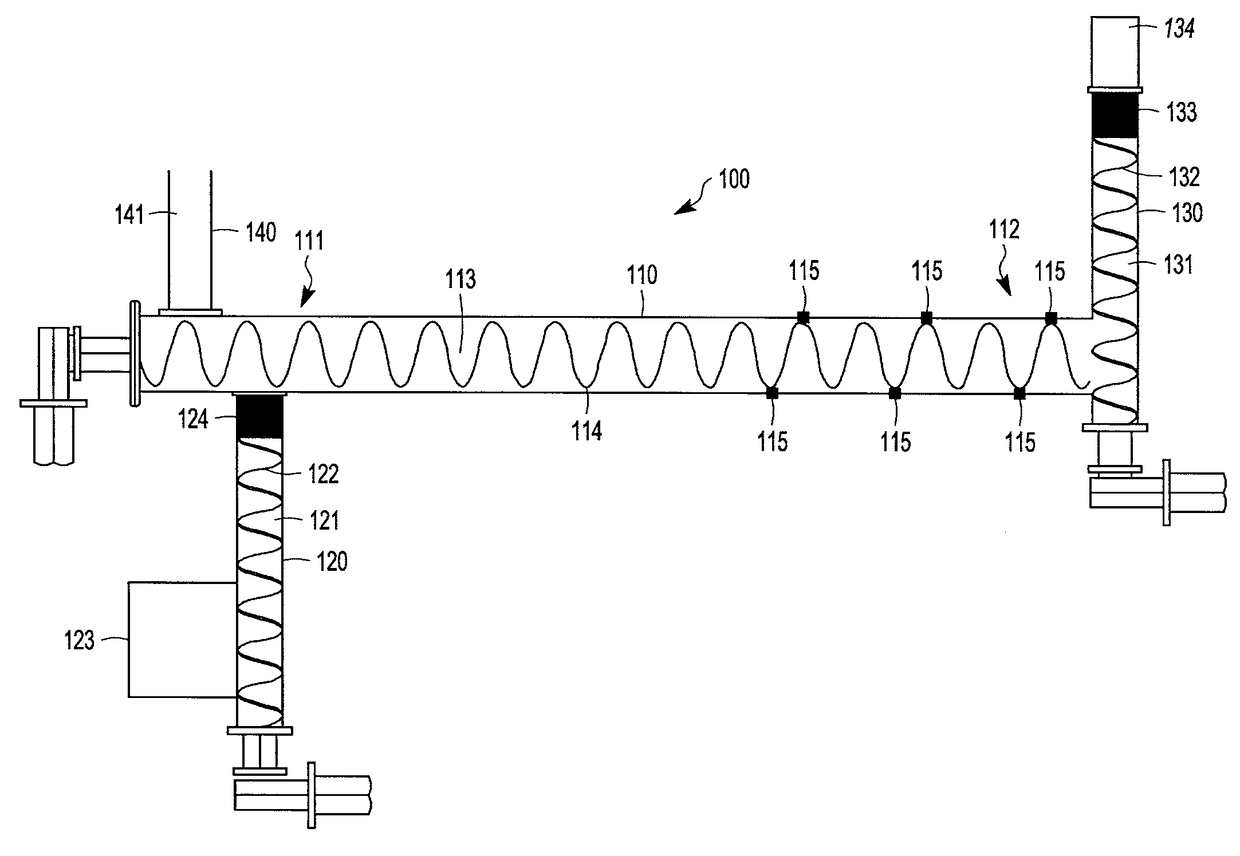

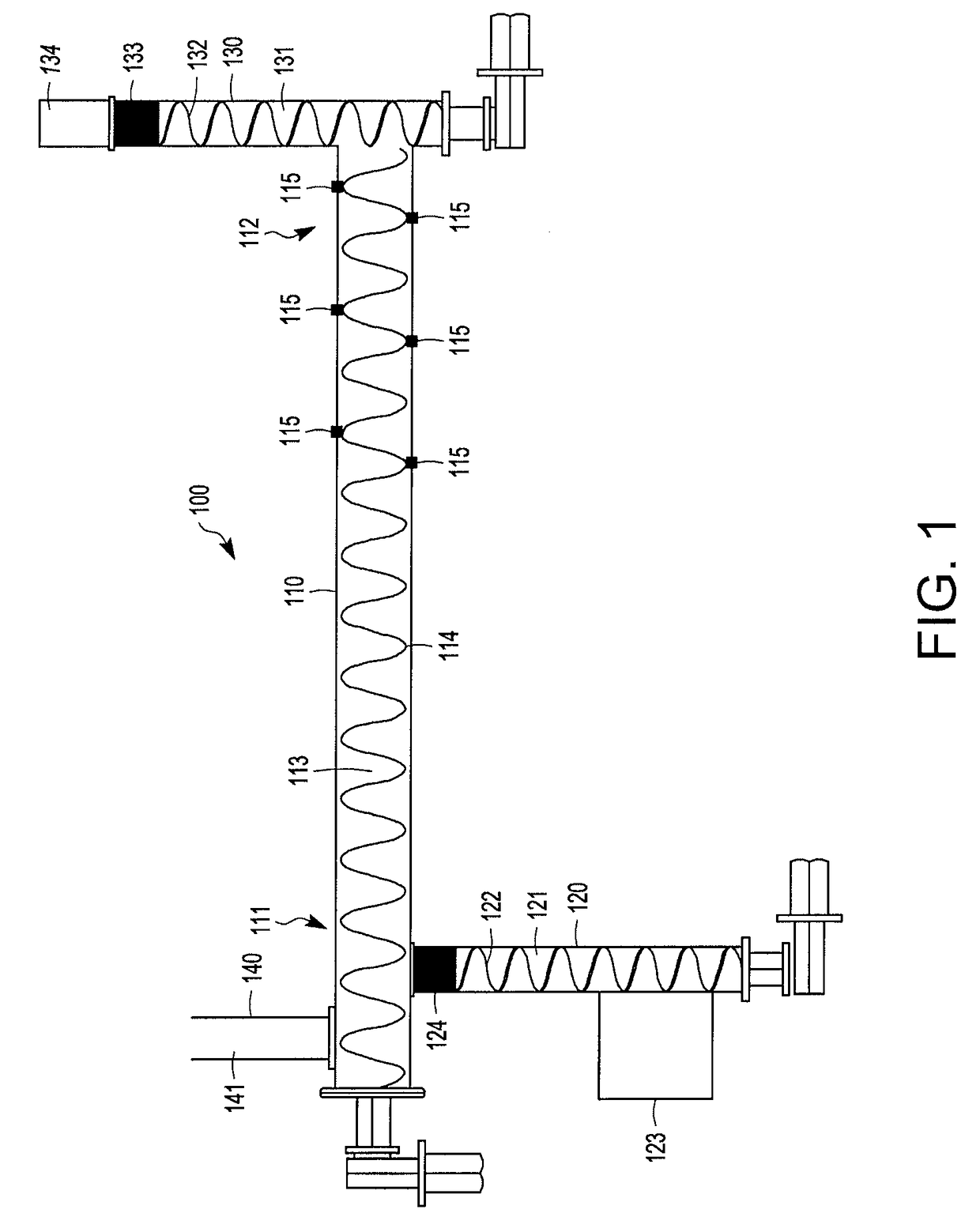

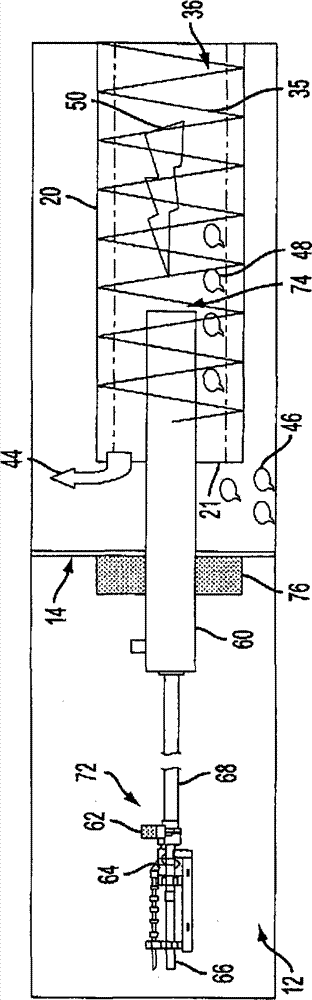

Scalable biomass reactor and method

ActiveUS8465562B2Efficient productionLarge capacityBiofuelsIndirect heating destructive distillationHydrogenCombustion

Owner:INDIANA UNIV RES & TECH CORP

Pyrolyzer furnace apparatus and method for operation thereof

InactiveUS8444828B2Weaken energyLower Level RequirementsMechanical conveying coke ovensDirect heating destructive distillationCombustion chamberDrive shaft

A pyrolyzer and method is provided for devolatizing coal and other volatile materials. The pyrolyzer has a pyrolyzer furnace housing having at least two screws laterally positioned adjacent and overlapping rotatably mounted within the furnace for moving volatile material through the pyrolyzer furnace housing. The screws have hollow drive shafts with a diverter inside for converging heated fluid to heat the volatile material moving through the pyrolyzer furnace housing. A combustion chamber combusts fuel to create heated exhaust gas for directing through the hollow drive shafts to heat the volatile material. The pyrolyzer furnace housing may have a double wall with a cavity between, capable of receiving heated fluid for further heating of volatile material moving through the pyrolyzer furnace housing.

Owner:NUCOR CORP

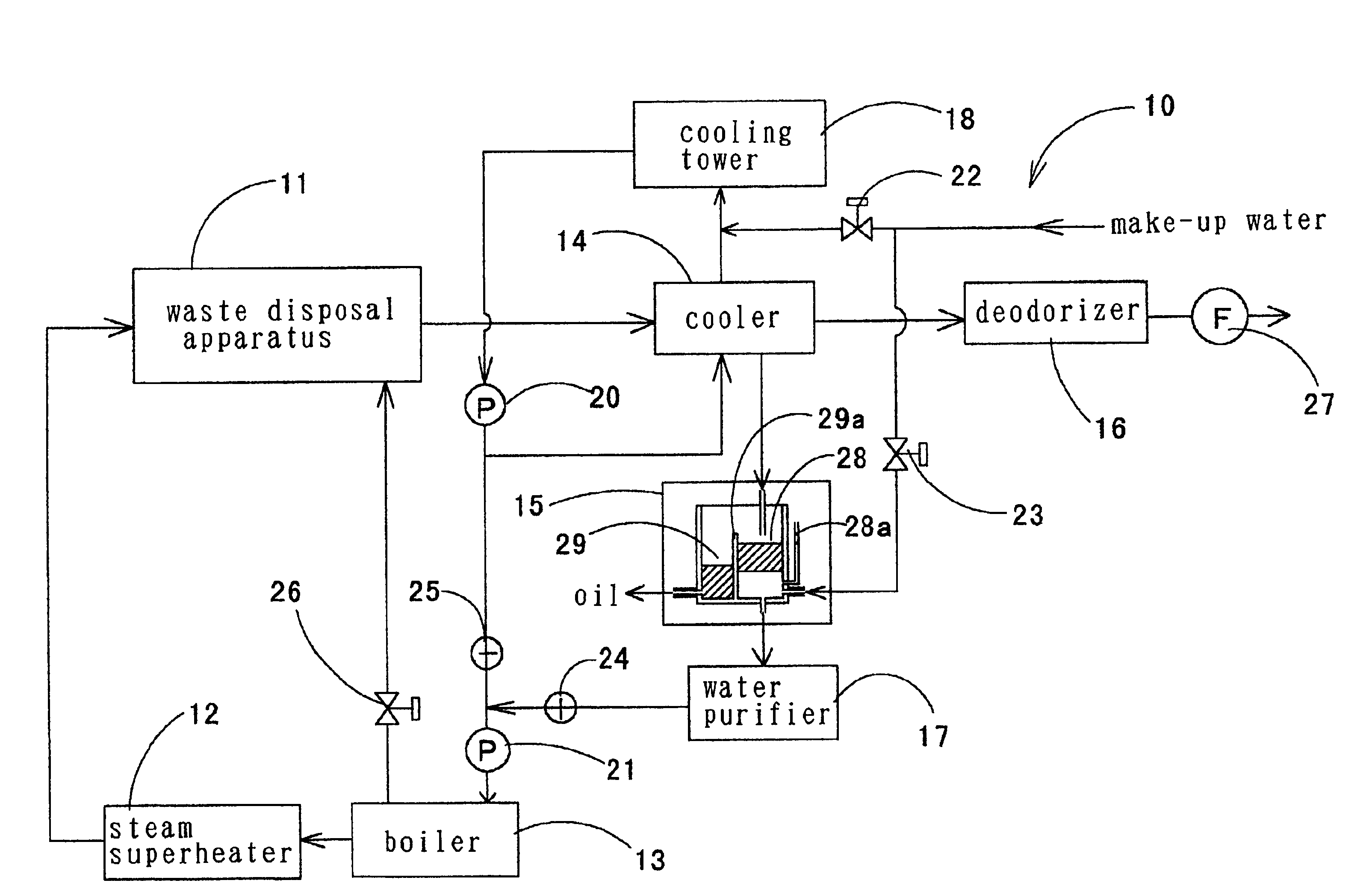

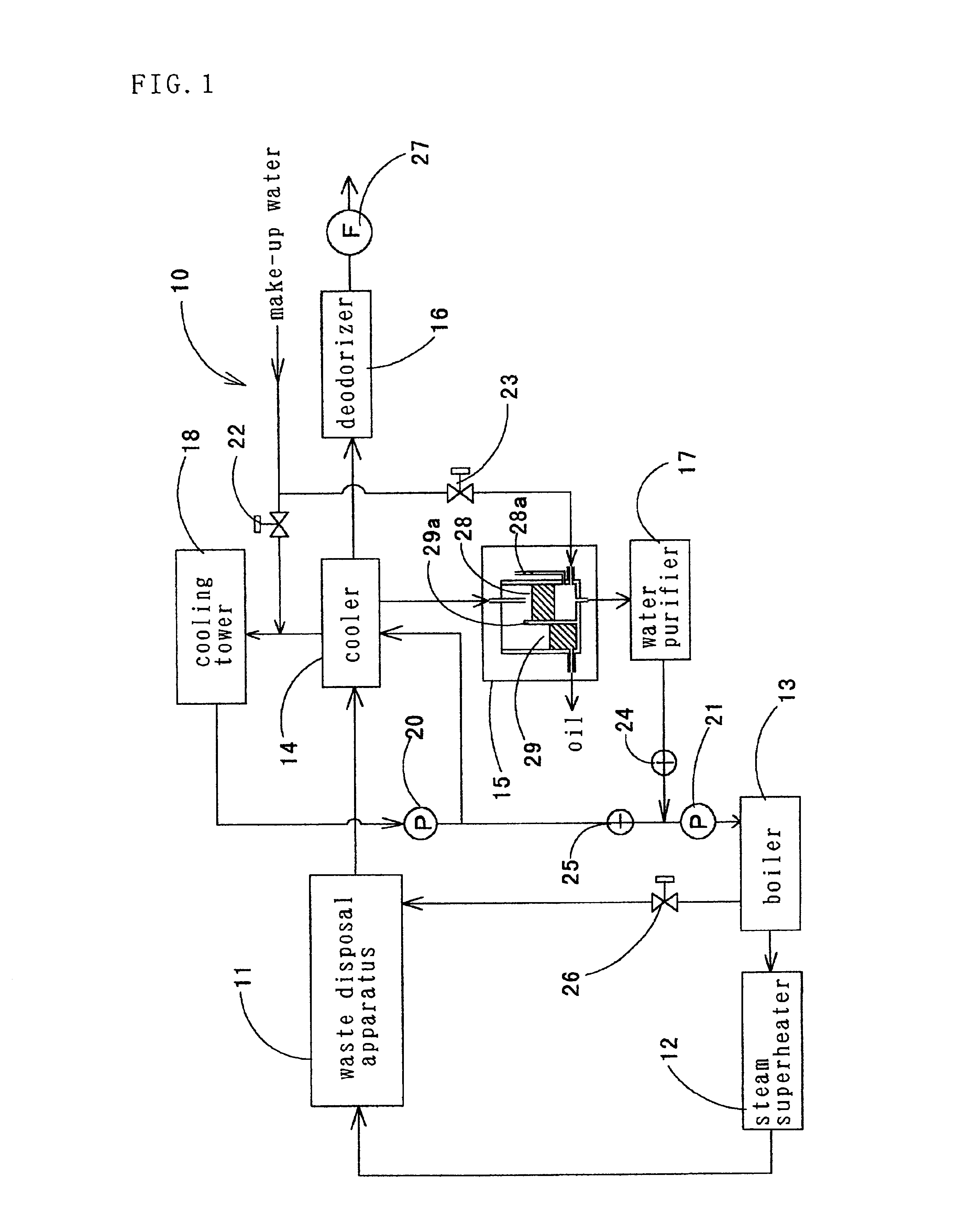

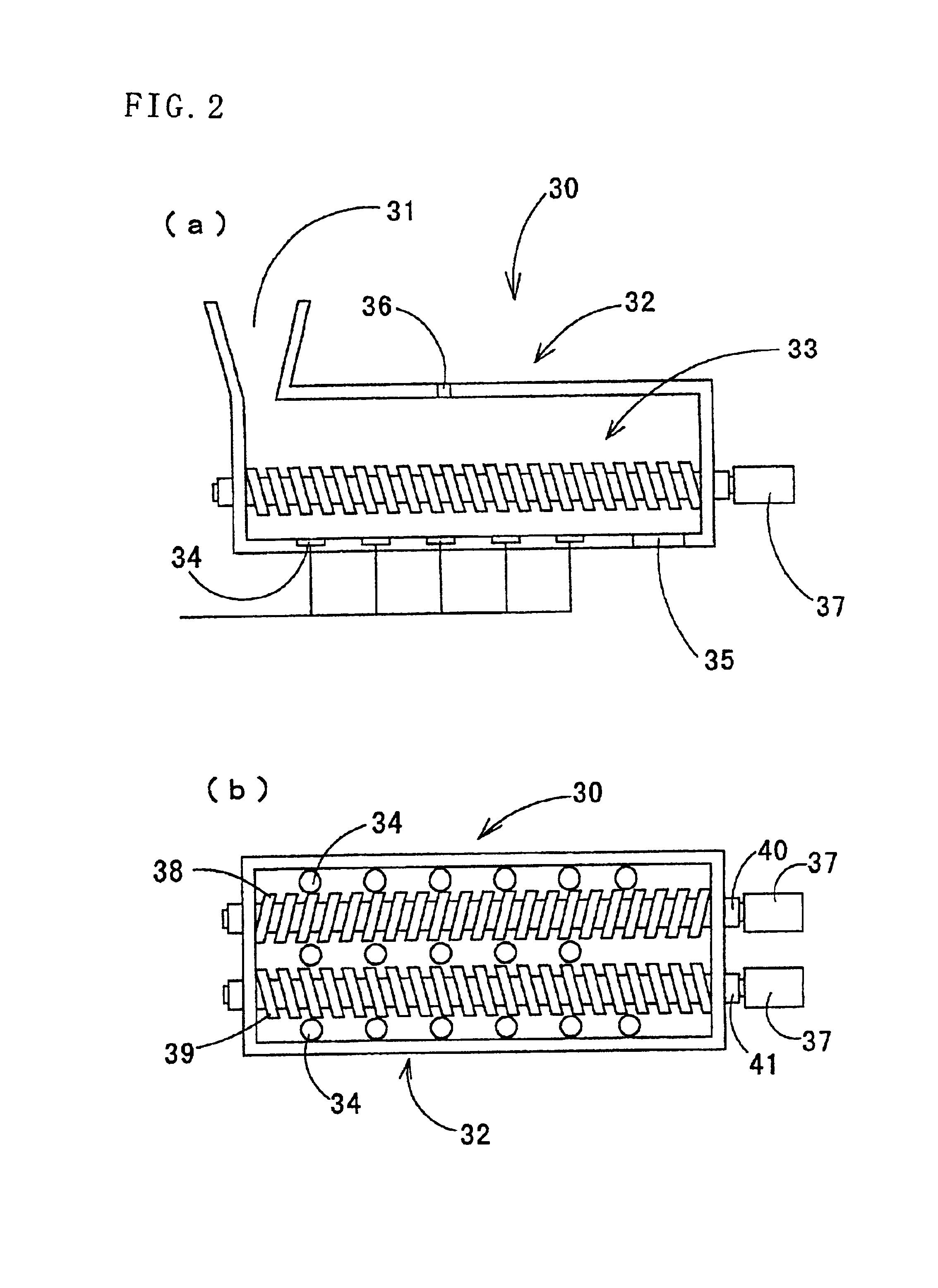

Waste treating method

InactiveUS6875317B1Efficient reuseAmount of wastes such as garbage can be reduced safely and efficientlySolid waste disposalDirect heating destructive distillationFood industrySludge

Wastes mainly containing any one or two or more of raw garbage, waste lumber, paper diapers, waste plastics, and organic sludge discharged from the food industry, common houses, etc. are exposed to high-temperature steam of 510 to 900° C. in an oxygen-free state, preferably while being stirred, to be carbonized. Thereby, the amount of wastes is reduced safely and efficiently with no fear of generating harmful substances such as dioxin, and moreover the carbonized wastes can be reused effectively for applications to fuel or the like.

Owner:TOYODA JIRO

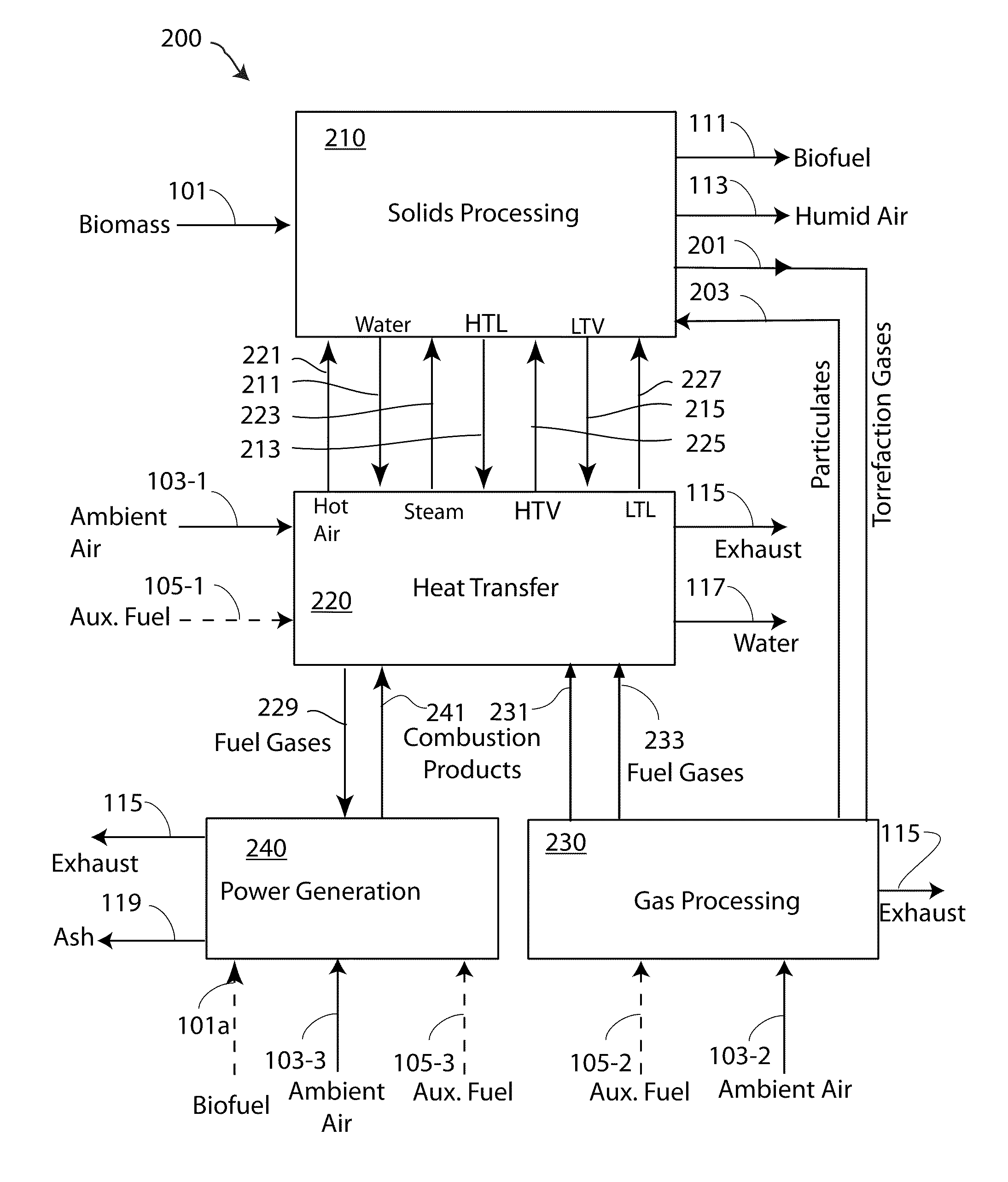

Method for conversion of biomass to biofuel

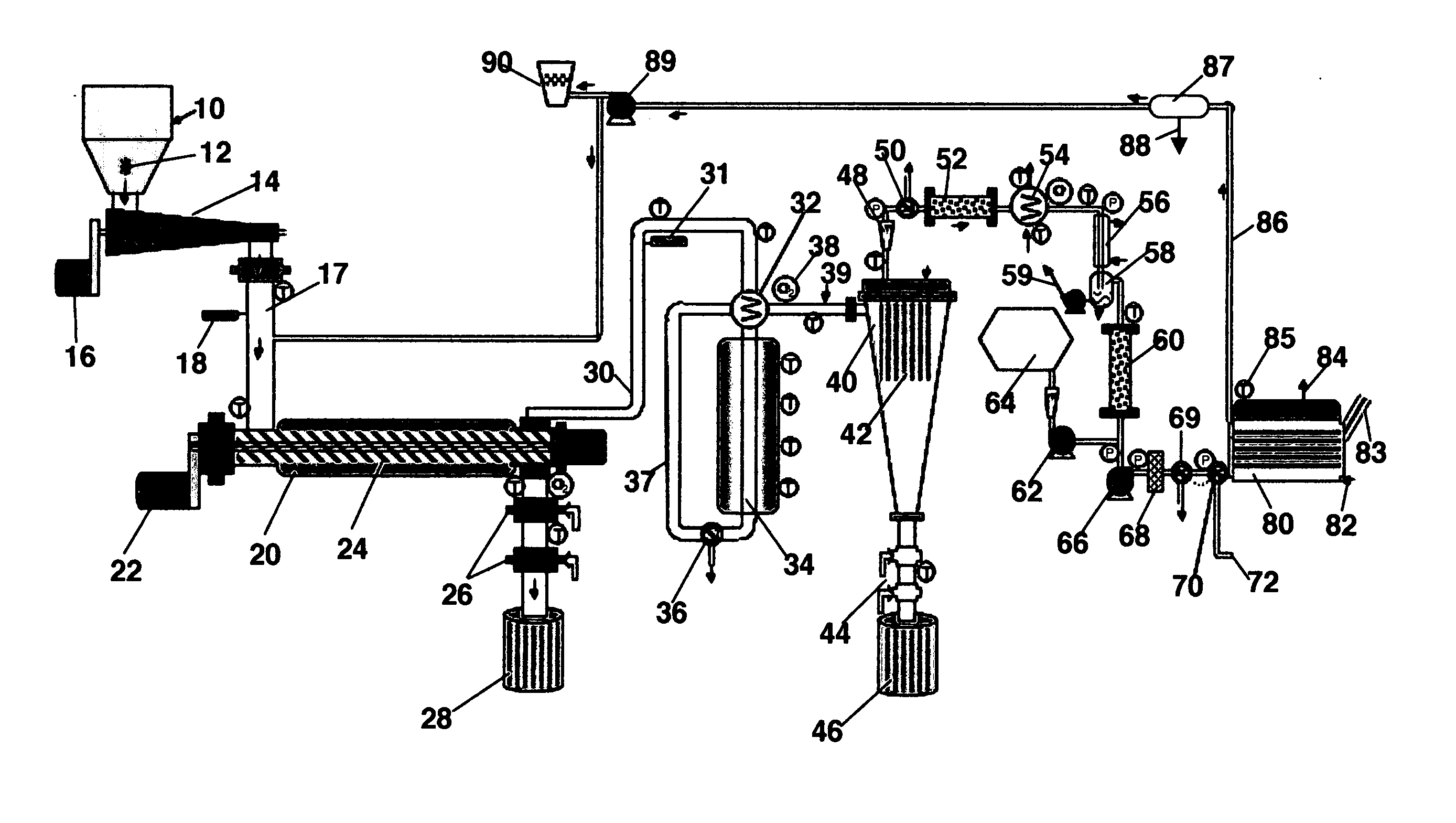

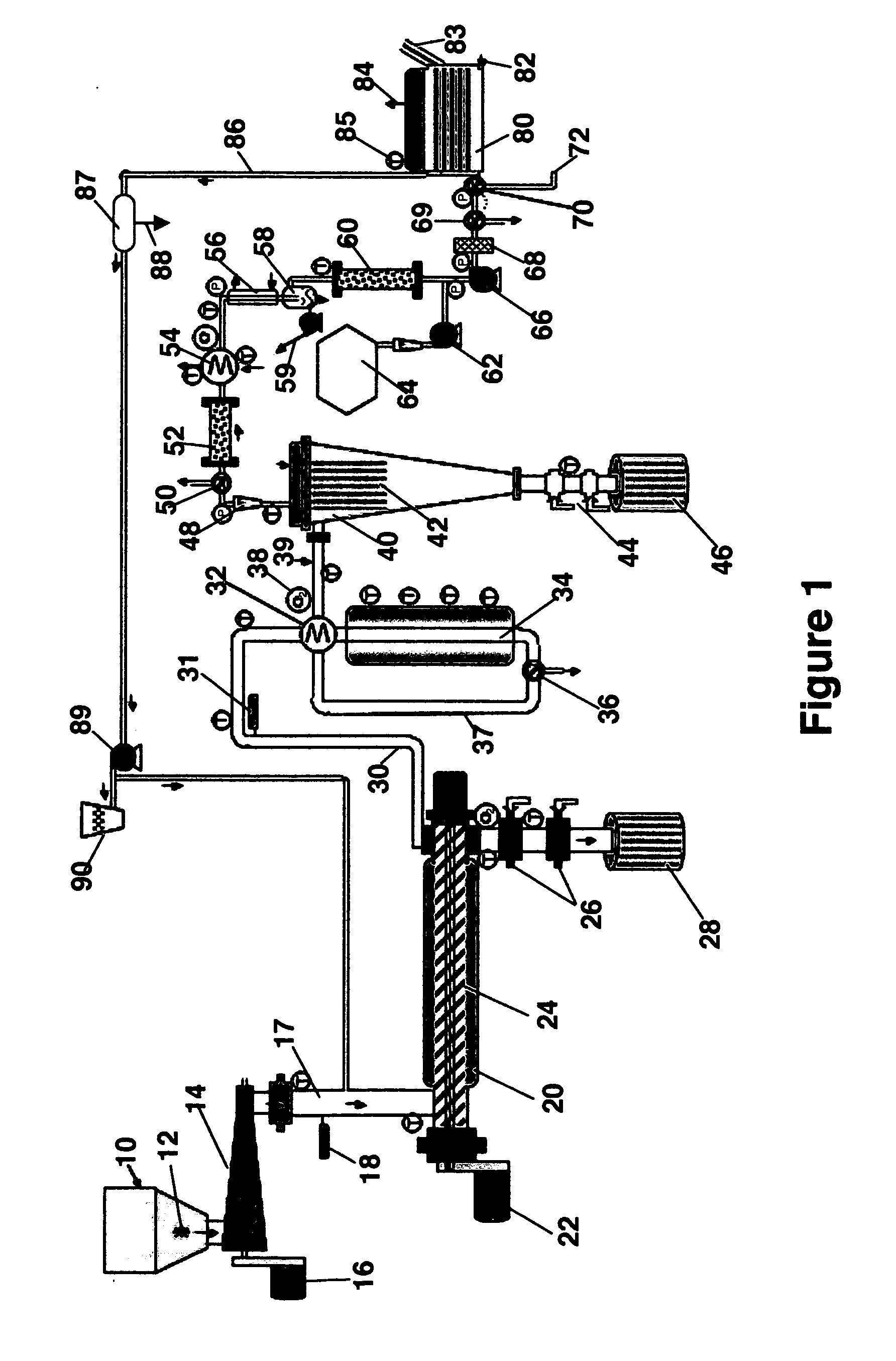

InactiveUS8669404B2Increase energy densityReduce shipping costsBiofuelsWaste based fuelSolid fuelBiofuel

An apparatus and method to convert carbonaceous materials, particularly biomass and those biomass resources which are remotely located, into a solid material, which may be a high performance solid fuel, are presented. This method, and the apparatus described as the means to accomplish this method, provides a continuous process which can be completely powered by the energy contained in the biomass. The heat, mechanical power and electrical power are provided from the energy in the biomass, through the methods described. In this way, the apparatus is free to operate in remote locations, where no power or auxiliary fuel sources are available.

Owner:RENEWABLE FUEL TECH

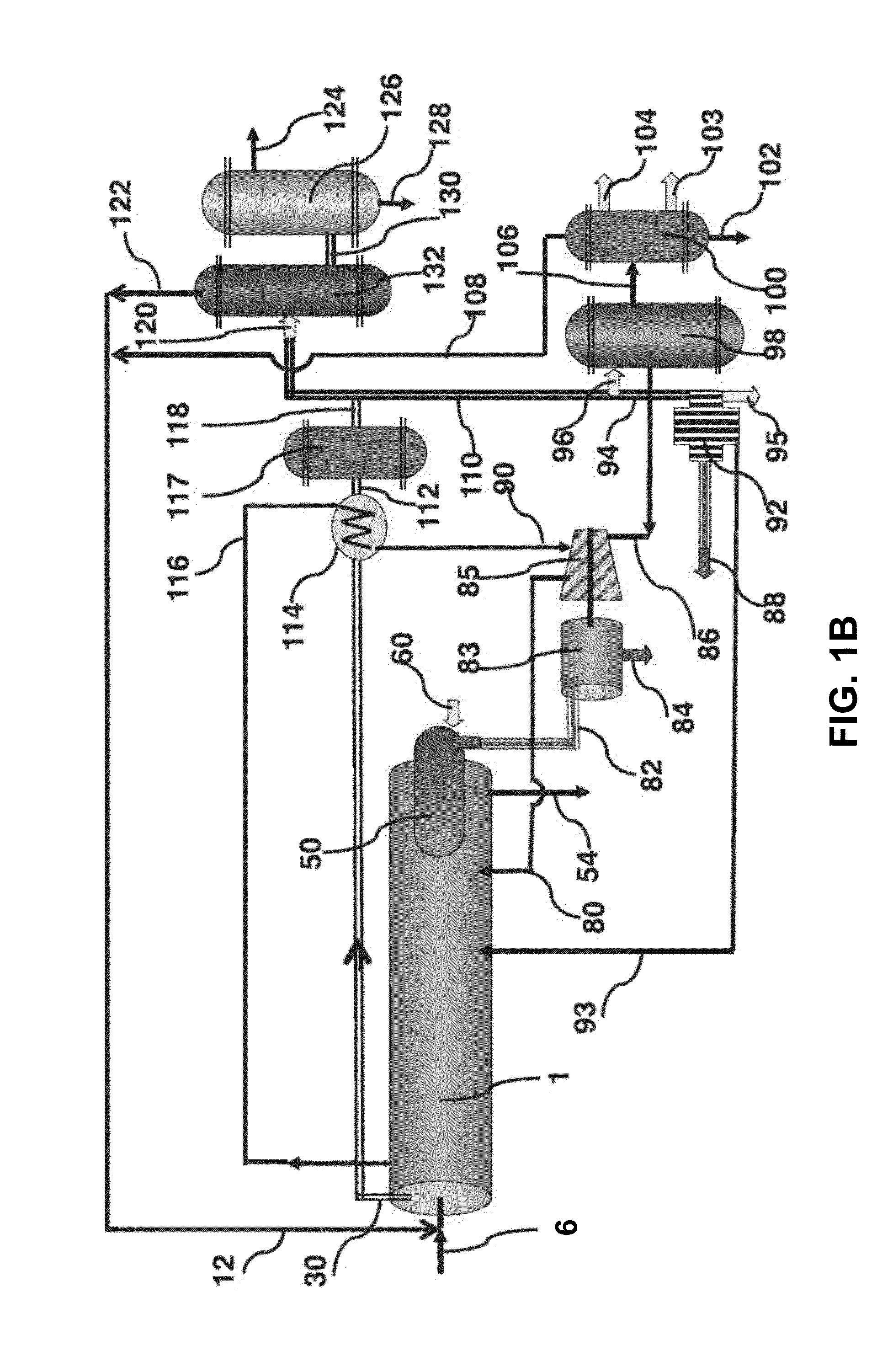

Process and system for converting carbonaceous feedstocks into energy without greenhouse gas emissions

ActiveUS7753973B2High hydrogen contentEasy to separateFuel cells groupingHydrogen separation using solid contactSludgeWaste oil

The process of the invention converts carbonaceous feedstock such as coal, hydrocarbon oil, natural gas, petroleum coke, oil shale, carbonaceous-containing waste oil, carbonaceous-containing medical waste, carbonaceous-containing military waste, carbonaceous-containing industrial waste, carbonaceous-containing medical waste, carbonaceous-containing sewage sludge and municipal solid waste, carbonaceous-containing agricultural waste, carbonaceous-containing biomass, biological and biochemical waste, and mixtures thereof into electrical energy without the production of unwanted greenhouse emissions. The process uses a steam / CO2 reformer operating in the exit range of at least 700° to about 1600° C. (1300-2900° F.) to convert the carbonaceous feedstock and a greenhouse gas stream into a synthesis gas comprising mostly carbon monoxide and hydrogen that contains poisons and the compounds that poison fuel cells. The syngas is sent to an interface zone to remove these poisons and other fouling compounds that are electrochemically oxidized in an electricity-producing fuel cell into an exit gas comprising carbon dioxide and water.

Owner:RAVEN SR INC

Process and system for converting waste to energy without burning

InactiveUS20150122243A1Large emissionsExothermal chemical reaction heat productionOther heat production devicesWaste streamFiltration

This invention relates to a power recovery process in waste steam / CO2 reformers whereby a waste stream can be made to release energy without having to burn the waste or the syngas. This invention does not make use of fuel cells as its critical component but makes use of highly exothermic chemical reactors using syngas to produce large amounts of heat, such as Fischer-Tropsch. It also relates to control or elimination of the emissions of greenhouse gases in the power recovery process of this invention with the goal of producing energy in the future carbonless world economy. A New Concept for a duplex kiln was developed that has the combined functionality of steam / CO2 reforming, heat transfer, solids removal, filtration, and heat recovery. New methods of carbon-sequestering where the syngas produced by steam / CO2 reforming can be used in Fischer-Tropsch processes that make high-carbon content compounds while recycling the methane and lighter hydrocarbons back to the reformer to further produce syngas at a higher H2 / CO ratio.

Owner:INTELLERGY INC

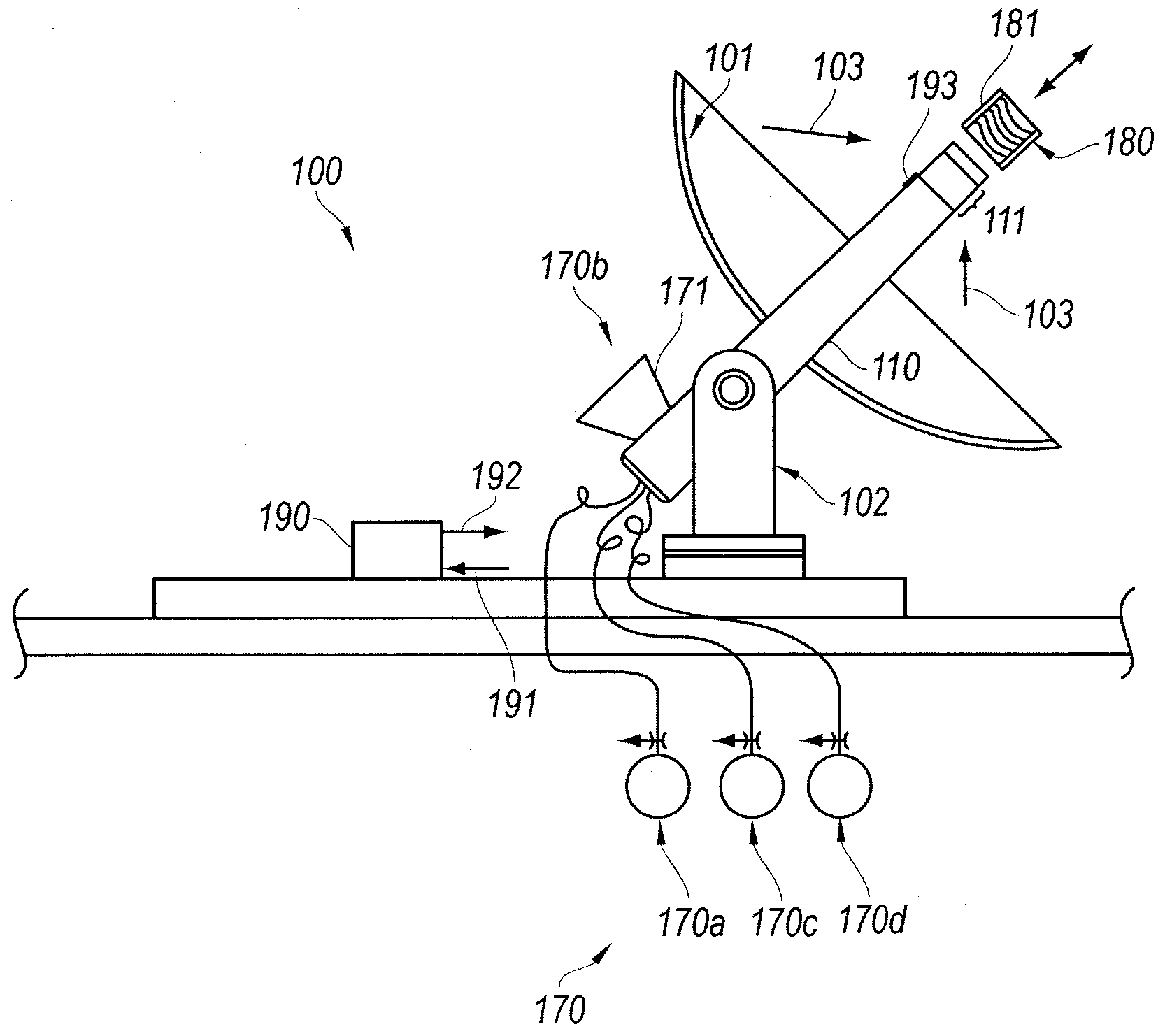

Chemical reactors with annularly positioned delivery and removal devices, and associated systems and methods

Chemical reactors with annularly positioned delivery and removal devices, and associated systems and methods. A reactor in accordance with a particular embodiment includes a reactor vessel having a light-transmissible surface proximate to a reaction zone, and a movable reactant delivery system positioned within the reactor vessel. The reactor can further include a product removal system positioned within the reactor vessel and positioned annularly inwardly or outwardly from the delivery system. A solar concentrator is positioned to direct solar radiation through the light-transmissible surface to the reaction zone.

Owner:ADVANCED GREEN INNOVATIONS LLC

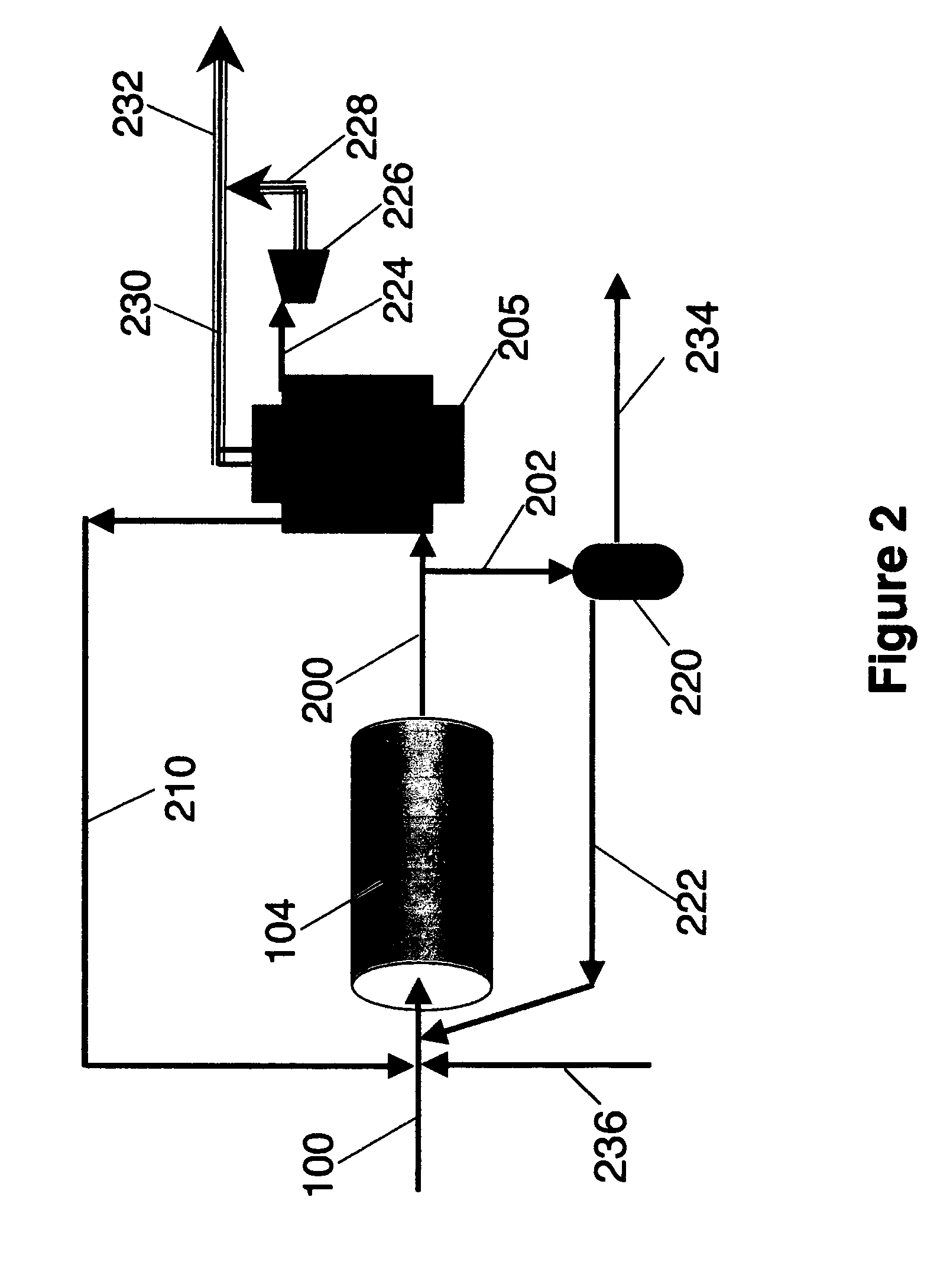

System and process for thermochemical treatment of matter containing organic compounds

The present document describes a system and a process for the thermochemical treatment a matter containing organic compounds such as biomass in the form of animals droppings. The system and process may be used for the production of useful energetic products such as biochar, bio-oil and gases from non-condensed vapors.

Owner:INST DE RECH & DE DEVEMENT & AGROENVIRONNEMENT INC IRDA +1

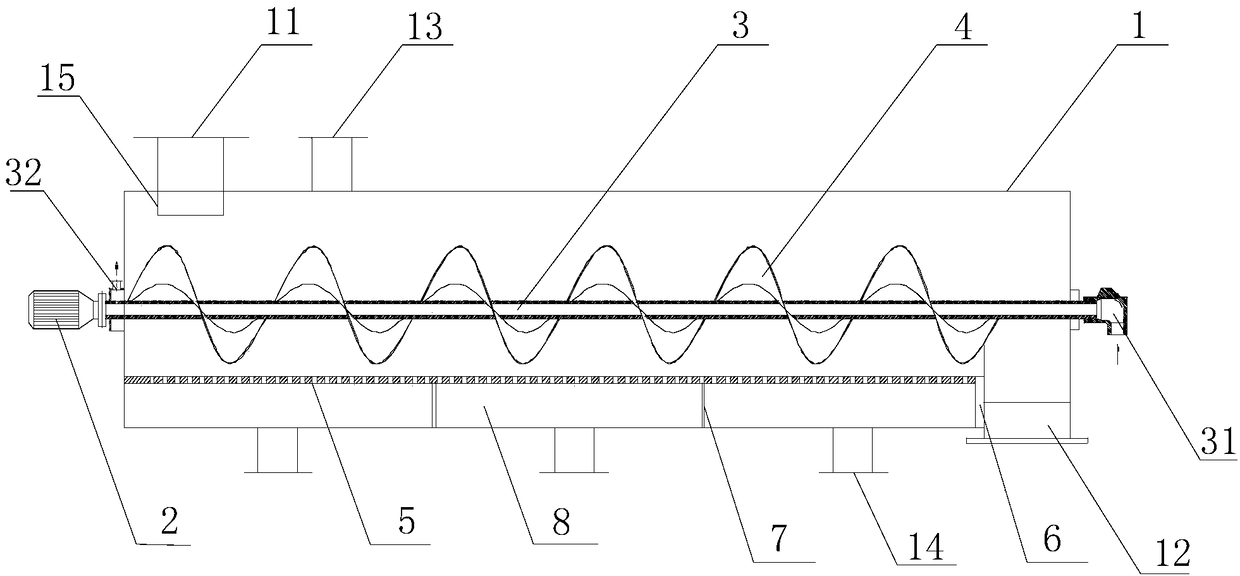

Multi-section spiral moving bed pyrolysis gasification device

PendingCN108148627AAvoid enteringGuaranteed availabilityDirect heating destructive distillationGasification processes detailsProcess engineeringMoving bed

The invention discloses a multi-section spiral moving bed pyrolysis gasification device which comprises a dry-section reactor, a pyrolysis-section reactor and a gasification-section reactor. The dry-section reactor is used for drying materials, the pyrolysis-section reactor is used for pyrolyzing the materials, the gasification-section reactor is used for gasifying the materials, the dry-section reactor, the pyrolysis-section reactor and the gasification-section reactor are provided with feeding ports and discharging ports, the discharging port of the dry-section reactor is connected with thefeeding port of the pyrolysis-section reactor, and the discharging port of the pyrolysis-section reactor is connected with the feeding port of the gasification-section reactor. The device has the advantages that the standing time of the materials is controlled by adjusting the rotating speed of a motor, and matching amount of gasifying agents and the materials is manually and accurately controlledby combining the sectioned air supply speed of an air-distribution plate, so that physical and chemical properties of target products can be controlled.

Owner:广东国能中林实业有限公司

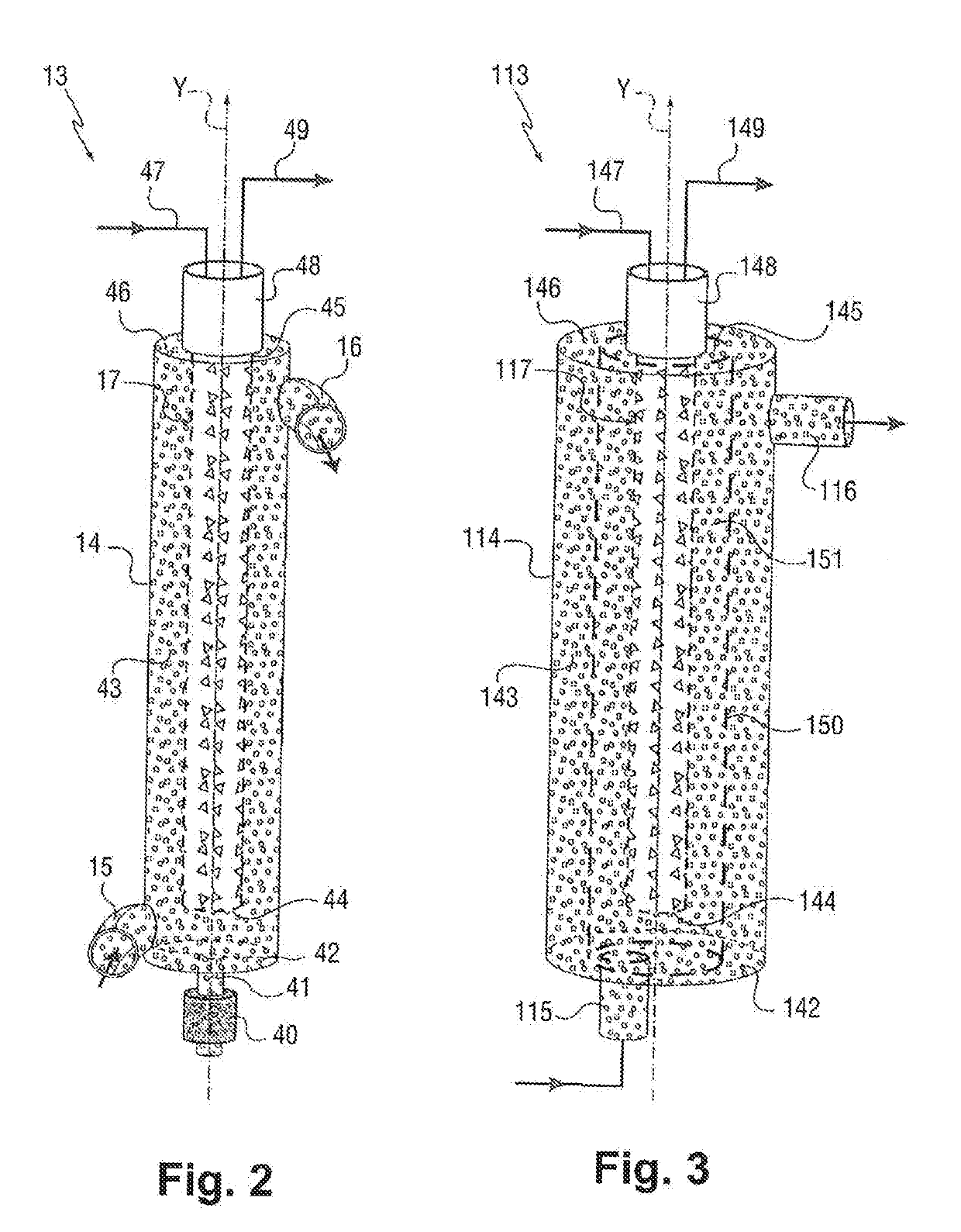

System and process for thermochemical treatment of matter containing organic compounds

ActiveUS9486774B2Avoid steam condensationBiofuelsWaste based fuelChemical compoundThermochemical reaction

The present document describes a system and a process for the thermochemical treatment a matter containing organic compounds such as biomass, for the production of useful energetic products such as biochar, bio-oil and gases from non-condensed vapors. The system comprises a reactor comprising a feedstock reservoir having entry and exit, a thermochemical reaction chamber having an entrance disposed under and coupled to the reservoir exit, an exit, and a first heating means for thermal treatment of the matter to produce a solid and a vapor. The system also comprises a feeder having at least one substantially vertical auger operatively coupled to the feedstock reservoir and the thermochemical reaction chamber exit to drive the matter downwardly from the feedstock reservoir exit through the thermochemical reaction chamber. A chamber for separation of the solid from the vapor which maintains the vapor in a gaseous state has an entrance coupled to the thermochemical reaction chamber exit, and an exit for exit of said vapor. The system also comprises a controller, operatively coupled to the first heating means for controlling temperature of the thermochemical reaction chamber, and a pump operatively coupled to the separation chamber exit for maintaining a light vacuum within the reactor and for helping exit of the vapor.

Owner:INST DE RECH & DE DEVEMENT & AGROENVIRONNEMENT INC IRDA +1

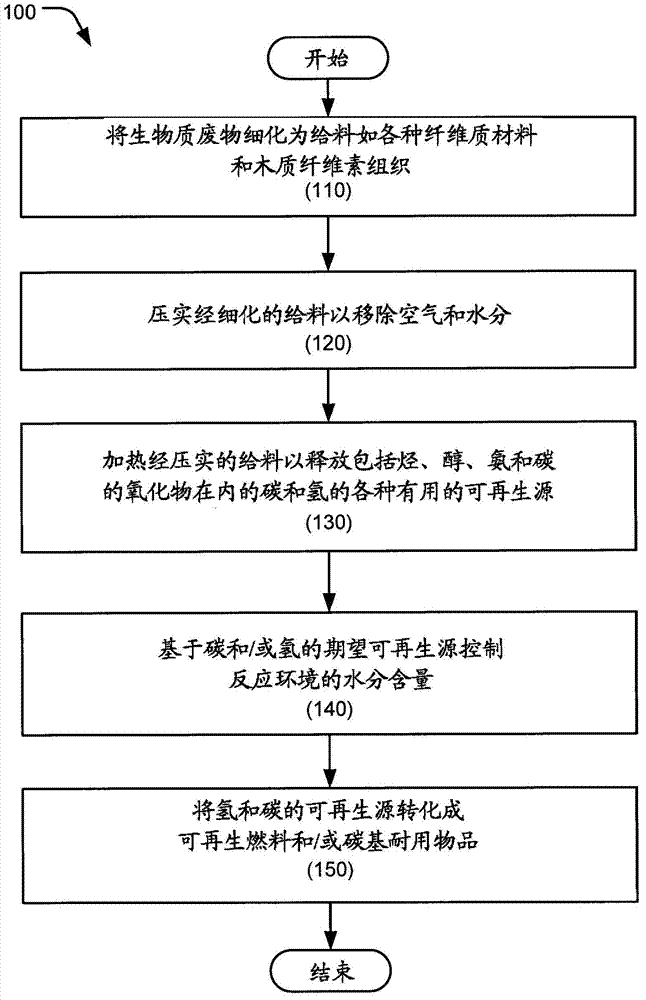

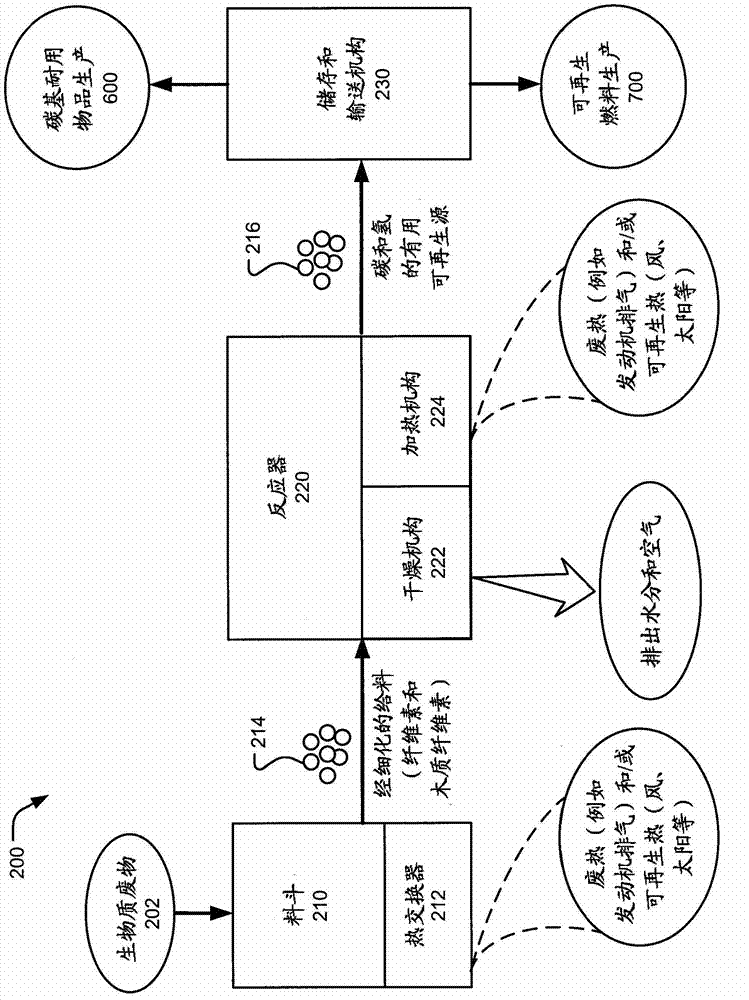

Carbon-based durable goods and renewable fuel from biomass waste dissociation

InactiveCN102906227AEmissions are minimized or eliminatedLow running costSolar heating energyCarbon compoundsHydrogenProcess engineering

Techniques, systems, apparatus and material are disclosed for generating renewable energy from biomass waste while sequestering carbon. In one aspect, a method performed by a reactor to dissociate raw biomass waste into a renewable source energy or a carbon byproduct or both includes receiving the raw biomass waste that includes carbon, hydrogen and oxygen to be dissociated under an anaerobic reaction. Waste heat is recovered from an external heat source to heat the received raw biomass waste. The heated raw biomass waste is dissociated to produce the renewable fuel, carbon byproduct or both. The dissociating includes compacting the heated raw biomass waste, generating heat from an internal heat source, and applying the generated heat to the compacted biomass waste under pressure.

Owner:MCALISTER TECH LLC

Induction heated gasifier

A method of removing organic components from a mixture containing organic and inorganic components which method involves providing an induction heated screw conveyor having an auger and passing the mixture through the induction heated screw conveyor while inductively heating the auger so as to heat the mixture in the induction heated screw conveyor primarily from the center of the induction heated screw conveyor. The mixture is heated to a temperature that is sufficient to cause the organic components in the mixture to separate from the mixture as a vapor. The oxygen concentration in the induction heated screw conveyor is controlled so as to gasify the organic components. The gasified organic components are removed and the remaining inorganic components are collected.

Owner:HERITAGE RES GROUP LLC

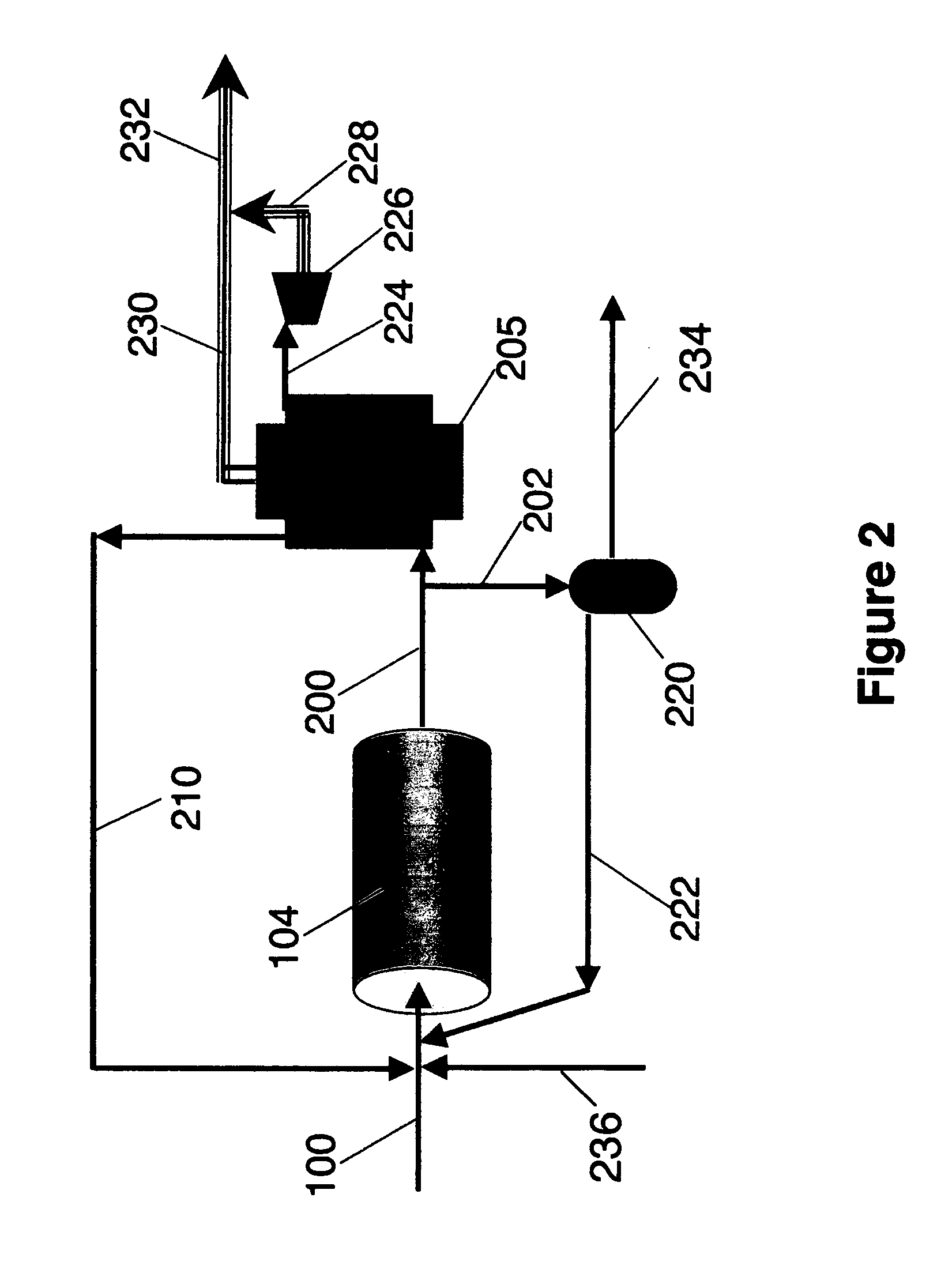

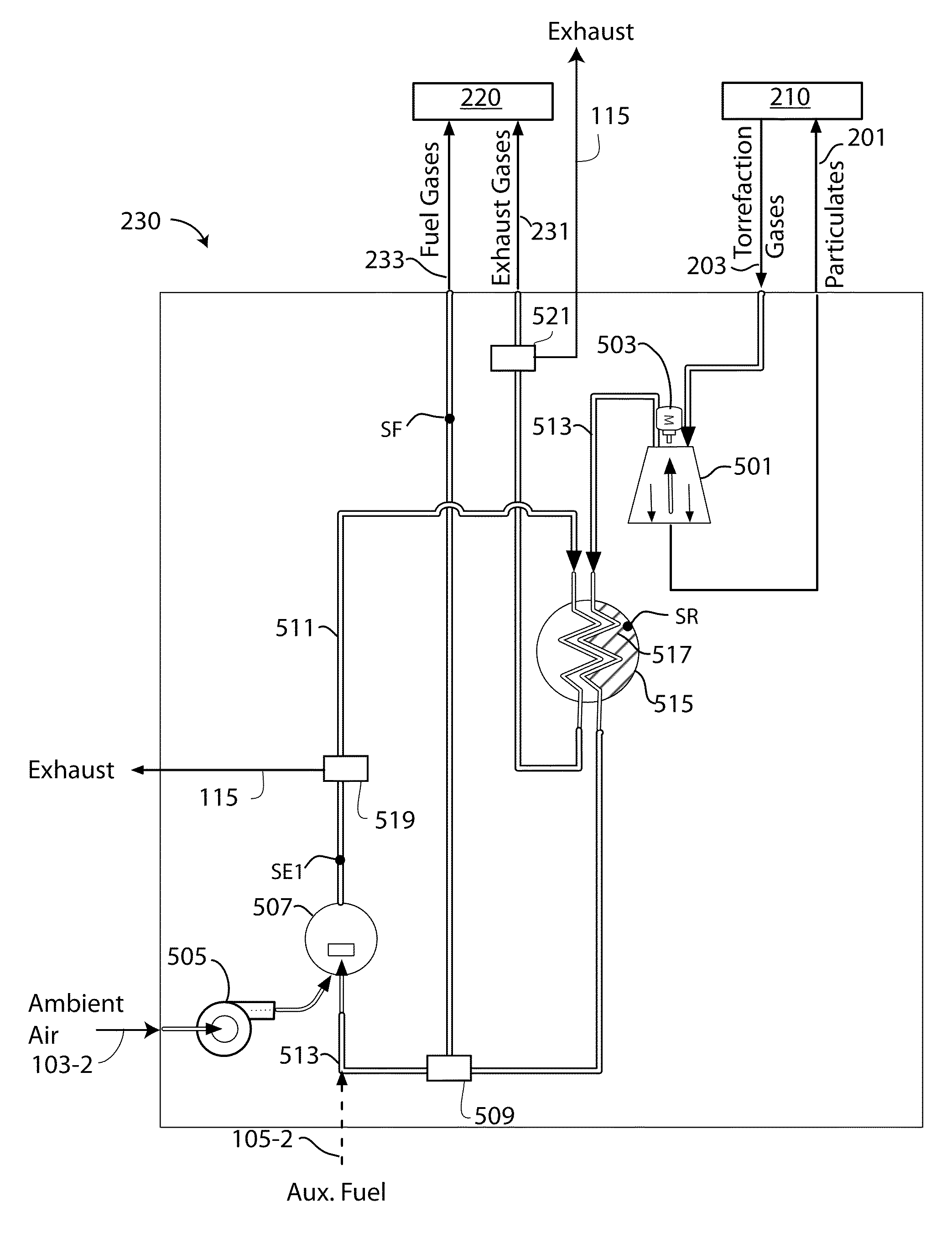

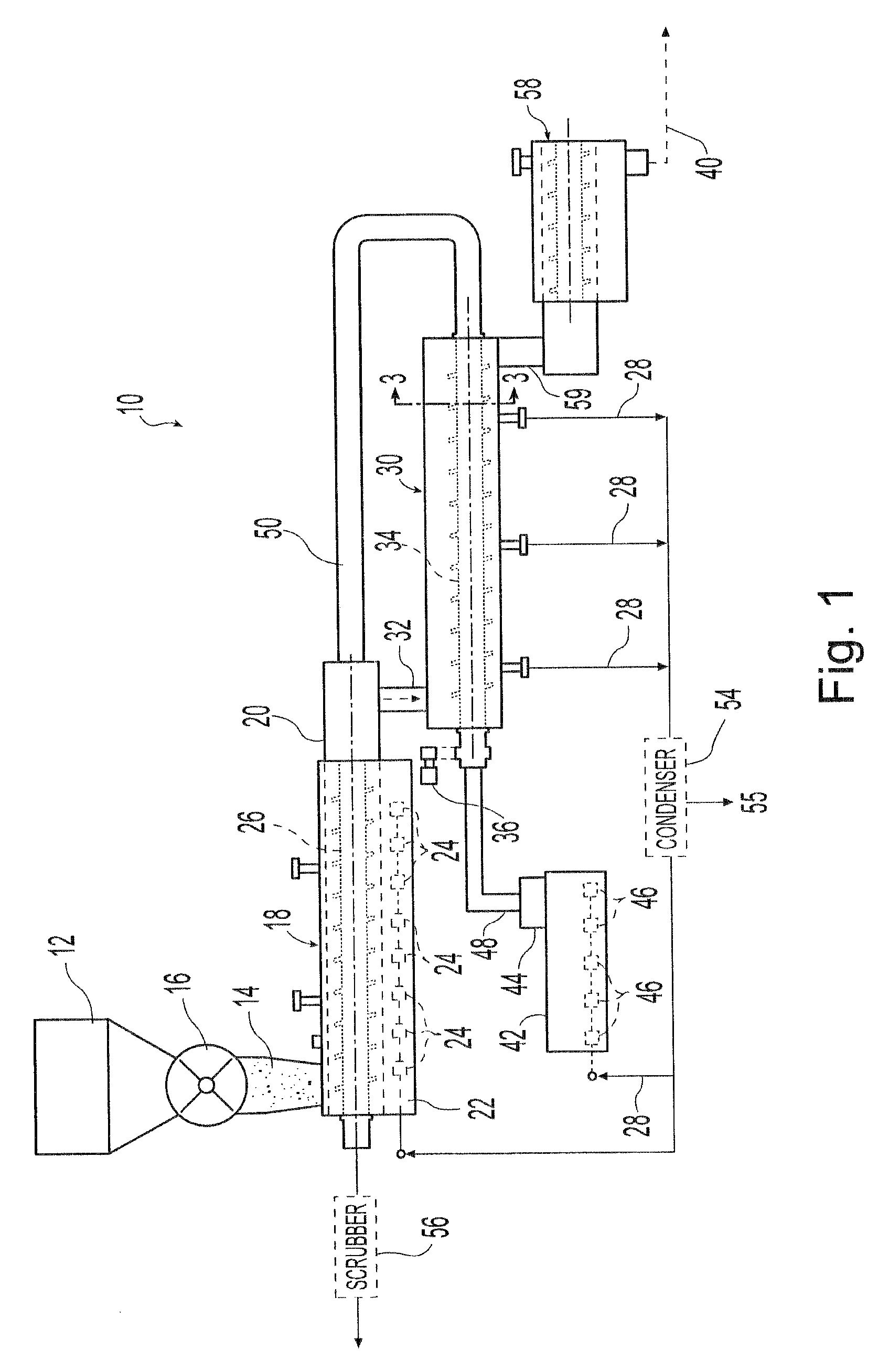

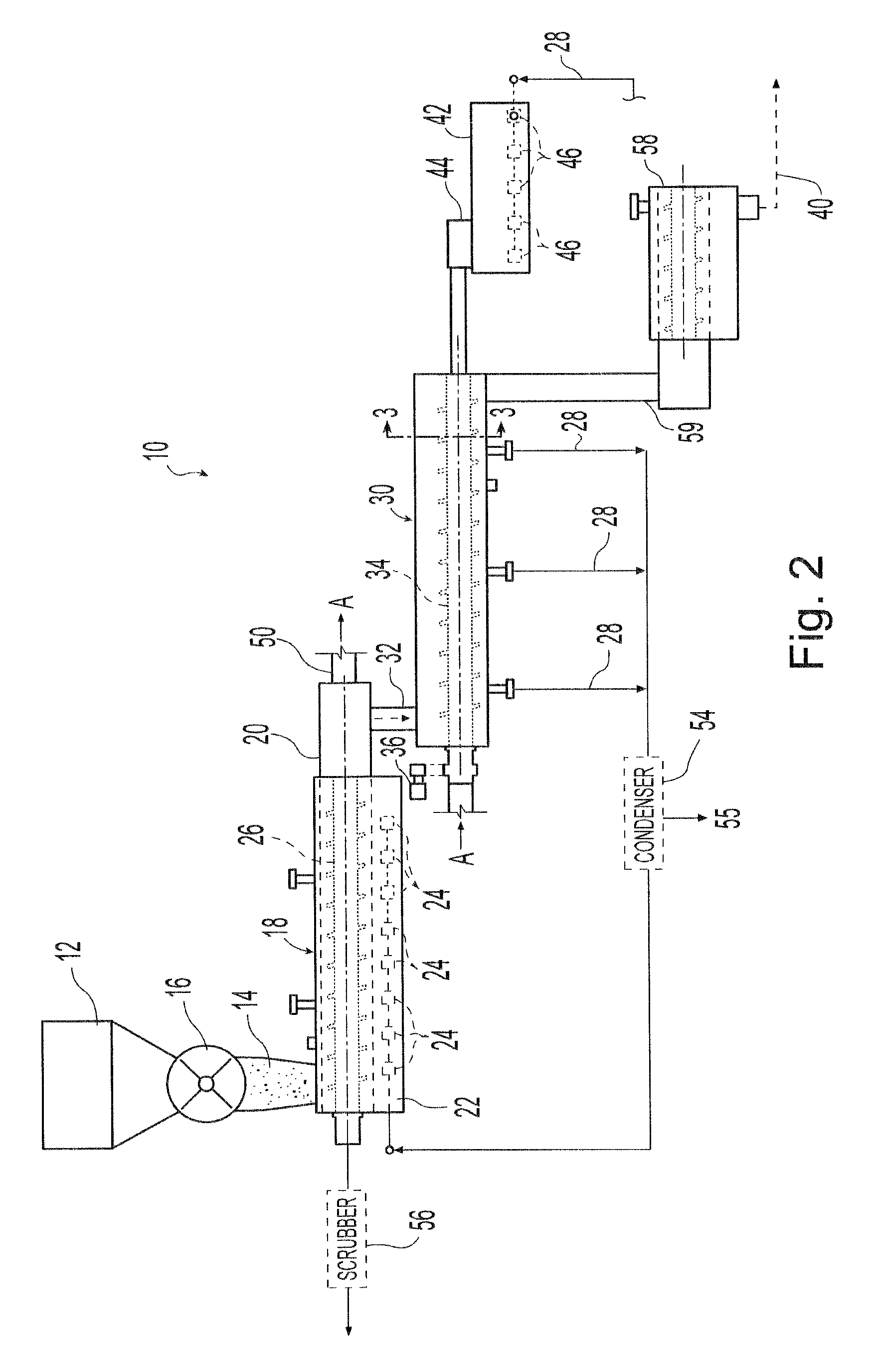

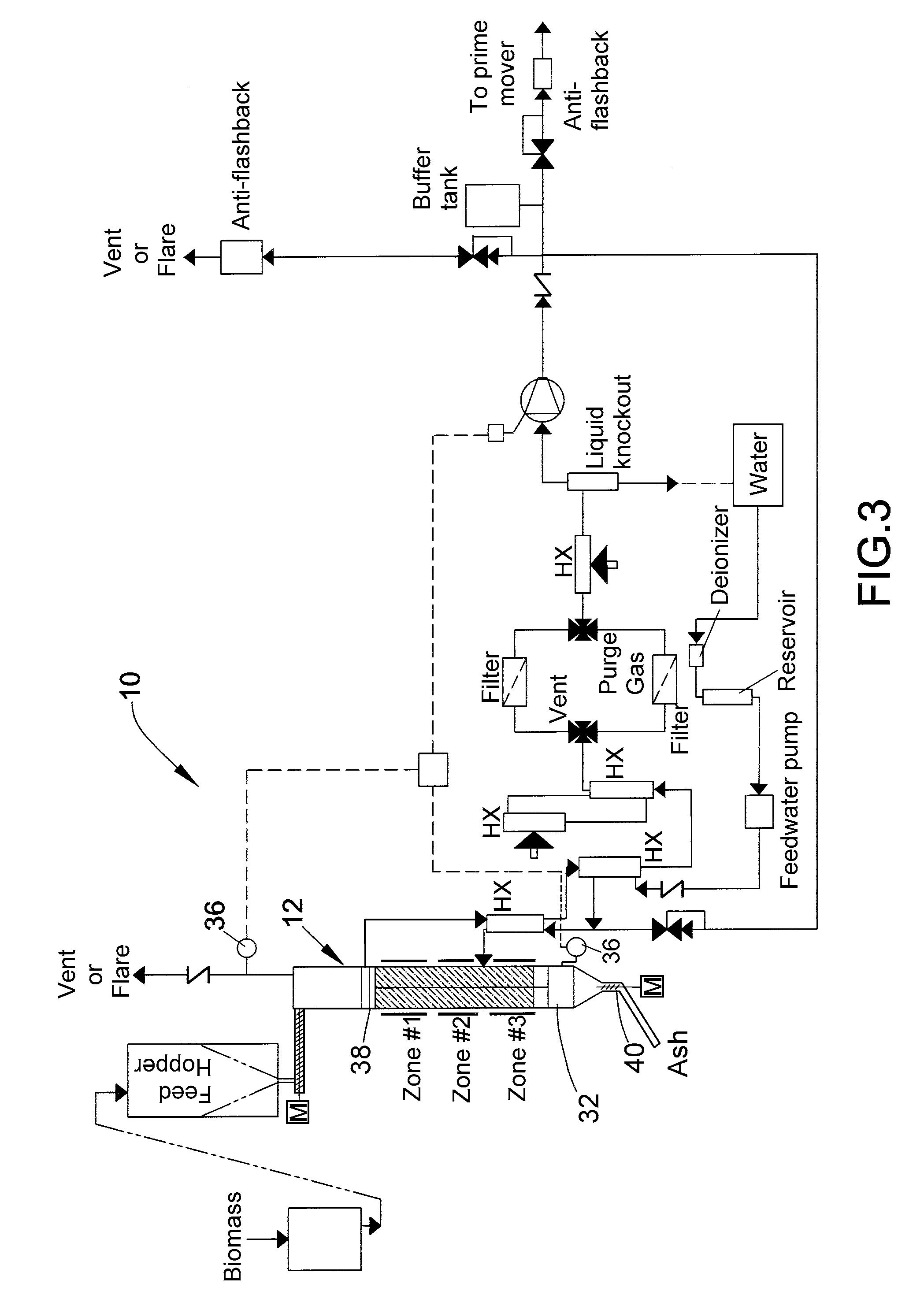

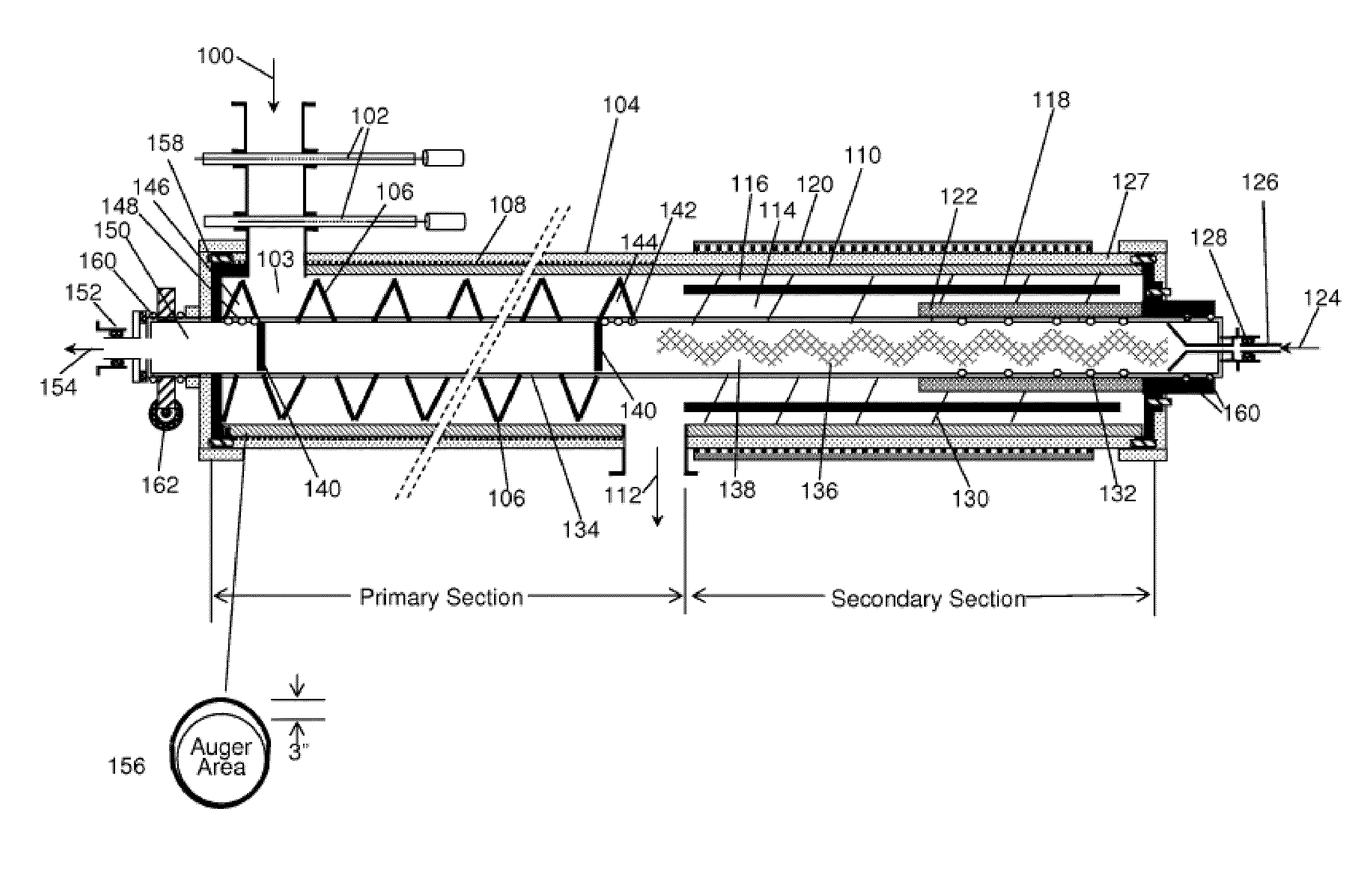

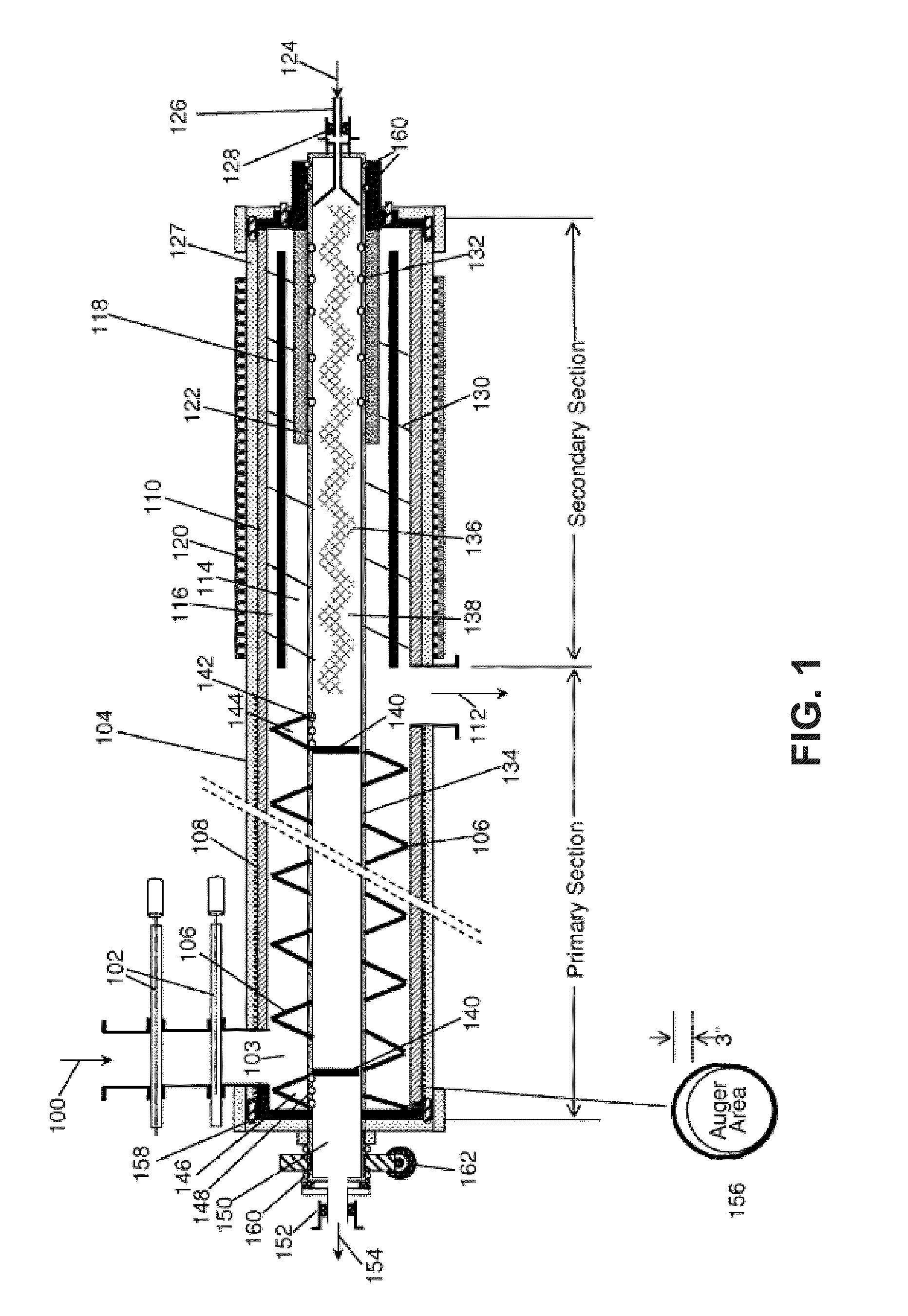

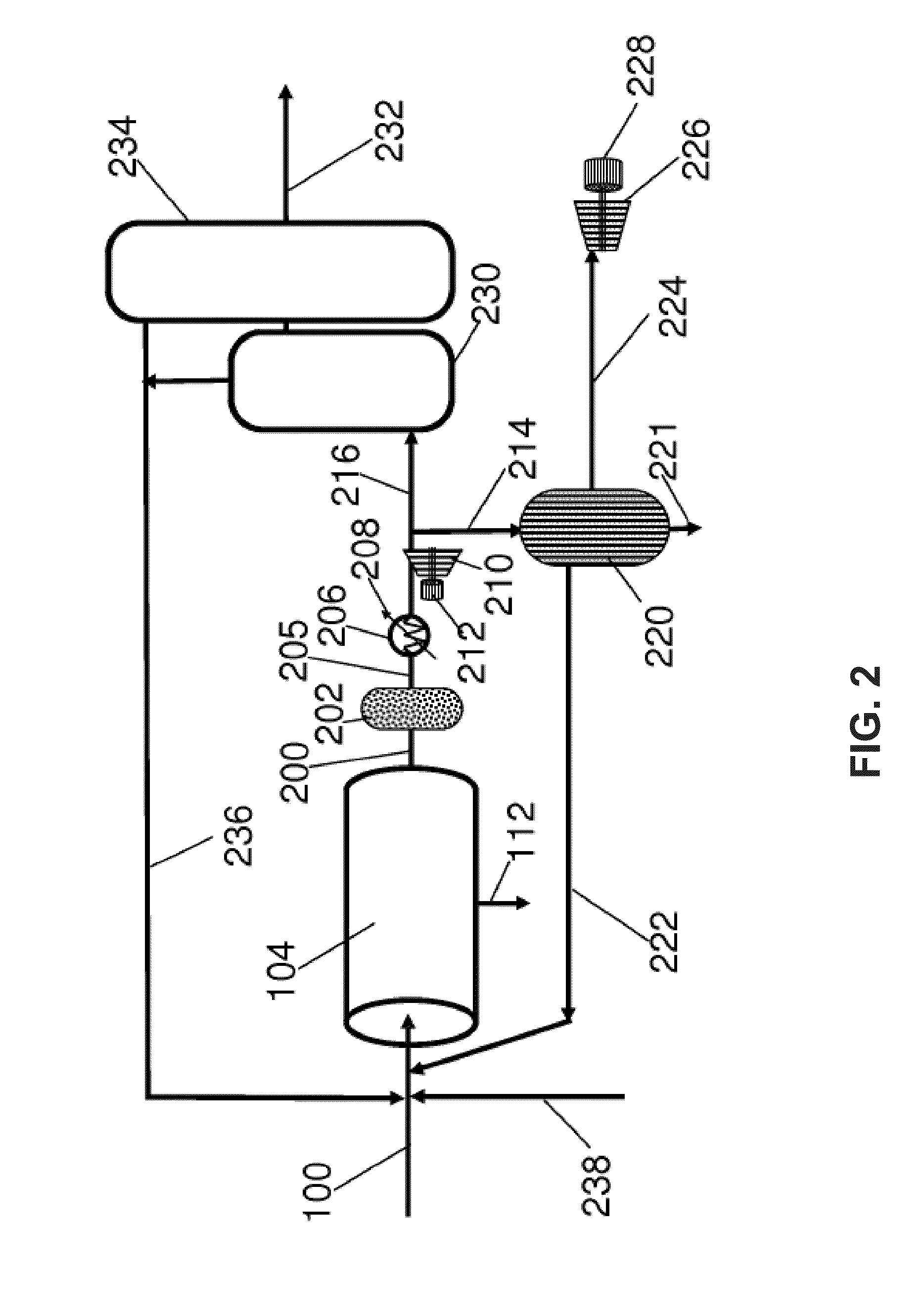

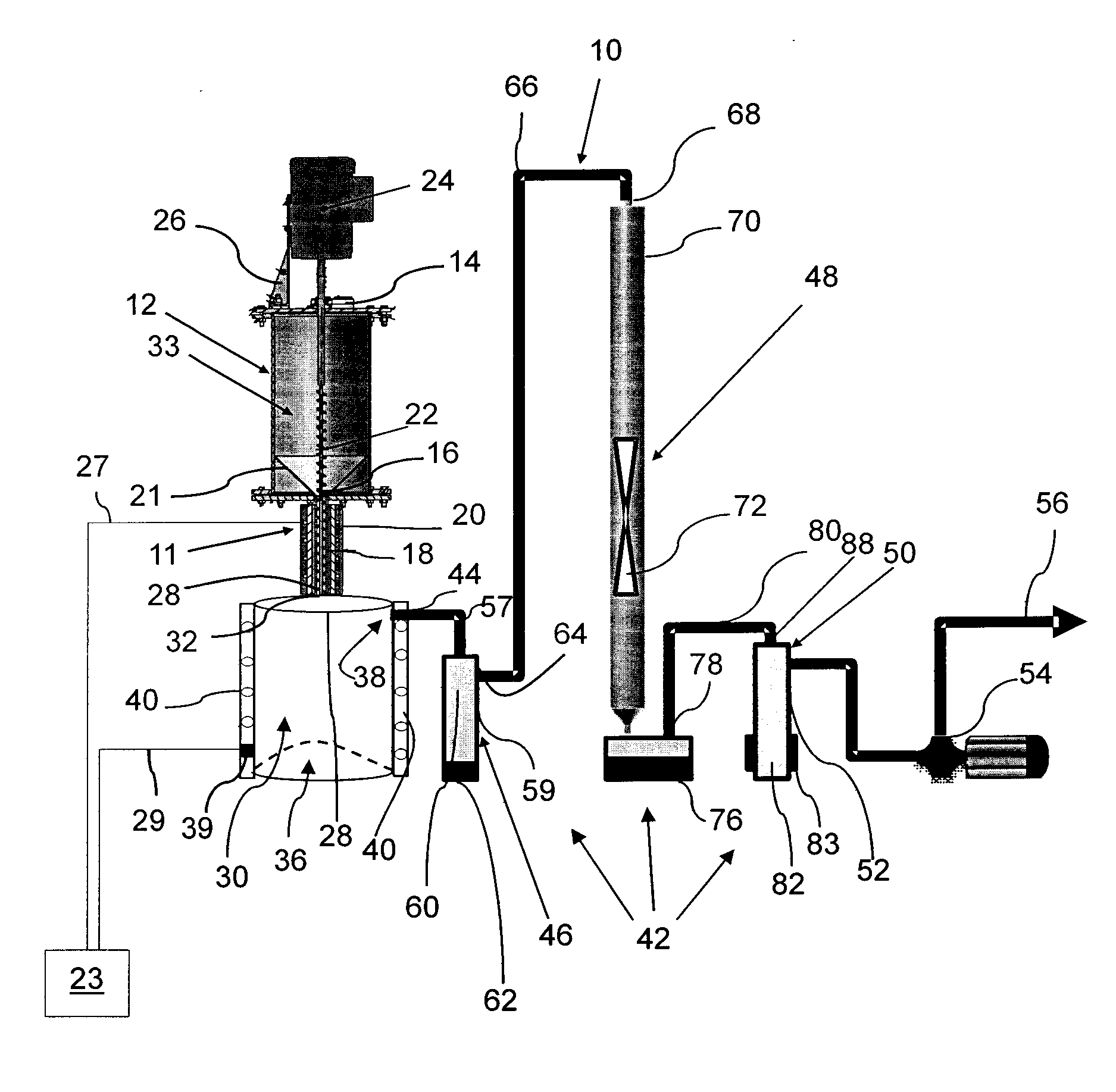

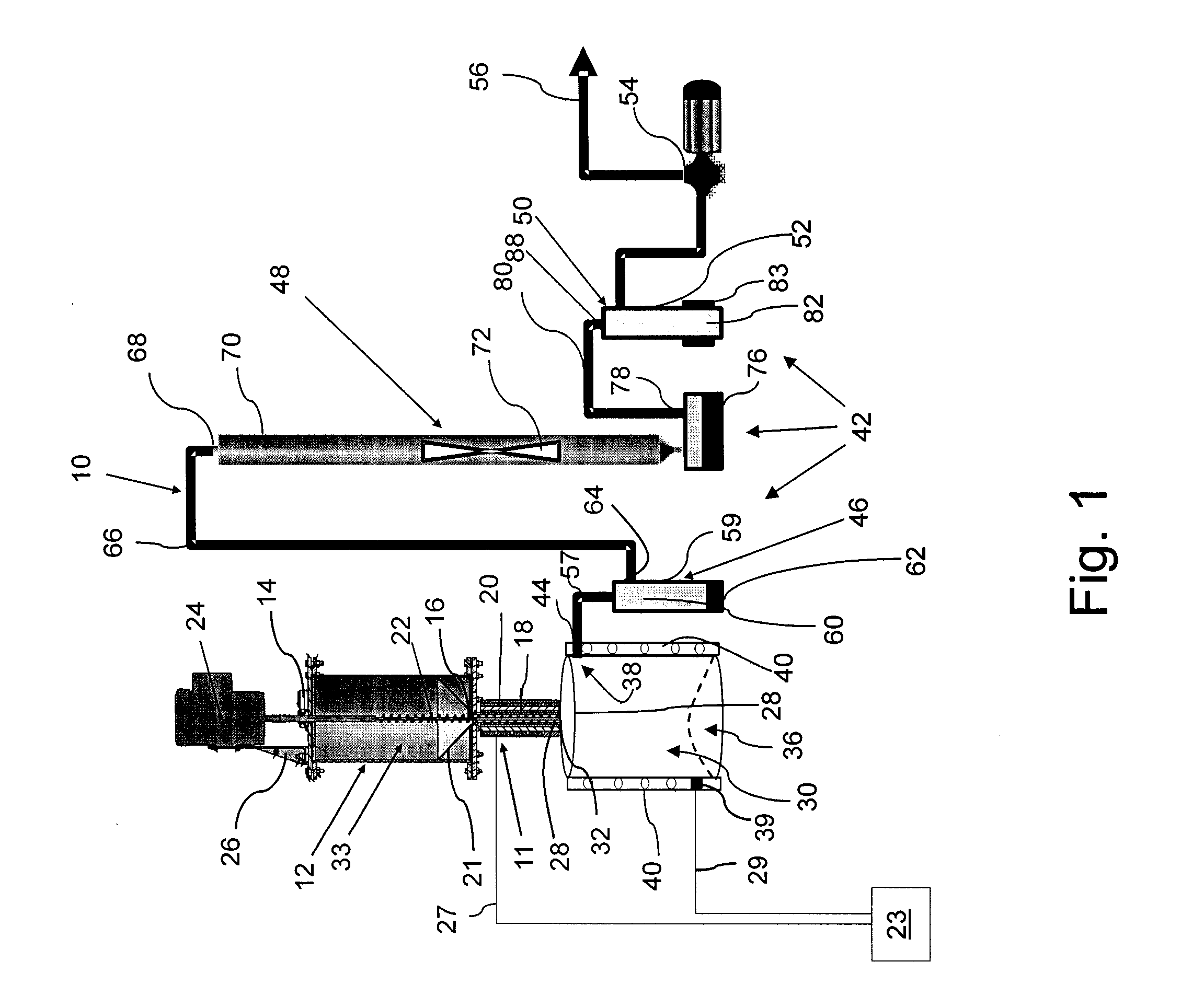

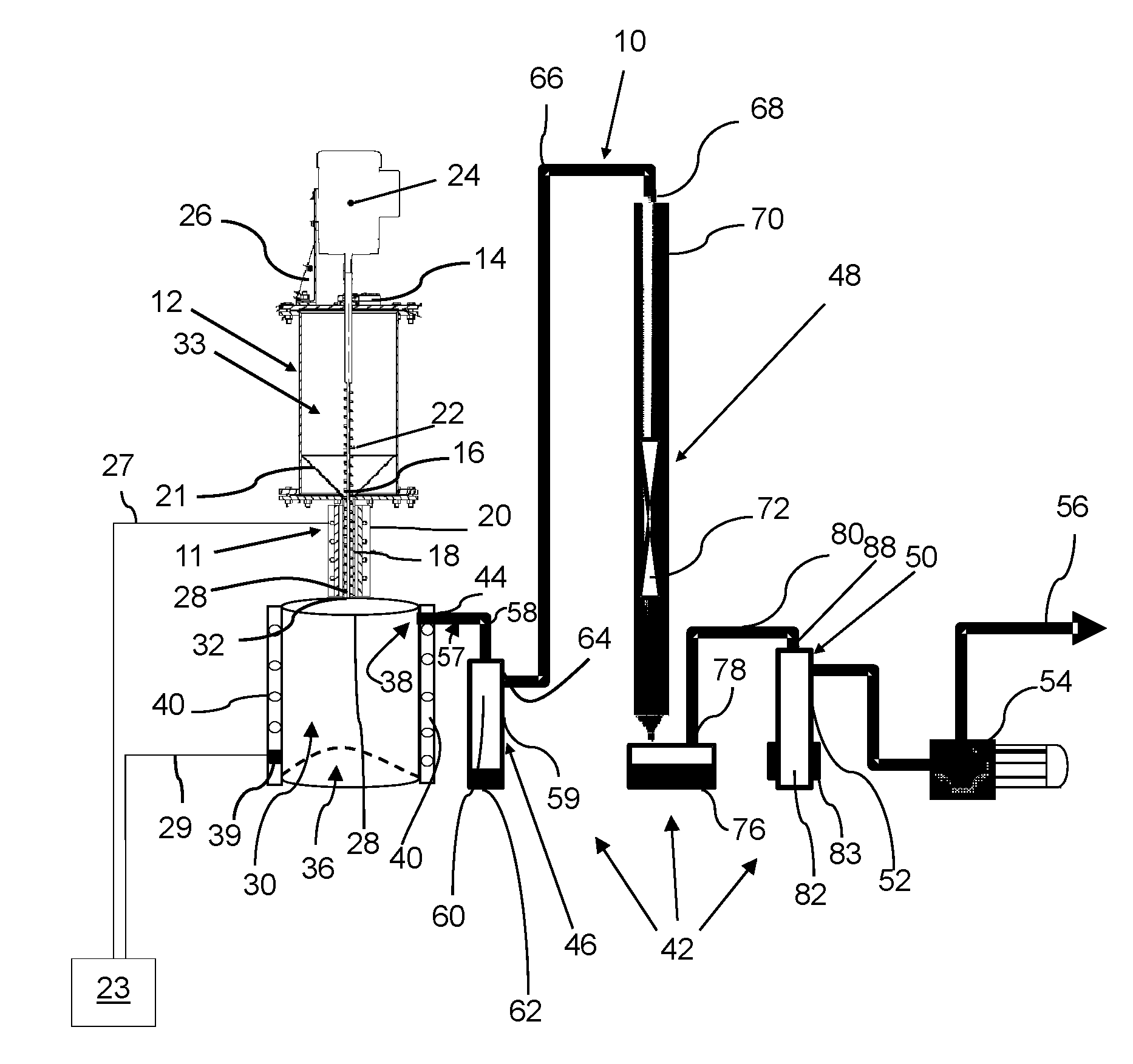

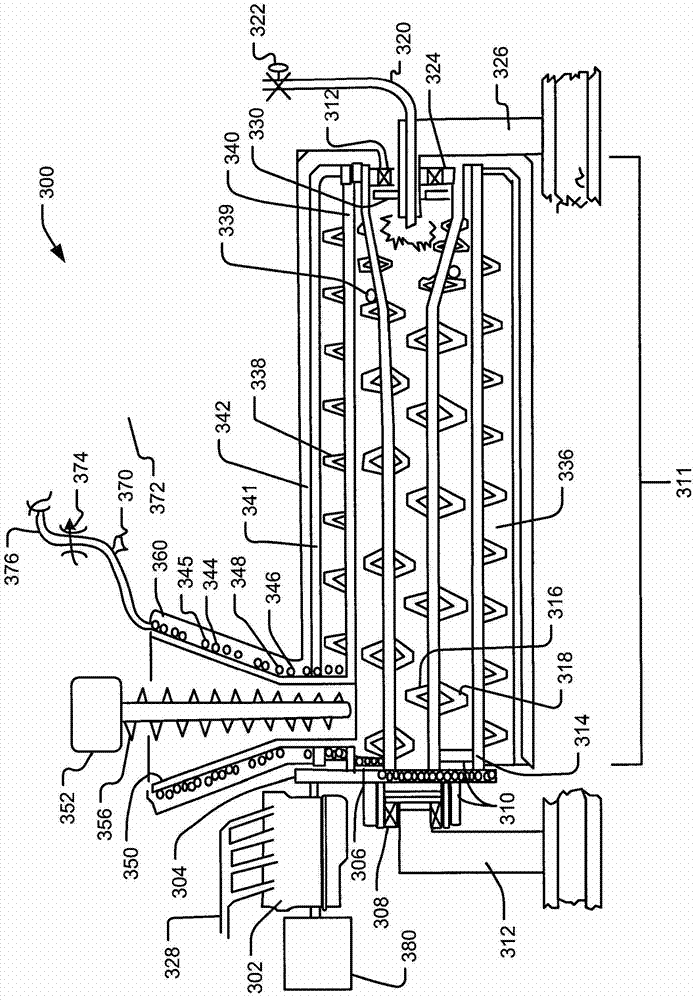

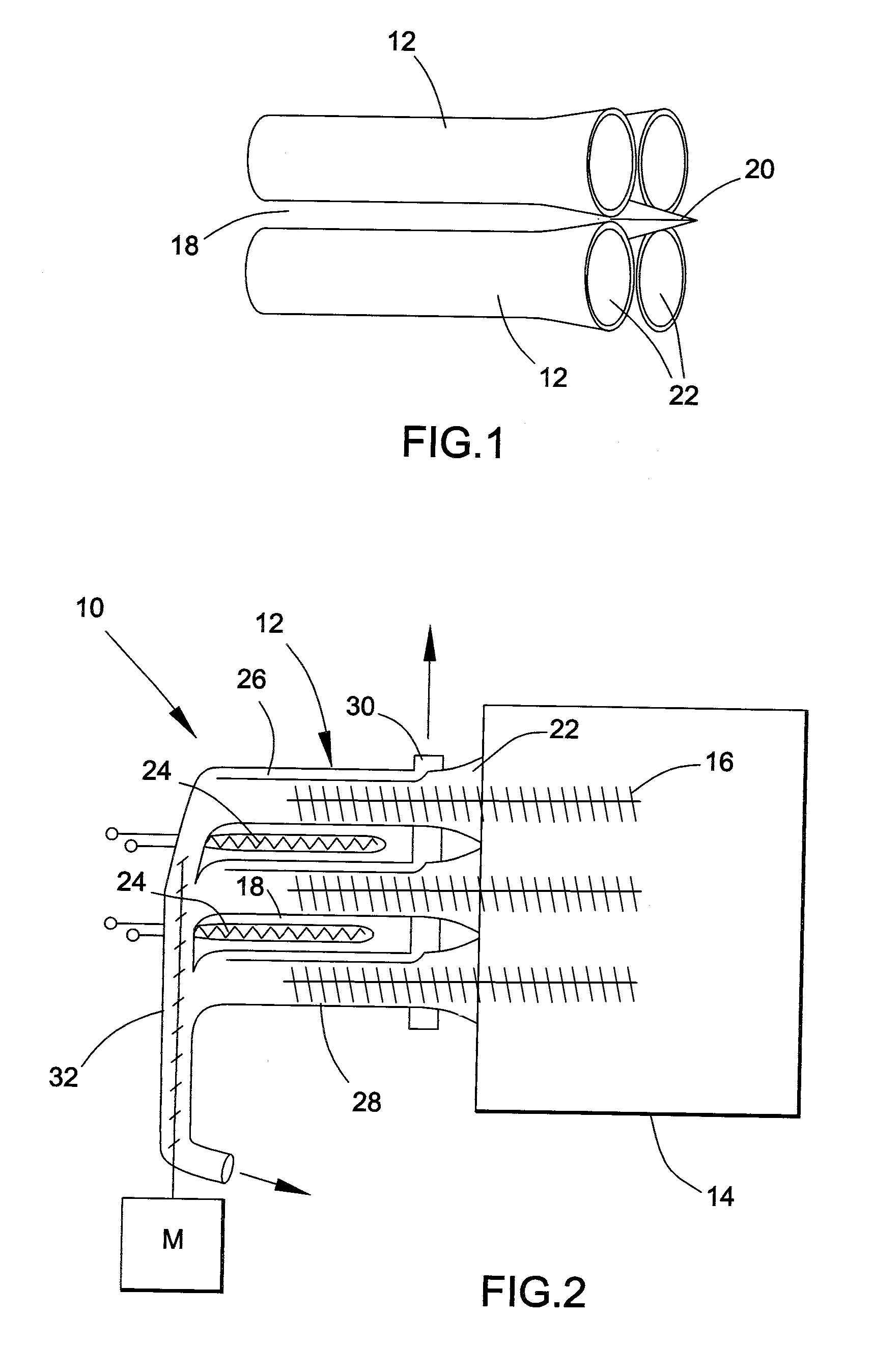

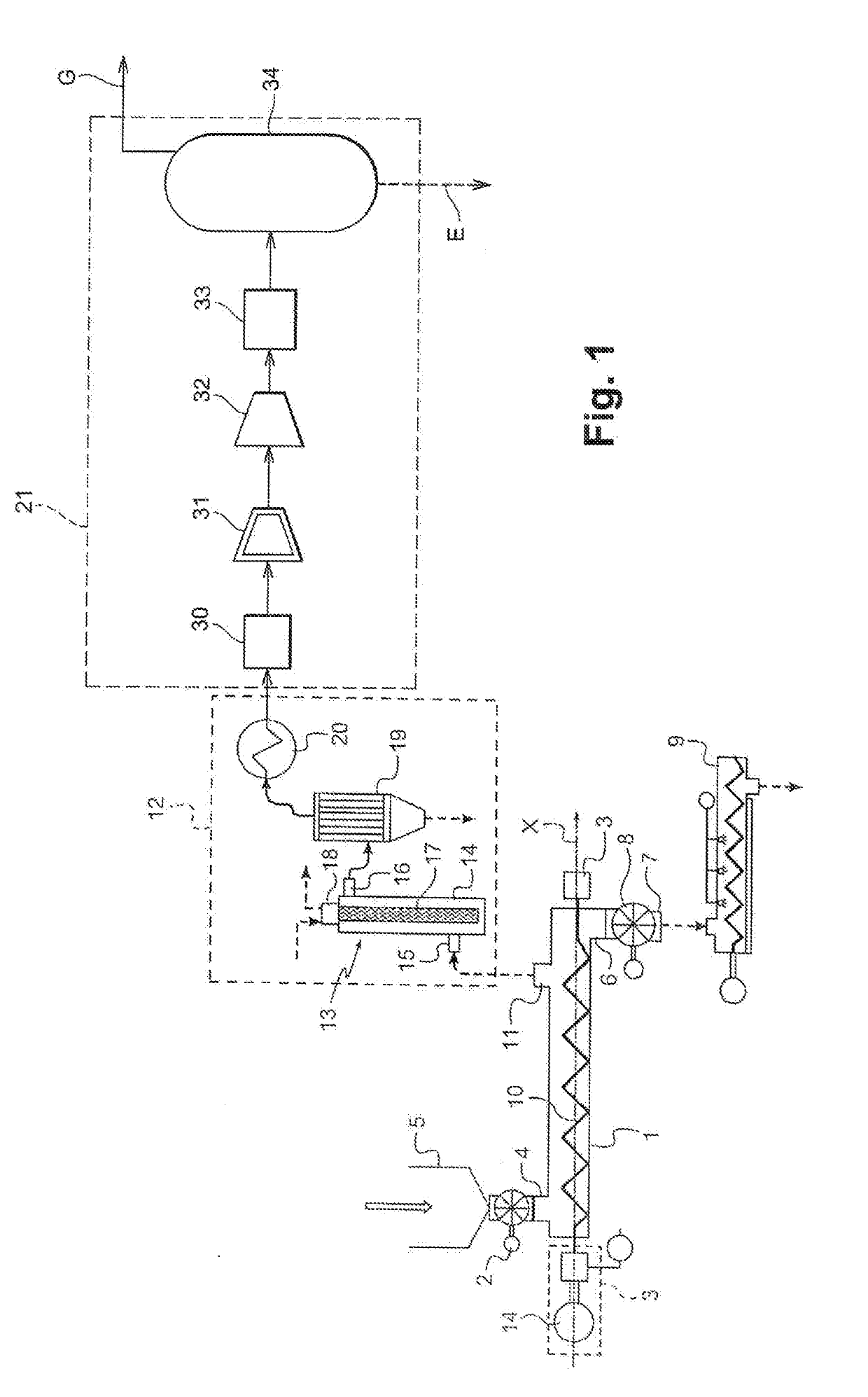

Process and system for duplex rotary reformer

ActiveUS20160130513A1Minimize GHG emissionEmission minimizationGasifier mechanical detailsWaste based fuelSyngasProcess engineering

Methods apparatus for producing fuel and power from the reformation of organic waste. Various embodiments include the use of steam to produce syngas in a Fischer-Tropsch reaction, followed by conversion of that syngas product to hydrogen. Some embodiments include the use of a heated auger both to heat the organic waste and further to cool the syngas.

Owner:RAVEN SR INC

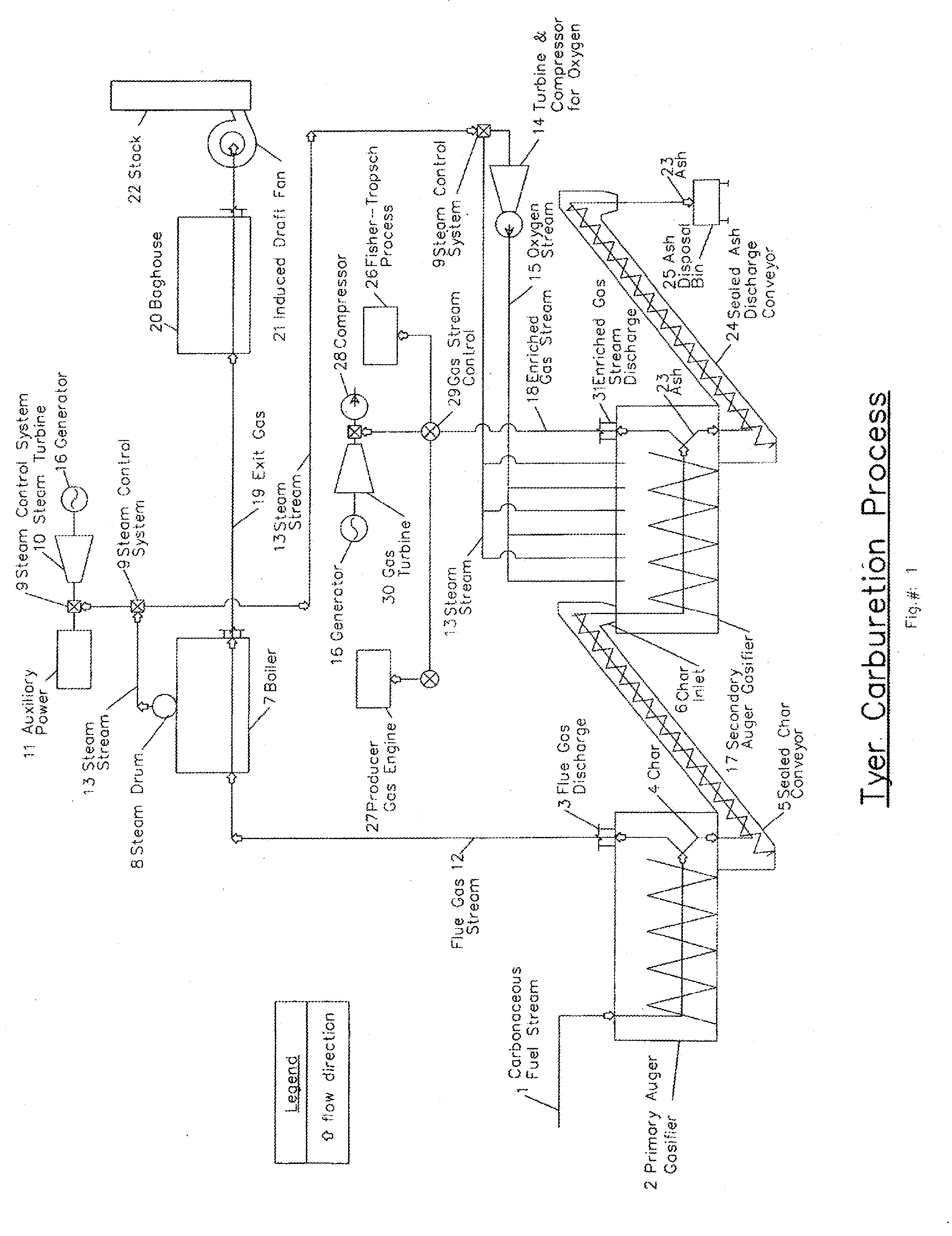

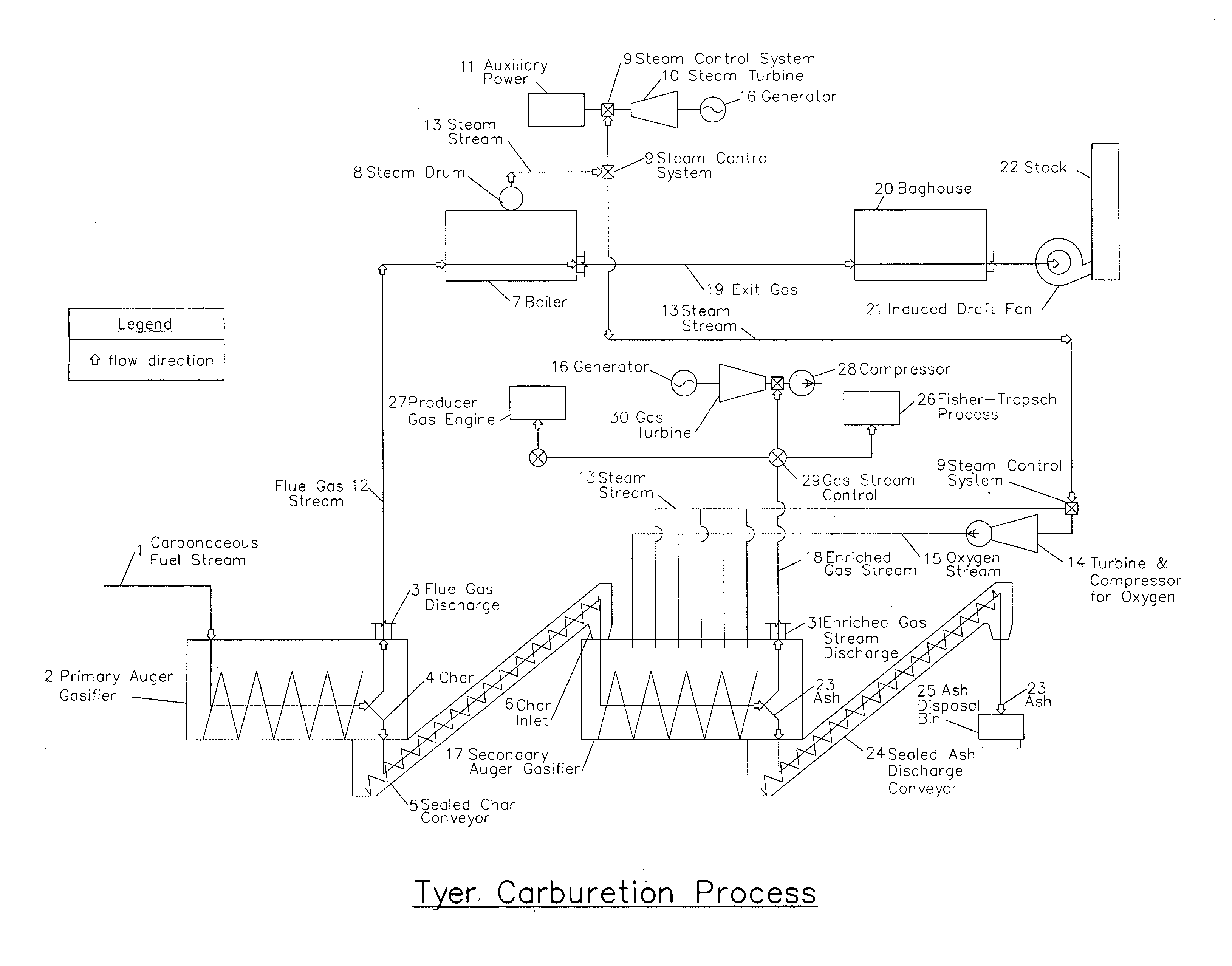

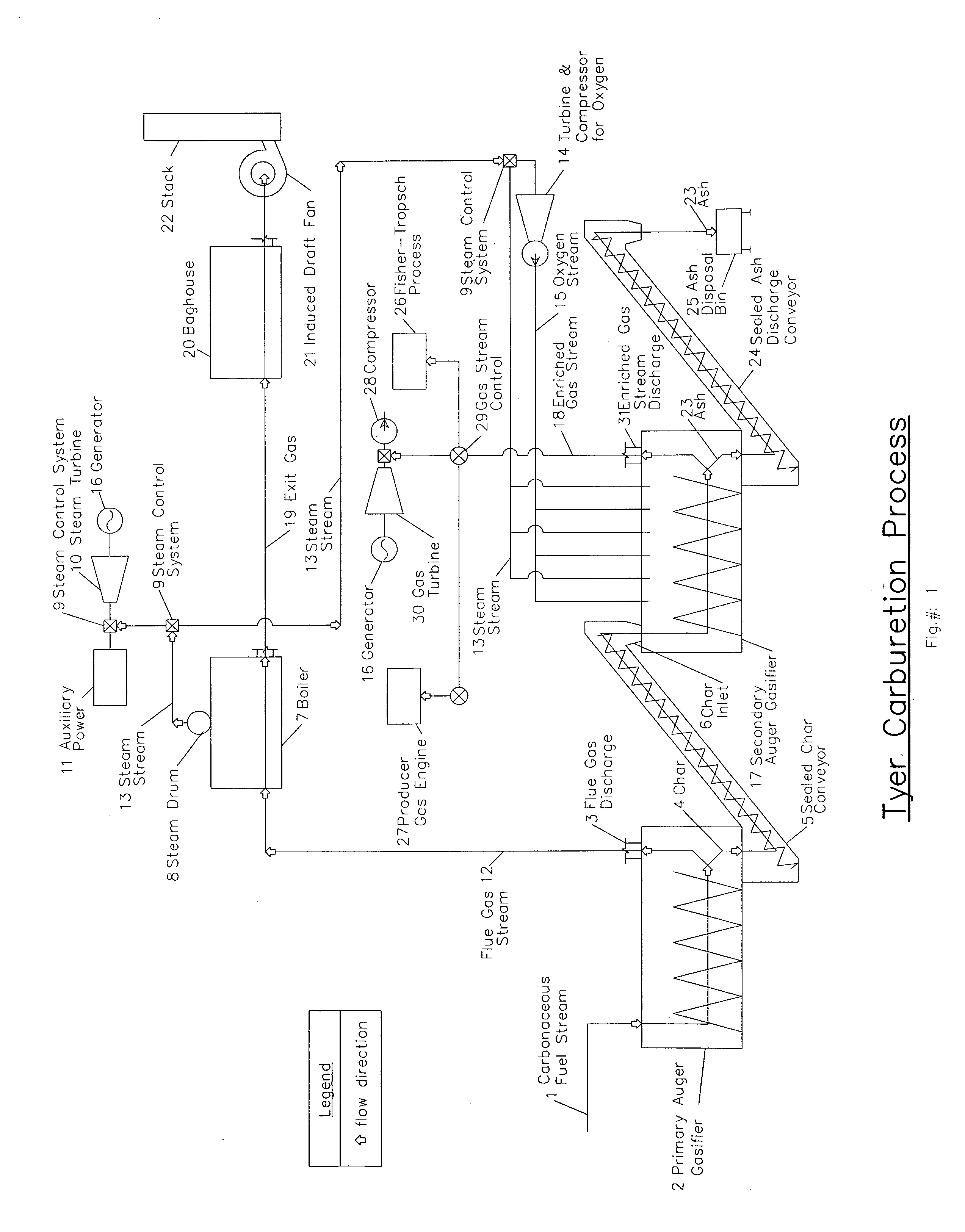

Tyer carburetion process

InactiveUS20140283453A1Easy to controlMaximize gasificationMuffle furnacesDirect heating destructive distillationCombustorWater-gas shift reaction

A means for improving prior art combined cycle combustor and / or gasifiers and / or plural thermodynamic cycle gasification systems by introducing and utilizing an auger for the continuous feeding, agitation, tumbling, advancement and discharge of heterogenous carbonaceous fuel. In addition to the aforementioned improvement, I have included provisions for Fontana's water gas shift reaction utilizing refectory embedded down-tubes that convey steam and oxygen into and through the chambers fluidized bed.

Owner:TYER SR ROBERT CLARK

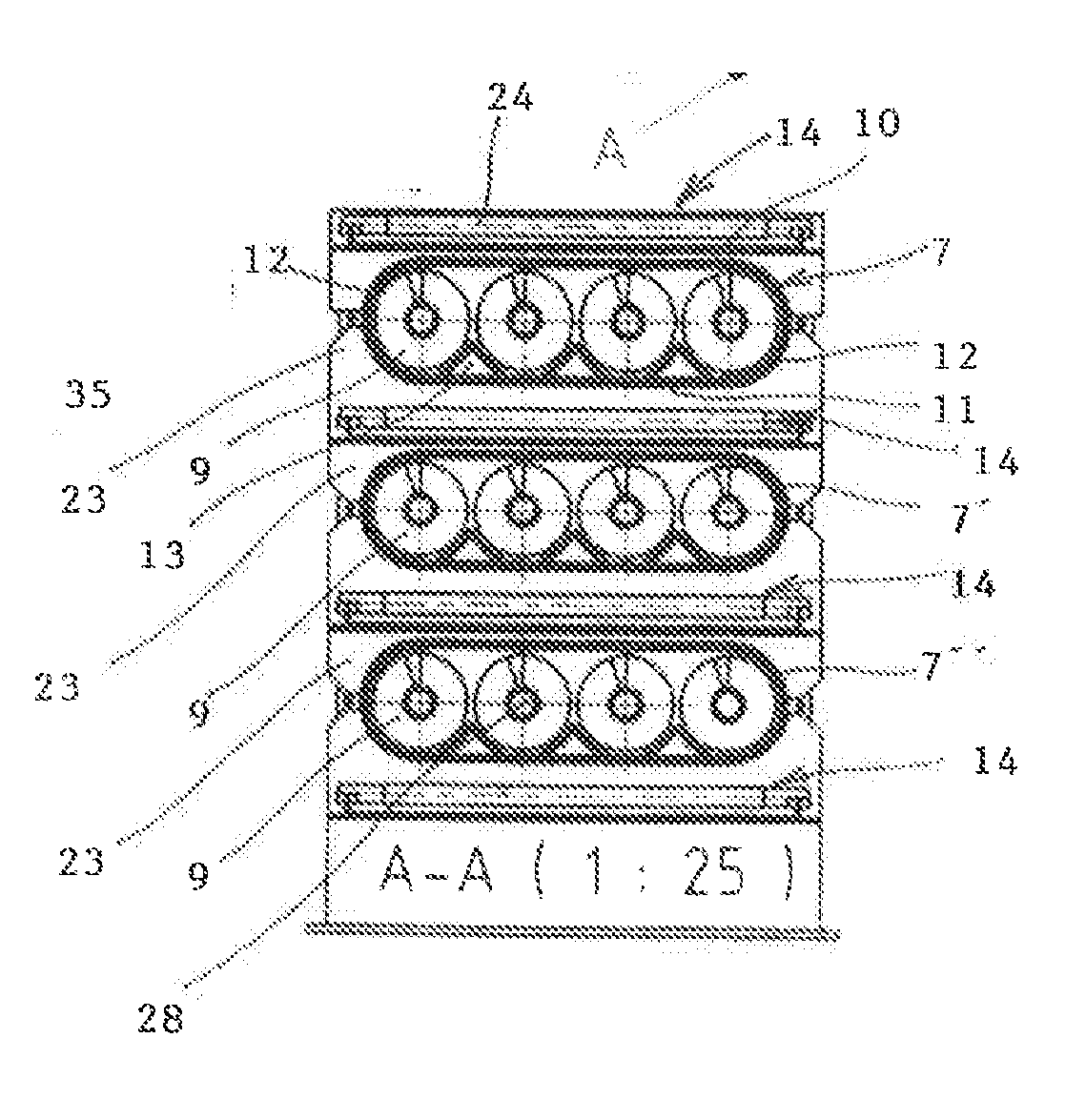

Device for the production of fuel gas from materials of organic and/or inorganic origin

ActiveUS20170158975A1Quality improvementAvoid accessInternal combustion piston enginesBiofuelsConvex sideProcess engineering

A device for producing fuel gas from materials of organic and / or inorganic origin, comprising filling chamber connected to at least one supply auger conveyor for supplying material from the filling chamber into a reactor comprising at least two heated gasification augers. The invention consists in the fact that each horizontal row of gasification augers is formed by a gasification body, the casing of which has a closed oval cross-section formed by an upper base, a lower base, and convex side walls each with circular arc profiles, wherein each gasifying body contains at least two gasification augers arranged side by side and mutually partially separated by longitudinal partitions that form half-grooves for gasifying augers. The device is provided with at least one electrical heater. The filling chamber is hermetically sealed.

Owner:JANCOK LUBOR

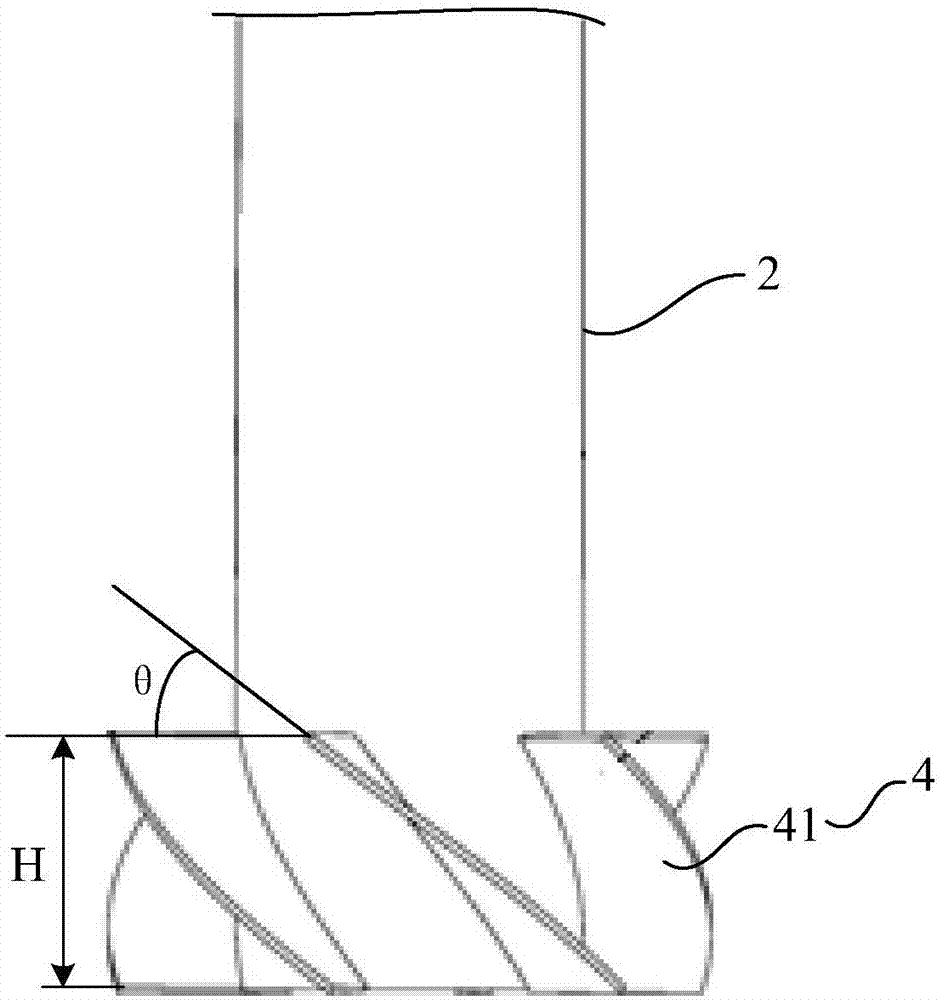

Biomass rotary propulsion pyrolysis device

ActiveCN107033934AImprove sealingImprove economyBiofuelsGasification processes detailsHelical bladeEngineering

Provided is a biomass rotary propulsion pyrolysis device. The device comprises a pyrolysis device body, the pyrolysis device body is connected to a rotary device, and comprises a feed pipe (1), a discharge pipe (8) and several pyrolysis pipes (4), the outlet of the feed pipe (1) is fixedly connected to the inlets of the several pyrolysis pipes (4) separately, the outlets of the several pyrolysis pipes (4) are fixedly connected to the inlet of the discharge pipe (8) separately, the feed pipe (1) is internally provided with a feed helical blade (2), the discharge pipe (8) is internally provided with a discharge helical blade (9), the pyrolysis pipes (4) are internally provided with pyrolysis helical blades (5), and several means one or more. Through the biomass rotary propulsion pyrolysis device, the problem of pool sealing caused by a complicated mechanism in which the helical blades need to rotate and transmit solely is solved, and the device has good economic and environmental protection effects.

Owner:武汉天颖环境工程股份有限公司

Device for Processing Scrap Rubber

ActiveUS20190264109A1Easy to useReduction of liquid fuel consumptionLiquid hydrocarbon mixture productionIndirect heating destructive distillationCycloneCombustor

A device for processing scrap rubber has a reactor with a screw conveyor disposed inside a heating chamber, a thermal decomposition unit, burners, a condenser, a cyclone filter, and devices for discharging solid residue and removing a gas-vapor mixture. The reactor has two sections connected in parallel. The thermal decomposition unit has screw conveyors in each section, the conveyors have axial heating pipes with a coil. Along the length of the conveyors plates are arranged at the corners of an equilateral triangle in contact with and perpendicular to the side surface of the heating tube. A cylinder furnace with an evaporator and a burner is connected to the ends of the pipes. An outlet of the condenser is connected to a liquid fraction separator, inlets of the coils are connected to an outlet of the evaporator, and an inlet of the evaporator is connected to an outlet from the separator.

Owner:SUSEKOV SERGEI PAVLOVICH

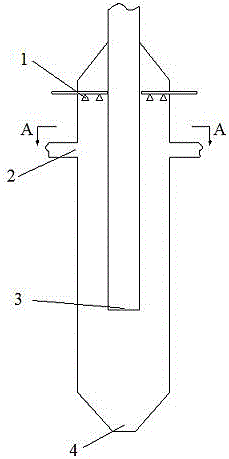

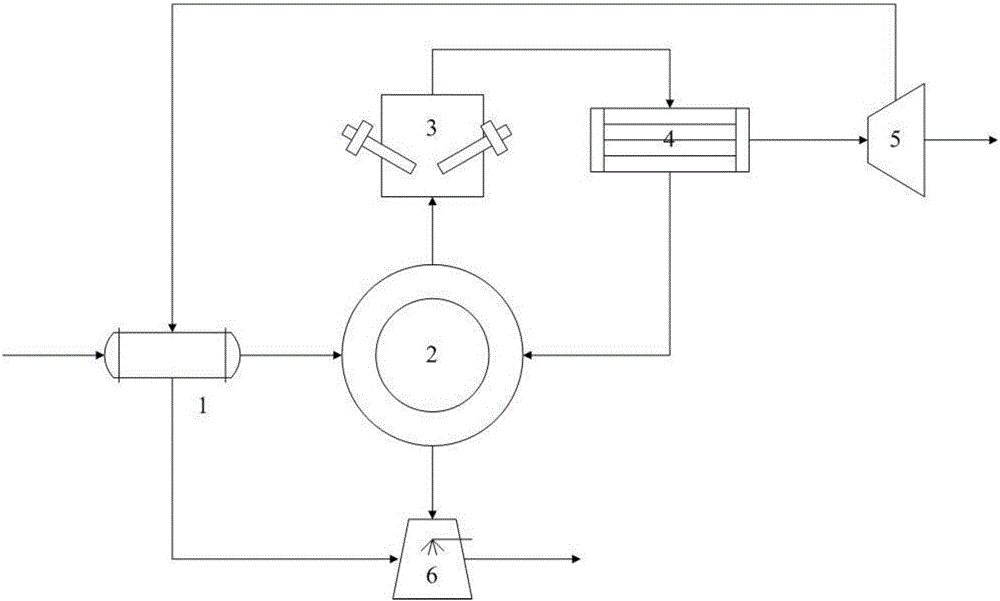

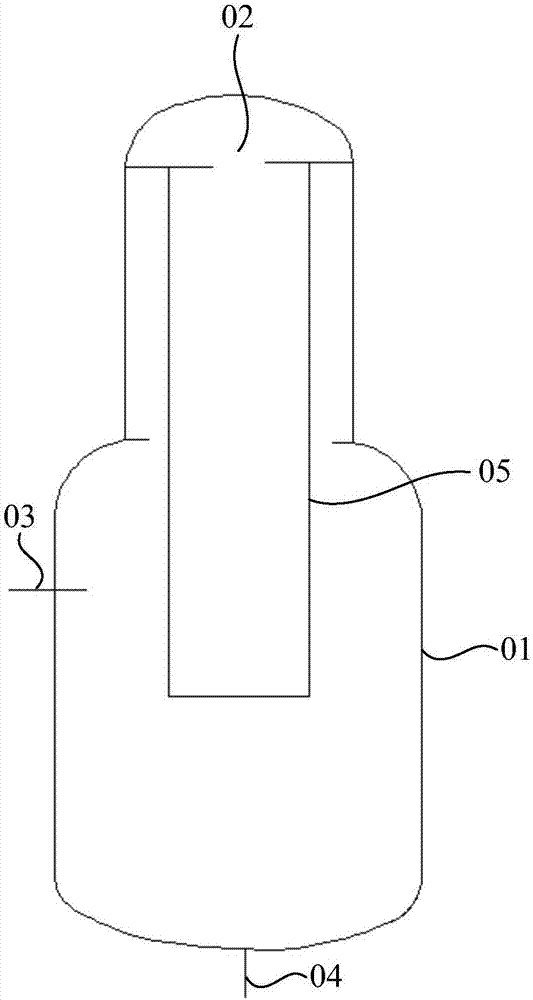

Sludge slurry gasification method and device

ActiveCN106316049AEasy to passImprove gasification efficiencySludge treatment by de-watering/drying/thickeningGasification processes detailsReduction treatmentEvaporation

The invention provides a sludge slurry gasification method and device. The device comprises an atomization range and a gasification region. The method comprises the following steps: carrying out crushing treatment on dewatered sludge by using ultrasonic, mixing with biomass and additives to prepare sludge slurry, atomizing the sludge slurry into small-particle liquid drops by using the device, and gasifying to obtain combustible gas. The atomized small-particle liquid drops move helically in the device along with the gas flow and are quickly gasified; and moisture in the liquid drops can generate a crushing action on solid particles in the sludge slurry in the heating-induced evaporation precipitation process, thereby further reducing the particle size, and enhancing the thermal mass transfer rate and gasification efficiency. The method solves the problems of hardening, wall adhesion and the like caused by wet sludge direct gasification, widens the applicability of the sludge gasification technique, and implements cyclic harmless and reduction treatment on the sludge.

Owner:莘县鲁开综合服务有限公司

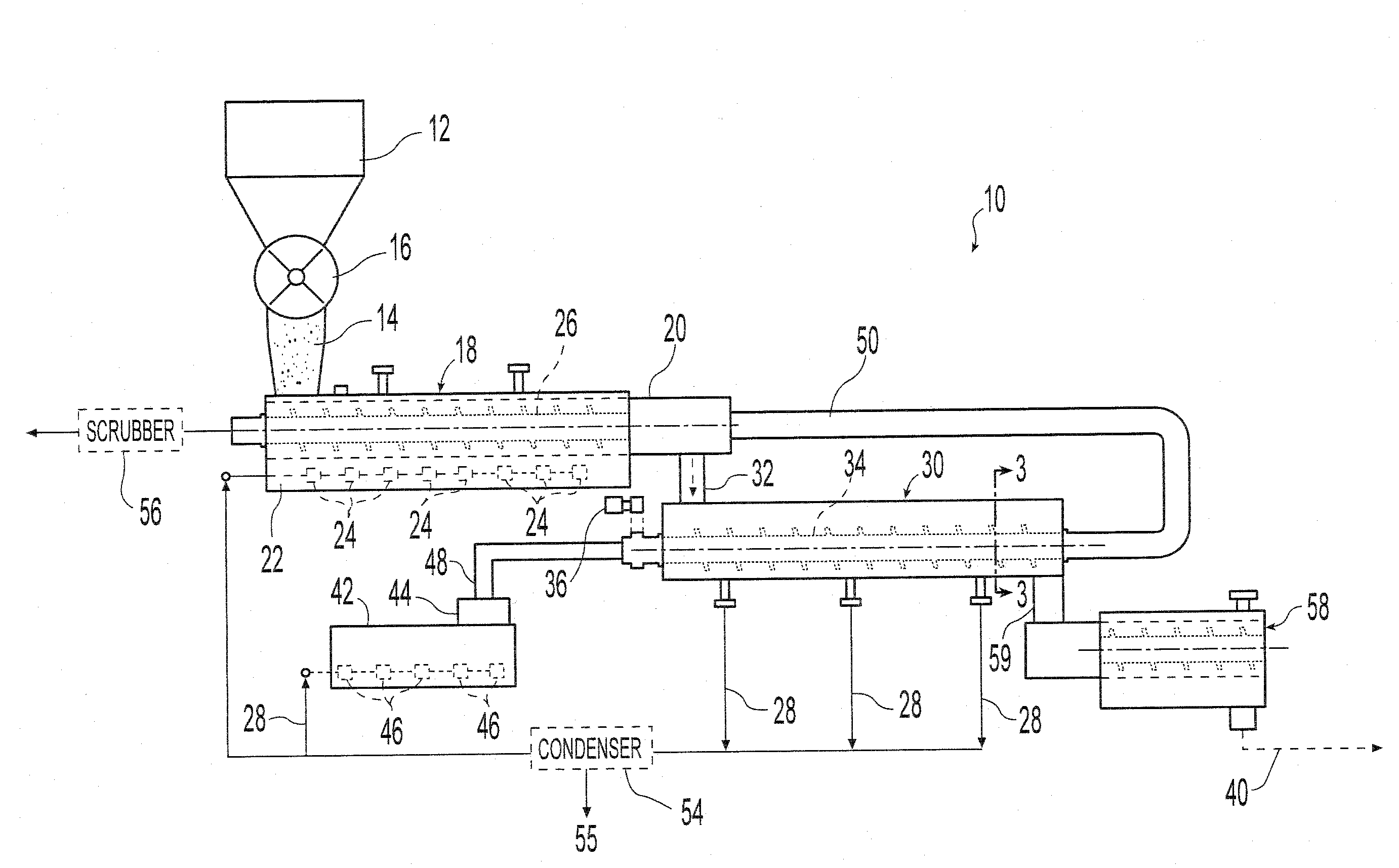

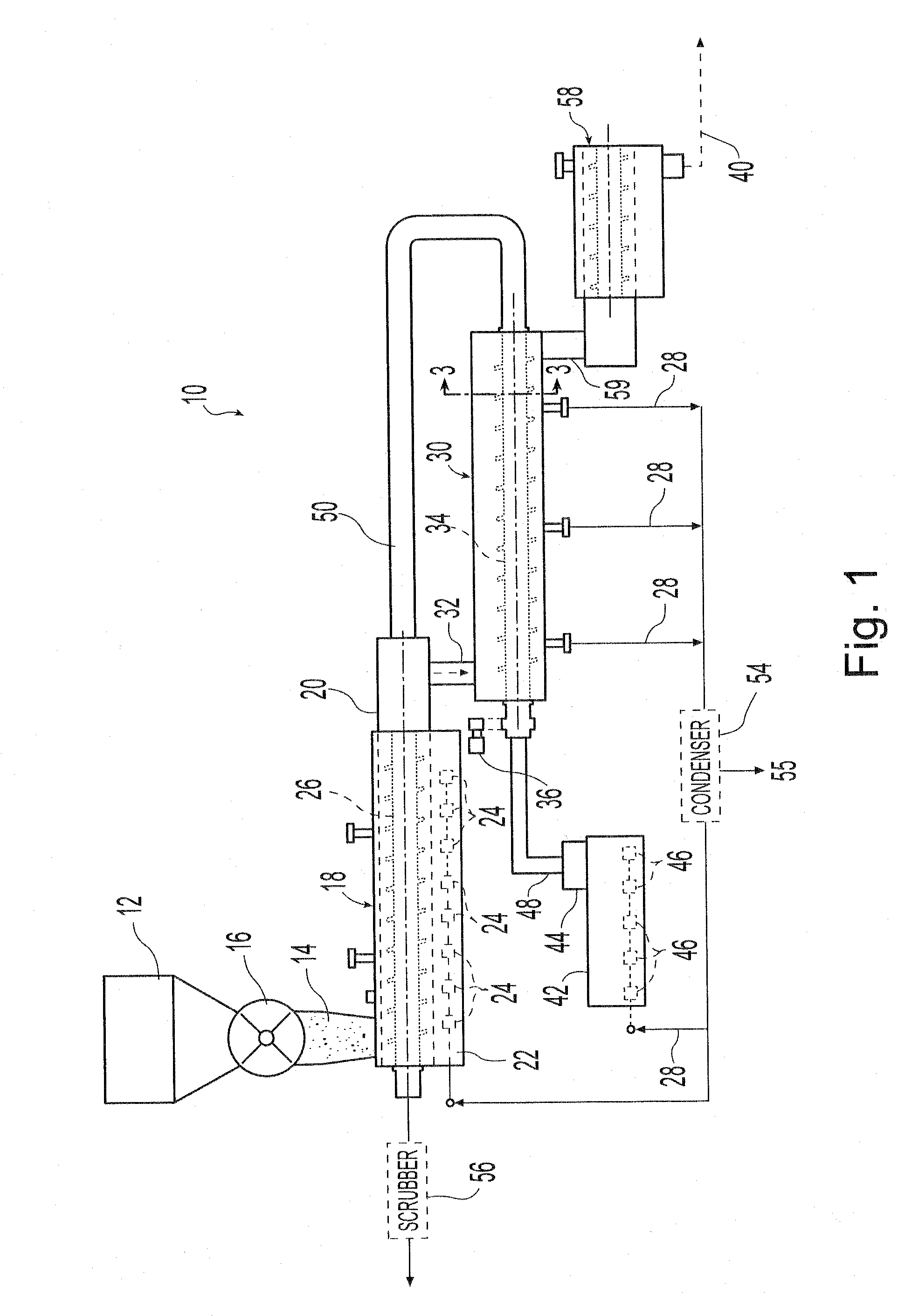

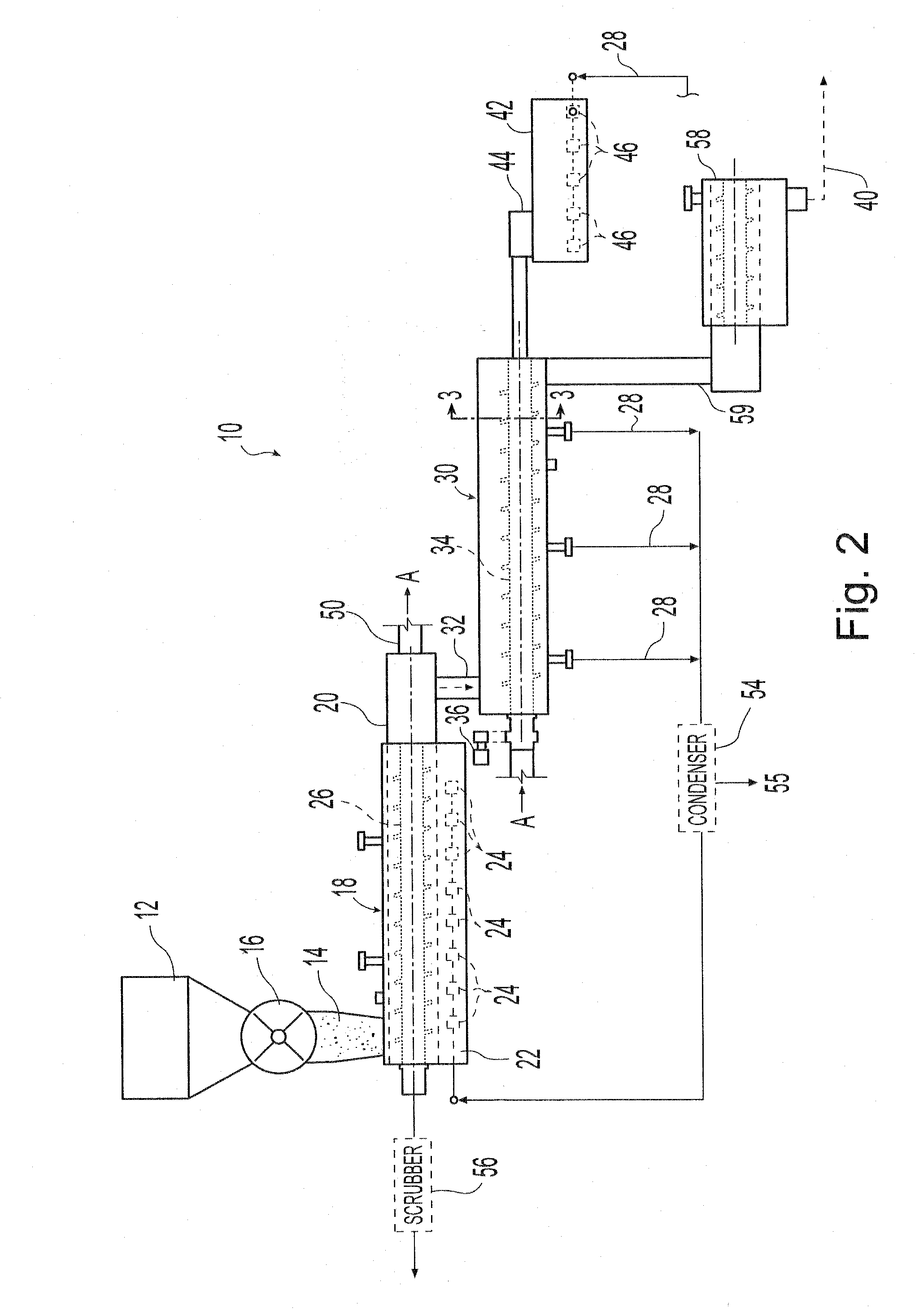

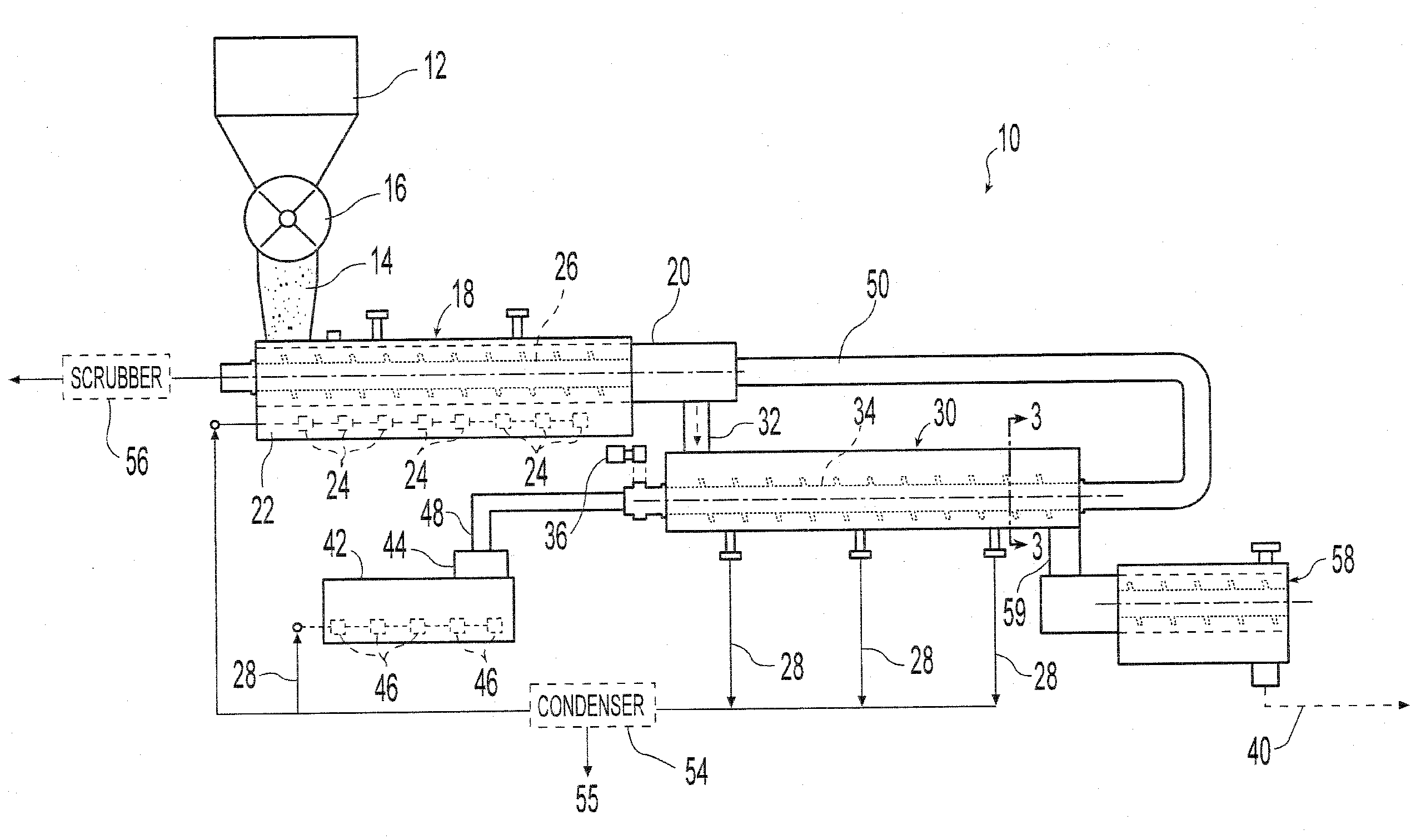

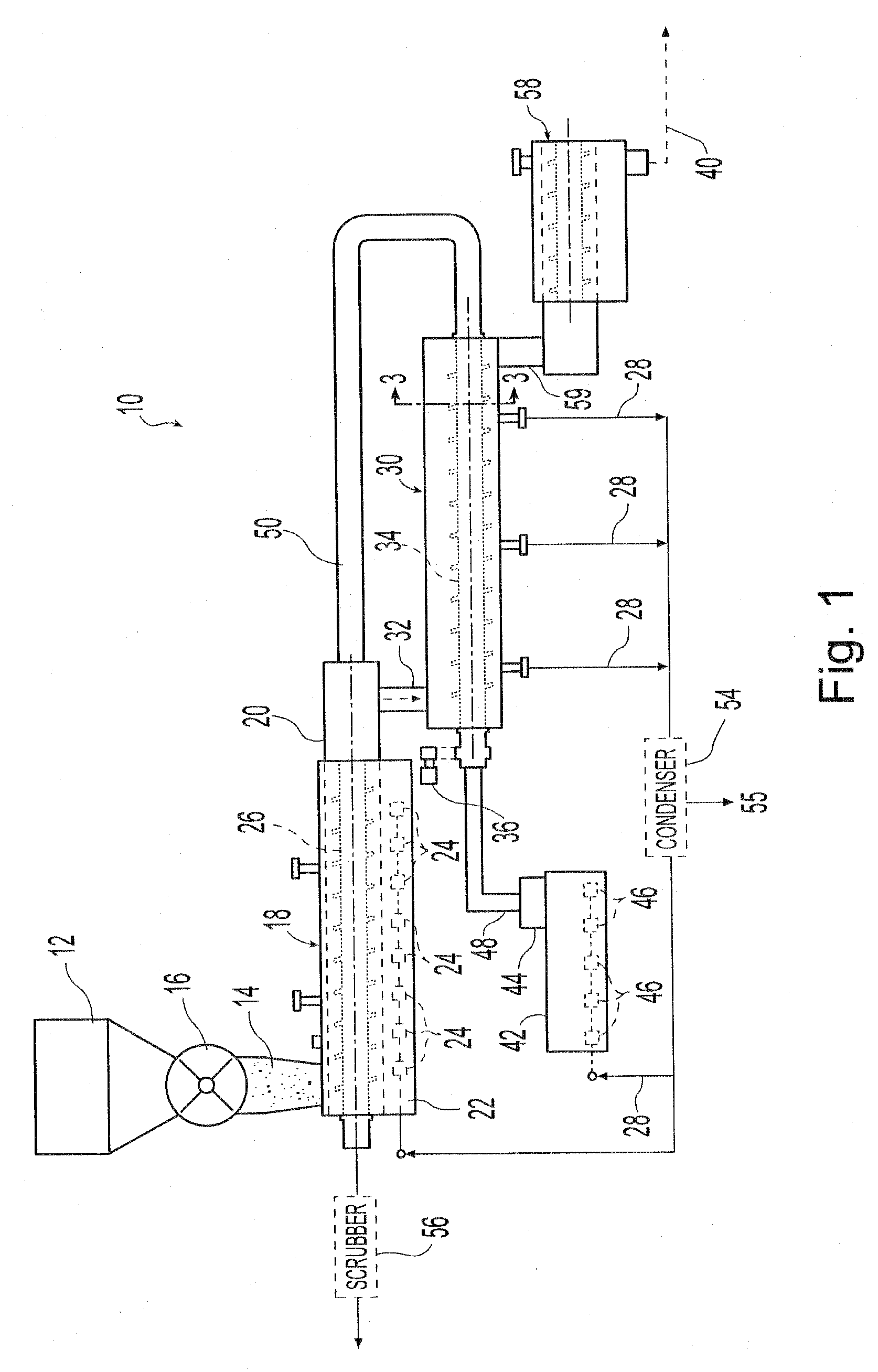

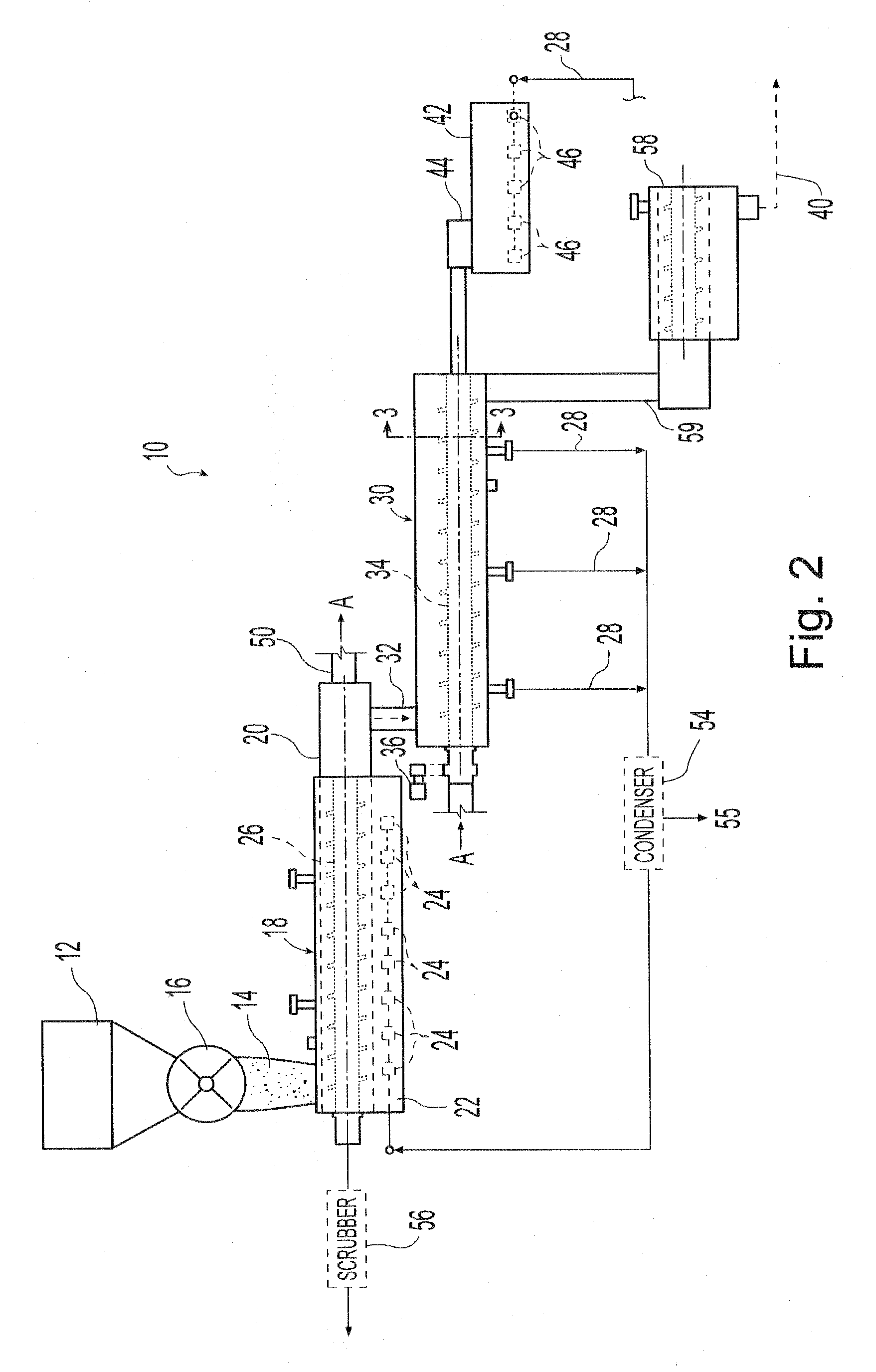

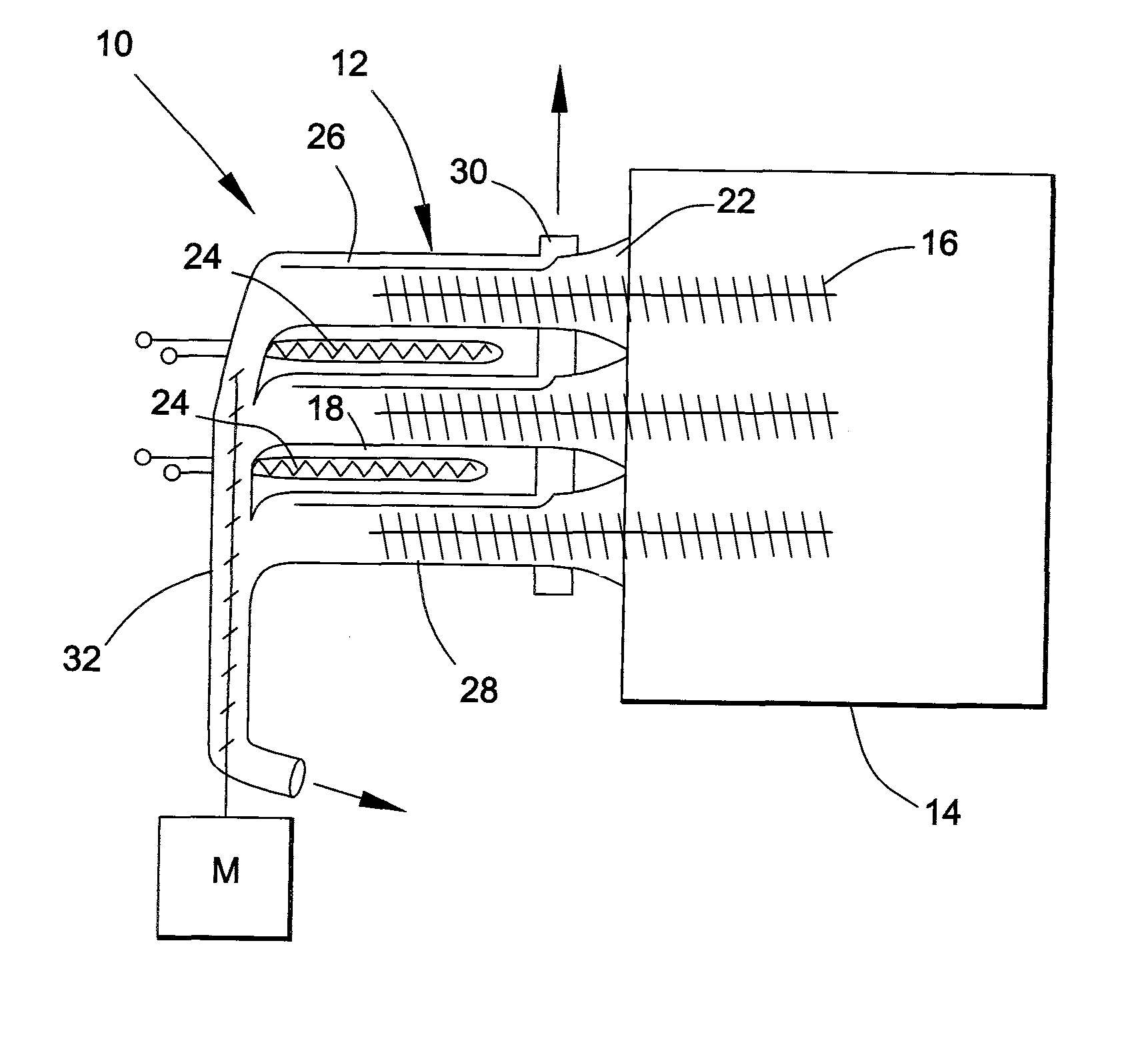

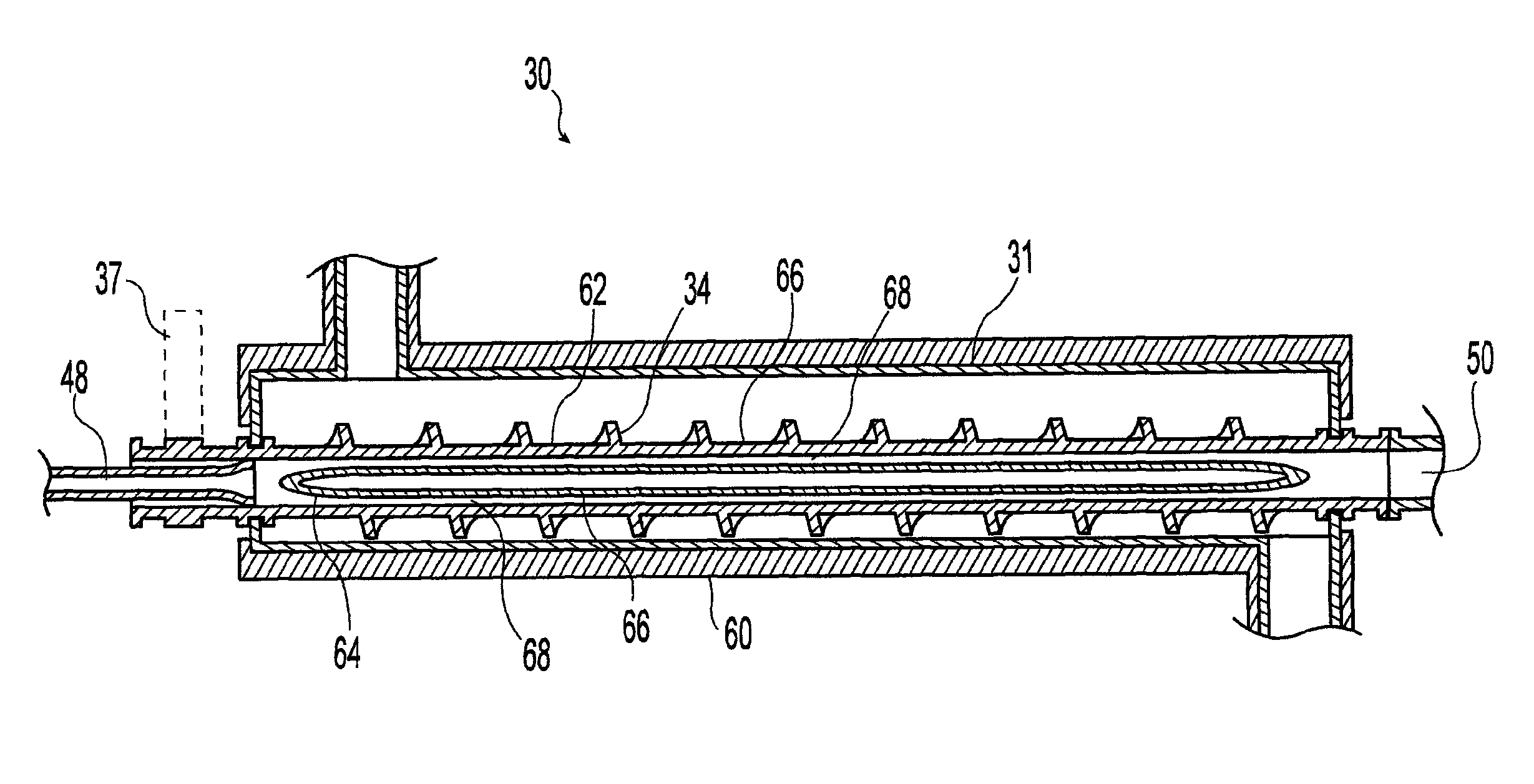

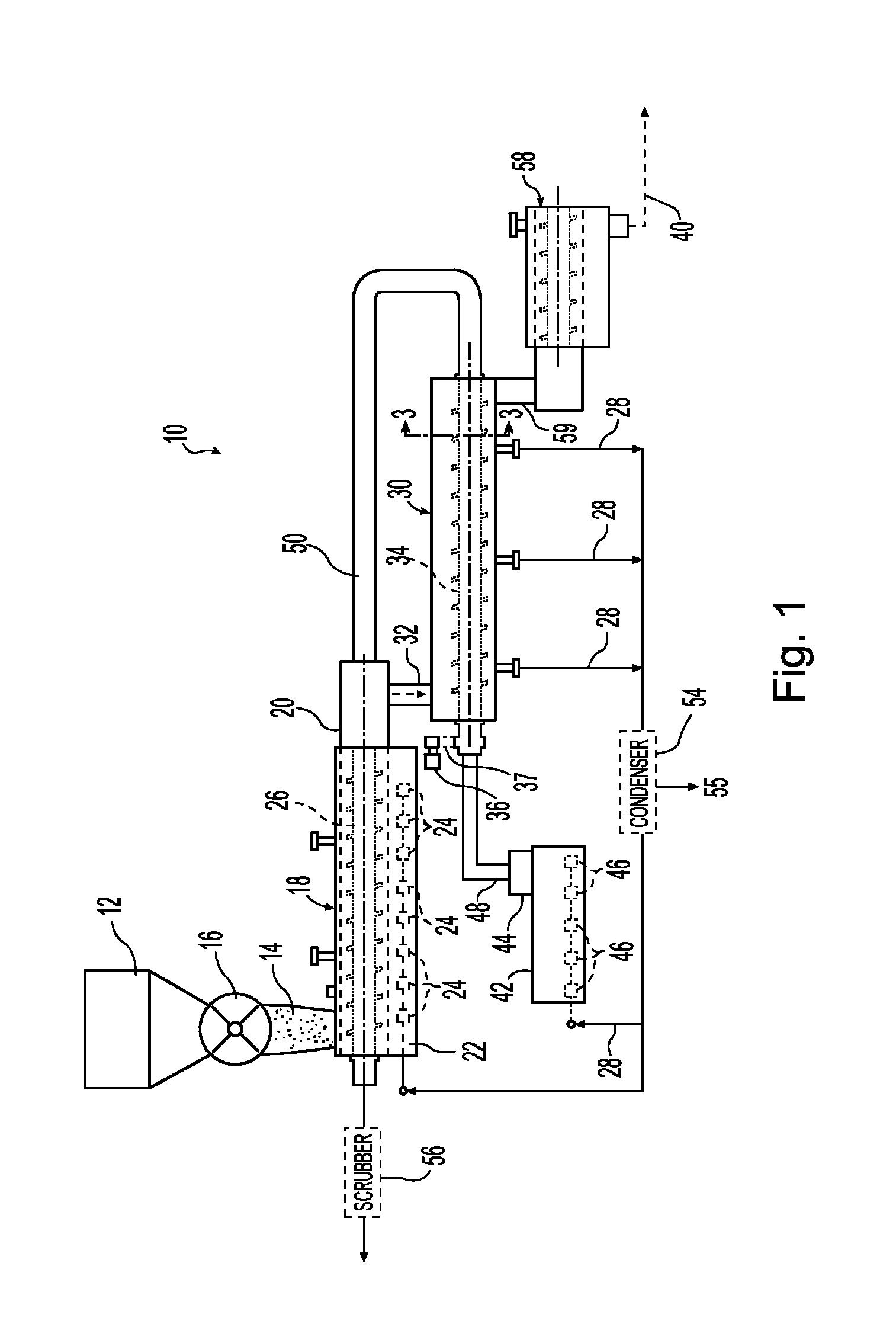

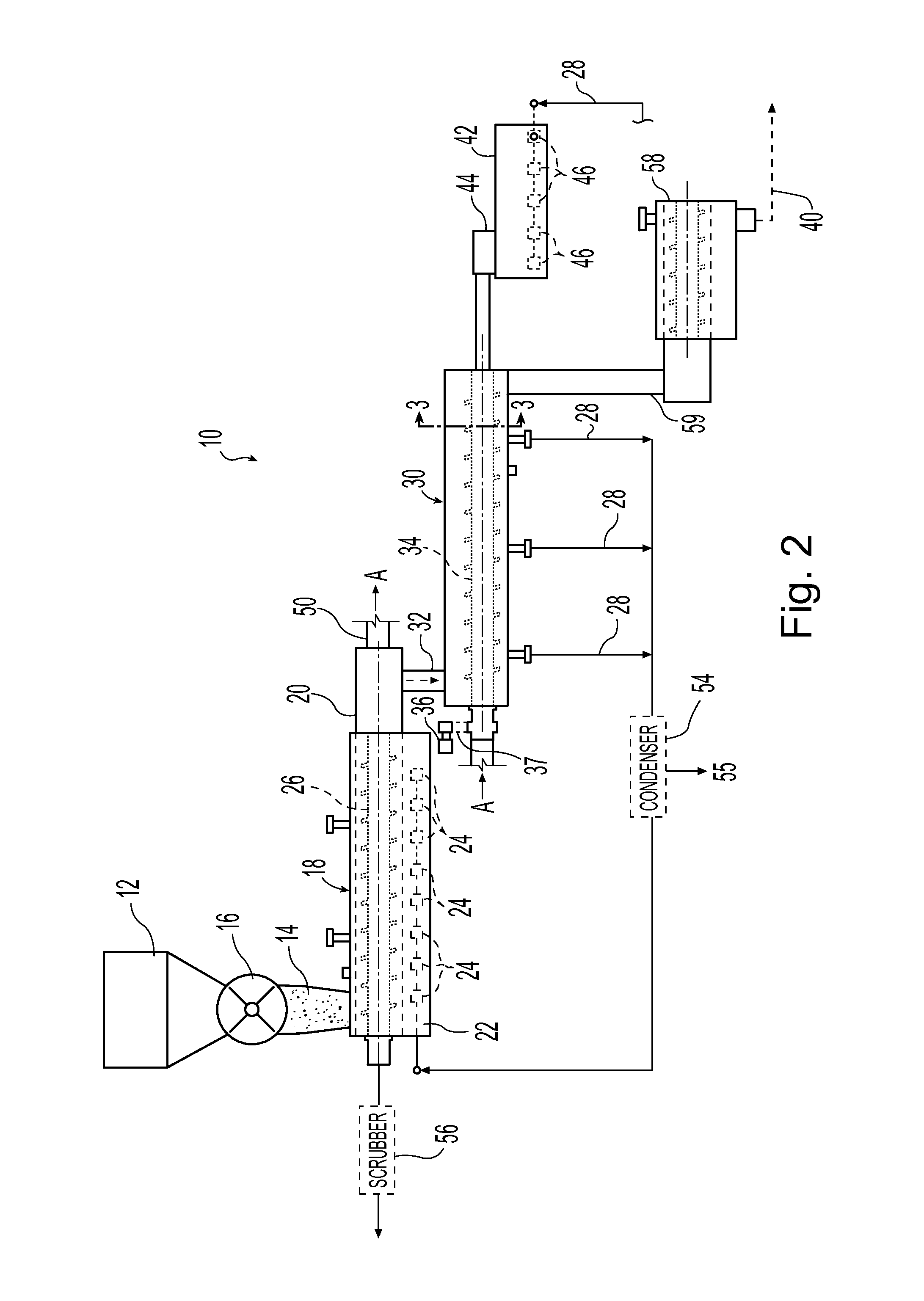

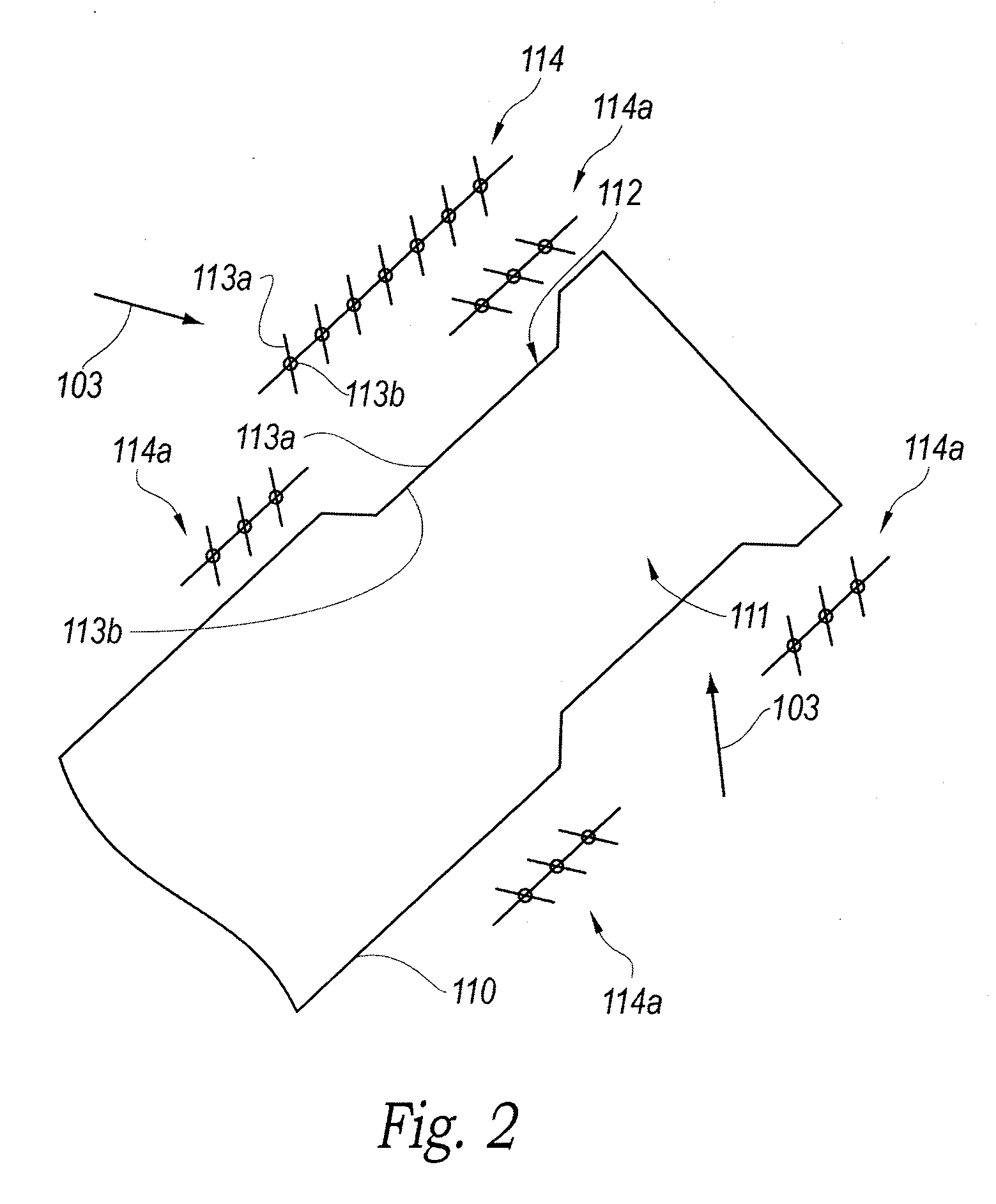

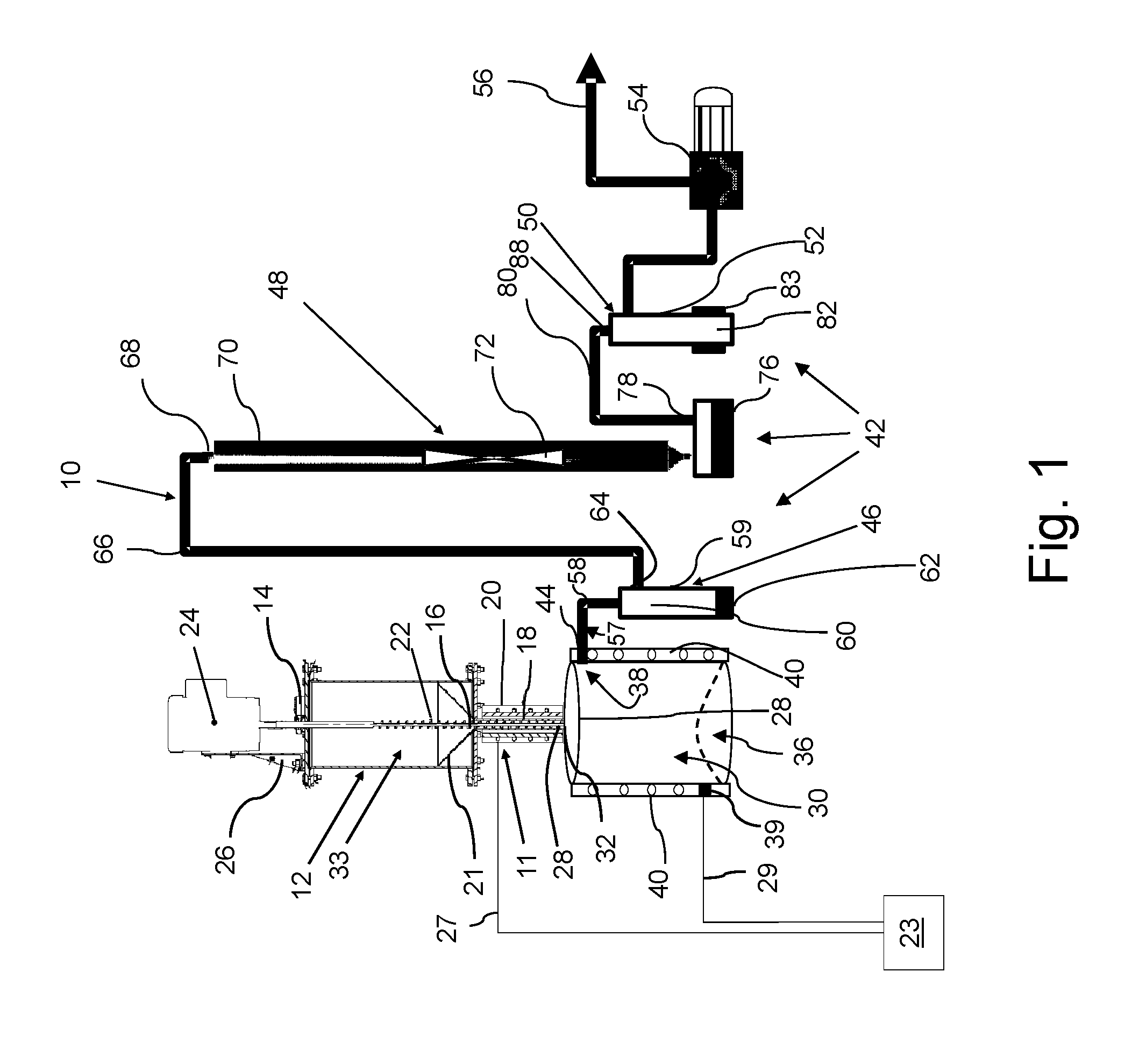

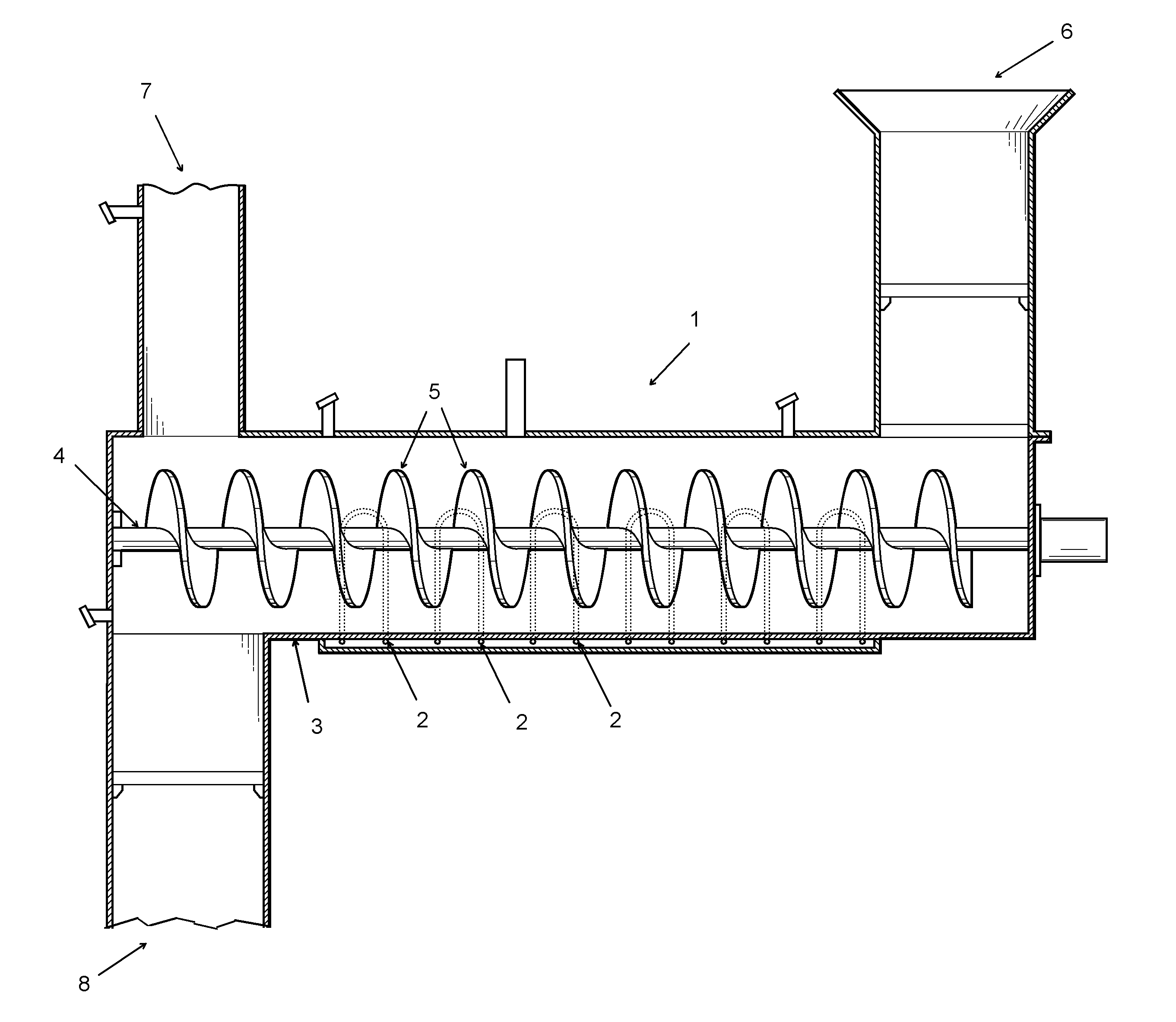

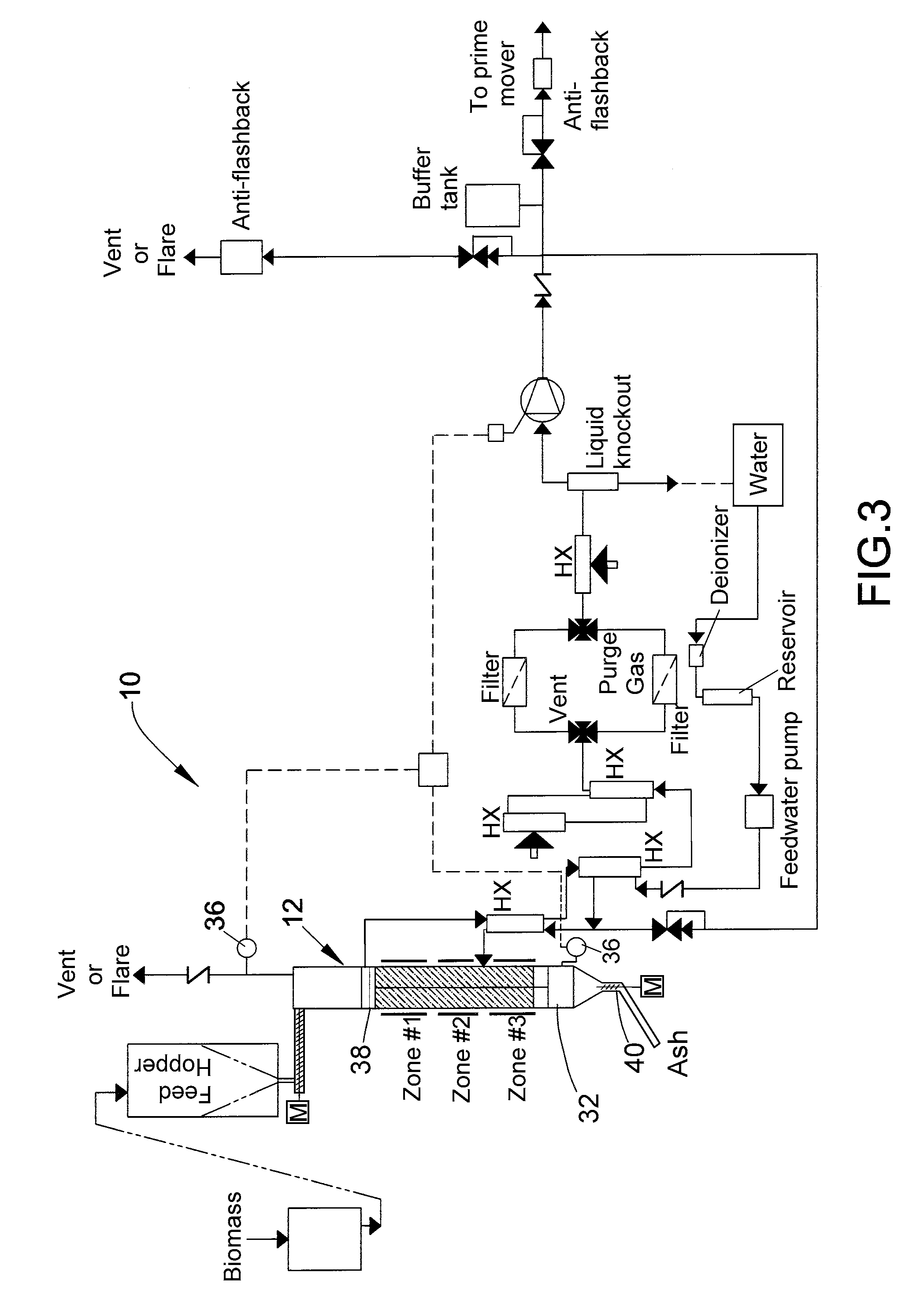

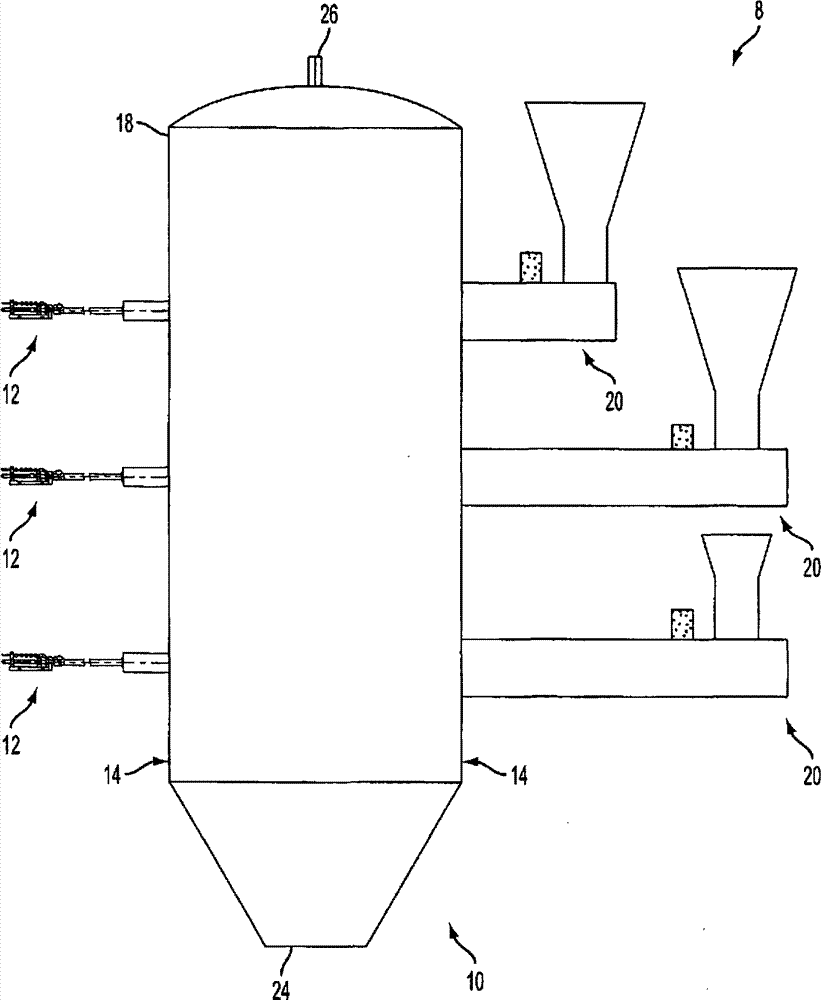

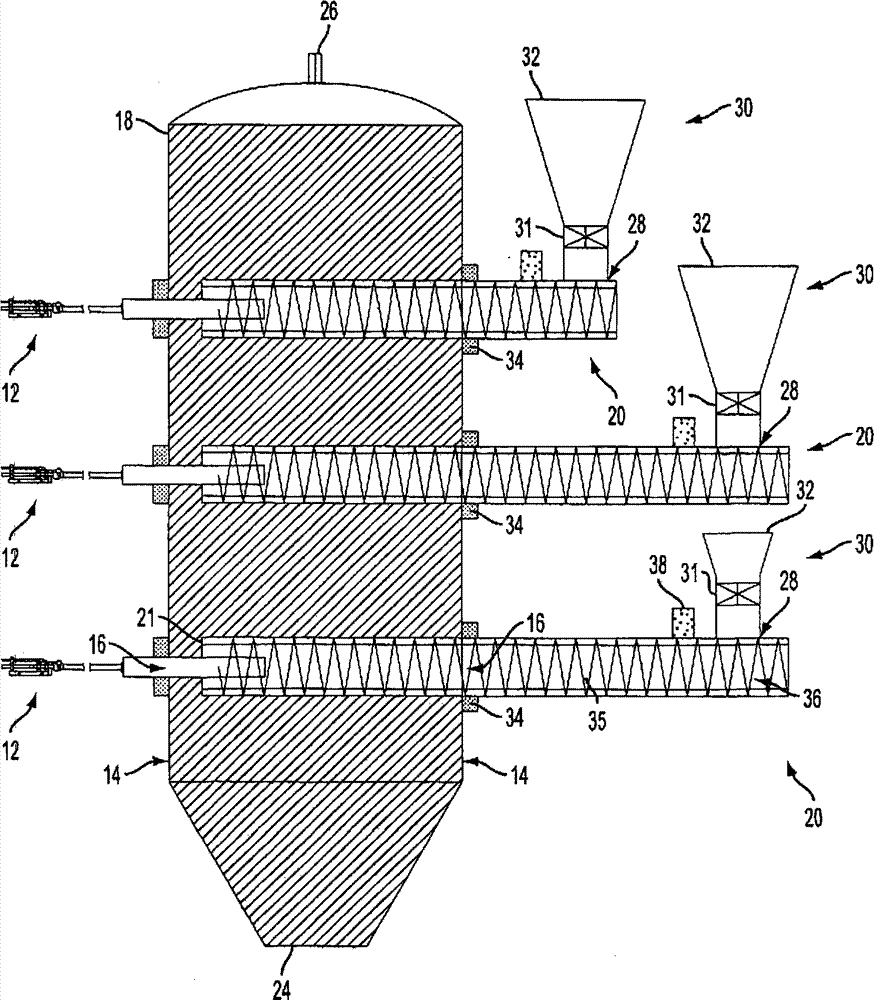

Scalable biomass reactor and method

ActiveUS20110094158A1Efficient productionLarge capacityBiofuelsIndirect heating destructive distillationHydrogenCombustion

A system and method capable of efficient production of synthesis gas from biomass materials in a manner which can be scaled to relatively large throughput capacities. the system is operable to compact a loose biomass material and simultaneously introduce the compacted biomass material into entrances of internal passages of multiple parallel reactors, heat the compacted biomass material within the reactors to a temperature at which organic molecules within the compacted biomass material break down to form ash and gases comprising carbon monoxide and hydrogen gases, inhibit combustion of the compacted biomass material when heated within the internal passages of the reactors, conduct the carbon monoxide and hydrogen gases through the reactors in a direction opposite the movement of the compacted biomass through the reactors, and remove the ash from the reactor.

Owner:INDIANA UNIV RES & TECH CORP

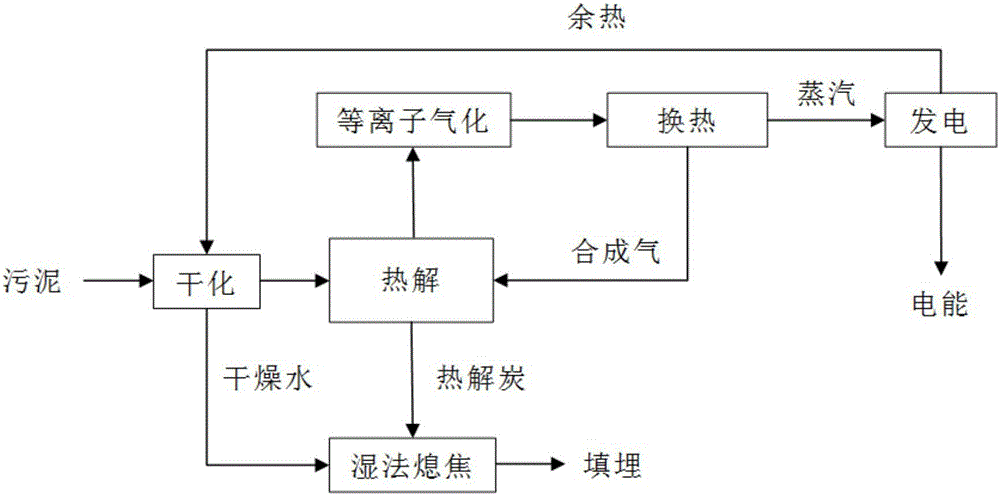

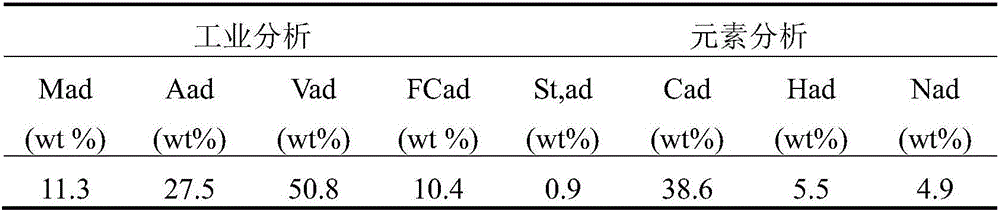

Method and system for sludge pyrolysis plasma gasifying generation

PendingCN106630527ARealize "harmless"Harmlessness does not occurCoke quenchingSludge treatment by pyrolysisElectricitySludge

The invention relates to a method and a system for sludge pyrolysis plasma gasifying generation. The method for sludge pyrolysis plasma gasifying generation comprises the following steps: feeding sludge into a heat accumulating type rotary bed and performing pyrolysis treatment, thereby acquiring a pyrolytic gas liquid mixture and pyrolytic gas carbon; introducing the pyrolytic gas liquid mixture into a plasma gasification reaction chamber, thereby acquiring a synthesis gas; introducing the synthesis gas into a heat exchange device for performing heat exchange treatment, thereby acquiring steam and residual synthesis gas; and introducing the steam into a generation device. The system for sludge pyrolysis plasma gasifying generation comprises the heat accumulating type rotary bed, the plasma gasification reaction chamber, the heat exchange device, the generation device and a quenching device. According to the technical scheme provided by the invention, the clean and efficient method and system for sludge pyrolysis plasma gasifying are provided; the steam acquired from the synthesis gas through heat exchange treatment is utilized to generate electricity, so that the harmless, treatment, reduction and recycling of the sludge are realized; the running cost is low; the tar yield is ultralow; the pipeline is prevented from being blocked; and the industrialization and large-scale production can be easily realized.

Owner:SHENWU TECH GRP CO LTD

Tyer carburetion process

InactiveUS20110173887A1Maximizes exposureAccurately controlled movementHydrogenGasification processes detailsCombustorWater-gas shift reaction

A means for improving prior art combined cycle combustor and / or gasifiers and / or plural thermodynamic cycle gasification systems by introducing and utilizing an auger for the continuous feeding, agitation, tumbling, advancement and discharge of heterogeneous carbonaceous fuel. In addition to the aforementioned improvement, I have included provisions for Fontana's water gas shift reaction utilizing refractory embedded down-tubes that convey steam and oxygen into and through the chambers fluidized bed.

Owner:TYER SR ROBERT CLARK

Pyrolysis apparatus and method

The present invention relates to a pyrolysis apparatus comprising a pyrolysis chamber have a first end and a second end, a feed inlet connected adjacent the first end of the pyrolysis chamber, a biochar outlet connected adjacent the second end of the pyrolysis chamber, and a gas outlet in fluid communication with the pyrolysis chamber. The pyrolysis chamber and feed inlet further comprise centreless screw conveyors. The present invention alleviates the problems associated with dust, oils and tars being present in the generated syngas. The present invention can also be used in a method of continuously processing biomass.

Owner:RAINBOW BEE EATER IP PTY LTD

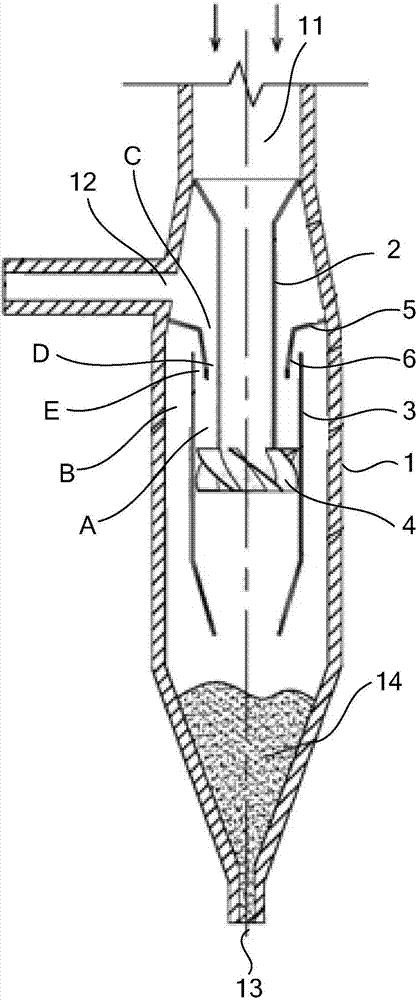

Gasifier

ActiveCN107446625AReduce dust contentReduce the burden of dust removalGasification processes detailsScrew type gasifiersEngineeringRotational flow

The invention discloses a gasifier and relates to the technical field of coal gasification equipment, which is invented for solving the problems that the content of carbocoal particles in synthesis gas exhausted from an existing gasifier is greater, and the burden of subsequent gas-solid separation is heavier. The gasifier comprises a casing, wherein a raw material inlet is formed in the top wall of the casing; an exhaust opening is formed in the side wall of the casing; a coke discharging opening is formed in the bottom wall of the casing; a built-in guide cylinder, a rotational flow inner cylinder and a rotational flow member are arranged in the casing; one end of the built-in guide cylinder is communicated with the raw material inlet, and the other end of the built-in guide cylinder downwards extends; the rotational flow inner cylinder is arranged at the outer part of the lower end of the built-in guide cylinder in a sleeving manner; in addition, the upper end of the rotational flow inner cylinder upwards extends to a position close to the exhaust opening; a first annular space is formed between one circumference of the inner wall of the rotational flow inner cylinder and the built-in guide cylinder; a second annular space is formed between one circumference of the outer wall of the rotational flow inner cylinder and the inner wall of the casing; the rotational flow member is arranged between the lower end of the built-in guide cylinder and the rotational flow inner cylinder. The gasifier disclosed by the invention is used for coal hydrogasification reaction.

Owner:ENN SCI & TECH DEV

Device for producing dihydrogen, method for producing dihydrogen using such a device and use of such a device

PendingUS20190256354A1Increase contentHeating up fastHydrogen separation by selective and reversible uptakeDispersed particle separationHydrogenEngineering

The invention relates to a device for producing a dihydrogen gas including an enclosure, means for conveying the product into the enclosure, which comprise a screw mounted so as to rotate in the enclosure about a geometric axis of rotation, means for heating the screw by the Joule effect, and a unit for removing impurities present in the gas. The invention also relates to a method for manufacturing dihydrogen using such a device as well as to a use of the device for the treatment of a product such as CSR material or polymer material.

Owner:E T I A EVALUATION TECHQUE INGIE & APPL

Pulse detonation coal gasification system

A pulse detonation device is provided for delivering a shock wave into a gasification device to promote a localized coal gasification reaction in the gasification device. The pulse detonation device includes a fuel inlet for receiving fuel, an air inlet for receiving air, a pulse detonation chamber wherein the fuel and air are configured to mix, and an ignition device for igniting the mixture of fuel and air. The ignition of the mixture of fuel and air creates a shock wave in the pulse detonation chamber. Further, the pulse detonation chamber is attached to a gasification chamber and is configured to extend into a coal feed tube that extends into the gasification chamber, with the shock wave configured to exit the pulse detonation chamber and interact with coal in the coal feed tube.

Owner:BHA ALTAIR

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com