New energy power battery shell, aluminum alloy and manufacturing method thereof

A power battery and aluminum alloy technology, applied in the field of aluminum alloy, can solve the problems of insufficient deep drawing performance, lower production efficiency, large aluminum alloy grains, etc., and achieve good plastic deformation ability, sufficient static recrystallization, and fast heating speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] In this embodiment, an aluminum alloy for a new energy power battery case is manufactured, and its composition and weight percentage are: Si: 0.30%, Fe: 0.55%, Cu: 0.05%, Mn: 1.05%, Mg: 0.05%, Zn: 0.03%, Ti: 0.04%, the balance is Al and unavoidable impurities less than 0.05% for a single element and less than 0.15% for the total amount.

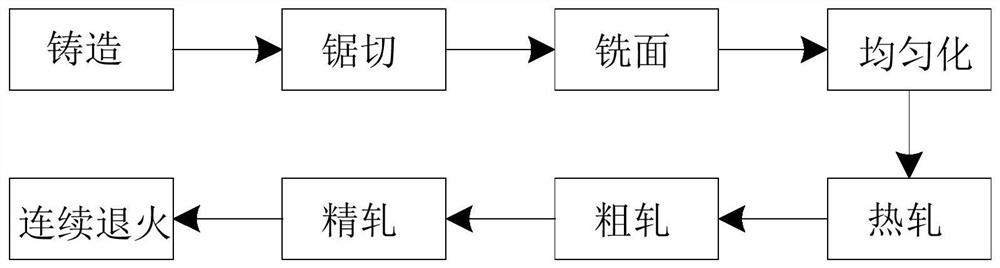

[0048] use figure 1 The method shown is manufactured as follows:

[0049] (1) Casting: Add the raw materials into the melting furnace according to the weight percentage of each component, the melting temperature is 760°C, electromagnetic stirring is performed 3 times, each time for 10 minutes, the refining temperature is 750°C, the refining time is 20 minutes, and the casting temperature is 705°C ℃.

[0050](2) Sawing: Cut an ingot with a thickness of 550mm, a width of 1400mm, and a length of 7200mm. The head is sawed to 200mm, and the tail is sawed to 100mm. After sawing, the length of the ingot is 6900mm, the thickness is 550mm, an...

Embodiment 2

[0059] In this example, an aluminum alloy for a new energy power battery shell is manufactured, and its composition and weight percentage are: Si: 0.17%, Fe: 0.60%, Cu: 0.08%, Mn: 0.90%, Mg: 0.02%, Zn: 0.01%, Ti: 0.02%, the balance is Al and unavoidable impurities less than 0.05% for a single element and less than 0.15% for the total amount.

[0060] use figure 1 The method shown is manufactured as follows:

[0061] (1) Casting: Add the raw materials into the melting furnace according to the weight percentage of each component, the melting temperature is 740°C, electromagnetic stirring is performed twice, each time for 12 minutes, the refining temperature is 730°C, the refining time is 15 minutes, and the casting temperature is 695 ℃.

[0062] (2) Sawing: Cut an ingot with a thickness of 550mm, a width of 1400mm, and a length of 7200mm. The head is sawed to 200mm, and the tail is sawed to 100mm. After sawing, the length of the ingot is 6900mm, the thickness is 550mm, and the...

Embodiment 3

[0071] In this embodiment, an aluminum alloy for a new energy power battery shell is manufactured, and its composition and weight percentage are: Si: 0.20%, Fe: 0.50%, Cu: 0.02%, Mn: 0.92%, Mg: 0.03%, Zn: 0.04%, Ti: 0.03%, the balance is Al and unavoidable impurities less than 0.05% for a single element and less than 0.15% for the total amount.

[0072] use figure 1 The method shown is manufactured as follows:

[0073] (1) Casting: Add the raw materials into the melting furnace according to the weight percentage of each component, the melting temperature is 750°C, electromagnetic stirring is performed 3 times, each time for 8 minutes, the refining temperature is 740°C, the refining time is 15 minutes, and the casting temperature is 700°C ℃.

[0074] (2) Sawing: Cut an ingot with a thickness of 550mm, a width of 1400mm, and a length of 7200mm. The head is sawed to 200mm, and the tail is sawed to 100mm. After sawing, the length of the ingot is 6900mm, the thickness is 550mm, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com