Method for preparing GCr15 bearing steel through rolling-isothermal spheroidizing annealing treatment

A technology of isothermal spheroidizing annealing and isothermal treatment, applied in the field of heat treatment of metallurgical materials, can solve the problem of long spheroidization time, and achieve the effects of short isothermal time, fast dissolution rate and high rolling temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Smelt molten steel and cast it into billet, the thickness of billet is 25mm;

[0041] Treat the billet isothermally at 1000±5°C for 60 minutes;

[0042] The isothermally treated slab is subjected to single-pass hot rolling at 1000±5°C to refine the austenite grains, with a reduction ratio of 28%, to make a hot-rolled plate with a thickness of 18mm;

[0043] Air-cool the hot-rolled sheet to 780±5°C, then carry out 3 passes of warm rolling, the total reduction rate is 67%, the pass pressures are 28%, 31% and 44% respectively, and the final rolling temperature is 760±5°C. Warm rolled plate, thickness 6mm;

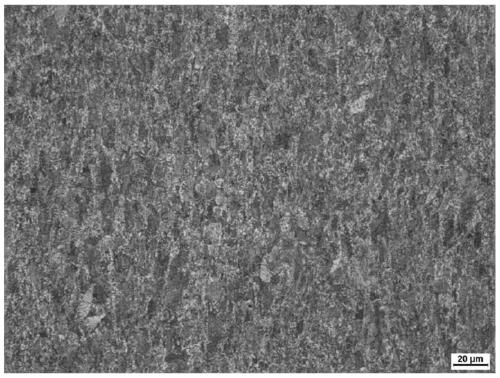

[0044] When the temperature of the warm-rolled sheet is 760±5°C, the warm-rolled sheet is placed in a heat treatment furnace with a temperature of 760±5°C, and the warm-rolled sheet is cooled to room temperature with the furnace to obtain a furnace-cold and warm-rolled sheet; the metallographic structure is as follows: figure 1As shown, the structure is a mixed struct...

Embodiment 2

[0047] Method is with embodiment 1, and difference is;

[0048] (1) Thickness of slab is 30mm; slab isothermally treated for 40min;

[0049] (2) The reduction ratio of hot rolling is 25%, and the thickness of hot rolling plate is 22.5mm;

[0050] (3) Carry out 5 passes of warm rolling, the total reduction rate is 70%, the pass reduction rates are respectively 20%, 22%, 21%, 27% and 15%, and the thickness of the warm rolled plate is 6.9mm;

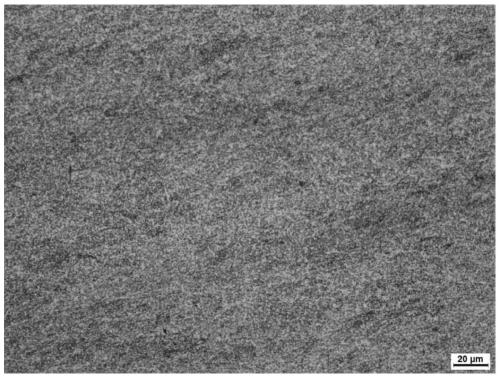

[0051] (4) 40 minutes of isothermal treatment once; 40 minutes of second isothermal treatment;

[0052] The spheroidization grade of GCr15 bearing steel is grade 1, and the surface microhardness is 195HV.

Embodiment 3

[0054] Method is with embodiment 1, and difference is;

[0055] (1) The thickness of the billet is 20mm; the billet is isothermally treated for 50 minutes;

[0056] (2) The reduction rate of hot rolling is 30%, and the thickness of hot rolling plate is 14mm;

[0057] (3) Carry out 4 passes of warm rolling, the total reduction rate is 60%, the pass reduction rates are respectively 21%, 27%, 15% and 18%, and the thickness of the warm rolled plate is 5.6mm;

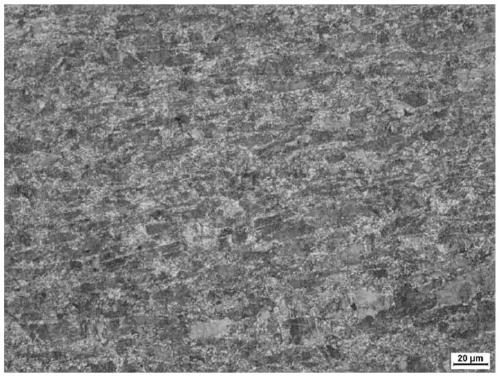

[0058] (4) 50 minutes of isothermal treatment once; 50 minutes of second isothermal treatment;

[0059] The spheroidization grade of GCr15 bearing steel is grade 1, and the surface microhardness is 198HV.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com