All-solid state li ion batteries comprising mechanically flexible ceramic electrolytes and manufacturing methods for the same

By using mechanically flexible ceramic solid-state electrolyte and freeze-casting technology of nanoparticle slurry in Li-ion batteries, the existing battery's difficulties in balancing energy density, cycle life and safety are solved, and efficient and safe battery performance is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

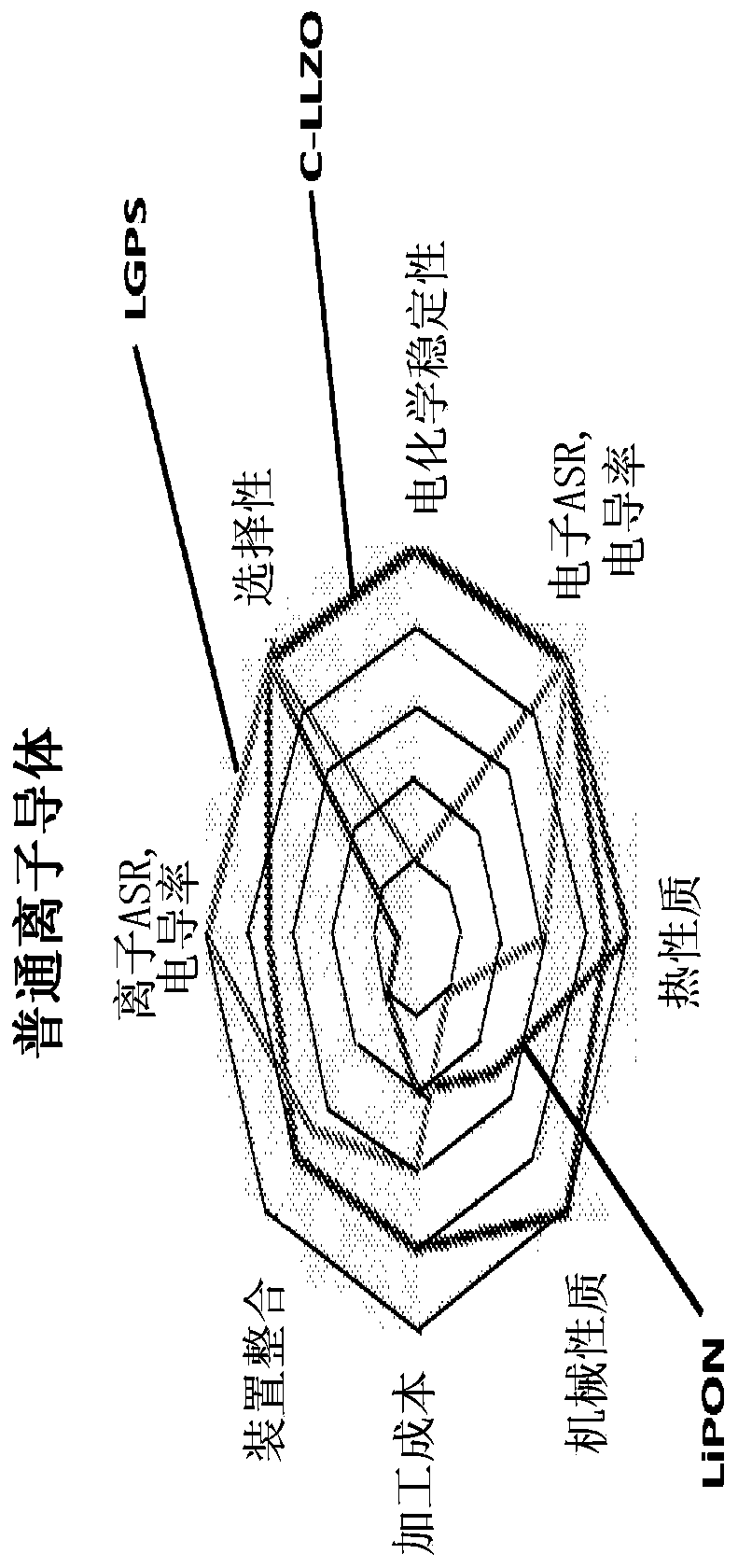

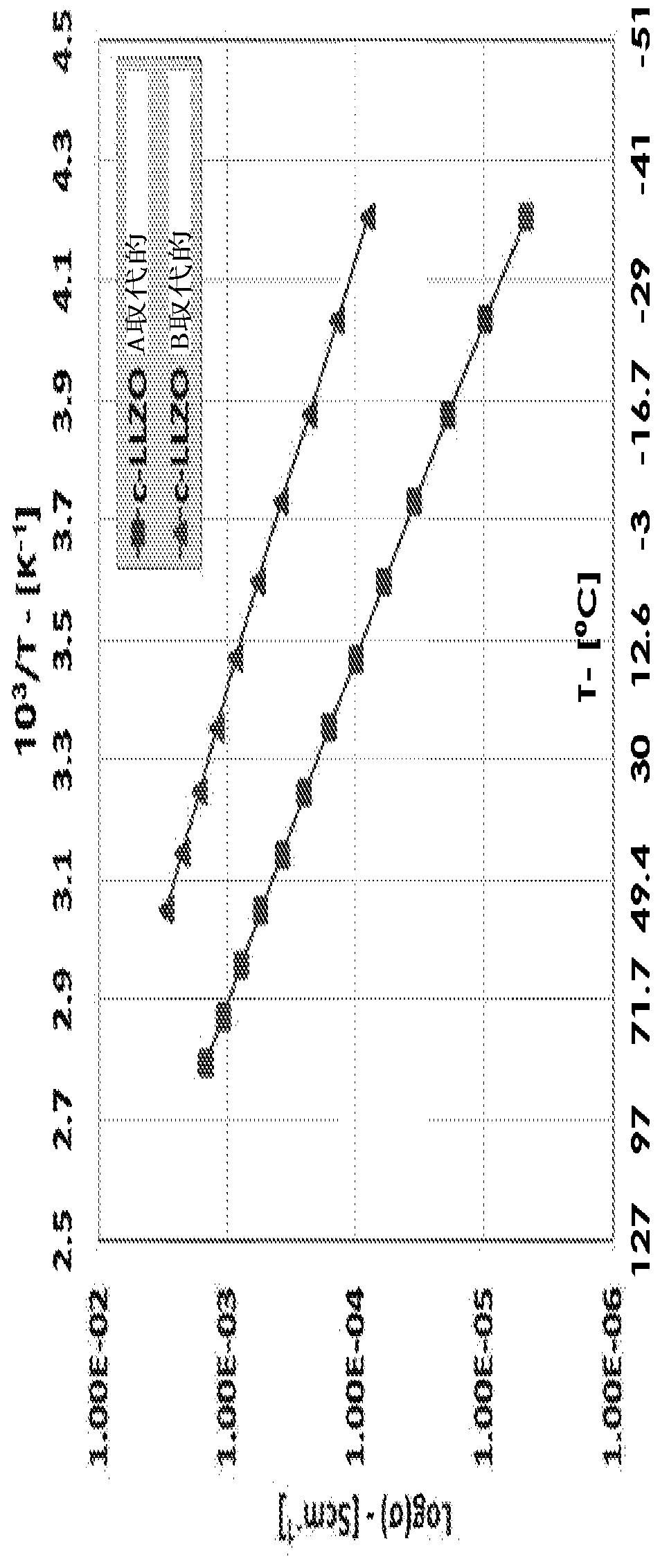

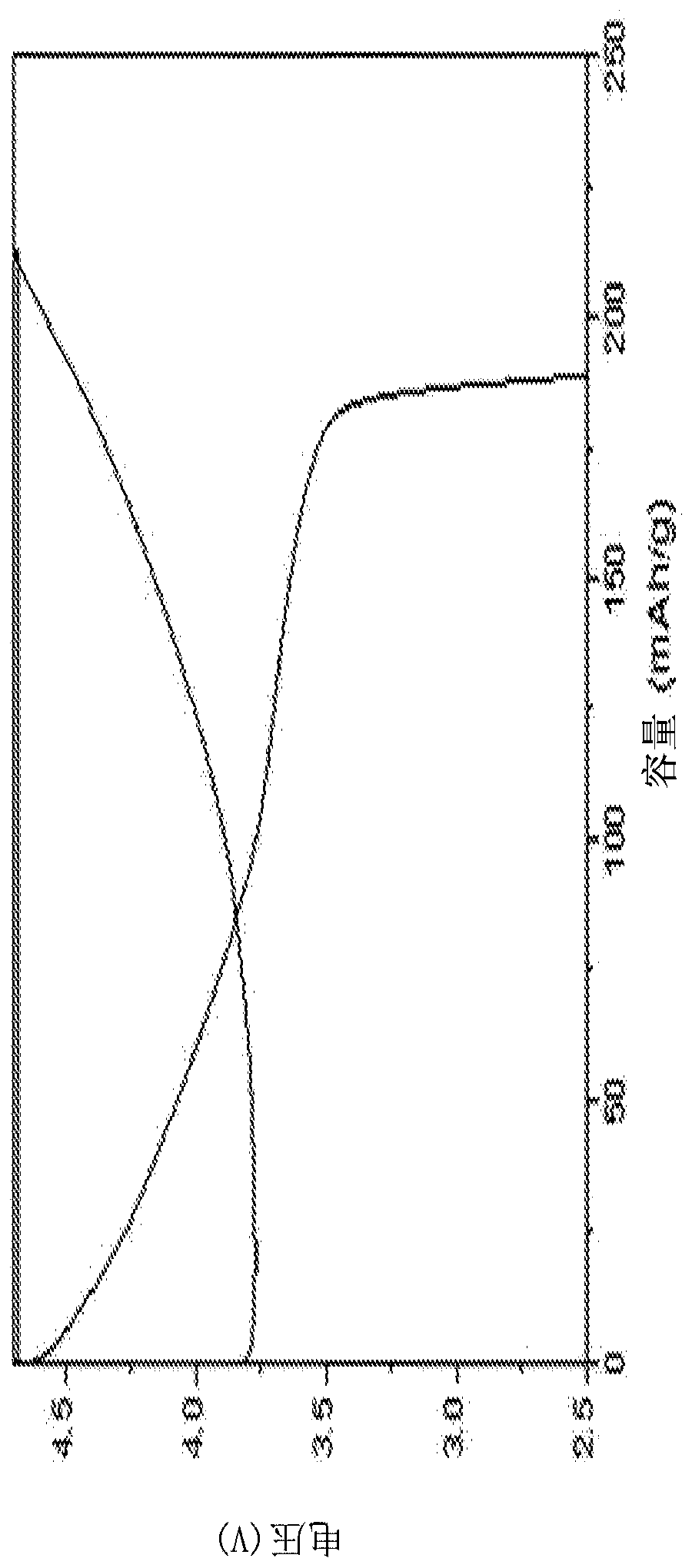

[0058] Disclosed herein is an all-solid-state mechanically flexible Li-ion battery (LIB) with a mechanically flexible solid-state ceramic electrolyte formed by preparing a nanoparticle slurry of ceramic ultra-high-speed ionic conductors in accordance with the present disclosure, and freeze casting the slurry or casting, and preferably combined with sintering. The nanoparticle slurry is formed into a thin film by casting, preferably followed by sintering at temperatures below 1100°C, and then the structure in the LIB is further formed. Their conductivity at operating temperature is preferably similar to that of liquid electrolytes, i.e., 10 -6 -1 S cm -1 , and the activation energy is less than 0.6 eV.

[0059] Disclosed herein is an all-solid-state mechanically flexible LIB comprising a ceramic solid-state electrolyte comprising lithium selected from the group consisting of perovskite-type oxides, NASICON-structured lithium electrolytes, and transition metal oxide-containing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

| roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com