Hot rolling repairing method for corroded eccentric-wear waste oil pipe

A repair method and oil pipe technology, applied in the direction of metal rolling, etc., can solve the problems of uneven axial temperature distribution in the heated area of the oil pipe, failure to meet the repair requirements of the oil pipe, and large thermal stress of the oil pipe, and achieve strong metal fluidity and rolling The effect of high temperature and guaranteed surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

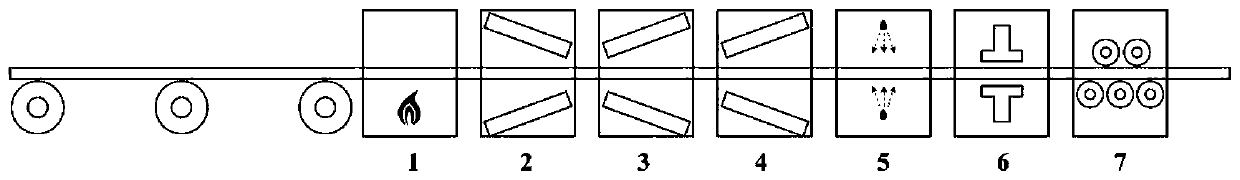

Image

Examples

Embodiment 1

[0044] The first step: primary election. Tubing with the following characteristics will not meet the screening criteria: inability to straighten, crack and perforation of the pipe body, severe deformation, inability to remove the lining, leakage at 5MPa, etc.

[0045] The second step: flaw detection. Use non-destructive flaw detection, thickness gauge and other equipment to classify the tubing: Class I tubing: eccentric wear depth does not exceed 10% of the standard wall thickness; Class II tubing: 10% <Partial wear depth≤30% of standard wall thickness; Type III tubing: 30% <Partial wear depth≤40% of standard wall thickness; scrap tubing: Partial wear depth exceeds 40% of standard wall thickness. After flaw detection, select II and III oil pipes for repair.

[0046] The third step: descaling and polishing. Clean and polish the oil, rust, scale, corrosion products and other impurities on the inner and outer walls of the waste tubing.

[0047] The fourth step: uniform heating. Use ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com