Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

47results about How to "Raise the rolling temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

390MPa-grade low-cost hot rolling structural steel plate and manufacture method thereof

The invention provides a 390MPa-grade low-cost hot rolling structural steel plate and a manufacture method of the 390MPa-grade low-cost hot rolling structural steel plate. The 390MPa-grade low-cost hot rolling structural steel plate is prepared from the following components in percentage by weight: 0.15 to 0.20% of C, 0.05 to 0.20% of Si, 0.1 to 0.5% of Mn, 0.0005 to 0.004% of B, not greater than 0.0060% of N, 0.02 to 0.05% of Al, 0.015 to 0.025% of Ti, 0.0025 to 0.0060% of Ca, 0.12 to 0.2% of Ca / Al, and the balance of Fe. The manufacture method comprises steps as follows: melting by a converter; refining outside the converter; continuously casting; and rolling; Al is added to remove oxygen during refining, and Ti is added for fixing nitrogen, so that O is not greater than 0.002%, and N is not greater than 0.006%; boron is added for alloying before ending the refining, and an Si-Ca line is fed; a temperature in hot-charging of a continuous casting blank is more than 840 DEG C; a slab blank is processed by heating to reach the temperature of 1100 to 1180 DEG C, maintaining the temperature for 2 to 3 hours, roughly rolling at the temperature of 1020 to 1100 DEG C, wherein an intermediate blank / finished product is in thickness of 5; refining at the temperature of 950 to 1000 DEG C, wherein accumulation deformation is more than 50%; finally rolling at the temperature of 850 to 900 DEG C, cooling to reach the temperature of 500 to 600 DEG C at 6 to 20 DEG C per second after rolling, and coiling, and then cooling by air. The manufacture method is simple in technology and low in cost; and the product is high in toughness and plasticity and high in welding performance.

Owner:ANGANG STEEL CO LTD

High-strength high-toughness X80 hot rolling coiled sheet for spiral buried arc welding and production method thereof

The invention provides an X80 hot rolling steel plate used for a high-obdurability spiral hidden arc welded tube and a production method thereof, which belong to the technical field of steel rolling. The X80 hot rolling steel plate comprises the following compositions in weight percentage: 0.03 to 0.08 weight percent of carbon, 0.10 to 0.25 weight percent of silicon, 1.60 to 1.95 weight percent of manganese, 0.09 to 0.11 weight percent of niobium, 0.020 to 0.030 weight percent of vanadium, 0.010 to 0.020 weight percent of titanium, 0.10 to 0.30 weight percent of molybdenum, 0.10 to 0.30 weight percent of copper, 0.10 to 0.30 weight percent of nickel, 0 to 0.30 weight percent of Cr, less than or equal to 0.018 weight percent of phosphor, less than or equal to 0.003 weight percent of sulfur, less than or equal to 0.006 weight percent of nitrogen, 0 to 0.0005 weight percent of boron, less than or equal to 0.0003 weight percent of hydrogen, and the balance being ferrum and unavoidable trace impurities. The production method comprises the following steps: heating the compositions at a temperature of between 1,150 and 1220 DEG C; stopping rough rolling at a temperature of between 1,020 and 1,080 DEG C; stopping fine rolling at a temperature of between 800 and 840 DEG C; coiling the rolled steel sheet at a temperature of between 400 and 480 DEG C; and performing fine rolling according to the compression ratio, that is the thickness of an intermediate billet to that of finishing outlet is more than or equal to 3. The X80 hot rolling steel plate is particularly suitable to be used in a gas pipeline with high pressure, long distance and large aperture.

Owner:SHOUGANG CORPORATION

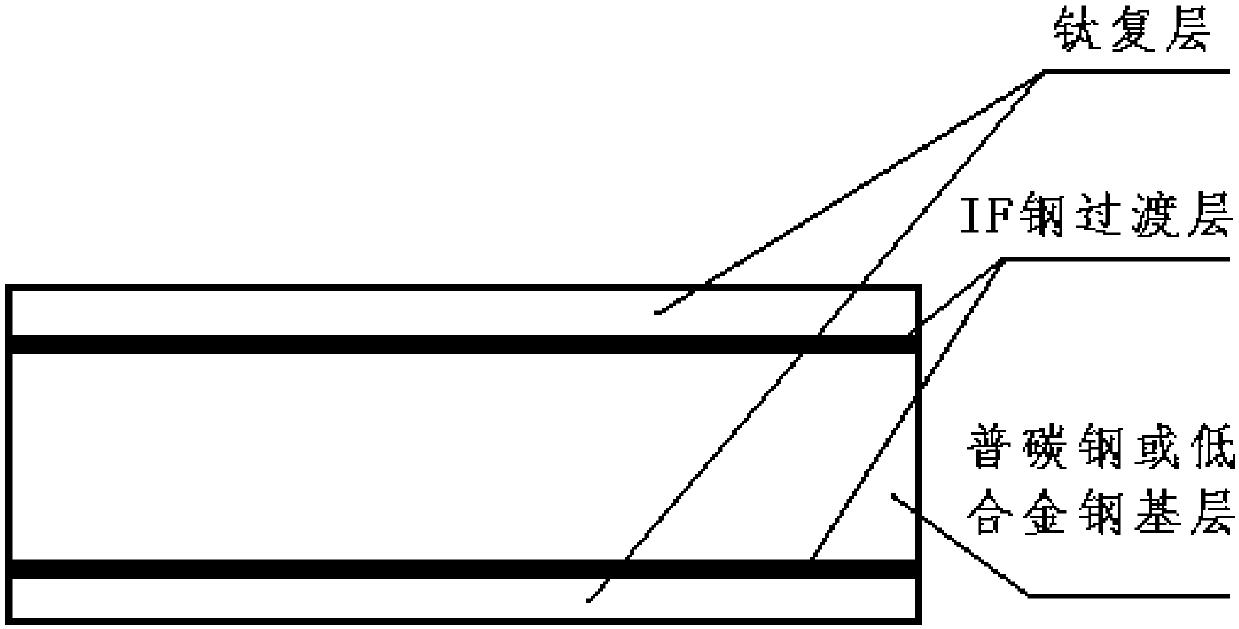

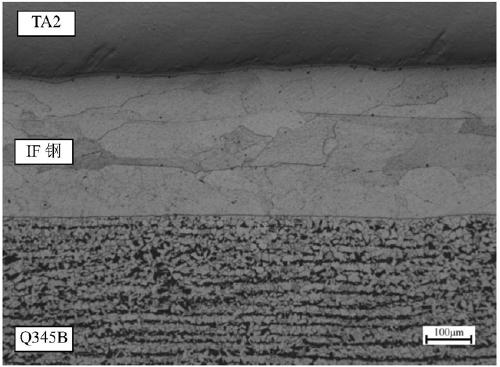

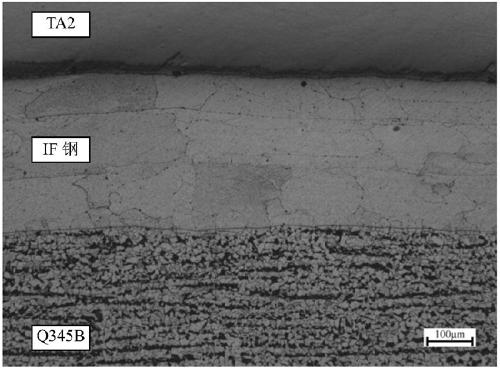

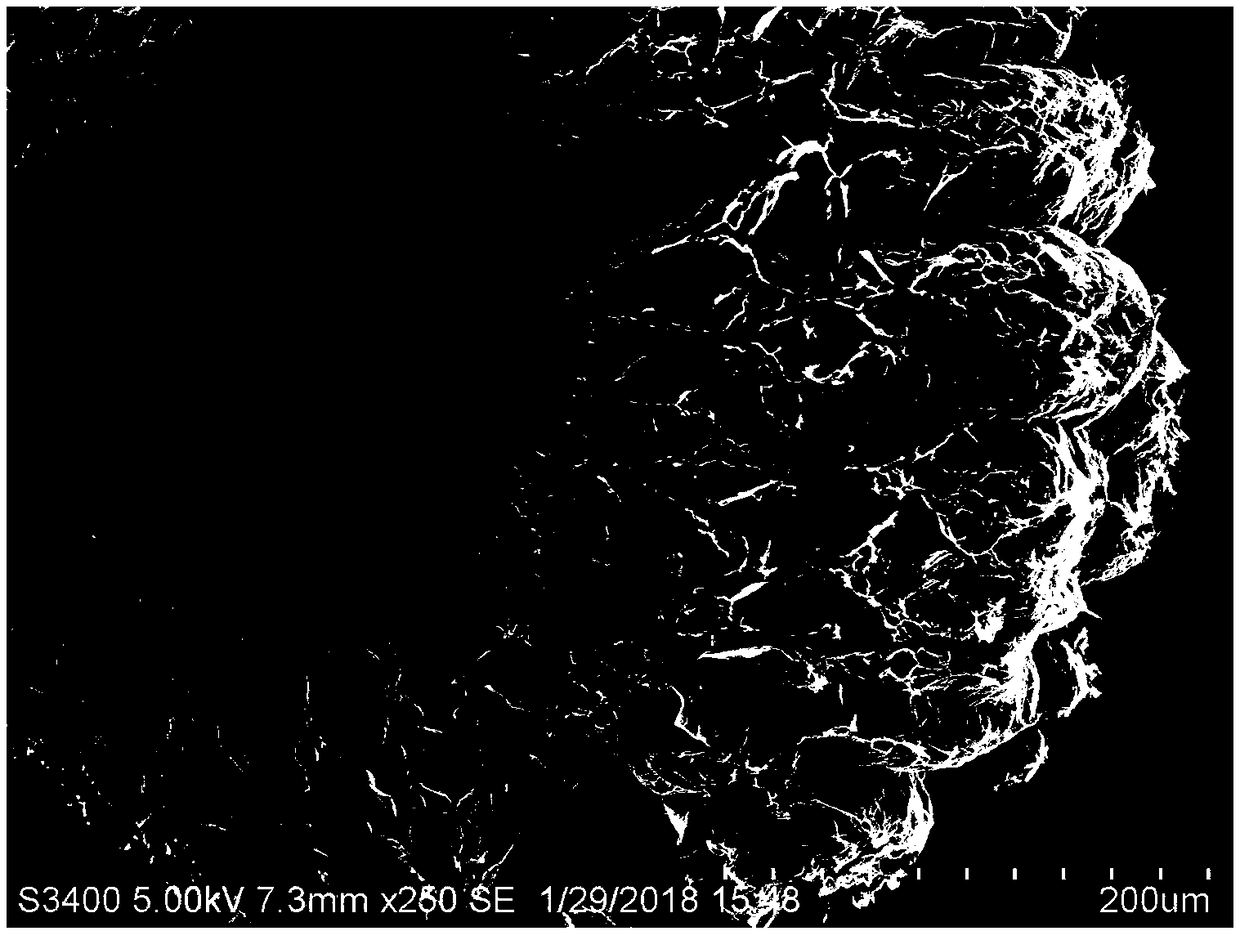

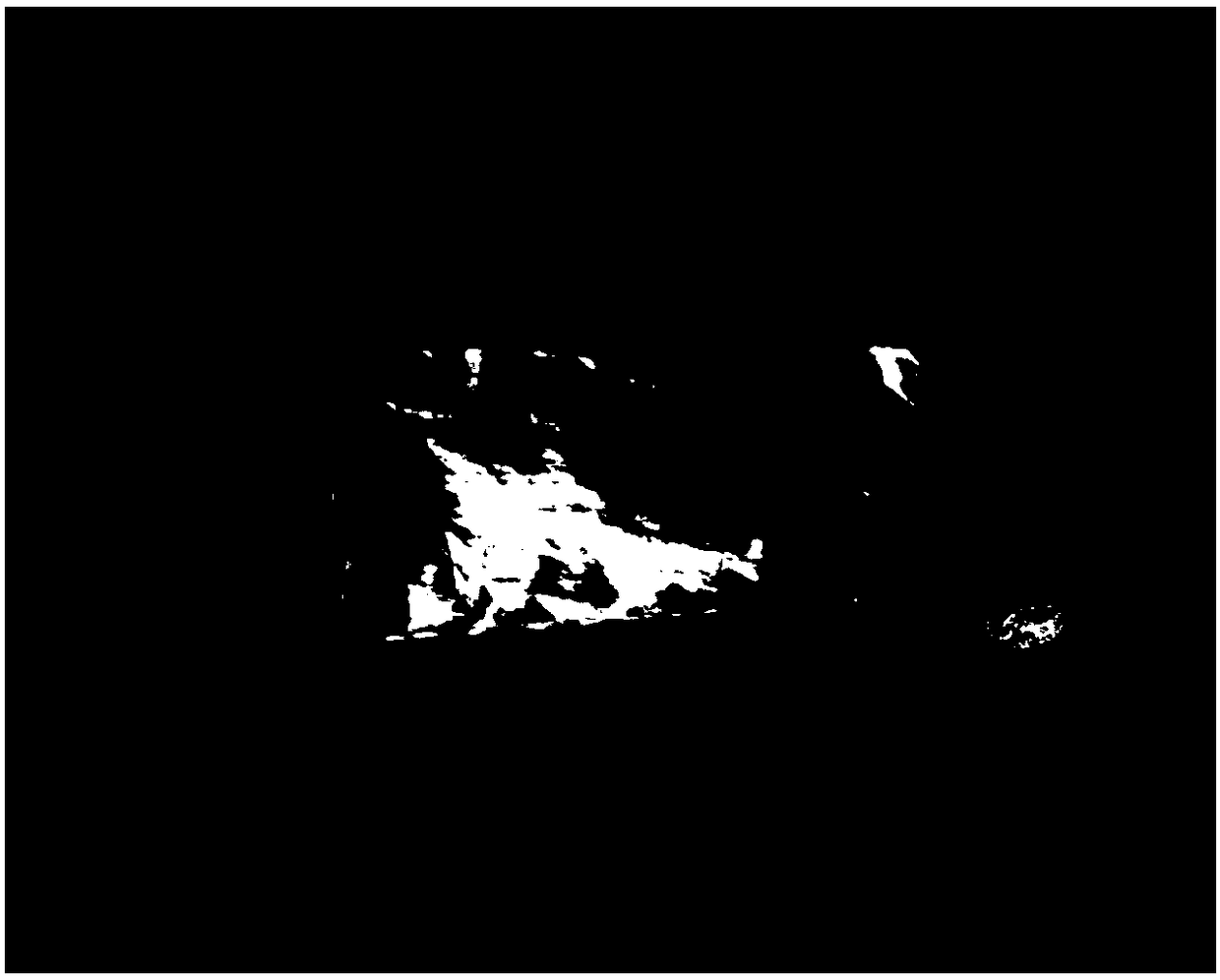

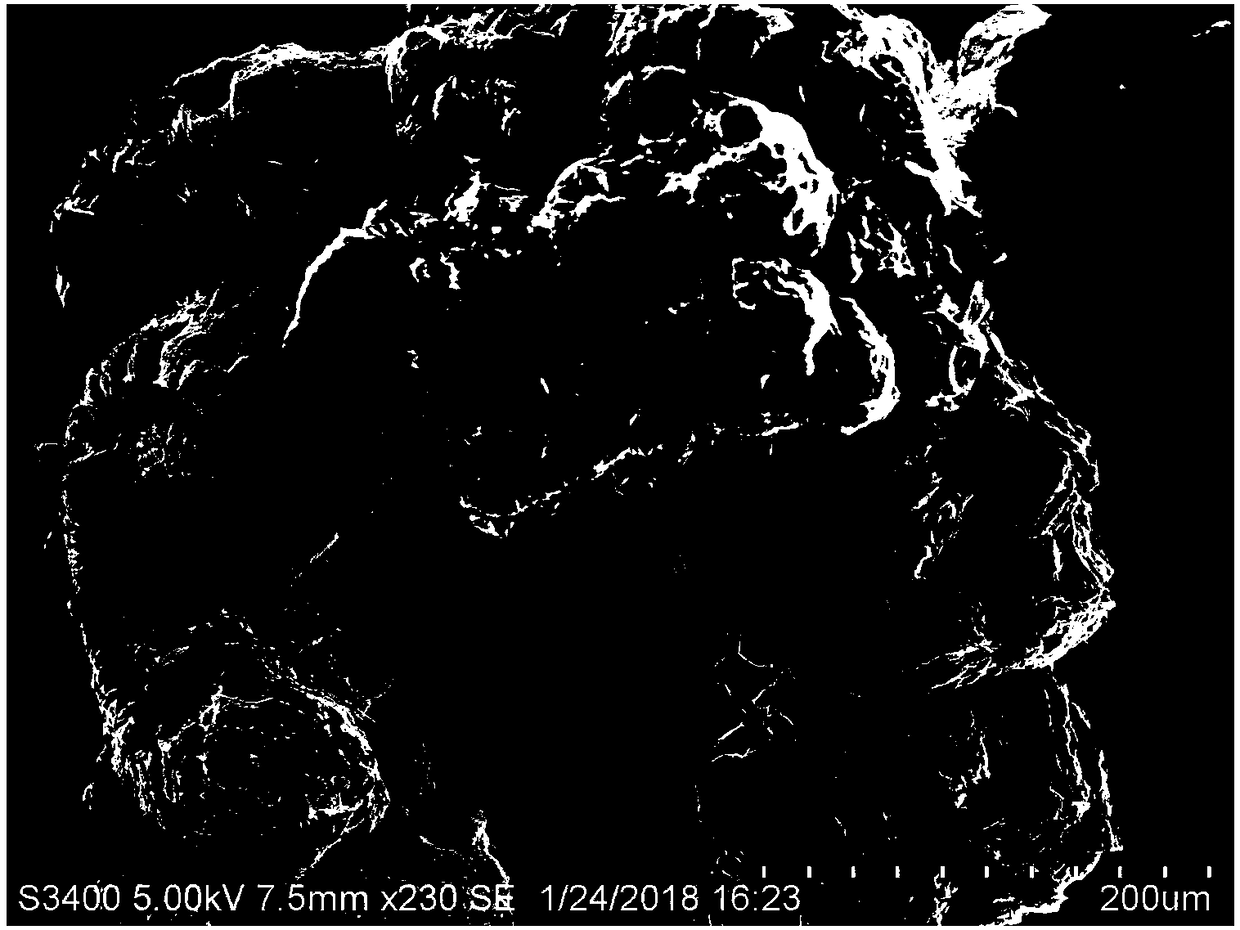

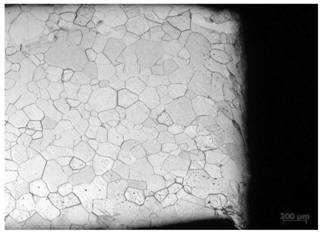

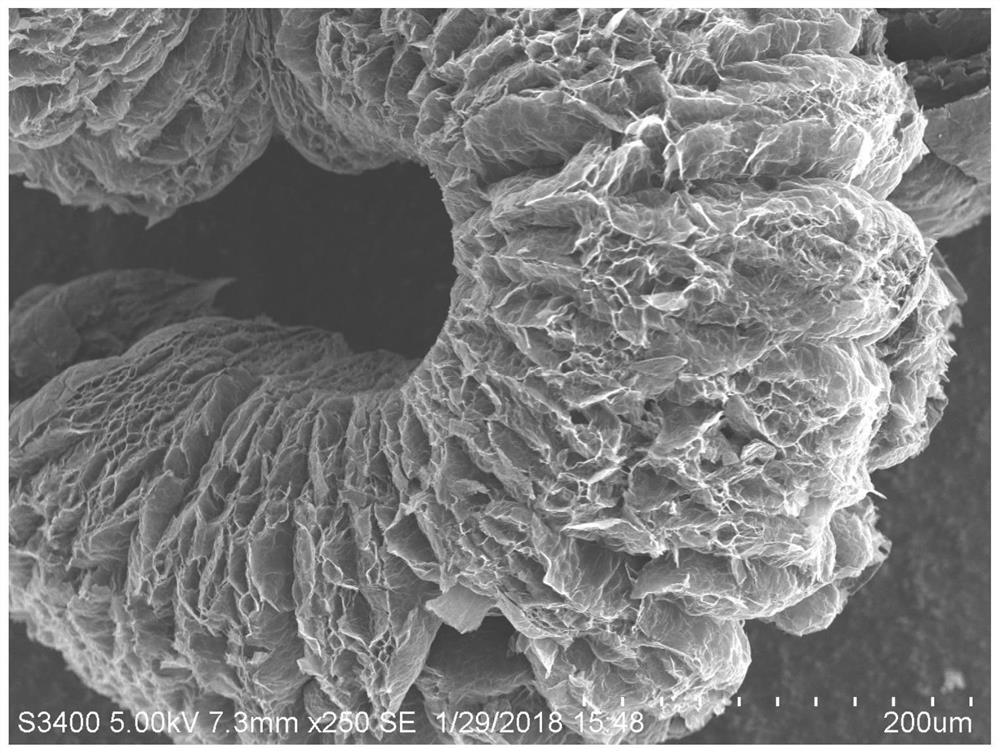

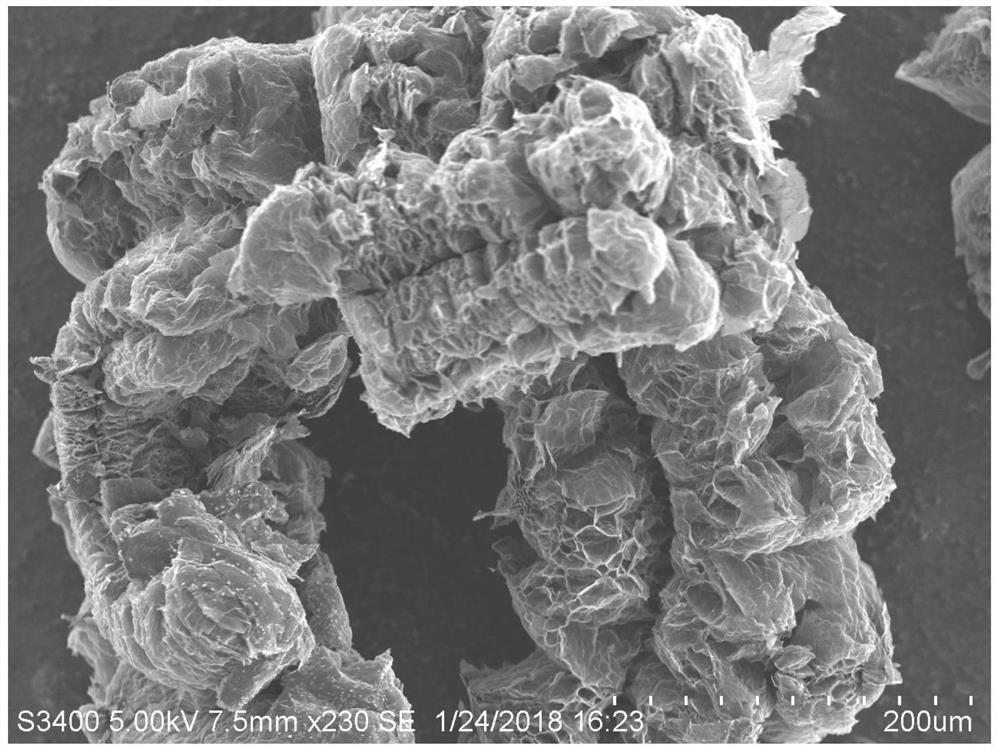

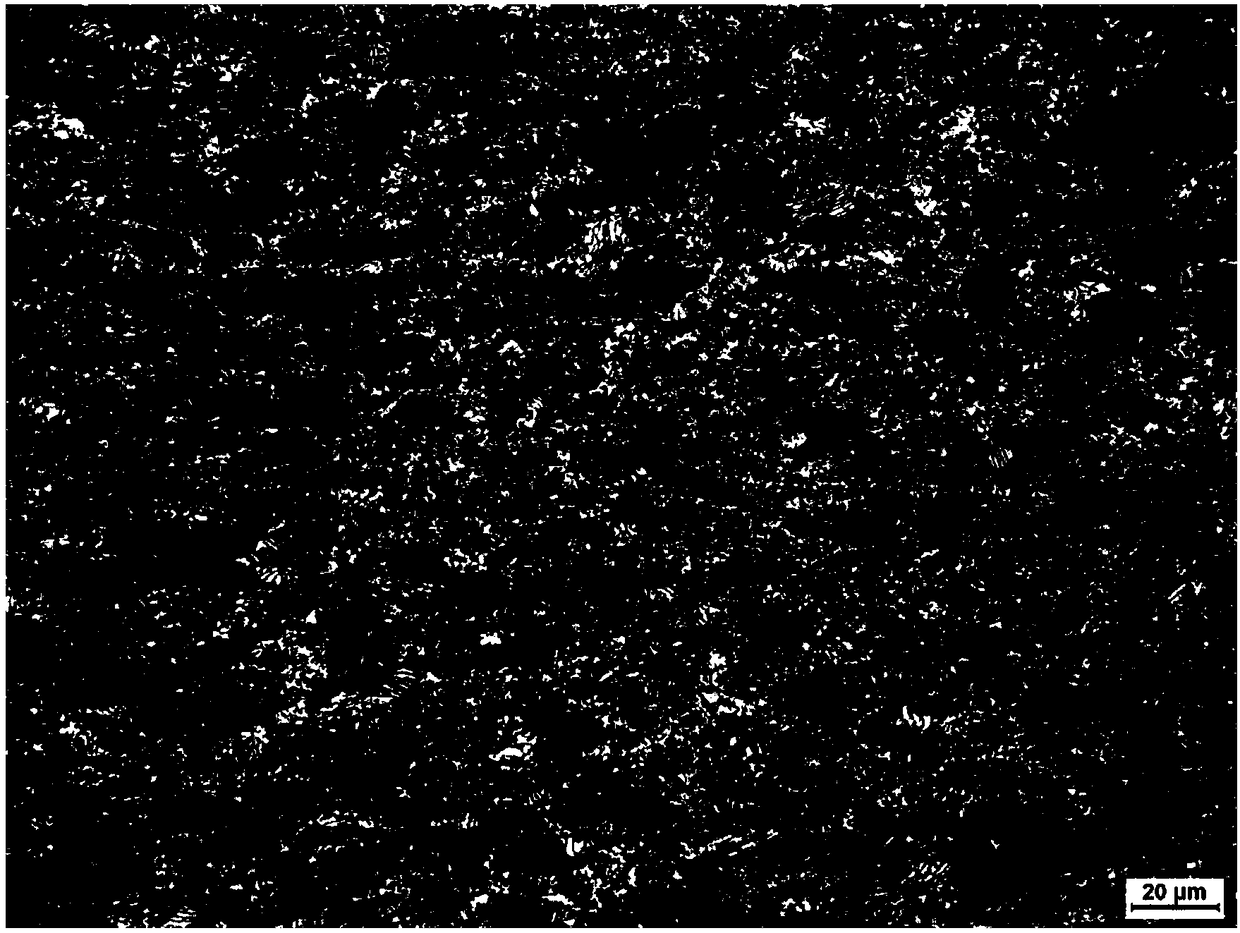

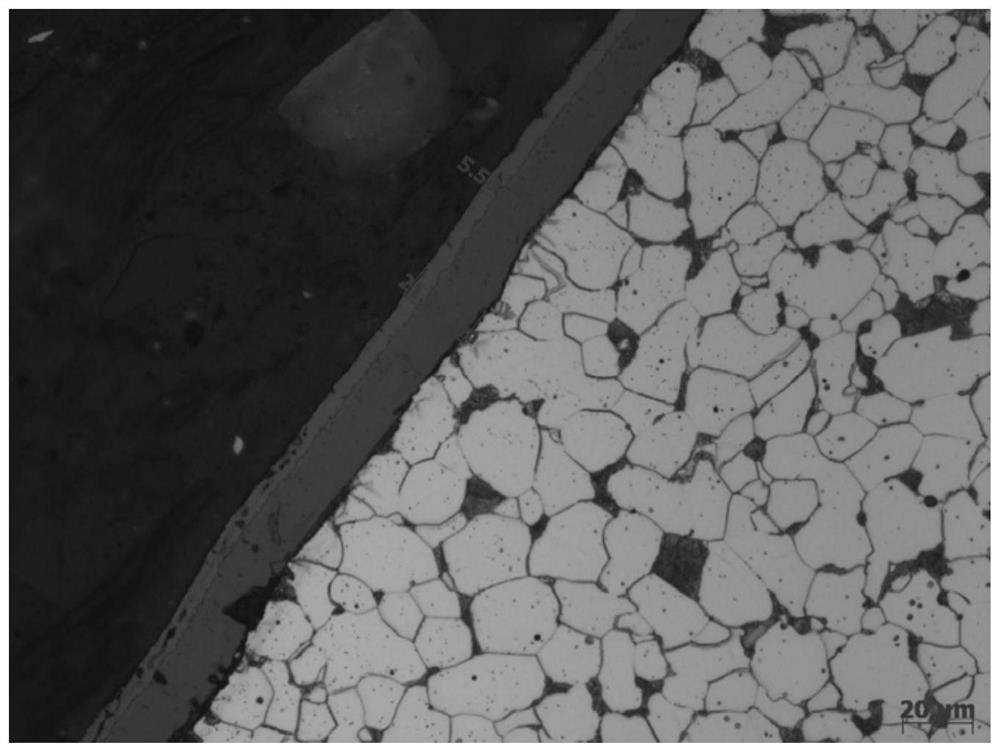

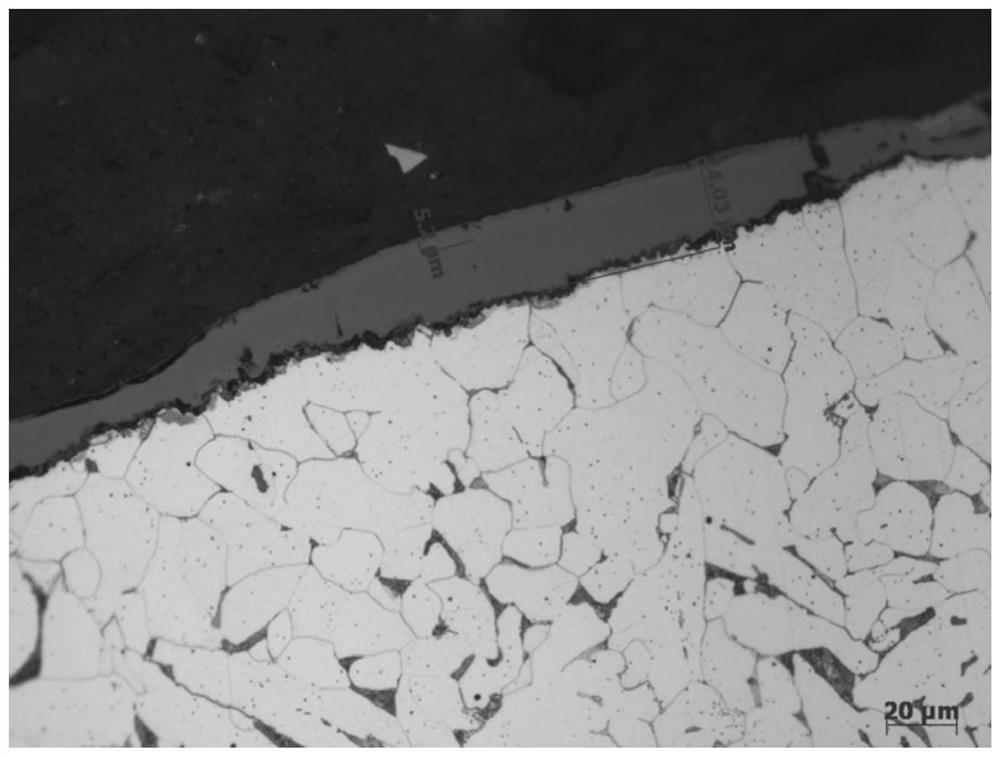

Double-sided titanium steel composite plate taking IF steel as transition layer and high-temperature preparation method thereof

ActiveCN109695000AImprove distributionImprove and enhance bond qualityMetal layered productsComposite plateMechanical property

The invention discloses a double-sided titanium steel composite plate taking IF steel as a transition layer and a high-temperature preparation method thereof. A composite blank for preparing the composite plate comprises a base material, the IF steel and a titanium composite material, wherein the base material is plain carbon steel or low alloy steel with C less than or equal to 0.22%, the titanium composite material is industrial pure titanium TA2, the thickness ratio of the base material to the titanium composite material is 5-10, the length and width of the titanium composite material are smaller than those of the base material, and the margin between the titanium composite material and four sides of the base material is 60-100 mm; and the vacuum welded composite blank is heated to 1040-1060 EDG C for heat preservation, the heat preservation time is 1 min / mm * the total thickness of the composite blank, the initial rolling temperature is 1020-1040 DEG C, the single-pass reduction rate is 15%-25%, the total reduction rate is greater than or equal to 70%, the finish rolling temperature is greater than or equal to 850 DEG C, air cooling is carried out to a room temperature, the thickness of the rolled IF steel transition layer is 280-320 [mu]m, and the double-sided titanium steel composite plate with the thickness of 6-75 mm is obtained after plate splitting, and excellent corrosion resistance and mechanical properties are achieved.

Owner:ANGANG STEEL CO LTD

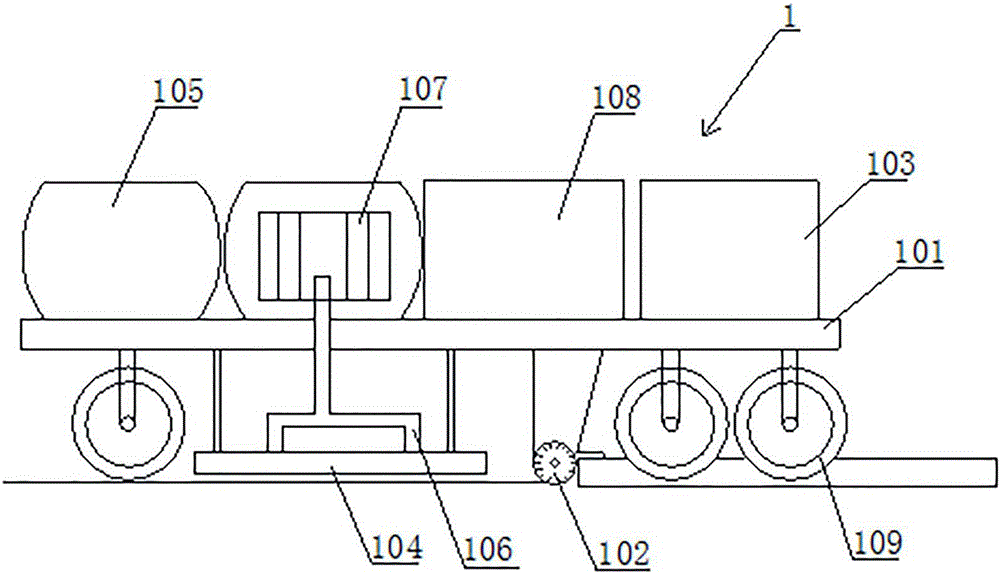

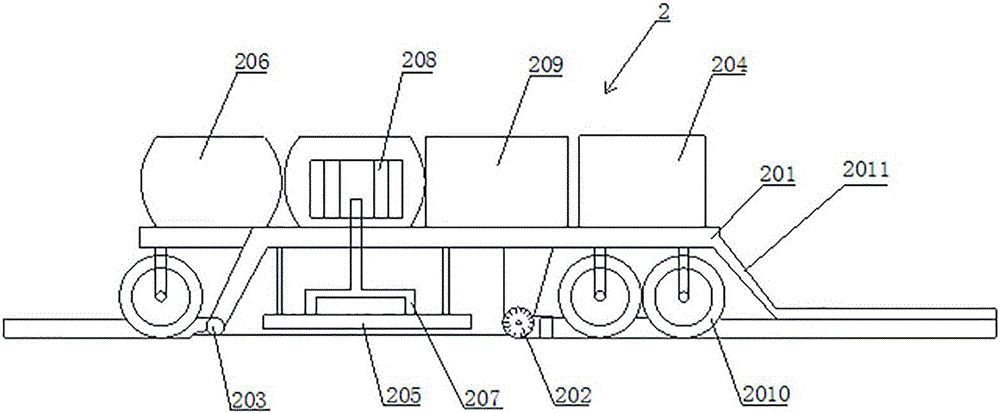

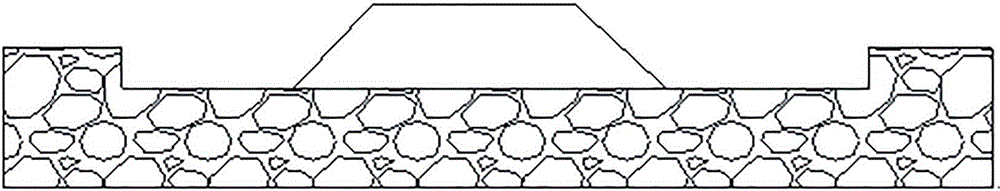

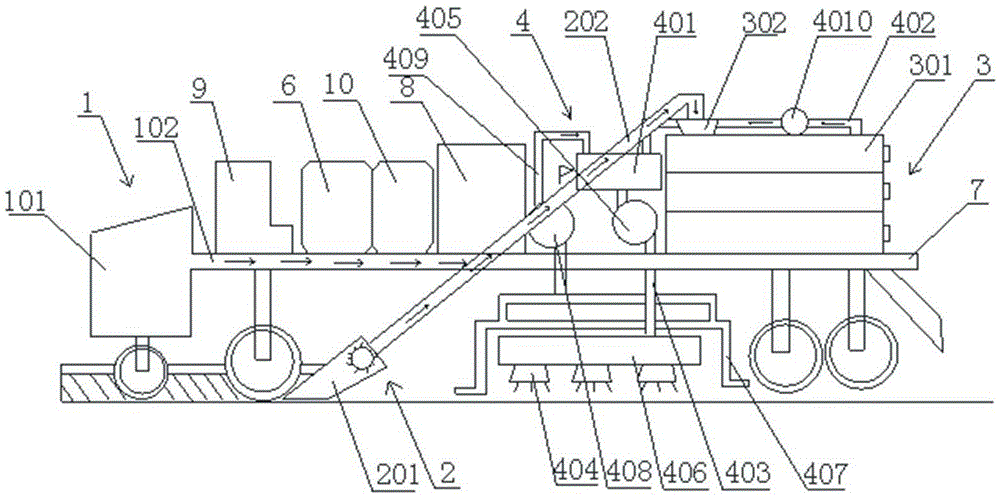

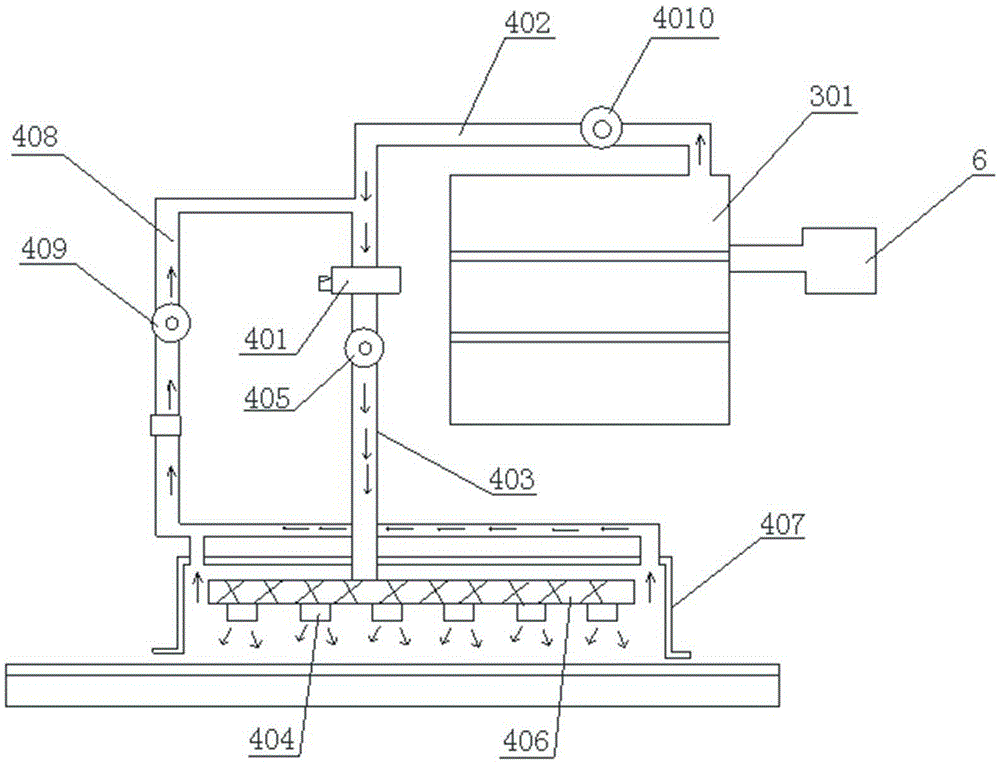

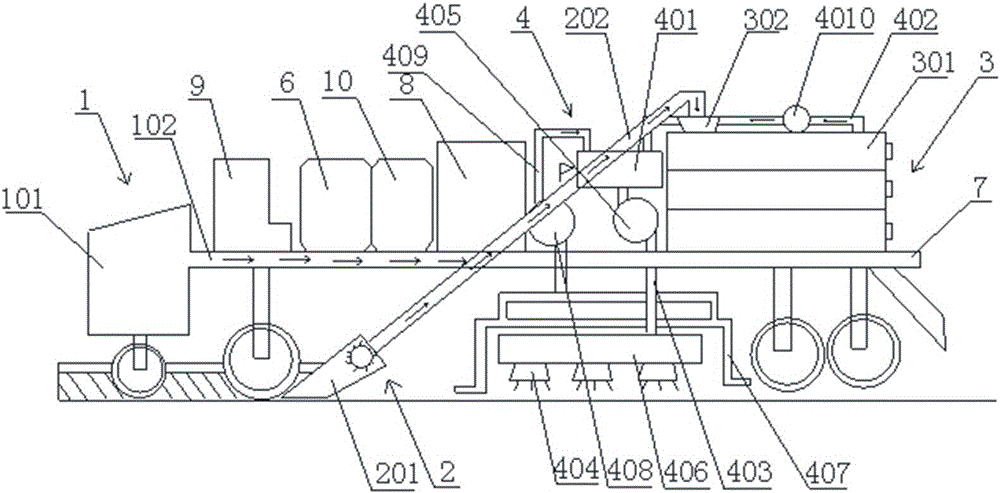

Hot in-place asphalt pavement recycling construction method involving layered heating, raking and moving-type blending

ActiveCN105113365AEvenly heatedImprove heating efficiencyRoads maintainenceSurface layerEconomic benefits

The invention discloses a hot in-place asphalt pavement recycling construction method involving layered heating, raking and moving-type blending. The method comprises the following steps: heating the asphalt pavement at a surface layer until the temperature is 70-80 DEG C, then raking the asphalt pavement at the surface layer, and collecting to form first recycled materials; heating the asphalt pavement at an inner layer until the temperature is 70-80 DEG C, then raking the asphalt pavement at the inner layer, and collecting to form second recycled materials; mixing the first recycled materials, the second recycled materials and a new asphalt mixture together, and heating to 140-160 DEG C to obtain a mixture; and uniformly spreading the mixture to the pavement, and densely rolling to obtain a recycled asphalt pavement. According to the invention, a two-layer heating and two-time raking way is adopted, so that the heating efficiency is obviously improved; compared with the temperature of 140 DEG C required for traditional asphalt heating, the temperature is obviously reduced, so that black asphalt dust generated by high temperature does not exist; and the recycled pavement is heated more uniformly, so that the heating fuel can be greatly saved, and social and economic benefits are remarkable.

Owner:JILIN JIAPENG GRP

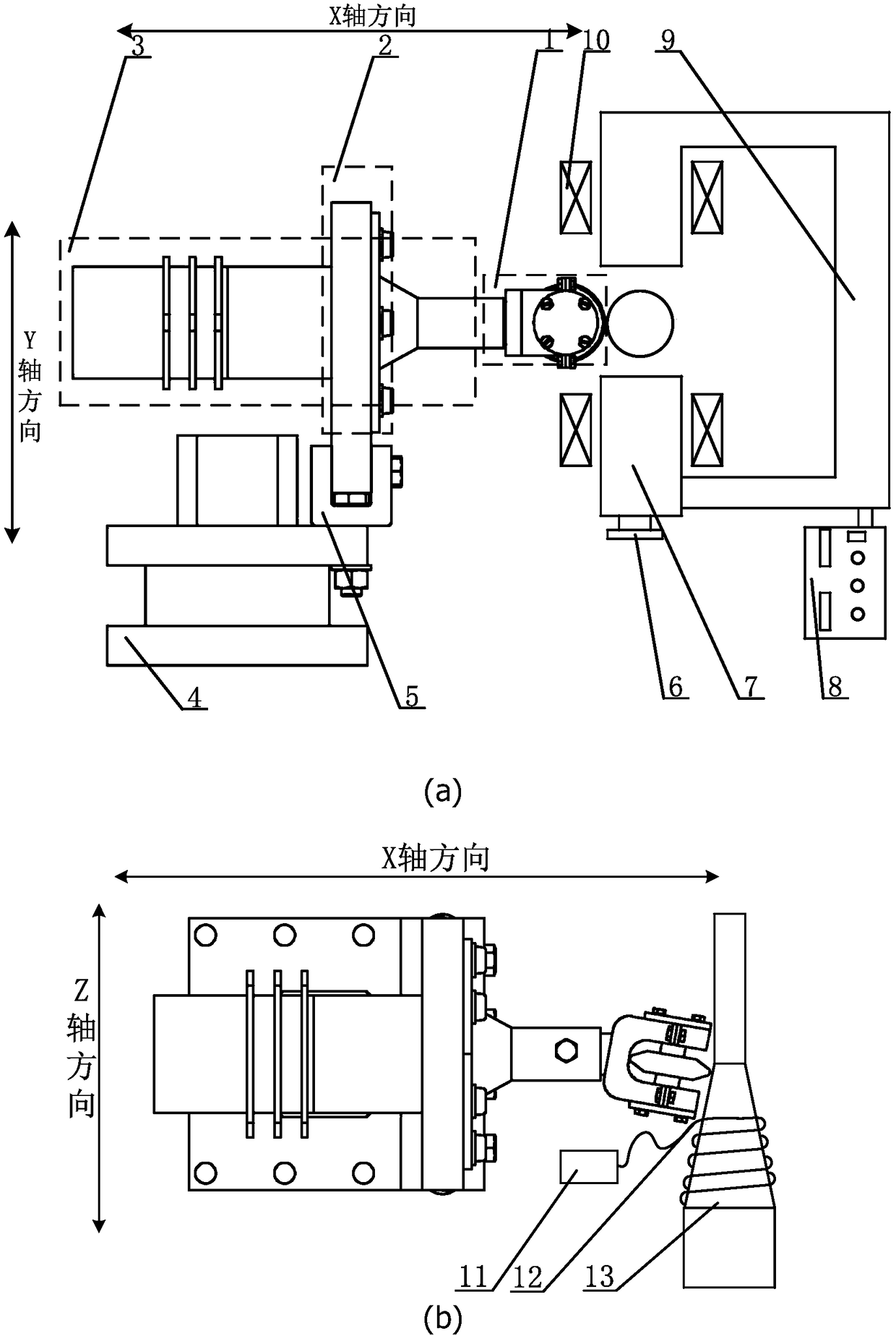

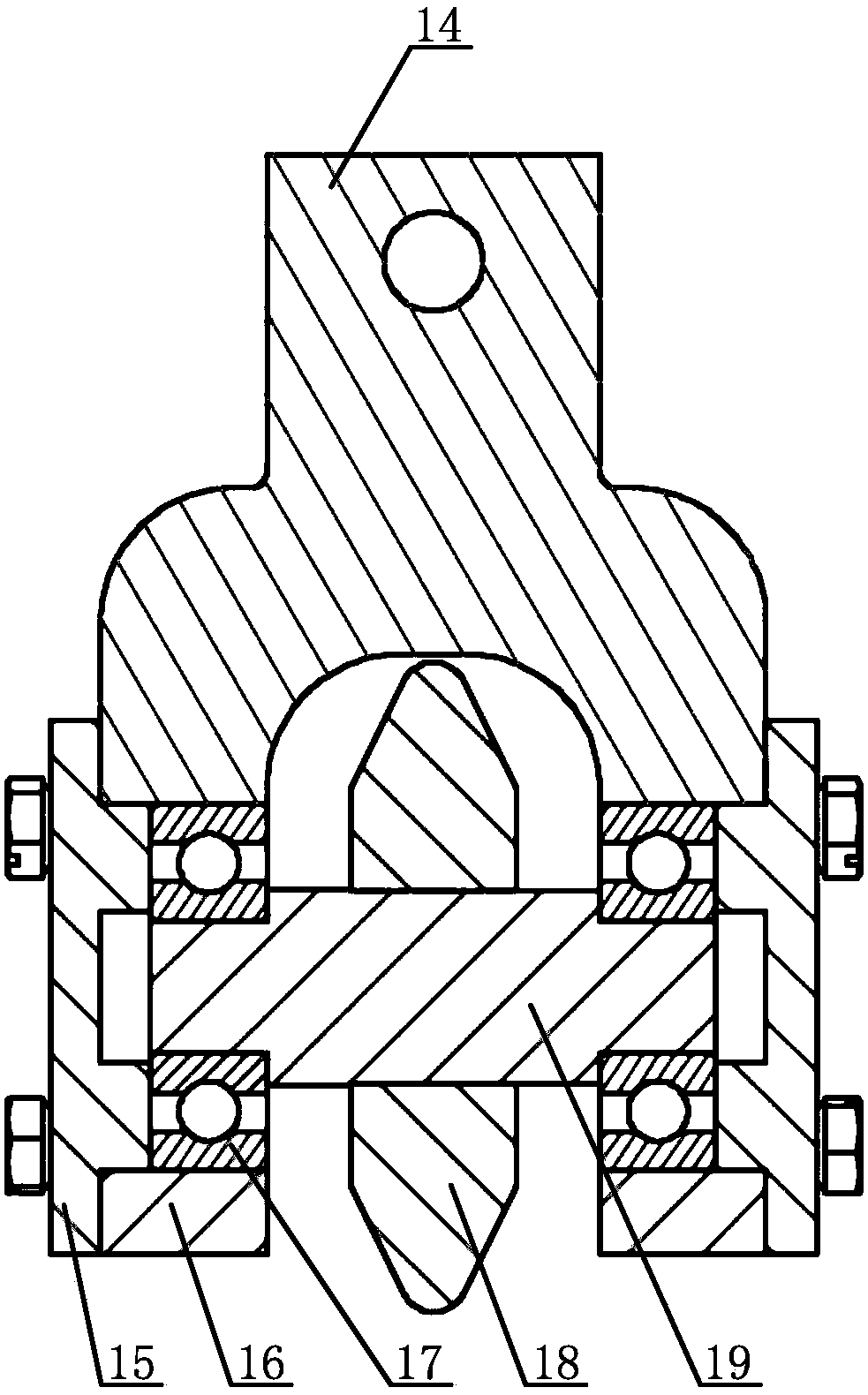

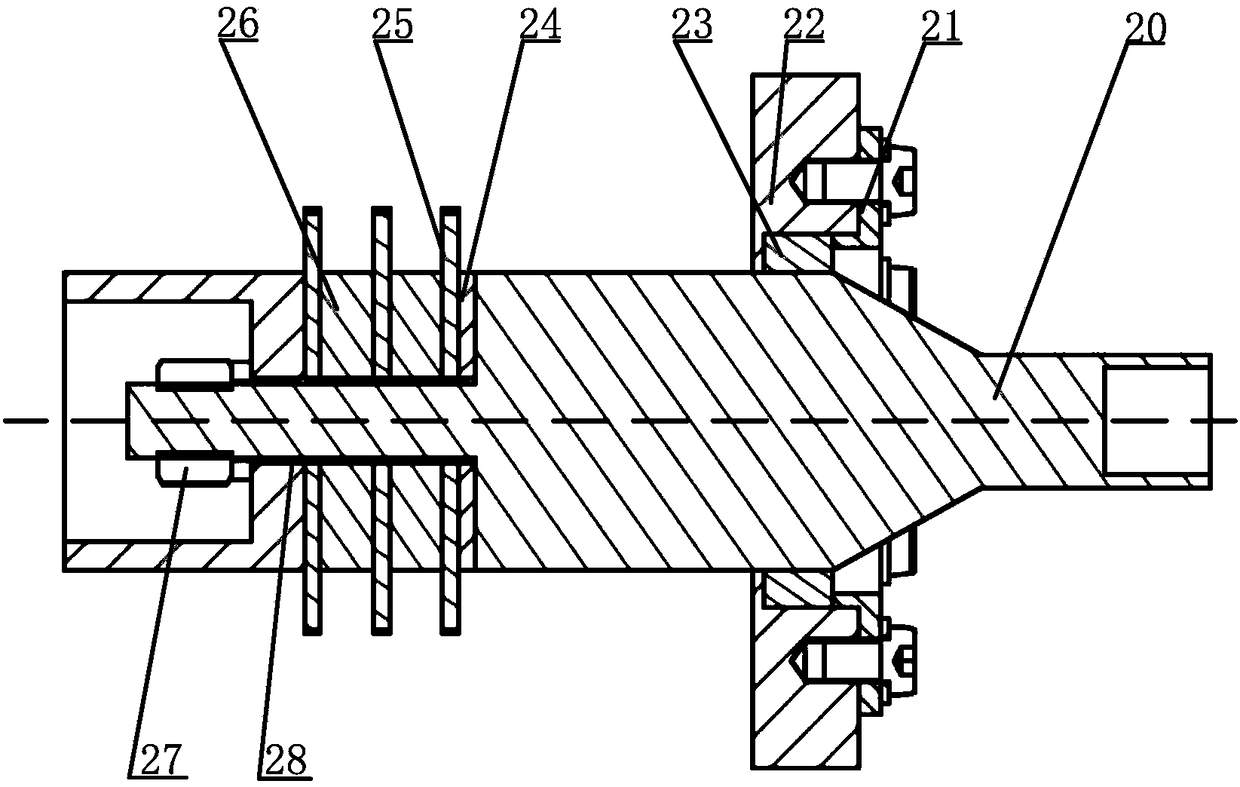

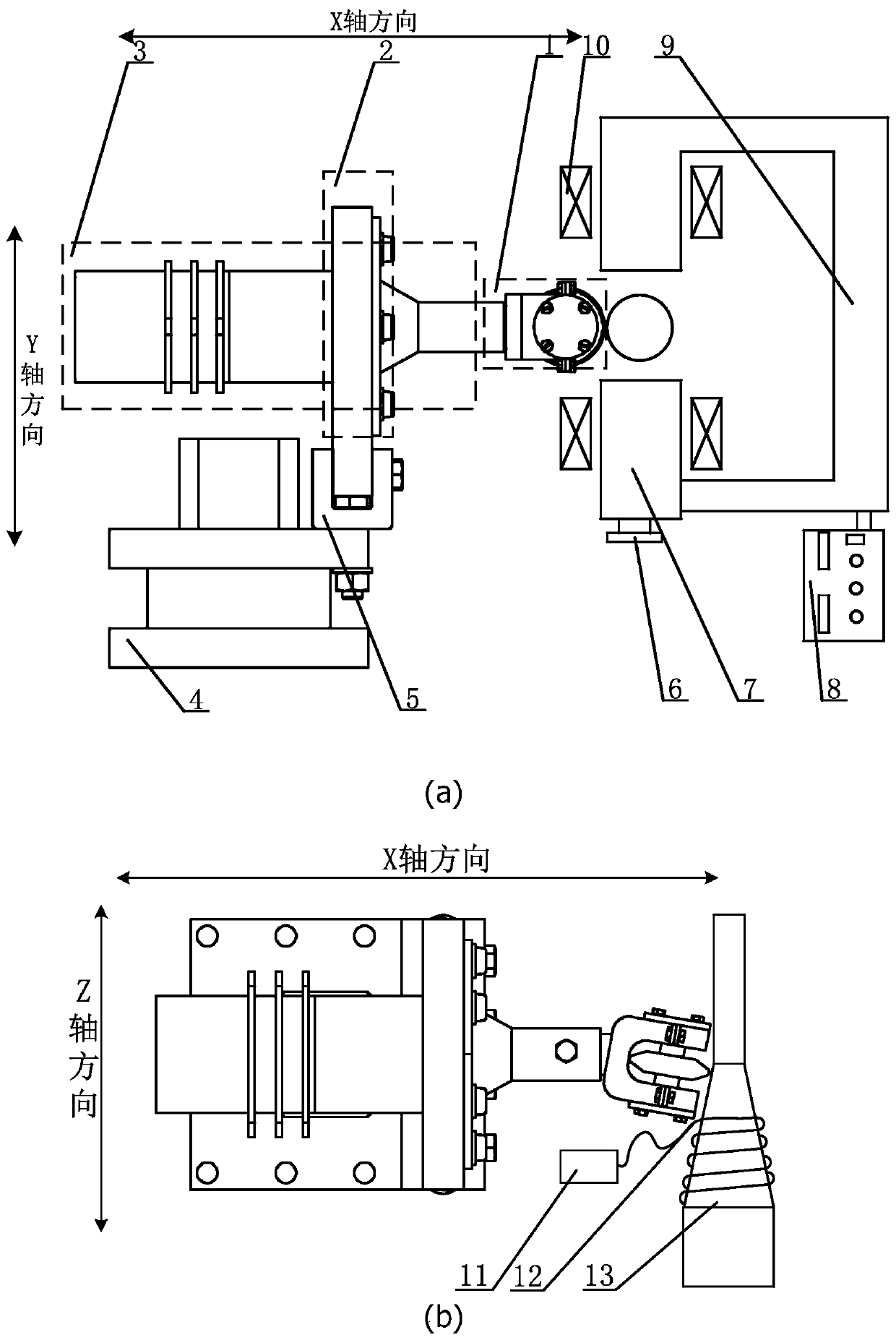

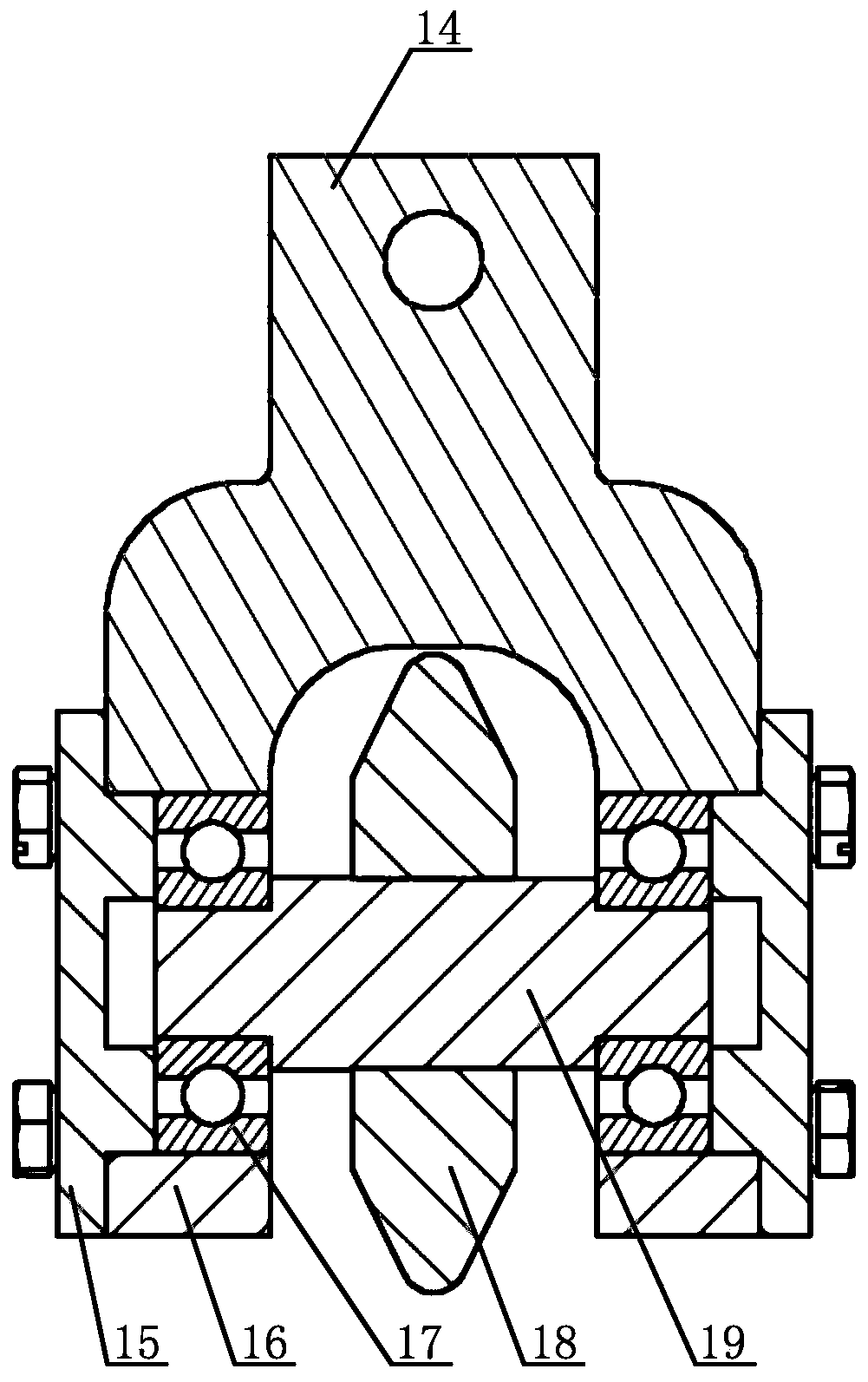

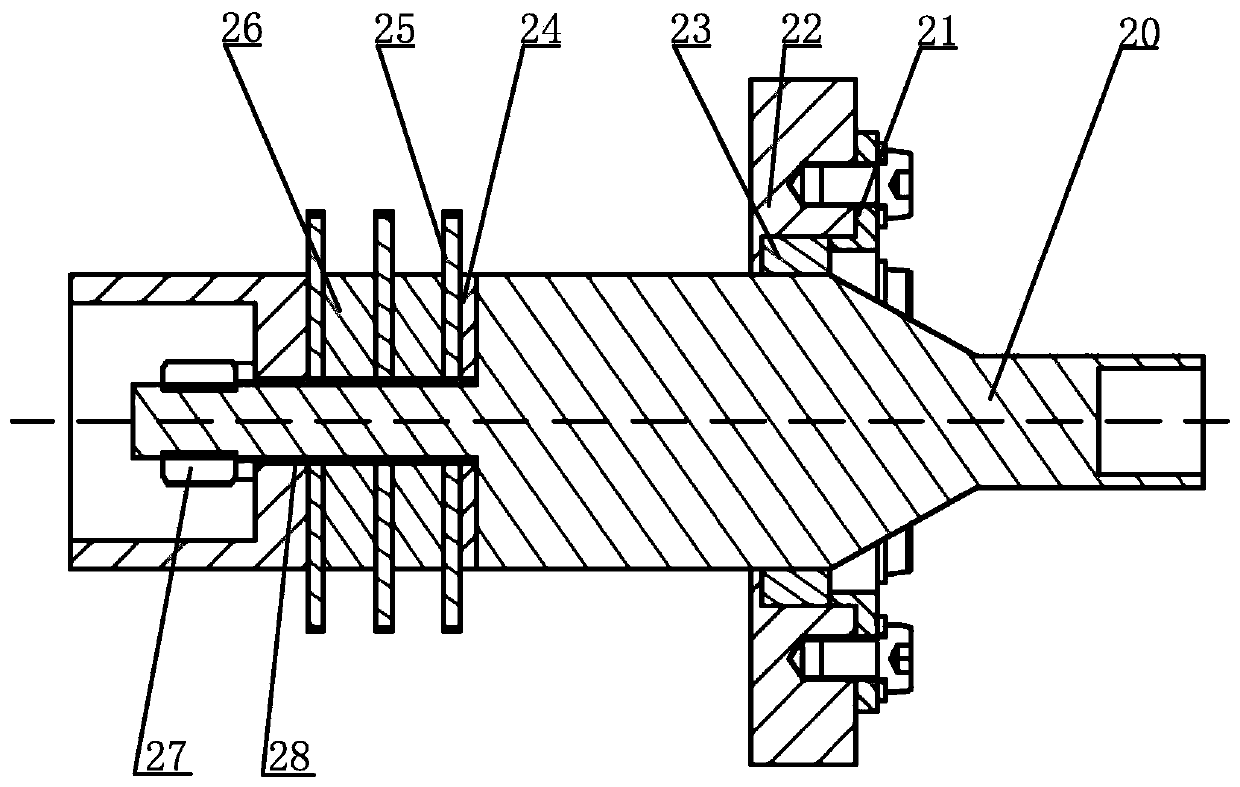

Multi-field coupling roll finishing device for conical surface

The invention provides a multi-field coupling roll finishing device for a conical surface. Multi-field coupling particularly means coupling of a high-temperature thermal field, a variable frequency pulsed magnet field and an ultrasonic field. The multi-field coupling roll finishing device comprises a rolling knife, an amplitude-change pole, a transducer, an ultrasonic generator, a thermocouple coil, a temperature controller, a pulsed magnet field intensifying system, a dynamometer and a mounting rack. A novel rolling knife structure is designed, so that different rolling wheels can be replacedaccording to different rolling workpieces, meanwhile, different rolling angles can be replaced according to different conical surface angles of workpieces, and accordingly, the use is convenient andreliable. According to the multi-field coupling roll finishing device, the heating temperatures of the workpieces can be controlled by a temperature controller, the rolling temperature of the workpieces is increased, and the atomic vitality of the workpieces is enhanced, dislocation movement is overcome, the resistance is reduced, and accordingly, a favorable rolling surface quality is acquired. The conical workpieces are placed in a pulsed magnet field acting region, so that the hardness and the wear resistance of the workpieces are improved. The value of a rolling force in a rolling processcan be monitored in real time by the dynamometer, and the rolling force in the rolling process is kept constant by feedback of a digital control system. An ultrasonic rolling system which can be mounted on a common lathe is designed to roll a conical-surface shaft part, the surface roughness of the part can be reduced, the surface hardness is improved, and favorable surface quality and mechanicalperformance are acquired.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

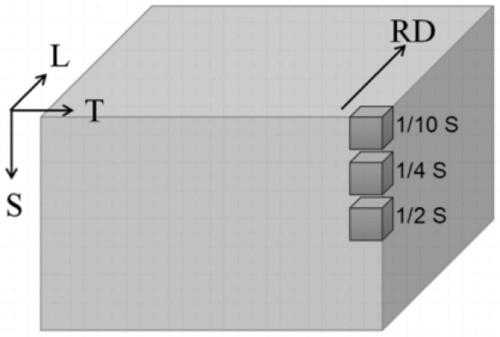

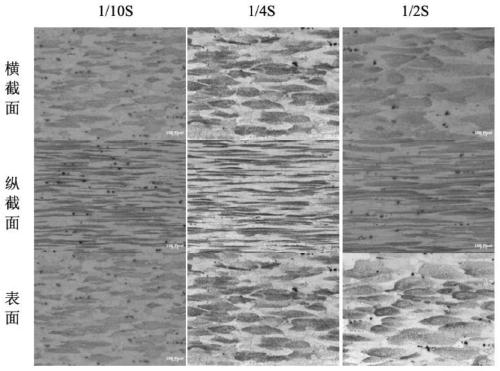

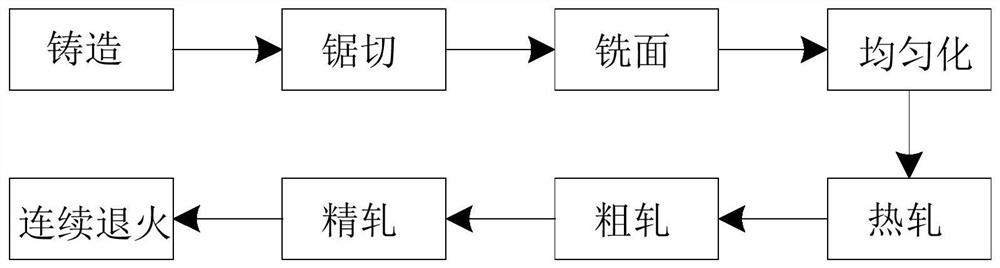

Preparation process of high-strength 7150 aluminum alloy medium plate

The invention belongs to the technical field of aluminum alloy manufacturing, and relates to a preparation process of a high-strength 7150 aluminum alloy medium plate. Raw material ingredients comprise: Si <= 0.50%, Fe <= 0.50%, Cu: 2.10-2.20%, Mn <= 0.01%, Mg: 2.15-2.35%, Cr <= 0.02%, Zn <= 6.65%, Ti <= 0.03%, Zr: 0.10-0.12%, single impurity <= 0.01%, total <= 0.15%, and the balance Al. The product formulation and casting process are optimized, the homogenization system is improved, initial rolling temperature is improved, high rolling-reduction rolling is adopted, the solid solution processis optimized, quenching delay time is strictly controlled, the quenching speed is improved, stretching delay time is strictly controlled, the optimal amount of stretching is selected, the aging process is improved, and finally the 7150 medium plate with excellent properties is obtained.

Owner:TIANJIN ZHONGWANG ALUMINUM IND CO LTD

Rolling method of high-grade non-oriented silicon steel

ActiveCN108655173AIncrease heat of deformationReduced edge cracking tendencyRoll force/gap control deviceTension/compression control deviceTemperature controlReduction ratio

The invention relates to a rolling method of high-grade non-oriented silicon steel. Through four-time rolling, reduction ratios are increased so as to increase deformation heat of strip steel, so thata rolling temperature of the strip steel is increased, and a temperature of an incoming material is controlled to reach 55 DEG C to 60 DEG C; the scheme of the four-time reduction ratios comprises that the reduction ratio for the first time is 37 percent to 41 percent, the reduction ratio for the second time is 36 percent to 39 percent, and the reduction ratio for the third time is 34 percent to37 percent; rolling force for the four times is respectively controlled as follows: 4750kN to 5000kN, 4600kN to 5000kN, 4400kN to 4600kN and 3900kN to 4200kN; and unit tension adjustment on rolling atthe previous two times is carried out. The rolling method of the high-grade non-oriented silicon steel disclosed by the invention has the advantages that the rolling times are simplified, the trend of edge cracking of an edge part of the strip steel is reduced, and production of double -rib wave is reduced.

Owner:ANGANG STEEL CO LTD

Asphalt pavement hot in-place recycling layered heating method

The present invention discloses an asphalt pavement hot in-place recycling layered heating method comprising the following steps: a pavement recycled material harrowed by heating is collected and mixed with new asphalt to obtain a regenerated mixture; the regenerated mixture is first put into a heating mixing device for the first time heating mixing, and then sent to another heating mixing device for second time heating mixing, the heating mixing is repeated for multiple times until the regenerated mixture is heated from original 70-80 DEG Cto 140-160 DEG C; and the mixed heated regenerated mixture is directly discharged, and received by a followed pavement paver, and the regenerated mixture is paved on a recycled pavement, and finally is compacted by a road roller. The temperature of the regenerated mixture heated by the regenerated mixture layered heating method is raised to 140-160 DEG C, the final paving rolling temperature is enhanced; and asphalt smoke dust and a large quantity of heat generated by the heating are recycled, and waste flue gas is reused after recycling combustion.

Owner:嘉鹏精工科技(大连)有限公司

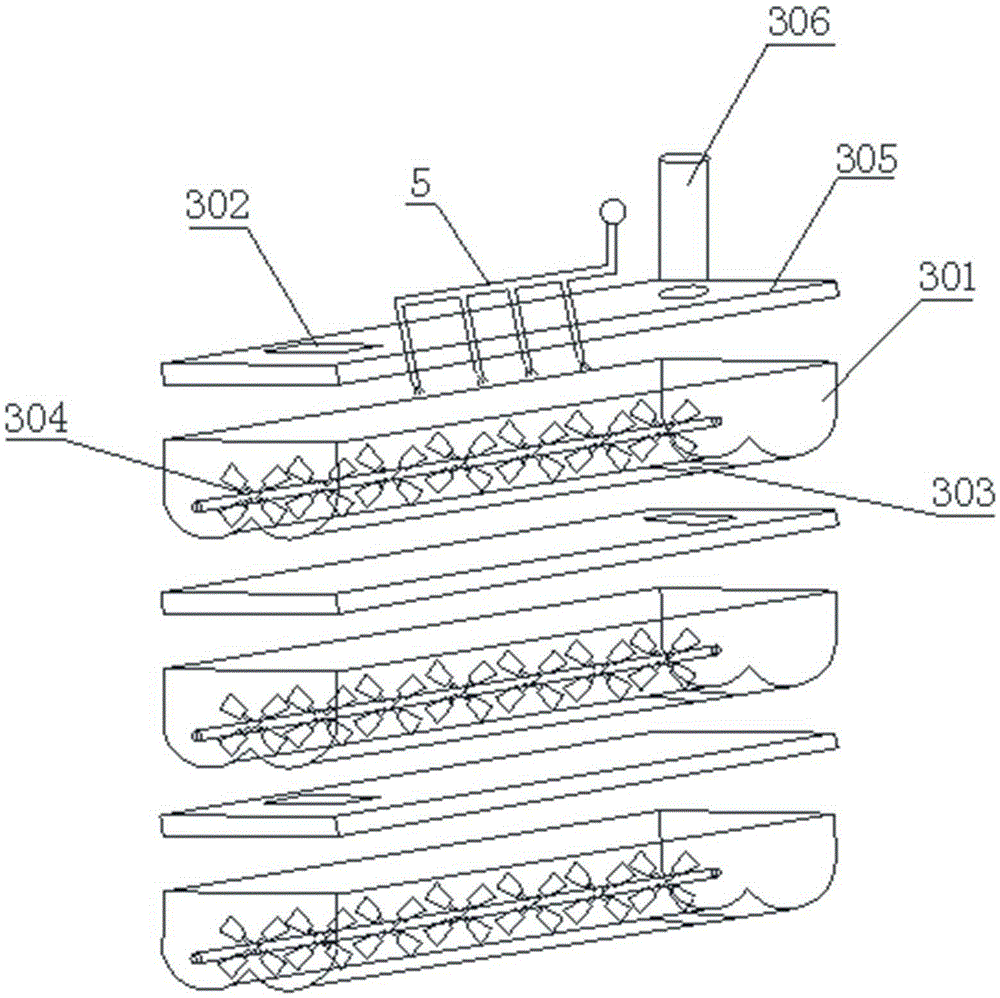

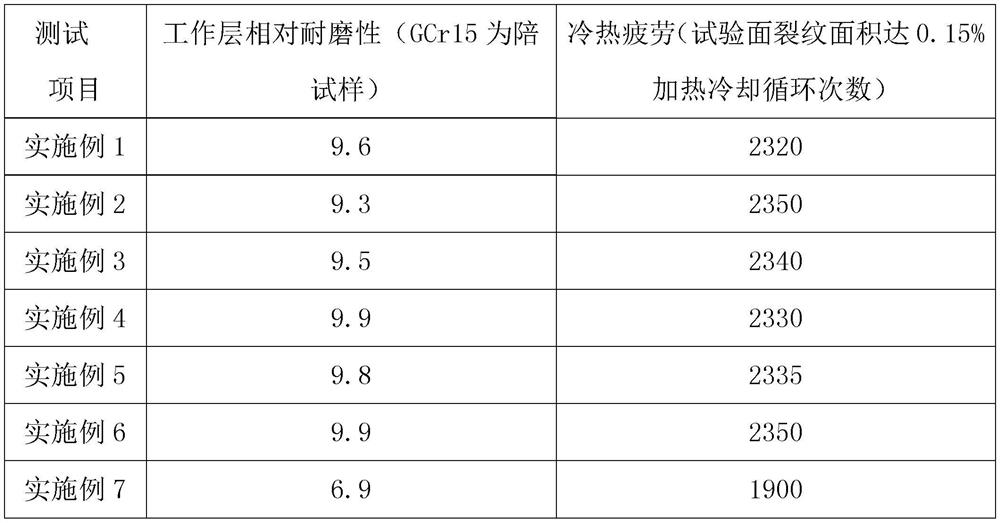

Preparation method of rough rolling high-speed steel working roll for full endless rolling of sheet billets

PendingCN113547099AExtend the machine cycleImprove wear resistanceFurnace typesProcess efficiency improvementTemperingFerrochrome

The invention discloses a preparation method of a rough rolling high-speed steel working roll for full endless rolling of sheet billets. The preparation method comprises the following steps that A, scrap steel, ferronickel, ferrovanadium, ferrochromium, ferromolybdenum, ferrotungsten and electrode powder are taken as raw materials, a line frequency furnace is adopted for smelting outer-layer molten iron and core molten iron; B, the product manufacturing mode is centrifugal composite manufacturing, and after smelting components reach the standard, outer-layer molten iron and core molten iron are heated, discharged out of a furnace and poured; C, after pouring is completed, a box is opened in a cold mode, and rough machining is conducted after the box is opened in the cold mode; D, after machining is completed, a roll body is subjected to quenching heating and overall tempering treatment; and E, after quenching heating is finished, finish machining is conducted, and detection is conducted till a finished product is obtained. According to the method, the requirements of short-process endless rolling technologies such as ESP are met, and the roll quality is improved.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

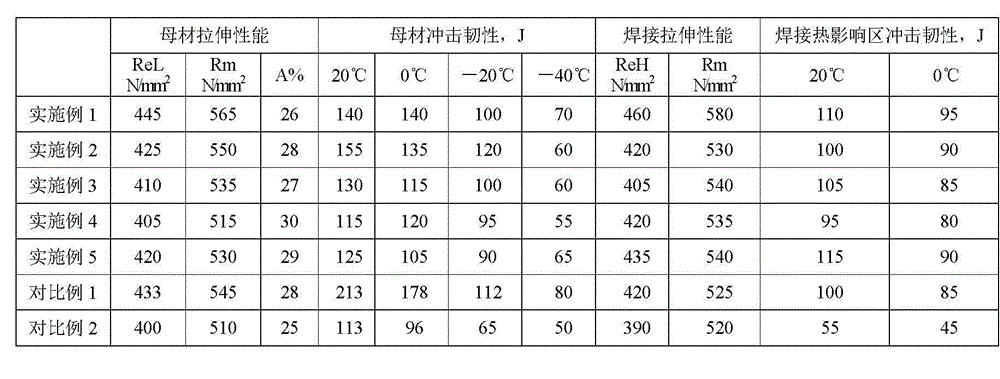

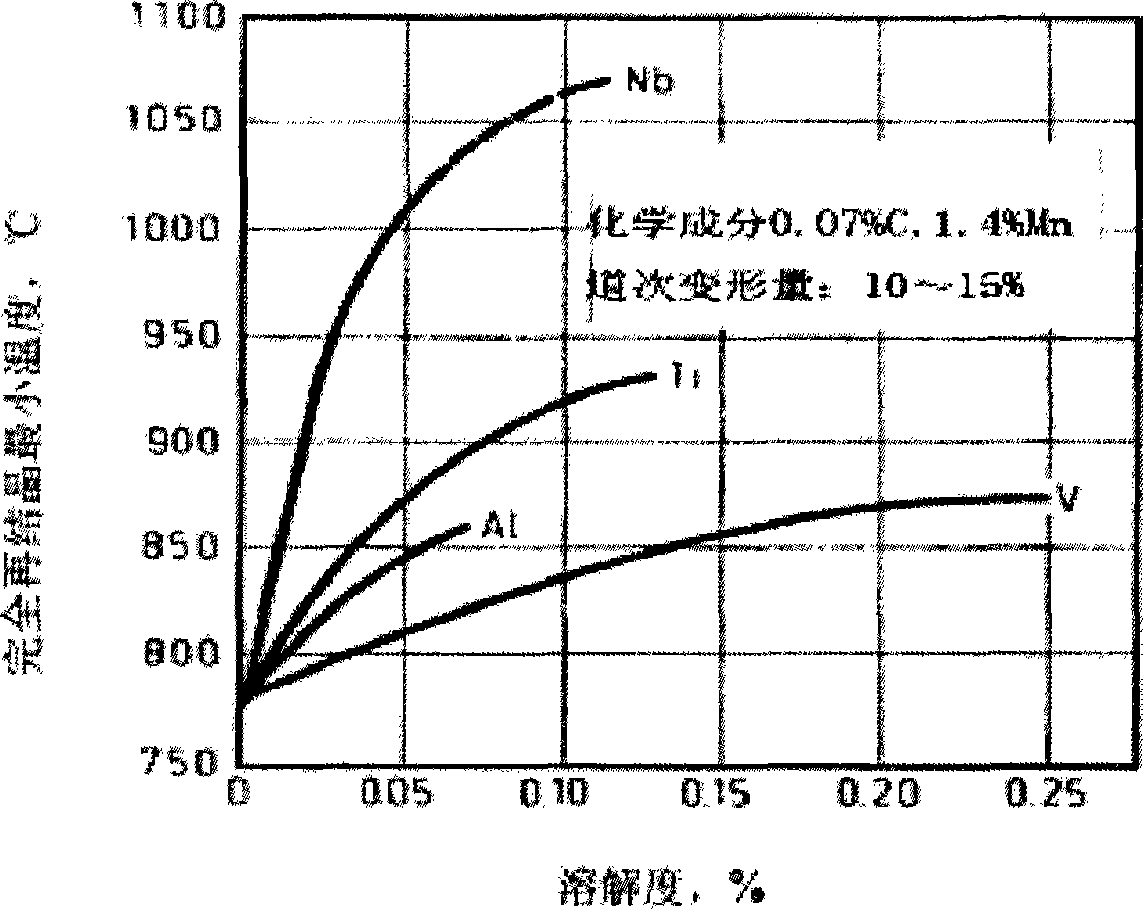

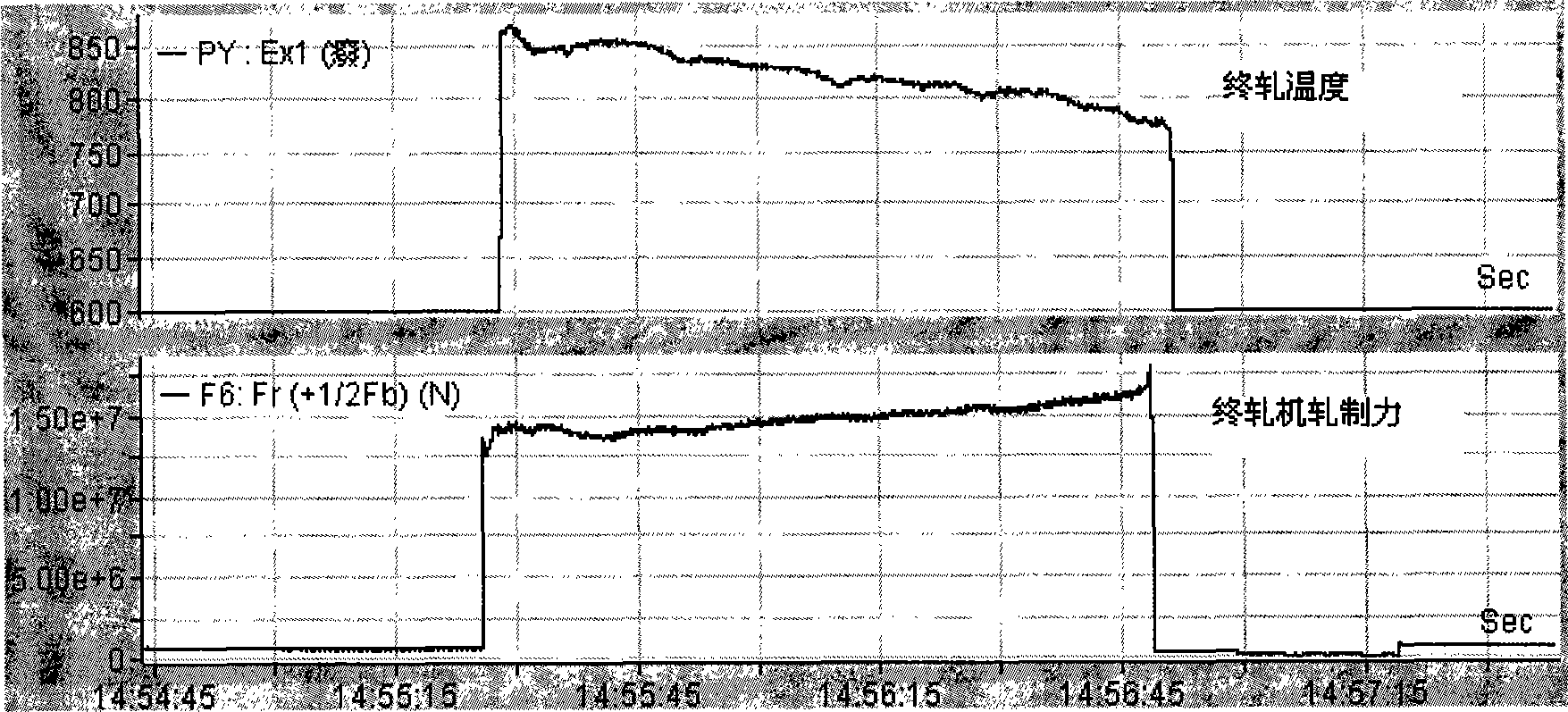

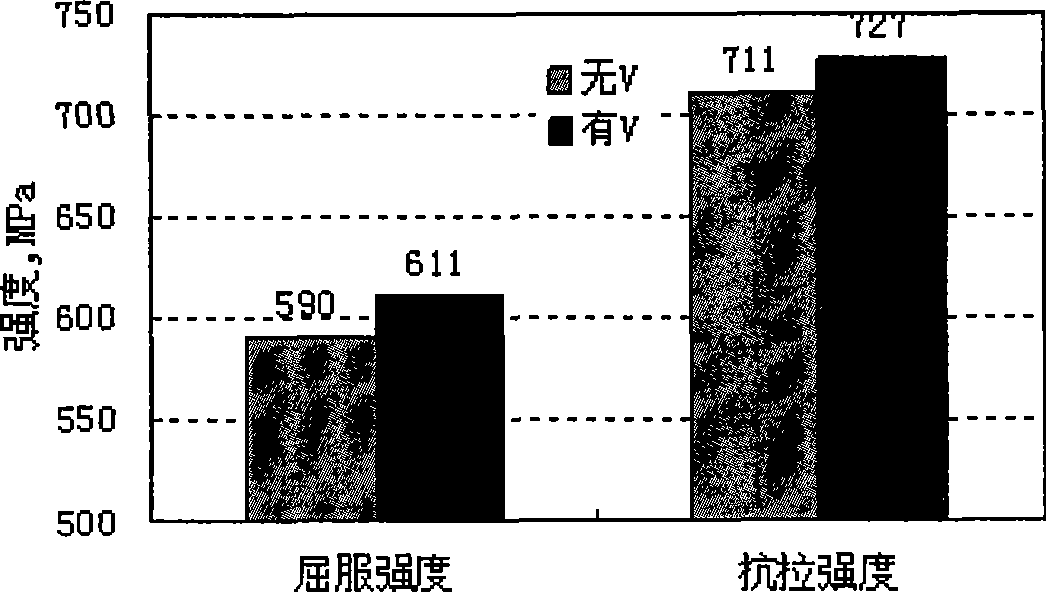

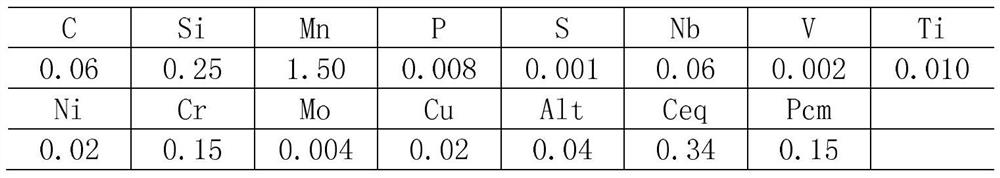

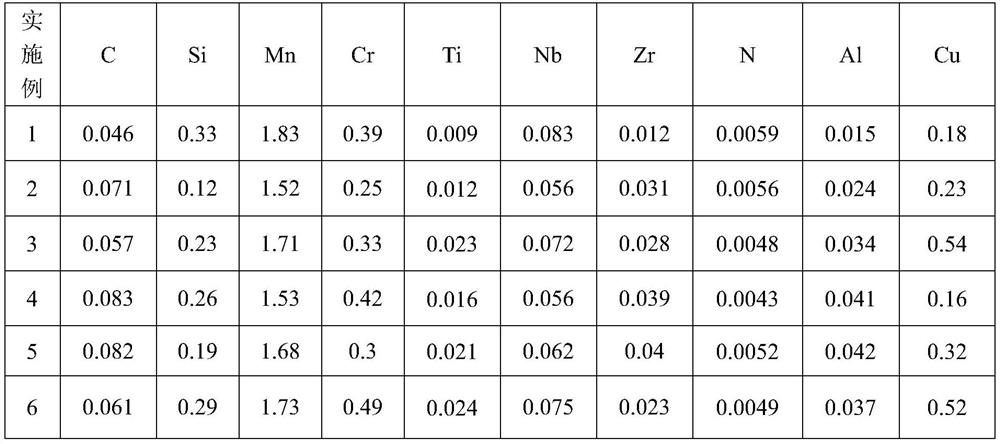

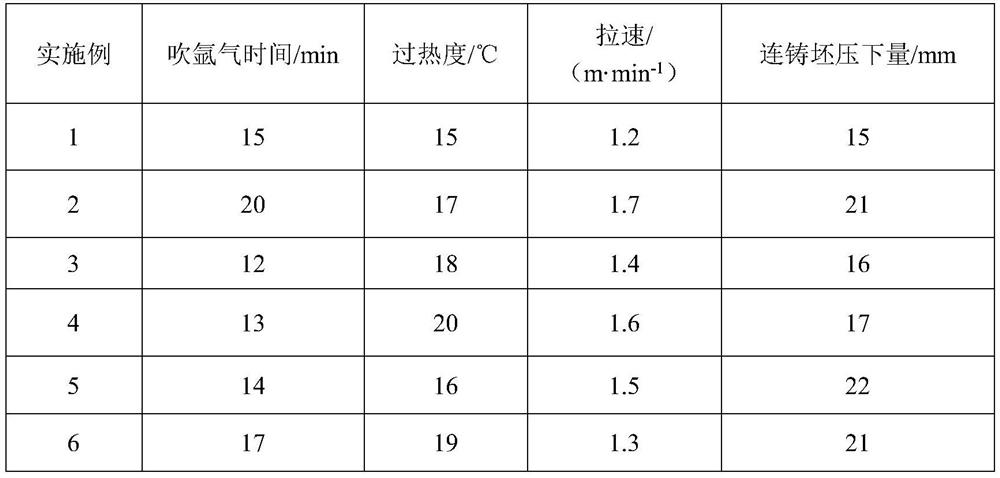

Steel plate for low-carbon high-niobium extra-high strength welding structure and method for manufacturing same

InactiveCN101619422ARaise the rolling temperatureIncrease productivityTemperature control deviceNiobiumRotary furnace

The invention provides a steel plate for a low-carbon high-niobium high strength welding structure. The steel plate comprises the following chemical components in percentage by weight: 0.015 to 0.075 percent of C, 0.20 to 0.50 percent of Si, 1.63 to 2.0 percent of Mn, 0.081 to 0.12 percent of Nb, 0.005 to 0.030 percent of Ti, 0.0005 to 0.0030 percent of B, 0.50 to 0.95 percent of Cr, 0.70 to 1.25 percent of Cu, 0.50 to 1.50 percent of Ni, 0.30 to 0.60 percent of Mo, 0.010 to 0.050 percent of Als, and the balance of Fe and inevitable impurities. The method for manufacturing the steel plate comprises the steps of molten iron pretreatment, rotary furnace smelting, refining, continuous casting and rolling, wherein the rolling process adopts the HTP plus RPC process, the heating temperature before rolling is between 1,140 and 1,220 DEG C, and two-stage controlled rolling is adopted. The steel plate is low in carbon content and high in Nb content, so that the initial rolling temperature of the non-recrystallization controlled rolling is increased, the temperature holding time is short, and the manufacturing efficiency is high; because the carbon content and the carbon equivalent are low, the welding performance is good; and with the HTP plus RPC plus annealing process, the steel plate for the welding structure with good toughness and plasticity and the yield strength more than or equal to 960N / mm<2> can be manufactured.

Owner:ANGANG STEEL CO LTD +1

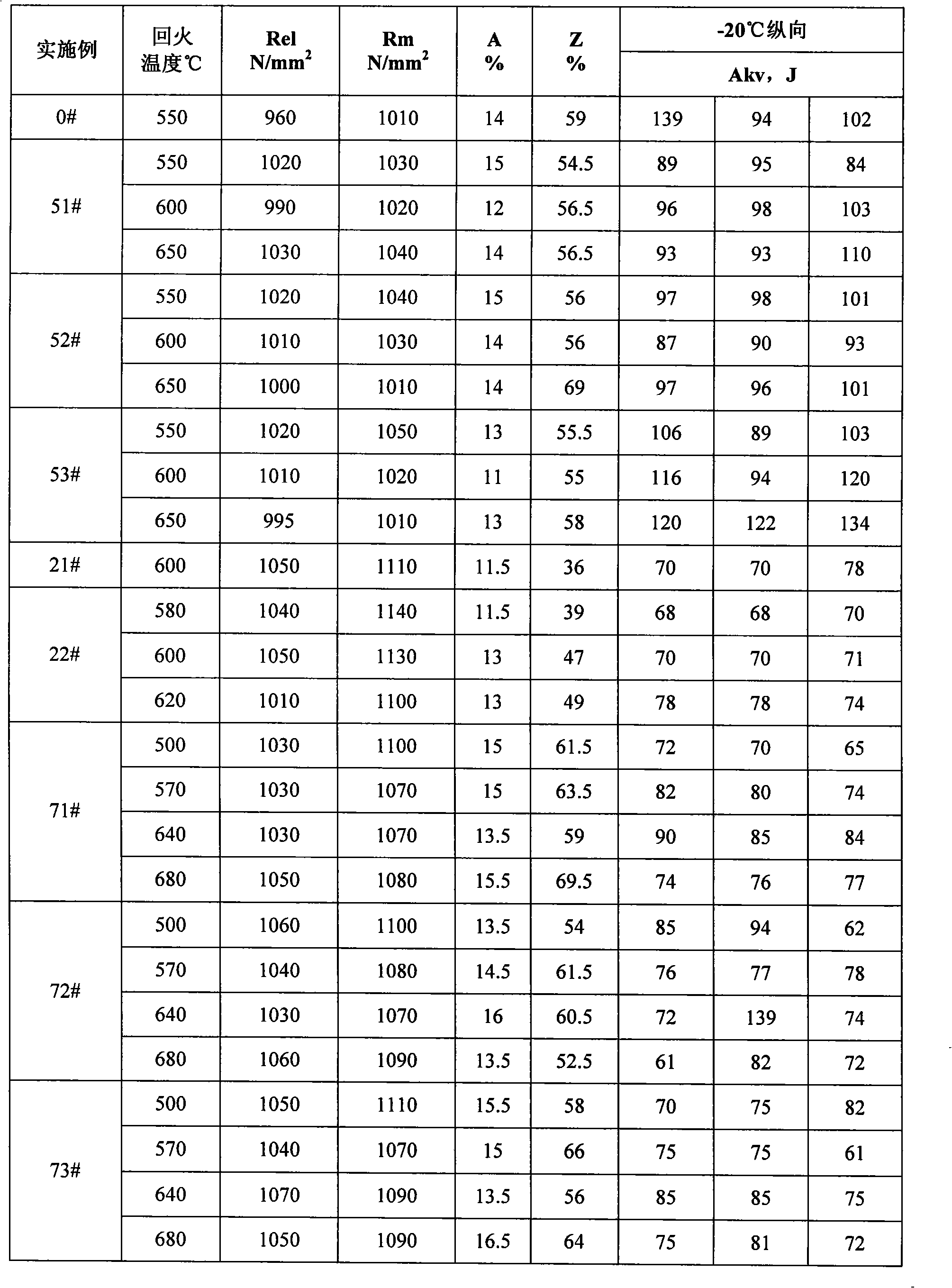

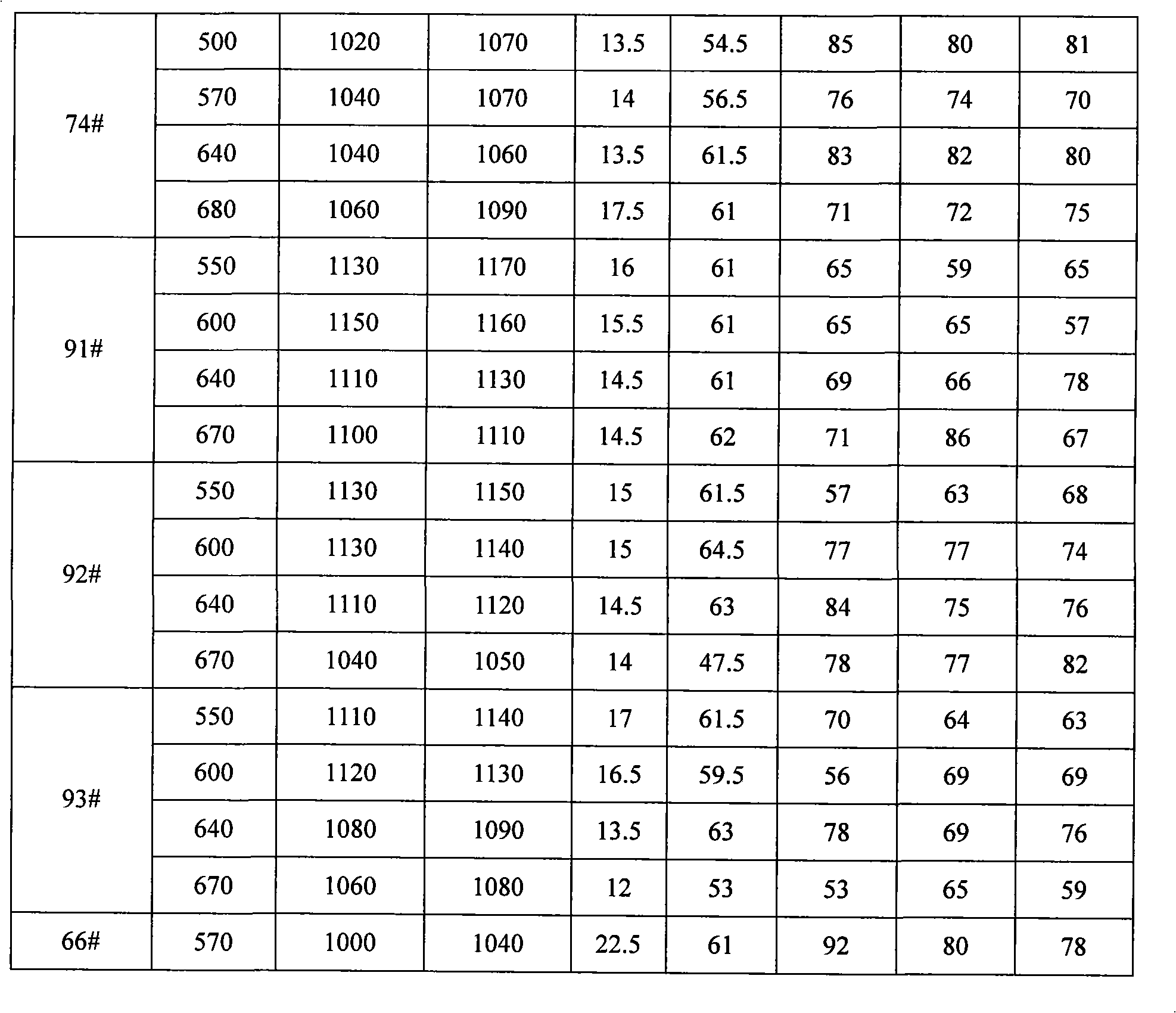

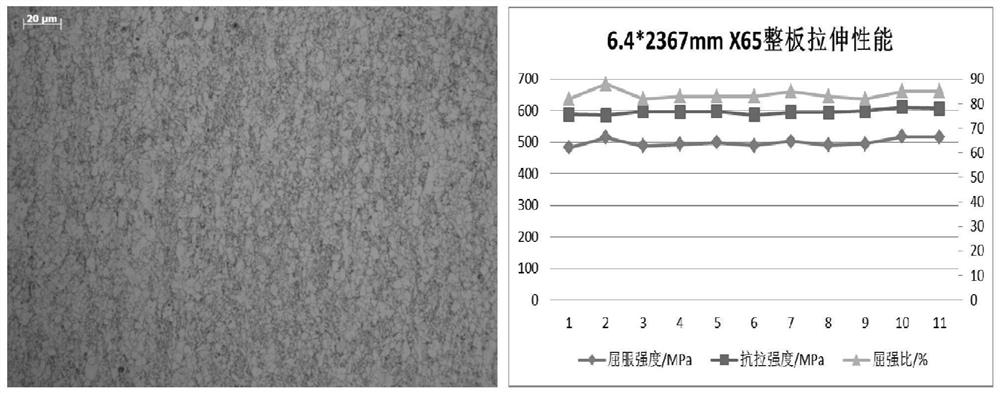

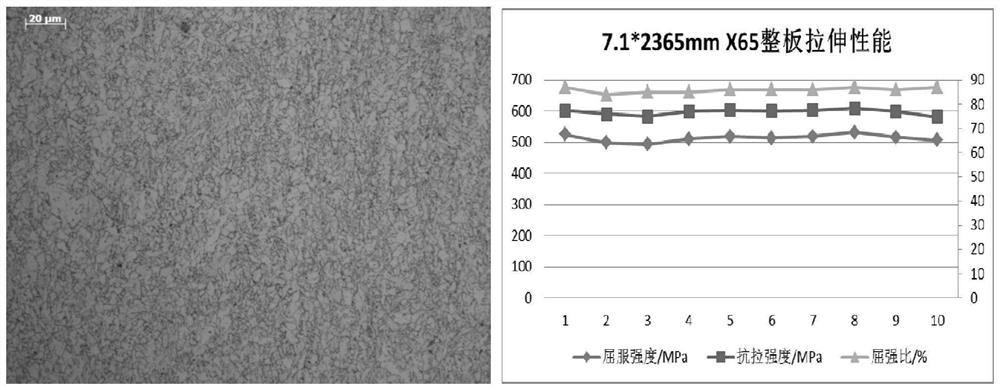

Thin-specification X65 steel-grade pipeline steel of single-stand steckel mill and rolling method

InactiveCN111790754AImprove temperature uniformityImprove the uniformity of mechanical propertiesTemperature control deviceTension/compression control deviceLine tubingRolling mill

The invention discloses thin-specification X65 steel-grade pipeline steel of a single-rack steckel mill and a rolling method. The steel is composed of the following components in percentage by weight:0.03 to 0.07 percent of C; 0.10 to 0.30 percent of Si, 1.30 to 1.70 percent of Mn, less than or equal to 0.015 percent of P, less than or equal to 0.0050 percent of S, 0.040 to 0.060 percent of Nb, less than or equal to 0.10 percent of V, 0.006 to 0.020 percent of Ti, 0.10 to 0.25 percent of Cr, less than or equal to 0.30 percent of Ni, less than or equal to 0.10 percent of Mo, less than or equalto 0.10 percent of Cu, 0.015 to 0.050 percent of Al and the balance of Fe and impurities. According to the rolling method, a blank with the thickness of 150 mm is used for producing the thin-specification pipeline steel plate with the finished product specification of (6-8) mm X65 grade. By controlling the tapping temperature, the coiling furnace temperature, the second-stage initial rolling temperature, the rough rolling final pass reduction rate, the final rolling speed, ACC cooling and the like, the thin-specification X65 steel-grade pipeline steel plate with the performance and the plateshape meeting the requirements is obtained, the productivity and the yield of a rolling mill are improved, and the performance percent of pass is high.

Owner:NANJING IRON & STEEL CO LTD

Base metal wire rod special for 1,420 MPa-level PC steel bar and preparation method of base metal wire rod

The invention discloses a base metal wire rod special for a 1,420 MPa-level PC steel bar and a preparation method of the base metal wire rod. The base metal wire rod is prepared from following chemical components in percent by mass including 0.27%-0.32% of C, 0.80%-1.00% of Si, 1.0%-1.20% of Mn, 0.010%-0.017% of Ti, smaller than or equal to 0.025% of P, smaller than or equal to 0.025% of S, smaller than or equal to 0.010% of Mo, smaller than or equal to 0.0060% of N, smaller than or equal to 2.0% of Si+Mn, larger than or equal to 160 of Si:N and the balance Fe and inevitable impurities. The preparation method of the base metal wire rod includes the procedures of heating, rough intermediate rolling, pre-finish rolling, precontrol cooling, finish rolling, control cooling, spinning and slow cooling. Through optimization design of the steel components and coupling control of the steel rolling process, the rolling starting temperature, the finish rolling entering temperature and the spinning temperature of steel are properly increased, slow cooling is adopted after rolling is completed, thus, the residual stress and the quantity of saturated N and C gap atoms of the rolled base metal wire rod special for the PC steel bar are reduced, the natural aging time is shortened, the aging comprehensive performance is improved, the requirements for manufacturing the PC steel bar by downstreamusers are met, and the quality accidents such as drawing breakage, quenching cracks, lag breakage and upset head cracking are avoided.

Owner:WUKUN STEEL

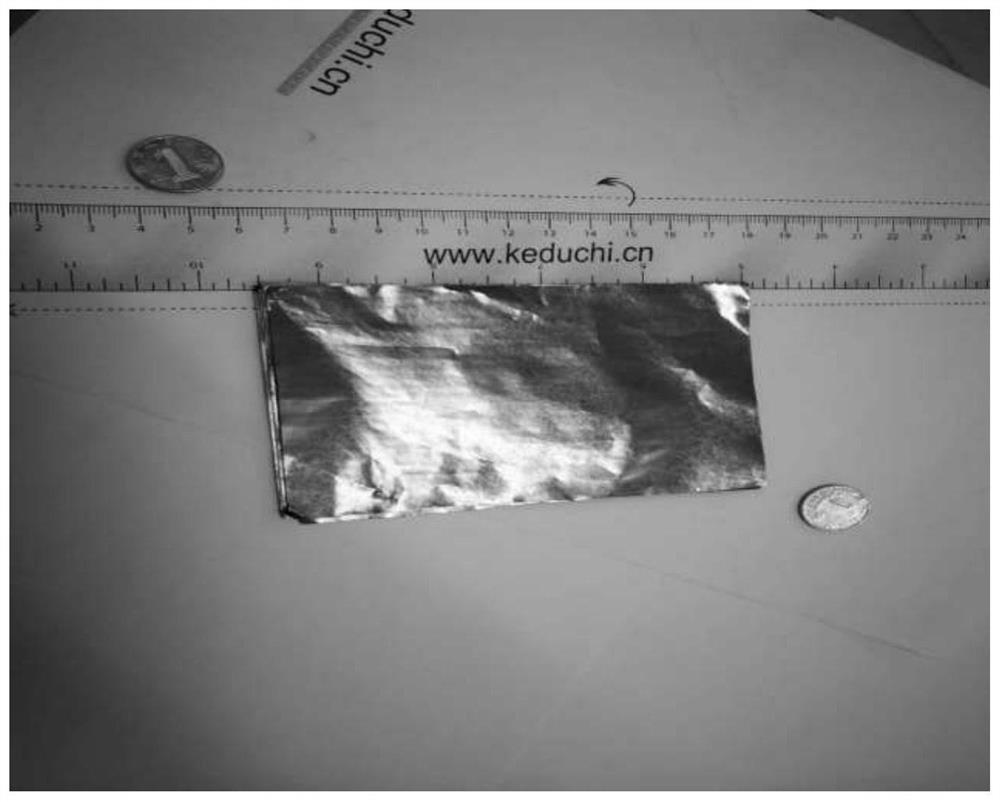

Heat conducting graphite paper and preparation method thereof

ActiveCN108373152AExpel as soon as possibleLow costGraphiteModifications by conduction heat transferHeat conductingPotassium dichromate

The invention relates to a preparation method of heat conducting graphite paper. The method comprises the following steps: mixing crystalline flake graphite with a sulfuric acid solution to obtain a first mixture; adding potassium dichromate powder into the first mixture to obtain a second mixture; washing the second mixture by using water to obtain a prefabricated product; placing the prefabricated product in a chamber, vacuumizing the chamber firstly, then introducing inert gas into the chamber and performing high-temperature expansion treatment to obtain an expanded graphite material; and carrying out rolling on the expanded graphite material at least once to obtain the heat conducting graphite paper. The invention further provides the heat conducting graphite paper.

Owner:乌兰察布市大盛石墨新材料股份有限公司

Method for manufacturing difficult-to-deform tin-bismuth alloy pre-formed soldering lug

ActiveCN109513747AImprove deformationGuaranteed normal processingMetal rolling arrangementsLow speedMaterial Crack

The invention discloses a method for manufacturing a difficult-to-deform tin-bismuth alloy pre-formed soldering lug. The method is characterized in that a core process adopts a two-section type temperature-regulating variable-speed and turning calendaring process, namely low-temperature high-speed large-rolling-reduction rough rolling and high-temperature low-speed small-rolling-reduction fine rolling; a temperature, speed and a rolling direction in a calendaring process are controlled, and other processes comprising low-temperature smelting, residual stress relief hot-levelling, rolling, cutting and the like are combined, so that high-efficiency manufacturing for the difficult-to-deform tin-bismuth alloy pre-formed soldering lug is realized. The manufacturing process for the pre-formed soldering lug can effectively solve the problems that a tin-bismuth alloy with intrinsic brittleness and difficult-to-deform characteristic easily generates material crack and the like in a large-deformation-amount processing process, and total deformation amount of the alloy can be 98% or more. The process is simple in flow, can greatly improve production efficiency of a tin-bismuth pre-formed lug,and reduces production energy consumption.

Owner:SHENZHEN XINGHONGTAI TIN +1

New energy power battery shell, aluminum alloy and manufacturing method thereof

PendingCN111647775AImprove plastic deformation abilityFulfil requirementsCell component detailsPower batteryMetallurgy

The invention provides a new energy power battery shell, an aluminum alloy and a manufacturing method thereof. The aluminum alloy is prepared from the following components in percentage by weight: 0.17 to 0.30 percent of Si, 0.50 to 0.60 percent of Fe, 0.02 to 0.08 percent of Cu, 0.90 to 1.05 percent of Mn, 0.02 to 0.06 percent of Mg, less than or equal to 0.05 percent, 0.015 to 0.04 percent of Ti, and the balance of Al and the unavoidable impurities with the single element of less than or equal to 0.05 percent and the total amount of less than 0.15 percent. The aluminum alloy provided by theinvention has good plastic deformation capacity, and can meet the requirement on deep drawability and the requirement on surface quality of the battery shell.

Owner:YINBANG CLAD MATERIAL

Hot rolling repairing method for corroded eccentric-wear waste oil pipe

InactiveCN111203685AHeating evenlyRaise the rolling temperatureMetal rolling arrangementsEconomic benefitsProcess engineering

The invention provides a hot rolling repairing method for corroded eccentric-wear waste oil pipes. According to the method, the screened waste oil pipes are taken as raw material pipes, a natural gasheating furnace is used for heating the waste oil pipes with the eccentric wear depth which is larger than 10% of the standard wall thickness and smaller than or equal to 40% of the standard wall thickness to 1250 DEG C, then two sets of three-roller beveling type hot rolling units are adopted for continuous hot rolling to perform uniform diameter expanding wall reducing treatment and uniform diameter reducing wall increasing treatment on the oil pipes, and finally cooling and precision forging sizing treatment are conducted. According to the method, the adopted natural gas heating furnace ensures uniform heating of the whole oil pipes, the cracking phenomenon caused by uneven heating in a traditional hot rolling repairing process is avoided, the repaired oil pipes meet related standard requirements, and remarkable economic benefits are achieved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

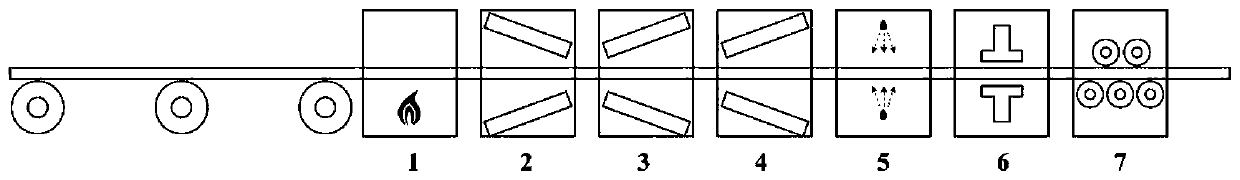

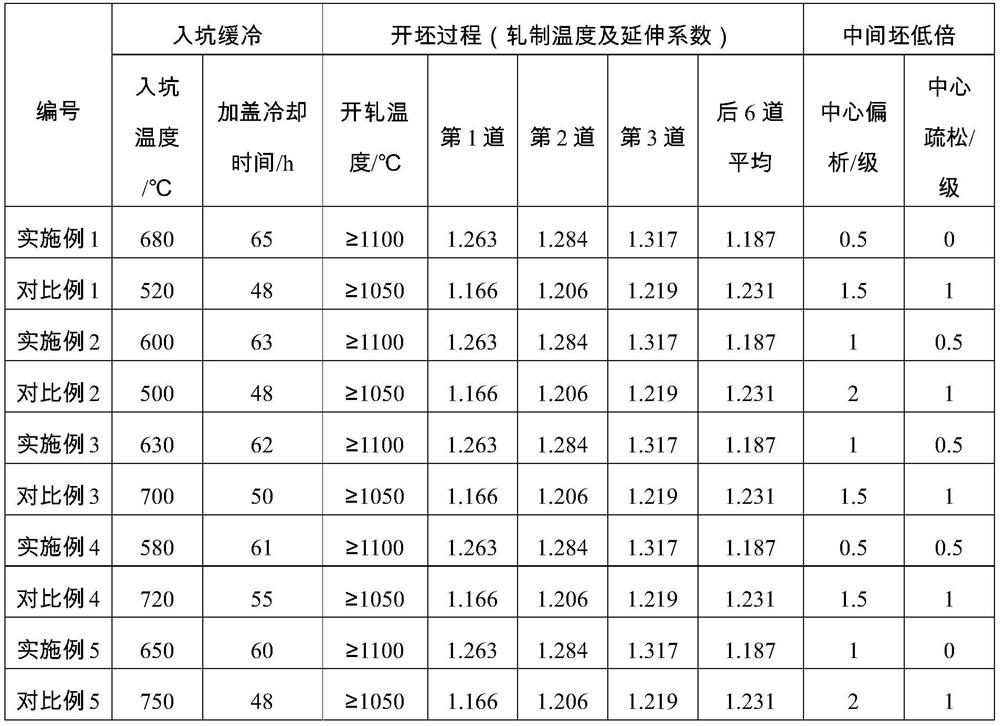

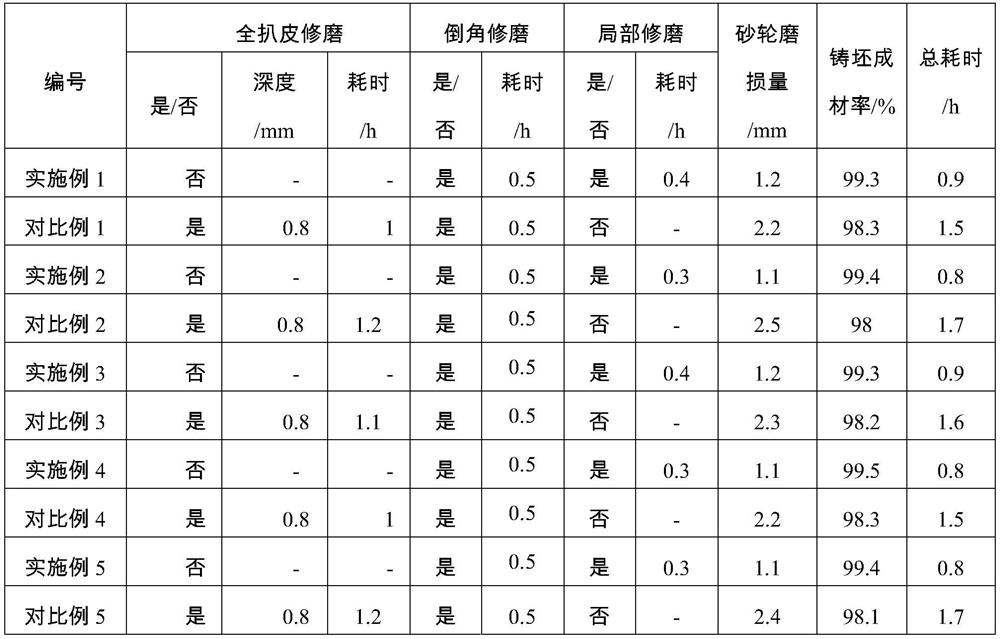

Technical method for improving quality of high-strength cable steel casting blanks

ActiveCN112322865AAvoid abnormal structures and surface and internal cracksReduce grinding amountEdge grinding machinesTemperature control deviceManufacturing engineeringSlow cooling

The invention discloses a technical method for improving the quality of high-strength cable steel casting blanks. The technical method comprises the steps that (1) the casting blanks enter a pit at the temperature of 550-680 DEG C to be slowly cooled, the blanks are stacked like a Chinese character 'jing', the blanks are subjected to capping cooling firstly at the cooling speed of 6-8 DEG C / h, andafter the temperature reaches 300 DEG C, the casting blanks are subjected to uncapping cooling to 200 DEG C or below and then taken out of the pit; (2) cogging is conducted, specifically, the castingblanks are heated and then rolled, and the initial rolling temperature is larger than or equal to 1100 DEG C; (3) shot blasting flaw detection is carried out, specifically, the shot diameter is 0.5-1.0 mm, and the shot blasting advancing speed of the casting blanks is 0.2-0.3 m / s; and (4) local coping is conducted, specifically, the coping modes include mechanical point coping and chamfer coping.According to the technical method, for the high-strength cable steel casting blanks, the temperature of pit entry for slow cooling and the cooling speed are controlled, and thus generation of abnormal structures, surface cracks and internal cracks of the casting blanks is effectively avoided; and by adoption of mechanical point coping and chamfer coping, the yield and the production efficiency are improved, and the comprehensive benefit is remarkable.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE +2

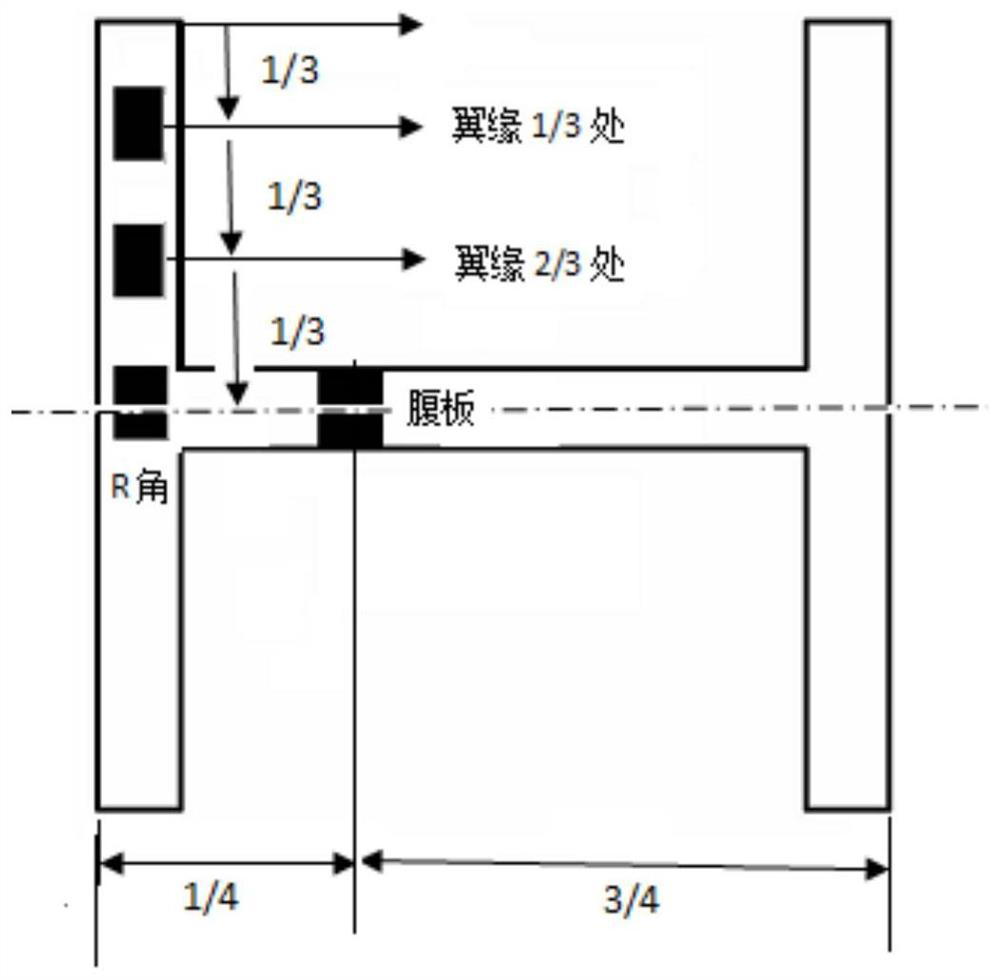

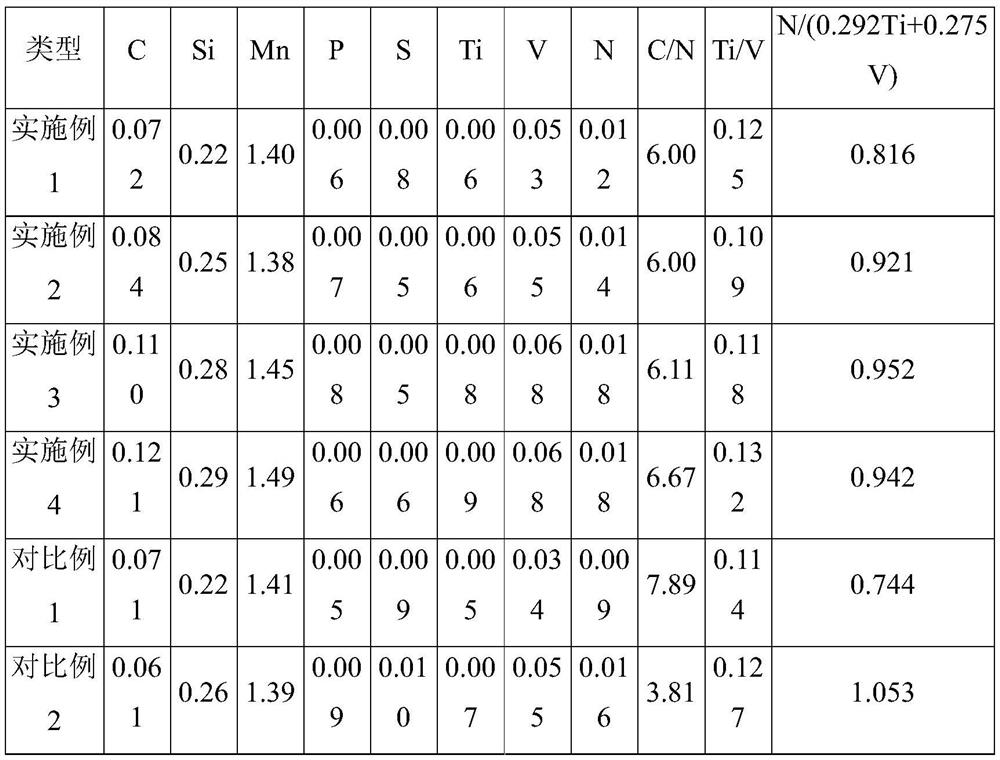

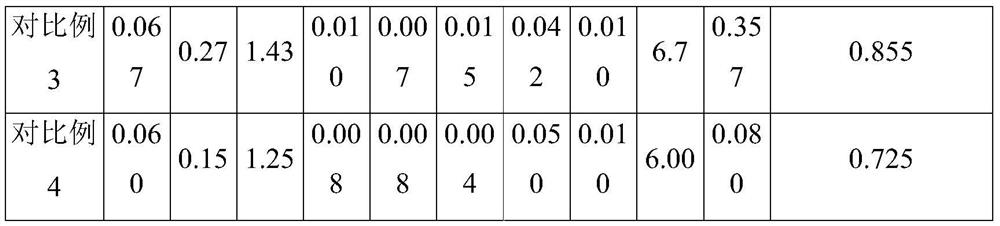

V-N microalloyed 550 MPa hot-rolled thick-wall H-shaped steel and production process thereof

ActiveCN112746221APromote precipitationIncrease the precipitation strength effectTemperature control deviceFurnace typesThick wallUltimate tensile strength

The invention relates to V-N microalloyed 550 MPa hot-rolled thick-wall H-shaped steel and a production process thereof, belongs to the technical field of building structural steel, and solves the problem that the use requirements for high strength (yield strength is greater than or equal to 550 MPa), high toughness (impact energy at -40 DEG C is greater than or equal to 150 J) and uniform section performance of the hot-rolled thick-wall H-shaped steel cannot be met in the prior art. The V-N microalloyed 550 MPa hot-rolled thick-wall H-shaped steel comprises the following chemical components including, by mass, 0.07%-0.13% of C, 0.20%-0.30% of Si, 1.35%-1.55% of Mn, less than or equal to 0.020% of P, less than or equal to 0.015% of S, 0.04%-0.07% of V, 0.005%-0.010% of Ti, 0.011%-0.022% of N and the balance Fe and inevitable impurities. Through the V-N microalloying effect, high strength and high toughness are guaranteed, and meanwhile the uniformity of the section performance of the thick-wall H-shaped steel is enhanced.

Owner:CENT IRON & STEEL RES INST +1

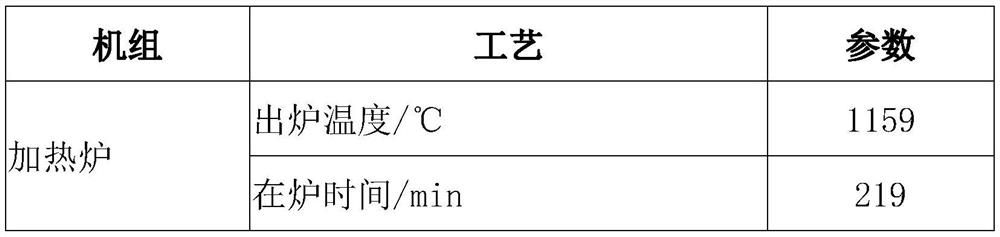

TMCP steel plate tail plate shape control method

PendingCN113617854AReduce waiting timeRaise the rolling temperatureProfile control deviceMetallurgyEngineering

The invention discloses a TMCP steel plate tail plate shape control method. The method comprises the following steps that S1, in a heating process stage, tapping temperature and in-furnace time are set according to the thickness of a steel plate; S2, in the rough rolling process stage, the reduction rate, the rolling speed and the accelerated speed of the final pass are controlled; S3, between the rough rolling process stage and the finish rolling process stage, the temperature waiting time of the steel plate is controlled according to the thickness of the steel plate, the rolling starting temperature of the steel plate in the finish rolling process stage is increased, and the temperature waiting time is shortened; S4, in the finish rolling process stage, the reduction rate, the rolling speed and the accelerated speed of the final pass are controlled; and S5, in the MULPIC online cooling process stage, shielding parameters of the tail of the steel plate are set according to the thickness of the steel plate. Through reasonable steel plate heating, rough rolling process, finish rolling process and MULPIC online cooling process, supercooling of the tail plate shape of the steel plate is avoided, the transition uniformity of the tail temperature of the steel plate is improved, the good tail plate shape of the steel plate is obtained after the steel plate is cooled by the MULPIC, and the influence of the poor tail plate shape on the subsequent production efficiency of the steel plate is reduced.

Owner:BAOSTEEL ZHANJIANG IRON & STEEL CO LTD

Ultra-low iron loss non-oriented silicon steel and production method thereof

ActiveCN114045433AReduce iron lossGuaranteed MagneticFurnace typesHeat treatment furnacesMolten steelSilicon

The invention discloses an ultra-low iron loss non-oriented silicon steel and a production method thereof. The production method comprises the steps that adopting molten iron desulfurization, converter smelting and RH furnace refining sequentially for steel smelting, and finally obtaining molten steel which comprises, by mass percent, smaller than or equal to 0.003% of C, 2.8%-3.4% of Si, 0.1%-0.5% of Mn, 0.6%-1.3% of Al, smaller than or equal to 0.0015% of S, smaller than or equal to 0.0020% of N, smaller than or equal to 0.03% of P, smaller than or equal to 0.003% of Ti, smaller than or equal to 0.003% of V and smaller than or equal to 0.003% of Nb, the sum of Si and Al is larger than or equal to 3.80% and smaller than or equal to 4.15%, and the balance of Fe and inevitable impurities; continuously casting molten steel obtained by smelting into a continuous casting blank; heating the continuous casting blank, and performing multi-pass rolling to obtain a hot-rolled coil plate; shearing the two side parts of the hot-rolled coil plate; carrying out normalizing pickling, wherein the normalizing temperature ranges from 900 DEG C to 930 DEG C, and the normalizing time ranges from 30 s to 60 s; and obtaining the non-oriented silicon steel with the thickness of 0.35-0.5 mm through multi-pass cold rolling, wherein the reduction rate during first-pass cold rolling is larger than or equal to 37%, and the rolling speed ranges from 70 m / min to 180 m / min. The non-oriented silicon steel prepared by the method has ultralow iron loss and is not easy to break during cold rolling.

Owner:ZHANGJIAGANG YANGTZE RIVER COLD ROLLED PLATE CO LTD +2

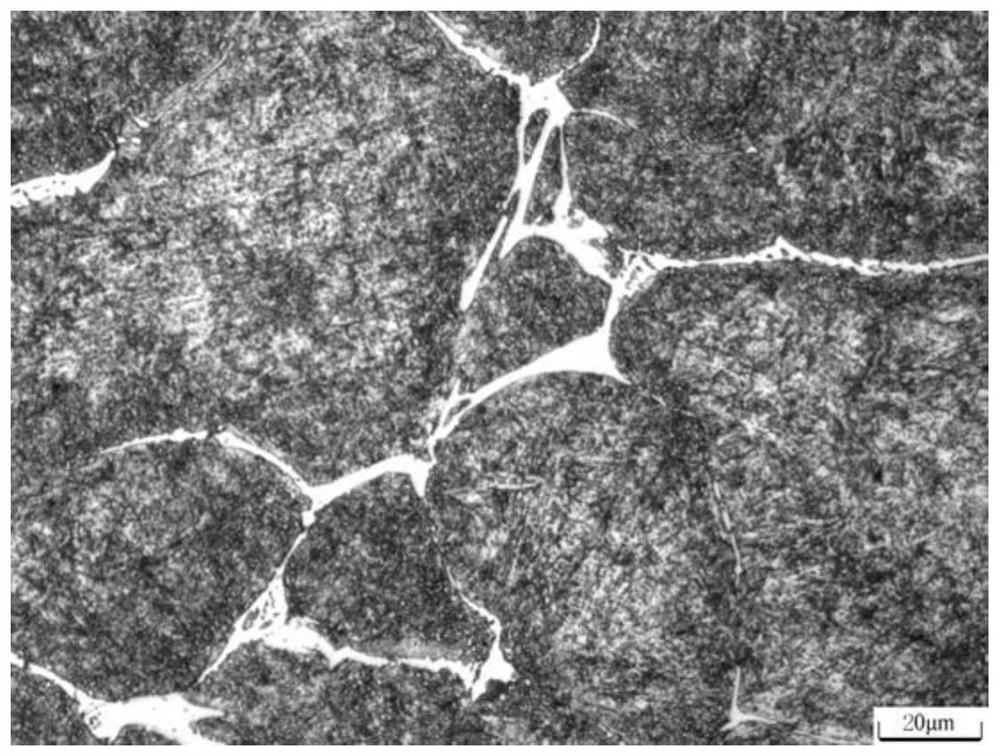

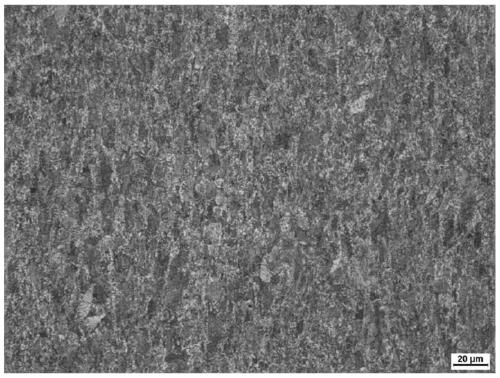

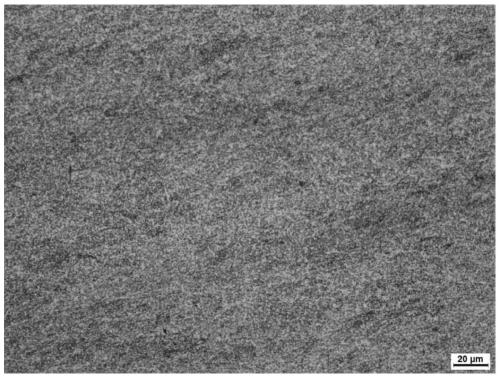

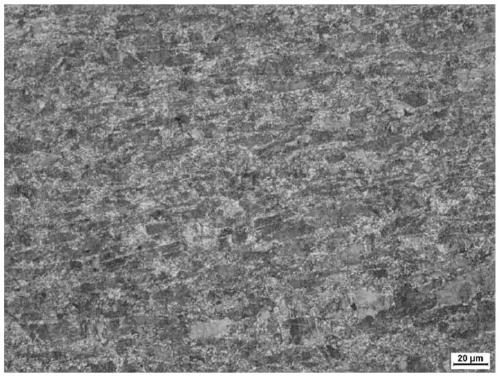

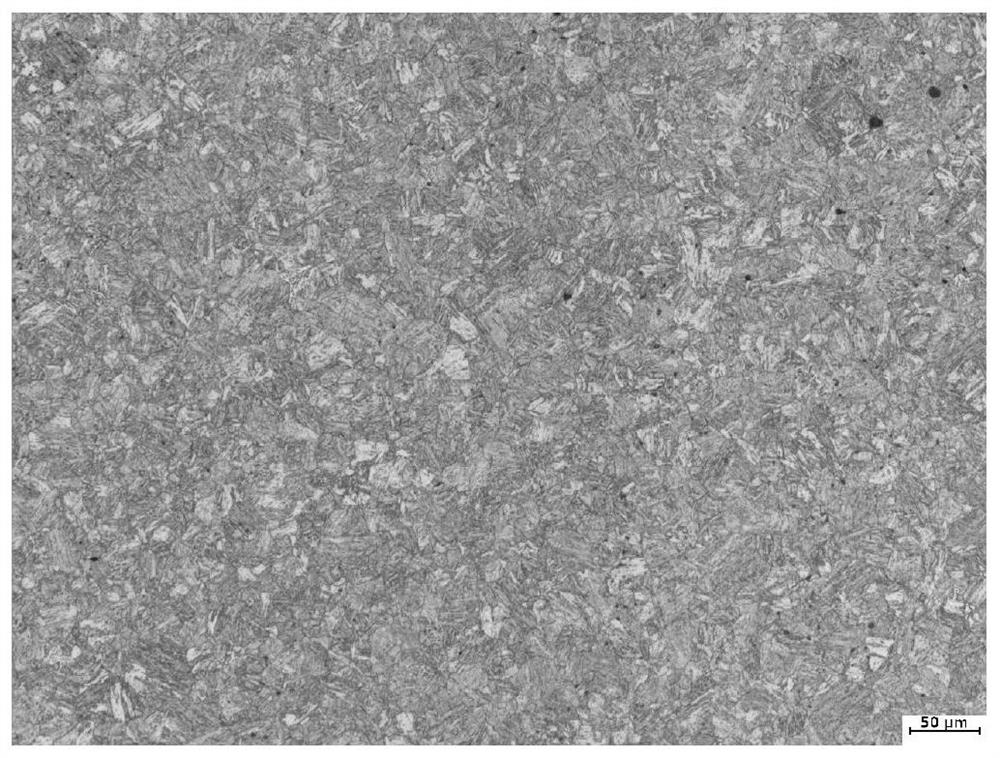

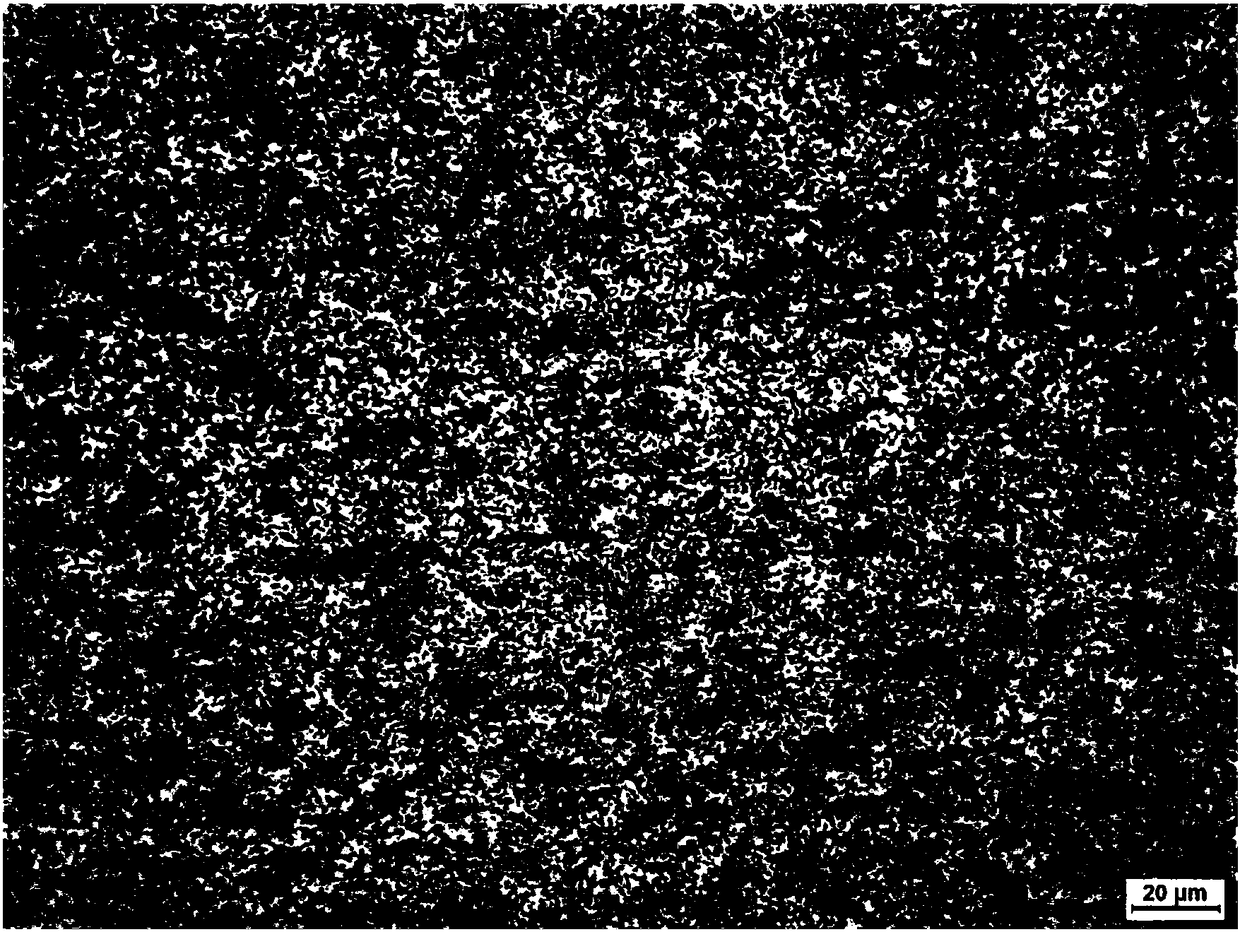

Method for preparing GCr15 bearing steel through rolling-isothermal spheroidizing annealing treatment

InactiveCN110283975AFast dissolutionIsothermal spheroidizing annealing is beneficial toReduction rateAdditive ingredient

The invention provides a method for preparing GCr15 bearing steel through rolling-isothermal spheroidizing annealing treatment. The method comprises the following steps of (1) conducting smelting-casting according to GCr15 bearing steel ingredients and conducting isothermal treatment on a casting blank at 1000+ / -5 DEG C; (2) conducting single-pass hot rolling at 1000+ / -5 DEG C; (3) conducting cold-cooling on a hot rolled plate to 780+ / -5 DEG C and then conducting multi-pass warm rolling at the total reduction rate of 60-70%; (4) placing a warm rolled plate at 760+ / -5 DEG C in an isothermal thermal treatment furnace and then conducting furnace cooling; and (5) heating the thermal treatment furnace to 820+ / -5 DEG C and conducting primary isothermal treatment; conducting cooling to 720+ / -5 DEG C and conducting secondary isothermal treatment; and conducting cooling to 600+ / -5 DEG C and then taking out the rolled plate to be subjected to air cooling. Through the method, the good spheroidized structure can be formed just through short-time isothermal treatment, the isothermal time of the technological process is short, energy consumption is low, and the production efficiency is high.

Owner:NORTHEASTERN UNIV

Thermally conductive graphite paper and preparation method thereof

ActiveCN108373152BExpel as soon as possibleLow costGraphiteModifications by conduction heat transferHeat conductingPotassium dichromate

The invention relates to a preparation method of heat conducting graphite paper. The method comprises the following steps: mixing crystalline flake graphite with a sulfuric acid solution to obtain a first mixture; adding potassium dichromate powder into the first mixture to obtain a second mixture; washing the second mixture by using water to obtain a prefabricated product; placing the prefabricated product in a chamber, vacuumizing the chamber firstly, then introducing inert gas into the chamber and performing high-temperature expansion treatment to obtain an expanded graphite material; and carrying out rolling on the expanded graphite material at least once to obtain the heat conducting graphite paper. The invention further provides the heat conducting graphite paper.

Owner:乌兰察布市大盛石墨新材料股份有限公司

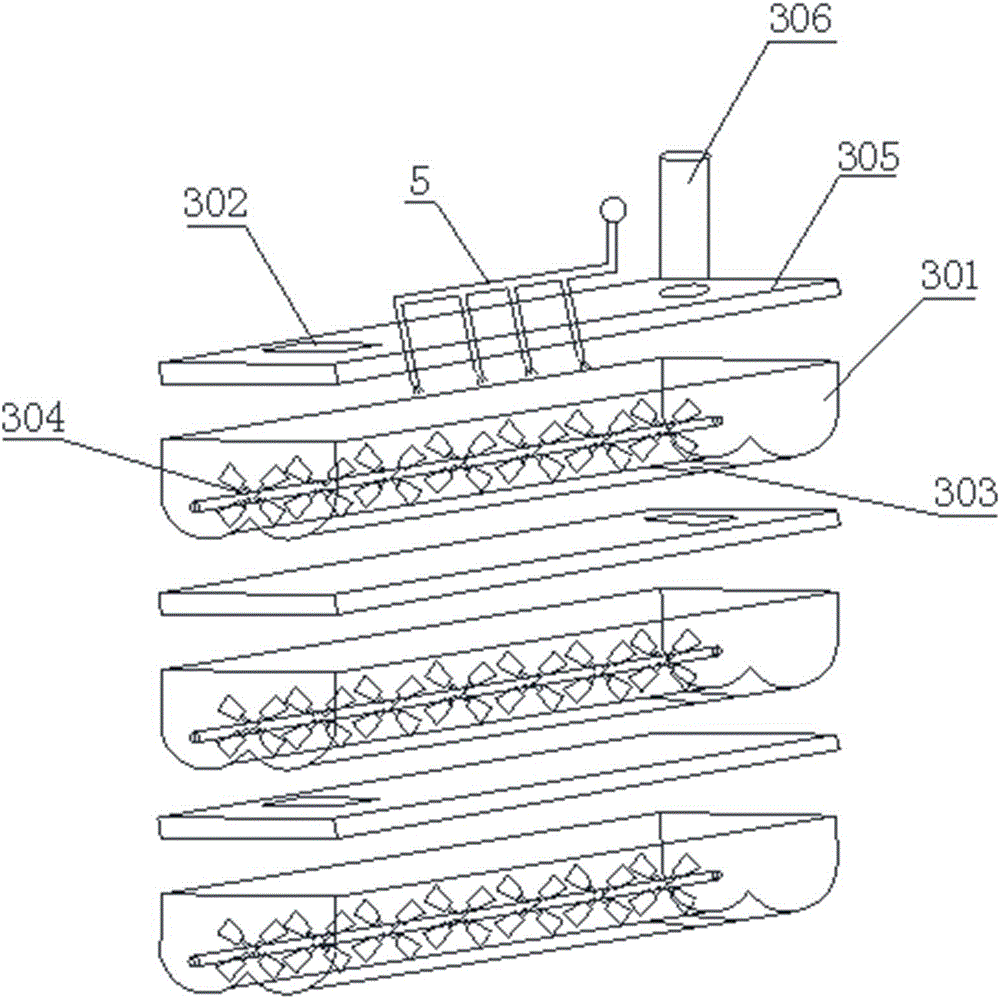

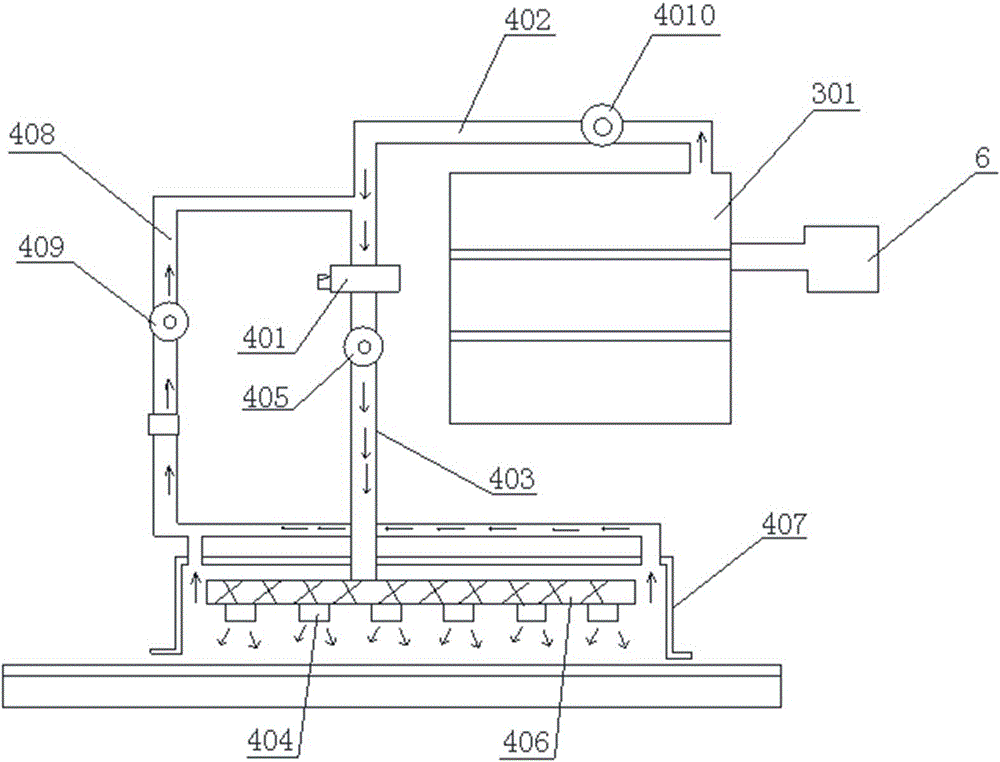

A high-end passenger ferry steel with a thickness of less than 12mm and its manufacturing method

Owner:NANJING IRON & STEEL CO LTD

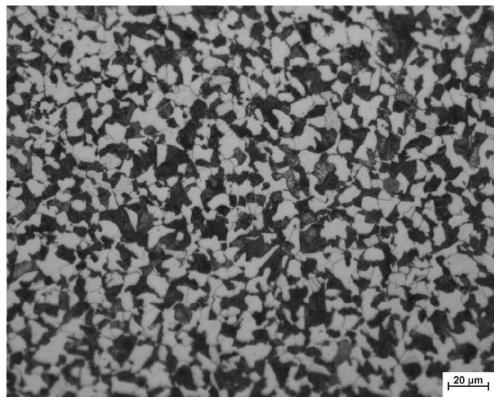

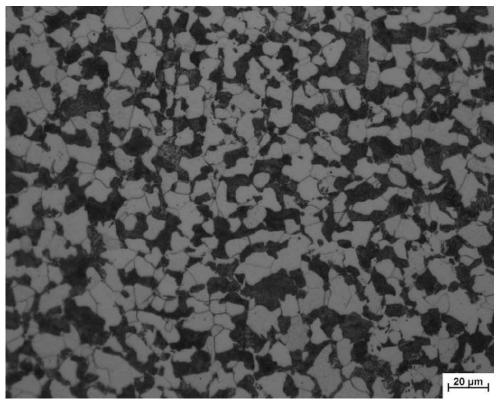

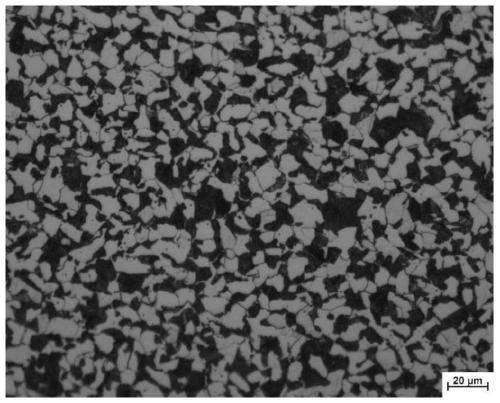

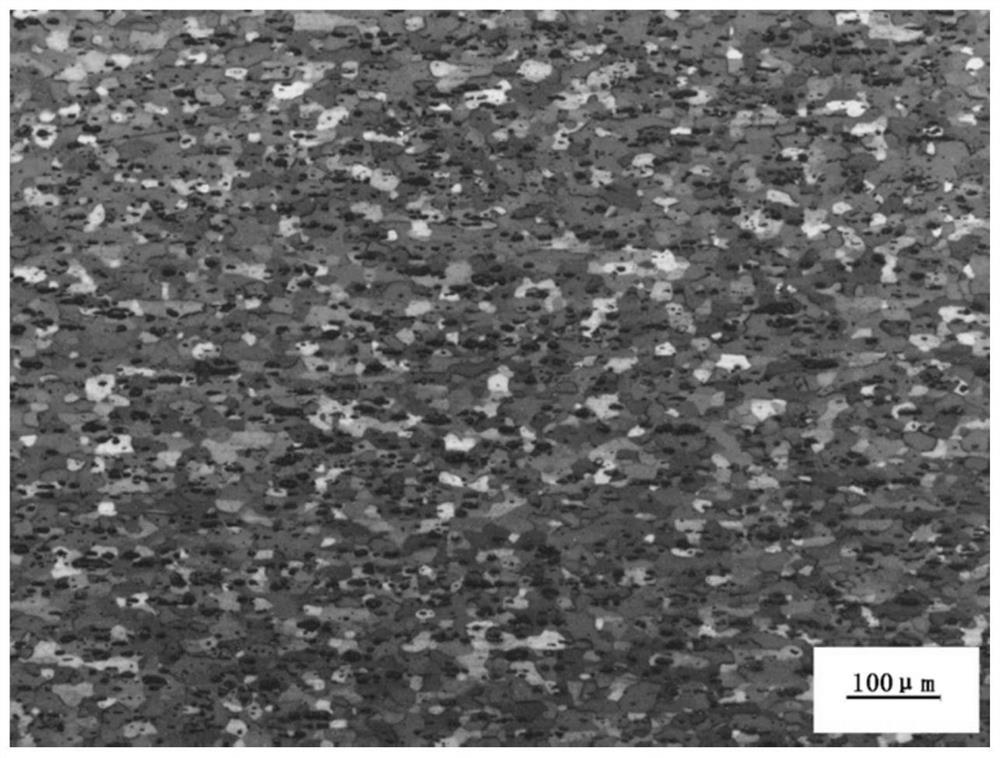

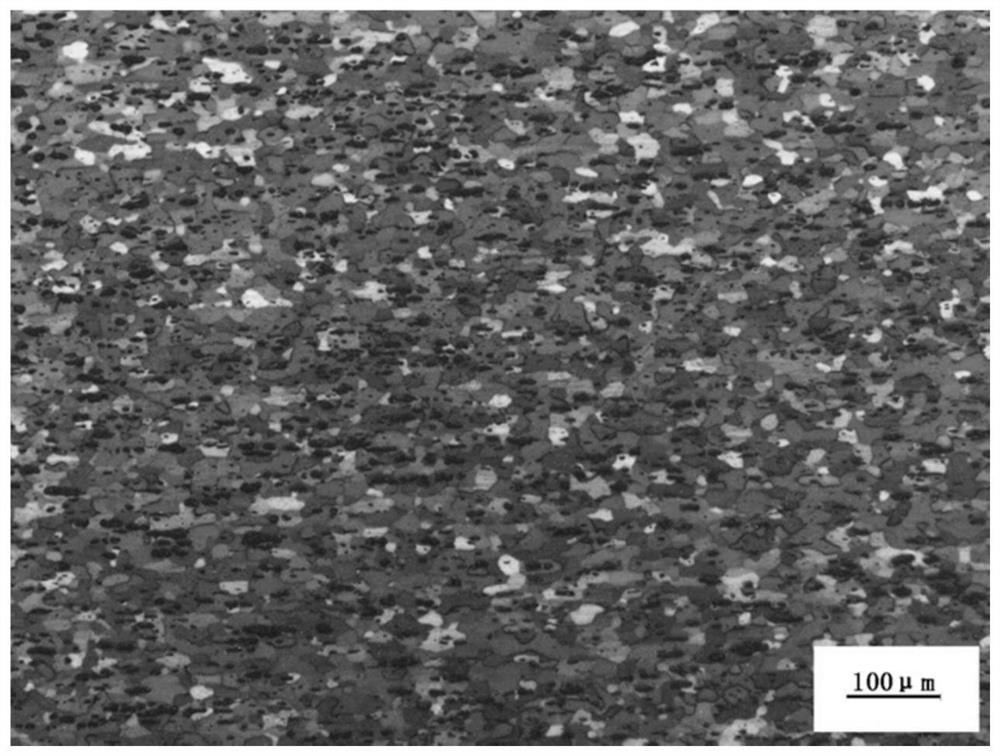

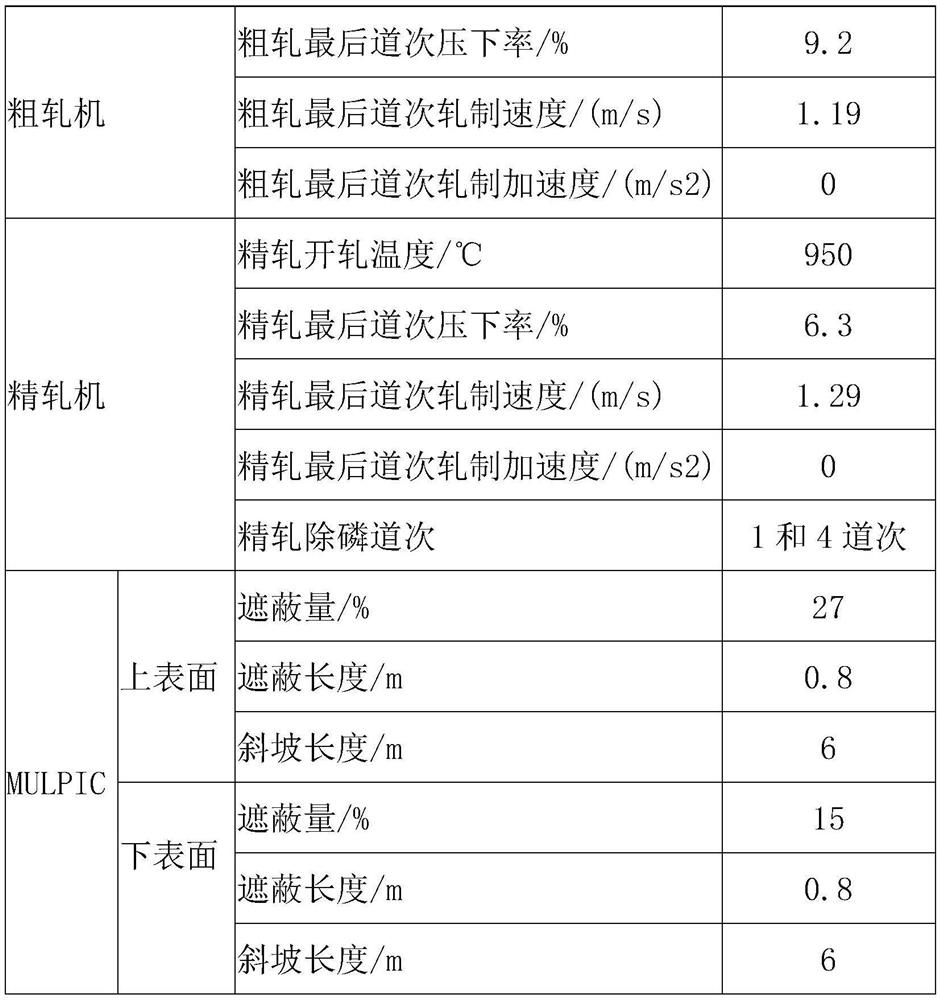

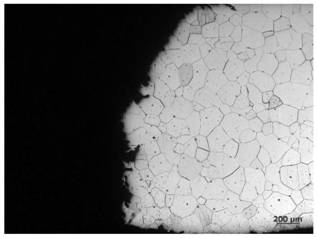

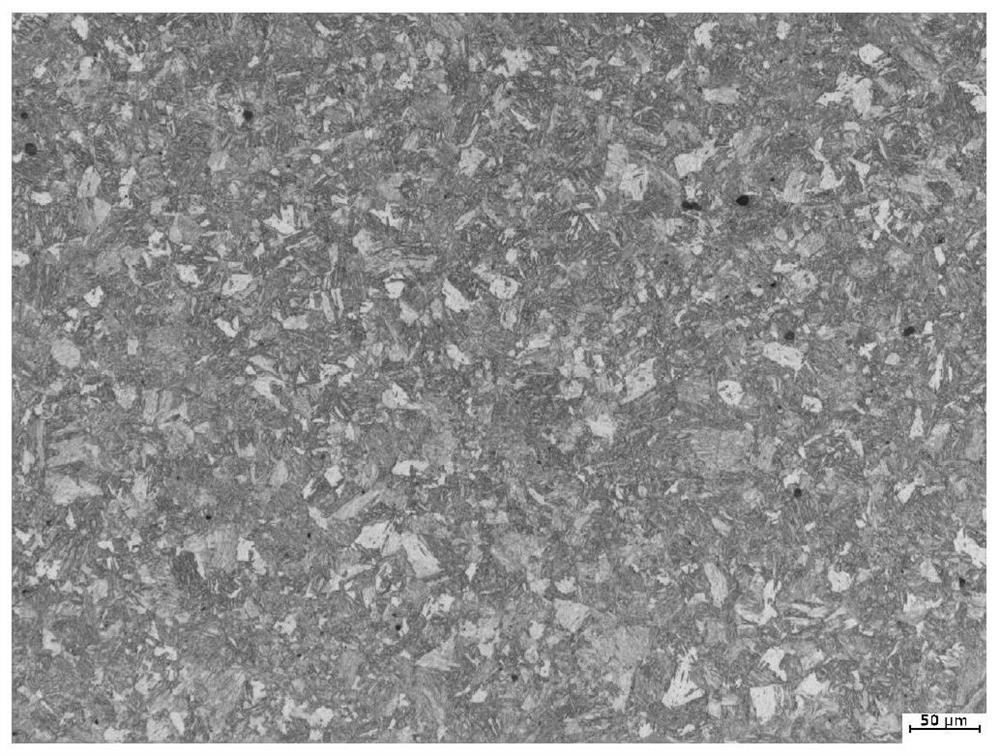

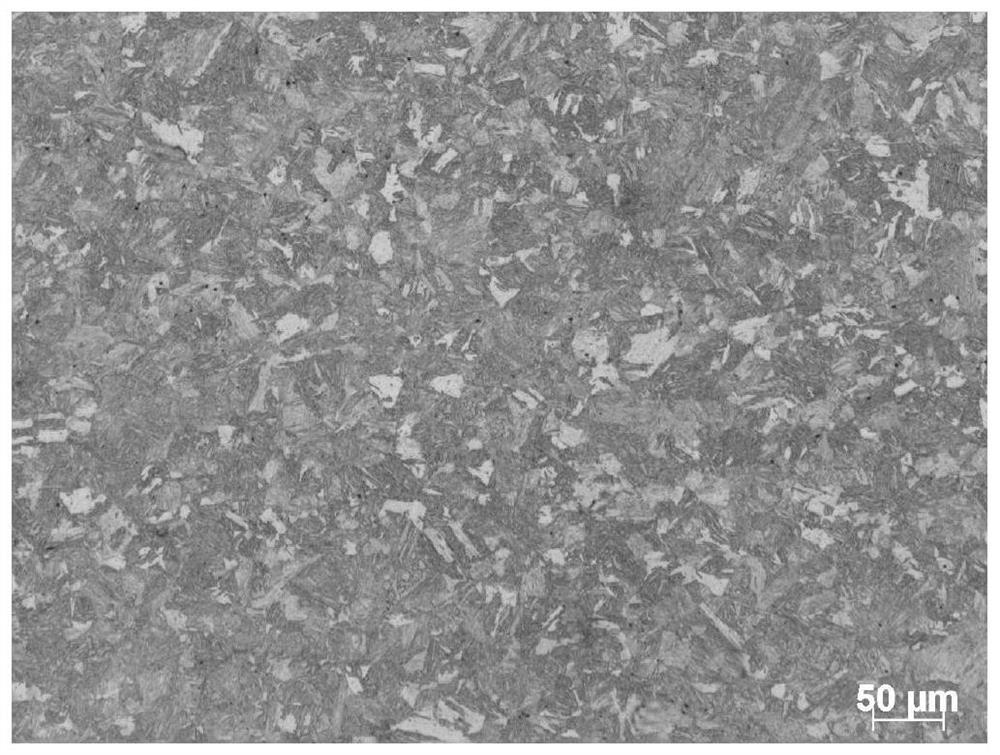

A kind of on-line rapid spheroidizing annealing method of gcr15 bearing steel after hot rolling

The invention belongs to the field of heat treatment of bearing steel, and particularly relates to an online rapid spheroidizing annealing method after hot rolling of GCr15 bearing steel. In order to solve the problem of too long spheroidization time in the existing GCr15 bearing steel during the spheroidization process, through the reasonable selection of rolling temperature and the use of optimized spheroidization process, the proeutectoid carbides during the rolling process are controlled. Precipitation through deformation induction shortens the time required for spheroidizing annealing and improves energy efficiency. The method of the present invention adopts an online spheroidizing annealing method, and only requires a short subsequent spheroidizing treatment time to form a relatively good spheroidized structure. From the observation and analysis of the metallographic structure, the structure after spheroidizing annealing is fine ferrite and fine dispersed spherical carbide particles. The spheroidization grade can reach level 1, the hardness is 200HV, and the hardness also meets the usage requirements.

Owner:NORTHEASTERN UNIV LIAONING

Plain carbon steel wire rod for wire drawing and production process

ActiveCN113680816AExcellent drawing performanceRapid coolingMetal rolling arrangementsWire rodSpinning

The invention discloses a plain carbon steel wire rod for wire drawing. The plain carbon steel wire rod has the steel mark of Q235L and comprises the following components of, by mass, 0.14%-0.18% of C, 0.12%-0.30% of Si, 0.40%-0.60% of Mn, less than or equal to 0.035% of P, less than or equal to 0.035% of S, less than or equal to 0.005% of N, and the balance iron. The invention further discloses a production process of the plain carbon steel wire rod for wire drawing. The production process comprises the following steps of adjusting the initial rolling temperature from 980-1030 DEG C to 1000-1050 DEG C; adjusting the temperature of a finishing mill group from 950 + / -20 DEG C to 1000 + / -10 DEG C; adjusting the spinning temperature from 930 + / -20 DEG C to 1040 + / -10 DEG C; and adjusting the speed of an air cooling line roller way from 0.18 m / s to 0.40 m / s. After adjustment, the tensile strength of the wire rod produced by using the process is 437 MPa, the elongation is 32.5%, the grain size is 8.0 grade, and the thickness of scale on the surface of the wire rod is 24-30 microns; and the drawing wire breakage rate of a downstream user is reduced from 5-6 times per disc to 1-2 times per disc, or the phenomenon of wire breakage does not exist.

Owner:TIANJIN IRON & STEEL GRP

A layered heating method for in-situ thermal regeneration of asphalt pavement

The present invention discloses an asphalt pavement hot in-place recycling layered heating method comprising the following steps: a pavement recycled material harrowed by heating is collected and mixed with new asphalt to obtain a regenerated mixture; the regenerated mixture is first put into a heating mixing device for the first time heating mixing, and then sent to another heating mixing device for second time heating mixing, the heating mixing is repeated for multiple times until the regenerated mixture is heated from original 70-80 DEG Cto 140-160 DEG C; and the mixed heated regenerated mixture is directly discharged, and received by a followed pavement paver, and the regenerated mixture is paved on a recycled pavement, and finally is compacted by a road roller. The temperature of the regenerated mixture heated by the regenerated mixture layered heating method is raised to 140-160 DEG C, the final paving rolling temperature is enhanced; and asphalt smoke dust and a large quantity of heat generated by the heating are recycled, and waste flue gas is reused after recycling combustion.

Owner:嘉鹏精工科技(大连)有限公司

An economical thick-walled high-strength toughness x70m hot-rolled steel plate and its manufacturing method

Owner:ANGANG STEEL CO LTD

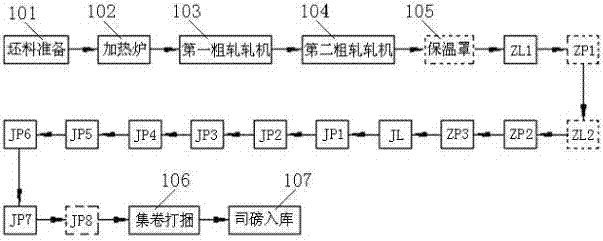

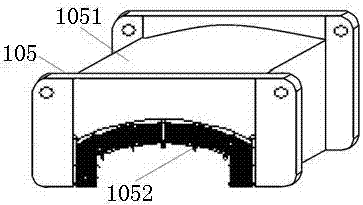

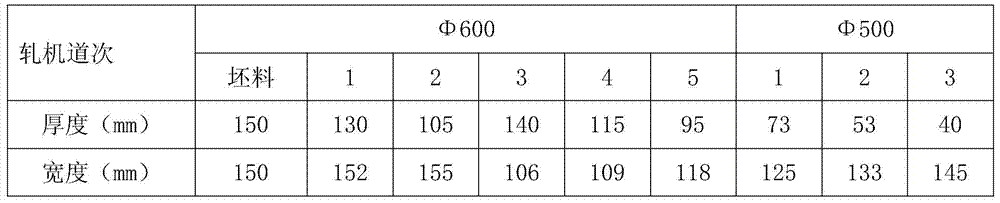

Ultra-thin hot-rolled narrow strip steel production line and its supporting technology

InactiveCN105057351BOptimize process systemReduce thicknessTemperature control deviceMetal rolling arrangementsProduction lineStrip steel

The invention discloses an ultra-thin hot-rolled narrow-strip steel production line and its supporting technology. A thermal insulation cover is installed on the steel-passing roller table from the second rough rolling mill to the first intermediate vertical rolling mill unit. The first intermediate rolling flat rolling mill and the second intermediate rolling vertical rolling mill are sequentially installed between the rolling mill unit and the second intermediate rolling flat rolling mill unit; The eighth finishing rolling flat rolling unit is installed between them. In the present invention, through the addition and modification of the main equipment and auxiliary facilities of the 3 / 4 continuous rolling mill production line, as well as the adjustment and optimization of the rolling line, billet, rolling temperature, rolling mill speed, roll matching system, etc., to achieve stable The purpose of producing ultra-thin hot-rolled narrow strip steel.

Owner:JIANGXI HONGDU STEELWORKS CO LTD

A device for multi-field coupling cone rolling

The invention provides a multi-field coupling roll finishing device for a conical surface. Multi-field coupling particularly means coupling of a high-temperature thermal field, a variable frequency pulsed magnet field and an ultrasonic field. The multi-field coupling roll finishing device comprises a rolling knife, an amplitude-change pole, a transducer, an ultrasonic generator, a thermocouple coil, a temperature controller, a pulsed magnet field intensifying system, a dynamometer and a mounting rack. A novel rolling knife structure is designed, so that different rolling wheels can be replacedaccording to different rolling workpieces, meanwhile, different rolling angles can be replaced according to different conical surface angles of workpieces, and accordingly, the use is convenient andreliable. According to the multi-field coupling roll finishing device, the heating temperatures of the workpieces can be controlled by a temperature controller, the rolling temperature of the workpieces is increased, and the atomic vitality of the workpieces is enhanced, dislocation movement is overcome, the resistance is reduced, and accordingly, a favorable rolling surface quality is acquired. The conical workpieces are placed in a pulsed magnet field acting region, so that the hardness and the wear resistance of the workpieces are improved. The value of a rolling force in a rolling processcan be monitored in real time by the dynamometer, and the rolling force in the rolling process is kept constant by feedback of a digital control system. An ultrasonic rolling system which can be mounted on a common lathe is designed to roll a conical-surface shaft part, the surface roughness of the part can be reduced, the surface hardness is improved, and favorable surface quality and mechanicalperformance are acquired.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Rolling technology of microalloy V-N steel

The invention discloses a rolling technology of microalloy V-N steel. The austenitizing temperature ranges from 1200 DEG C to 1300 DEG C, and heat preservation time is 600s; the finish rolling temperature ranges from 900 DEG C to 950 DEG C; and the rolling deformation amount is controlled to range 30 percent to 40 percent, and air cooling is adopted after rolling. According to the rolling technology, the structure and the performance of the microalloy V-N steel are obviously improved.

Owner:QINGDAO YUGUANG PRECISION CASTING FACTORY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com