Hot in-place asphalt pavement recycling construction method involving layered heating, raking and moving-type blending

A technology of asphalt pavement and construction method, which is applied in the field of asphalt pavement construction, can solve the problems of a large amount of asphalt smoke, uneven heating, and environmental pollution, and achieve the effects of improving heating efficiency, uniform heating, and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

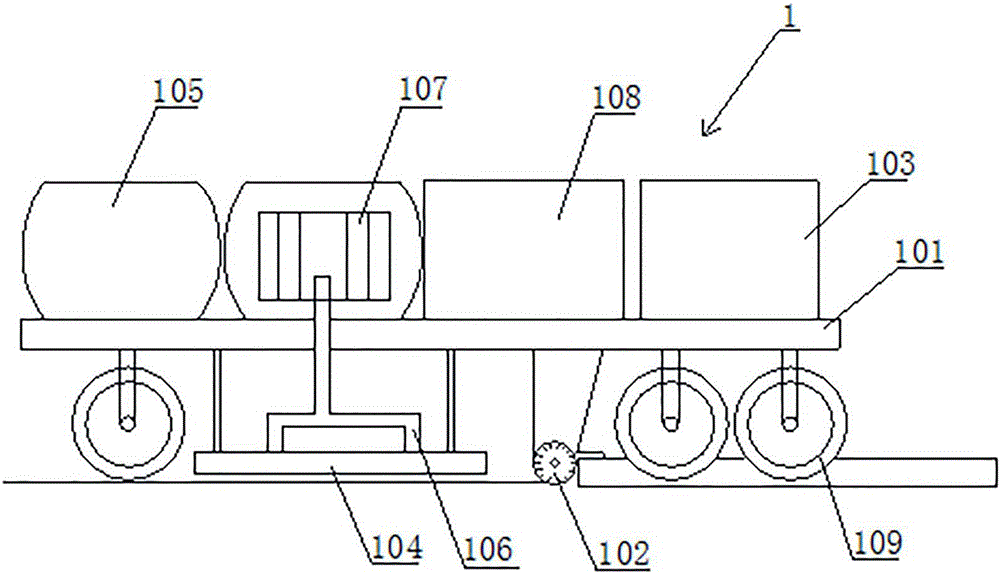

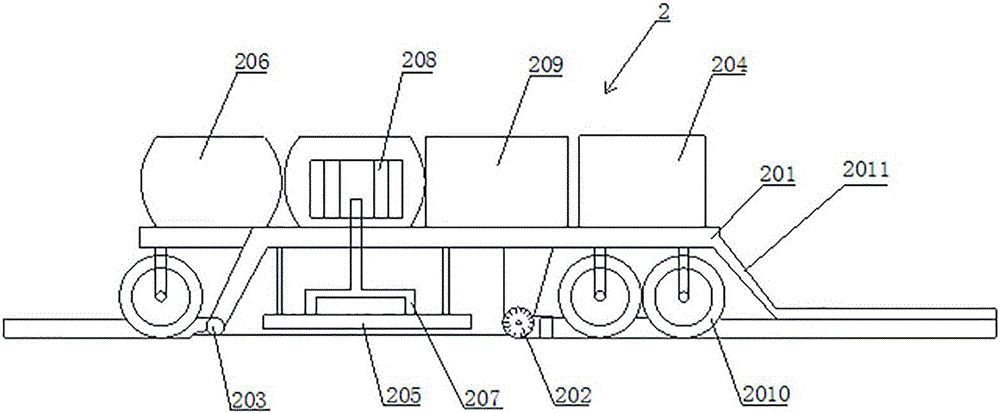

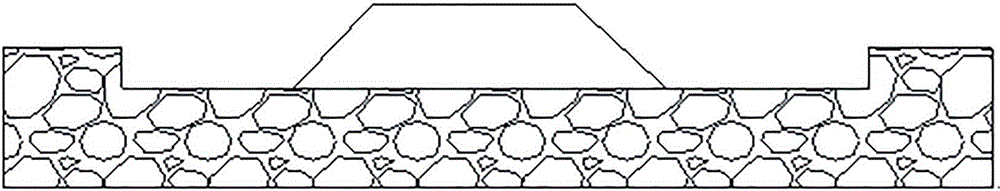

[0026] The invention provides an in-situ thermal regeneration construction method of asphalt pavement with layered heating, raking and moving mixing. It adopts the method of heating and raking twice in two layers, and the heating efficiency is significantly improved, and the temperature of 140°C is significantly lower than that of traditional asphalt heating. , black asphalt dust produced by high temperature does not exist, and the regenerated road surface is heated more evenly, which can greatly save heating fuel, and the social and economic benefits are very obvious. A detailed description will be given below.

[0027] A construction method for hot-in-place regeneration of asphalt pavement with layered heating, raking and moving mixing, comprising the following steps:

[0028] (1) Heat the surface asphalt pavement to 70--80°C, then rake the surface asphalt pavement and collect it to form the first recycled material;

[0029] (2) Heating the asphalt pavement of the inner lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com