Heat conducting graphite paper and preparation method thereof

A technology of thermally conductive graphite and flake graphite, applied in the directions of graphite, chemical instruments and methods, and modification by conduction and heat transfer, etc., can solve the problems of low thermal conductivity of thermally conductive paper, difficult to meet the technical application requirements of high-power electronic products, etc., and achieve cost Low, increased surface smoothness, easy handling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

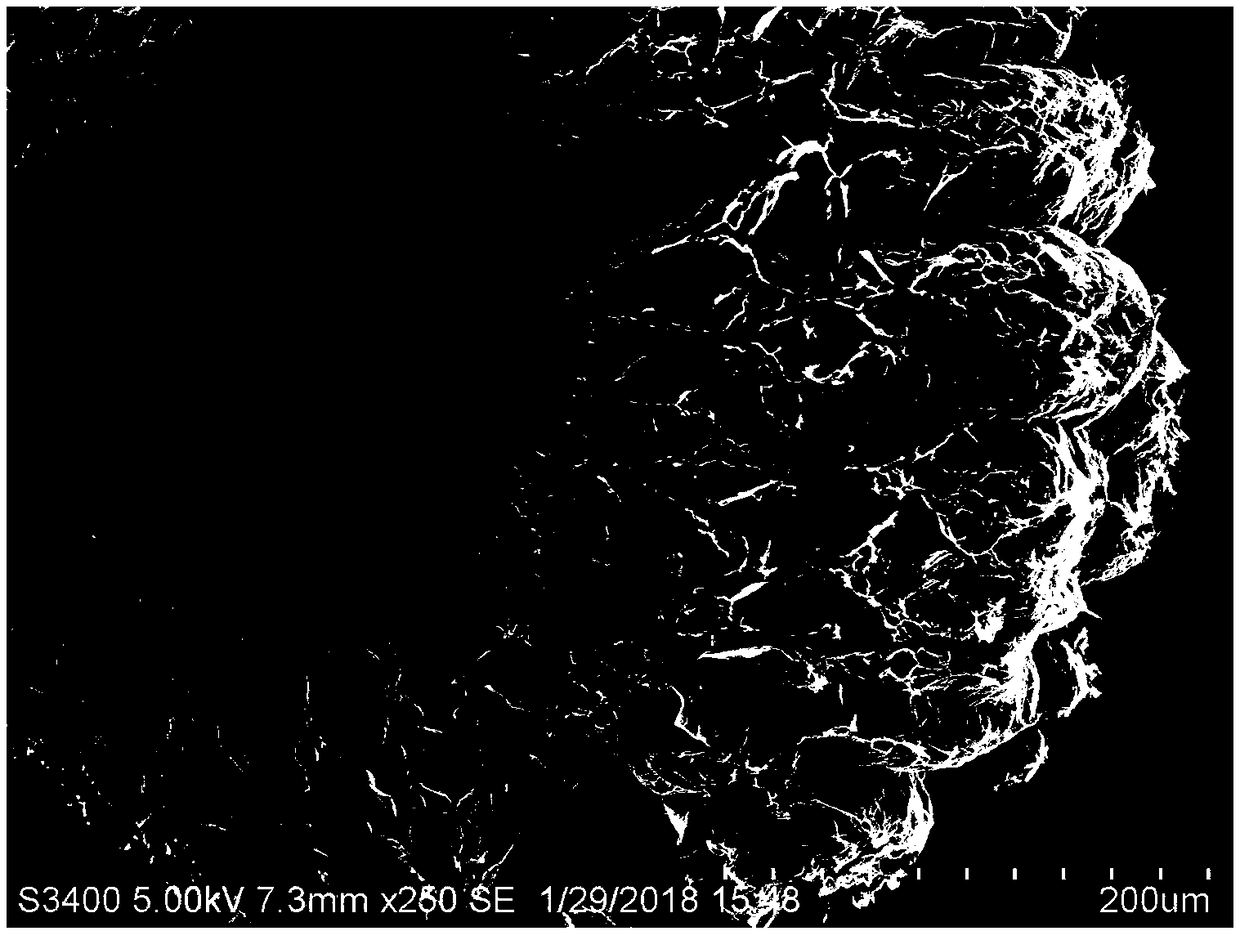

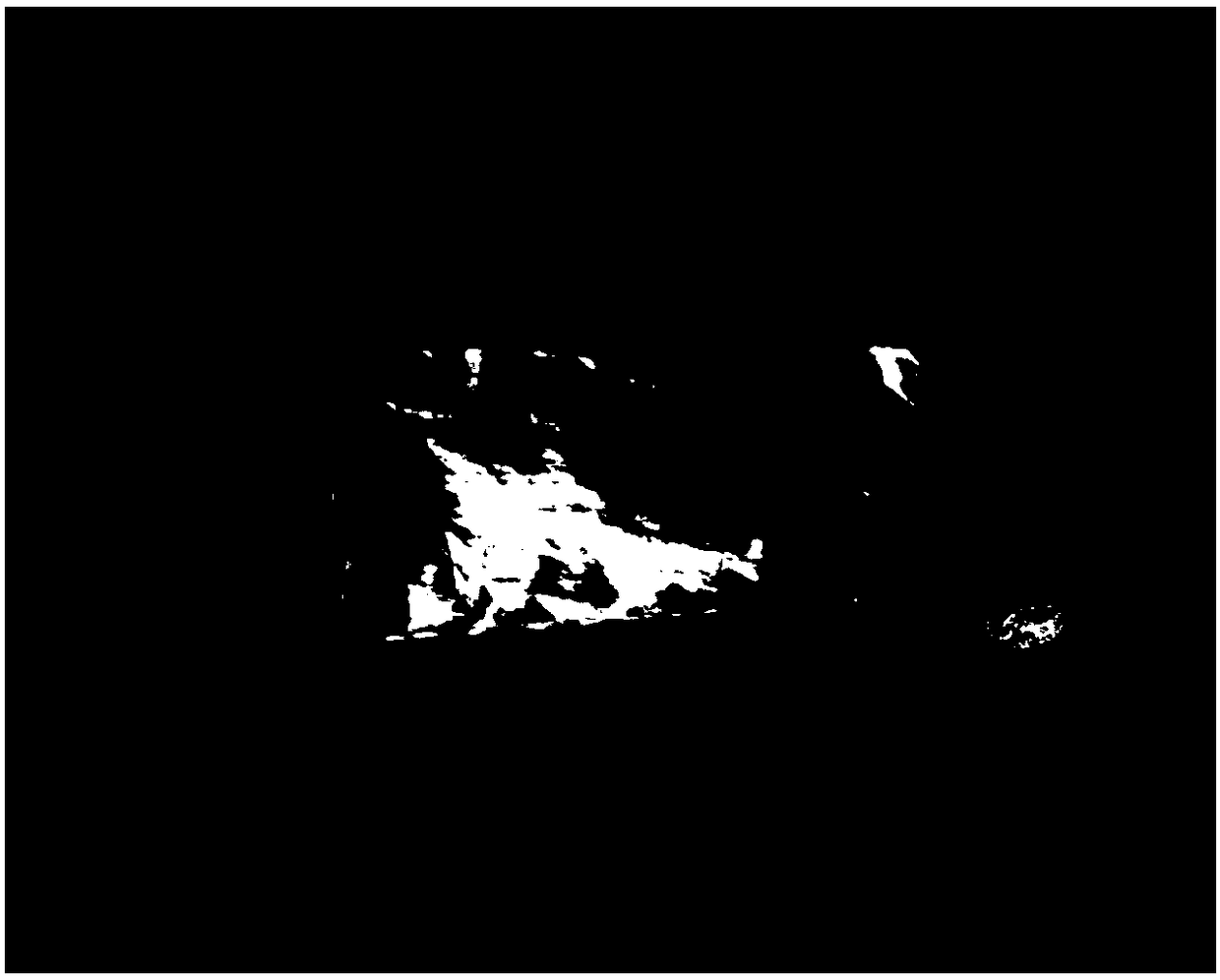

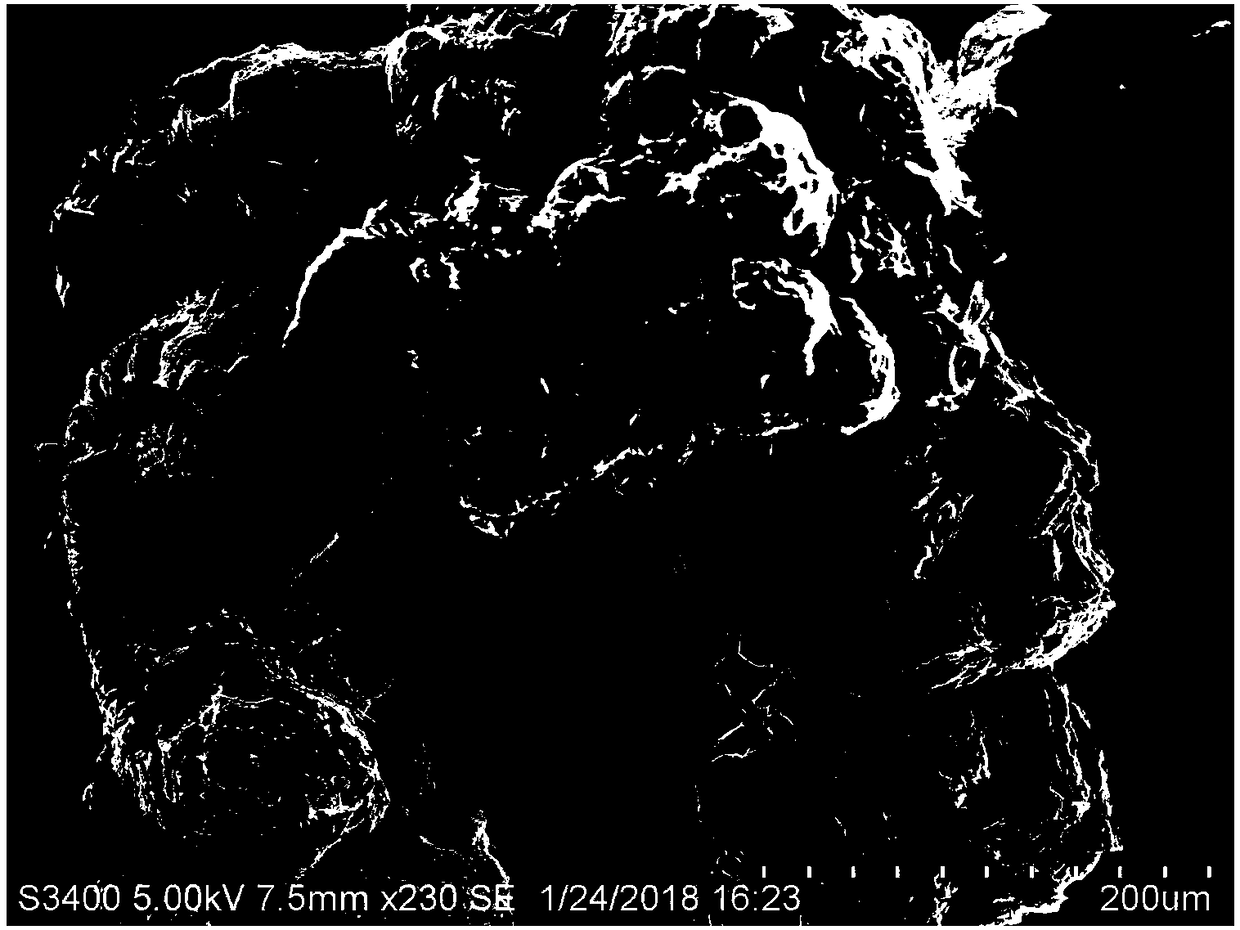

Image

Examples

preparation example Construction

[0015] The invention provides a preparation method of heat-conducting graphite paper. The preparation method comprises the following steps:

[0016] S1, mixing graphite flakes with sulfuric acid solution to obtain a first mixture, wherein the mass ratio of graphite flakes to sulfuric acid solution is 1:2 to 1:3, and the mass fraction of sulfuric acid in the sulfuric acid solution is 58% to 65% %;

[0017] S2, adding potassium dichromate solution to the first mixture to obtain a second mixture, wherein the mass ratio of potassium dichromate powder to the flake graphite is 0.2:1 to 0.3:1;

[0018] S3, washing the second mixture with water to obtain a preform;

[0019] S4, placing the preform in a chamber, firstly evacuating the chamber, then introducing an inert gas into the chamber, and performing high-temperature expansion treatment to obtain an expanded graphite material;

[0020] S5, rolling the expanded graphite material at least once to obtain thermally conductive graph...

Embodiment (1

[0035] The preparation method of heat-conducting graphite paper described in this embodiment comprises the following steps:

[0036] (1) The graphite ore is purified and pulverized to obtain flake graphite. The flake graphite and sulfuric acid solution are placed in the mixer for 15 minutes, wherein the quality of the flake graphite is 100±5Kg, the sulfuric acid concentration is about 65%, and the quality of the sulfuric acid solution used is 230±5Kg.

[0037] (2) Slowly add 25±0.5Kg of potassium dichromate powder with a content greater than 99% into the mixer, stir for 15 minutes, and let stand for 40 minutes to obtain the second mixture.

[0038] (3) washing the second mixture with water until the pH value is 6, and drying to obtain a preform.

[0039] (4) Place the preform in the chamber, first evacuate the chamber, and then continuously pass into the chamber an inert gas composed of nitrogen, argon and hydrogen with a volume ratio of 94:5:1. gas, the rate of introduction...

Embodiment (2

[0060] The preparation method of heat-conducting graphite paper described in this embodiment comprises the following steps:

[0061] (1) The graphite ore is purified and pulverized to obtain flake graphite. The graphite flakes and the sulfuric acid solution are placed in a mixer for 10 minutes, wherein the graphite flakes have a mass of 100±5Kg, and the sulfuric acid solution with a mass fraction of about 50% has a mass of 250±5Kg.

[0062] (2) Slowly add 20±0.5Kg of potassium dichromate powder with a solid content greater than 99% into the mixer, stir for 10 minutes, and let stand for 30 minutes to obtain the second mixture.

[0063] (3) washing the second mixture with water until the pH value is 6, and drying to obtain a preform.

[0064] (4) Place the preform in the chamber, first evacuate the chamber, and then continuously pass into the chamber an inert gas composed of nitrogen, argon and hydrogen with a volume ratio of 94:5:1. gas. The feed rate of the inert gas is 3×1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com