Steel plate for low-carbon high-niobium extra-high strength welding structure and method for manufacturing same

An ultra-high-strength, welded structure technology, applied in the direction of temperature control, etc., can solve the problems of low steel plate strength level, low production efficiency, low controlled rolling temperature, etc., achieve small rolling load, high production efficiency, and improve rolling start. The effect of temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below by way of examples.

[0029] See Table 1 for the chemical composition of the steel grades of the embodiments of the present invention.

[0030] The process parameters of the corresponding steel types in the embodiments of the present invention are shown in Table 2.

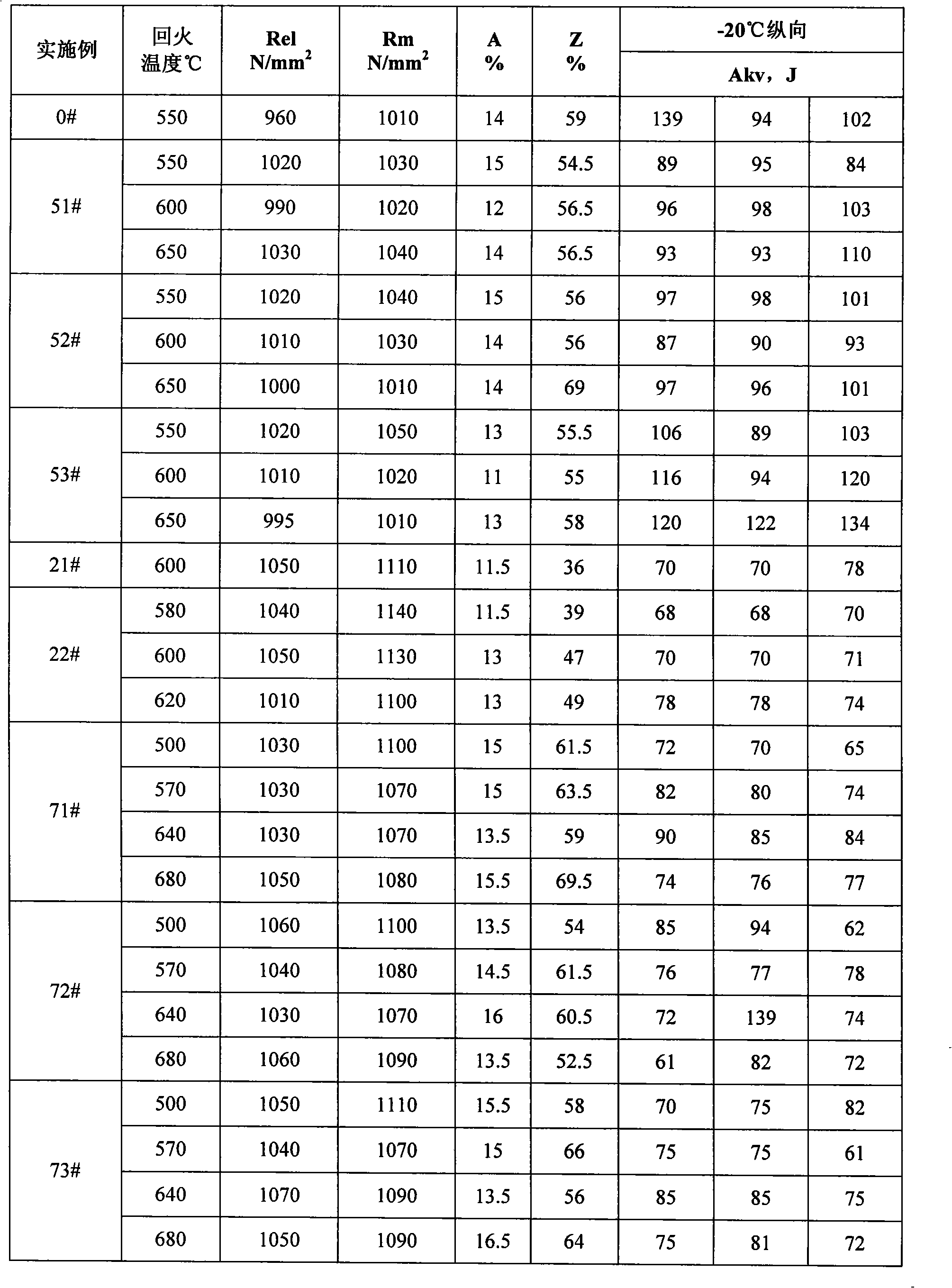

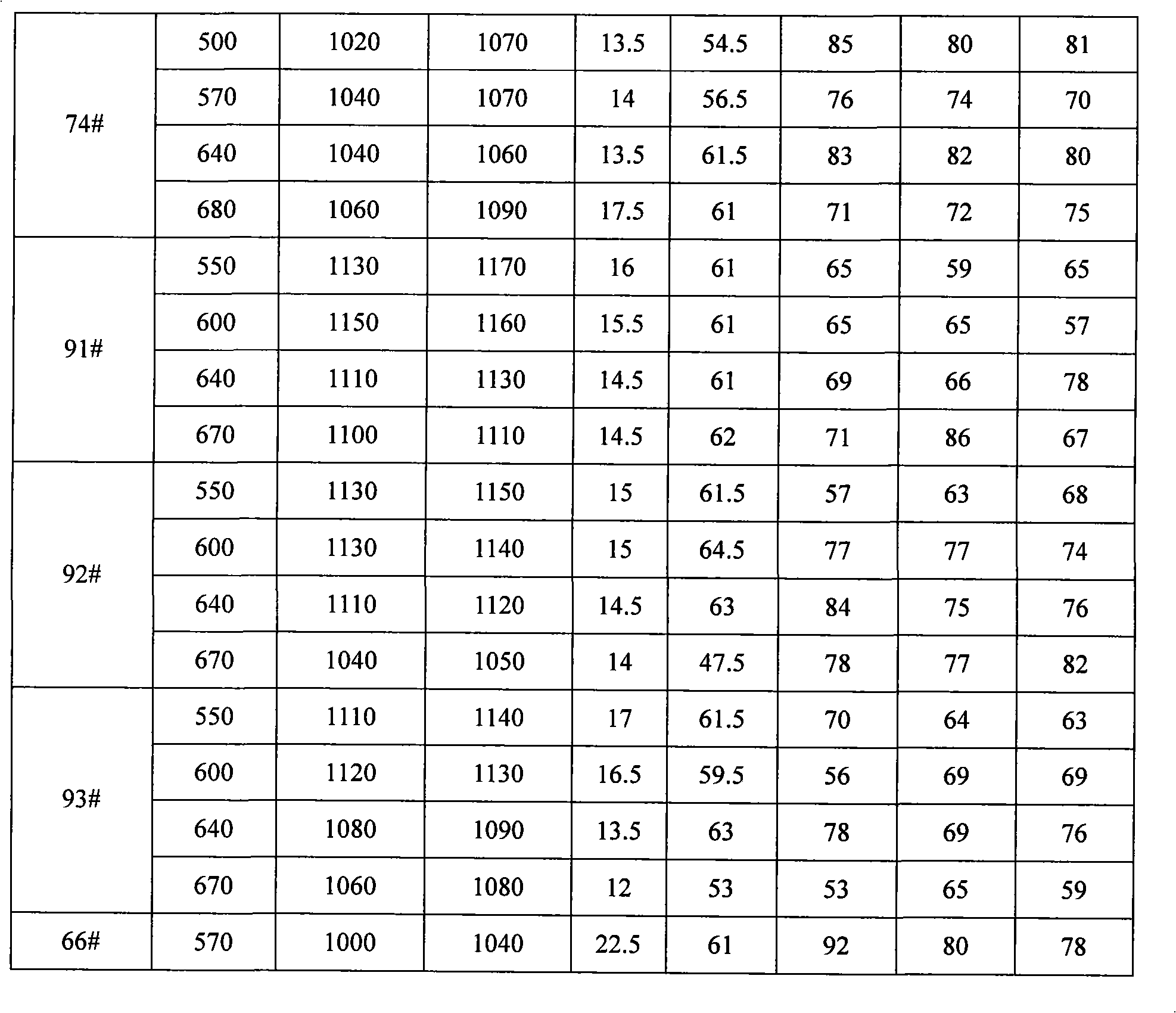

[0031] The mechanical properties of the corresponding steel types in the examples of the present invention are shown in Table 3.

[0032] Table 1, the smelting composition (Wt%) of steel grade of the embodiment of the present invention

[0033] Example

C

Si

mn

P

S

Cu

Ni

Cr

Mo

Nb

Ti

V

Bt

als

0#

0.05

0.22

1.65

0.010

0.005

1.25

1.50

0.81

0.3

0.075

0.02

0.07

0.0013

0.03

51#52#53#

0.047

0.25

1.63

0.010

0.010

1.14

1.00

0.52

0.59

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com