Asphalt pavement hot in-place recycling layered heating method

A technology of asphalt pavement and heating method, which is applied in the direction of roads, roads, road repairs, etc., can solve the problems of energy waste, fugitive emission of waste asphalt smoke, pollution of the environment, etc., achieve energy saving, change the problem of fugitive emission, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

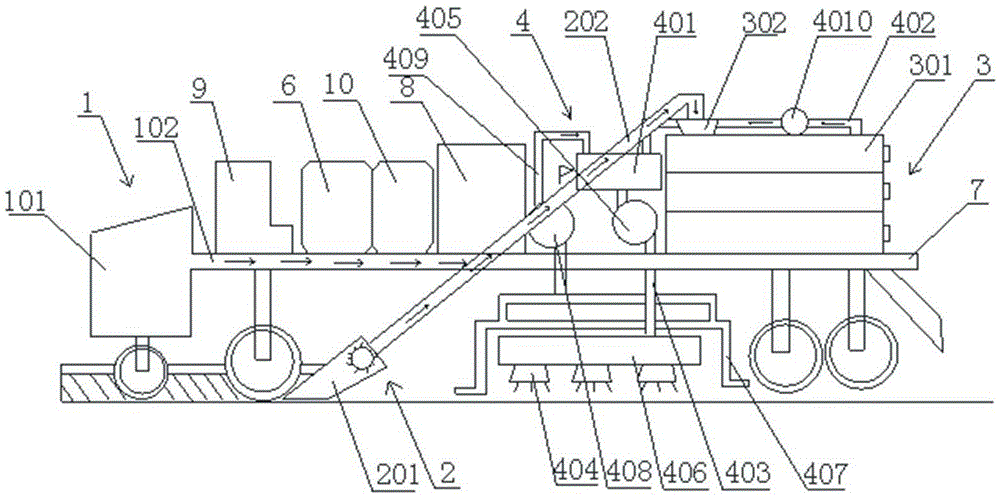

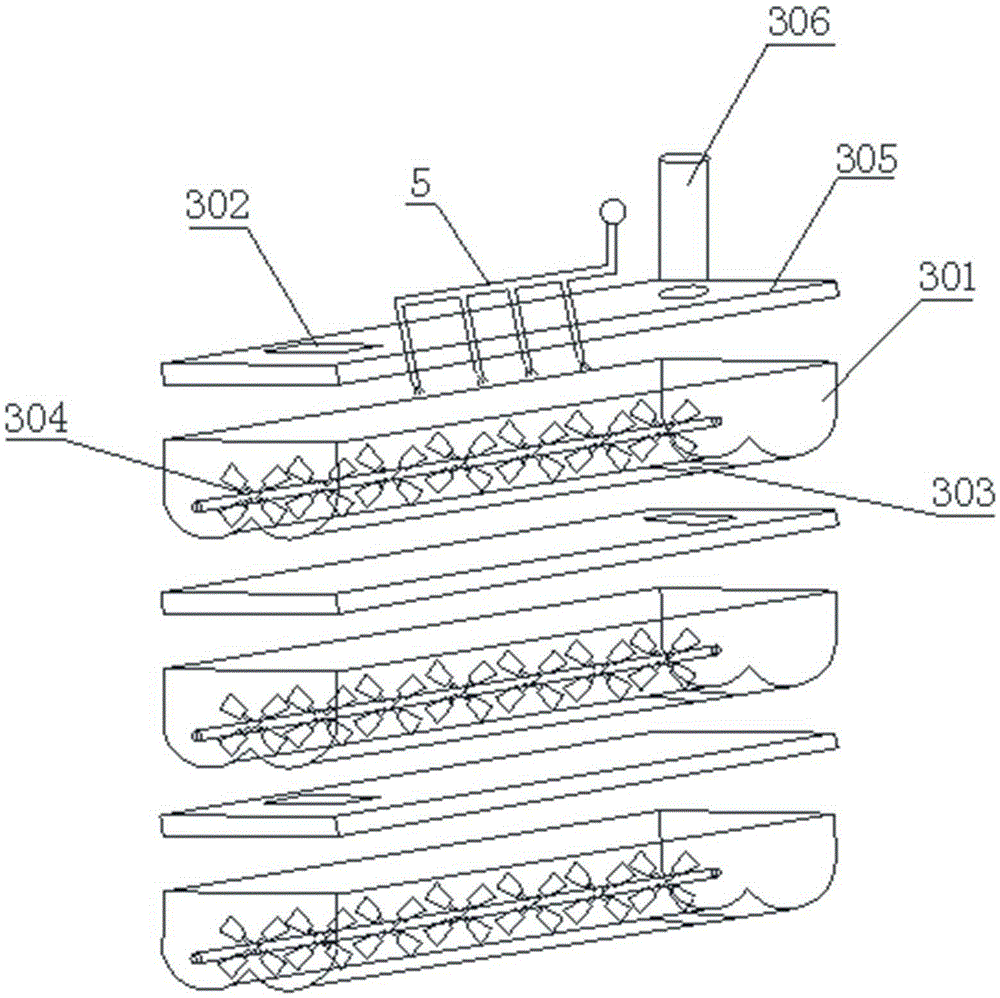

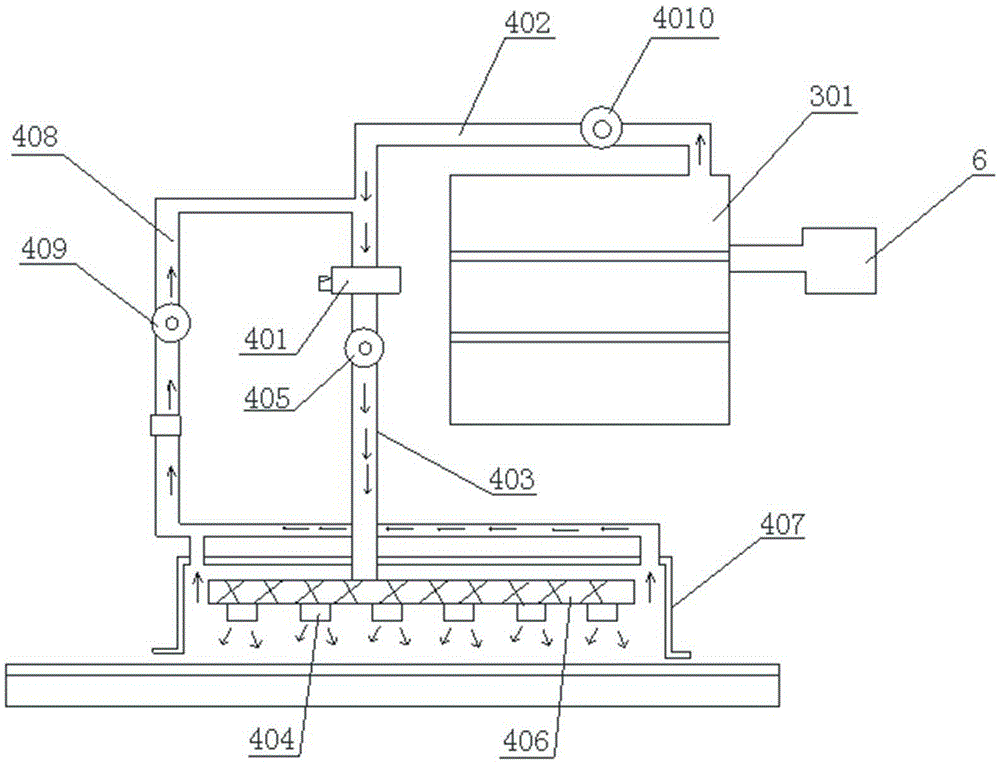

[0020] The invention provides a layered heating method for in-situ thermal regeneration of asphalt pavement. The method adopts the method of layered heating of the recycled mixture, and the heating times can be set according to the heating target temperature. Uniformity, so that the quality of the regenerated pavement can be fully guaranteed. In addition, in the process of heating the recycled materials multiple times, the present invention also recovers the asphalt fume and a large amount of heat generated by heating, and recycles the waste flue gas after burning, and uses it for the heating plate of the regenerator to heat and keep the road surface warm. It has fully changed the problem of unorganized emission of waste asphalt smoke and dust from traditional recycling units, saved energy, and enhanced the competitiveness of independent innovation.

[0021] The present invention will be described in detail below.

[0022] A layered heating method for in-situ thermal regenera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com