Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

374results about "Pyrolysis reactions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

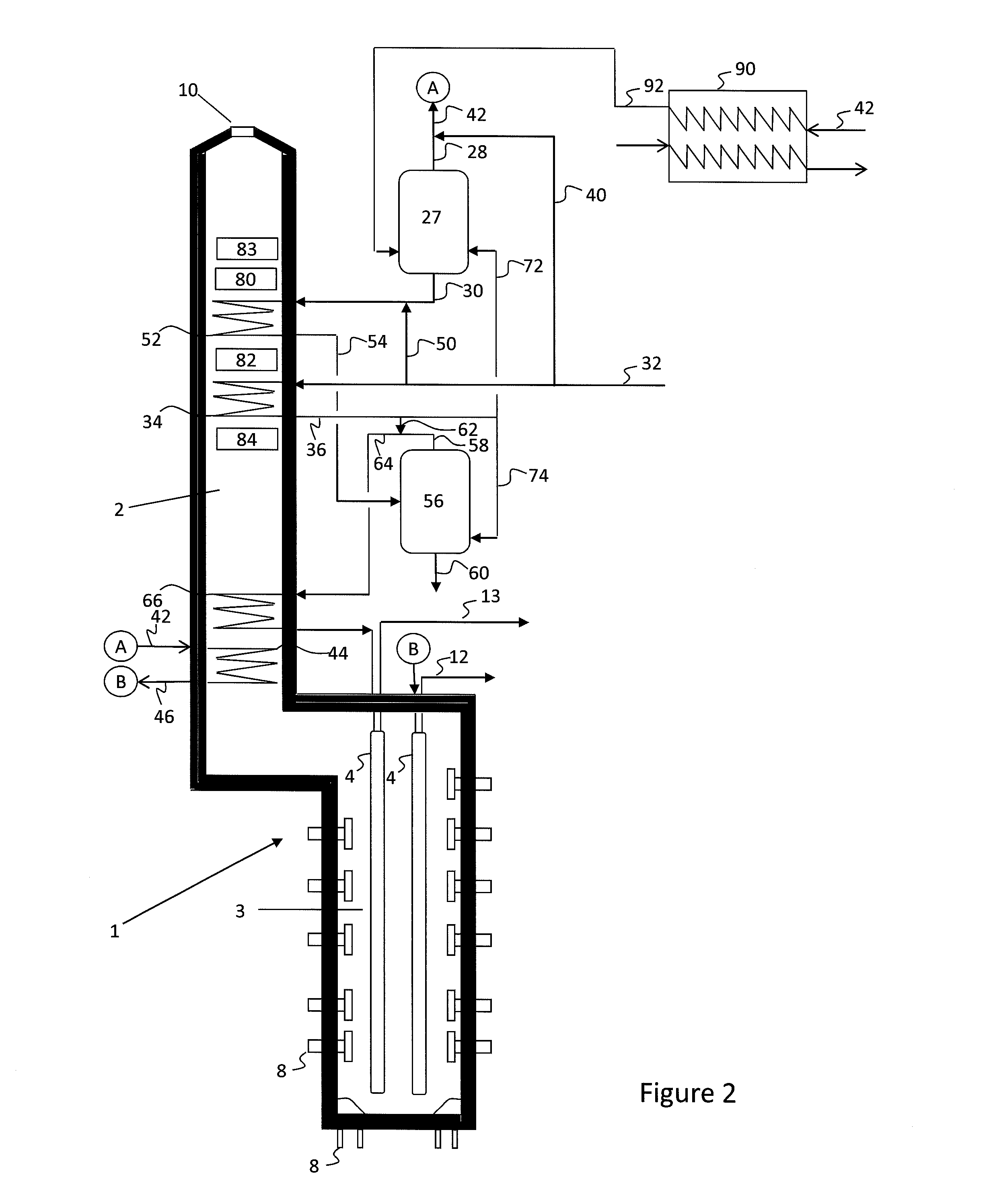

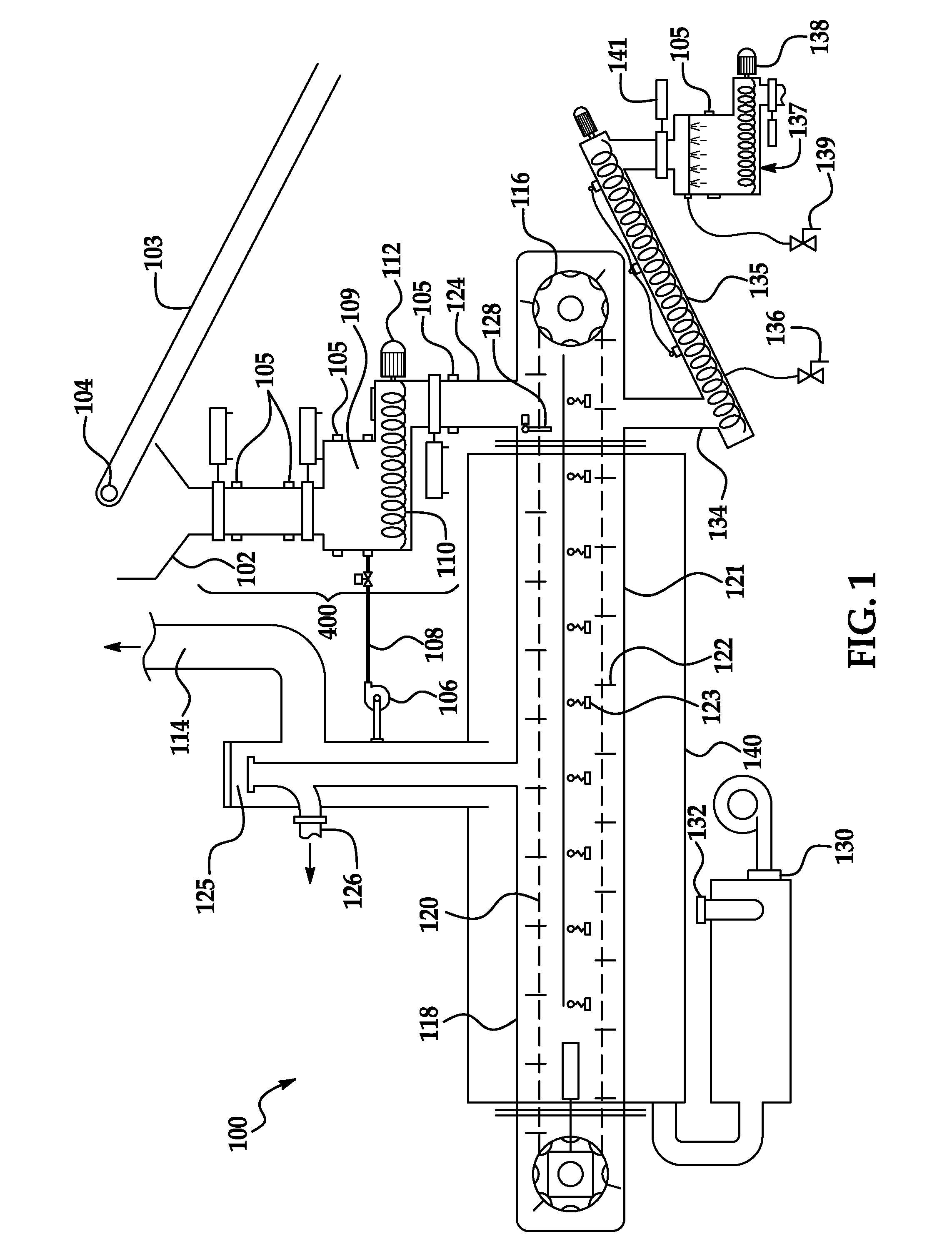

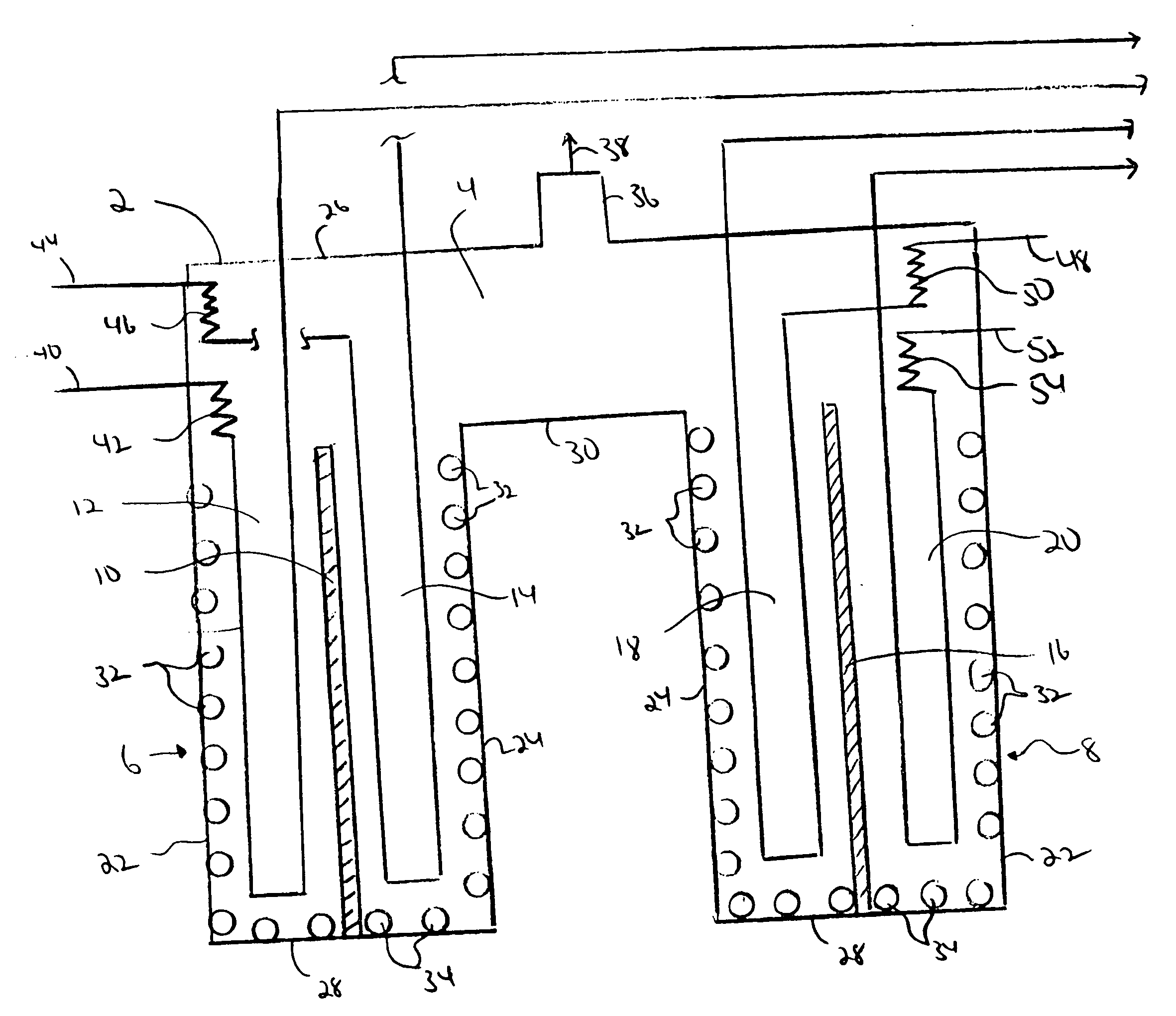

Pyrolytic reactor

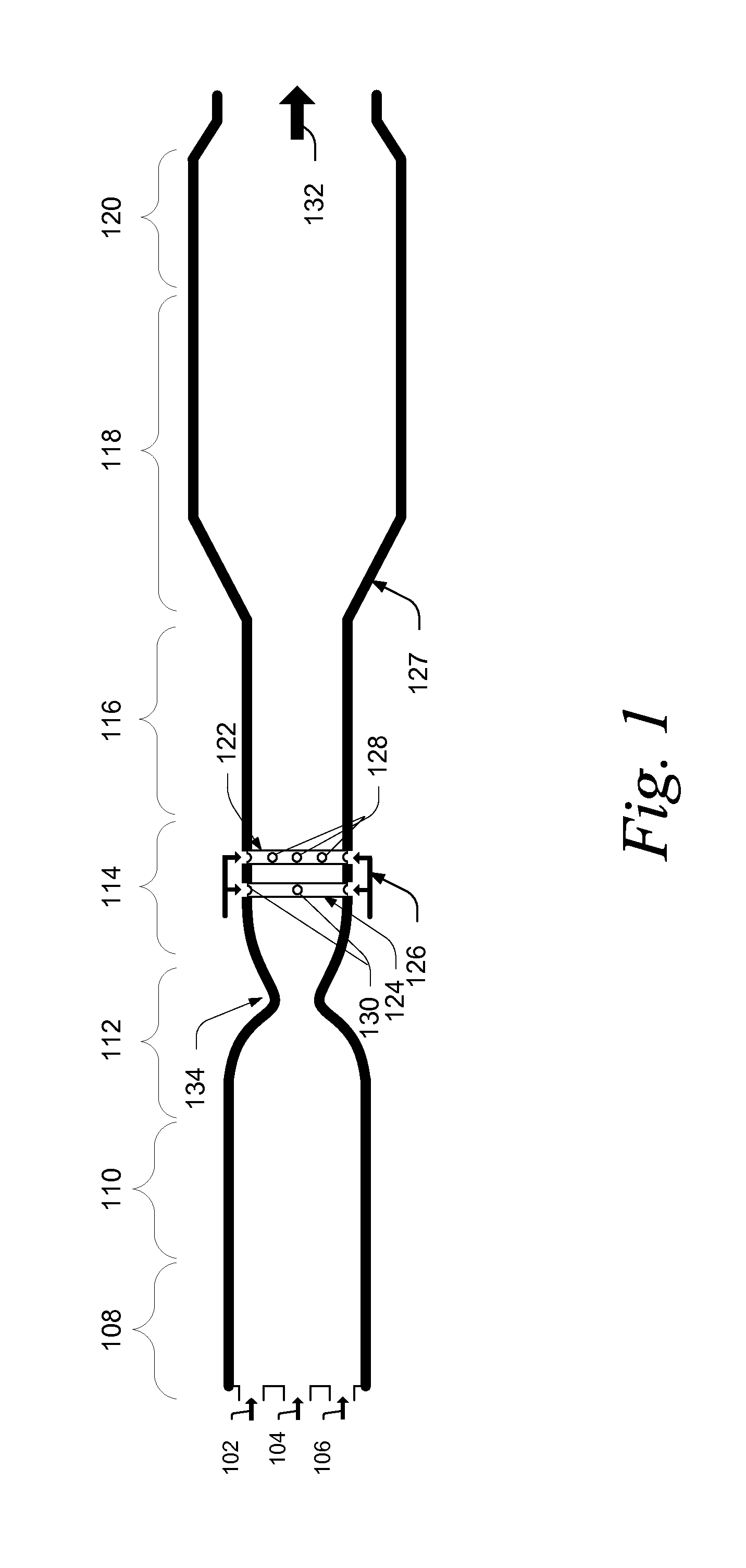

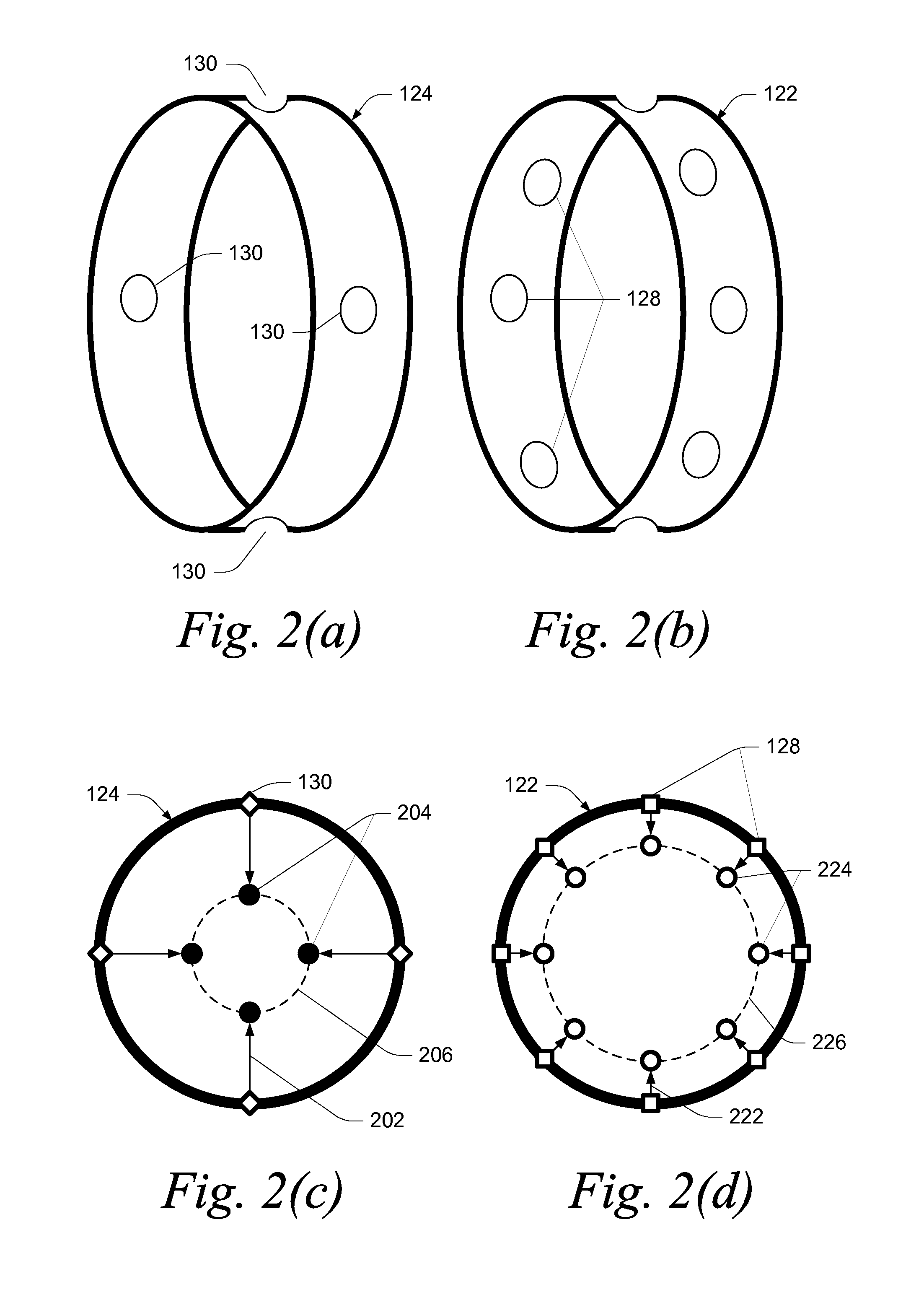

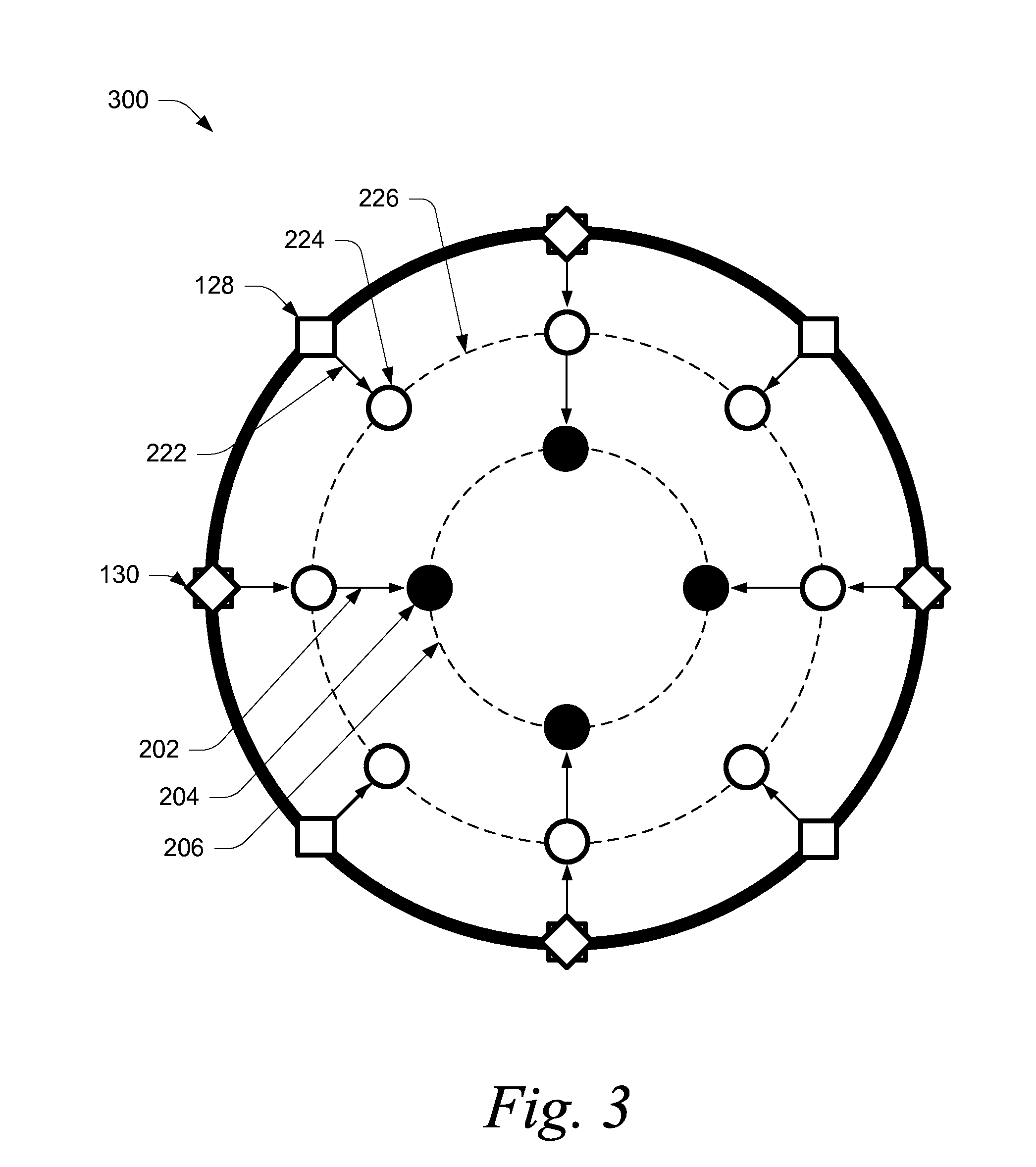

A pyrolytic reactor comprising a fuel injection zone, a combustion zone adjacent to the fuel injections zone, an expansion zone adjacent to the combustion zone, a feedstock injection zone comprising a plurality of injection nozzles and disposed adjacent to the expansion zone, a mixing zone configured to mix a carrier stream and feed material and disposed adjacent to the feedstock injection zone, and a reaction zone adjacent to the mixing zone. The plurality of injection nozzles are radially distributed in a first assembly defining a first plane transverse to the feedstock injection zone and in a second assembly transverse to the feedstock injection zone.

Owner:UOP LLC

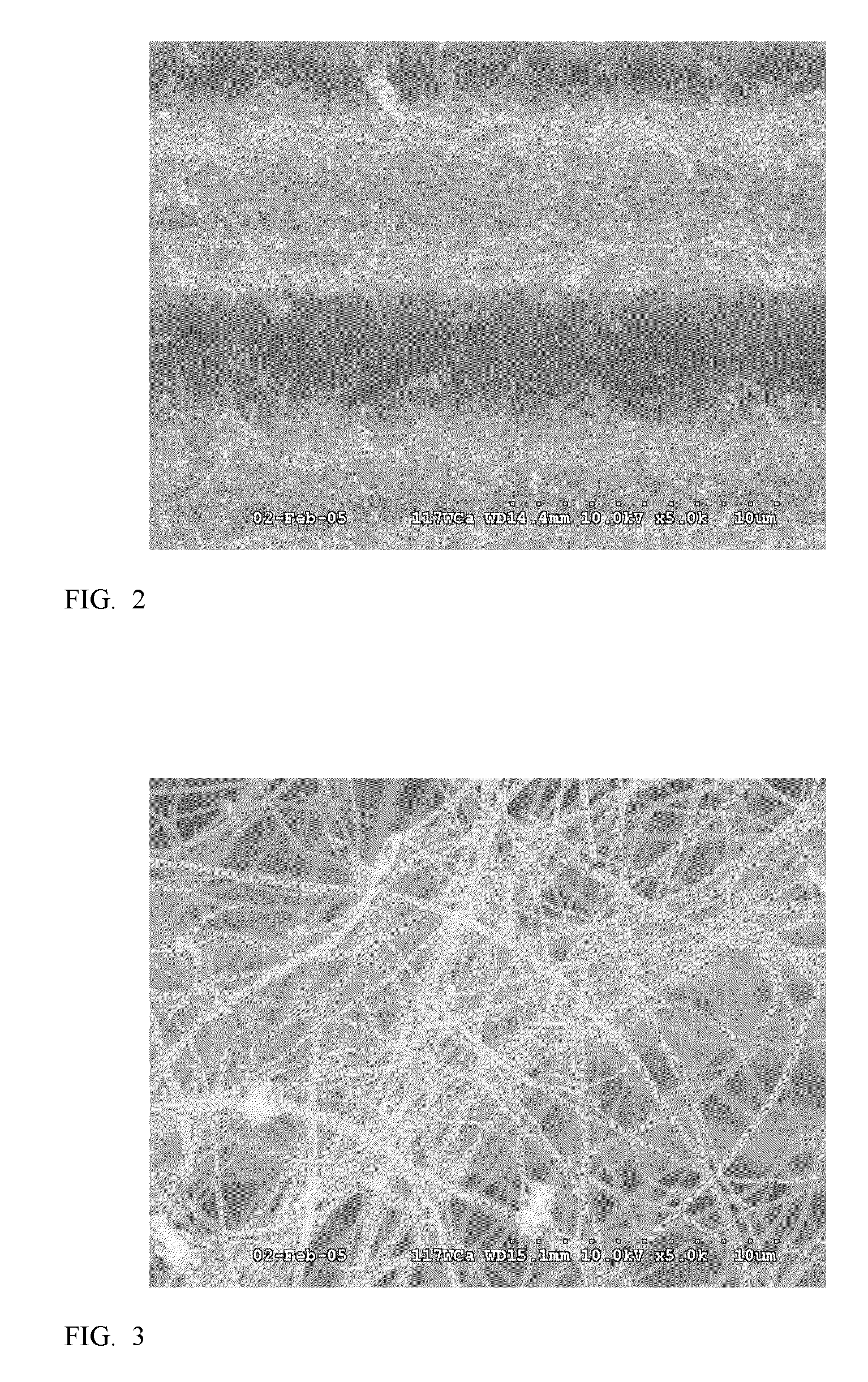

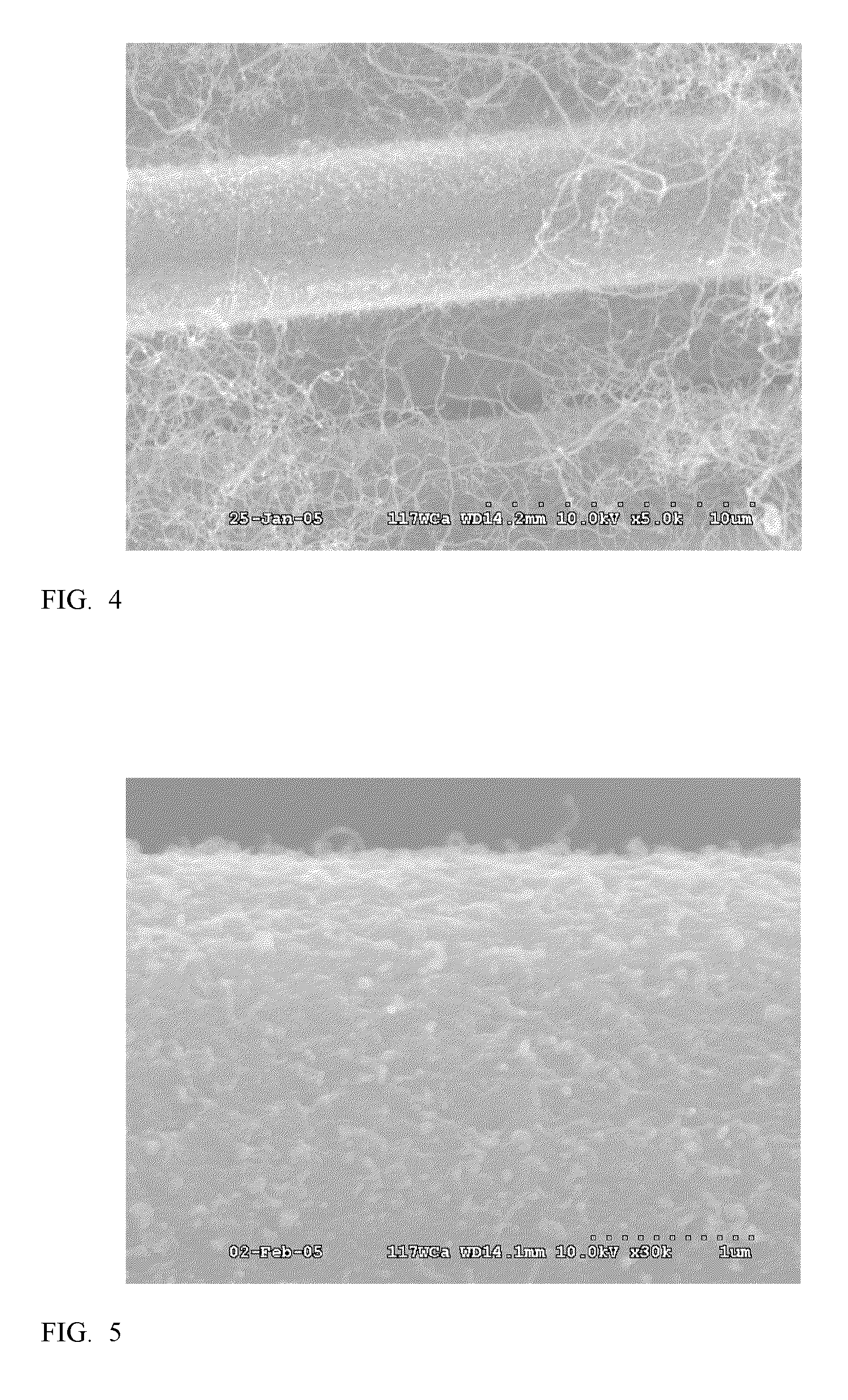

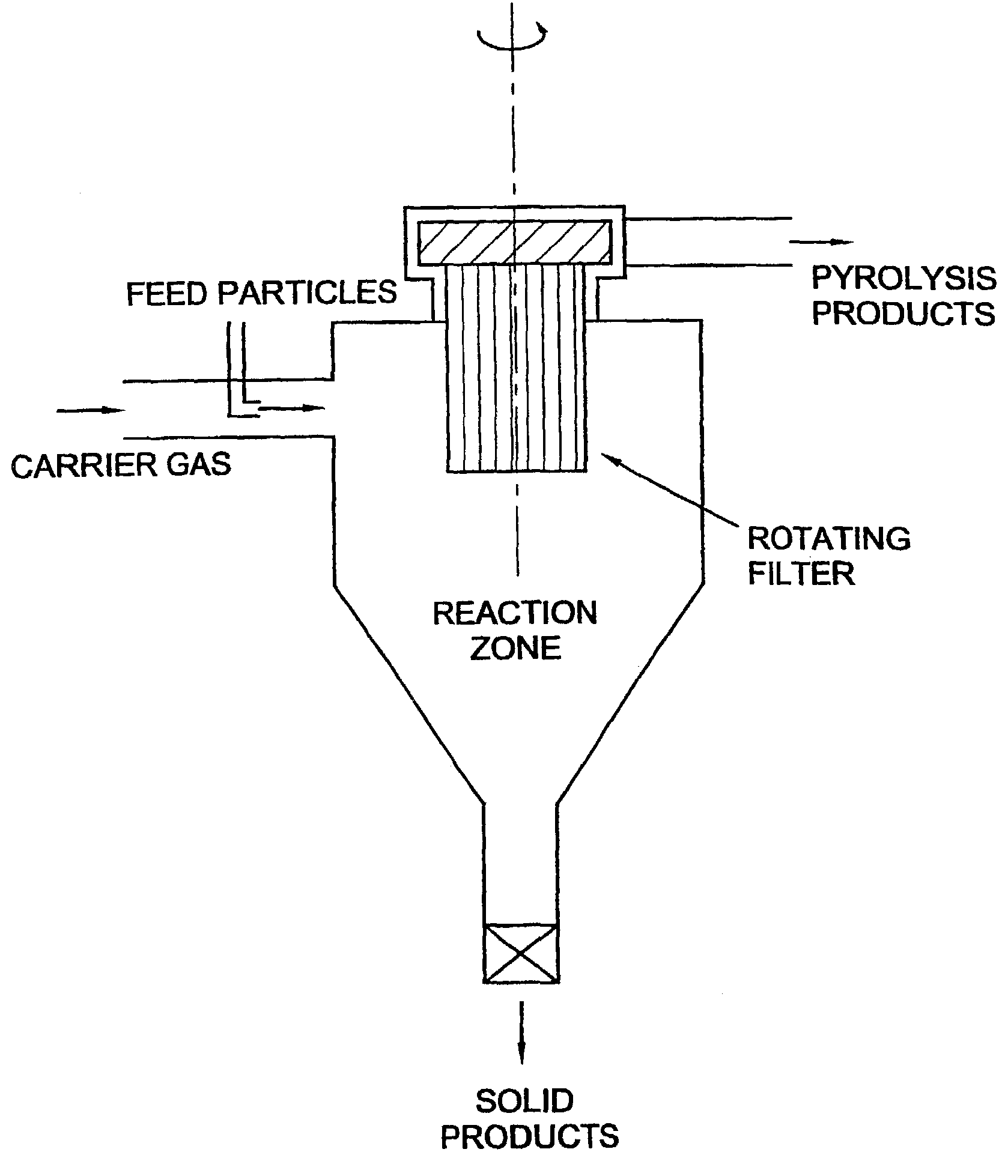

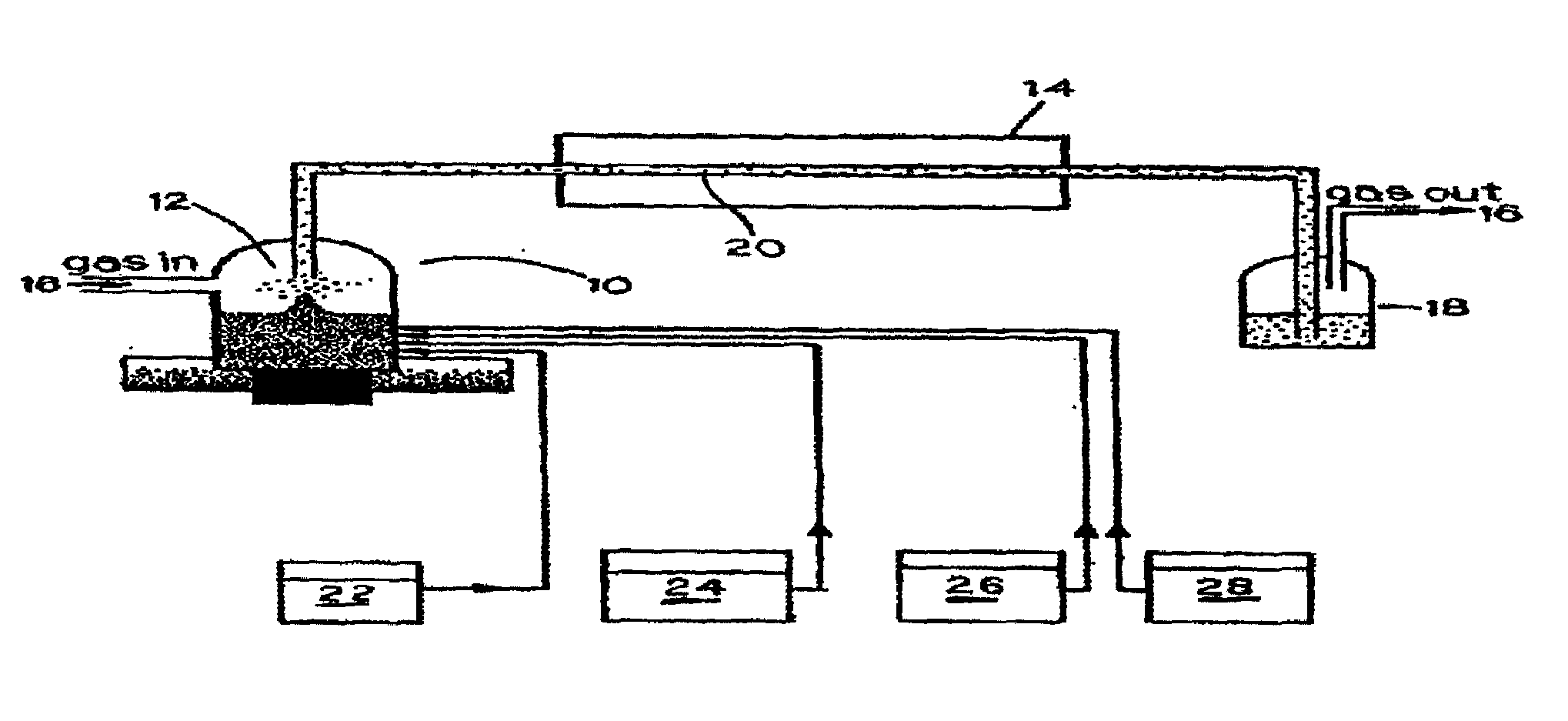

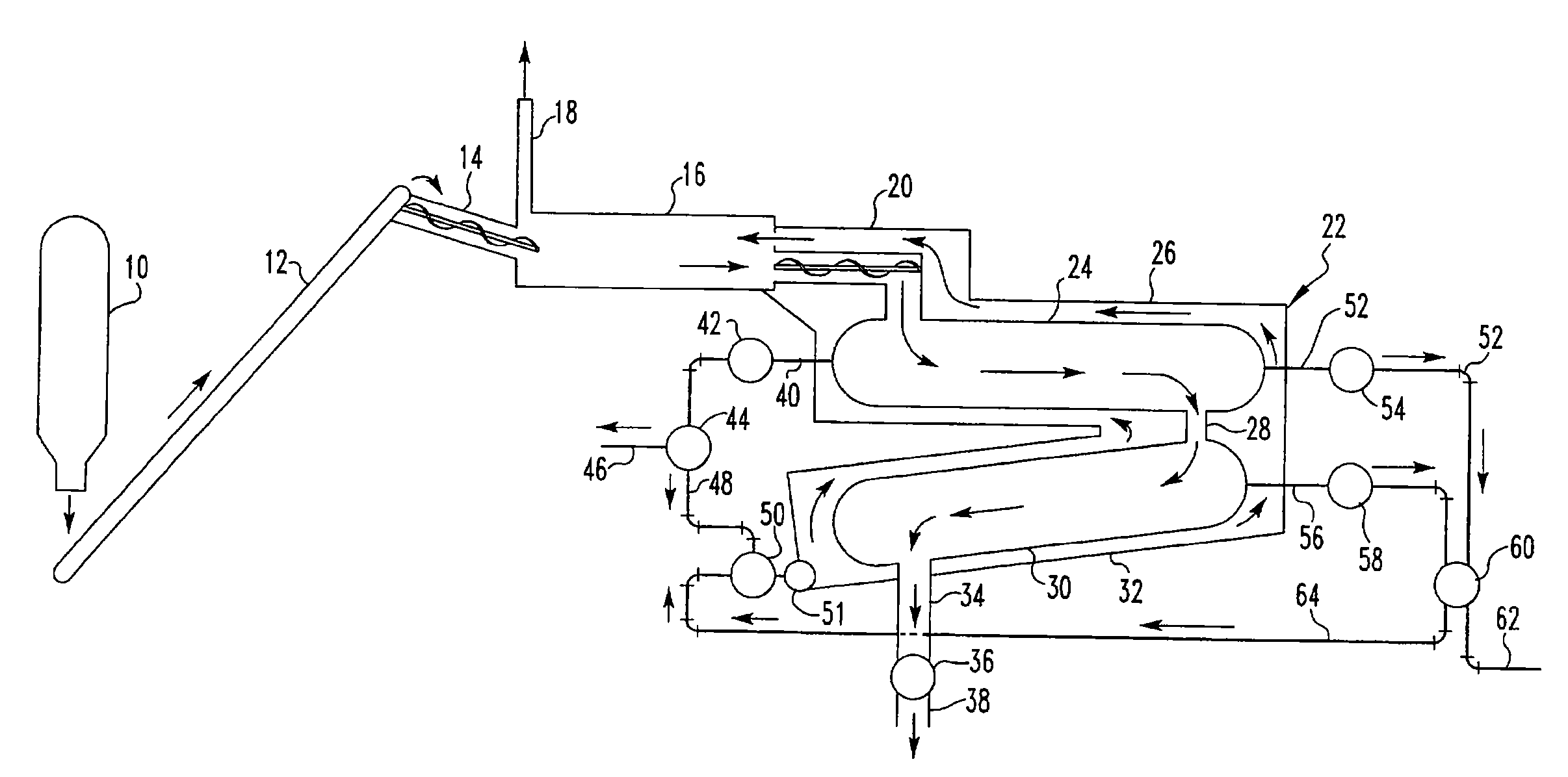

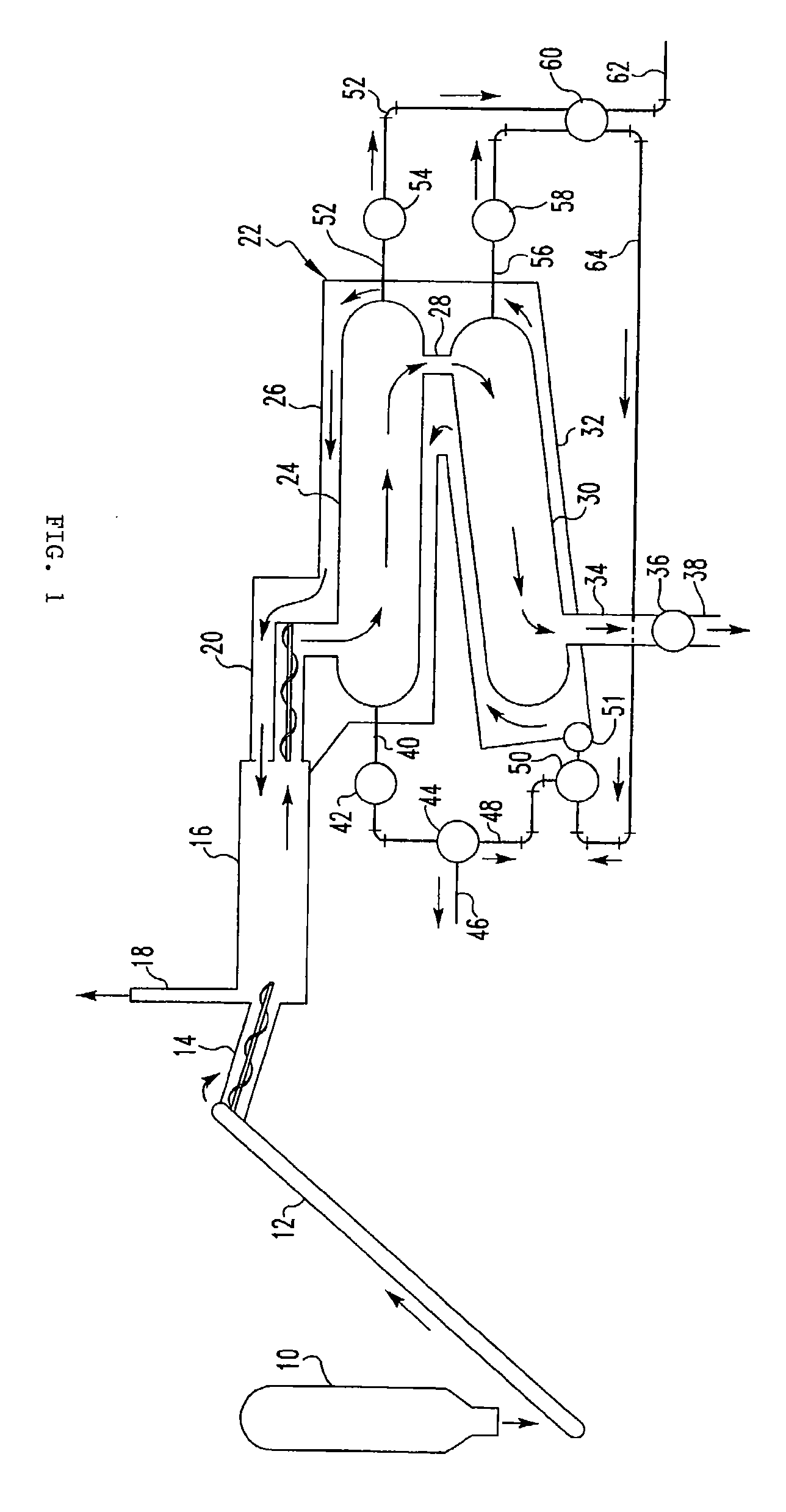

Continuous process for the production of carbon nanofiber reinforced continuous fiber preforms and composites made therefrom

ActiveUS20090220409A1Limited utilityLow yieldMaterial nanotechnologyIndividual molecule manipulationFiberCarbon fibers

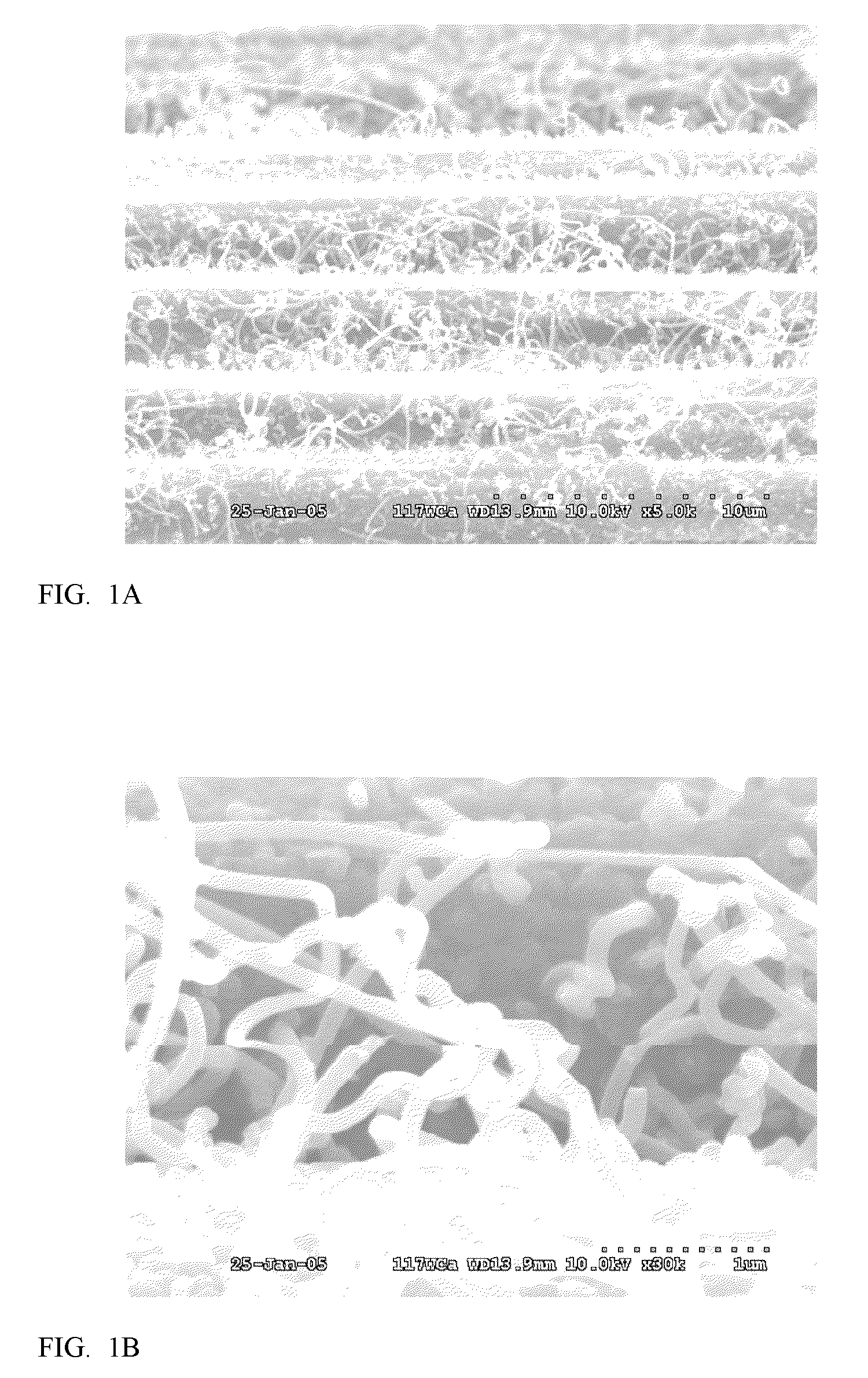

This invention provides a continuous process for the growth of vapor grown carbon fiber (VGCNT) reinforced continuous fiber preforms for the manufacture of articles with useful mechanical, electrical, and thermal characteristics. Continuous fiber preforms are treated with a catalyst or catalyst precursor and processed to yield VGCNT produced in situ resulting in a highly entangled mass of VGCNT infused with the continuous fiber preform. The continuous process disclosed herein provides denser and more uniform carbon nanotubes and provides the opportunity to fine-tune the variables both within an individual preform and between different preforms depending on the characteristics of the carbon nanotubes desired. The resulting continuous fiber preforms are essentially endless and are high in volume fraction of VGCNT and exhibit high surface area useful for many applications. The invention also provides for composites made from the preforms.

Owner:PERFORMANCE POLYMER SOLUTIONS

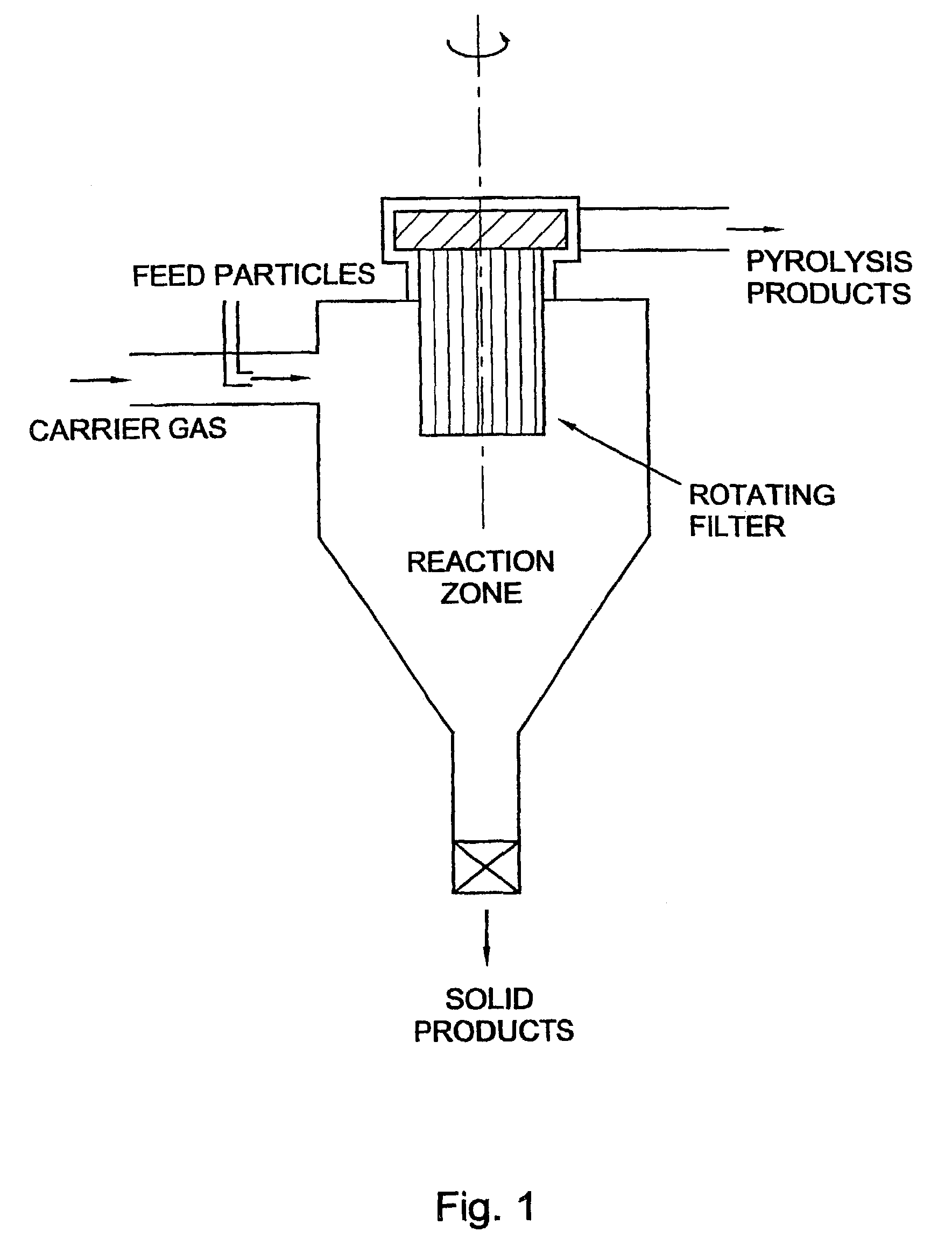

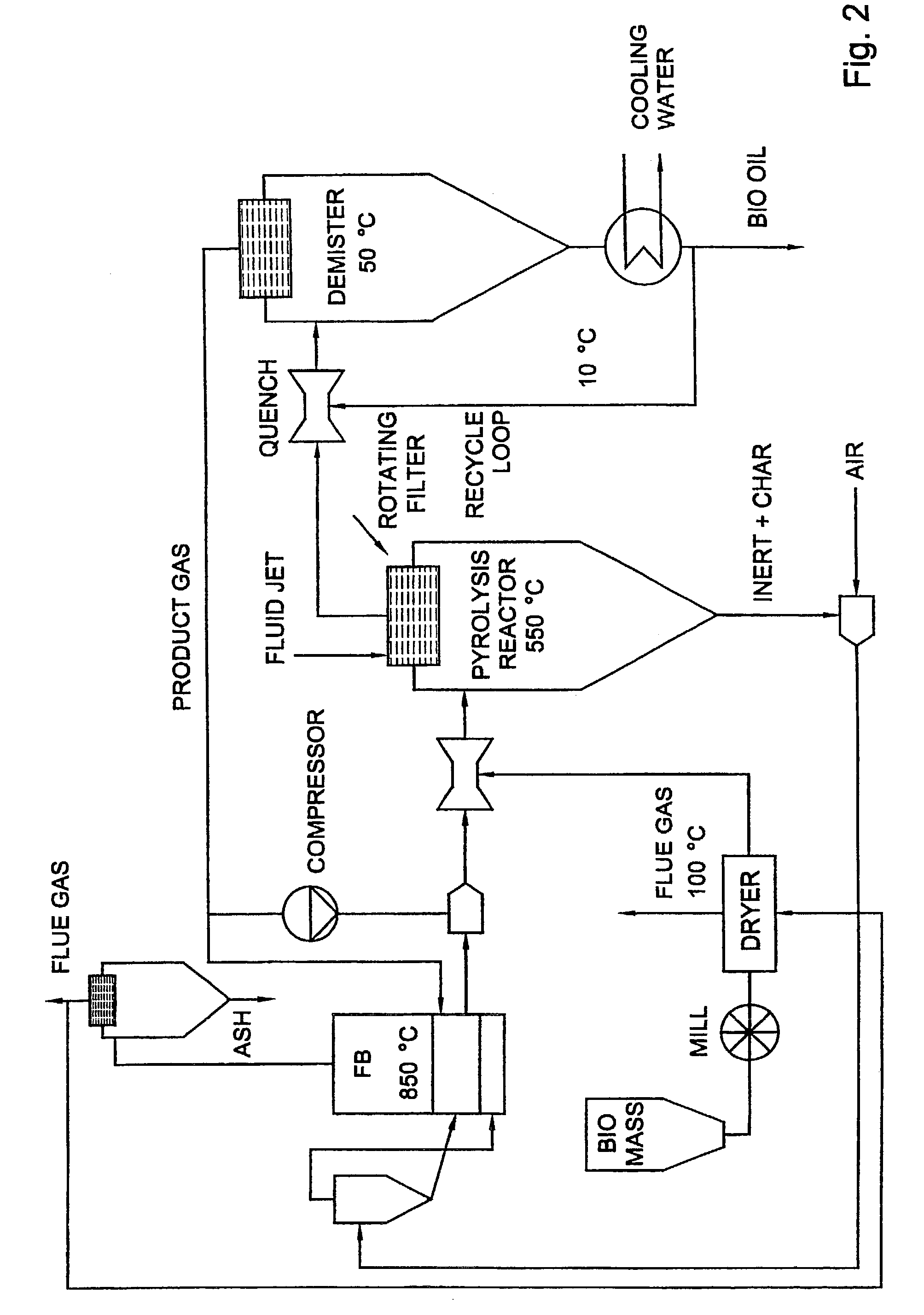

Flash-pyrolysis in a cyclone

InactiveUS7202389B1Excessive crackingCombination devicesDispersed particle filtrationParticulatesCyclone

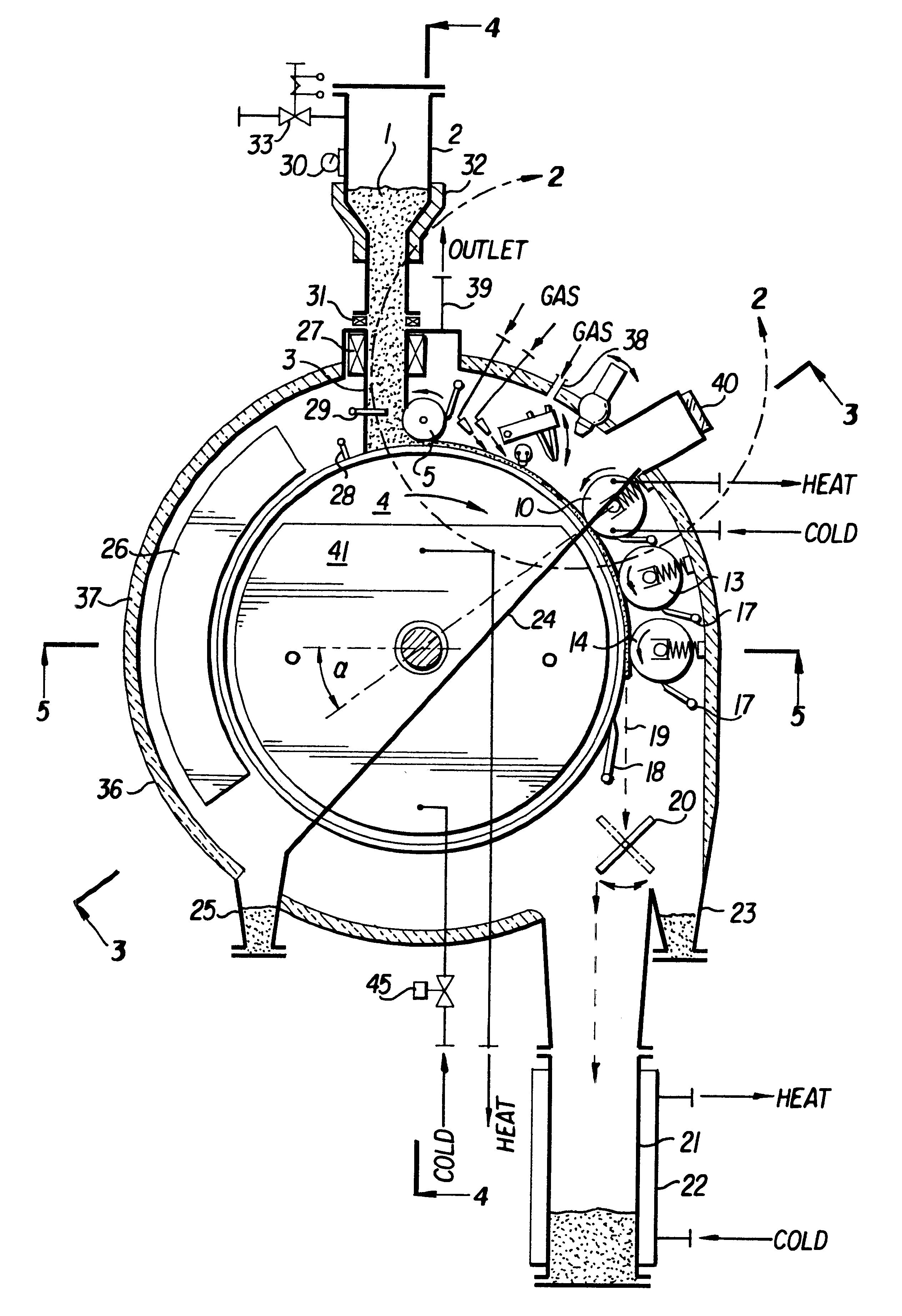

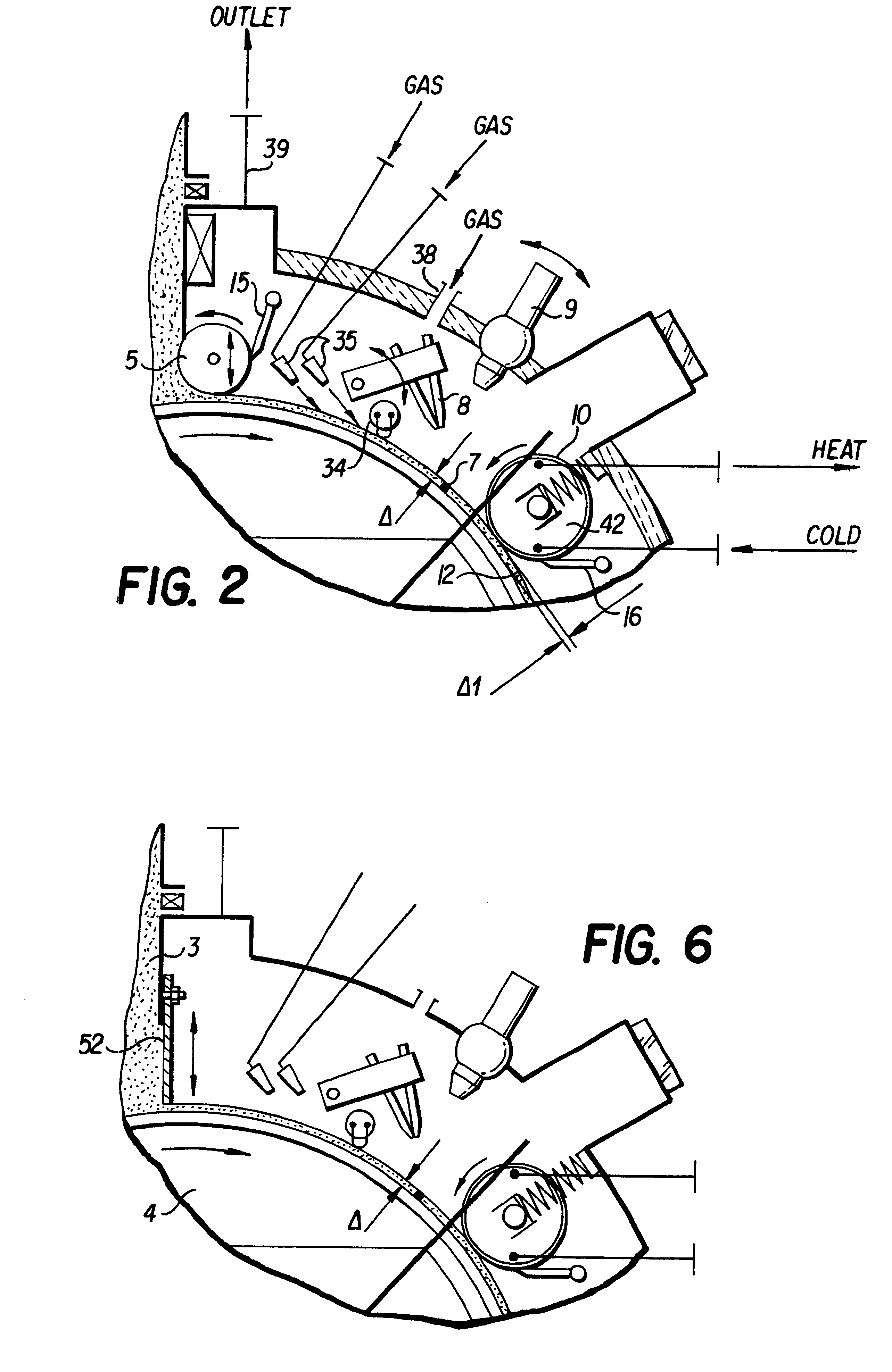

A process for the pyrolysis of carbonaceous material is carried out in a cyclone reactor which is fitted with enhanced filtering equipment. In addition the invention relates to the use of a cyclone fitted with a rotating filter as a pyrolysis reactor. By using a cyclone of the rotating separator type as a pyrolysis reactor, carbonaceous material, such as biomass, can effectively be converted in a product having excellent chemical properties and which product is free from particulate matter.

Owner:UNIVERSITY OF TWENTE

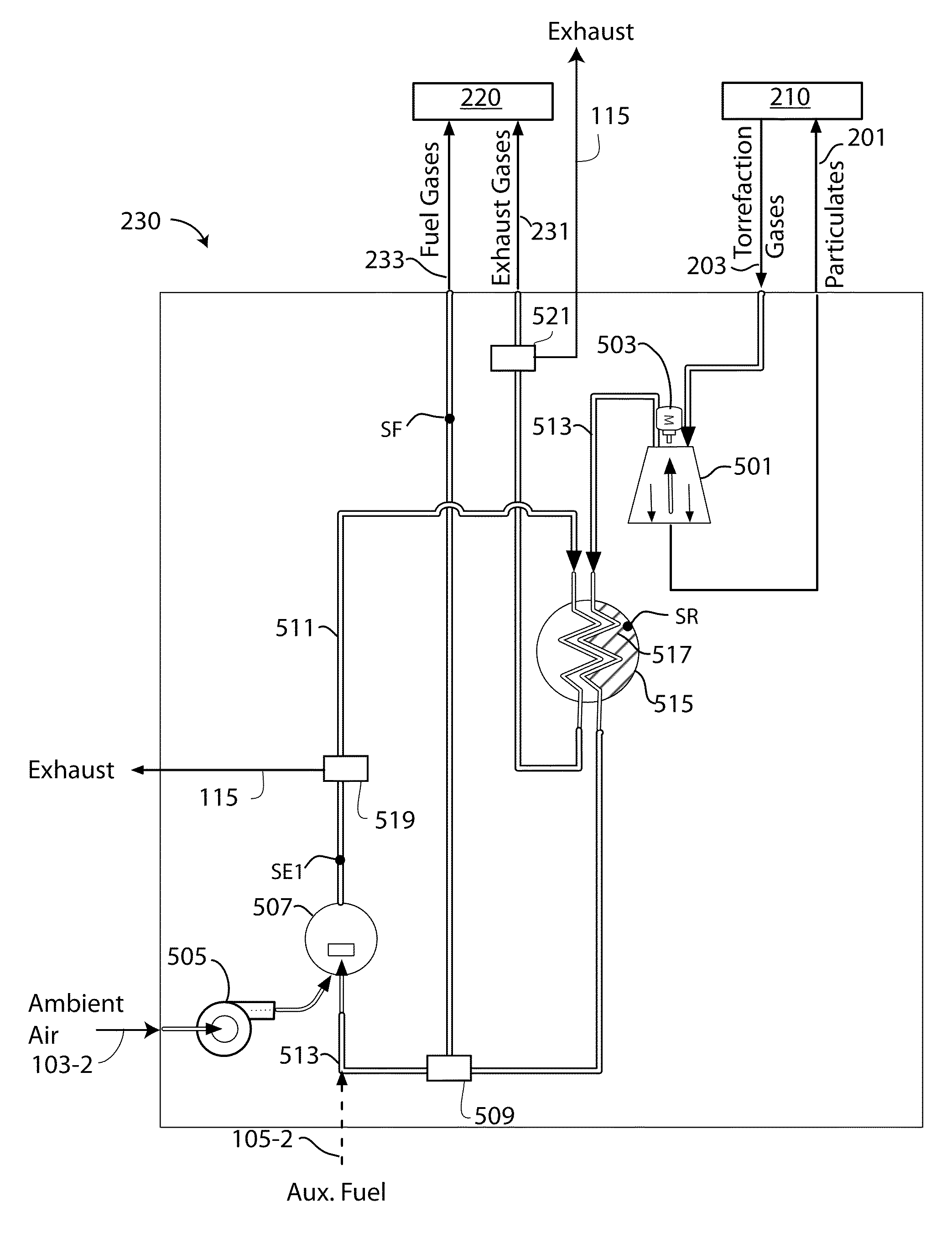

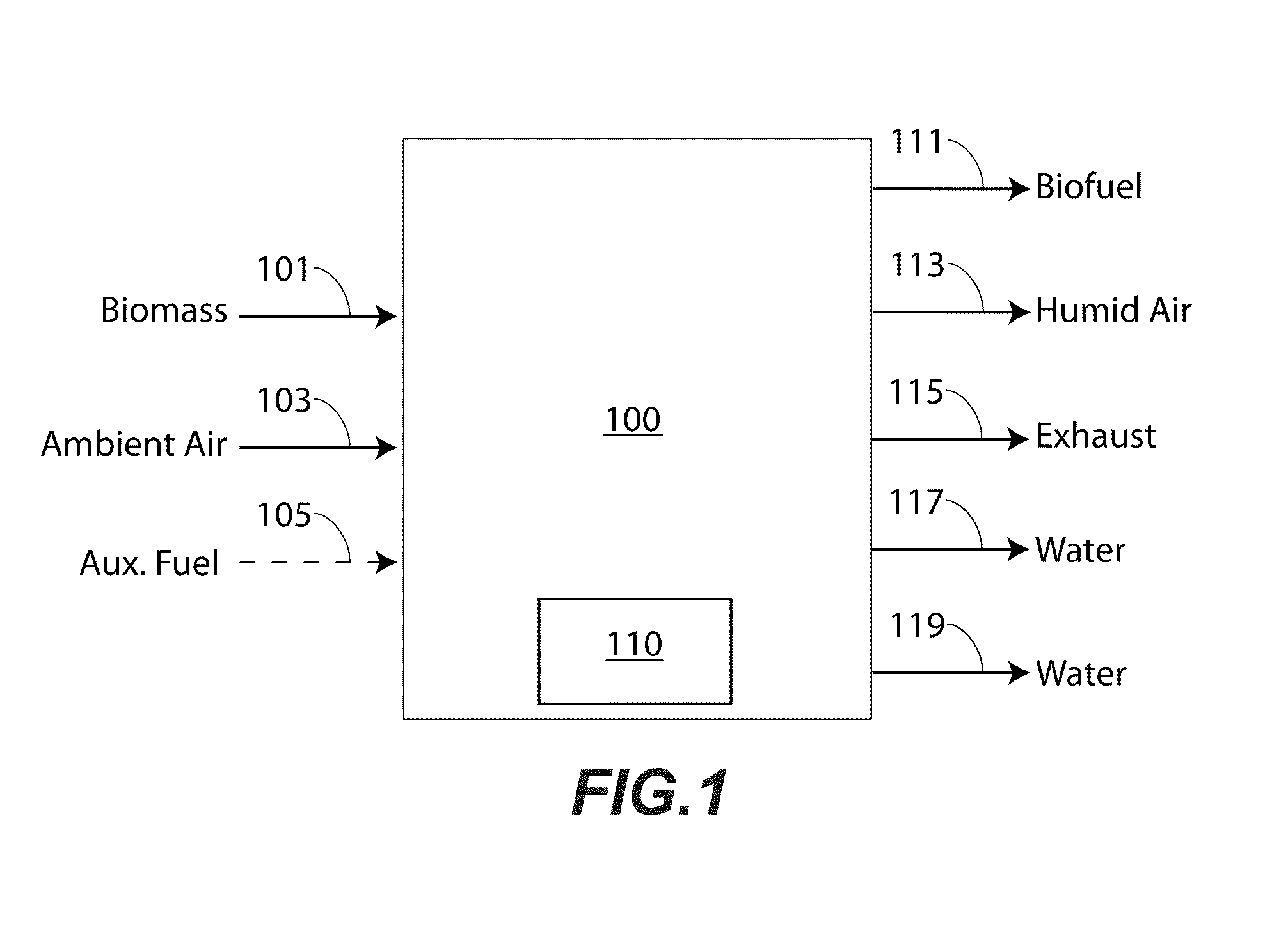

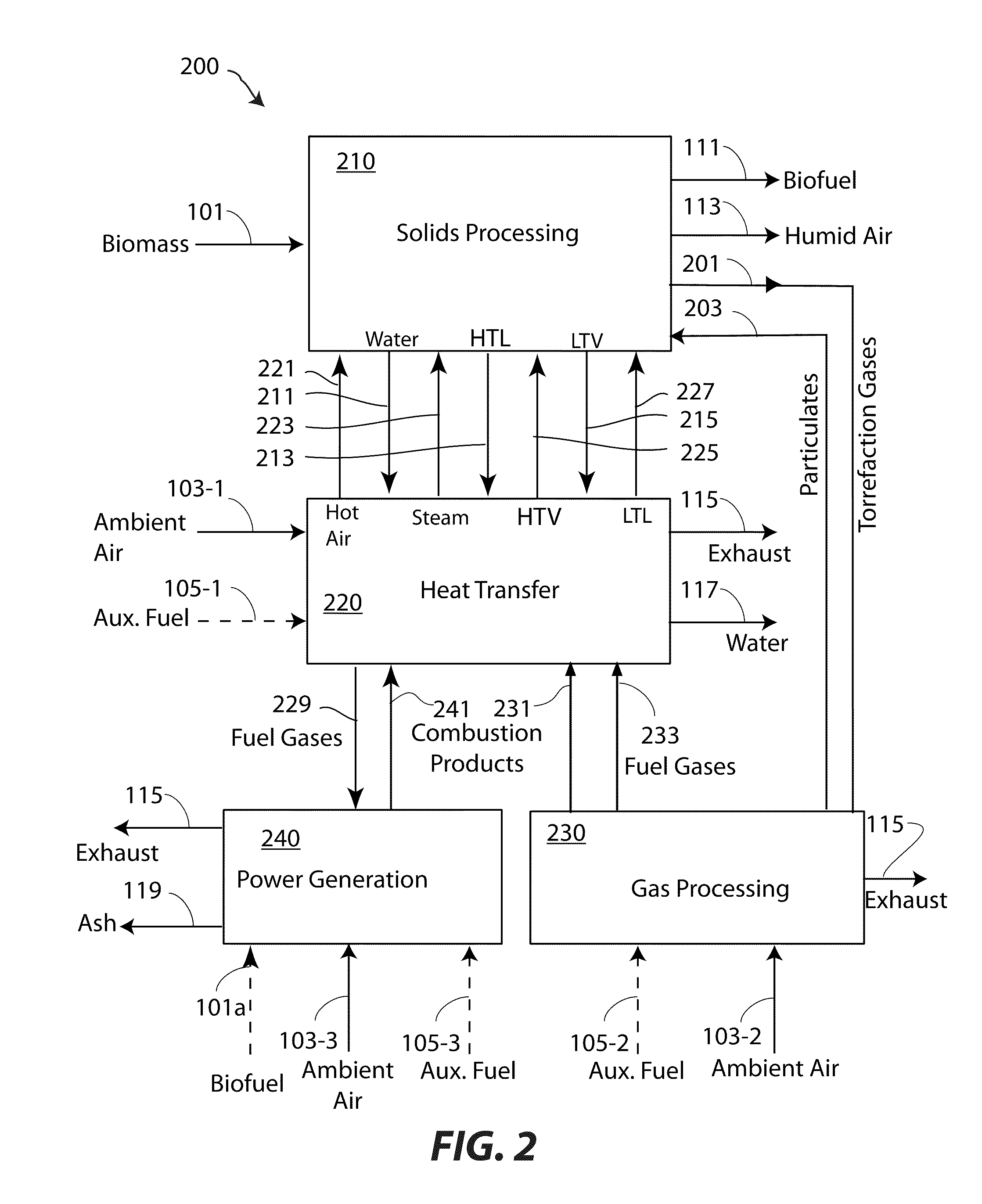

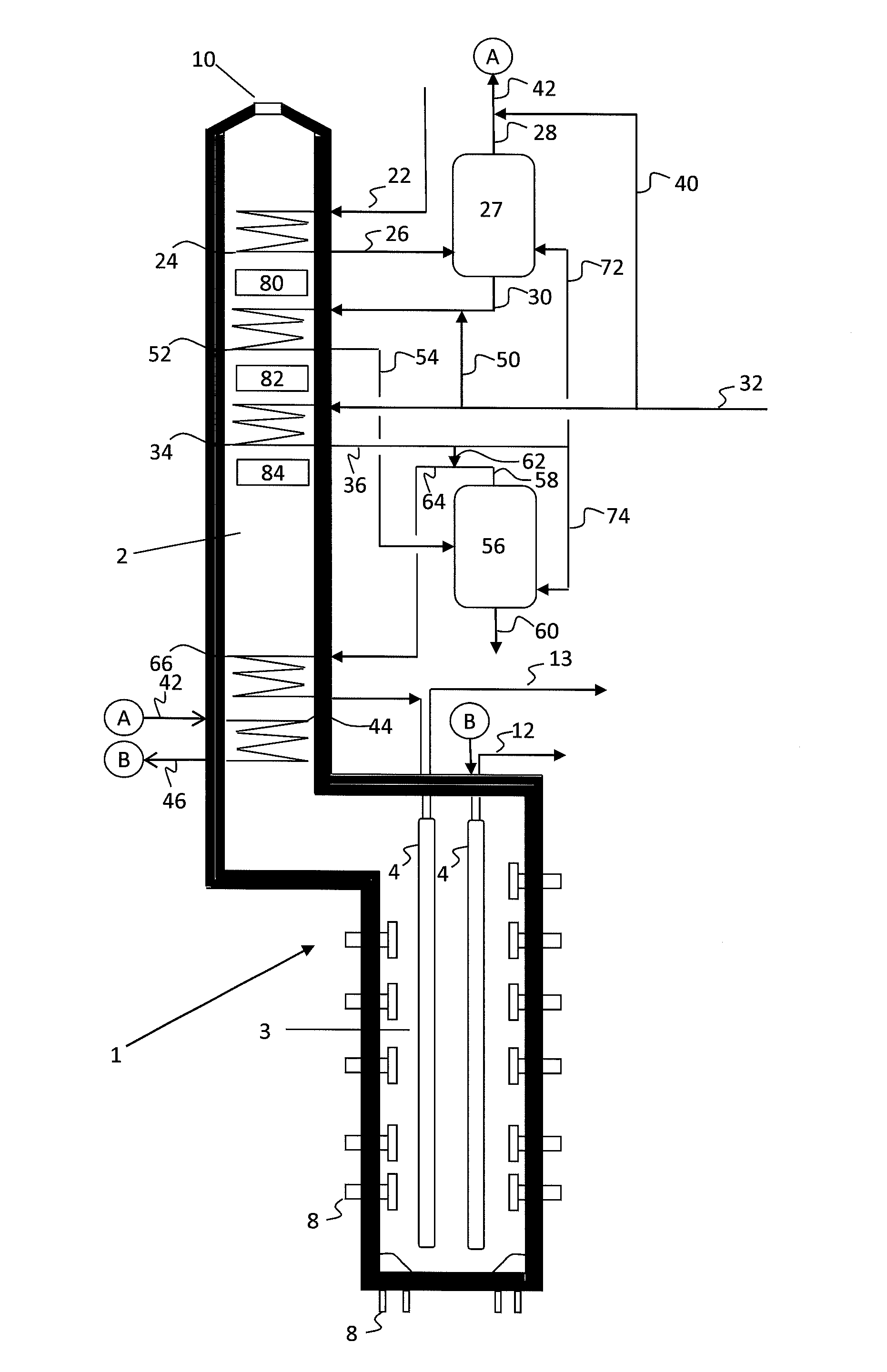

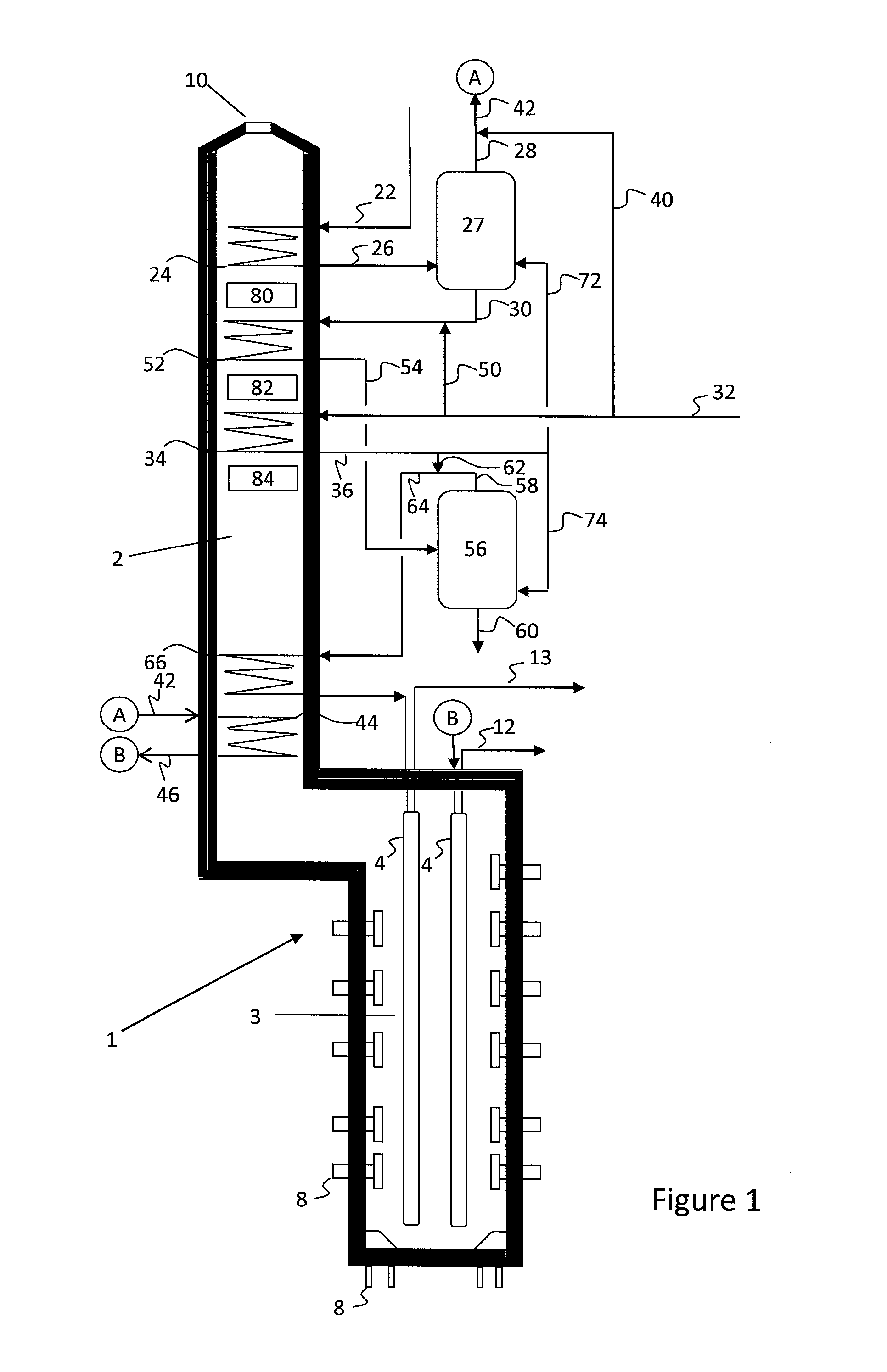

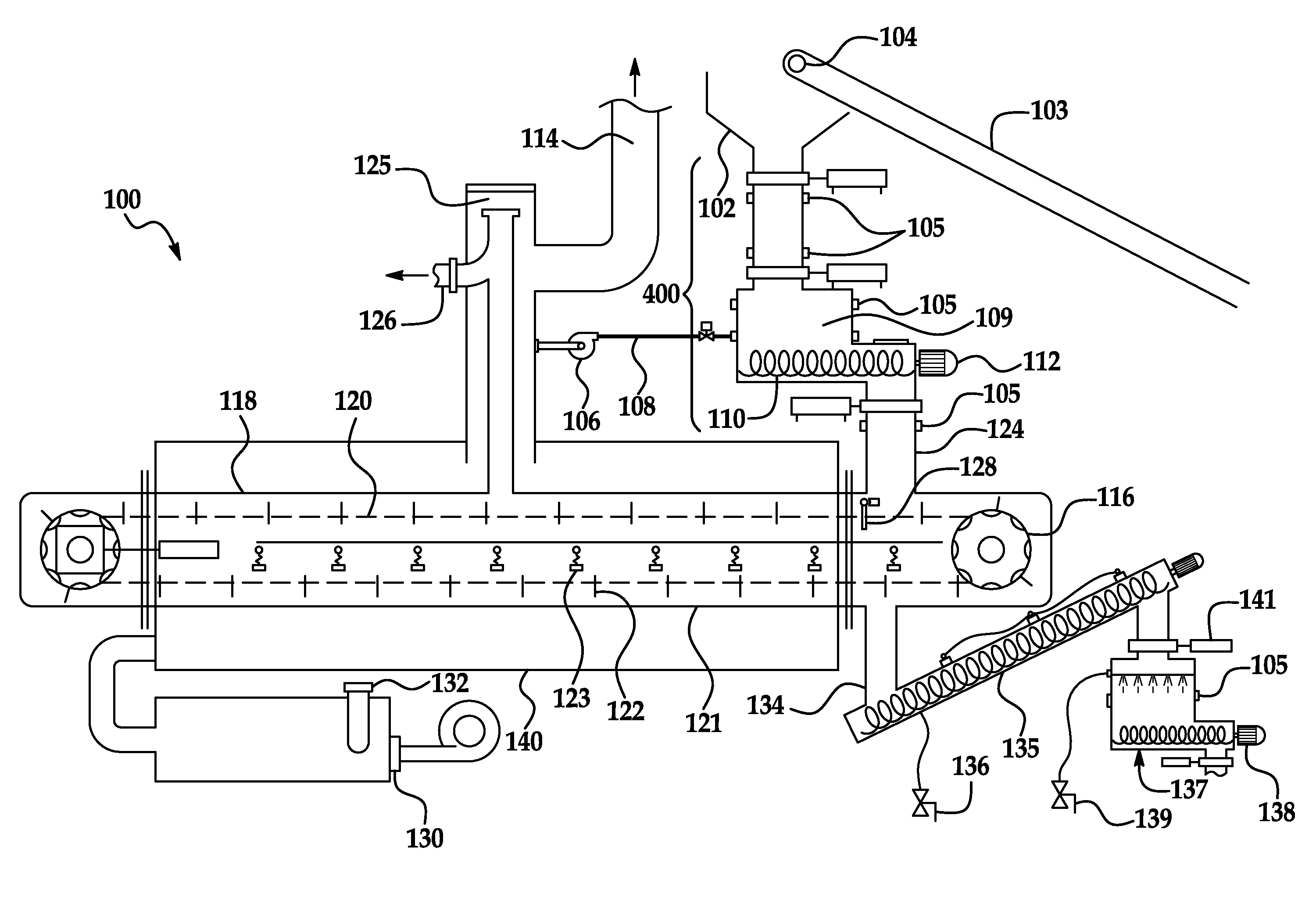

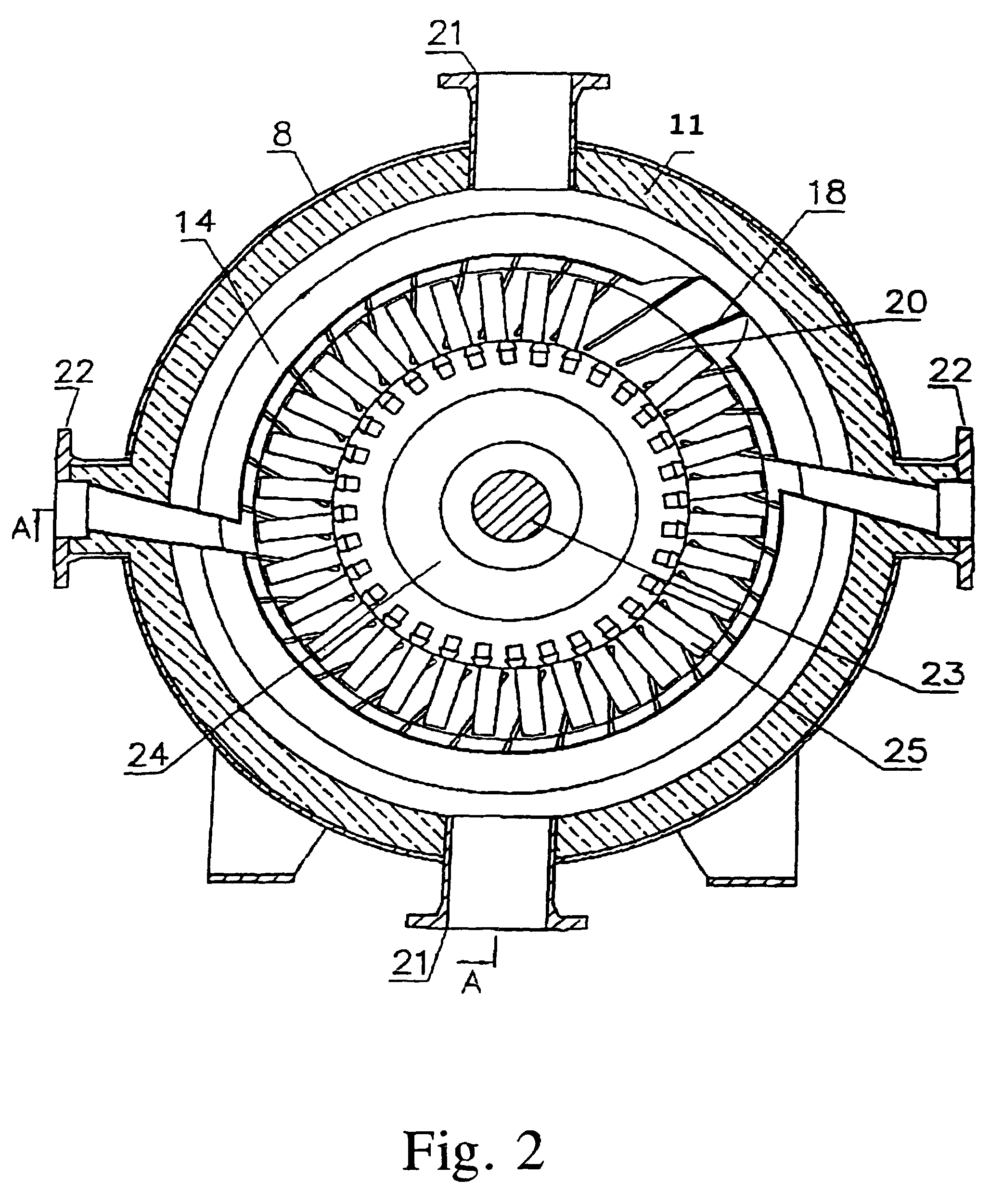

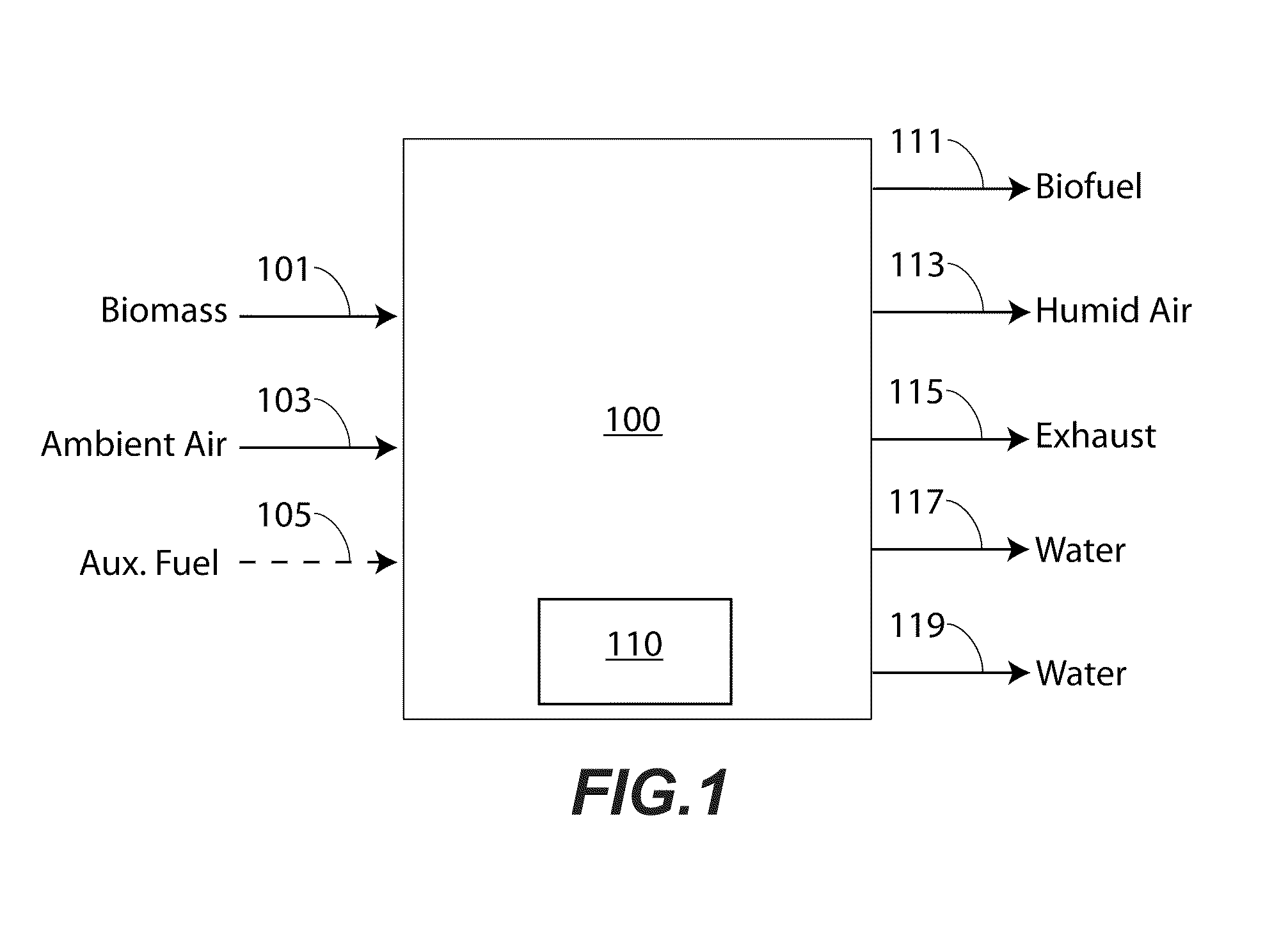

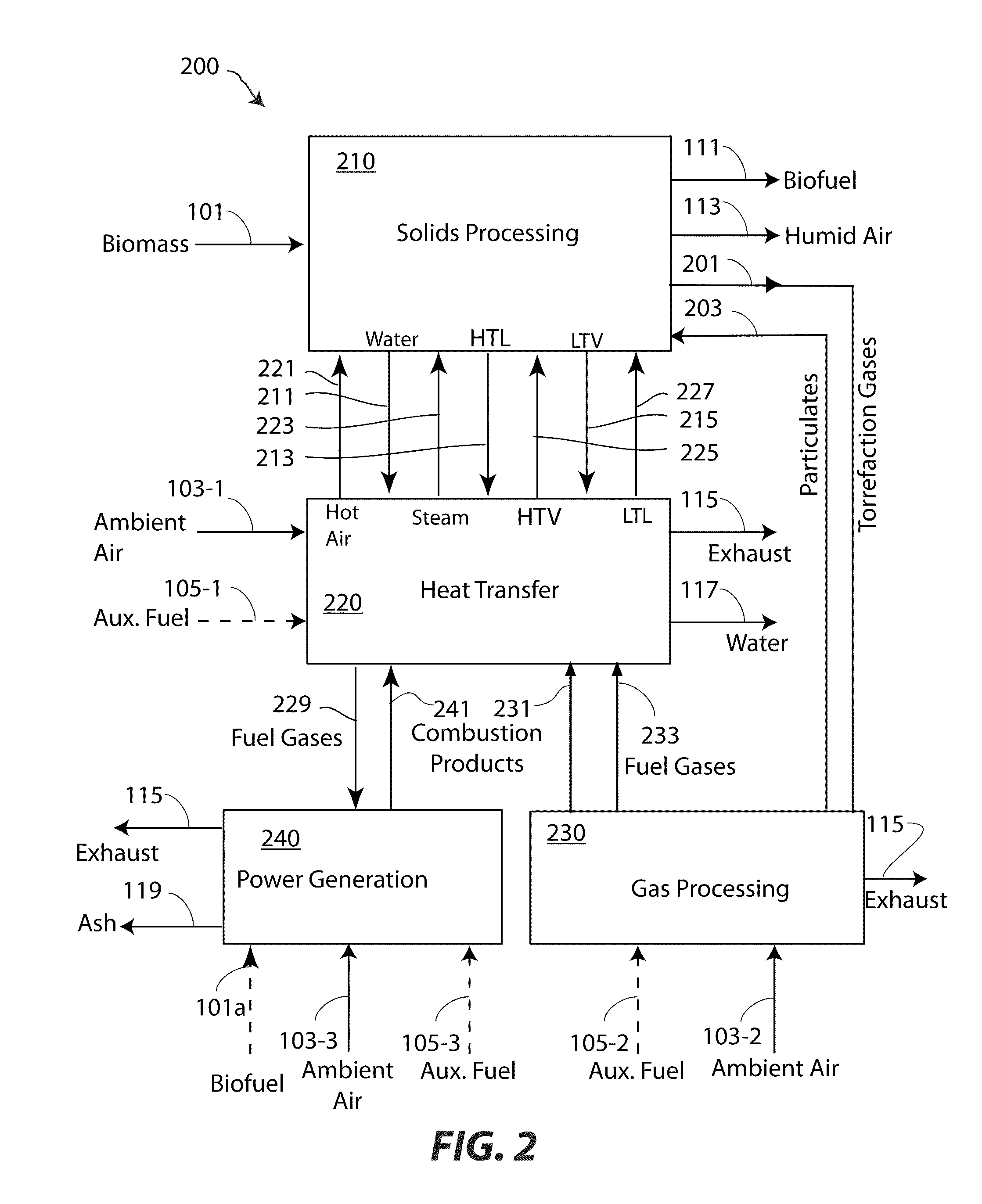

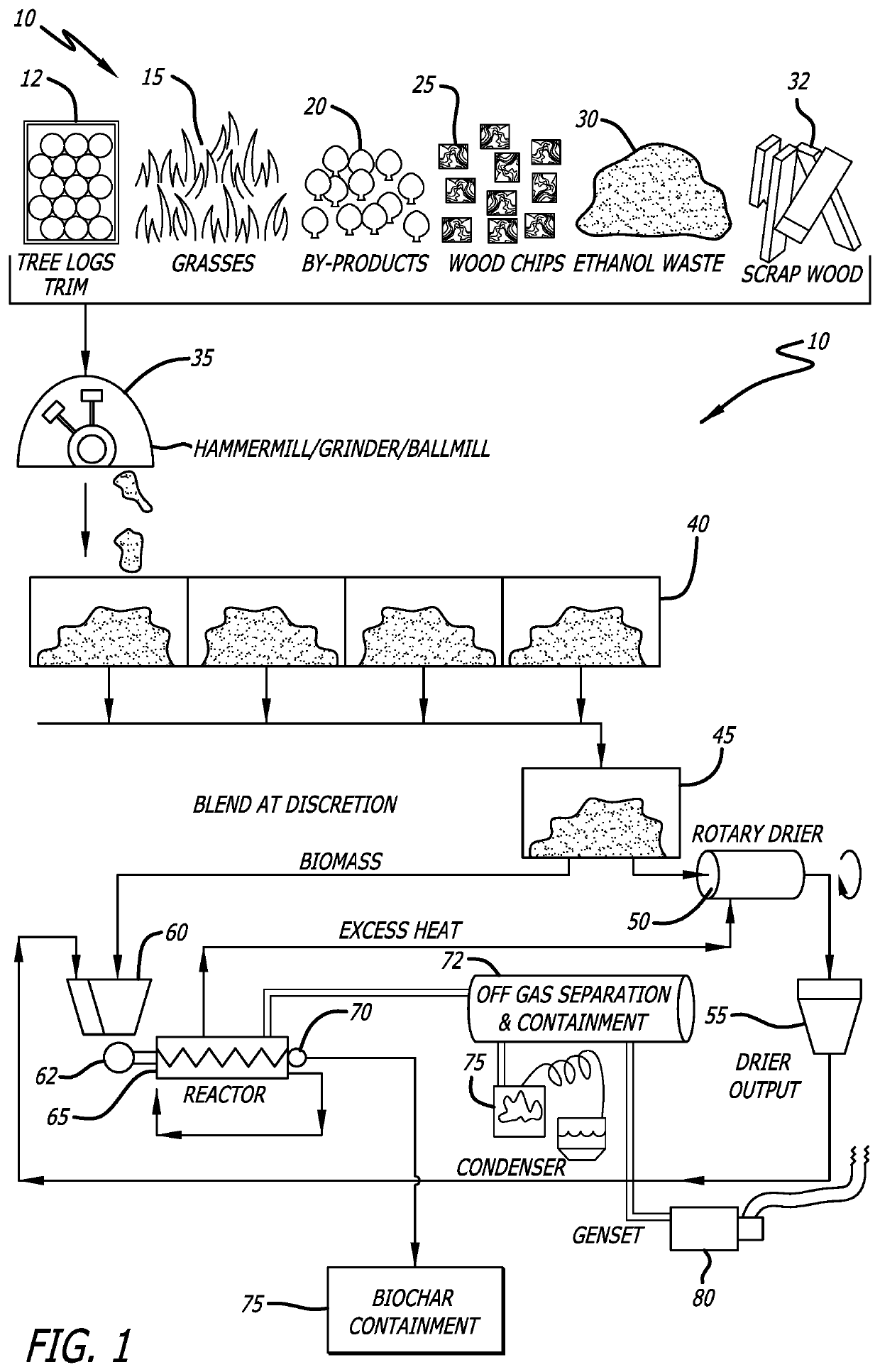

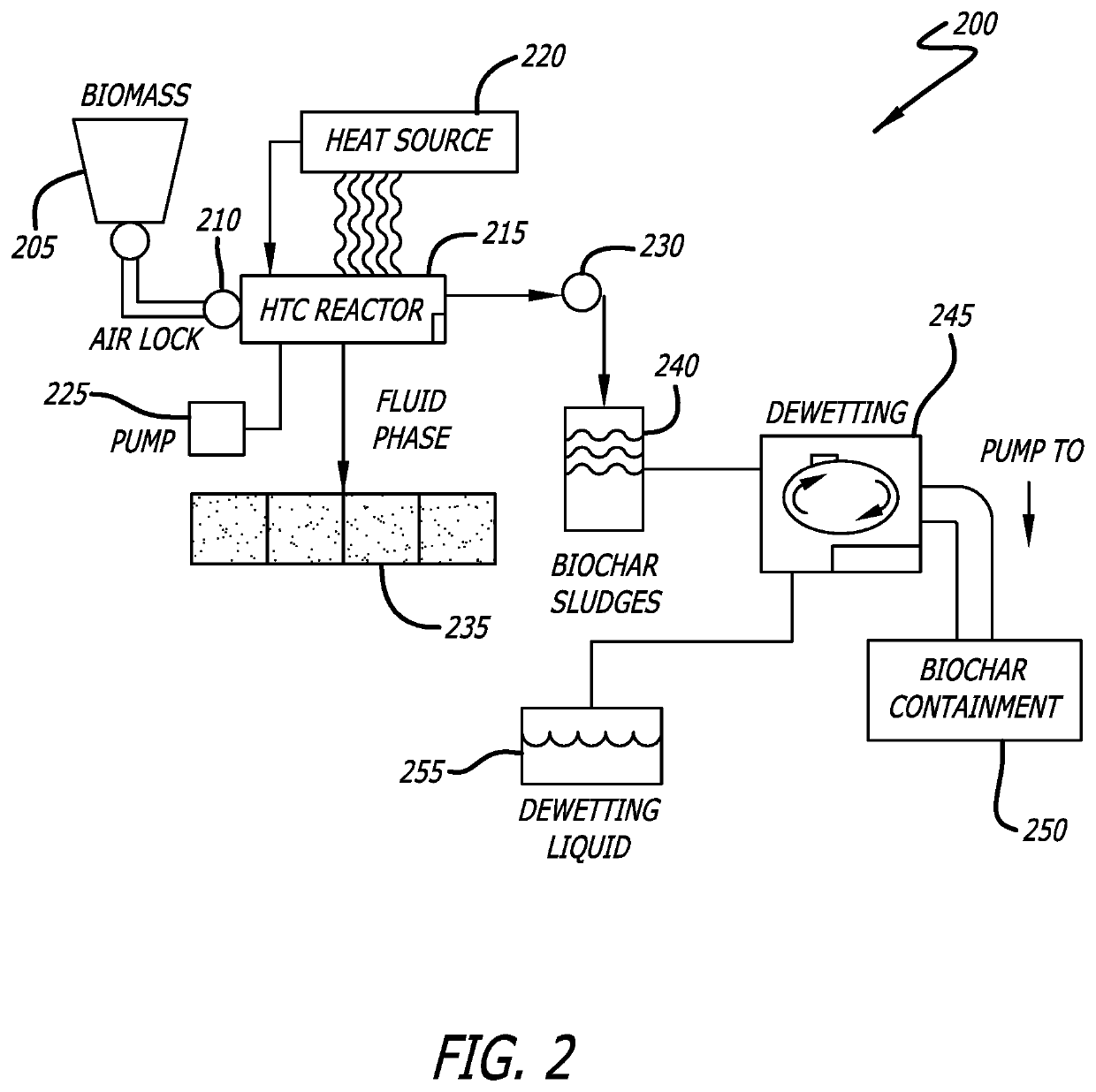

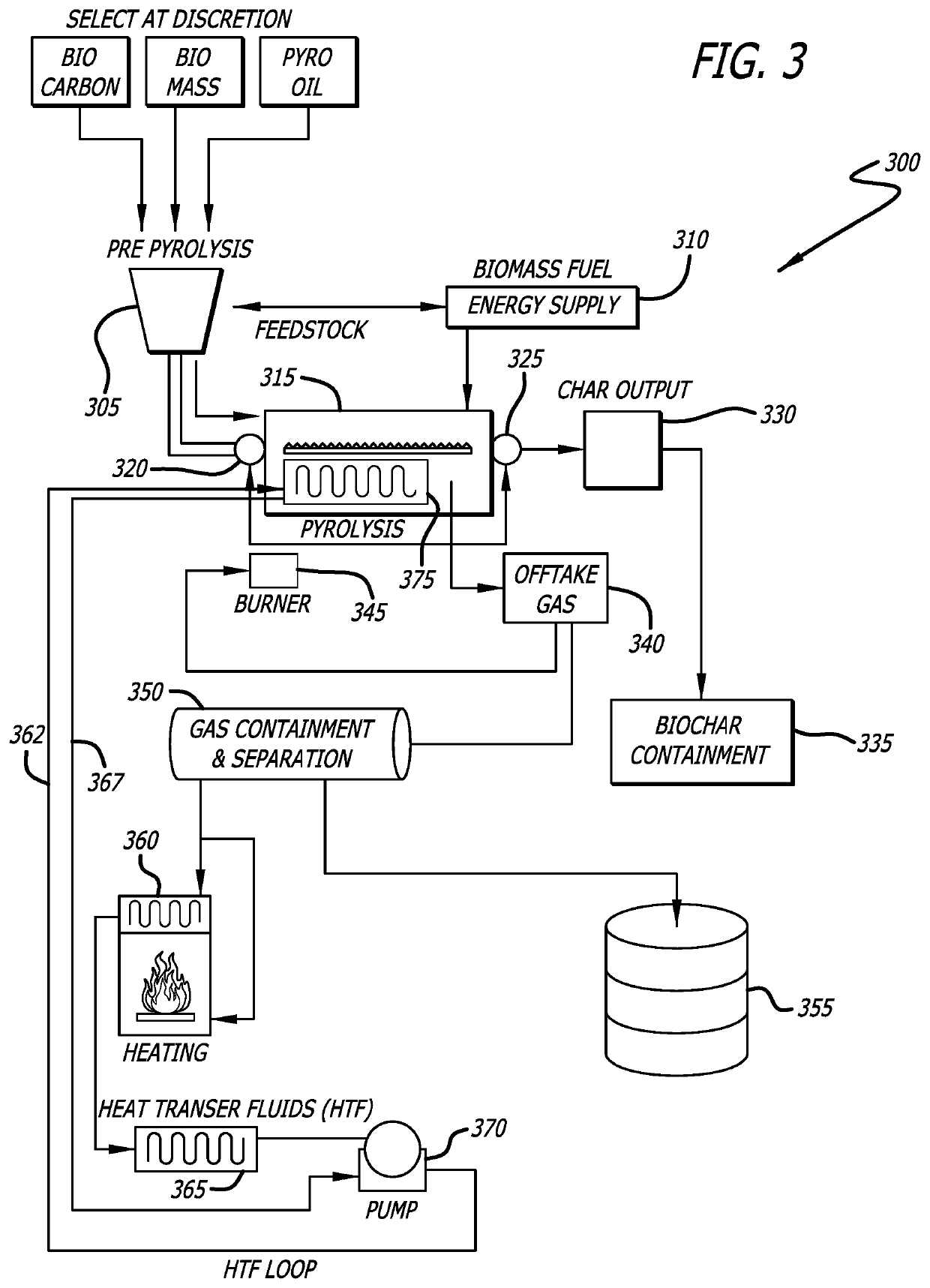

Device and method for conversion of biomass to biofuel

Embodiments presented herein describe an apparatus and method to convert carbonaceous materials, particularly biomass and those biomass resources which are remotely located, into a high performance solid fuel. This method, and the apparatus described as the means to accomplish this method, provides a continuous process which can be completely powered by the energy contained in the biomass. The heat, mechanical power and electrical power are provided from the energy in the biomass, through the methods described. In this way, the apparatus is free to operate in remote locations, where no power or auxiliary fuel sources are available.

Owner:RENEWABLE FUEL TECH

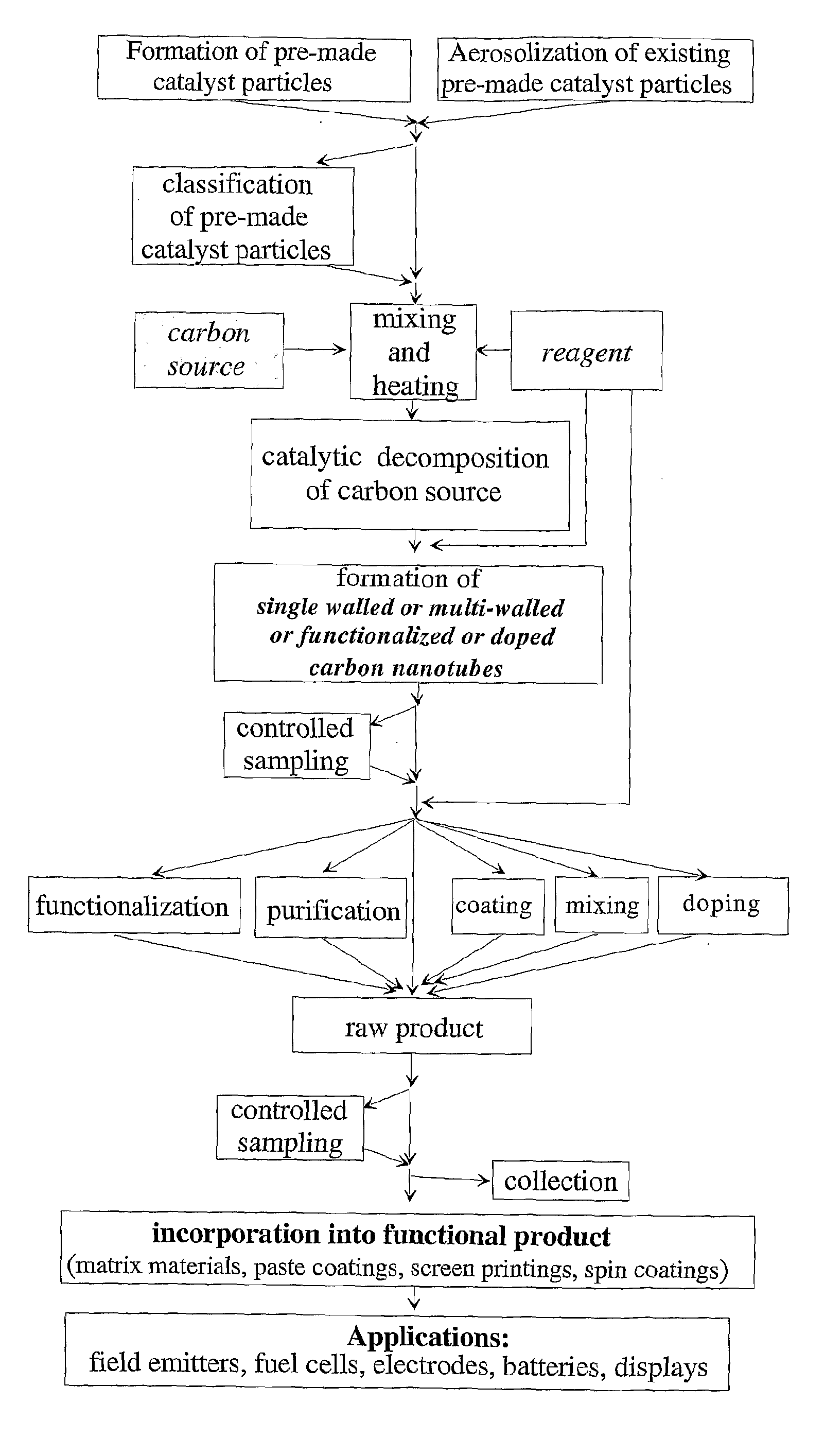

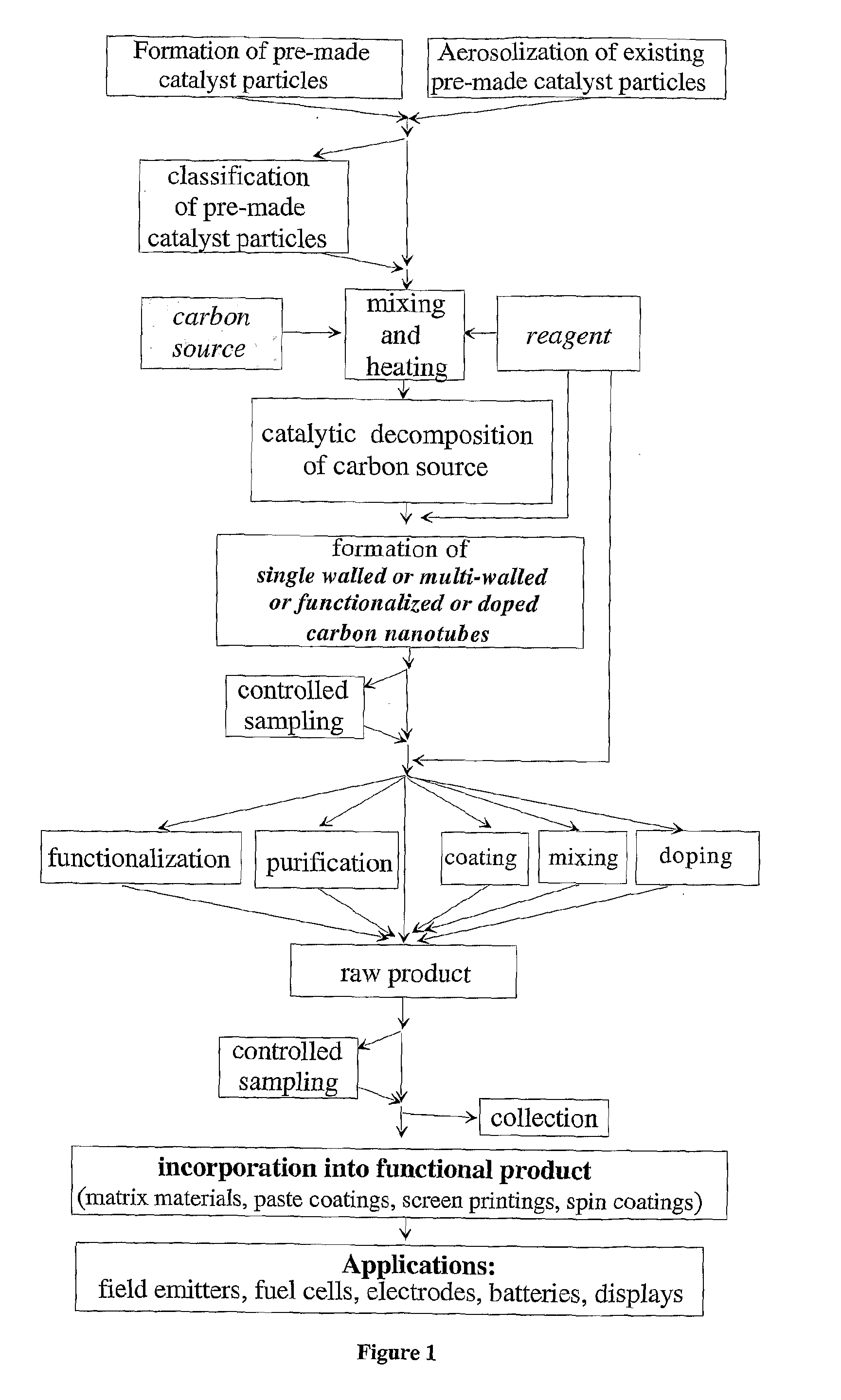

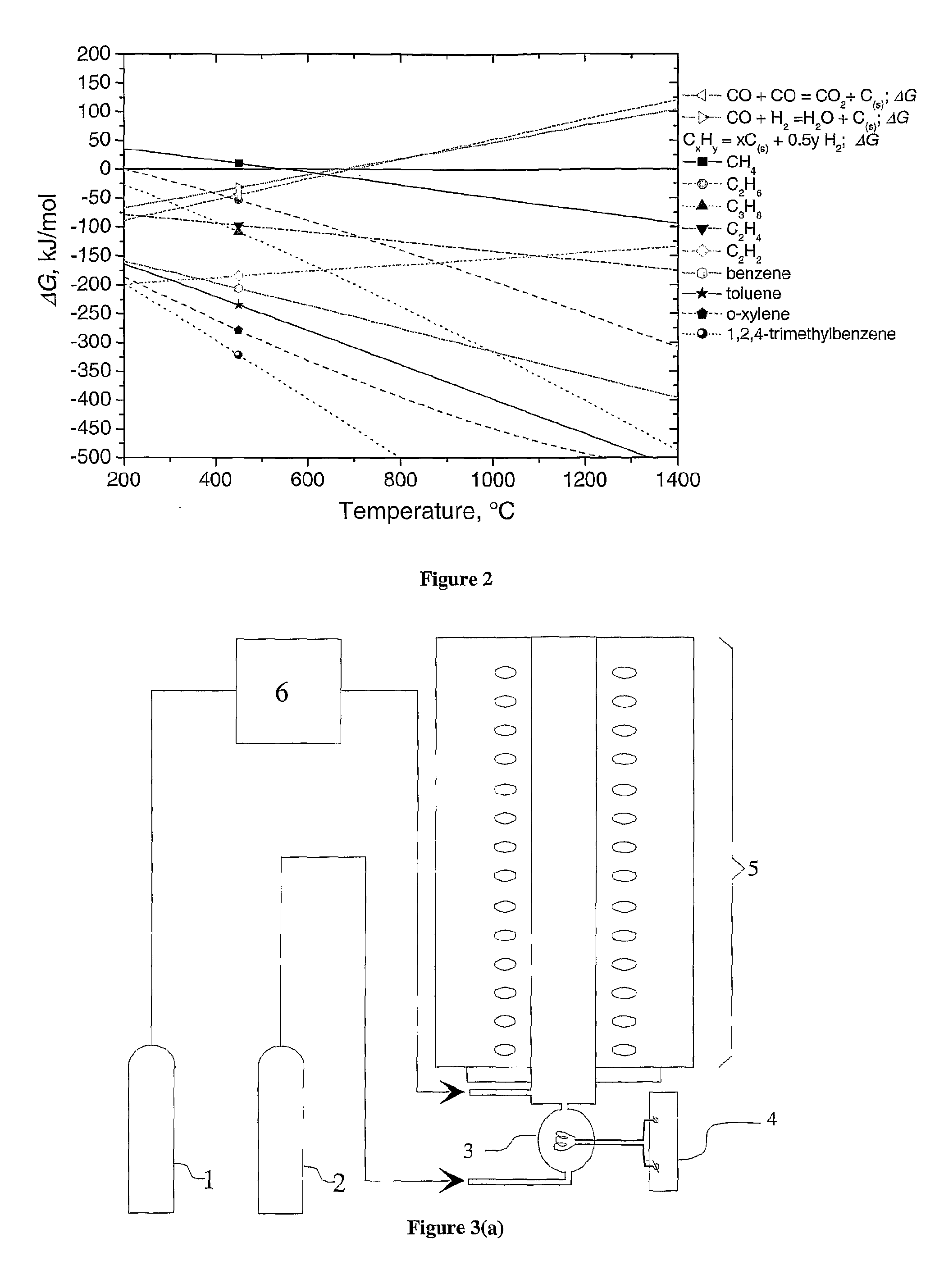

Single, multi-walled, functionalized and doped carbon nanotubes and composites thereof

The present invention relates to single walled and multi-walled carbon nanotubes (CNTs), functionalized CNTs and carbon nanotube composites with controlled properties, to a method for aerosol synthesis of single walled and multi-walled carbon nanotubes, functionalized CNTs and carbon nanotube composites with controlled properties from pre-made catalyst particles and a carbon source in the presence of reagents and additives, to functional, matrix and composite materials composed thereof and structures and devices fabricated from the same in continuous or batch CNT reactors. The present invention allows all or part of the processes of synthesis of CNTs, their purification, doping, functionalization, coating, mixing and deposition to be combined in one continuous procedure and in which the catalyst synthesis, the CNT synthesis, and their functionalization, doping, coating, mixing and deposition can be separately controlled.

Owner:CANATU OY

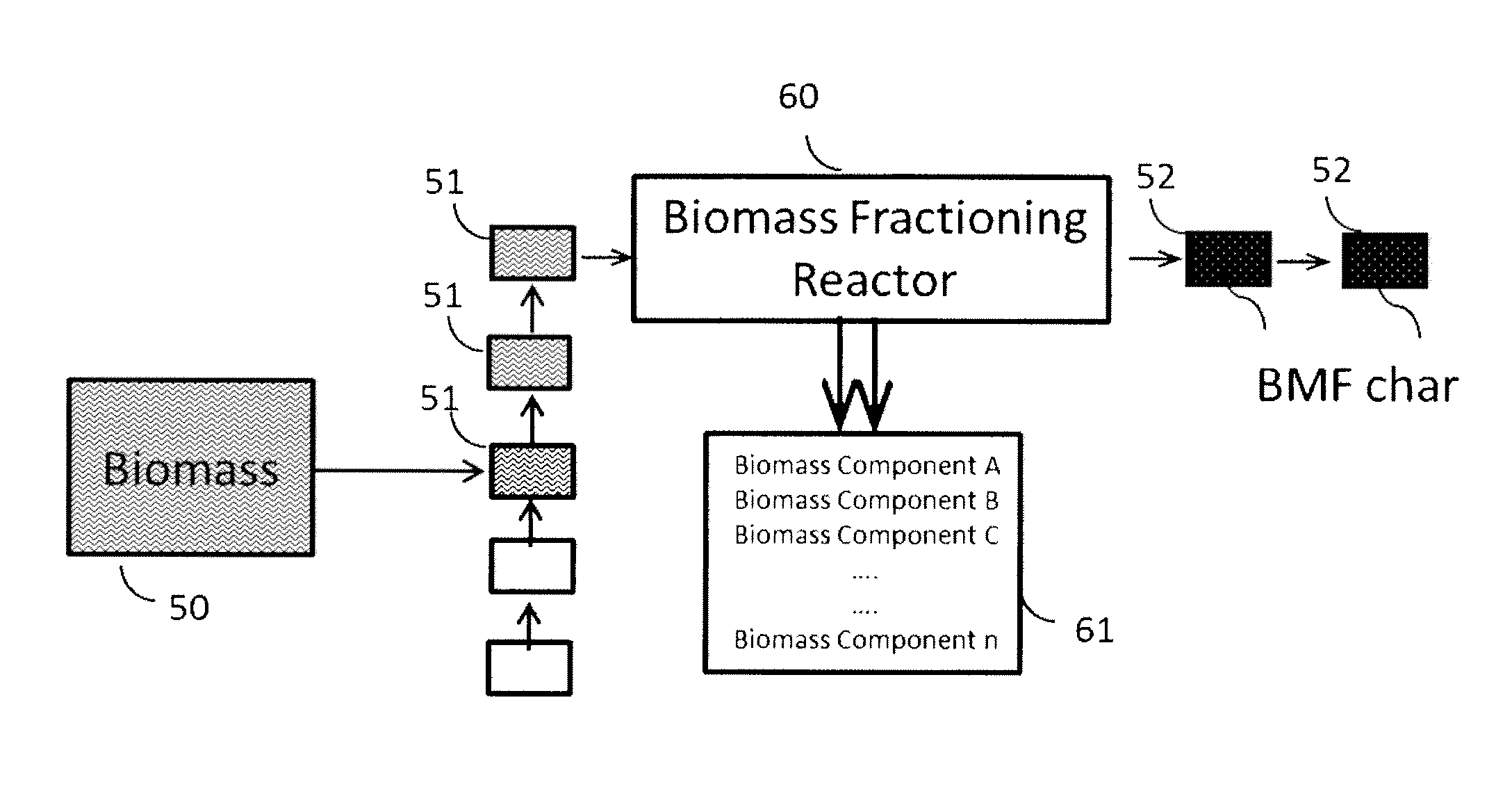

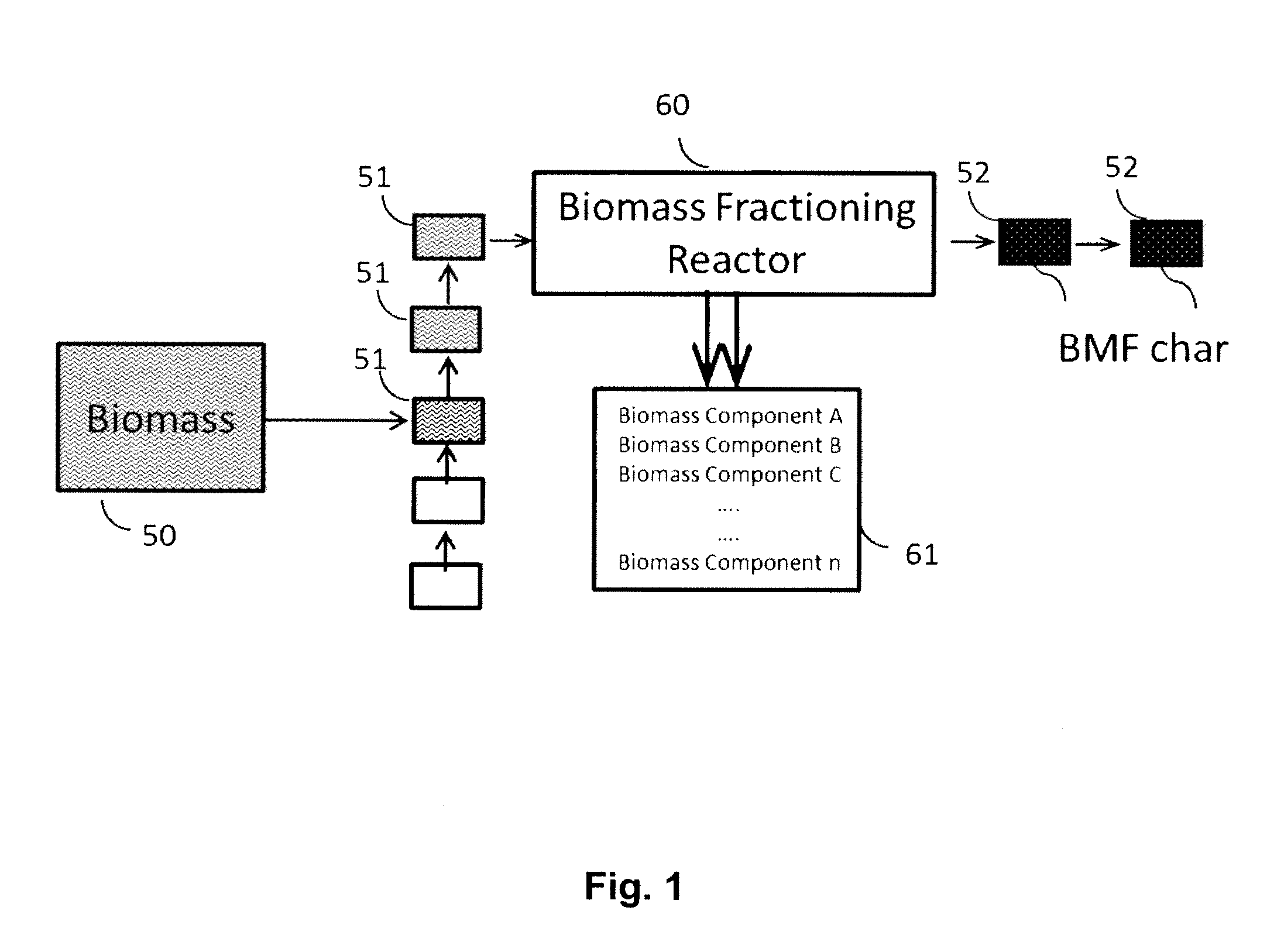

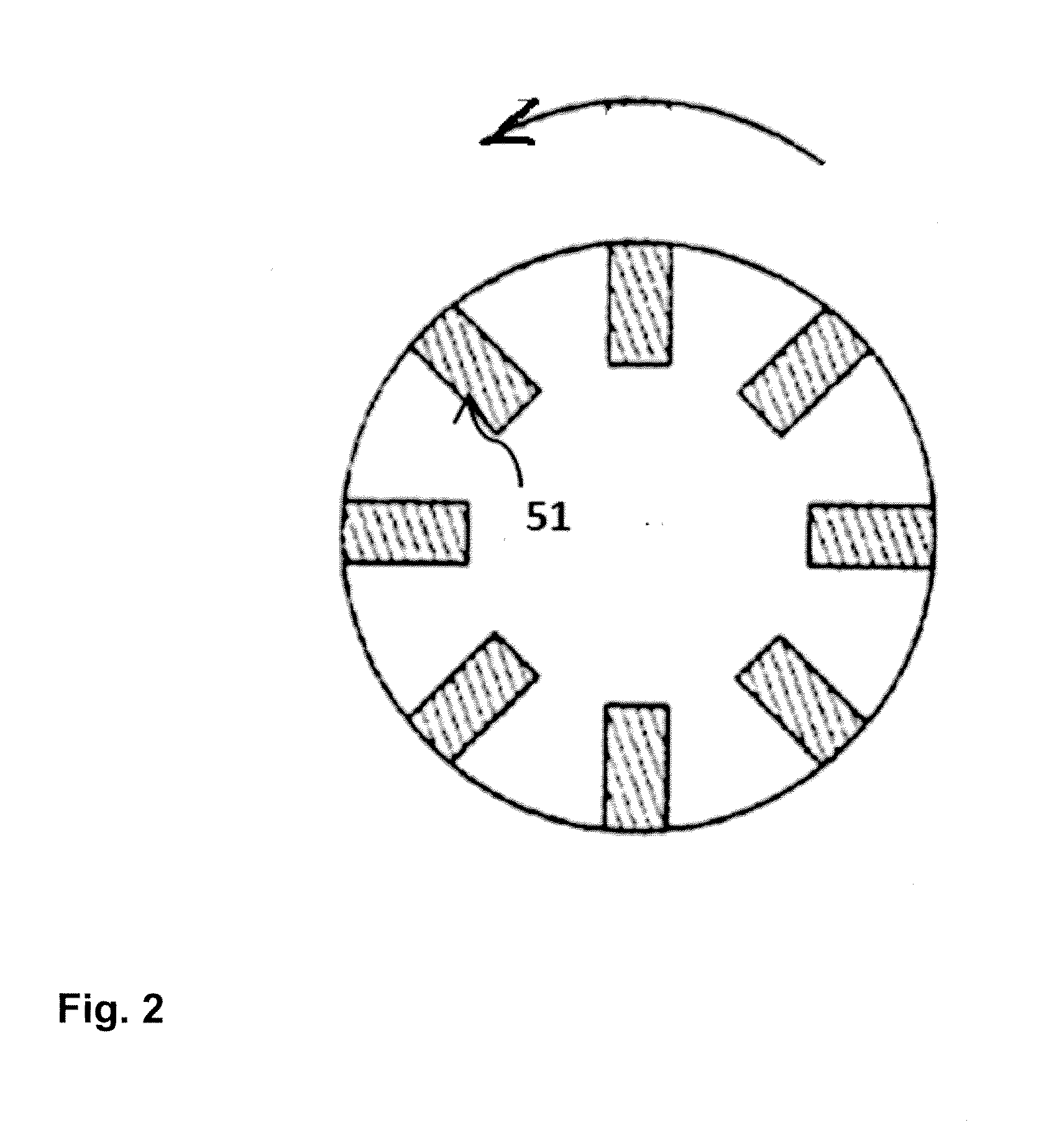

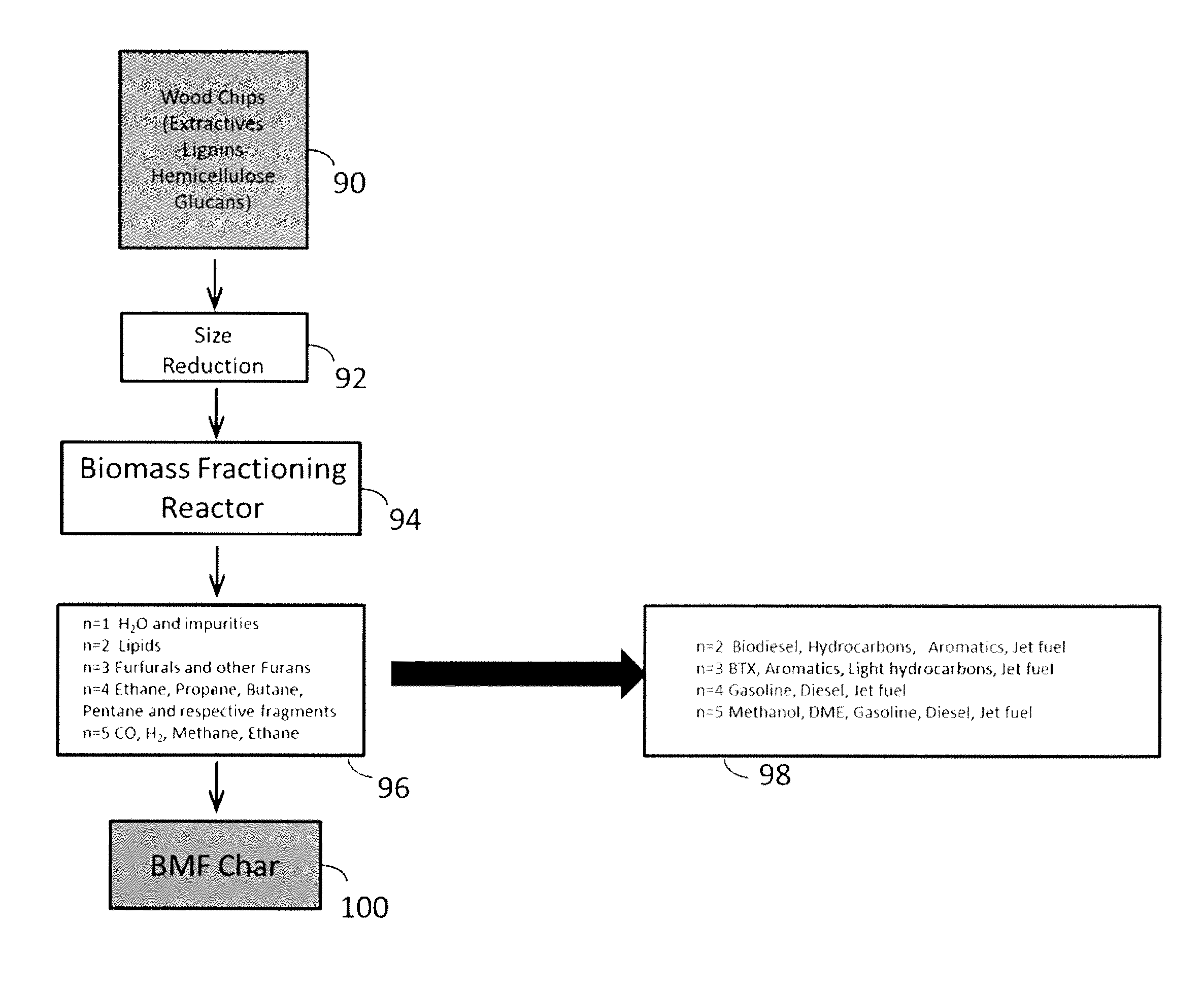

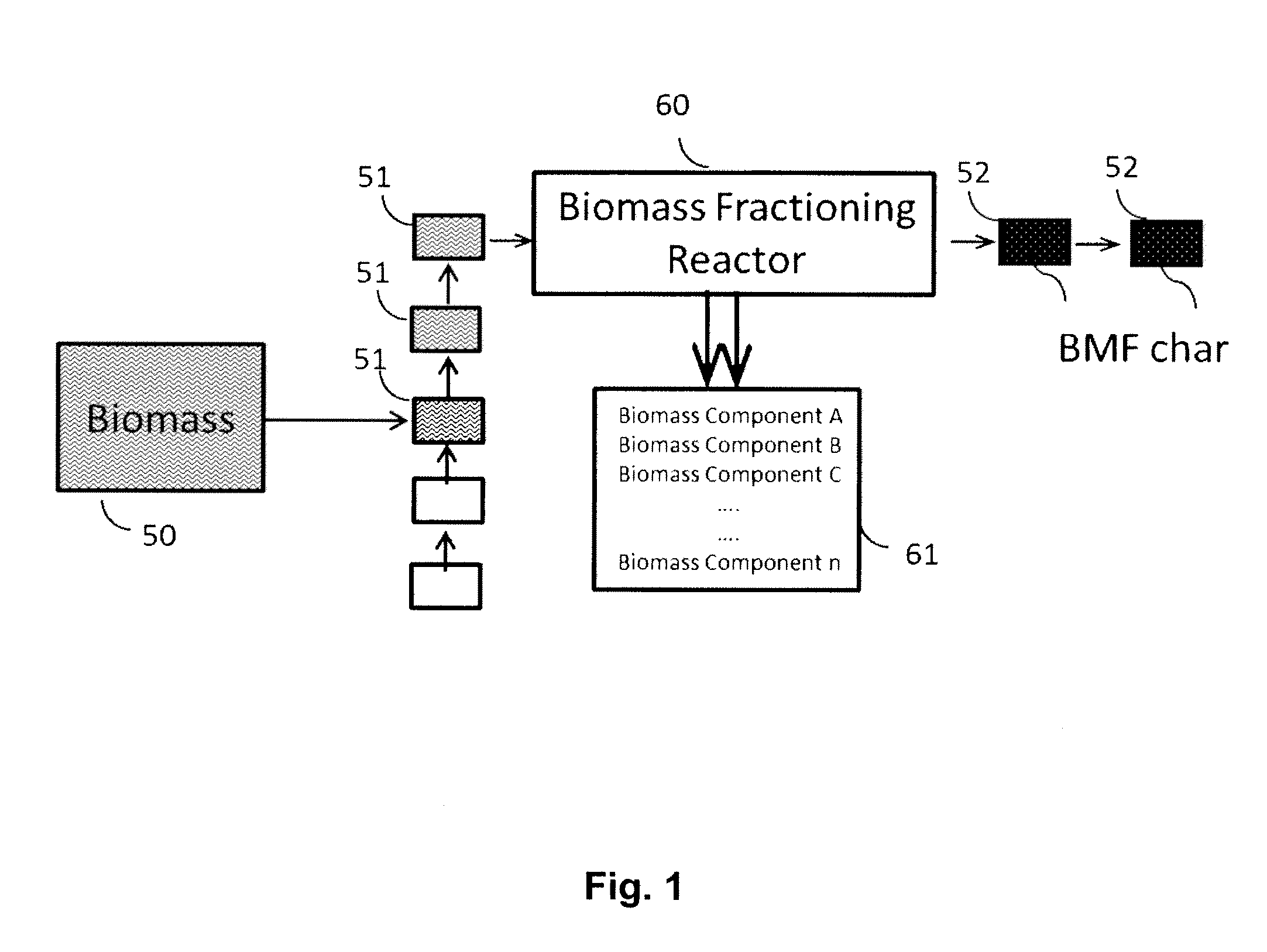

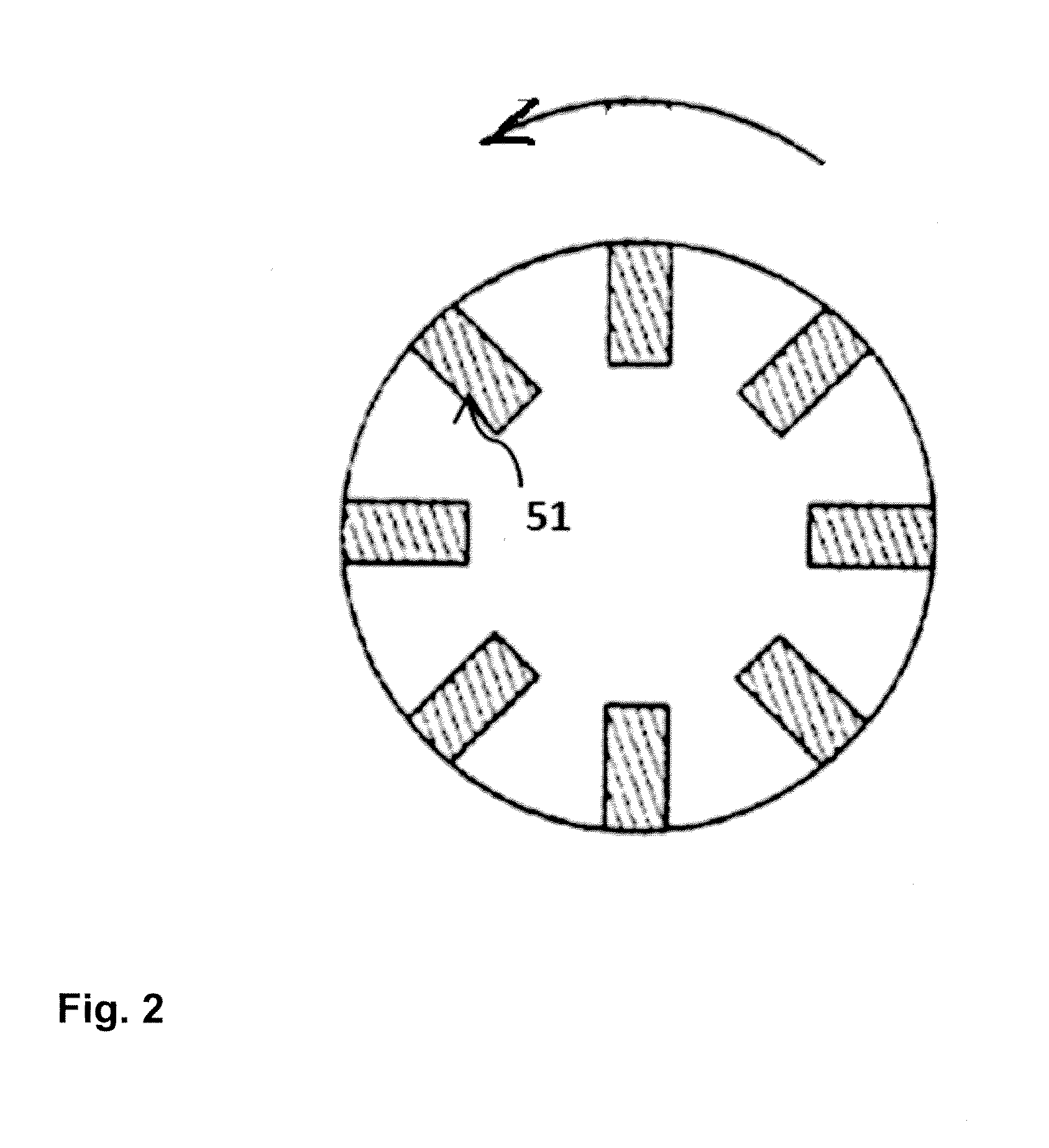

Method for biomass fractioning by enhancing biomass thermal conductivity

A method is disclosed for generating useful chemical intermediates from biomass using a novel pyrolysis reactor that utilizes the inherent thermal properties of carbon under compression as the biomass is subjected to sequential or concurrent temperature ramps. The ramps are sufficient to volatilize and selectively create different components, while the pressure application aids the selective decomposition of the biomass.

Owner:COOL PLANET ENERGY SYST

Thermal cracking of crudes and heavy feeds to produce olefins in pyrolysis reactor

ActiveUS20160097002A1Alleviate cokingReduce foulingThermal non-catalytic crackingTreatment with plural serial stages onlyHydrocarbon mixturesReactor system

Systems and processes for efficiently cracking of hydrocarbon mixtures, such as mixtures including compounds having a normal boiling temperature of greater than 450° C., 500° C., or even greater than 550° C., such as whole crudes for example, are disclosed.

Owner:LUMMUS TECH LLC

Method for the preparation of porous, carbon-based material

InactiveUS20070013094A1Few process stepsWidely-variableSemi-permeable membranesSurgeryPorous carbonCarbonization

The invention relates to a method for the preparation of porous carbon-based material comprising the steps provision of a polymer film provided in the form of a sheet or a coating; as well as pyrolysis and / or carbonization of the polymer film in an atmosphere that is essentially free of oxygen at temperatures in the range of 80° C. to 3,500° C. The invention further relates to carbon-based material producible according to the method mentioned above.

Owner:CINVENTION AG

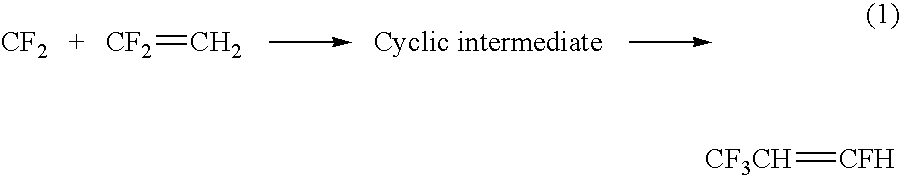

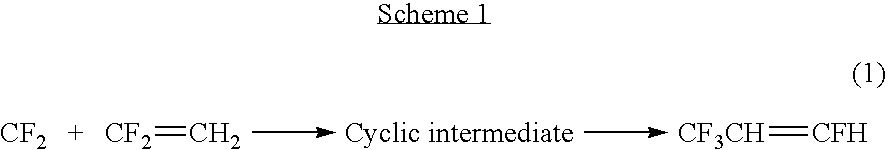

Processes for synthesis of 1,3,3,3-tetrafluoropropene

Disclosed is a process for the synthesis of 1,3,3,3-tetrafluoropropene which comprises, in one embodiment, reacting a compound of CF3X1 with a compound of CX2H═CHX3, wherein X1, X2, and X3 are each independently selected from the group consisting of fluorine, chlorine, bromine and iodine, to produce a reaction product comprising a compound of CF3CH═CHX3, wherein X3 is as described above; and when X3 is not fluorine, fluorinating the compound to produce 1,3,3,3-tetrafluoropropene. The process in another embodiment comprises preparing tetrafluoropropene comprising thermally cracking one or more compounds capable of producing a reaction mixture which preferably comprises diflurocarbene radicals and vinylidene fluoride, and converting said reaction mixture into—tetrafluoropropene (1,3,3,3-tetrafluoropropene).

Owner:HONEYWELL INT INC

Processes for synthesis of 1,3,3,3-tetrafluoropropene

ActiveUS7371904B2Thermal non-catalytic crackingPreparation by halogen replacementBromine1,3,3,3-Tetrafluoropropene

Disclosed is a process for the synthesis of 1,3,3,3-tetrafluoropropene which comprises, in one embodiment, reacting a compound of CF3X1 with a compound of CX2H═CHX3, wherein X1, X2, and X3 are each independently selected from the group consisting of fluorine, chlorine, bromine and iodine, to produce a reaction product comprising a compound of CF3CH═CHX3, wherein X3 is as described above; and when X3 is not fluorine, fluorinating the compound to produce 1,3,3,3-tetrafluoropropene. The process in another embodiment comprises preparing tetrafluoropropene comprising thermally cracking one or more compounds capable of producing a reaction mixture which preferably comprises diflurocarbene radicals and vinylidene fluoride, and converting said reaction mixture into—tetrafluoropropene (1,3,3,3-tetrafluoropropene).

Owner:HONEYWELL INT INC

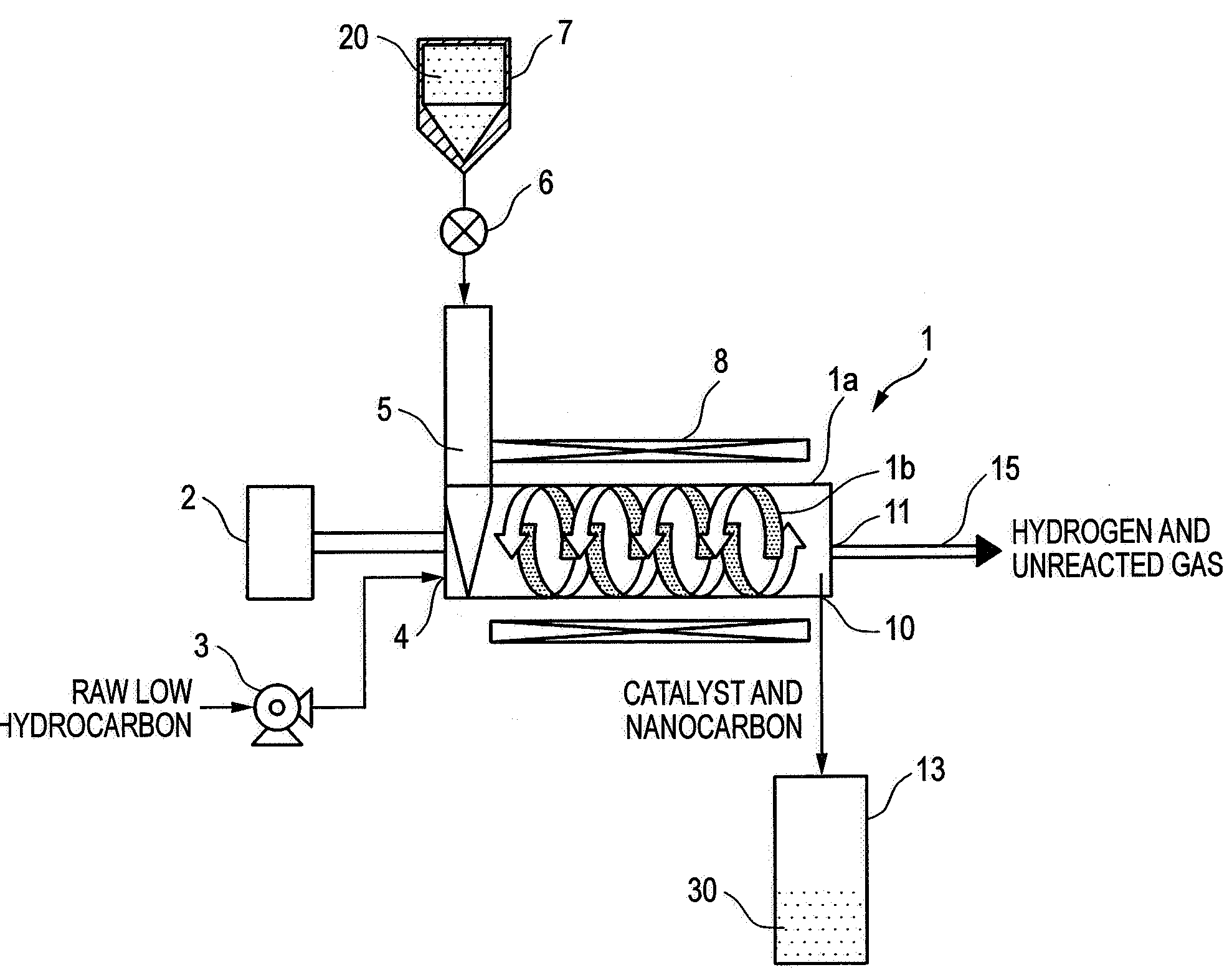

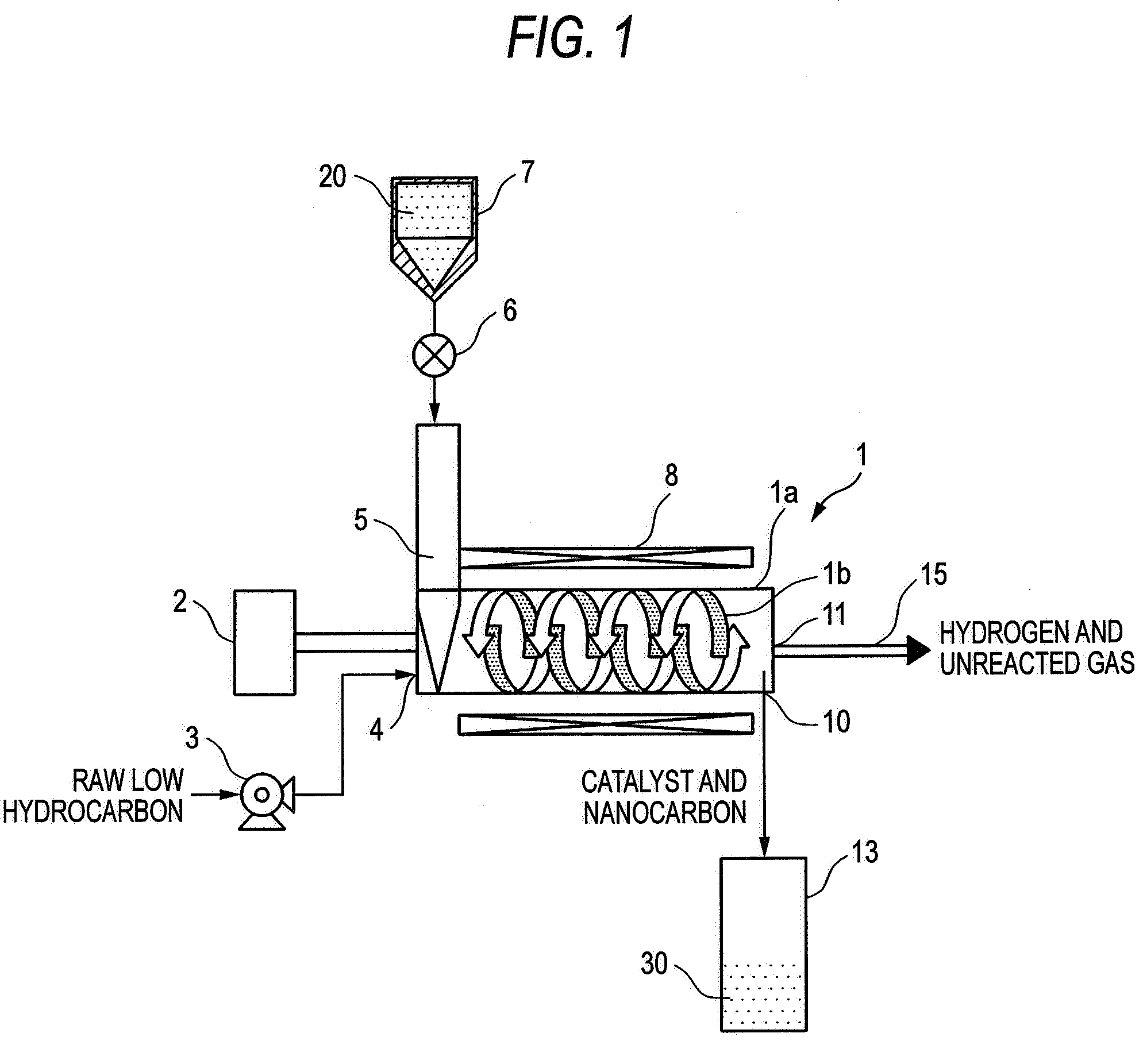

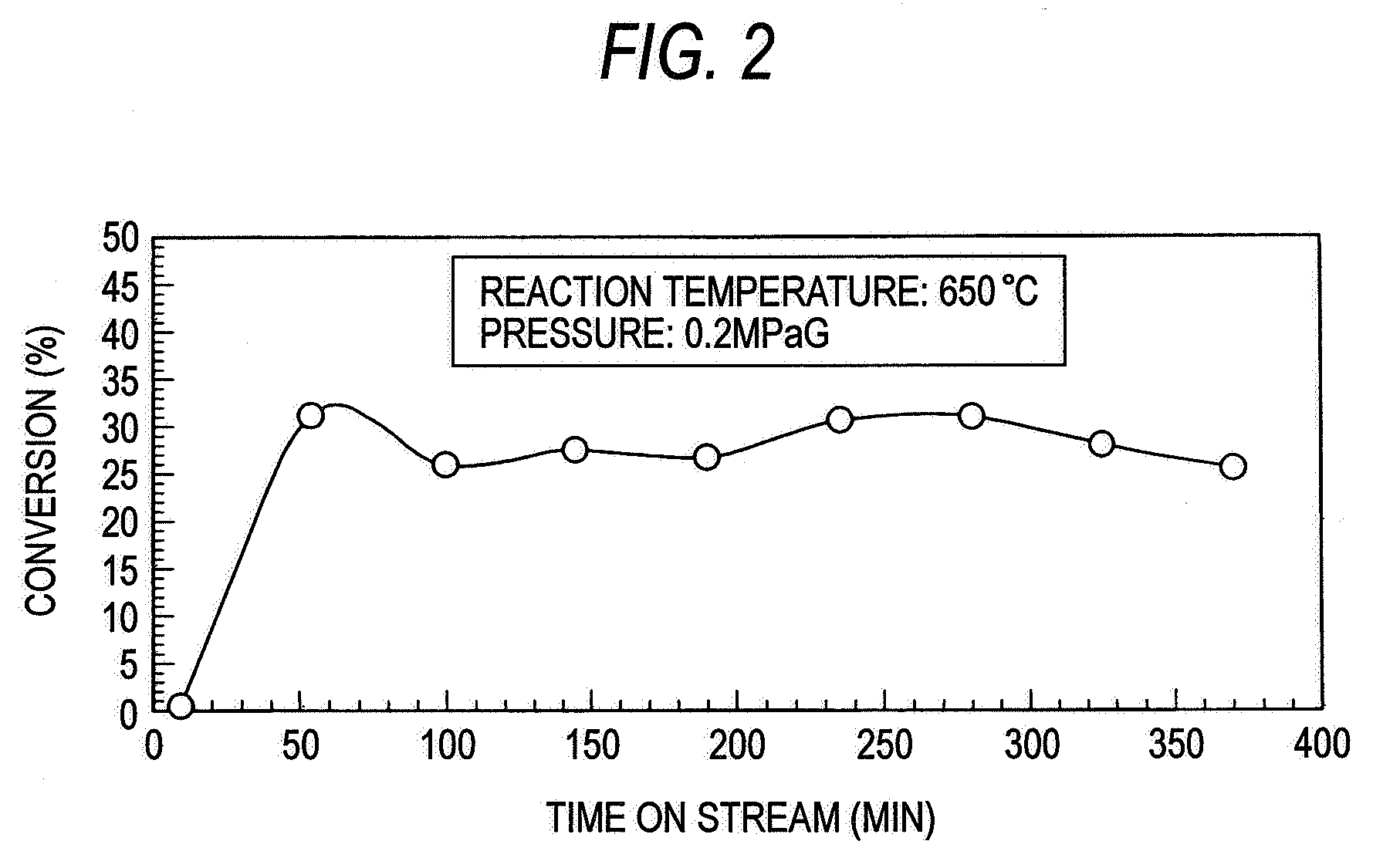

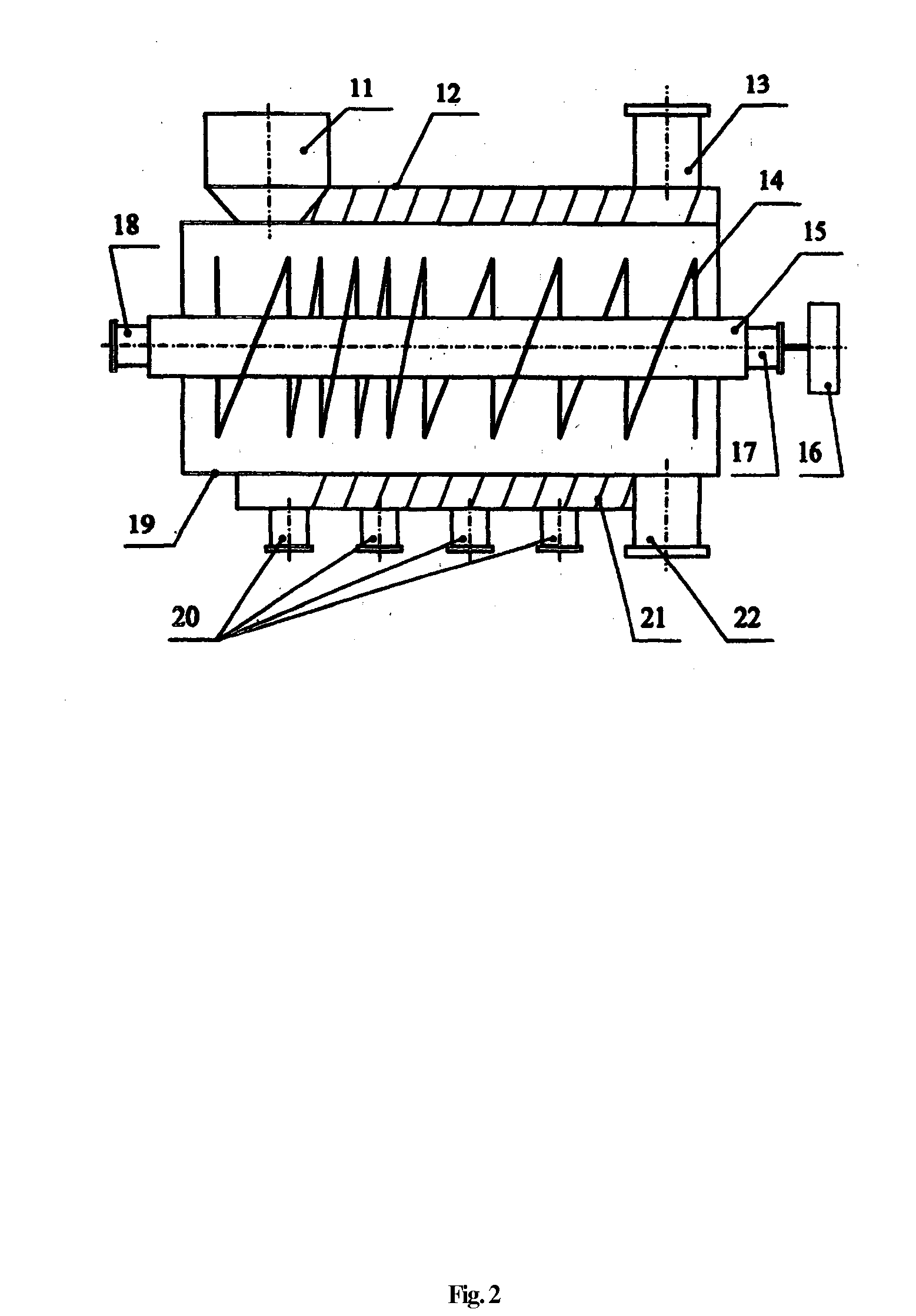

Method for producing nanocarbon and catalytic reaction device for producing nanocarbon

A cylindrical screw feeder main body, catalyst feeding portions for introducing a catalyst into the screw feeder main body, low hydrocarbon feeding portions for introducing a low hydrocarbon into the screw feeder main body as a raw material, a screw for conveying the catalyst and nanocarbon produced by pyrolysis of the low hydrocarbon in the feeder main body, a solid matter discharging portion for discharging the catalyst and the nanocarbon conveyed by the screw out of the screw feeder main body and a gas discharging portion for discharging the unreacted low hydrocarbon and hydrogen produced by the pyrolysis of the low hydrocarbon out of the screw feeder main body are provided. Nanocarbon grown with the catalyst as top with time is continuously discharged out of the screw feeder main body while unused catalyst is being fed thereto at the same amount as that of nanocarbon, allowing efficient continuous reaction.

Owner:KITAMI INST OF TECH +2

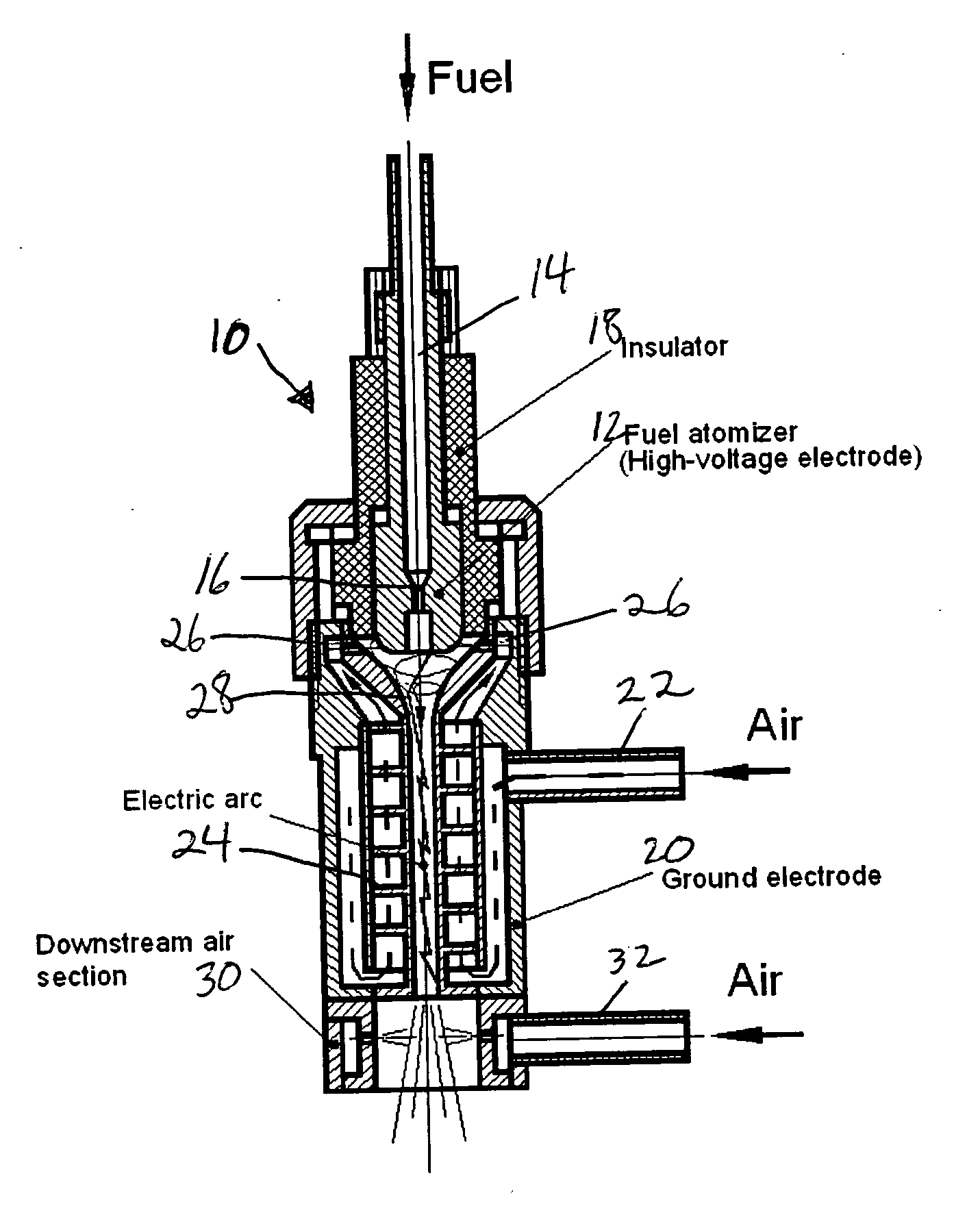

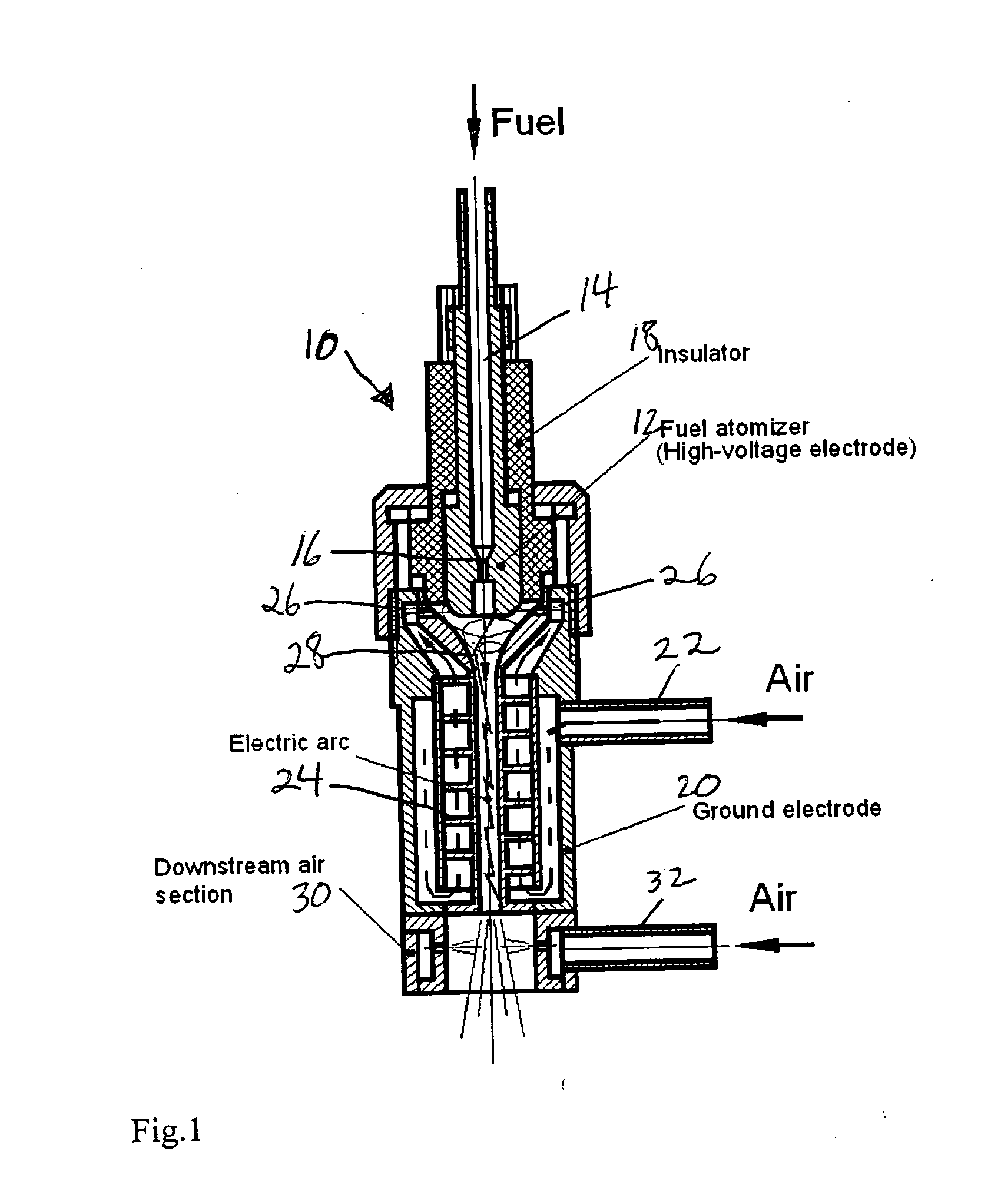

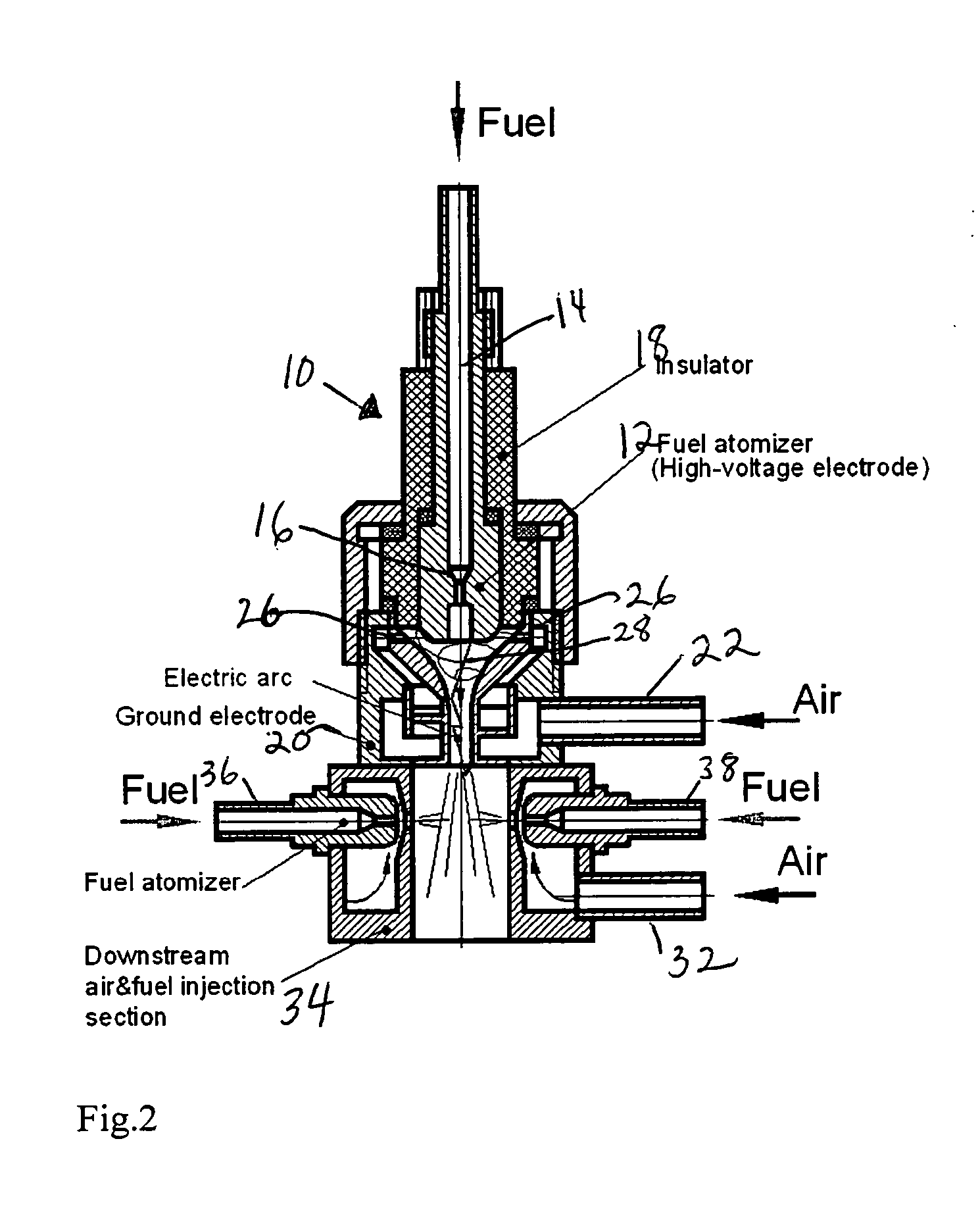

High enthalpy low power plasma reformer

High enthalpy low power plasma reformer. An annular ground electrode includes a air intake manifold and helical structure for directing an air helically along the ground electrode in a heat transfer relation. A high voltage electrode is spaced from the ground electrode to create a gap through which preheated air flows, the high voltage electrode including a passage for delivery of hydrocarbon fuel to an atomizer. A plasma discharge occurs within an electric arc discharge region within the annular ground electrode in which the fuel is partially pyrolized to produce hydrogen rich gas.

Owner:NANOENERGY GROUP UK

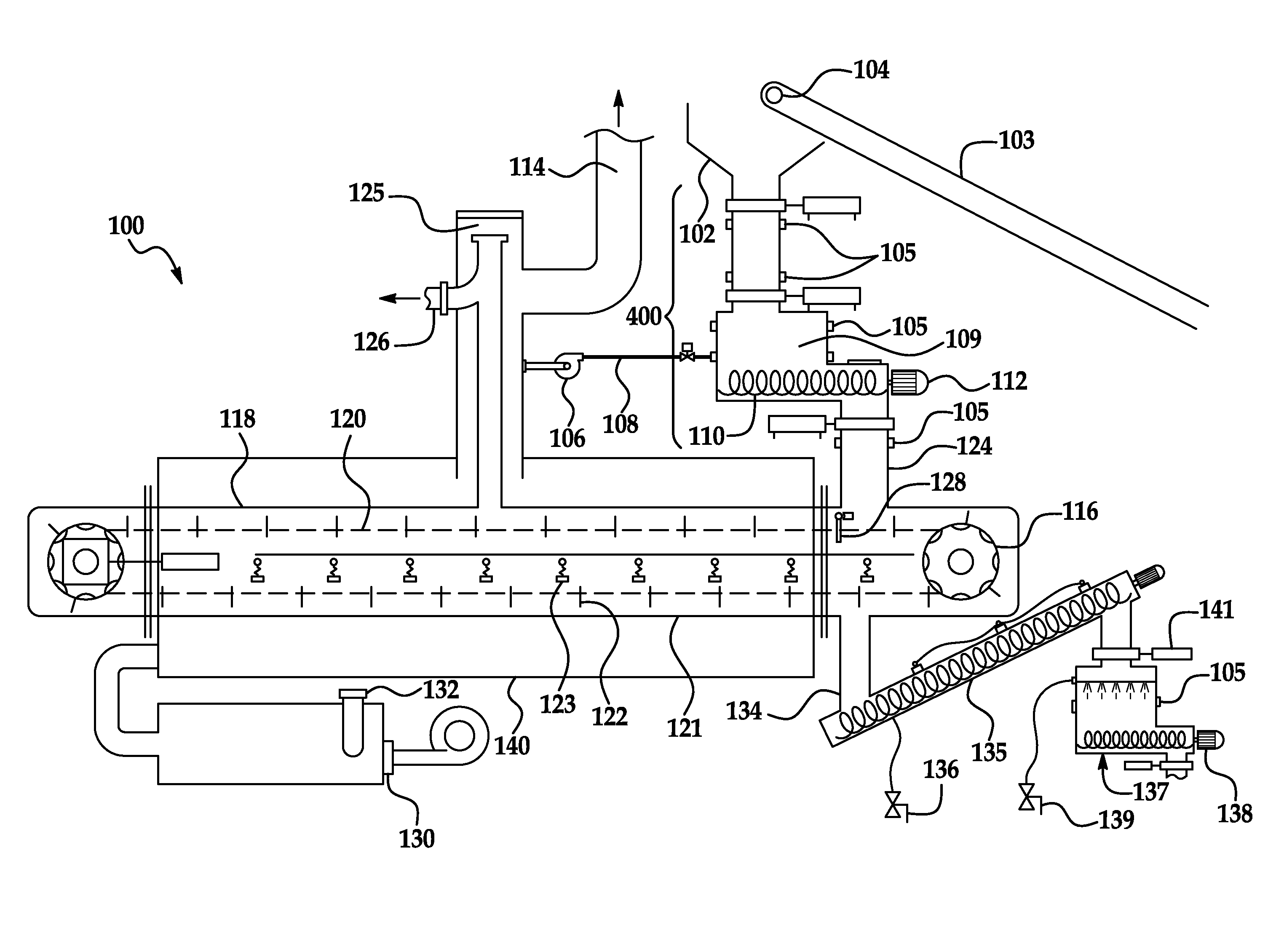

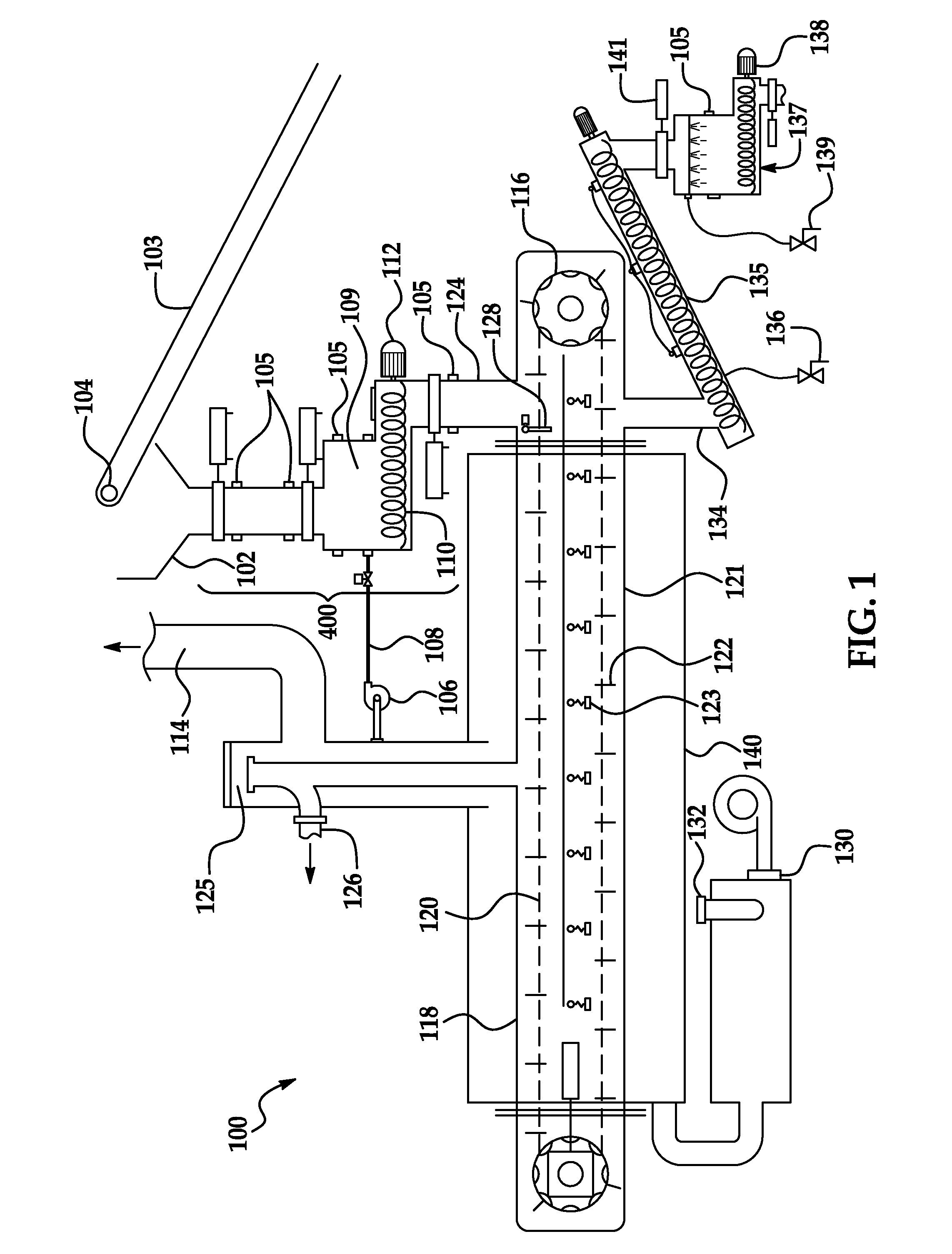

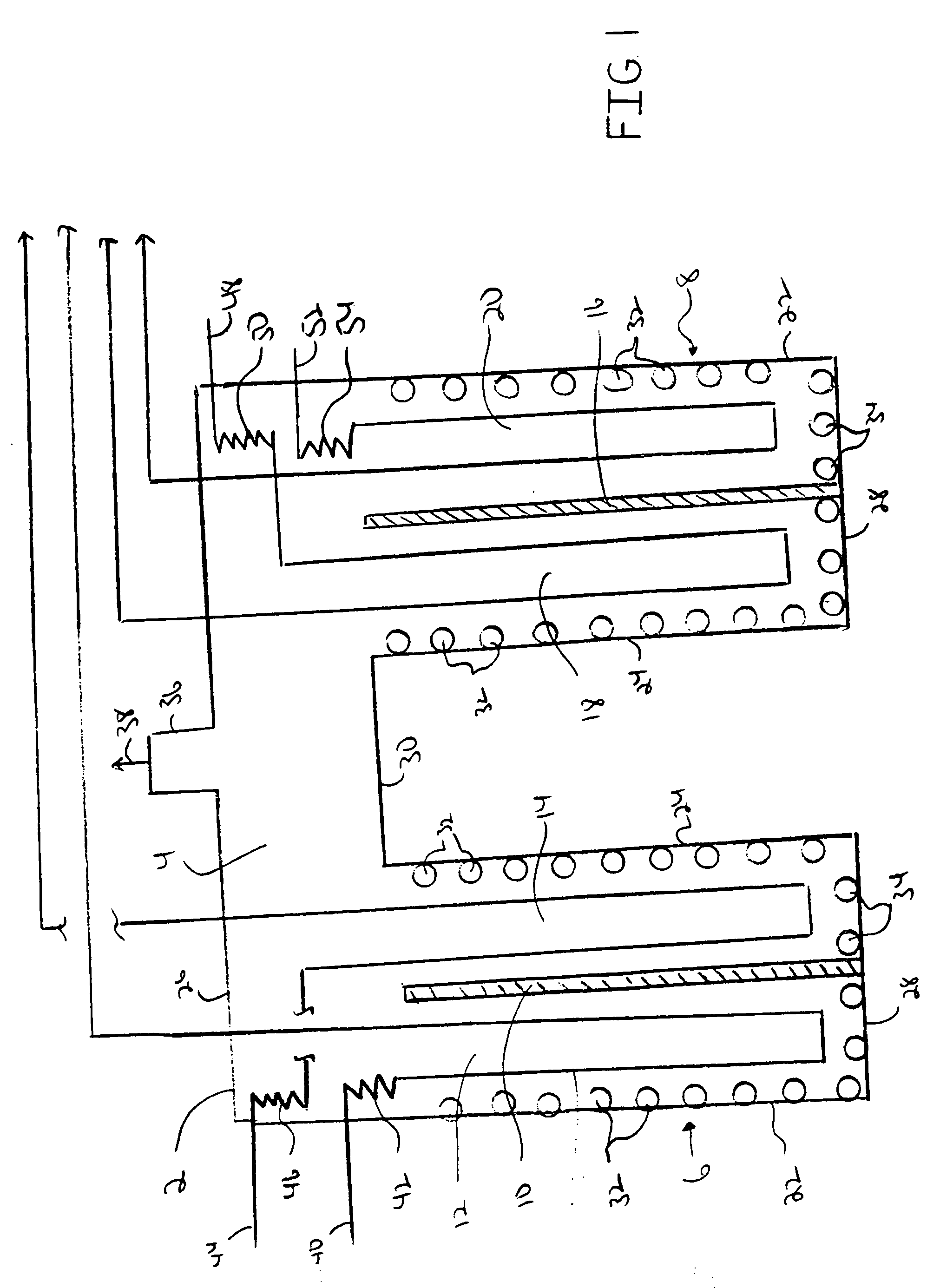

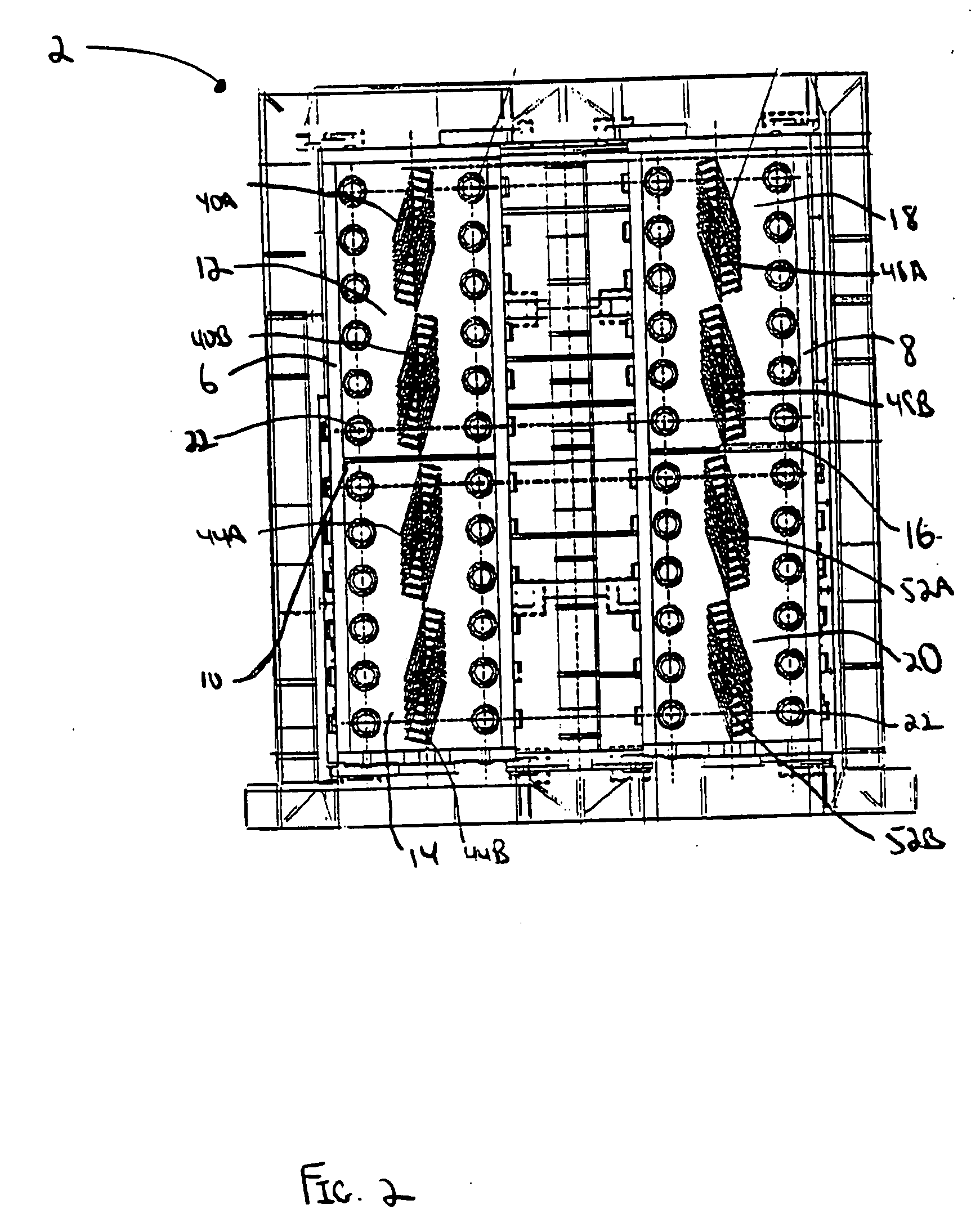

Chain drag system for treatment of carbaneous waste feedstock and method for the use thereof

ActiveUS8801904B2Prevent escapeCombustible gas coke oven heatingIndirect heating destructive distillationProgrammable logic controllerEngineering

A drag chain carbonizer is provided with a system and methods for anaerobic thermal transformation processing to convert waste into various solid carbonized products and varied further co-products. The drag-chain carbonizer includes an adjustable bed depth mechanism, a heating mechanism, a pressure management mechanism, and a chain tensioning mechanism containing at least one position sensor for communication of an actuator position to at least one programmable logic controller (PLC). Carbonaceous waste is transformed into useful co-products that can be re-introduced into the stream of commerce at various economically advantageous points. Depending upon the input materials and the parameters selected to process the waste, including real time economic and other market parameters, the system adjusts co-products output to reflect changing market conditions.

Owner:AEMERGE

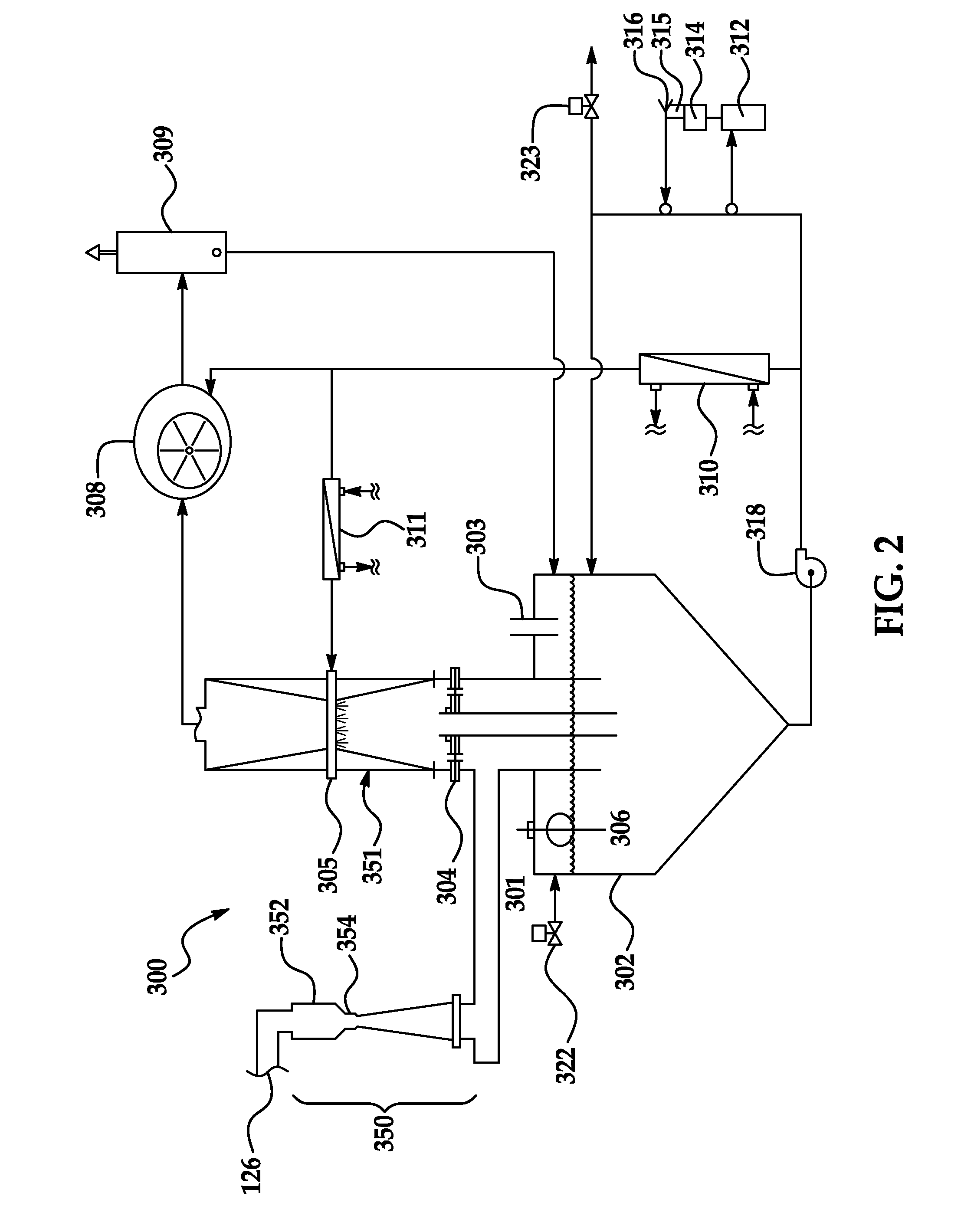

System and method for flexible conversion of feedstock to oil and gas

ActiveUS20140296586A1Minimize complexityLow costDirect heating destructive distillationBiofuelsChemical reactorProduct gas

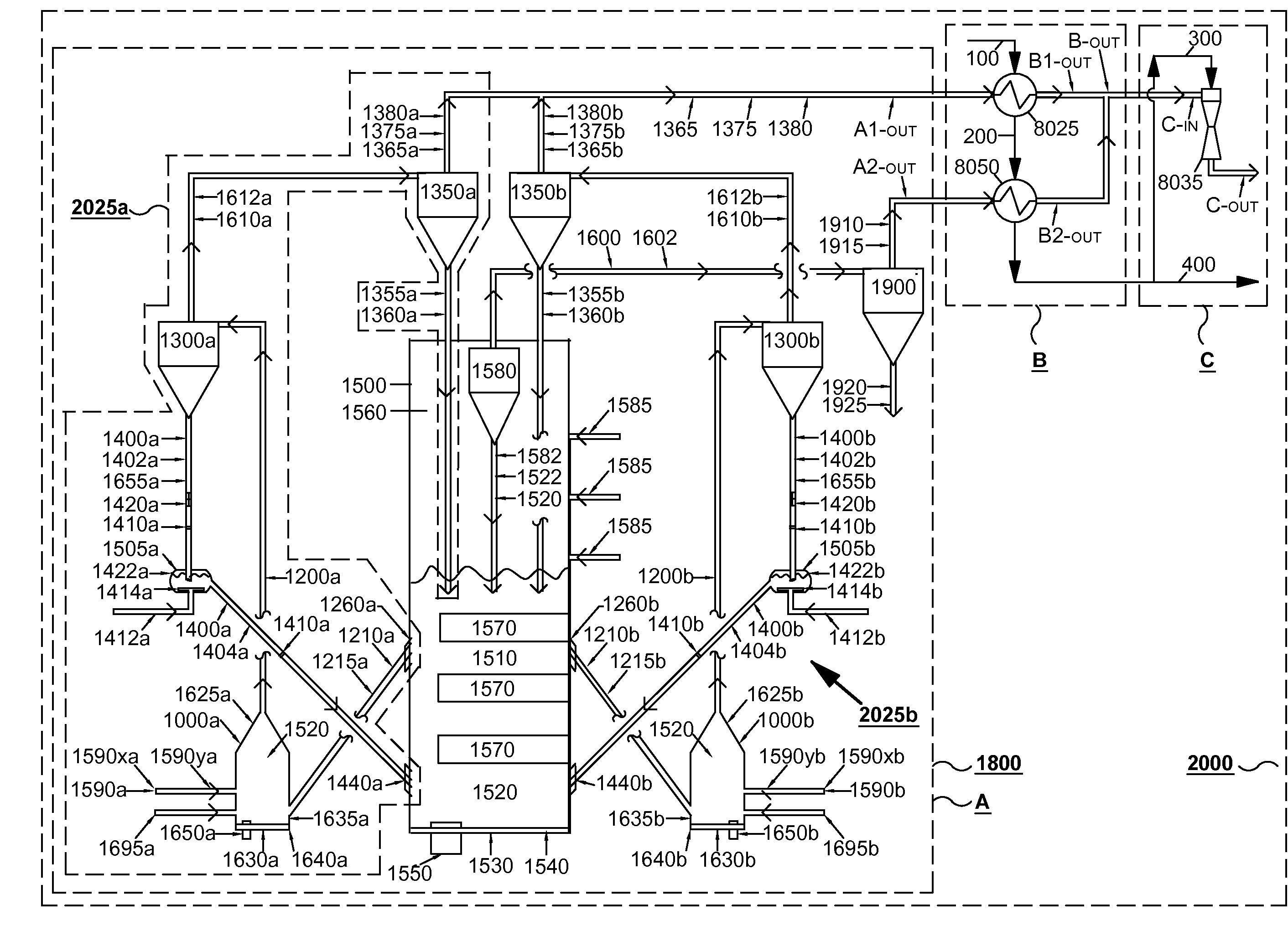

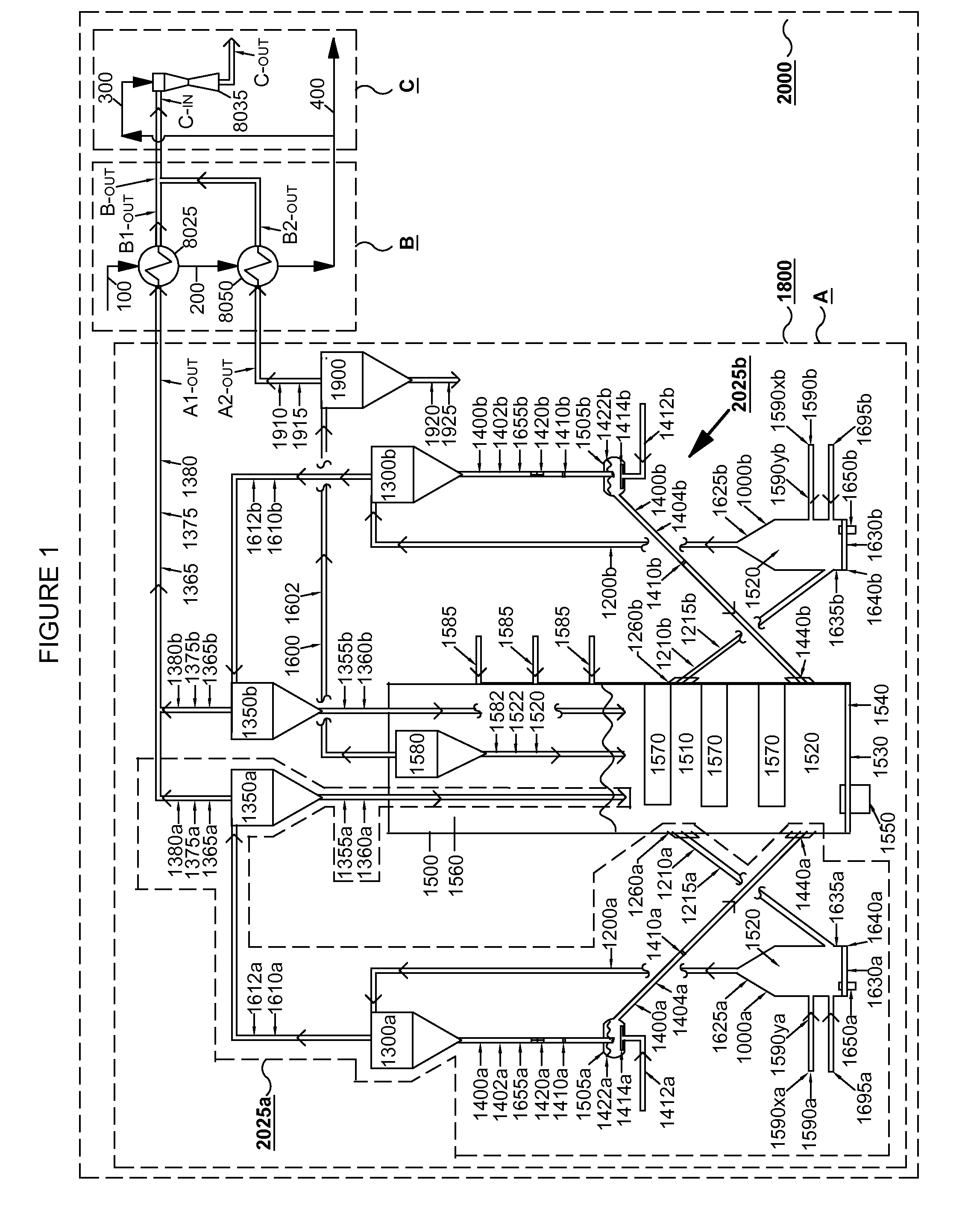

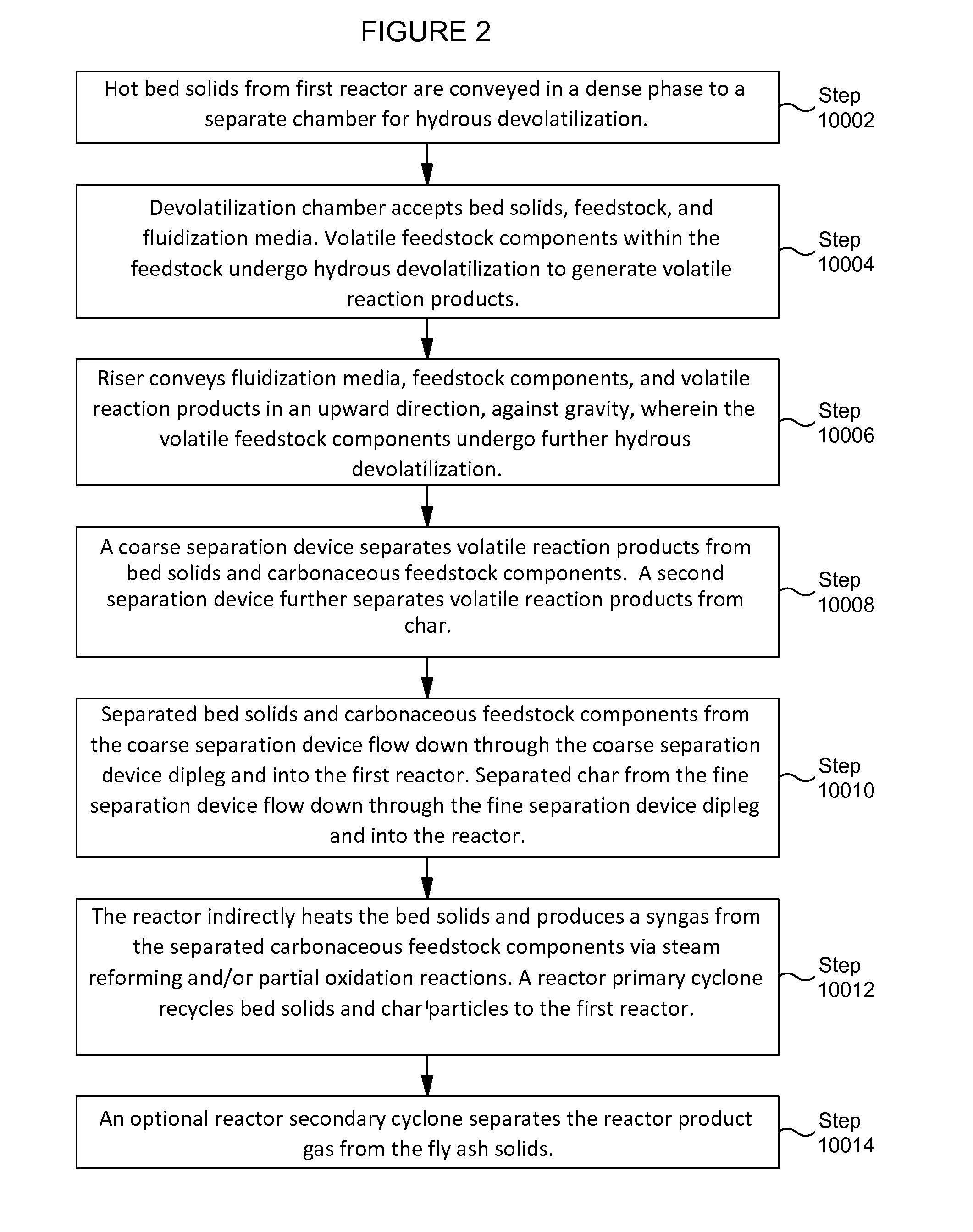

A feedstock flexible process for converting feedstock into oil and gas includes (i) indirectly heated hydrous devolatilization of volatile feedstock components, (ii) indirectly heated thermochemical conversion of fixed carbon feedstock components, (iii) heat integration and recovery, (iv) vapor and gas pressurization, and (v) vapor and gas clean-up and product recovery. A system and method for feedstock conversion includes a thermochemical reactor integrated with one or more hydrous devolatilization and solids circulation subsystems configured to accept a feedstock mixture, comprised of volatile feedstock components and fixed carbon feedstock components, and continuously produce a volatile reaction product stream therefrom, while simultaneously and continuously capturing, transferring, and converting the fixed carbon feedstock components to syngas.

Owner:THERMOCHEM RECOVERY INT

Chain drag carbonizer, system and method for the use thereof

ActiveUS20140008206A1Prevent escapeIndirect heating destructive distillationPyrolysis reactionsProgrammable logic controllerProcess engineering

A drag chain carbonizer is provided with a system and methods for anaerobic thermal transformation processing to convert waste into various solid carbonized products and varied further co-products. The drag-chain carbonizer includes an adjustable bed depth mechanism, a heating mechanism, a pressure management mechanism, and a chain tensioning mechanism containing at least one position sensor for communication of an actuator position to at least one programmable logic controller (PLC). Carbonaceous waste is transformed into useful co-products that can be re-introduced into the stream of commerce at various economically advantageous points. Depending upon the input materials and the parameters selected to process the waste, including real time economic and other market parameters, the system adjusts co-products output to reflect changing market conditions.

Owner:AEMERGE

Fibre matrix and a method of making a fibre matrix

ActiveUS20120156466A1Flow fastImprove impact resistanceWood working apparatusCeramic shaping apparatusCarbon fibersMaterials science

Owner:CARBON FIBER PREFORMS

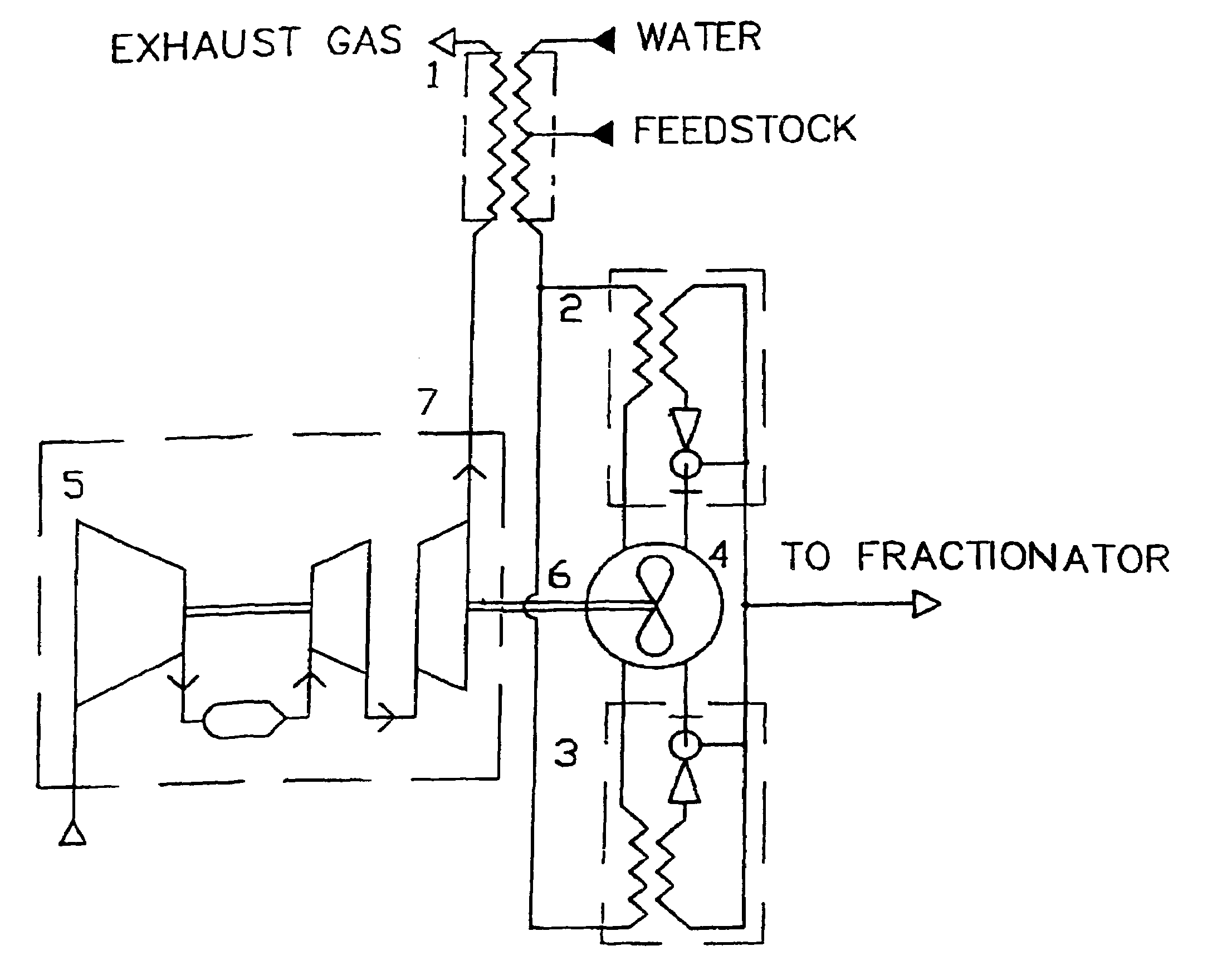

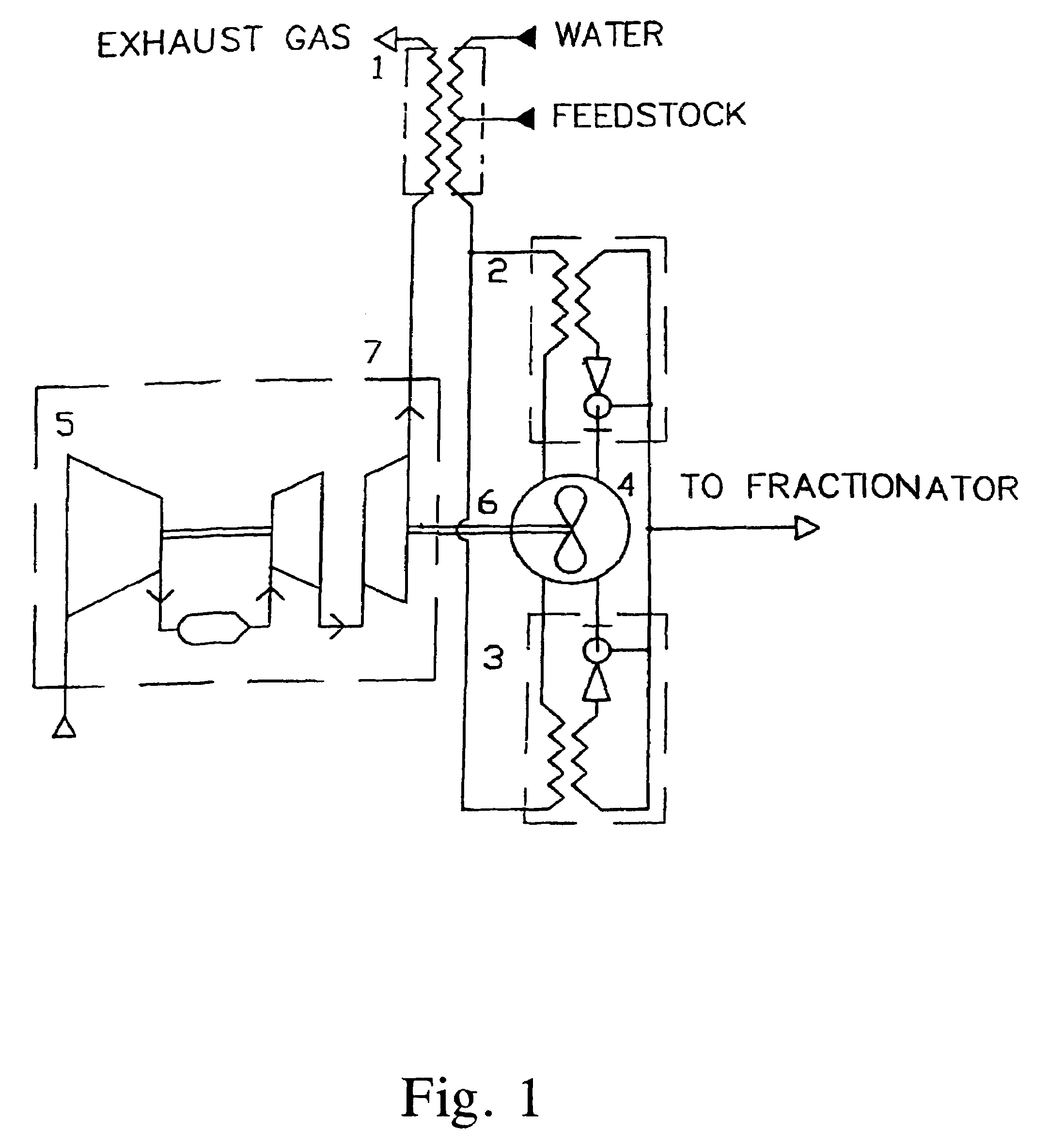

Process for producing low-molecular olefins by pyrolysis of hydrocarbons

InactiveUS7232937B2Simple designIncrease productionThermal non-catalytic crackingFlow mixersFractionationDiluent

Process for producing low-molecular olefins by pyrolysis of hydrocarbons comprising mixing of feedstock with steam-diluent, preheating the resulting mixture, rapid heating the said mixture up to pyrolysis temperature and maintaining this temperature inside reactor during residence time, quenching product stream and subsequent fractionation of products. The reactor has an annular work cavity where stationary blades and rotatable work blades are located. A ring vortex flow is created and maintained in the work cavity when the work blades are rotated. A heat needed for pyrolysis is generated due to hydrodynamic drag of rotated work blades. Heating the mixture up to pyrolysis temperature is performed by mixing with hot process stream recirculated in the work cavity for a negligible time in comparison with the residence time. The process enables increase of the low-molecular olefins yield.

Owner:COOLBROOK

Method for conversion of biomass to biofuel

InactiveUS8669404B2Increase energy densityReduce shipping costsBiofuelsWaste based fuelSolid fuelBiofuel

An apparatus and method to convert carbonaceous materials, particularly biomass and those biomass resources which are remotely located, into a solid material, which may be a high performance solid fuel, are presented. This method, and the apparatus described as the means to accomplish this method, provides a continuous process which can be completely powered by the energy contained in the biomass. The heat, mechanical power and electrical power are provided from the energy in the biomass, through the methods described. In this way, the apparatus is free to operate in remote locations, where no power or auxiliary fuel sources are available.

Owner:RENEWABLE FUEL TECH

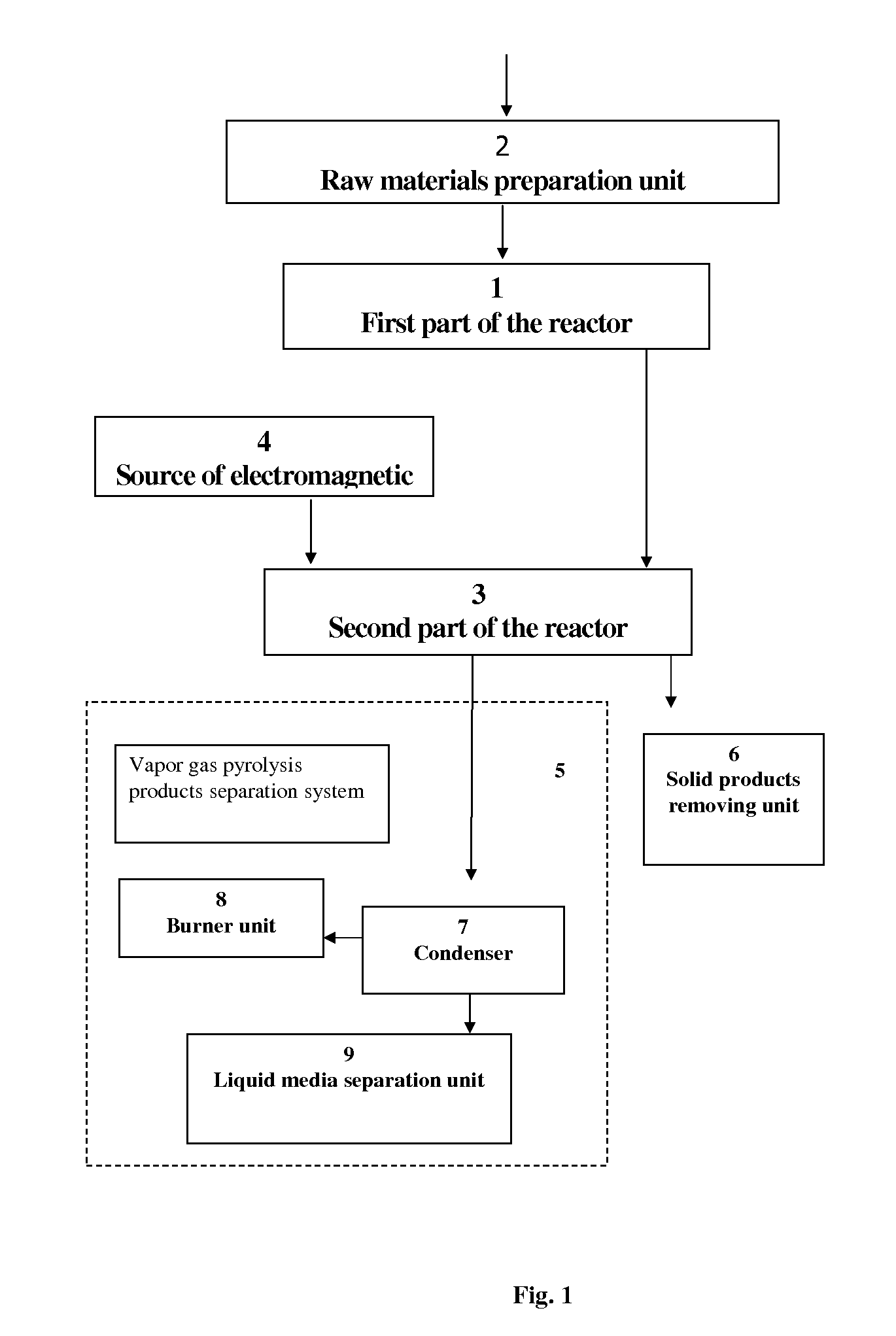

Method and Device for Processing Domestic and Industrial Organic Waste

ActiveUS20110048915A1Improve efficiencySpeed up the processElectrical coke oven heatingByproduct vaporizationWaste processingEnvironmental engineering

The invention relates to waste processing and to producing hydrocarbons from domestic and industrial organic waste by pyrolysis. The inventive waste processing method involves carrying out the first and second pyrolysis stages, fractionating pyrolysis products and processing each fraction for producing useful products. The second pyrolysis stage is carried out simultaneously with the electromagnetic action produced on the pyrolysis products. The device for carrying out said method comprises a two-sectional pyrolysis reactor. An electromagnetic source is arranged on the second section of the reactor. The output of the second section is connected to a system for dividing the vaporous pyrolysis products. The technical result consists in increasing the waste processing effectiveness and producing solid, liquid and vaporous fuel components.

Owner:ZAKRYTOE AKTSIONERNOYE OBSCHESTVO FINANSOVO PROMYSHLENNAYA GRUPPA TEZAURUM

Method for biomass fractioning by enhancing biomass thermal conductivity

A method is described for generating useful chemical intermediates from biomass using a novel pyrolysis reactor that utilizes the inherent thermal properties of carbon under compression as the biomass is subjected to sequential or concurrent temperature ramps. The ramps are sufficient to volatilize and selectively create different components, while the pressure application aids the selective decomposition of the biomass.

Owner:COOL PLANET ENERGY SYST

Multi zone cracking furnace

InactiveUS20080029434A1Increase flexibilityThermal non-catalytic crackingTreatment with plural serial cracking stages onlyMetallurgy

Owner:STONE & WEBSTER PROCESS TECH

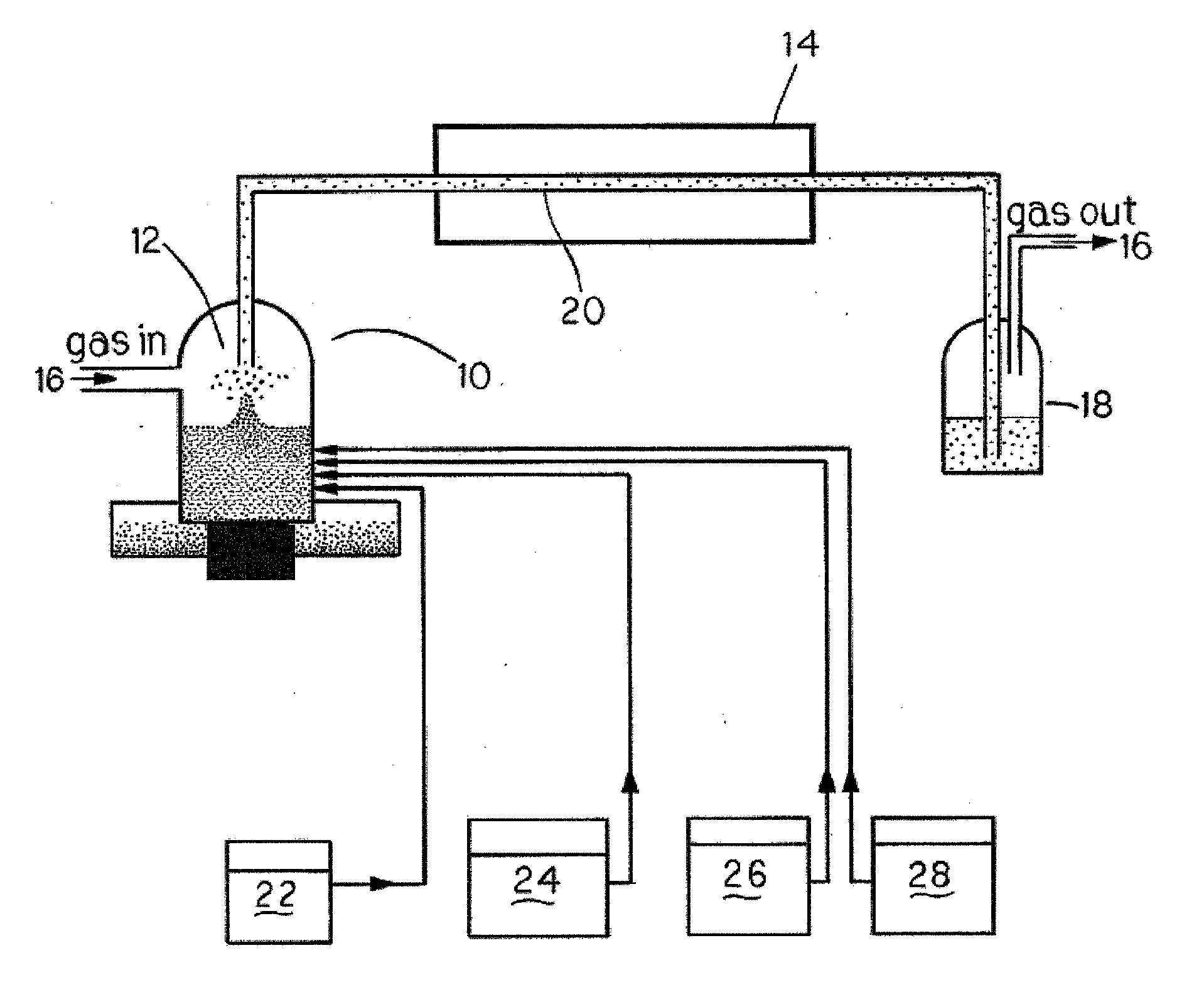

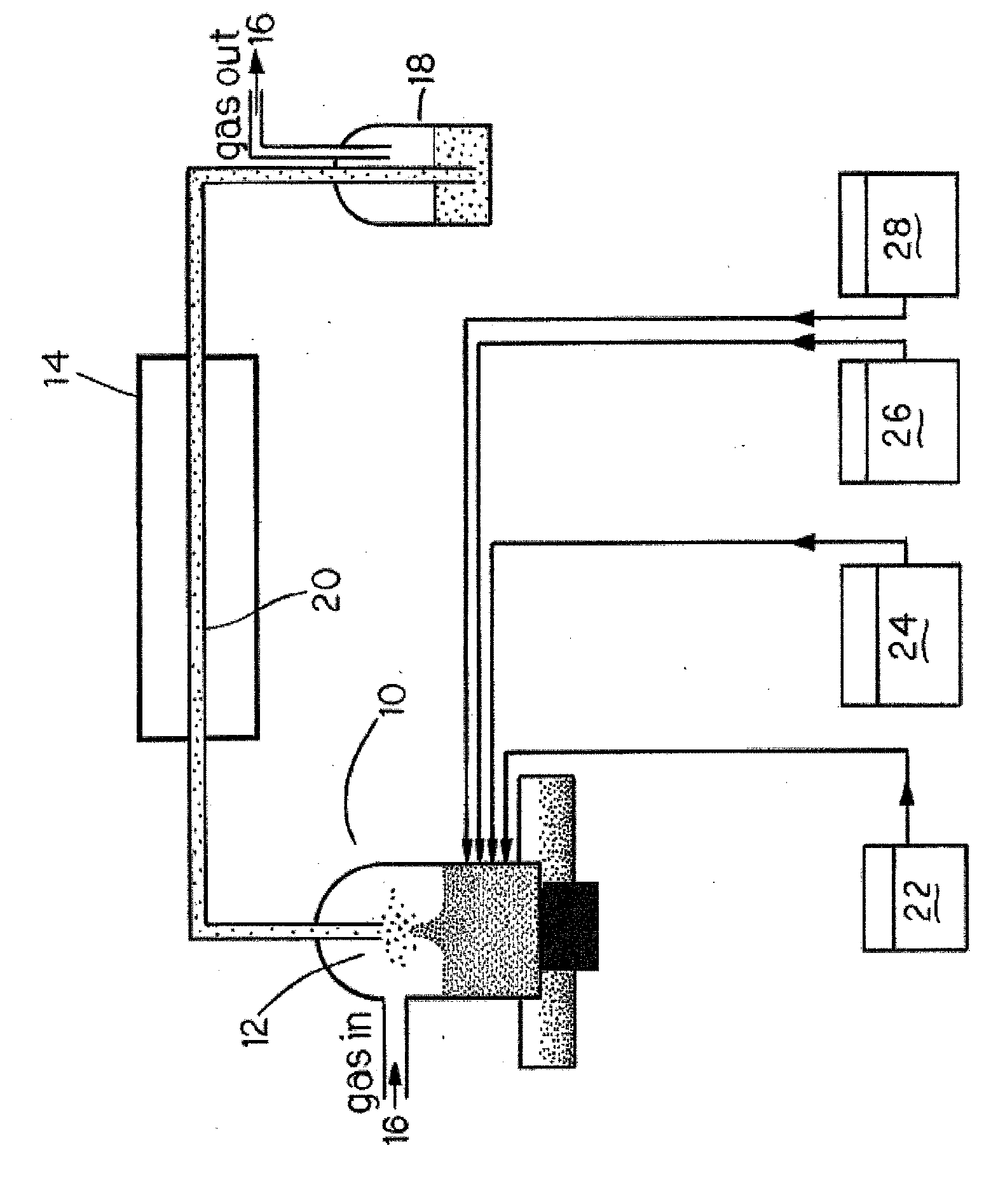

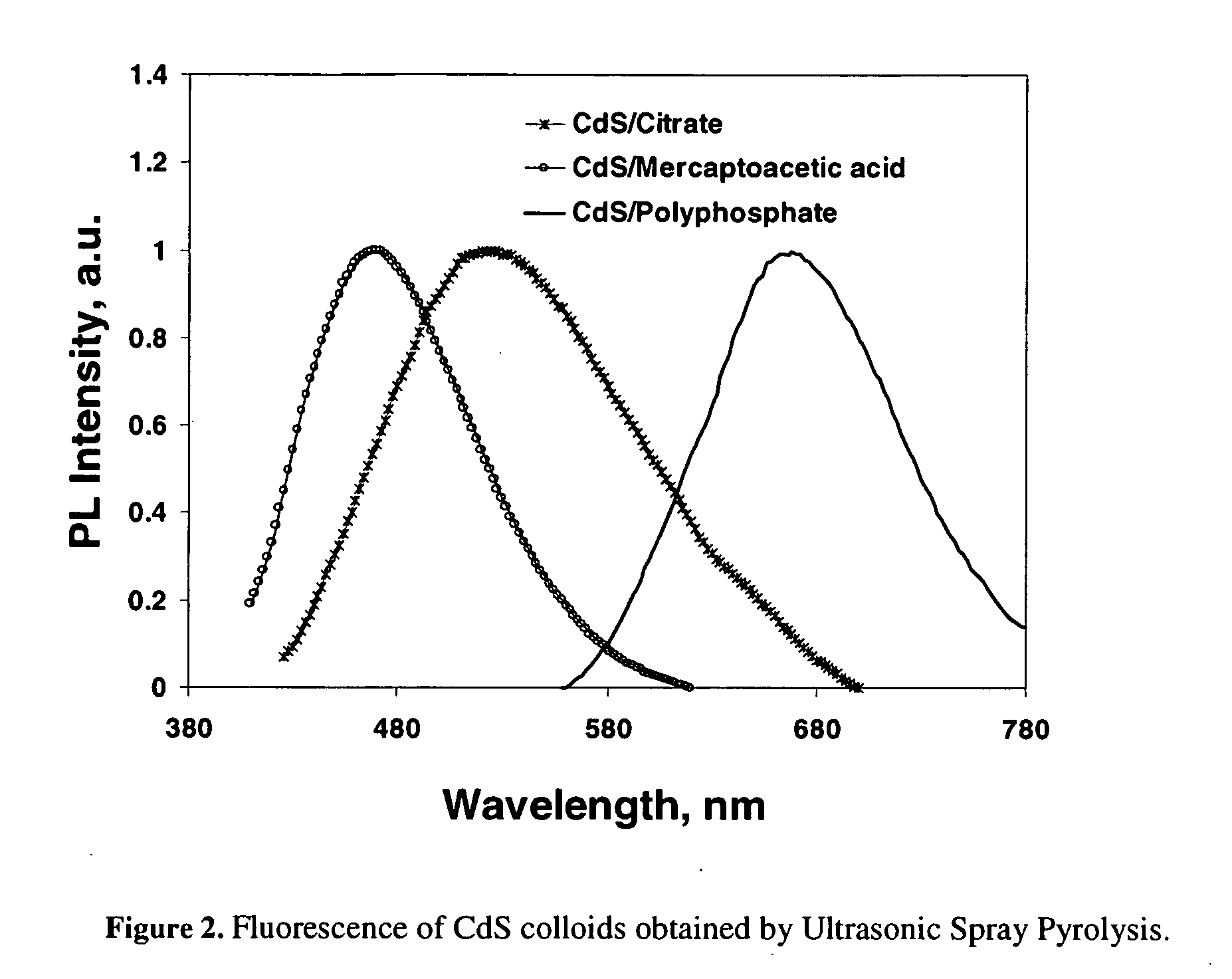

Controlled chemical aerosol flow synthesis of nanometer-sized particles and other nanometer-sized products

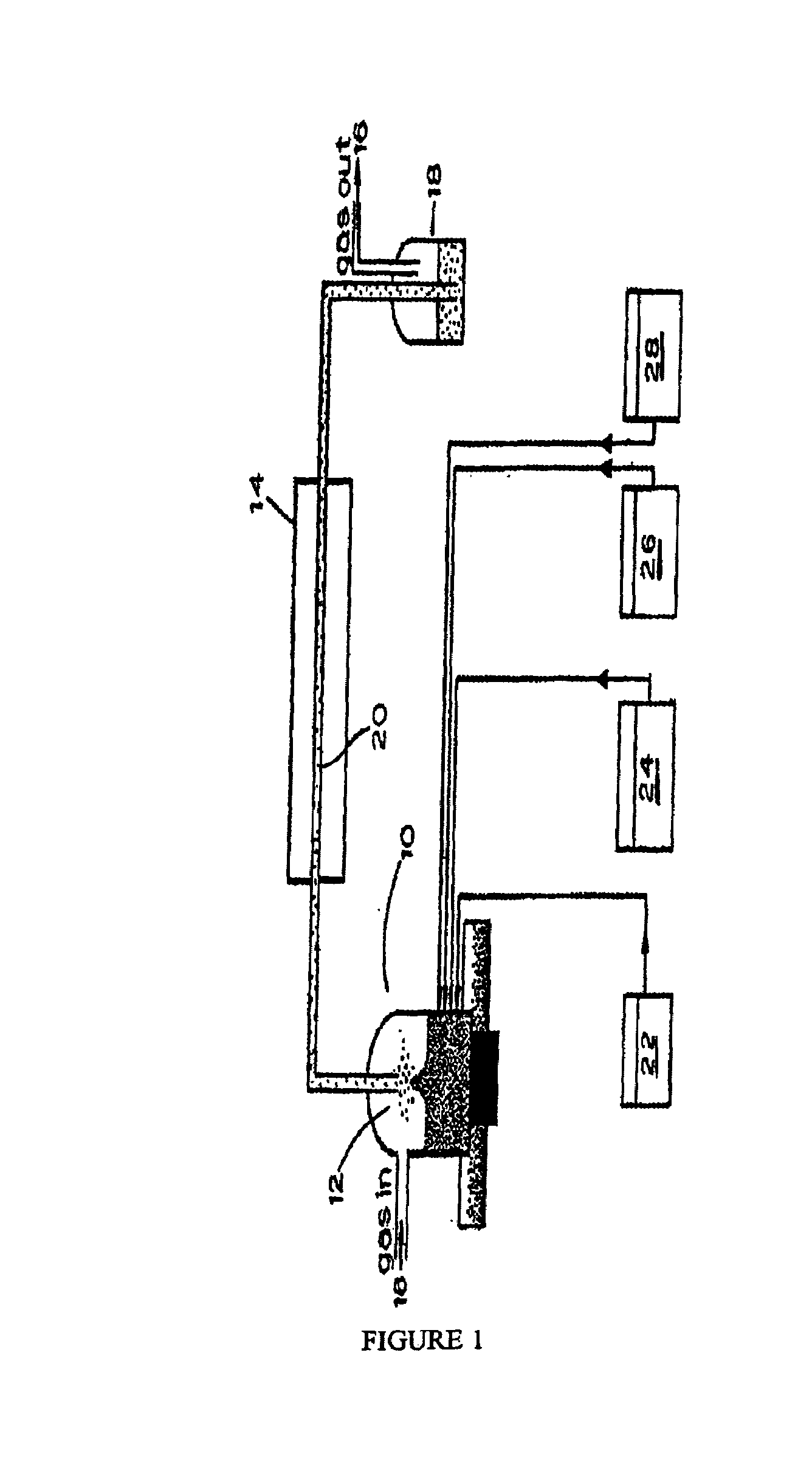

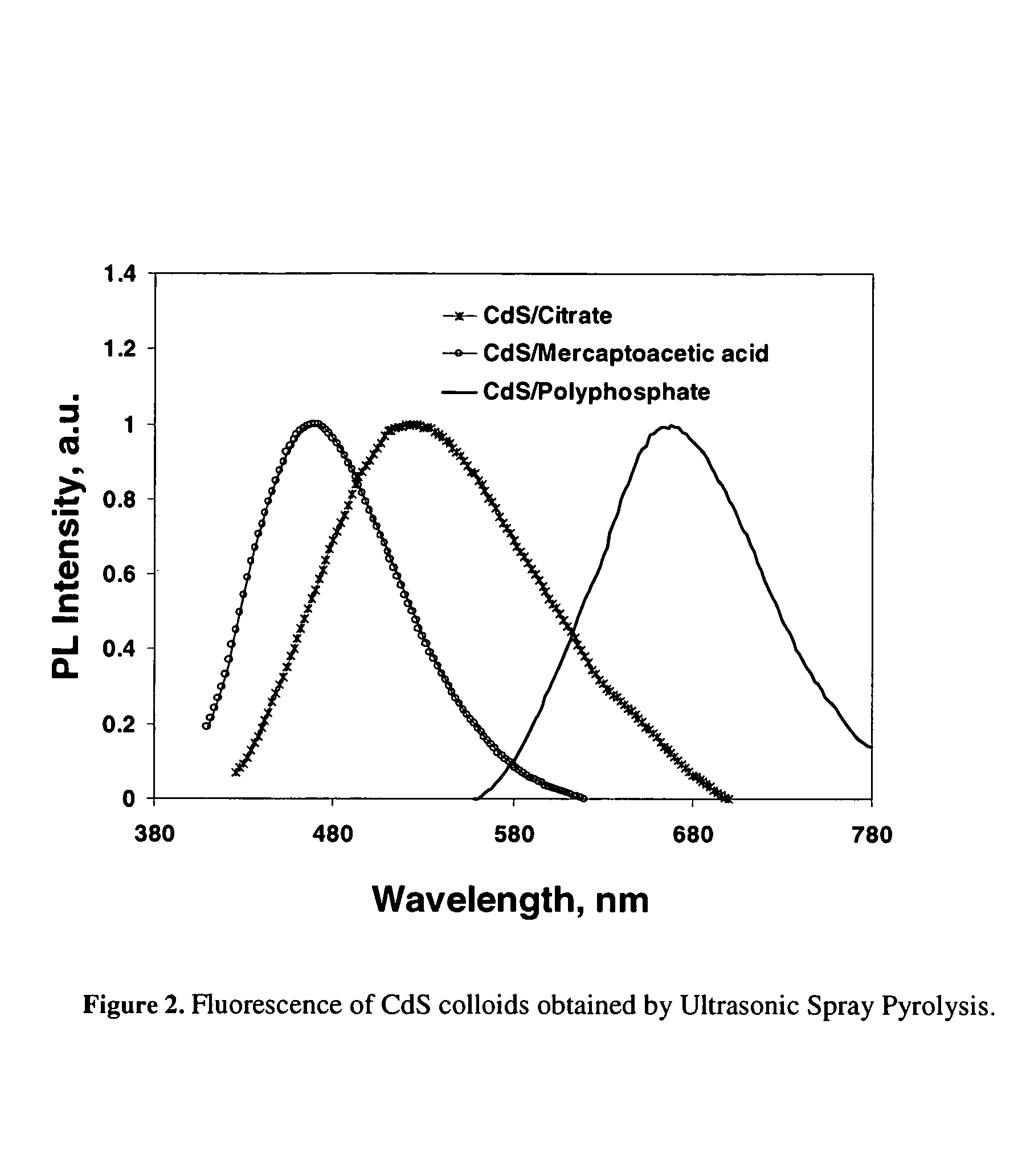

InactiveUS20060244164A1Production is limitedEasy to depositMaterial nanotechnologyOxide/hydroxide preparationBoiling pointCompound (substance)

A method and apparatus for producing nanometer-sized particles, the method including the steps of forming of mixture by mixing a first precursor reactant, a second precursor reactant, a surface-stabilizing surfactant, and a high boiling point liquid to form a mixture, forming a mist of droplets of the mixture, heating the droplets to cause a reaction between species of the first and second precursor reactants within the heated droplets, and collecting the nanometer-sized products.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

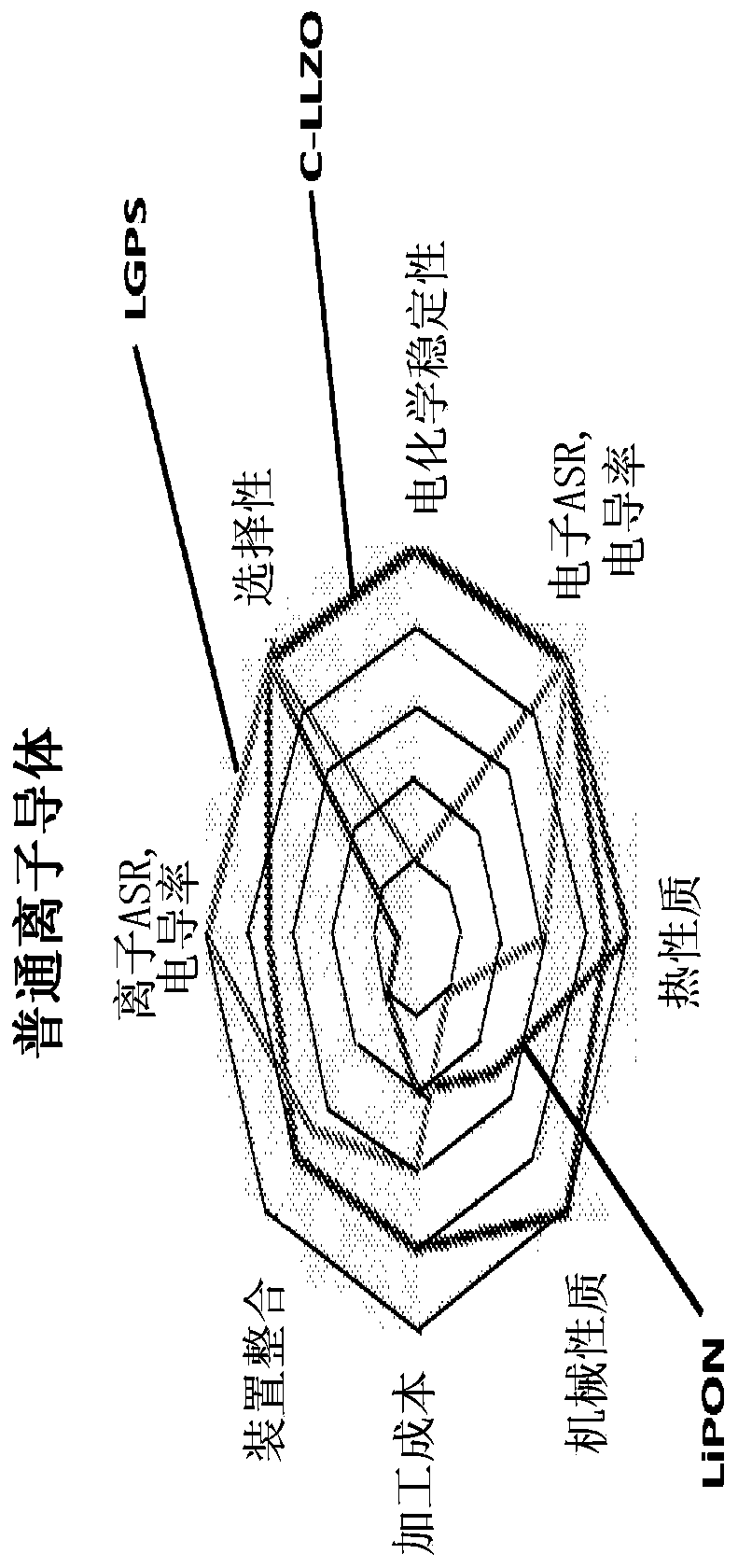

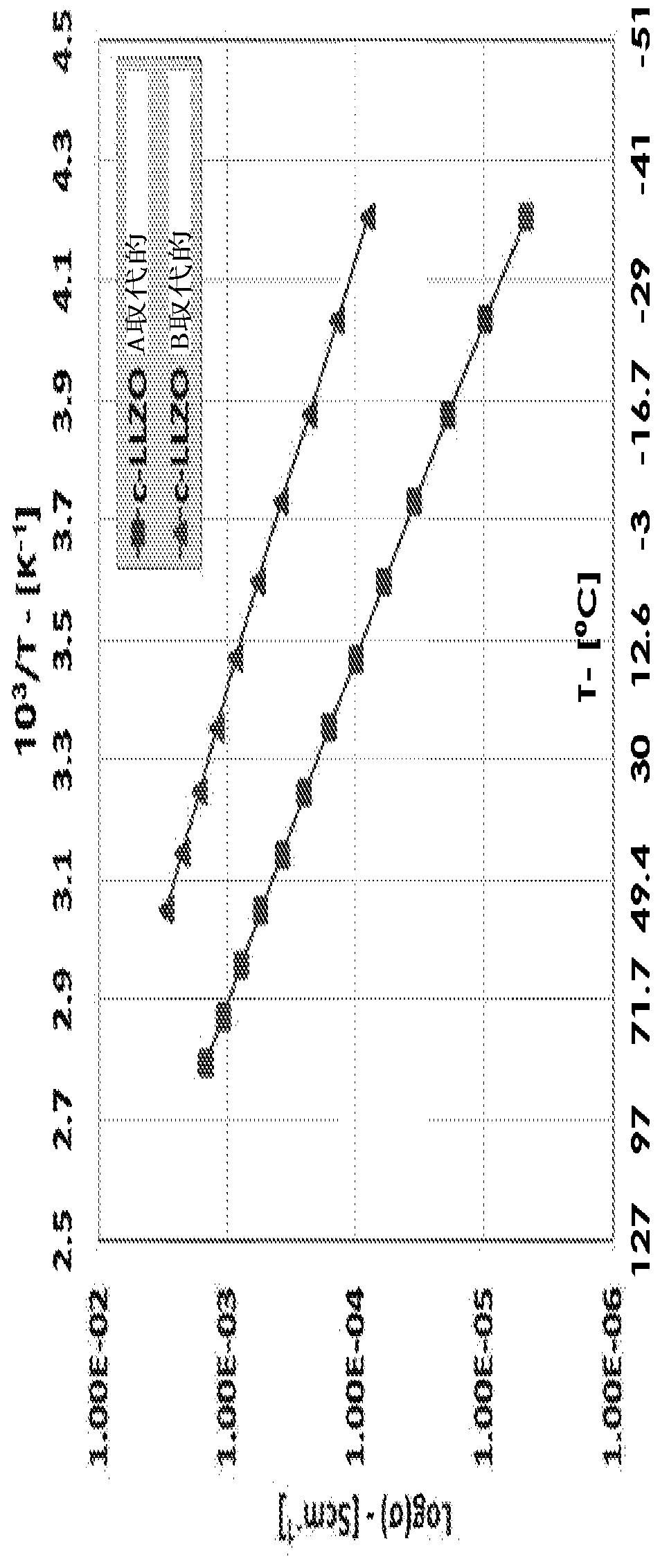

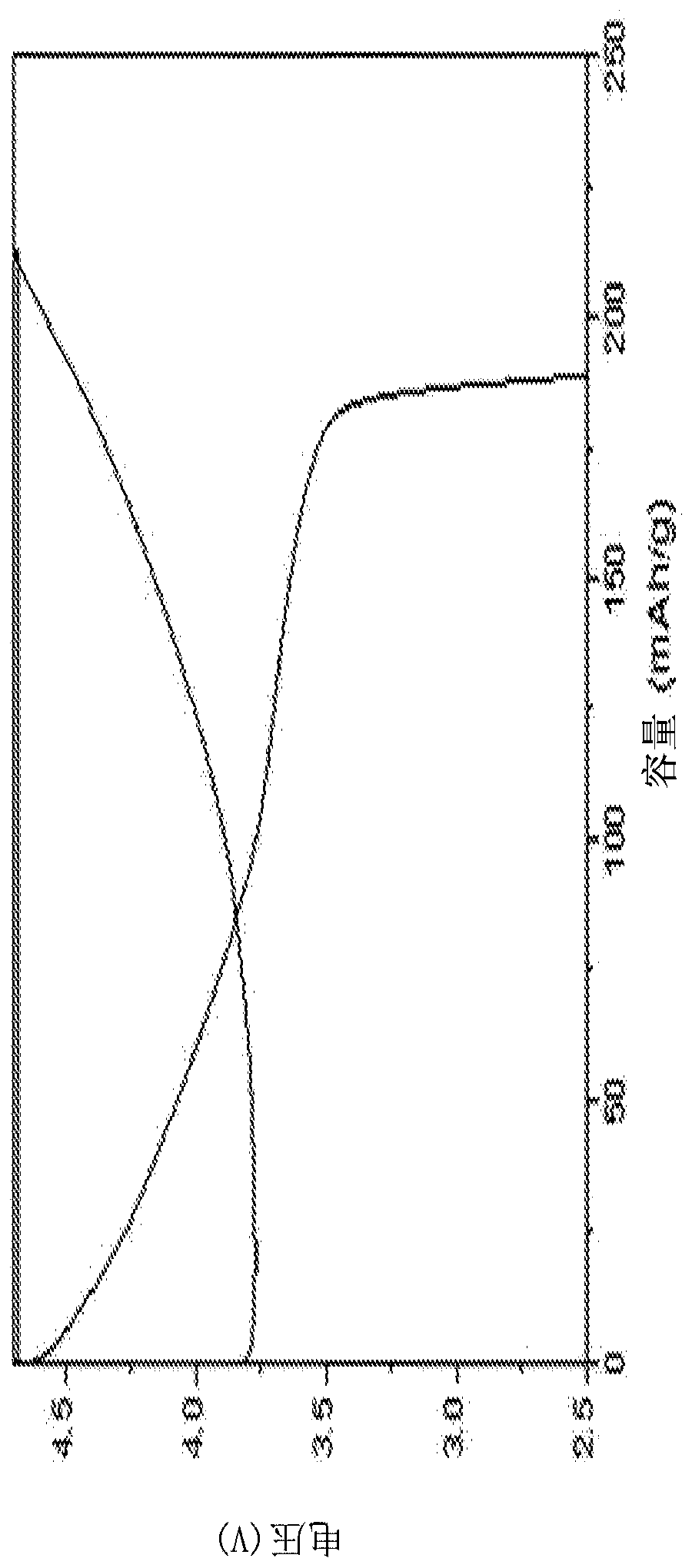

All-solid state li ion batteries comprising mechanically flexible ceramic electrolytes and manufacturing methods for the same

InactiveCN110088969ASolid electrolytesElectrode thermal treatmentSolid state electrolyteAll solid state

An all solid-state Li-ion battery having a mechanically flexible, ceramic, solid-state electrolyte having a lithium-conducting oxide composition selected from the group consisting of perovskite-type oxides, NASICON-structured lithium electrolytes, and garnet-type structures containing transition metal oxides. In particular, the garnet cubic lithiumlanthanium zirconium oxide (c-LLZO), c-LLZO-LSPO composite and varous lithium ion conducting sulfides are disclosed.

Owner:FISKER INC

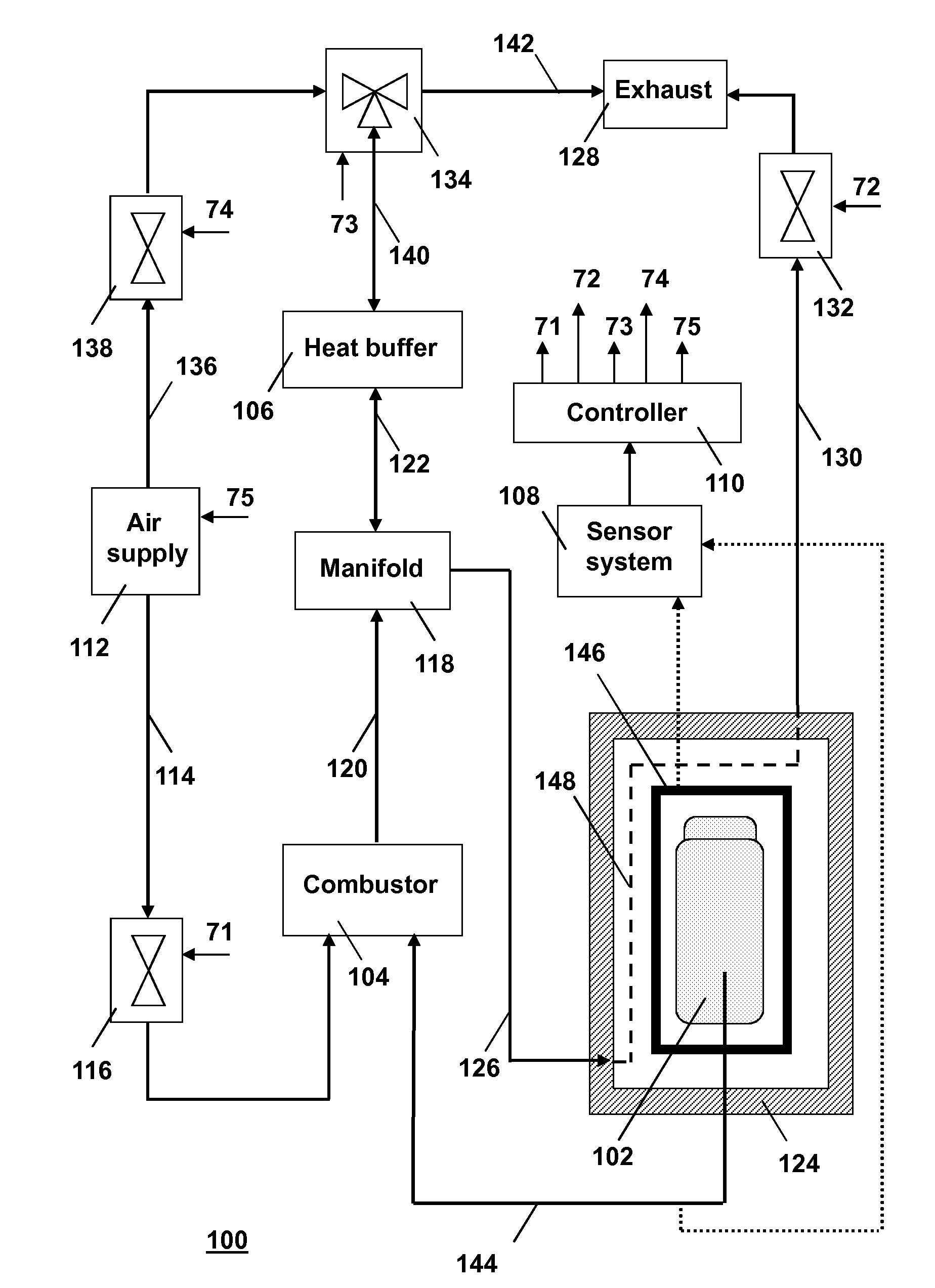

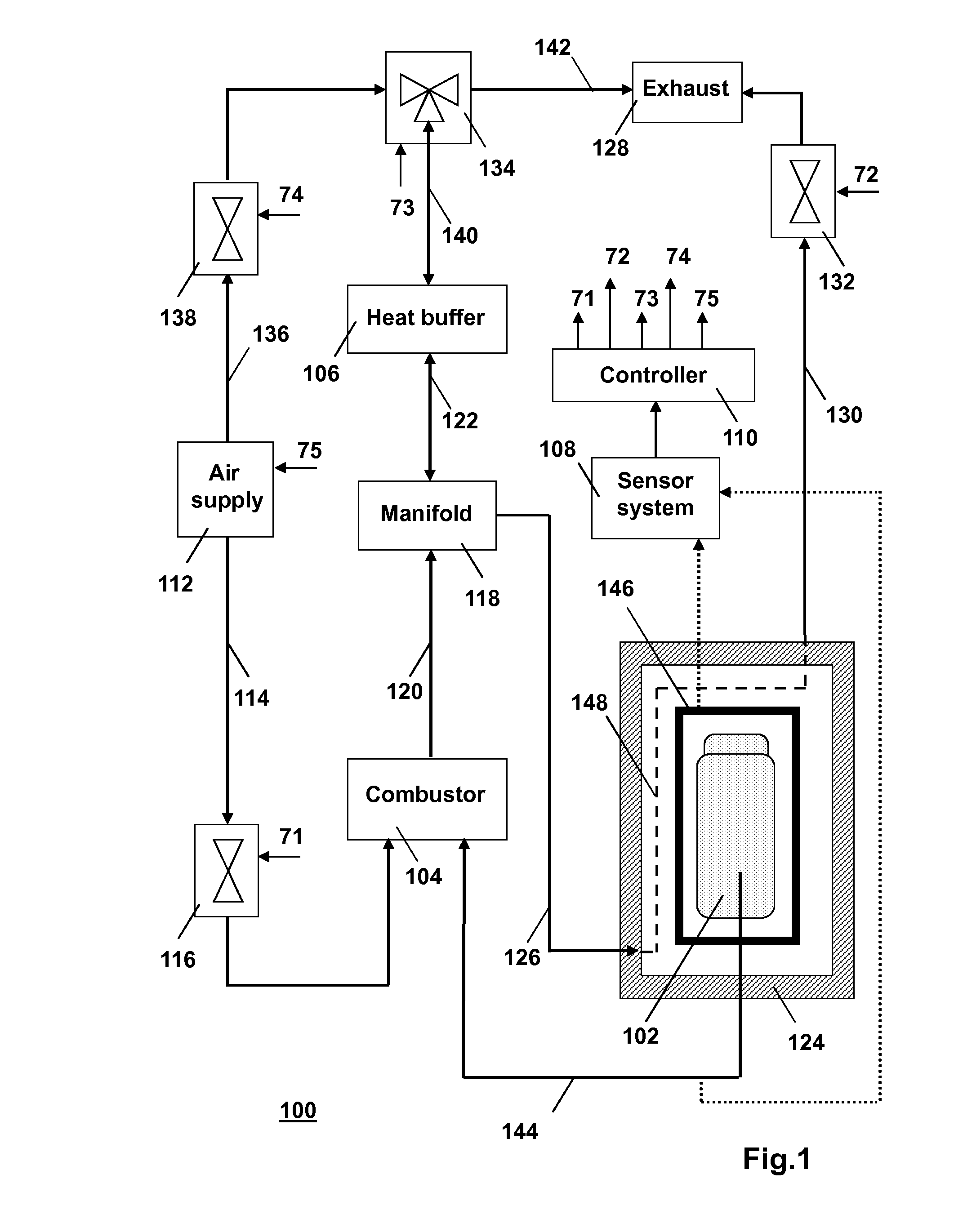

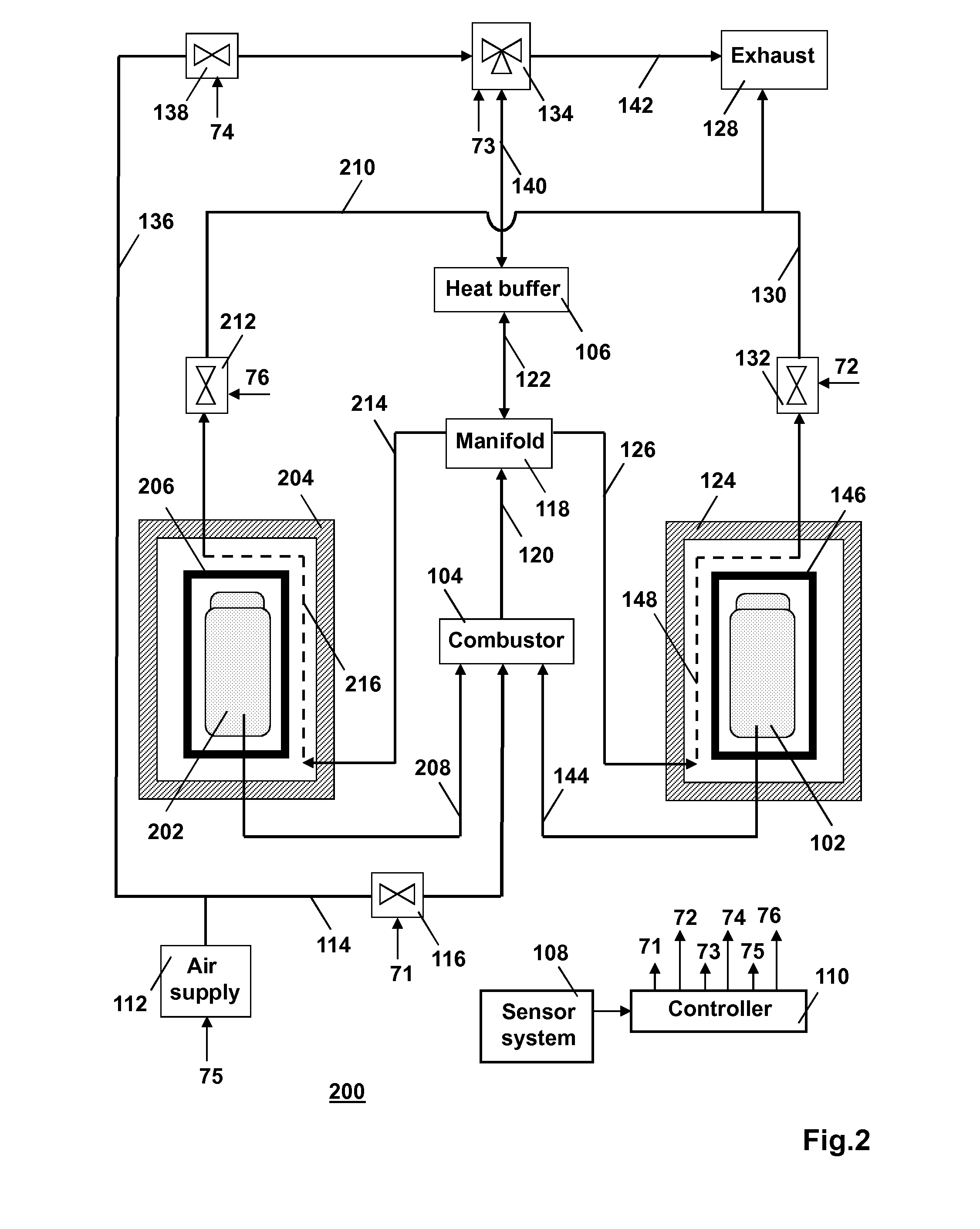

Batch-wise operated retort using temporary storage of heat

A batch of a substance, e.g., a biomass, is processed in a batch-wise operated retort under the application of heat. The substance releases a combustible process fluid during the processing. The process fluid is combusted for generating heat. The heat is supplied to the retort and / or stored in temporary heat storage in dependence on the progress of the processing for postponed heat supply to the retort.

Owner:SIEMONS ROLAND

Controlled chemical aerosol flow synthesis of nanometer-sized particles and other nanometer-sized products

InactiveUS7160489B2Production is limitedEasy to depositMaterial nanotechnologyOxide/hydroxide preparationBoiling pointSURFACTANT BLEND

A method and apparatus for producing nanometer-sized particles, the method including the steps of forming of mixture by mixing a first precursor reactant, a second precursor reactant, a surface-stabilizing surfactant, and a high boiling point liquid to form a mixture, forming a mist of droplets of the mixture, heating the droplets to cause a reaction between species of the first and second precursor reactants within the heated droplets, and collecting the nanometer-sized products.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

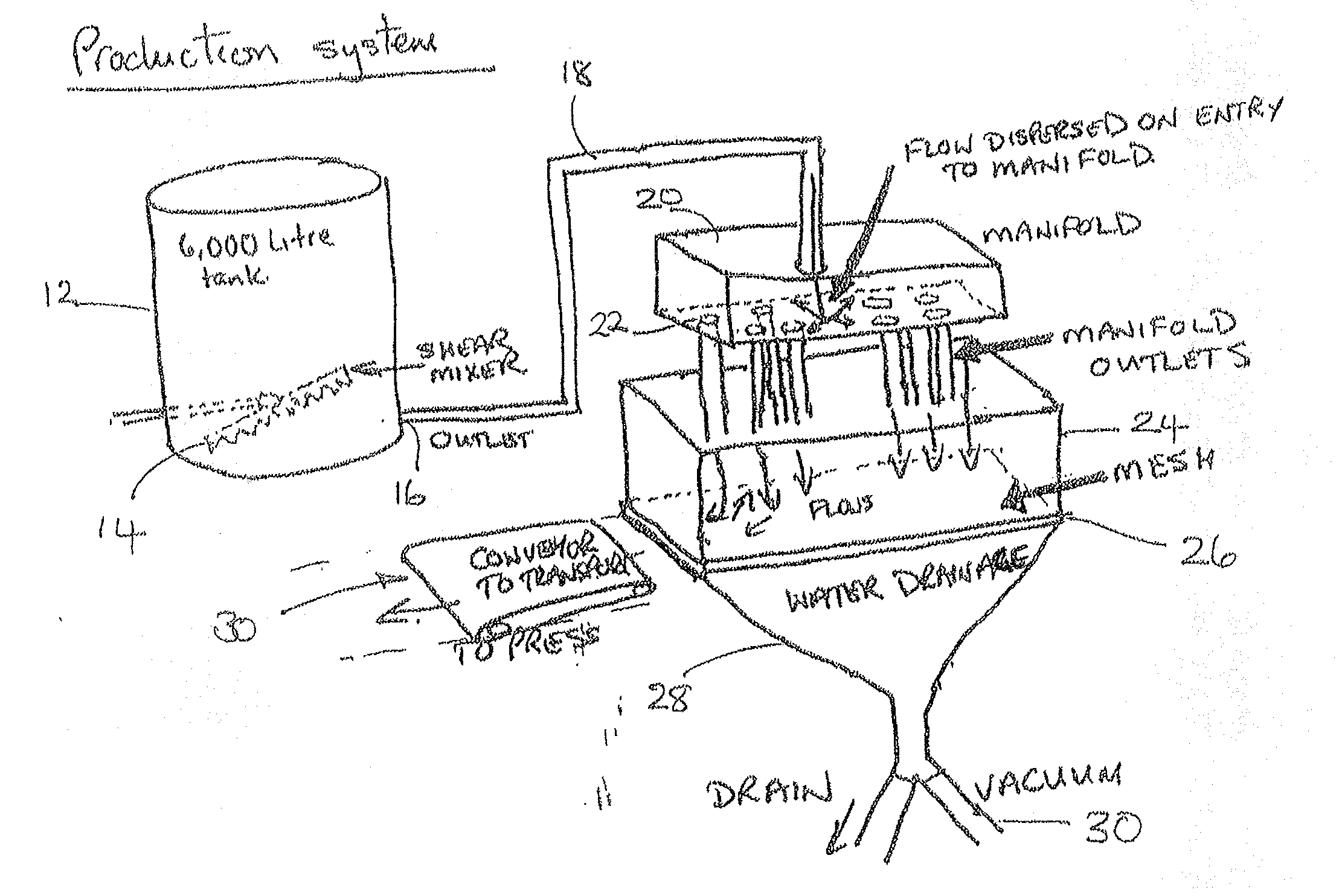

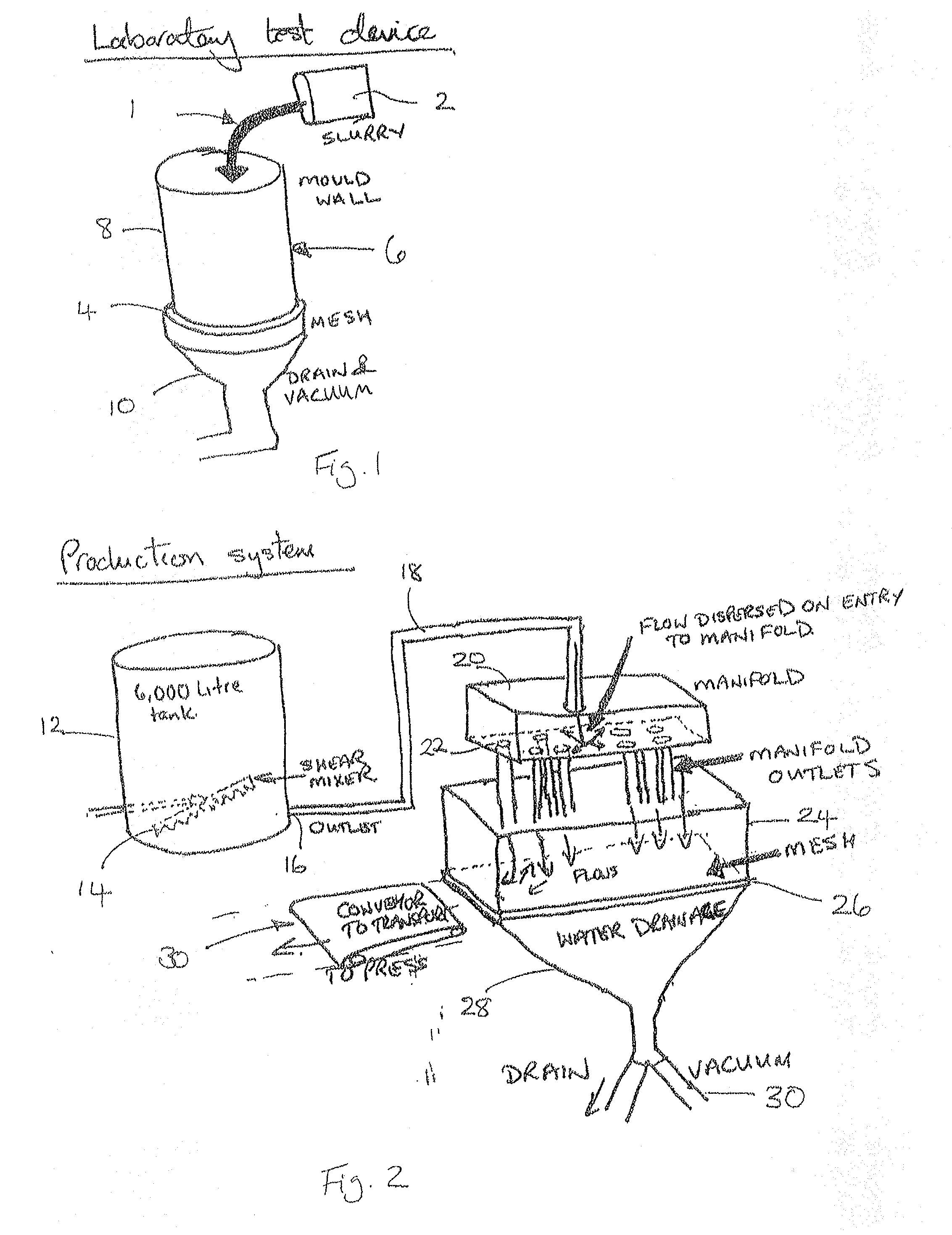

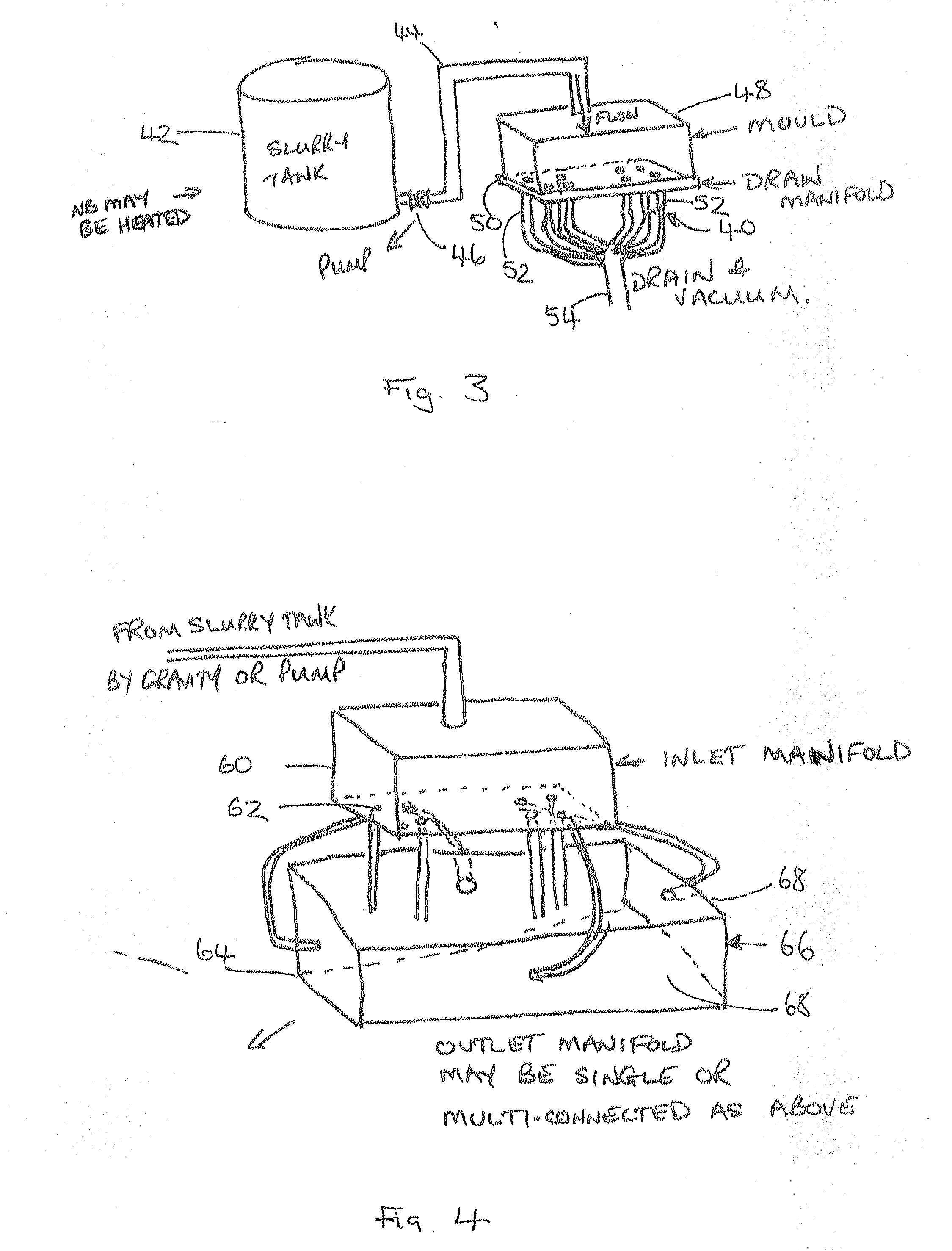

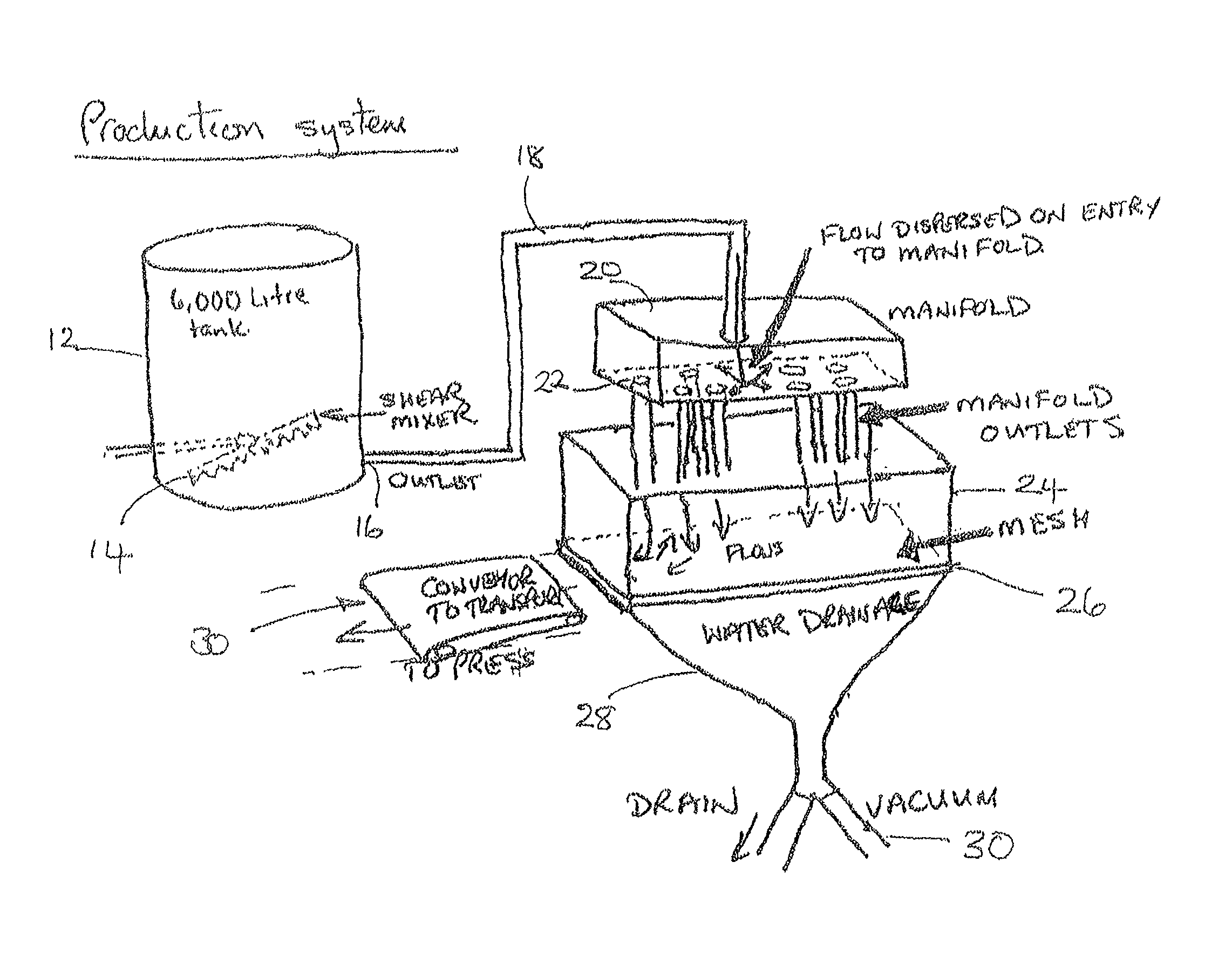

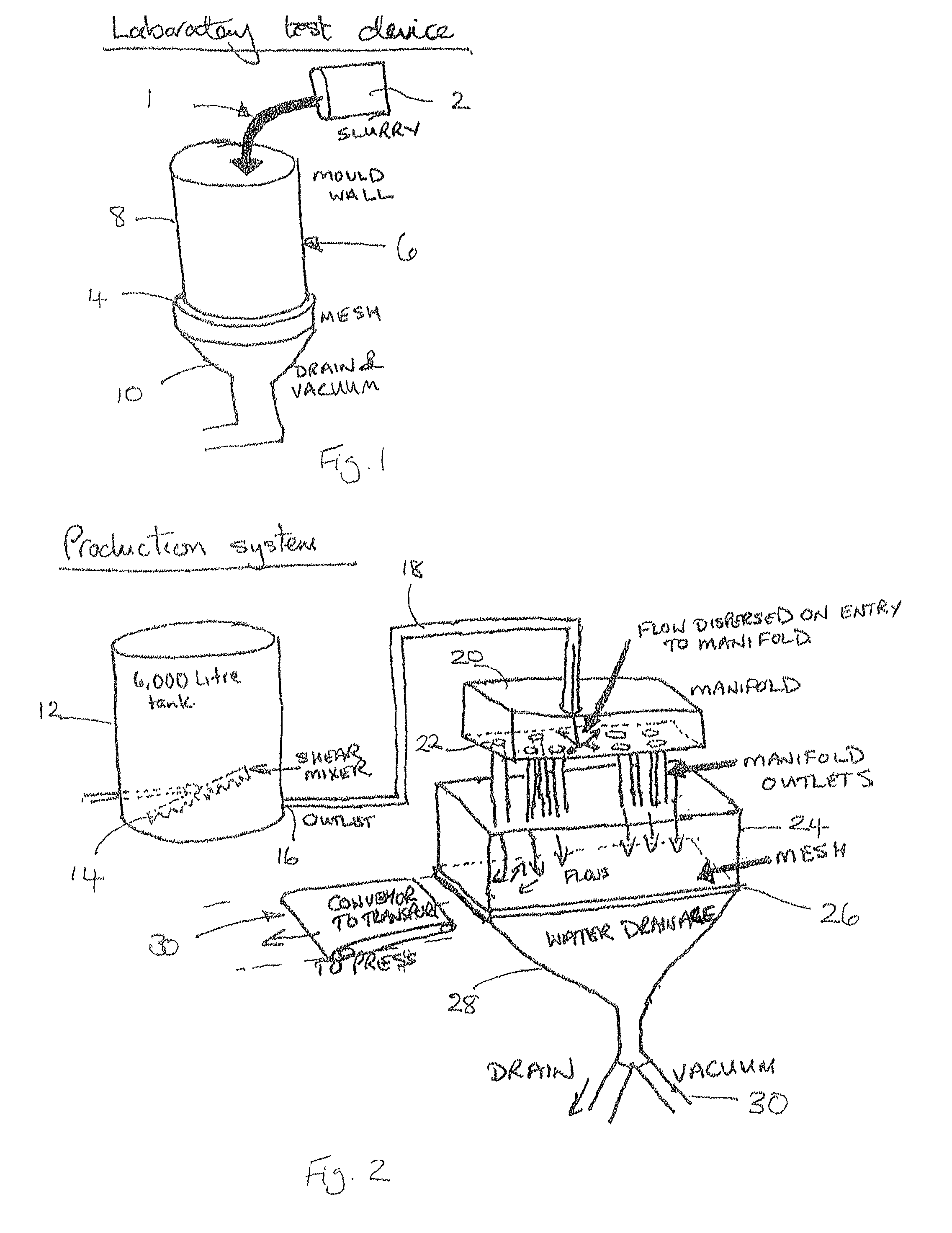

Fibre matrix and a method of making a fibre matrix

ActiveUS8580169B2Flow fastImprove impact resistanceArmourAdditive manufacturing apparatusCarbon fibersMaterials science

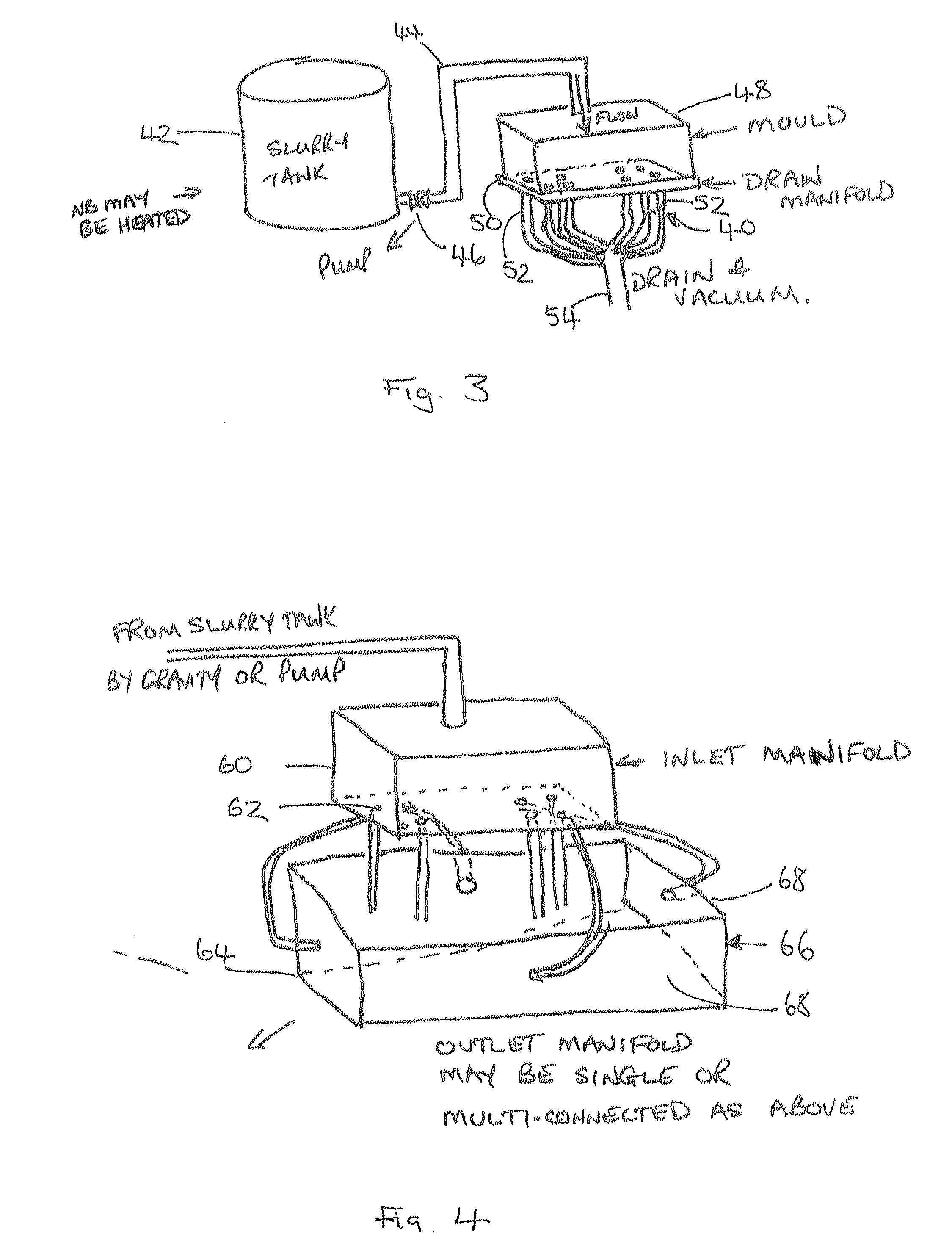

A method of forming a three dimensional fiber structure is disclosed which comprises the steps of a) providing a starting material which comprises liquid carrier, fibers and binder; b) passing the starting material over a substrate so as to deposit fibers onto the substrate; c) forming a three dimensional fiber matrix; and d) curing the binder. The flow of material onto the substrate may be controlled such that the flow of a starting material over the substrate is chaotic and fibers are laid down in a three dimensional structure containing a high proportion of voids. The preform may be pressurized while moist and is cured under pressure. The fibers may comprise carbon fibers; recycled carbon fiber has been found to be particularly useful. The resulting preform may be stochastic and is suitable for use in ablative and braking applications.

Owner:CARBON FIBER PREFORMS

Apparatus for self-propagating high temperature synthesis

InactiveUS6436356B1Carry-out safelyAvoid expansionOxygen/ozone/oxide/hydroxideNitrogen compoundsSelf-propagating high-temperature synthesisInorganic compound

The present invention relates to an apparatus for self-propagating high temperature synthesis of an inorganic compound from a combustible charge mixture of initial ingredients. The apparatus comprises mechanisms for continuously feeding the combustible charge into a reaction chamber and removing the synthesized compound therefrom. The apparatus also contains sensors to control and contain the combustion inside a combustion zone of the reaction chamber.

Owner:COMSYNTECH

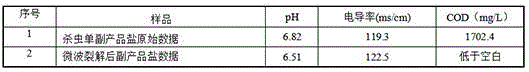

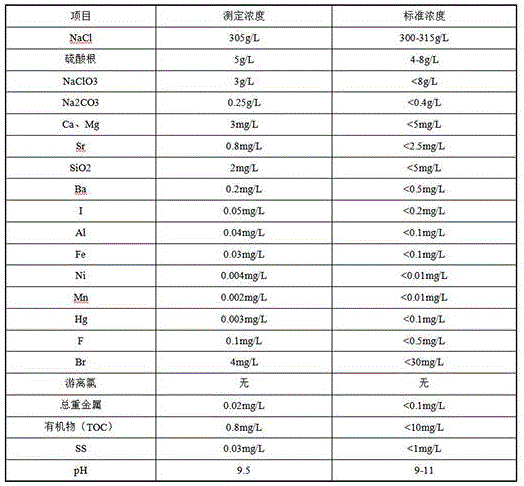

Method for refining and resource utilization of byproduct salt

InactiveCN106216360ANo problem of uneven removalHeating evenlyTransportation and packagingSolid waste disposalMicrowaveElectrolysis

The invention provides a method for refining and resource utilization of byproduct salt. The method comprises the following steps: (1), byproduct salt of certain mass is placed into a microwave cracking furnace; (2), a waste gas emission opening is arranged on the microwave cracking furnace; (3), waste gas emitted out of the waste gas emission opening enters a heat exchanger; (4), the waste gas passing through the heat exchanger is connected with a waste gas treatment device; (5), the byproduct salt subjected to treatment of the step (1) is tested; (6), the byproduct salt which is tested to be qualified in the step (5) is dissolved in pure water and is purified; (7), the purified salt is subjected to electrolysis with an ion-exchange film; and (8), after the purified salt is subjected to the electrolysis with the ion-exchange film, H2, Cl2, and NaOH can be obtained. The method is high in resource utilization degree and simple in technological process; identification of dangerous waste is not needed; waste salt can be subjected to resource utilization directly; most test and analysis cost can be omitted; automatic production is realized; and operation is simple.

Owner:NANJING GW ENVIRONMENT ENG

System and method for production of a renewable liquid fuel

ActiveUS20200056098A1Maintain and increase energy contentReduce the amount requiredDirect heating destructive distillationIndirect and direct heating destructive distillationEnvironmental engineeringLiquid fuel

Owner:SEIDNER MARC A

Pyrolytic process and apparatus for producing enhanced amounts of aromatc compounds

InactiveUS20080200738A1Thermal non-catalytic crackingCoal charges mechanical treatmentCompound aProcess engineering

Owner:RES POLYFLOW LLC

Popular searches

Hydrocarbon by hydrocarbon condensation Chemical/physical/physico-chemical nozzle-type rreactors Feed devices Hydrocarbon by hydrocarbon cracking Supercritical condition processes Catalyst activation/preparation Chemical/physical/physico-chemical stationary reactors Metal/metal-oxides/metal-hydroxide catalysts Artifical filament manufacture Vortex flow apparatus

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com