Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

49results about How to "Production to prevent" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

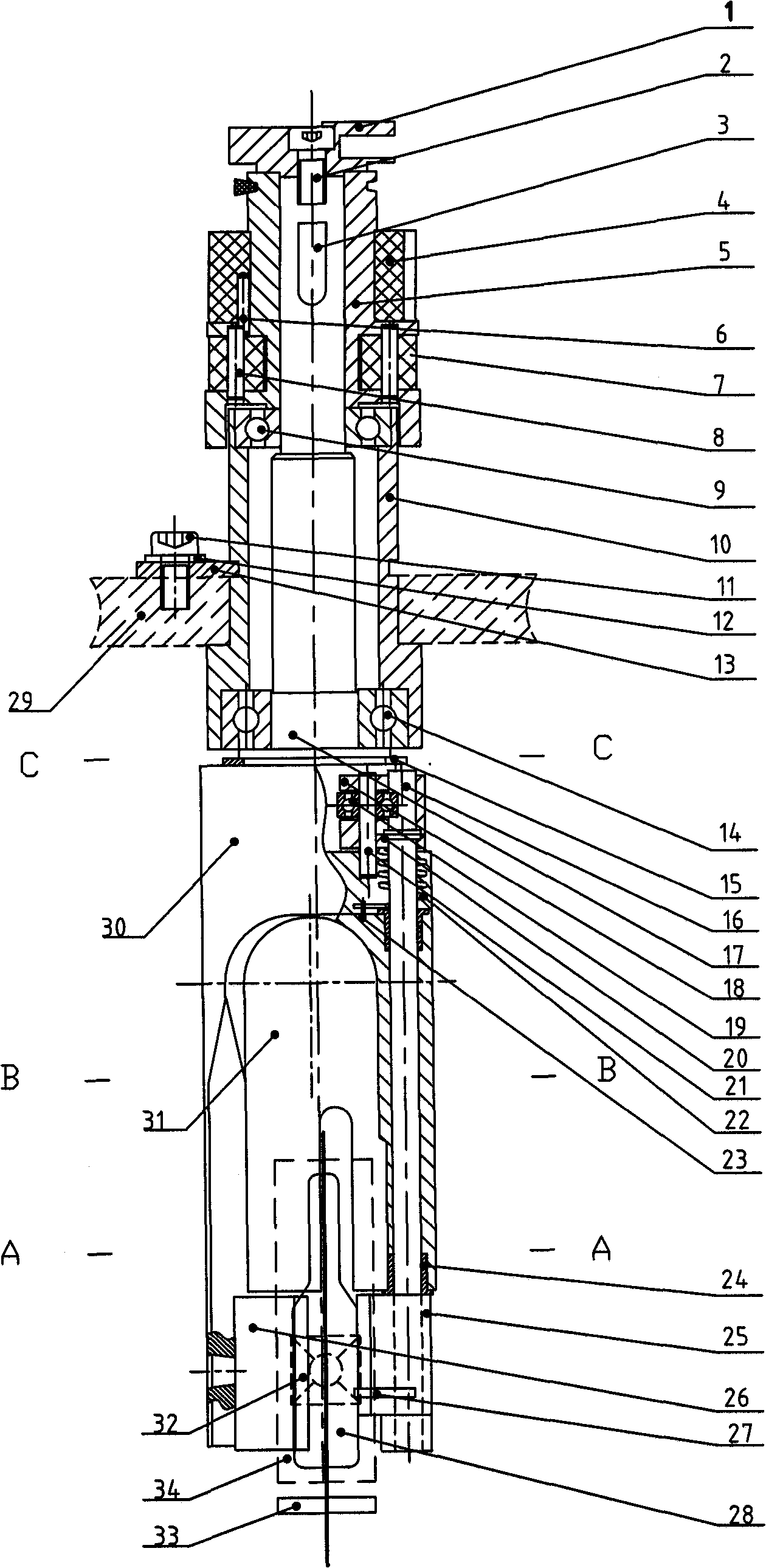

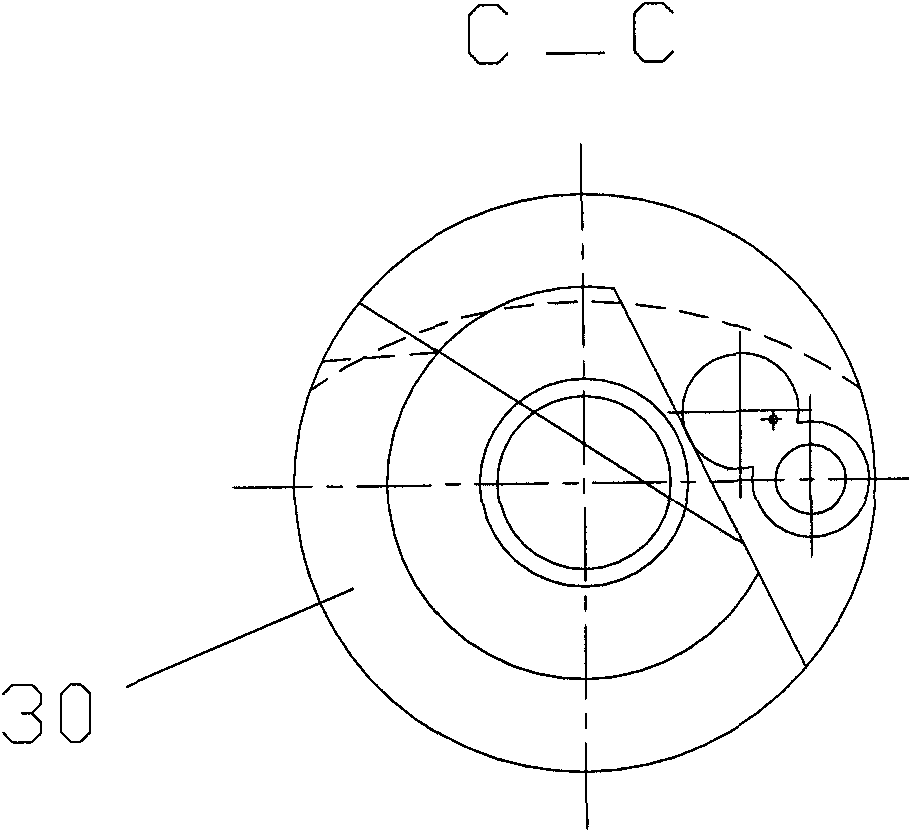

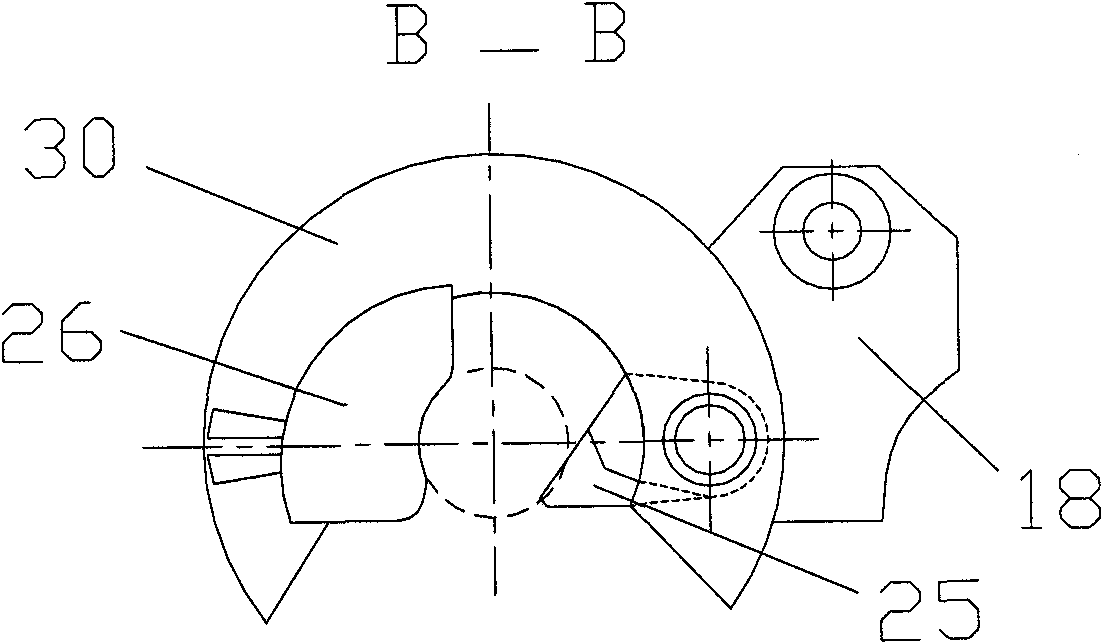

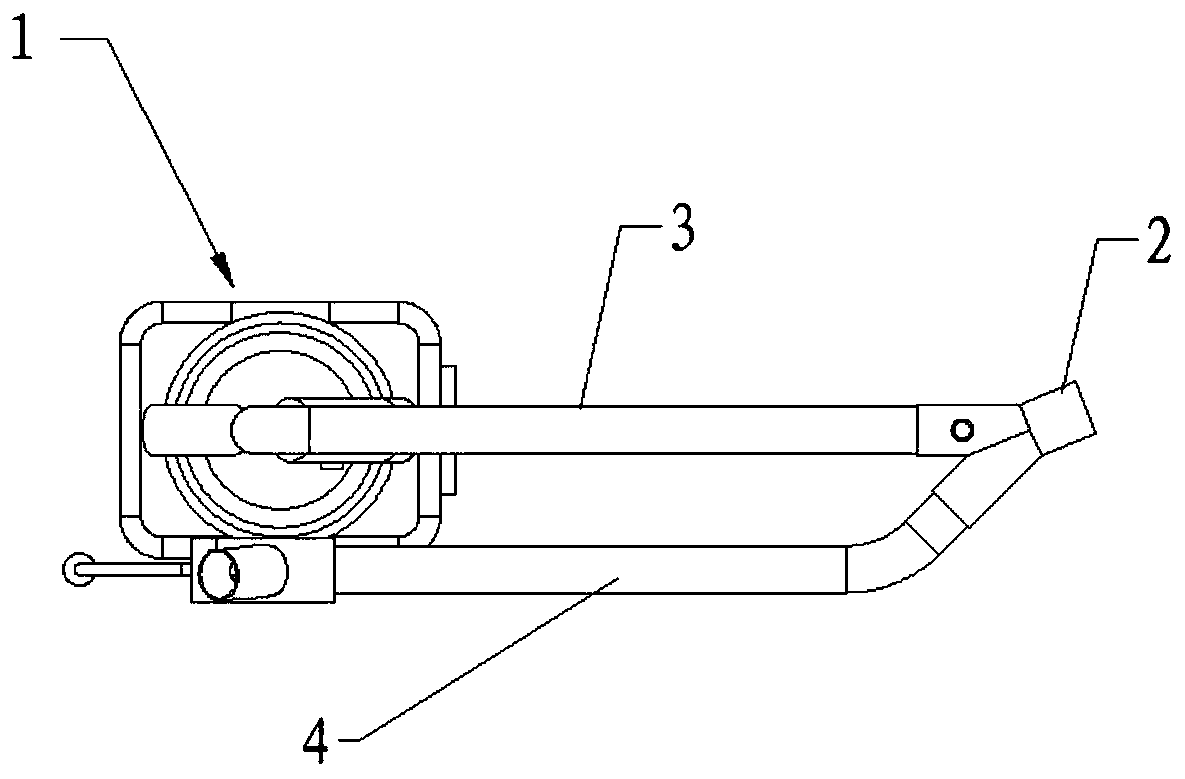

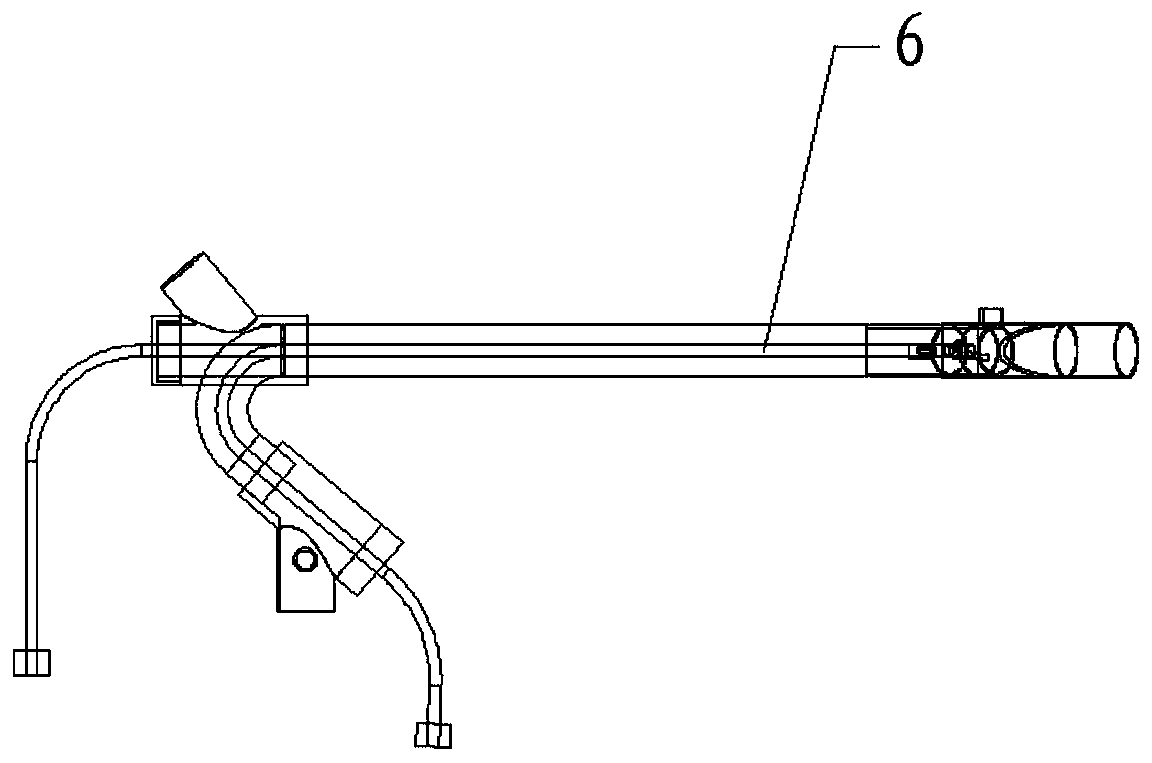

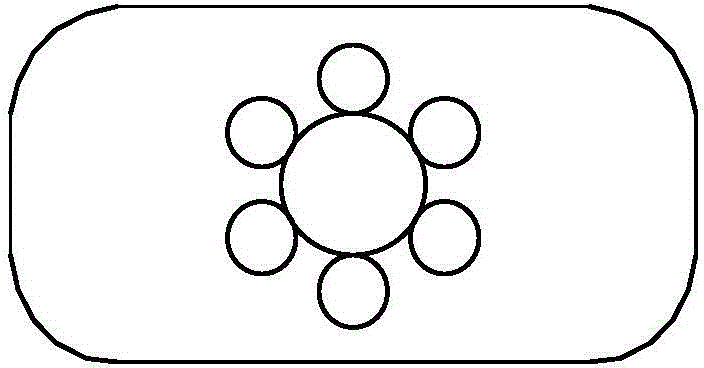

Method and equipment for visual detection of visible foreign matters in bottled liquid medicine

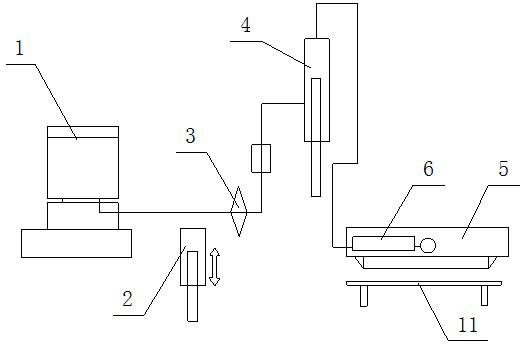

InactiveCN101806752ASimple structureImprove detection qualityOptically investigating flaws/contaminationStructural elementManipulator

The invention discloses a method and equipment for the visual detection of visible foreign matters in a bottled liquid medicine. The method comprises the following steps of: (1) obtaining a multi-frame continuous image from a current liquid medicine which is to be detected and is filled in a medicine bottle by using an industrial camera; (2) preprocessing the image: carrying out top-hat morphologic filtering on the obtained image by adopting a 7*7 circular template as a structural element; (3) extracting a moving object; (4) tracking the moving object; and (5) identifying and judging the image. The device comprises a bottle grabbing manipulator used for grabbing the medicine bottle and an image collecting and processing device arranged close to the bottle grabbing manipulator. The method and the device are suitable for detecting the visible foreign matters of a traditional small-capacity bottled liquid medicine and have the advantages of simple realization, good detection effect, high safety and reliability, extensive application range and the like.

Owner:长沙图创机电科技有限公司

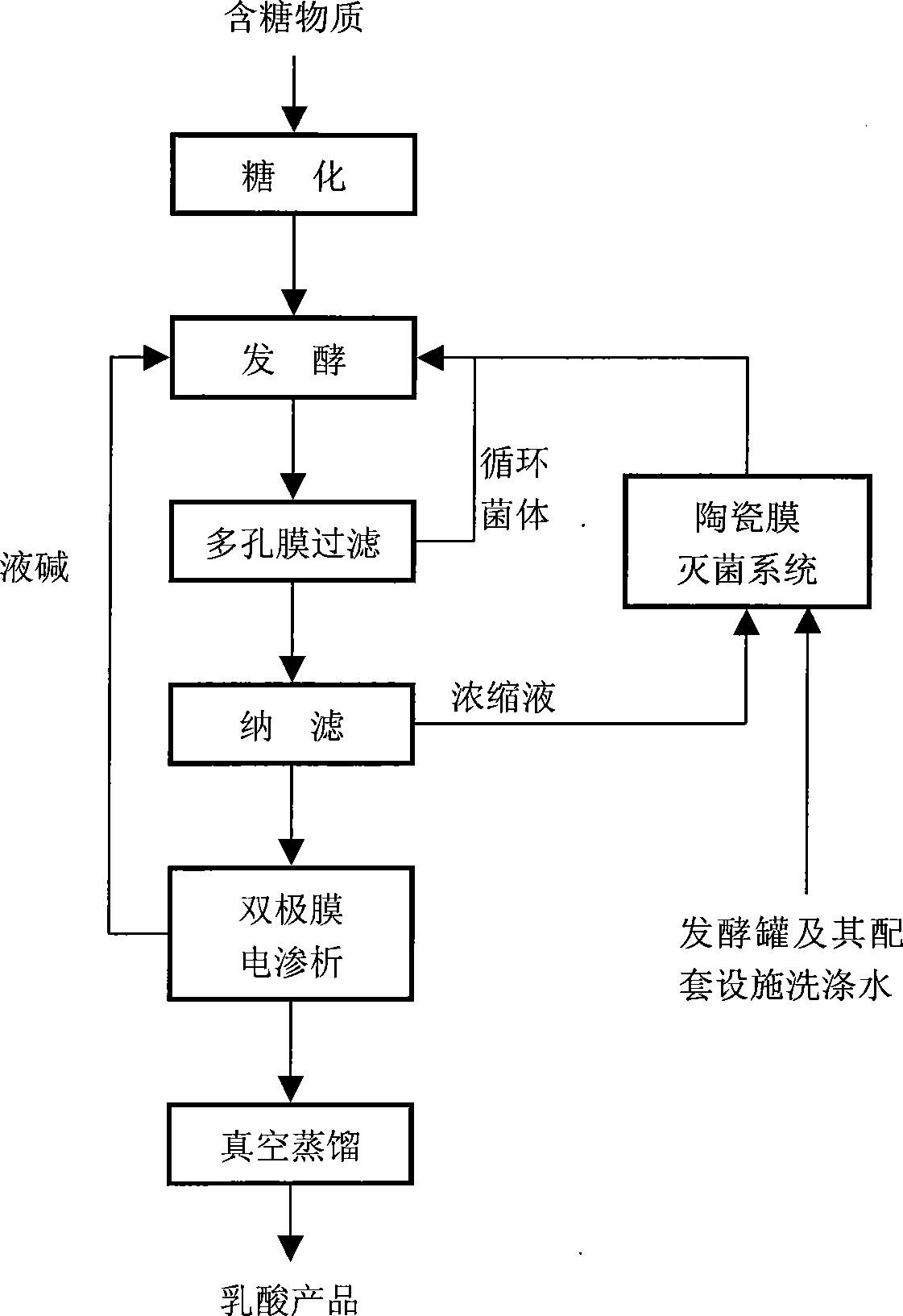

Clean production process of lactic acid

ActiveCN101392273AGreat advantageProduction to preventSemi-permeable membranesMicroorganism based processesPollutionElectrodialysis

Owner:NANJING TECH UNIV

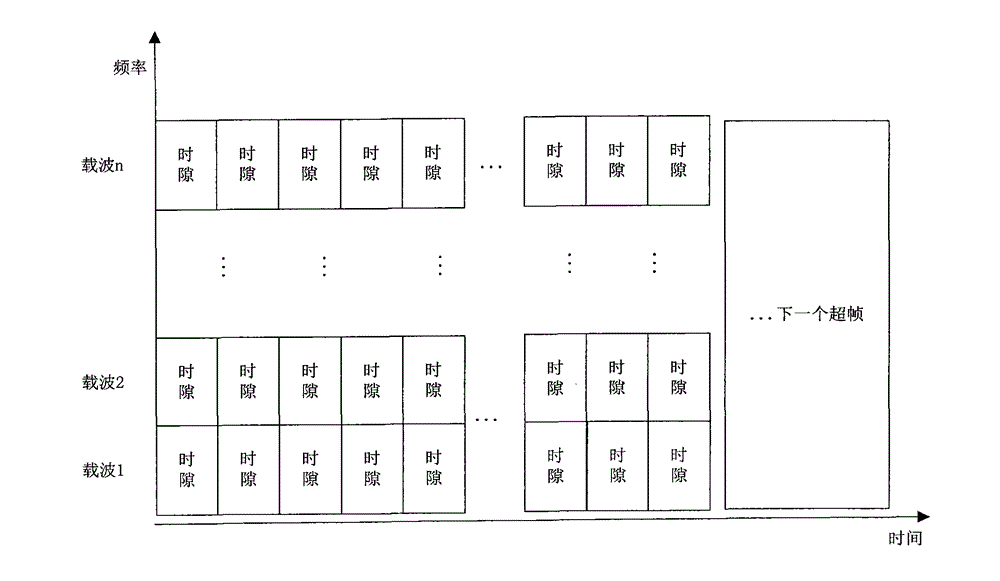

Method for distributing time slots in carrier channel in MF-TDMA (Multi-Frequency Time Division Multiple Address) satellite system

InactiveCN102752039AGuaranteed smoothnessGuaranteed real-timeRadio transmissionTransmission path multiple useResource utilizationCarrier signal

The invention discloses a method for distributing time slots in a carrier channel in an MF-TDMA (Multi-Frequency Time Division Multiple Address) satellite system. The method comprises the following steps: taking a time slot resource tree as a management model; introducing a priority positioning method and a binary coding conversion time slot cutting method; re-arraying the received application number of the time slots of each user terminal according to a sequence from big to small and marking a priority level; and dividing the number of the time slots of each user terminal into the sum of 2n time slot blocks according to a binary conversion method. During the distributing process, the prior distribution for a user with a large application number of the time slots is ensured; the operation delay is reduced; a big time slot space is firstly occupied by a big time slot block according to a priority distributing method based on a right-keeping principle; the rejection for the application caused by a time slot space firstly occupied by a small time slot block is avoided, so that the generation of time slot fragment is effectively eliminated; and the use rate of the resources is increased.

Owner:CHONGQING UNIV

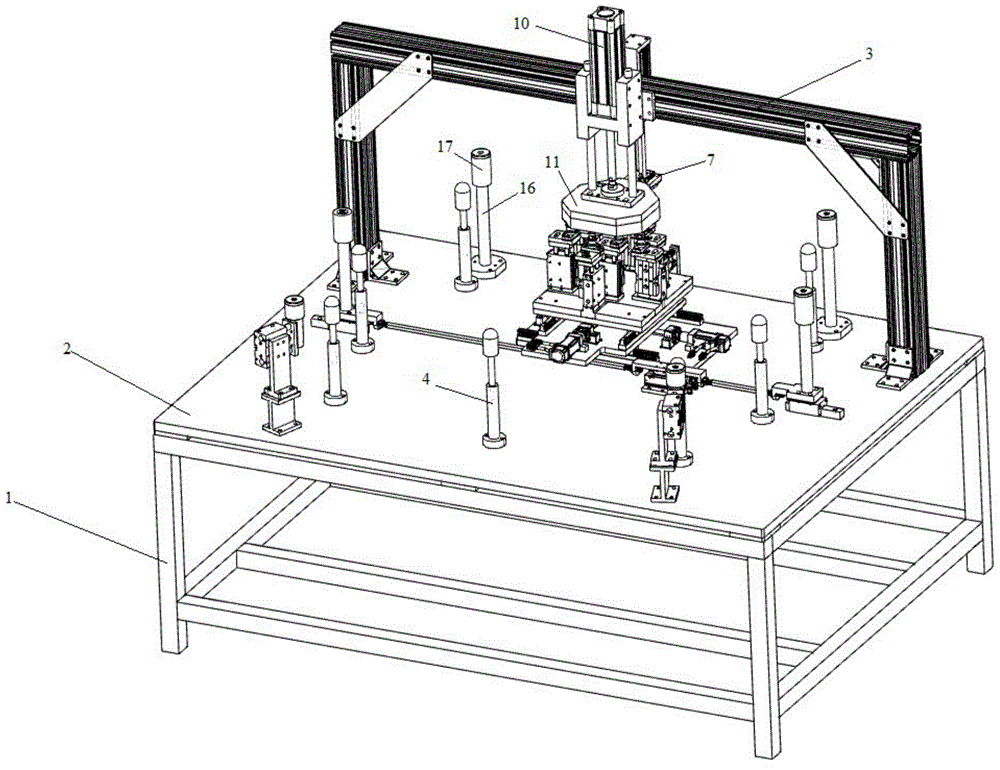

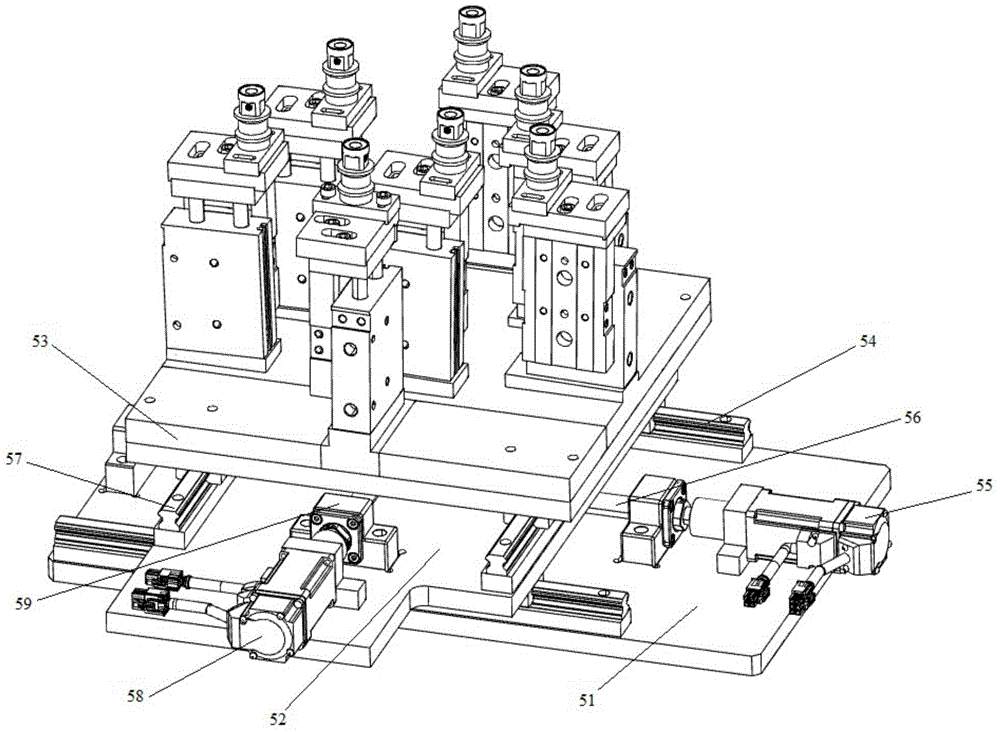

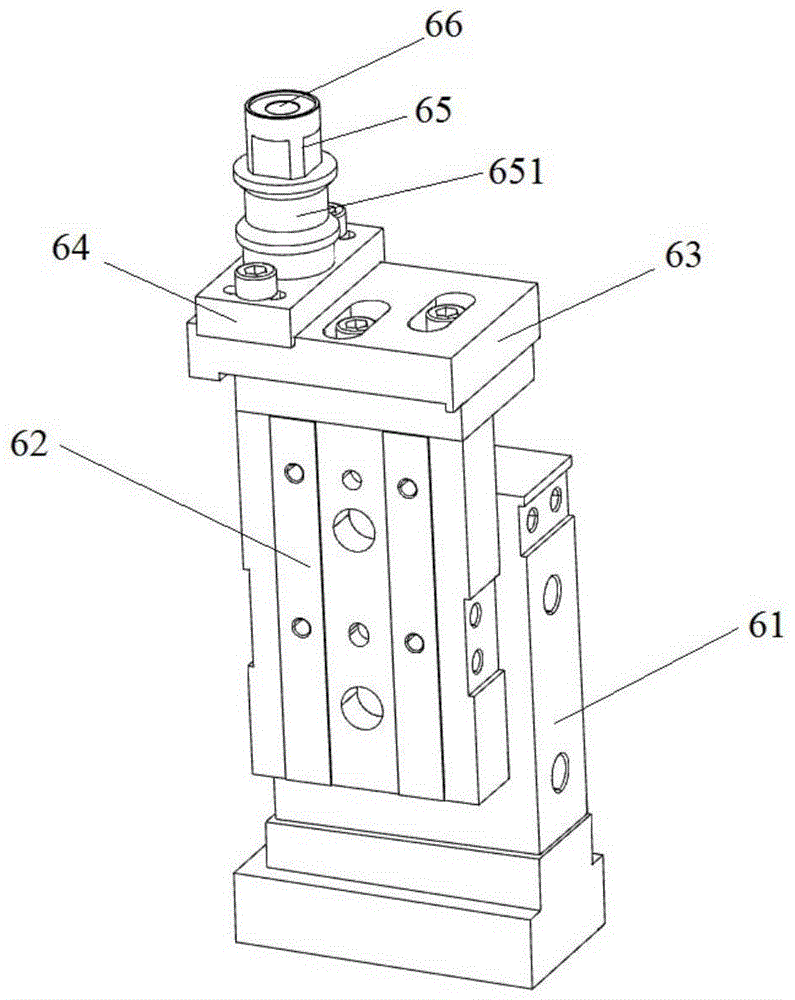

Multi-accessory high-precision automatic positioning and adhering equipment

The invention relates to multi-accessory high-precision automatic positioning and adhering equipment. The equipment comprises a rack, a working table, a fixing mechanism, a clamping mechanism and a limiting mechanism. A gantry support and multiple supporting pillars used for supporting a windshield are arranged on the working table, an electrical cabinet and a computer are further arranged on the rack, the equipment further comprises a pressing mechanism arranged on the gantry support, a positioning servo mechanism arranged on the working table and a shooting mechanism, the pressing mechanism, the positioning servo mechanism and the shooting mechanism are connected with the electrical cabinet through a circuit, and multiple pneumatic pressing mechanisms are arranged on the positioning servo mechanism and arranged on the working table movably through the positioning servo mechanism. Compared with the prior art, the structural arrangement is compact, module work division is clear, all the mechanisms cooperate with one another, in this way, windshield metal nails can be automatically positioned and adhere in a high-precision mode, positioning precision is high, adhering is firm, and production efficiency is effectively improved.

Owner:FUYAO GRP SHANGHAI AUTOMOBILE GLASS CO LTD

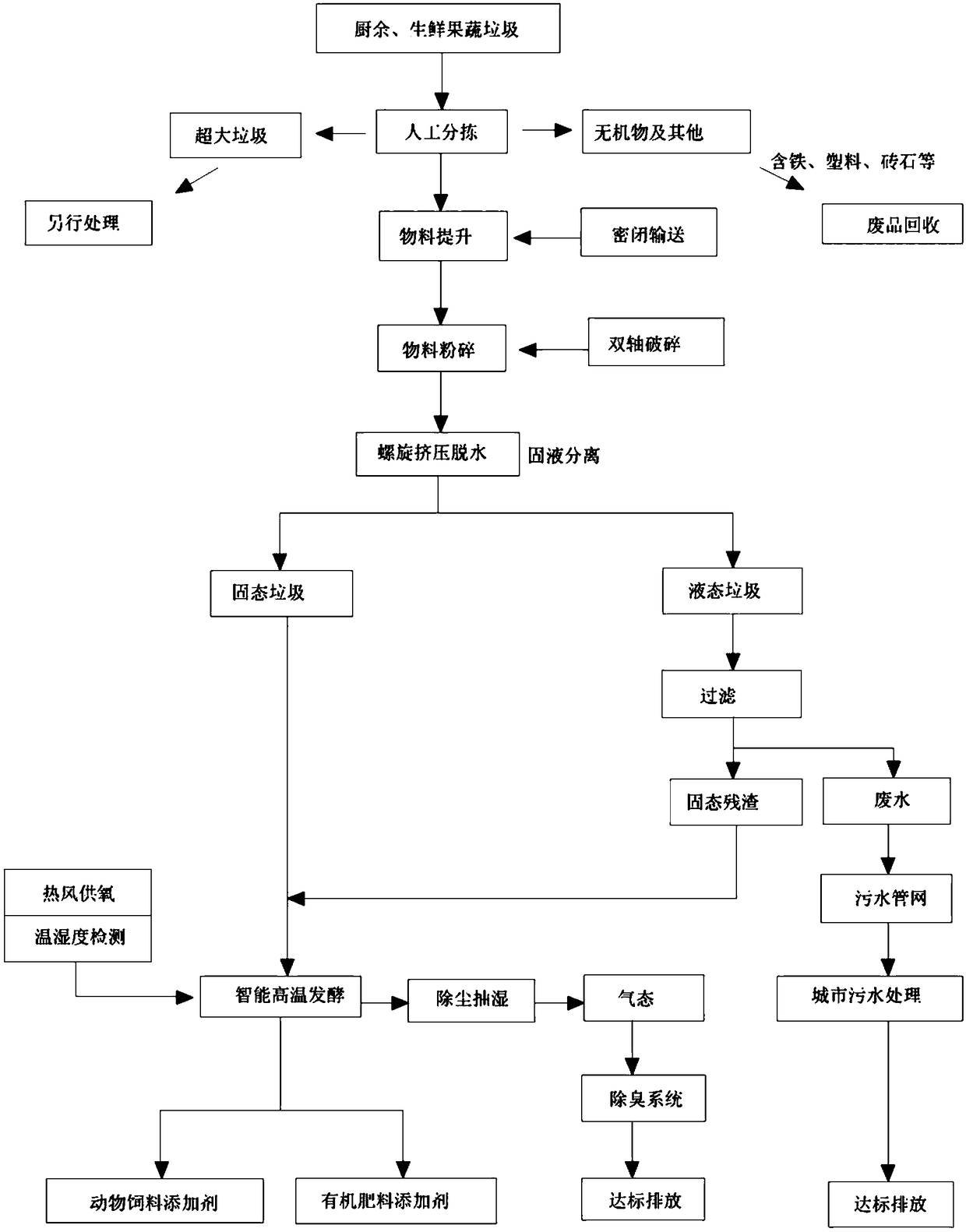

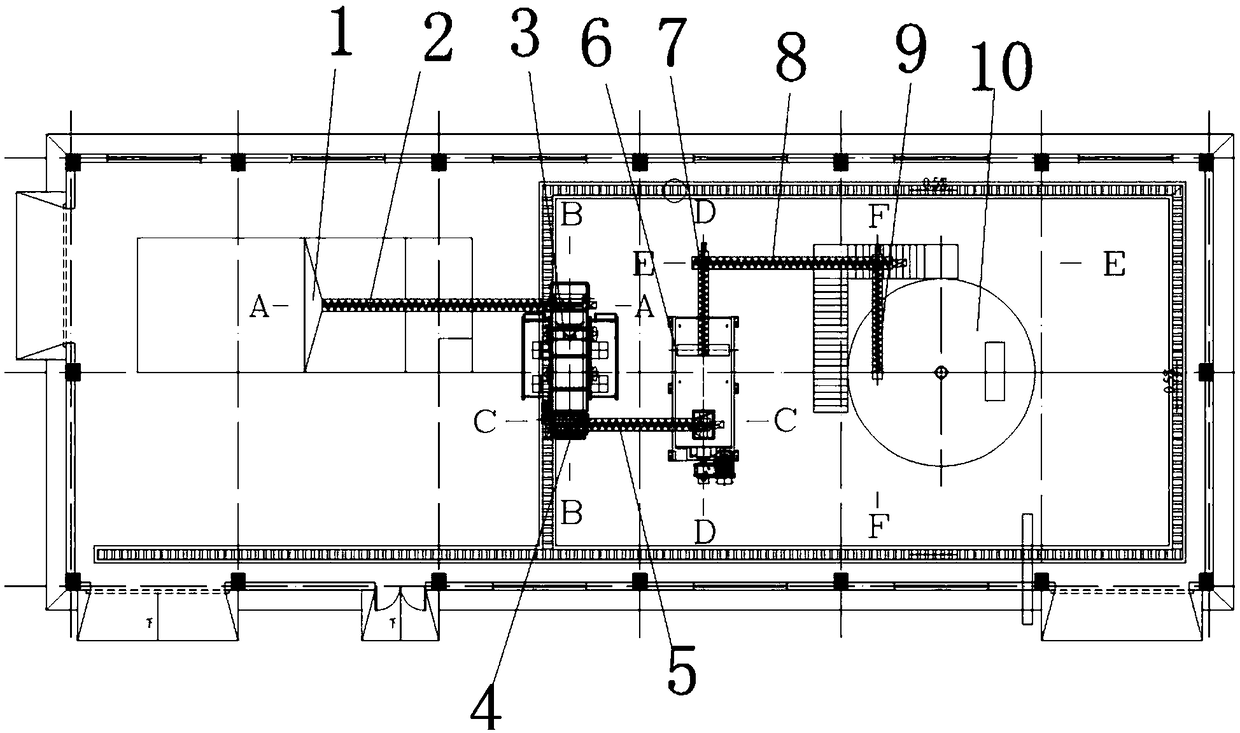

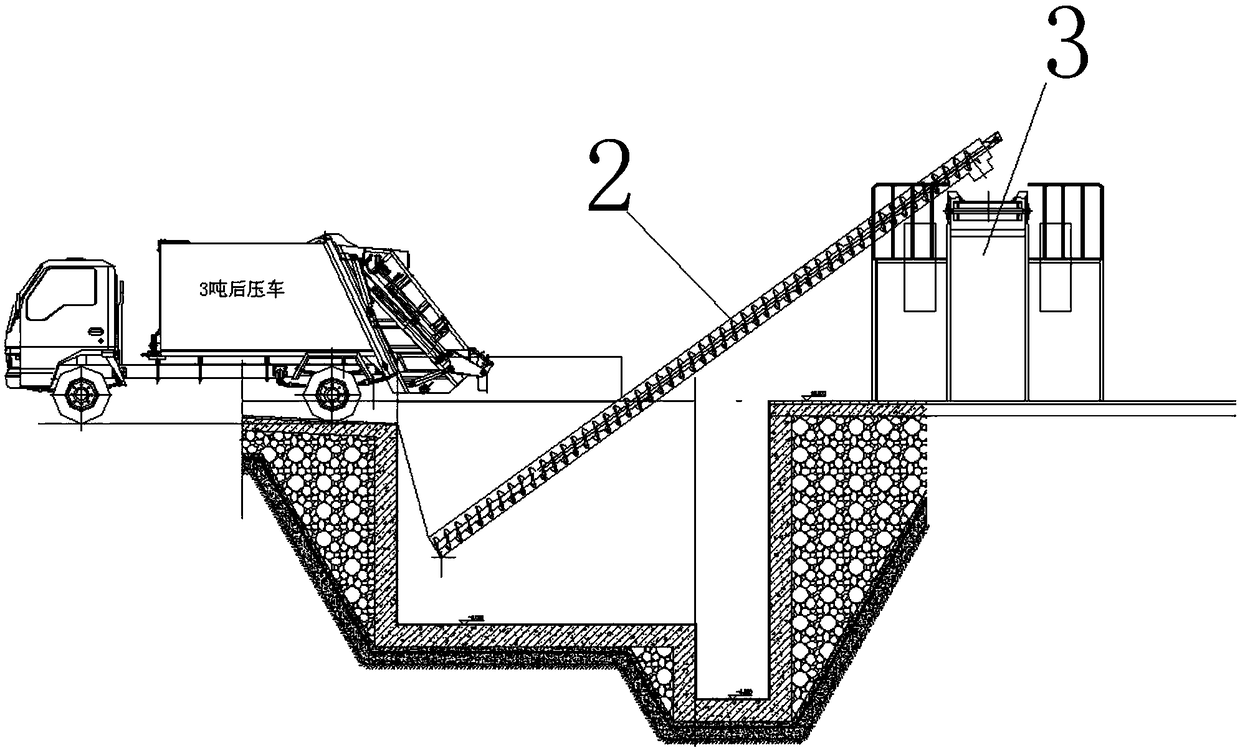

Wet garbage disposal device and technology

PendingCN109317501ARealize resource utilizationReduce disposal volumeSolid waste disposalTransportation and packagingResource utilizationLitter

The invention discloses a wet garbage disposal device and technology. The wet garbage disposal device comprises a material storage device, a feeding conveyor, a sorting conveyor, a crusher, a crushingconveyor, a dewatering machine, a dewatering conveyor, a filter residue conveyor, a fermentation conveyor and an intelligent fermentation tower; the feeding conveyor is obliquely arranged between thematerial storage device and the sorting conveyor, and the sorting conveyor is located above the material storage device; an input port of the crusher is located below an output port of the sorting conveyor; the crushing conveyor is obliquely arranged between an output port of the crusher and the dewatering machine; the dewatering conveyor is obliquely arranged at an output port of the dewateringmachine; the output end of the dewatering conveyor is connected to the input end of the filter residue conveyor; the output end of the filter residue conveyor is connected to the input end of the fermentation conveyor; and the output end of the fermentation conveyor is connected to the intelligent fermentation tower. The technology which is beneficial to the disposal of the device can be referredto the specification. According to the wet garbage disposal device and technology, garbage resource utilization can be realized, the garbage disposal amount can be decreased, and the quality of the living environment can be improved.

Owner:上海程胜环保科技有限公司

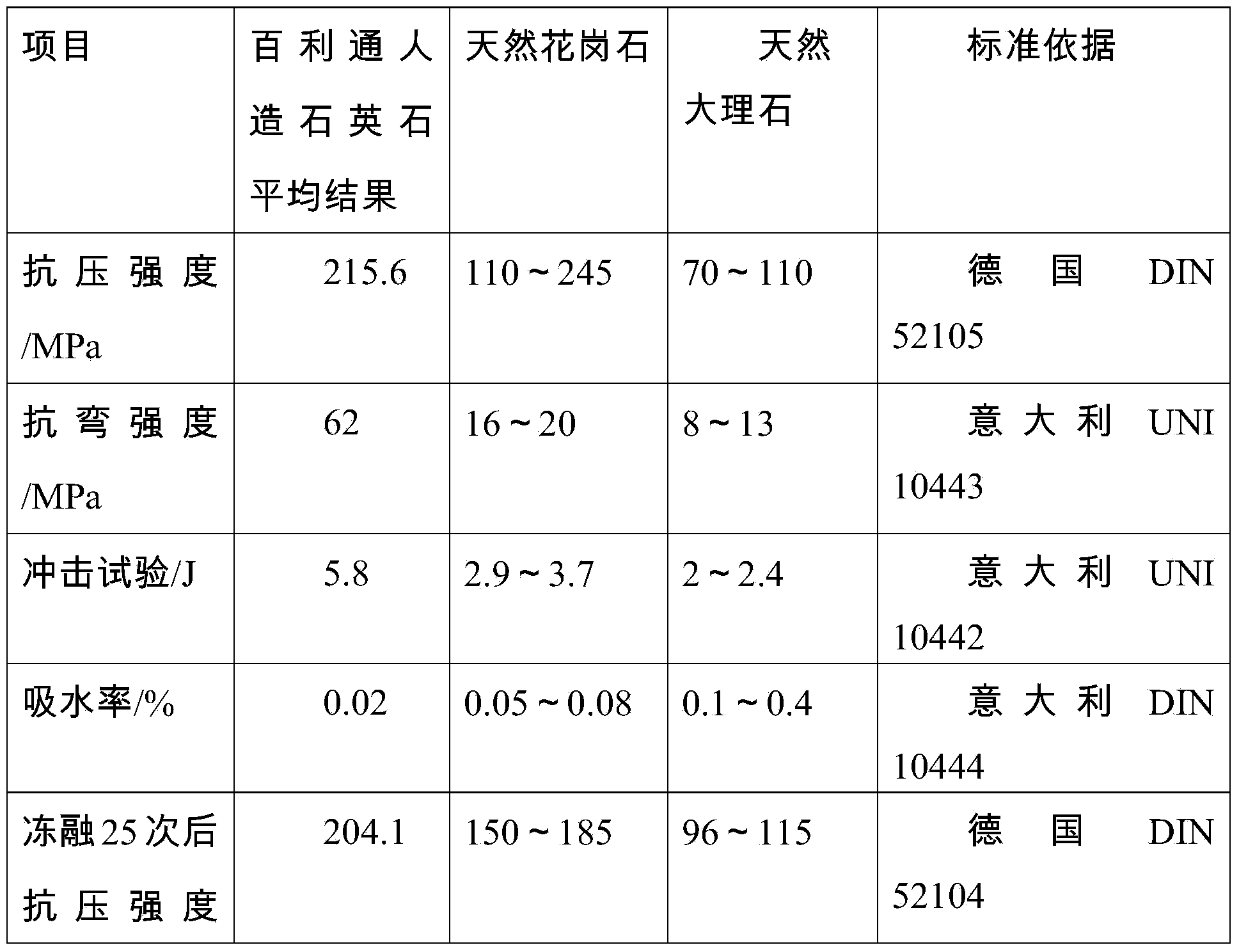

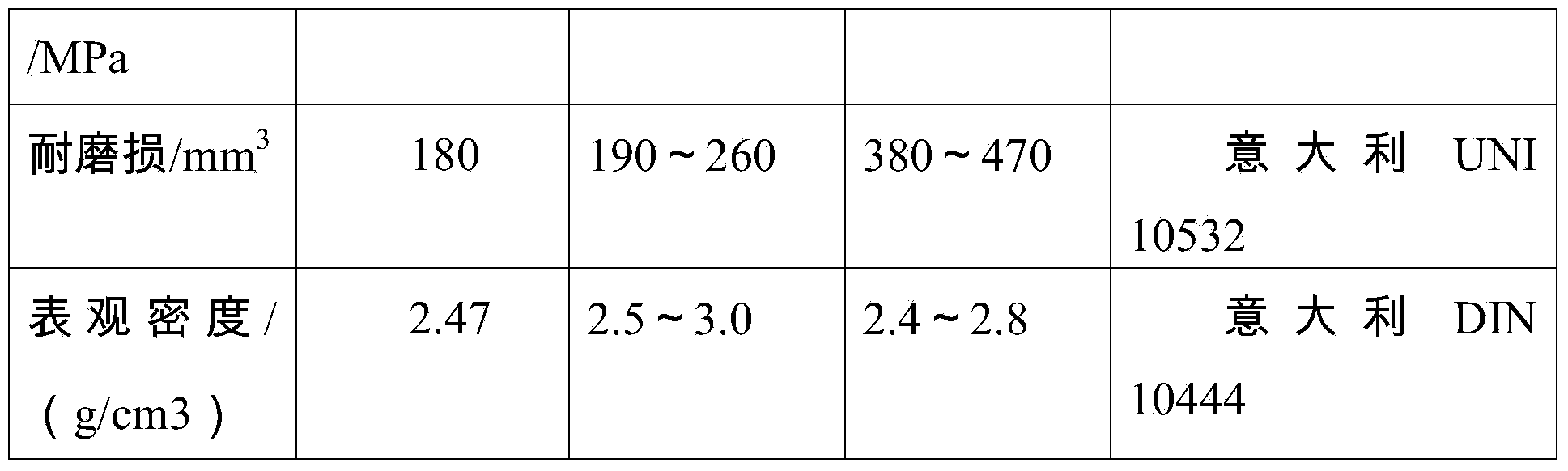

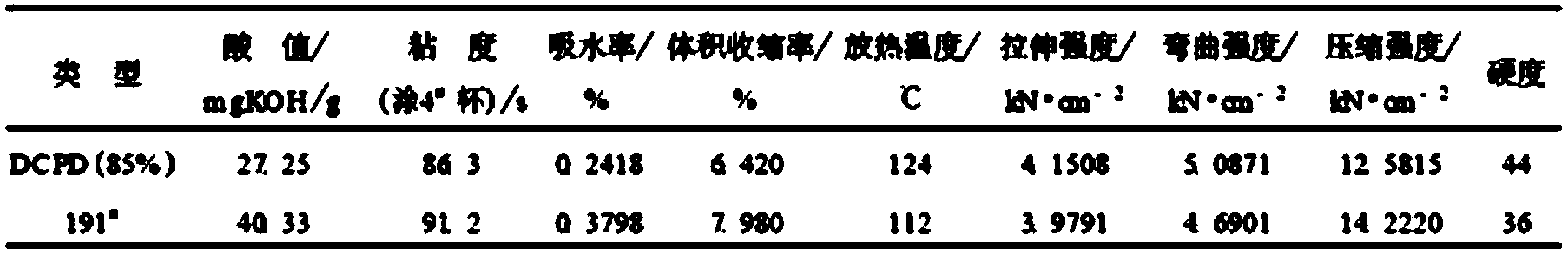

Method for manufacturing artificial colorized quartz composite stone with colorized quartz sand

InactiveCN104230214AProduction to preventSolve outstanding technical problemsAdhesiveConstruction aggregate

The invention provides a method for manufacturing artificial colorized quartz composite stone with colorized quartz sand. The method comprises the steps as follows: natural quartz powder is added into an adhesive and uniformly stirred; aggregate is added into a mixture of the natural quartz powder and the adhesive; an accelerant, a coupling agent and a curing agent are added and stirred uniformly; vacuum vibration suppression and curing are performed to obtain the artificial colorized quartz composite stone. The artificial colorized quartz composite stone comprises the raw materials in parts by weight as follows: 10-30 parts of the natural quartz powder, 7-20 parts of the adhesive and 50-85 parts of the artificial colorized quartz sand. The artificial colorized quartz sand is formed by drying and high-temperature sintering of the natural quartz powder wrapped with inorganic color size. With the adoption of the method, the colorized quartz sand is used as the aggregate, so that various pigment wastewater cannot be produced in machining such as cutting, grinding, polishing and the like after curing; production of pigment wastewater is avoided thoroughly from the source, and a pending technical problem on the sustainable development path in the artificial composite stone manufacturing field is solved.

Owner:张清

Treatment method for waste water of acephate producing process

InactiveCN101143813ASolve environmental problemsPrevent the occurrenceGroup 5/15 element organic compoundsCarboxylic acid salt preparationFiltrationAqueous sodium hydroxide

The invention discloses a method of processing the process wastewater in the production of acephate. The acephate process wastewater is poured into a reaction kettle, thirty percent of sodium hydroxide solution is dripped into the acephate process wastewater at a temperature between 30 DEG C and 40 DEG C, the pH value is contolled in a range of nine to nine point five, and the ammonia gas generated by reaction is absorbed by water, so that ammonia is produced; reaction liquid is desolventized under the conditions of temperature between 80 DEG C and 100 DEG C and vacuum between-0.08 MPa and-0.1 MPa, the desolventizing time is two to four hours, the temperature is then decreased to 18 to 20 DEG C, so that the reaction liquid is crystallized, the crystallizing time is half to five hours, and finally, sodium acetate trihydrate and mother liquid are produced by extraction and filtration. The invention has the advantages of simple technique, safety, low cost, no production of three wastes and environmental protection.

Owner:SHANGHAI TOPCARE MEDICAL SERVICES CO LTD

Organic garbage treatment method and organic garbage disposal tank

PendingCN108405578AReduce dosageProduction to preventBio-organic fraction processingSolid waste disposalHydrogenLitter

The invention relates to an organic garbage treatment method. The organic garbage treatment method comprises the following steps of mixing 55 to 65 parts of water and 35 to 45 parts of organic garbageby weight, and enabling the water surface to completely cover the organic garbage; aerating up from the bottom part of a solid and liquid mixture, heating the solid and liquid mixture to 70 to 80 DEGC, fermenting in a fermenting tank in a sealing way, and maintaining the temperature to 70 to 80 DEG C; adjusting the pH (potential of hydrogen) value of the liquid, and maintaining to be 6.0 to 8.0;leading the produced steam into a heating device; after heat exchange is completed, circulating back into the fermenting tank, wherein the organic garbage includes but not limited to excrement, straws, wine distillers, tree leaves and kitchen leftover organic garbage. The invention discloses an organic garbage treatment tank. The organic garbage treatment method and the organic garbage treatmenttank have the advantage that any chemical reagent is not added in the whole process, and the produced water steam and organic fertilizer can be directly used.

Owner:峨眉山市瑞丰生物科技有限责任公司

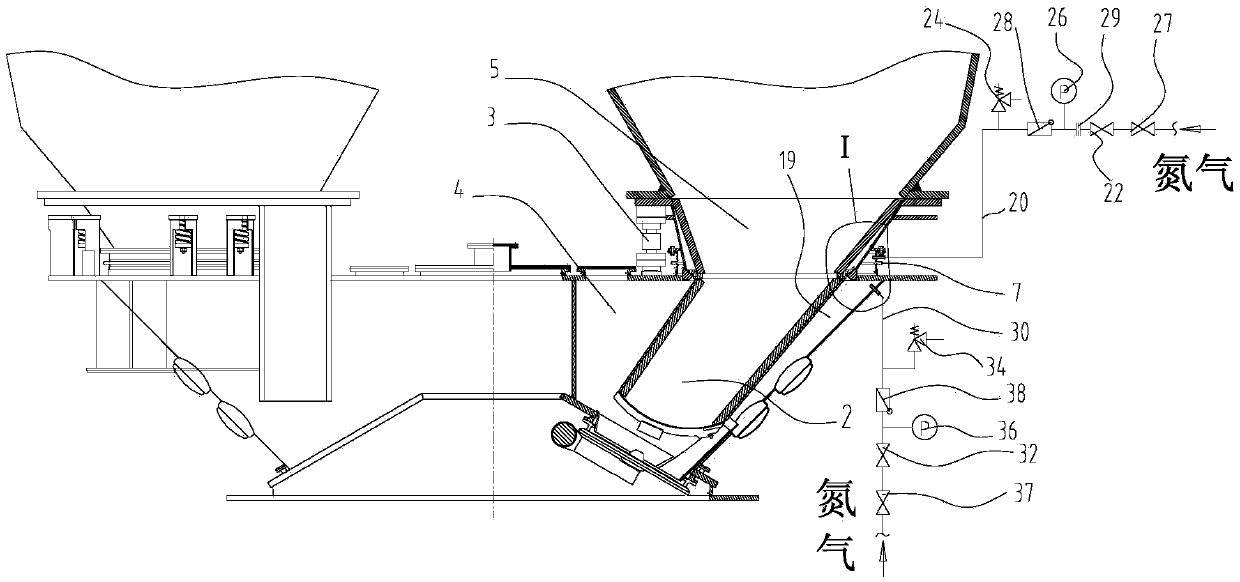

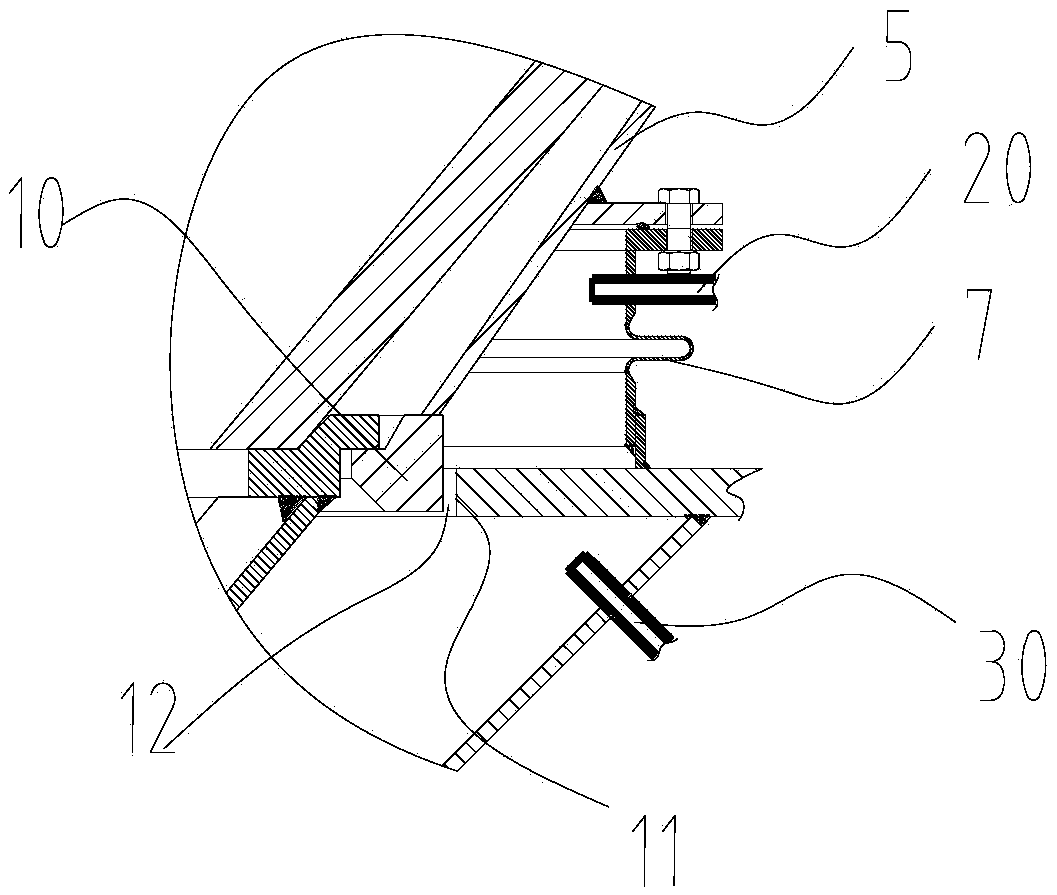

Purging device and technology of blast furnace charging bucket weighing system

ActiveCN105368999AEliminate gray tumorGuaranteed external interferenceBell-and-hopper arrangementDust arrestersEngineeringNitrogen source

The invention discloses a purging device and technology of a blast furnace charging bucket weighing system. The purging device comprises a ripple compensator purging mechanism and a lower valve box purging mechanism, wherein the ripple compensator purging mechanism comprises a first pipeline, and a first manual block valve, a first valve, a first pressure meter, a first one-way valve and a first decompression valve which are sequentially arranged on the first pipeline from outside to inside; the outer end of the first pipeline is connected with a nitrogen source; the inner end of the first pipeline is connected with the inner cavity of a ripple compensator; the lower valve box purging mechanism comprises a second pipeline, and a second manual block valve, a second valve, a second pressure meter, a second one-way valve and a second decompression valve which are sequentially arranged on the second pipeline from outside to inside; the outer end of the second pipeline is connected with a nitrogen source; and the inner end of the second pipeline is connected with a cavity. According to the purging device, the dusty gas can be effectively prevented from flowing or spreading into the inner cavity of the ripple compensator and the clearance between the bottom of a material flow regulating valve chute and the outer shell of a lower valve box.

Owner:武汉钢铁有限公司 +1

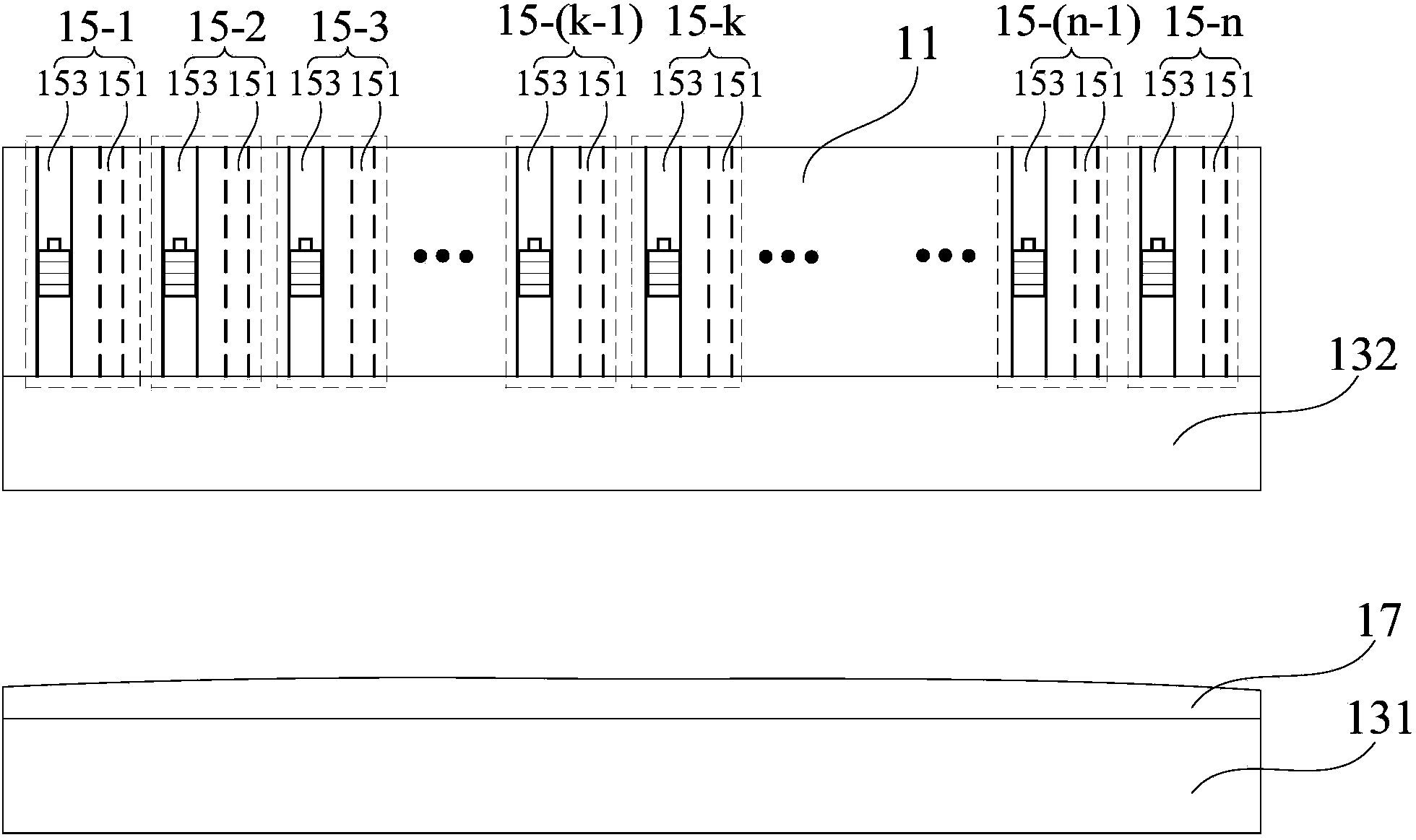

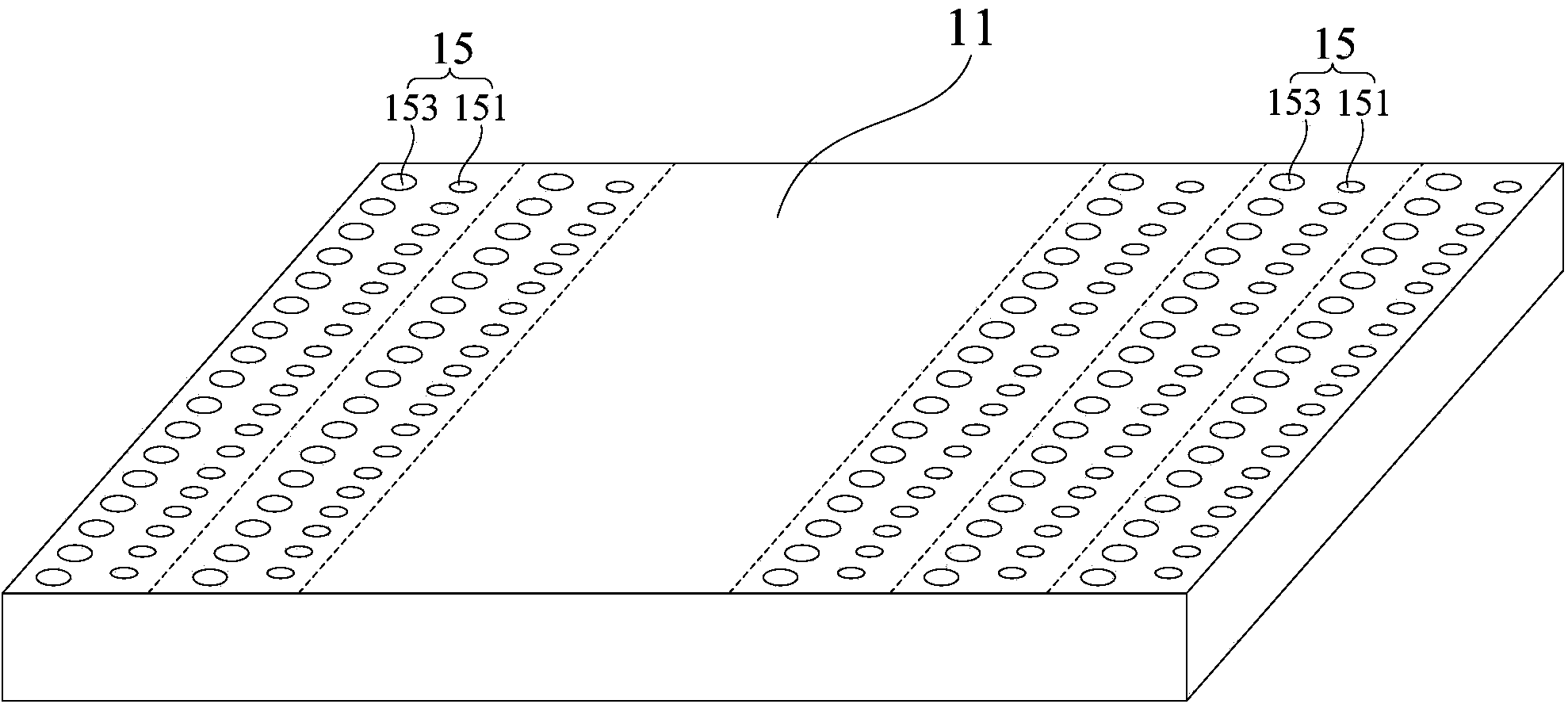

Fixture and method for overlapping glass cover plates in display equipment

InactiveCN103625087AImprove the tightness of the pressImprove cutting yieldLaminationLamination apparatusGlass coverCutting glass

The invention provides a fixture and a method for overlapping glass cover plates in display equipment. The overlapping fixture comprises an operation panel which is provided with an operation surface which corresponds to a glass cover plate to be overlapped; a plurality of pressure releasing structure pairs, which are arranged on the operation surface, absorb glass cover plates and release the glass cover plates gradually and sequentially by pressure releasing actions so as to overlap the glass cover plates with other glass cover plates; each pressure releasing structure pair comprises a column of adsorption hole structures and a column of pushing-pressing hole structures; the adsorption hole structures are connected with an air extracting device; the pushing-pressing hole structures are connected with a pressurizing device. Compared with the prior art, the fixture has the advantages that the glass cover plates can be gradually overlapped according to sections; during the gradual overlapping process, air between two glass cover plates to be overlapped is removed as much as possible, so that air bubbles between the two overlapped glass cover plates are controlled in the allowed range or even are eradicated, and the overlapping compactness of the glass cover plates and the yield of subsequent cut glass cover plates are improved.

Owner:SHANGHAI NISSIN MACHINE TOOL

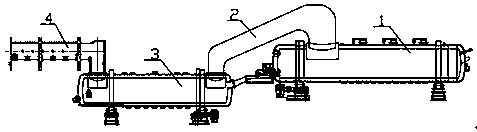

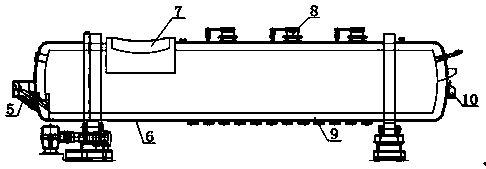

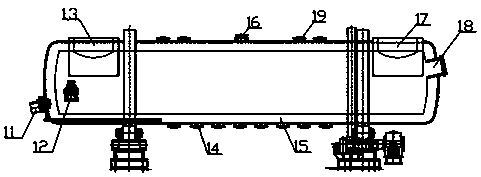

Low-grade scrap copper cleaning and smelting new process and device thereof

InactiveCN107828968AAvoid it happening againProduction to preventProcess efficiency improvementBrickSlag

The invention provides a low-grade scrap copper cleaning and smelting new process and a device thereof. A furnace body of a bottom blowing melting furnace is a cylindrical horizontal rotary smelting furnace, and is lined with refractory bricks; one end of the top of the furnace body is a scrap copper charging port, and a flue port is formed in the other end of the furnace body; a spraying gun portis formed in the bottom of the part, below the flue port, of the furnace body; the side surface of the part, at one end of the flue port, of the furnace body is connected with a copper discharge portdevice, and a slag discharge port device is arranged on the part, at the other end of the flue port, of the furnace body. A furnace body of a bottom blowing oxidation-reduction furnace is a cylindrical horizontal rotary smelting furnace, and is lined with refractory bricks; a flue connecting port and a flue port are formed in two ends of the top of the furnace body correspondingly, and an accessory unloading port and a natural gas burner are distributed at the upper part in sequence; a matte feed port is formed in one side of the natural gas burner; a copper discharge port device and a slag discharge port device are arranged on the other side of the natural gas burner; and a spraying gun port is formed in the bottom of the furnace body. The advantages of reduction of the heat loss, high production capacity and intensity, high efficiency, high smelting strength, high utilization rate of oxygen, good labor conditions, convenience in operation, high production efficiency, good economicalbenefits, energy conservation and environmental protection are achieved.

Owner:DONGYING FANGYUAN NONFERROUS METALS +2

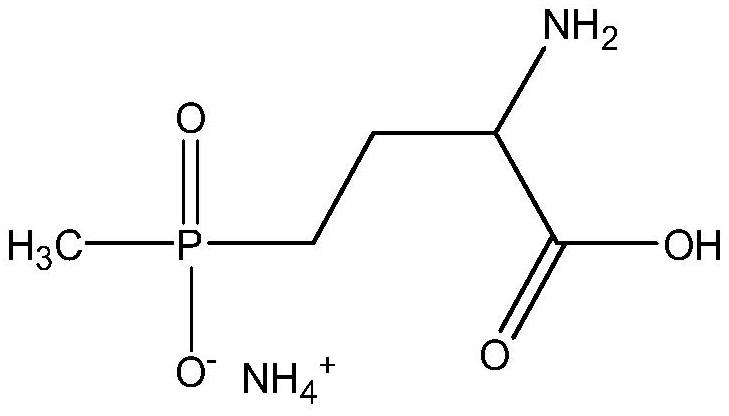

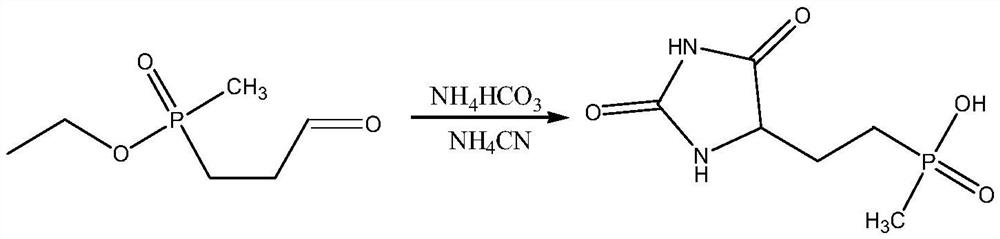

Synthesis method of glufosinate-ammonium

ActiveCN113045604ASerious lossLow effectivenessGroup 5/15 element organic compoundsChemical recyclingInorganic saltsHydantoin derivatives

The invention relates to the field of pesticides, in particular to a synthesis method of glufosinate-ammonium. The synthesis method of glufosinate-ammonium comprises the following steps: reacting a mixed aqueous solution of a hydantoin derivative, volatile alkali and a catalyst under 1.0-2.5 MPa, and after the reaction is finished, carrying out post-treatment to obtain glufosinate-ammonium, wherein the catalyst is a guanidine compound. The synthesis method of glufosinate-ammonium provided by the invention jumps out of the thought of separating glufosinate-ammonium from inorganic salt in the prior art, creatively adopts the mutual cooperation of volatile alkali and the catalyst (guanidine compound), and hydrolyzes the hydantoin derivative under the specific pressure of 1.0-2.5 MPa, so that the hydantoin compound is thoroughly hydrolyzed, the yield of glufosinate-ammonium is improved, meanwhile, the reaction time is shortened, acid-base neutralization is not needed after the reaction is finished, inorganic salt is not generated, generation of the inorganic salt in the glufosinate-ammonium preparation process is fundamentally eradicated, three wastes are not generated, the yield of glufosinate-ammonium is high, and industrial popularization is easy.

Owner:HEBEI VEYONG BIO CHEM

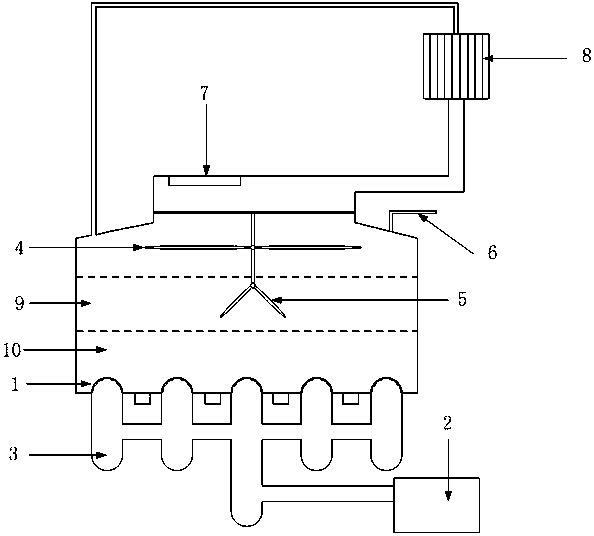

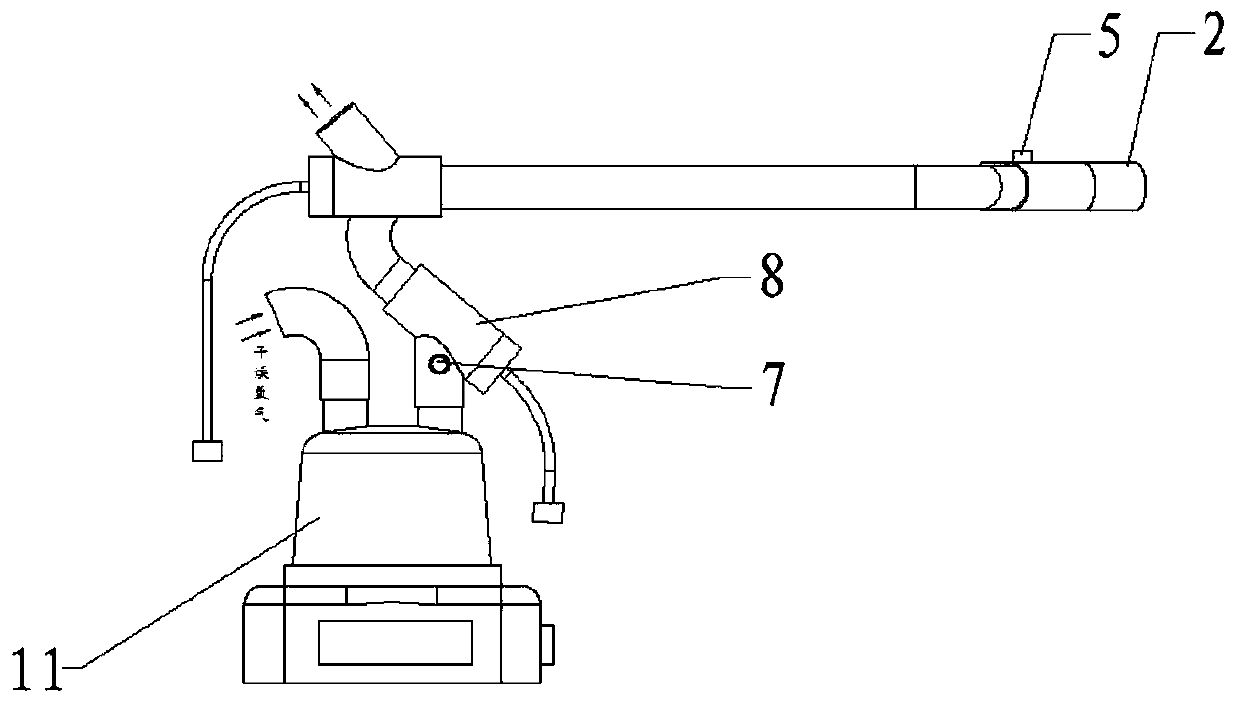

Humidifying and heating system for breathing machine

PendingCN110170099AEliminate the generation of condensation waterProduction to preventRespiratorsMedical devicesCondensed waterHeating system

The invention relates to the field of medical instruments, in particular to a humidifying and heating system for a breathing machine, comprising a mechanical atomizing humidifier, wherein one of connectors of the mechanical atomizing humidifier is communicated with the breathing machine, the other connector of the mechanical atomizing humidifier is communicated with a breathing circuit, and the breathing circuit is provided with a heating mechanism. By adopting the scheme, the generation of condensed water is fundamentally eliminated, and the gas can still be transmitted to the patients in danger in relative temperature and humidity.

Owner:SHAOXING UNDIS MEDICAL TECH CO LTD

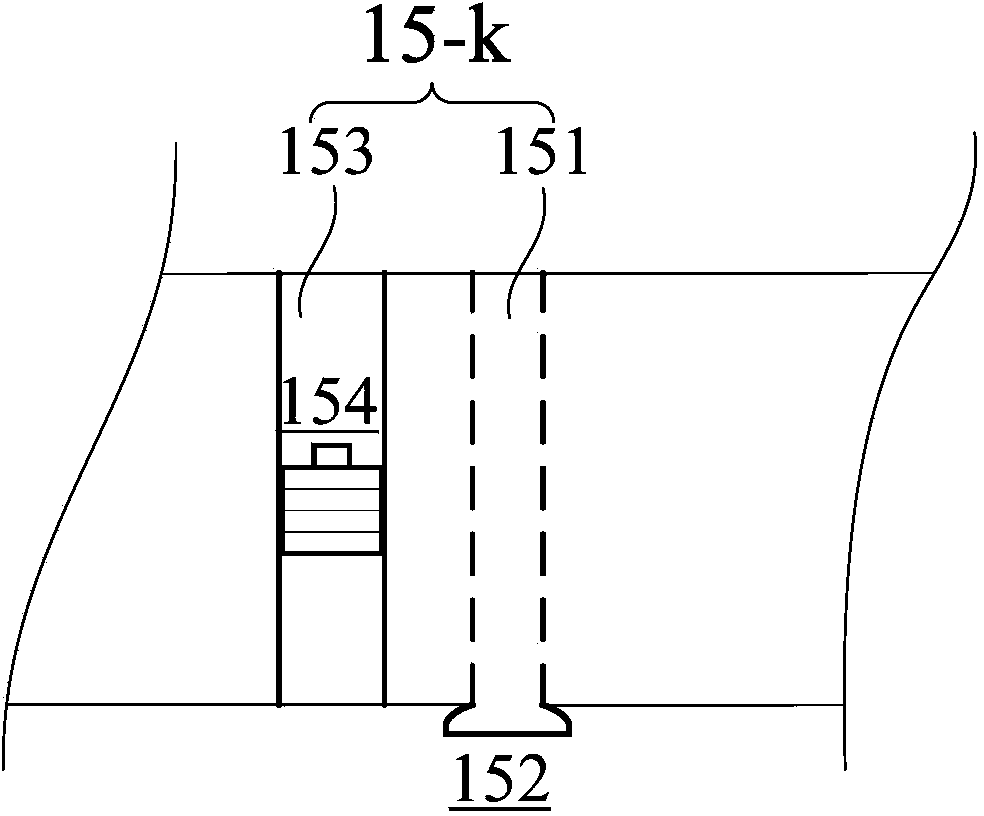

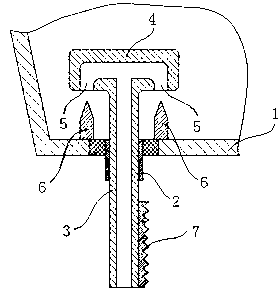

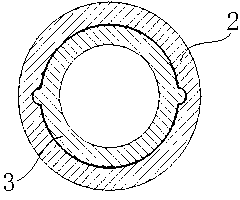

Pouring gate flow control device for preventing rotational flow from generating in continuous casting tundish

InactiveCN103111613APrevent the formation of swirlImprove cleanlinessMelt-holding vesselsLiquid steelTundish

The invention discloses a pouring gate flow control device for preventing a rotational flow from generating in a continuous casting tundish and belongs to the technical field of tundish pouring gate flow control devices. The pouring gate flow control device for preventing the rotational flow from generating in the continuous casting tundish comprises a liquid discharge pipe, a liquid inlet plate, flow guide holes, a flow control stopper rod and a lift mechanism. The liquid discharge pipe penetrates through the bottom of the tundish and extends into the inner portion of the tundish. The liquid discharge pipe is hollow. One end portion of the liquid discharge pipe, extending into the tundish, is fixedly connected with the liquid inlet plate. The top and the side faces of the liquid inlet plate are respectively sealed. One or more flow guide holes are formed in the bottom face of the liquid inlet plate. An opening of each flow guide hole is downward. Each flow guide hole is communicated with a hollow portion in the liquid discharge pipe. The flow control stopper rod is arranged right below the flow guide holes. The outer diameter of the flow control stopper rod is matched with the inner diameter of the corresponding flow guide hole. The flow control stopper rod is vertically arranged and fixed on the bottom of the tundish. The lift mechanism is arranged at one end, located outside the tundish, of the liquid discharge pipe and controls lift of the liquid discharge pipe and the liquid inlet plate. The pouring gate flow control device for preventing the rotational flow from generating in the continuous casting tundish can effectively prevent the rotational flow from generating and improve purity of liquid steel.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

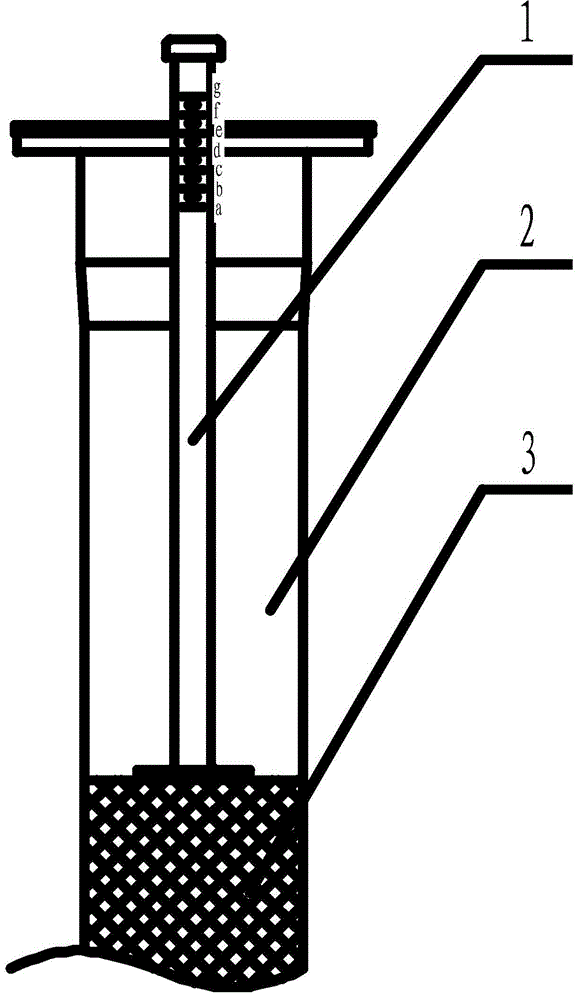

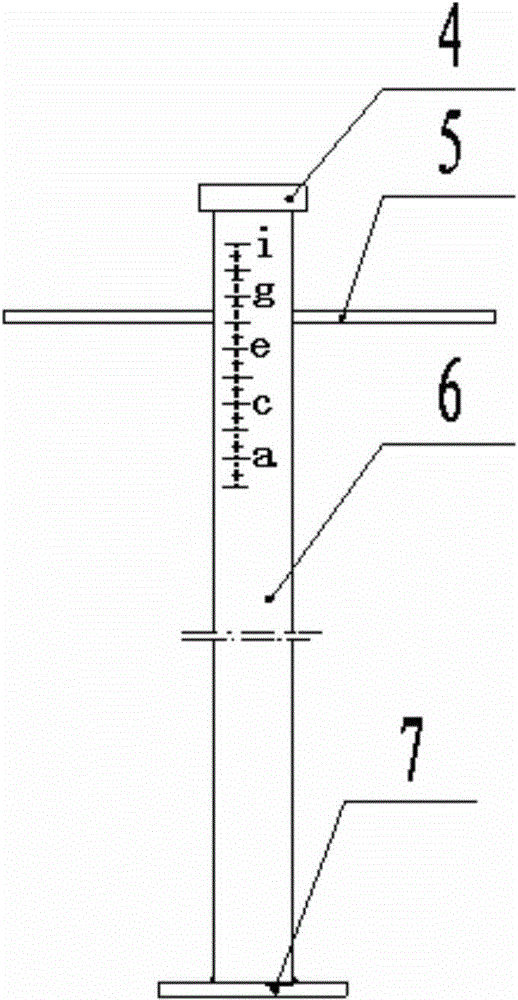

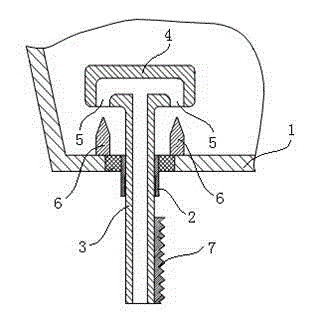

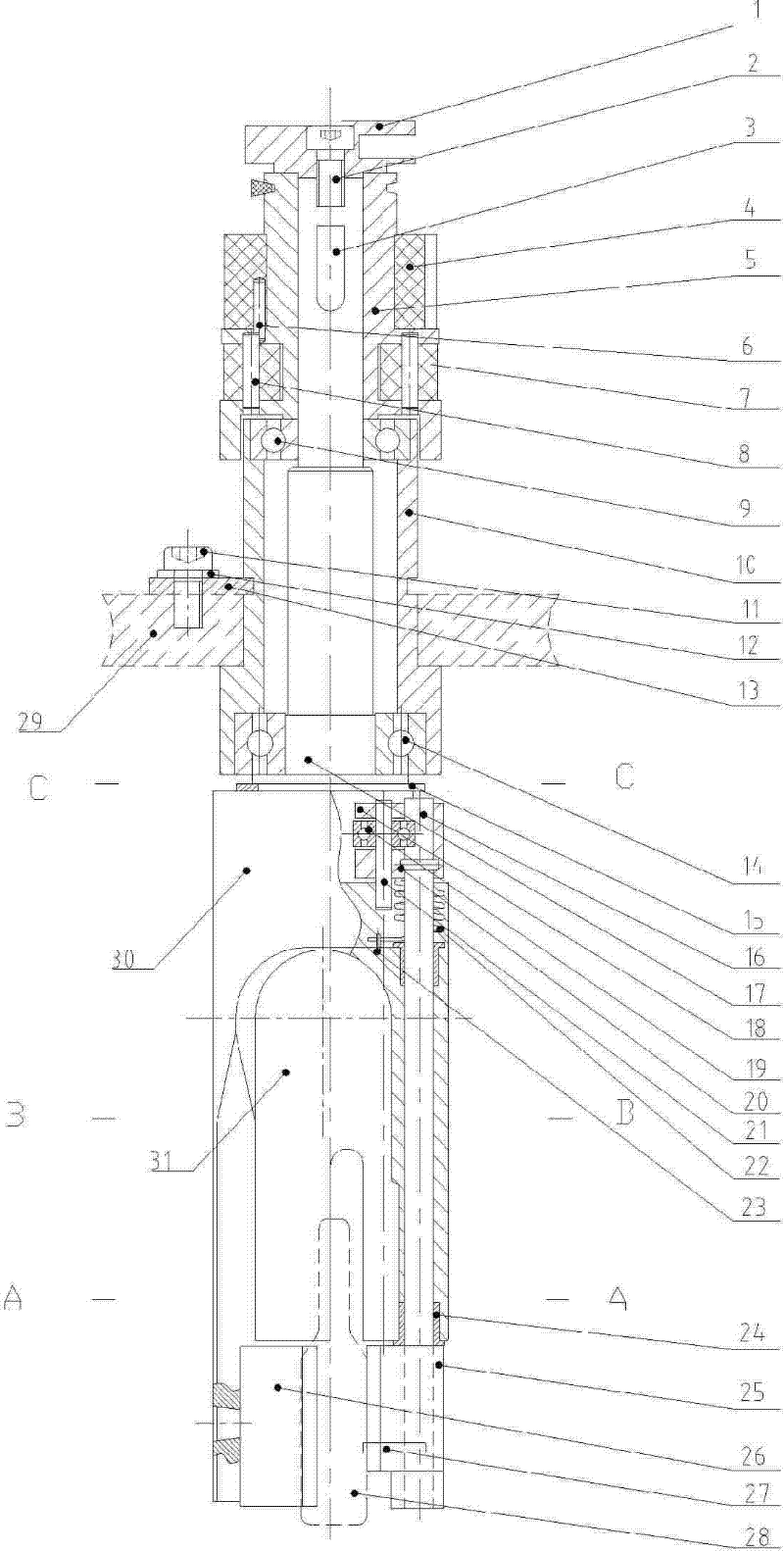

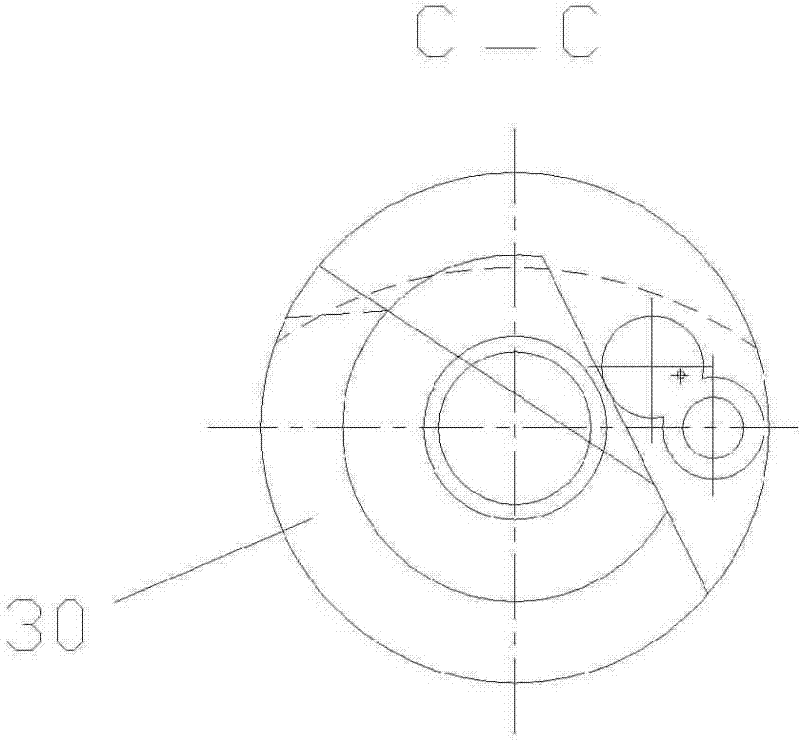

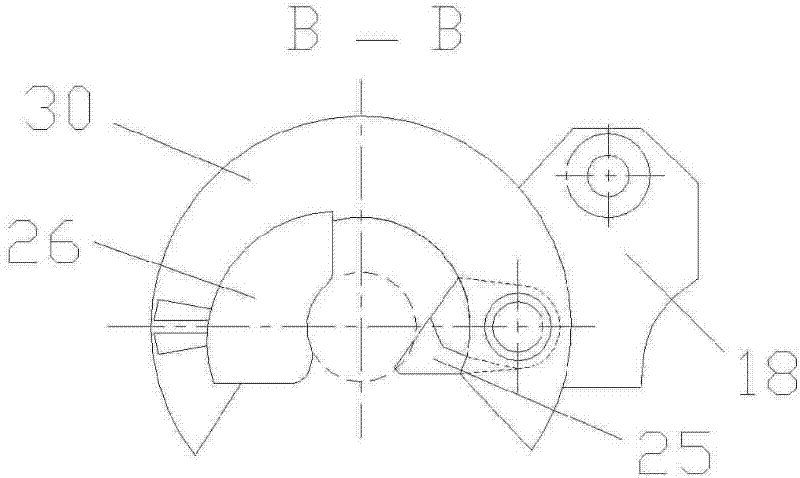

Device for measuring pouring amount of motor propellant

InactiveCN104535131AProduction to preventSolve storage problemsVolume measurement apparatus/methodsCombustion chamberPhysics

The invention provides a device for measuring the pouring mount of a motor propellant. The device comprises a nut, a positioning plate, a measuring rod and a measuring plate; a scale line is formed in the surface of the upper part of the measuring rod; the positioning plate sleeves the upper part of the measuring rod and is in sliding match with the measuring rod; the nut is mounted on the upper end surface of the measuring rod; the measuring plate is welded on the lower end surface of the measuring rod; the scale line in the surface of the measuring rod body includes 60 small grids which are arranged at intervals of 1mm; every ten small grids form a large grid; each grid is marked with English letters from a to j. According to the device, the level of the propellant is measured after pouring the propellant of a combustion chamber and before inserting a core, so that the pouring quality of the propellant of the combustion chamber can be quickly detected, and the reject ratio of the product is lowered down from 4% to 0%.

Owner:XIAN AEROSPACE CHEM PROPULTION PLANT

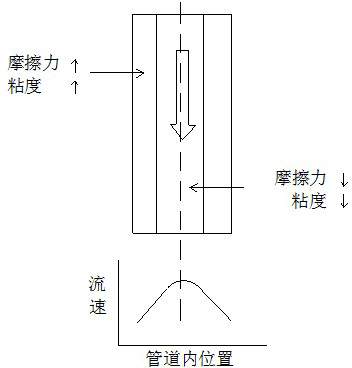

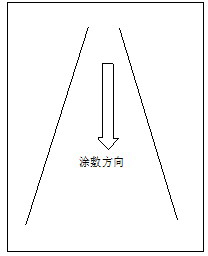

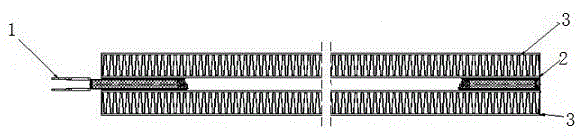

Slurry transportation pipeline system for high viscosity coating device

InactiveCN102423744ARetrofit smallLow costLiquid surface applicatorsCoatingsSlurry coatingProcess engineering

The invention which discloses a slurry transportation pipeline system for a high viscosity coating device belongs to the technical field of electronic slurry coating application. The system which comprises a coating machine nozzle is characterized in that: the front part of the coating machine nozzle is connected with a stationary stirrer which comprises a tubular housing and a stationary spiral stirring member arranged in the housing; and the spiral stirring member forms a spiral channel for making a high viscosity fluid in the housing generate a spiral motion. The slurry transportation pipeline system for the high viscosity coating device allows the uniformity of the slurry in the coating pipeline to be improved and the adverseness of coating strips caused by the uniformity difference before the slurry enters the nozzle to be avoided, so the coating film quality is improved.

Owner:SICHUAN COC DISPLAY DEVICES

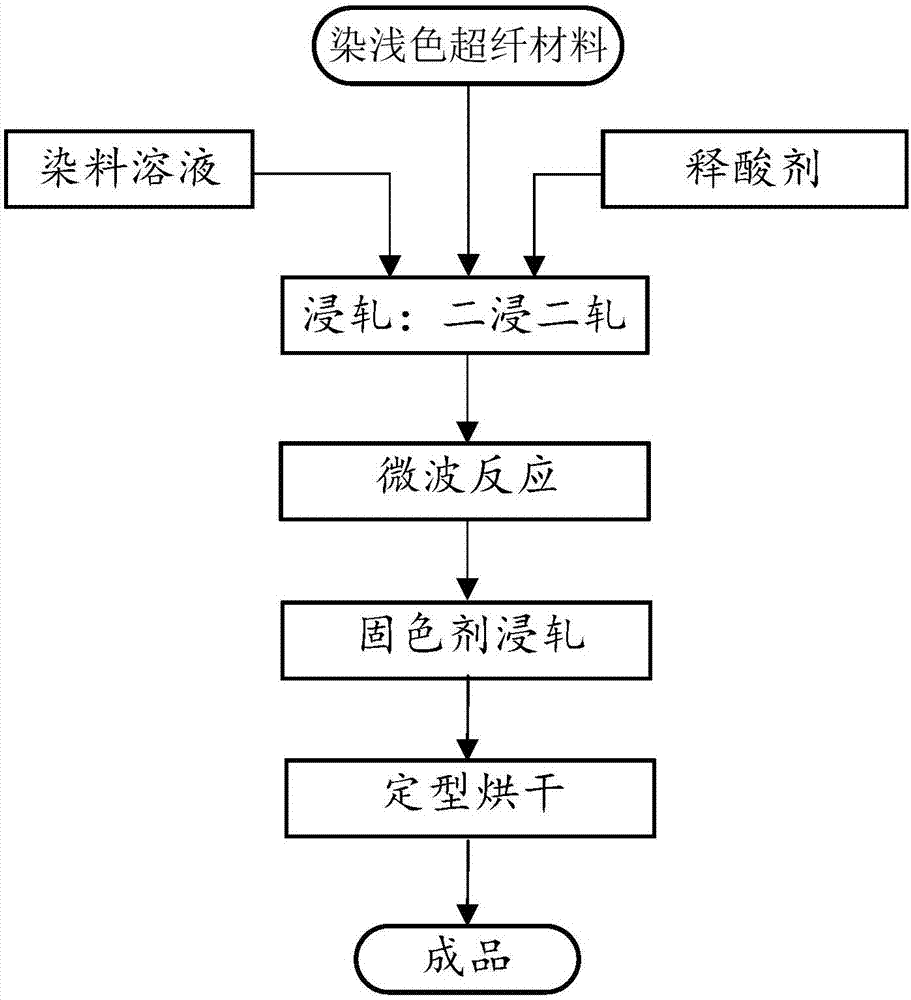

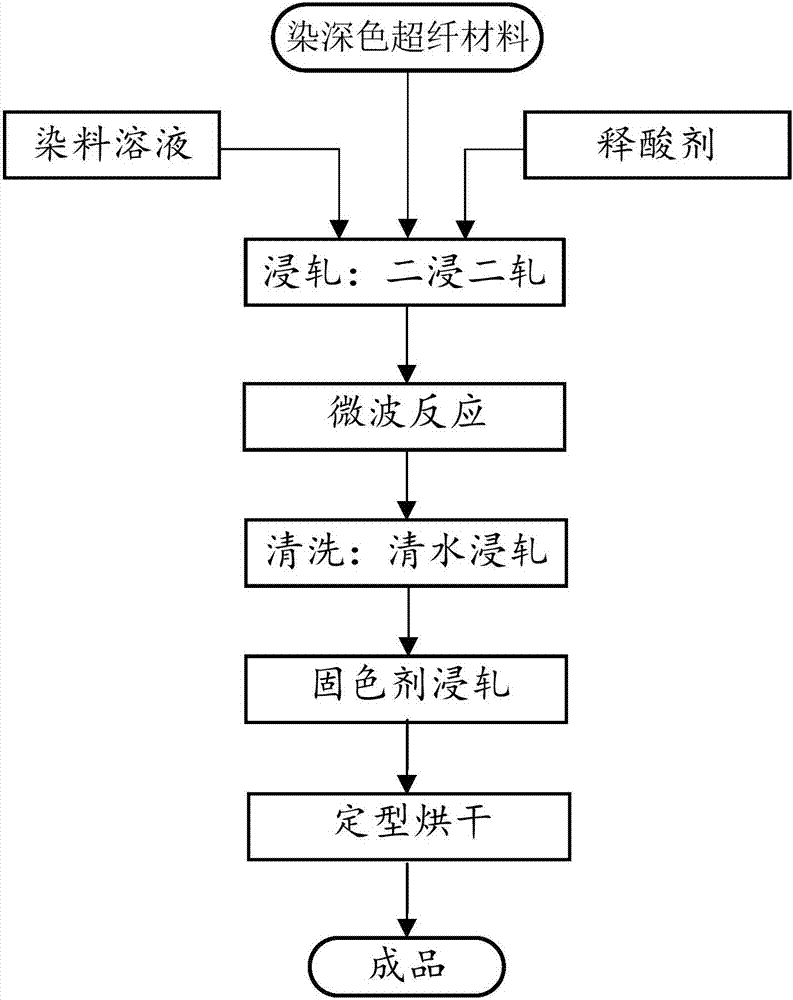

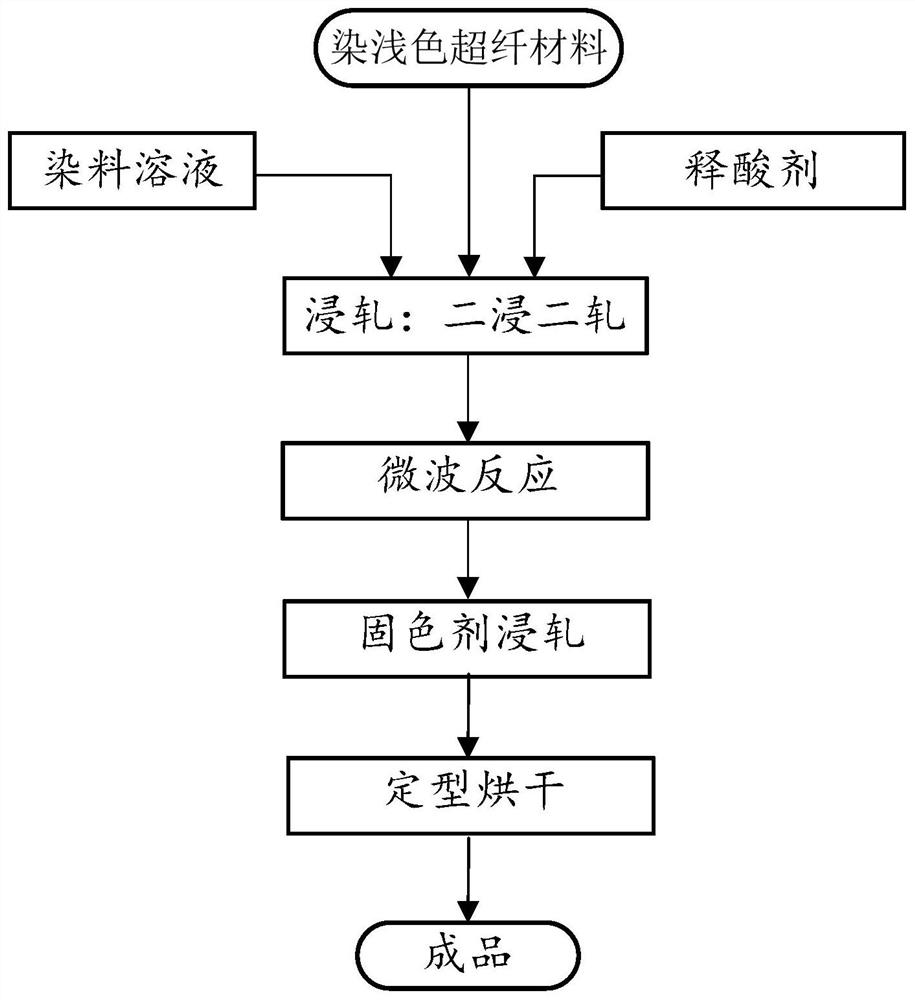

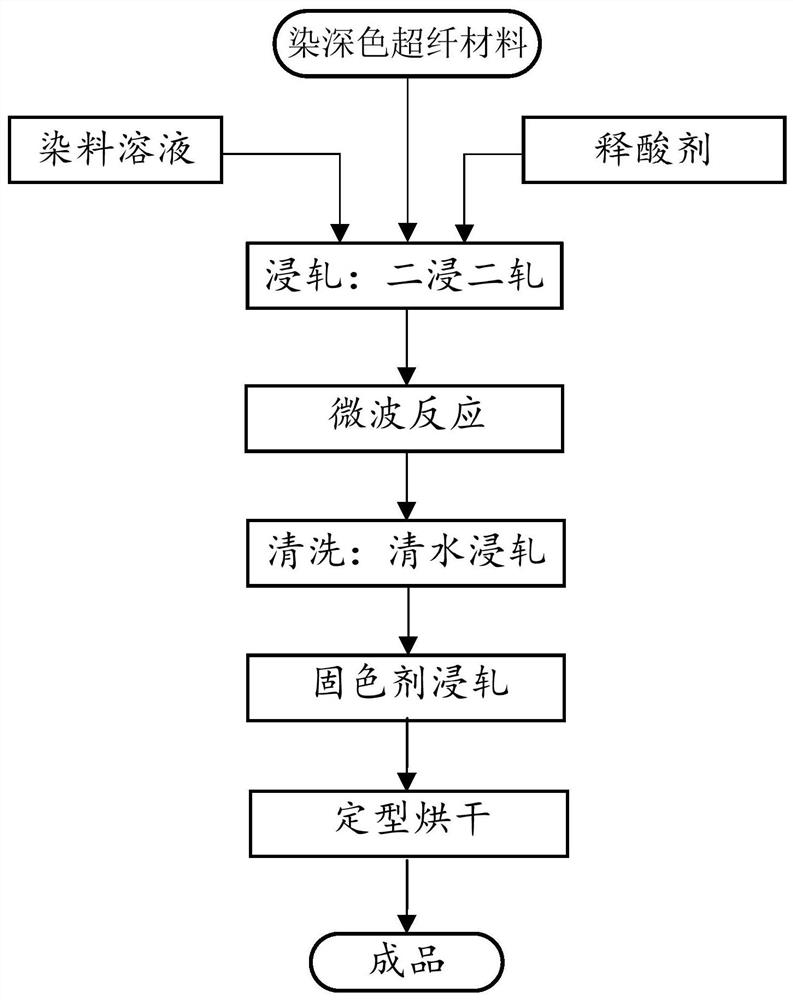

Wastewater-discharge-free continuous dyeing technology of microfiber material

ActiveCN106906677AIncrease productivityHigh speed dyeing effectDyeing processEnvironmental resistanceSizing

The invention discloses a wastewater-discharge-free continuous dyeing technology of a microfiber material, comprising the following steps: padding, dyeing the microfiber material with an acid dye paste through an alternative padding technology; adding an acid-releasing agent; carrying out a microwave reaction, using a microwave radiation device to boil and vaporize the acid dye paste on the microfiber material; and sizing and drying. The padding technology of the microfiber material is more efficient and more environment-friendly. There is no wastewater discharge during the whole process, thus according with the idea of environmental protection and sustainable development of industrial development nowadays. By the microwave reaction continuous-dyeing technology, the high-speed and high-efficiency dyeing efficiency is very remarkable. The cloth moving speed of the dyeing process can reach 10 meters / min. Production efficiency of the microfiber printing and dyeing industry is greatly raised. The invention provides a powerful technical support for the current rapidly-developed microfiber industry.

Owner:上海兴康超纤新材料有限公司

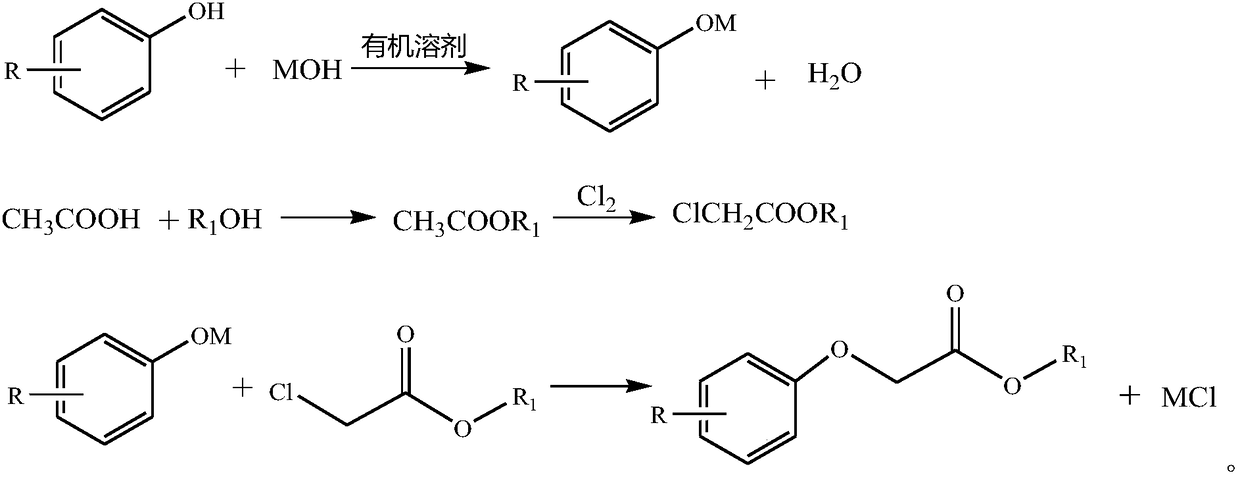

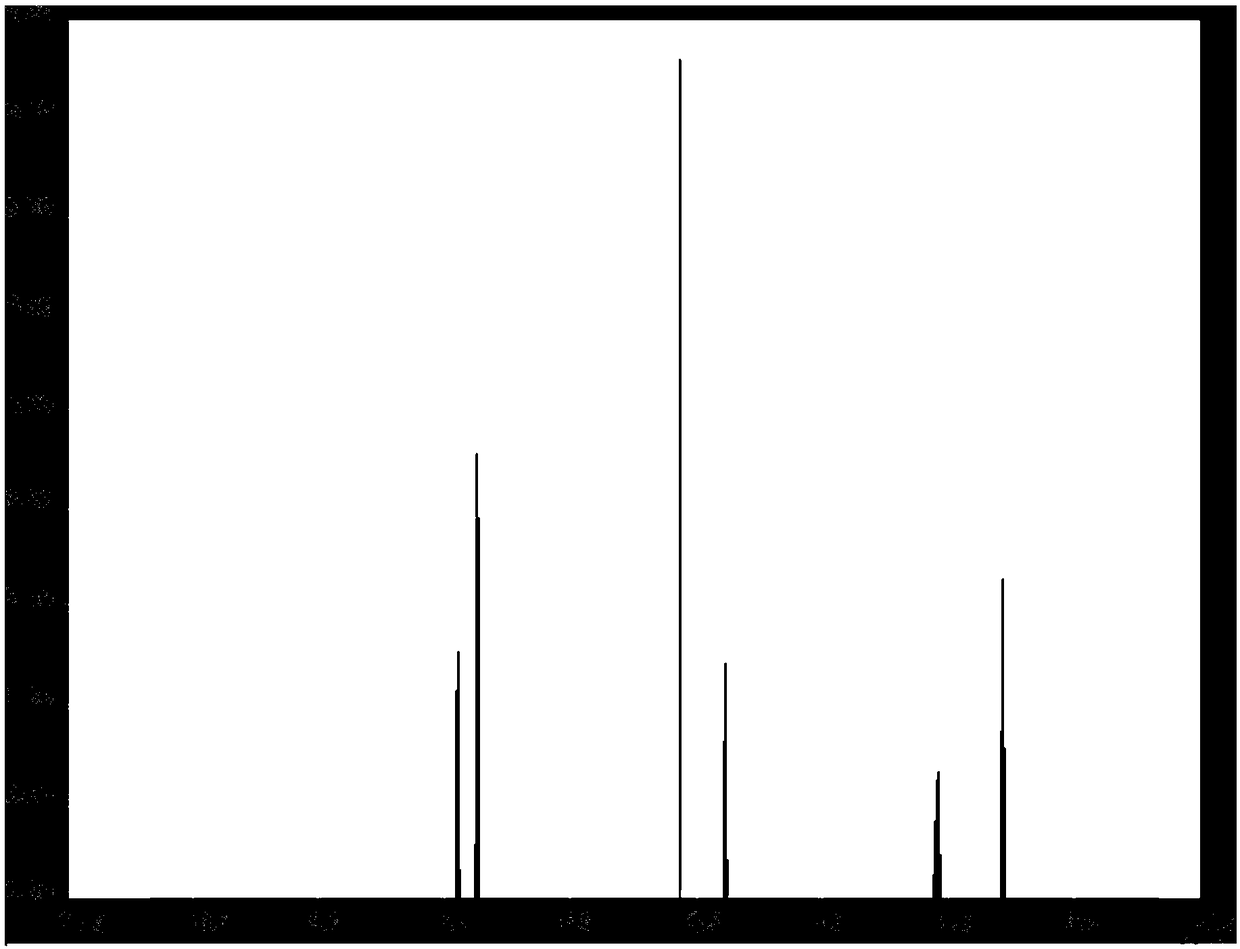

Preparation method of phenoxyacetic ester

InactiveCN108947835ARealize continuous productionImprove dehydration efficiencyOrganic compound preparationCarboxylic acid esters preparationIsobutanolChlorobenzene

The invention provides a preparation method of phenoxyacetic ester, wherein the preparation method includes the following steps: A) carrying out esterification reaction of acetic acid and alcohol to obtain acetic ester; B) introducing chlorine gas into acetic ester, and carrying out reaction to obtain chloroacetic ester; C) dehydrating a phenol compound and alkaline hydroxide into a salt in an organic solvent to obtain a salt of the phenol compound; D) after salt formation, mixing with chloracetic ester prepared in the step B), and carrying out condensation reaction to obtain phenoxyacetic ester, wherein the organic solvent is a mixture of any two kinds of toluene, xylene, chlorobenzene, phenol, butanol and isobutanol. The phenol is dehydrated into the salt in the mixed organic solvent, the system still maintains a uniform state in the dehydration process, continuous production is achieved, the dehydration efficiency is high and the efficiency of the whole production process is high. Moreover, the raw materials are easy to obtain, the production period is short, water is not needed in the reaction process, the energy consumption is low, the production cost is low, the yield of acetic acid is 99% or more, and the total yield of phenol can reach 99% or more.

Owner:SHANDONG RUNBO BIOTECH CO LTD

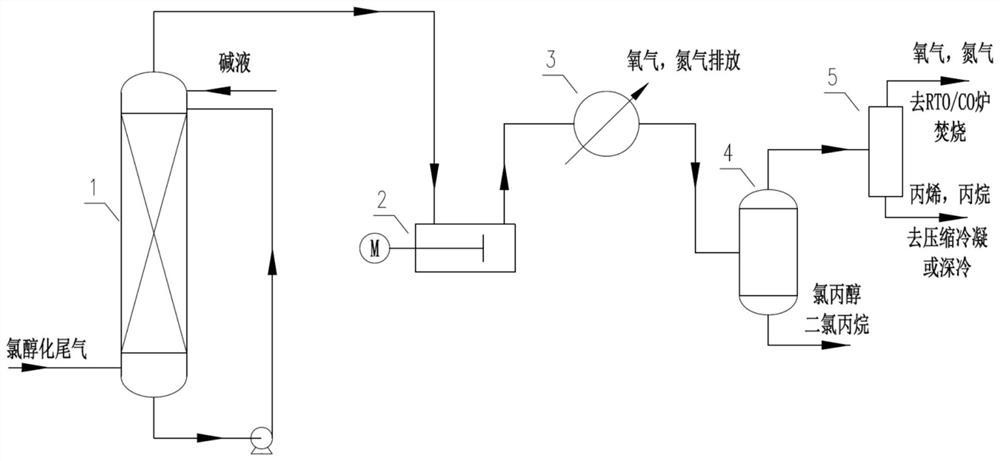

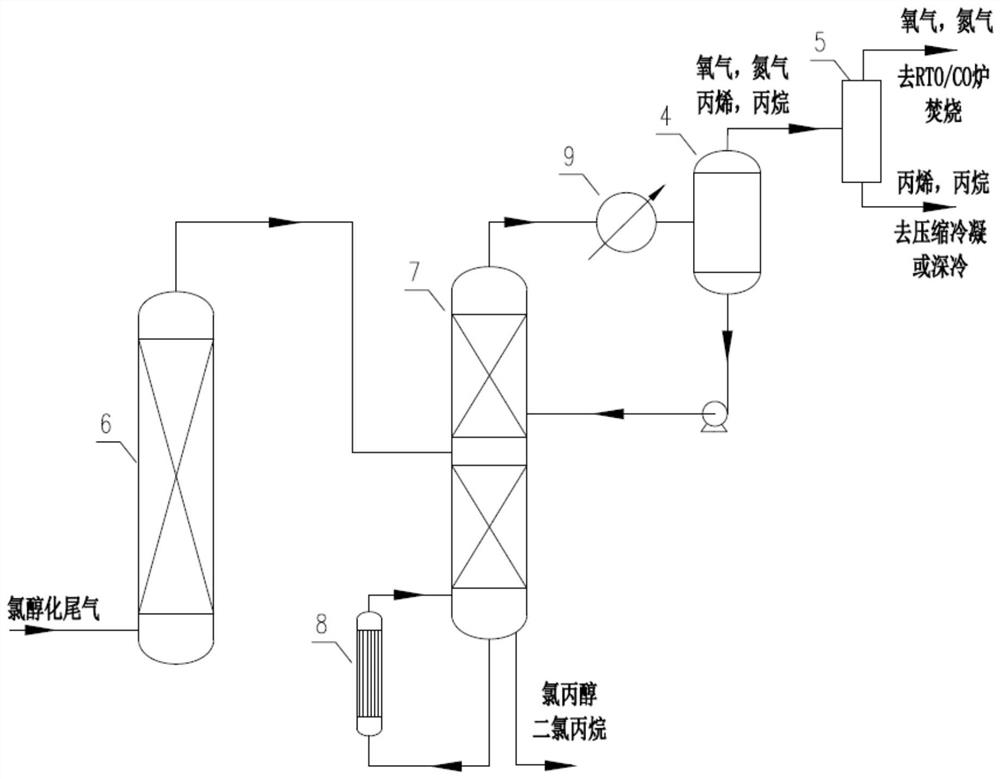

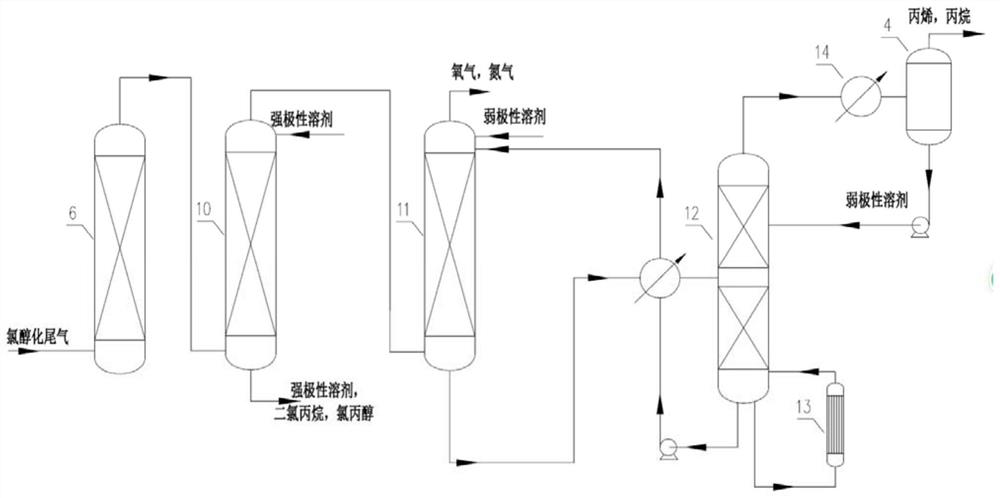

Chlorohydrination tail gas coupling treatment method

PendingCN111821832ASimple and fast operationLess investmentGas treatmentDispersed particle separationDichloropropanePropanol

The invention belongs to the field of tail gas treatment and discloses a chlorohydrination tail gas coupling treatment method. The method comprises the following steps of: firstly, absorbing chlorohydrination tail gas by alkali liquor or solid inorganic alkali or alkaline-earth metal oxide to remove acid gas, then separating chloropropanol and dichloropropane by compression condensation or pressurized rectification or solvent absorption, and finally separating propylene, propane, nitrogen and oxygen by membrane separation equipment or solvent absorption. Through coupling of multiple methods, targeted treatment is conducted according to different physical properties of components in the tail gas, harmful gas is thoroughly removed, the emission standard is achieved, meanwhile, propane and propylene are deeply recycled, and the recycling rate of propane and propylene reaches 90% or above.

Owner:南京佳华科技股份有限公司

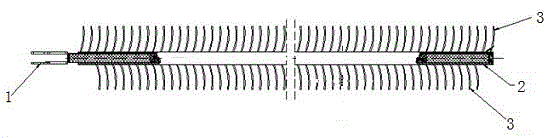

Novel oxide dust prevention PTC (positive temperature coefficient) electric heater element

InactiveCN104602374AAvoid pollutionProduction to preventHeating element shapesEngineeringAir pollution

The invention provides a novel oxide dust prevention PTC (positive temperature coefficient) electric heater element. An electroplated layer or oxide layer is uniformly arranged on each surface of the electric heater element contacting with air, generation of aluminum oxide is effectively stopped, air pollution is prevented, and dust such as aluminum oxide generated on the surfaces of the electric heater element due to direct contact of condensed water and aluminum tubes, radiating strips or aluminum strips is completely eliminated when the PTC electric heater element is used for a long time. Pollution to ambient environments is prevented, the service life is prolonged, and two processes are simple in treatment and low in cost.

Owner:WUHU HENGMEI ELECTRIC HEATING APPLIANCE

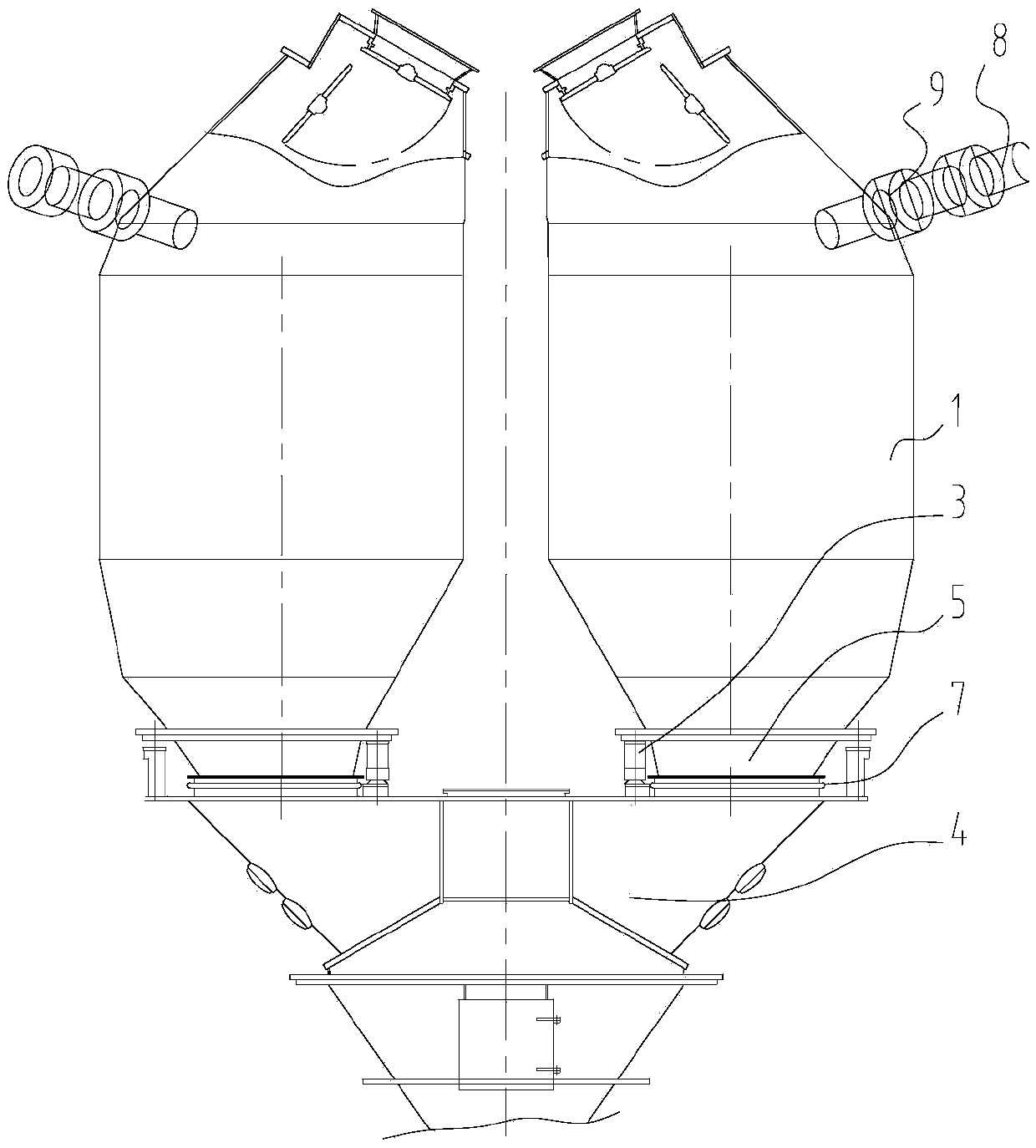

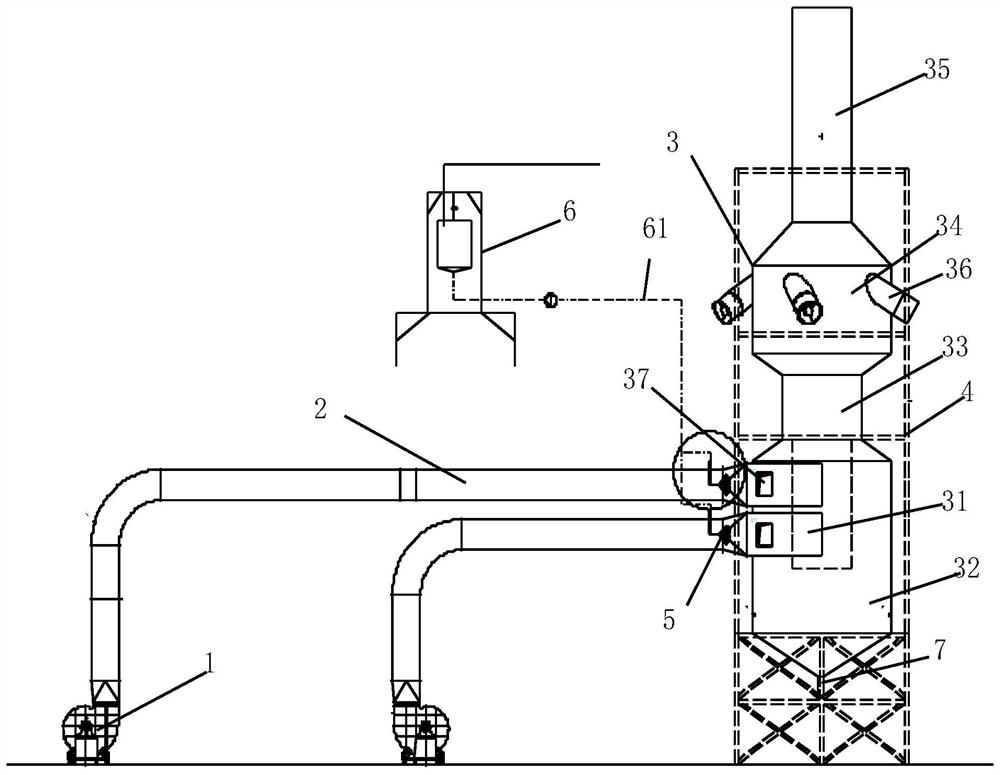

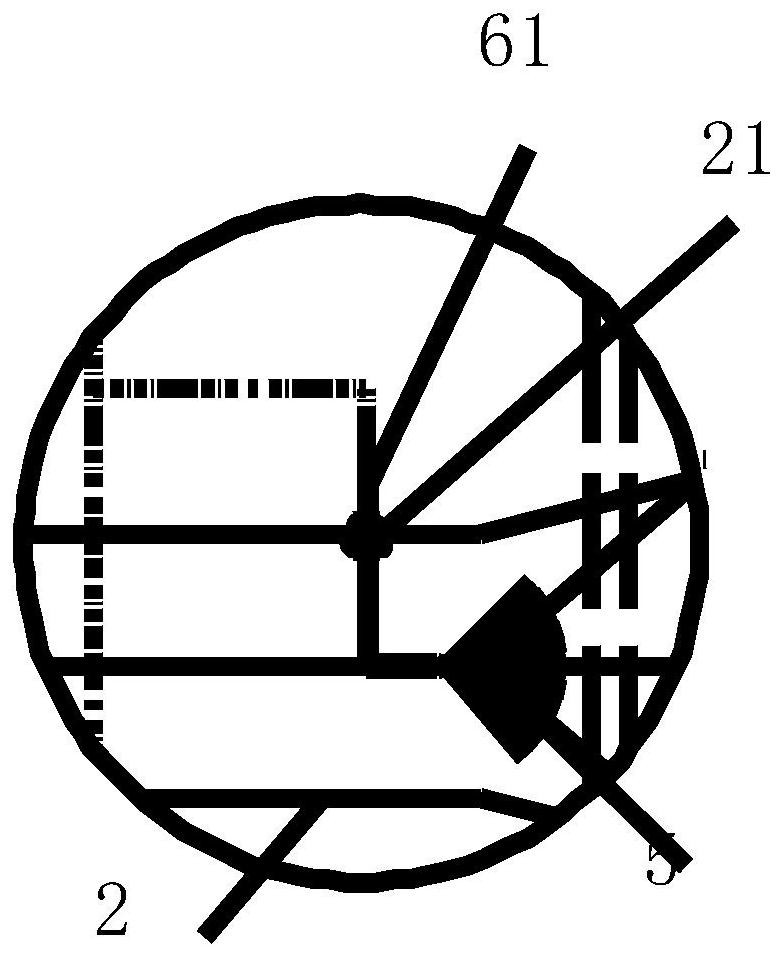

Dry tail gas treatment system

PendingCN112742145AThorough dust removalProduction to preventCombination devicesDrying solid materialsExhaust gasSewage

The invention discloses a dry tail gas treatment system which comprises a fan, a pipeline and a chimney, wherein one end of the fan is connected with a tail gas exhaust port of drying equipment, and the other end of the fan is communicated with the chimney through the pipeline; the chimney comprises a chimney pipe capable of adsorbing electric ions, and the chimney pipe is provided with a connecting port communicated with the pipeline. An atomizing nozzle capable of spraying electrified ionized water is arranged at the connecting port, the atomizing nozzle is connected with an electrified ionized water generating device, and a chimney water outlet is formed in the bottom of the chimney pipe; an electric dust removal process is adopted, so that the generation of sewage can be effectively avoided, and water pollution events are avoided; the chimney is used as a positive electrode for adsorption, and electric precipitation equipment does not need to be additionally arranged, so that the structure is omitted; and meanwhile, dust removal is more thorough due to the large-size design of the chimney.

Owner:GLOBE ENVIRONMENTAL SHANGHAI

Natural gas rare earth nano energy-saving additive

The invention discloses a natural gas rare earth nano energy-saving additive. The additive comprises an organic reagent solution and a rare earth solution; the organic reagent solution comprises n-butyl alcohol, isopropanol, acetone, isobutyl alcohol, n-octyl alcohol, trimethyl methanol, methyl isobutyl ketone and methyl tertiary butyl ether; and the rare earth solution comprises ferrocene, nickelacetate and cerium oxide. The natural gasrare earth nano energy-saving additive is added into natural gas, sufficient combustion of methane can be effectively promoted, energy is provided, generationof toxic gas such as phosphide, sulfide and carbon monoxide is completely eradicated, so that the effects of energy conservation and emission reduction are effectively achieved.

Owner:河北濡春新能源集团有限公司

A non-wastewater discharge continuous dyeing process for microfiber materials

ActiveCN106906677BIncrease productivityHigh speed dyeing effectDyeing processWastewaterProcess engineering

The invention discloses a non-wastewater discharge continuous dyeing process for superfiber materials. The steps include: padding, using acid dye color paste to dye the superfiber materials through alternate padding processes; adding an acid release agent; microwave reaction , using a microwave radiation device to boil and vaporize the acid dye color paste on the superfiber dye; and drying for setting. The microfiber material padding process of the present invention is more efficient and more environmentally friendly, and there is no waste water discharge in the whole process, which conforms to the concept of environmental protection and sustainable development of today's industrial development; the high-speed and efficient dyeing process obtained by using the microwave reaction continuous dyeing process of the present invention The effect is very remarkable. The speed of dyeing in this process can reach 10 m / min, which greatly improves the production efficiency of the microfiber printing and dyeing industry and provides a strong technical guarantee for the current extremely fast-growing microfiber industry.

Owner:上海兴康超纤新材料有限公司

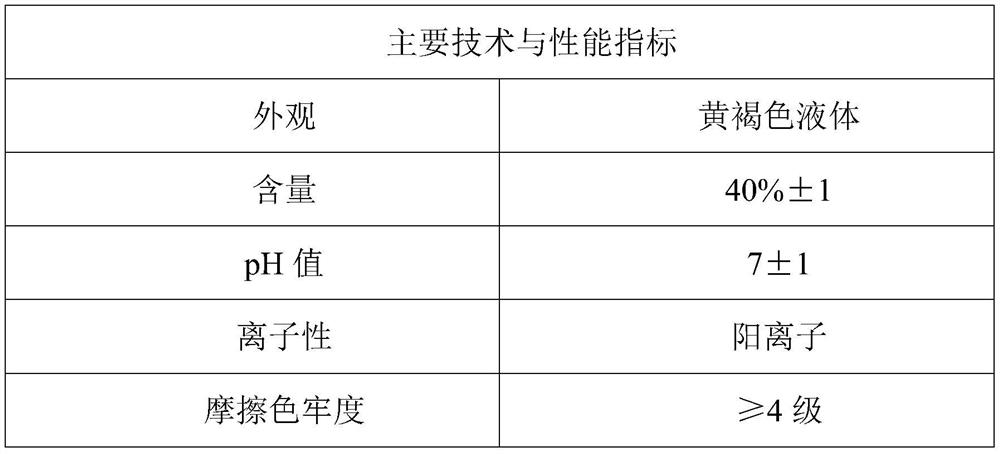

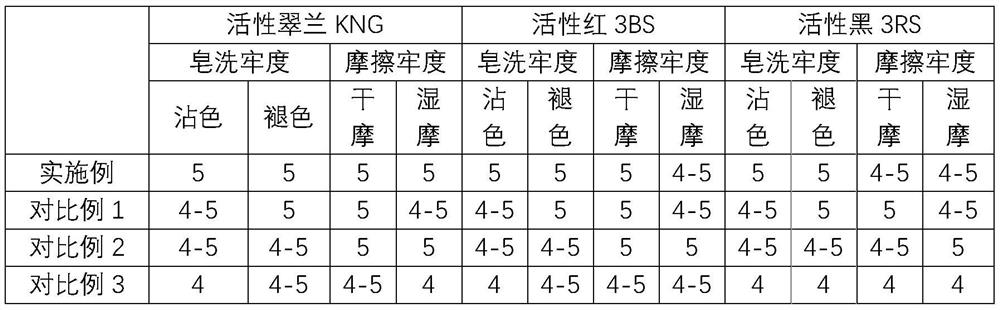

A kind of process method of using special acrylate wastewater to prepare color fixing agent

The invention discloses a process for preparing a color-fixing agent by using special acrylate waste water. The waste liquid produced by synthesizing specific acrylate is used as a raw material, and the monomeric acrylic acid and acrylate in the waste liquid are reused. The waste liquid, The dimethyl diallyl ammonium chloride, initiator, and chain transfer agent are mixed to prepare a color-fixing agent, especially a cationic polymer-type color-fixing agent, which realizes deep resource utilization of wastewater and near-zero discharge, creating A new industrial output has been achieved, and after comparing the prepared color fixing agent with other similar products on the market, the color fastness of the fabric after treatment with the color fixing agent has reached the national standard level 4 or above, and the effect of use is not inferior to similar products. products, even better than similar products.

Owner:DUPLUS CHEM OF ZHANGJIAGANG CITY

Flexible liquid crystal intermediate trans p-alkyl dicyclohexyl methanol benzene and preparation method thereof

InactiveCN103880595AExtended service lifeProduction to preventOrganic compound preparationPreparation by oxygen reductionPotassium borohydrideWater layer

The invention discloses a method for preparing a flexible liquid crystal intermediate trans p-alkyl dicyclohexyl methanol benzene. The method includes the following steps: A, mixing transformaldehyde, tetrahydrofuran and absolute ethyl alcohol, and cooling by using ice-salt bath; B, dripping by using a potassium borohydride solution; C, removing the ice-salt bath, and stirring at room temperature; D, adding a hydrochloric acid solution for neutralizing; E, adding dichloromethane for layering; F, extracting the separated water layer by using dichloromethane; G, washing the extraction liquid by using a sodium carbonate solution, and then drying the same by using anhydrous sodium sulfate; H, normal pressure distilling; I, adding petroleum ether for solution, and then cooling to crystallize; and J, carrying out suction filtering and purifying the crystal to obtain a white crystal finished product. By adopting the method, the defects of the prior art are solved, the purity of the finished product of flexible liquid crystal intermediate trans p-alkyl dicyclohexyl methanol benzene is improved, and the generation of acetic acid is avoided. In addition, the invention further provides trans p-alkyl dicyclohexyl methanol benzene prepared by the method.

Owner:SHIJIAZHUANG CROWN DISPLAY MATERIAL

Pouring gate flow control device for preventing rotational flow from generating in continuous casting tundish

InactiveCN103111613BChange the way of entering the discharge pipeImprove cleanlinessMelt-holding vesselsEngineeringLiquid steel

The invention discloses a pouring gate flow control device for preventing a rotational flow from generating in a continuous casting tundish and belongs to the technical field of tundish pouring gate flow control devices. The pouring gate flow control device for preventing the rotational flow from generating in the continuous casting tundish comprises a liquid discharge pipe, a liquid inlet plate, flow guide holes, a flow control stopper rod and a lift mechanism. The liquid discharge pipe penetrates through the bottom of the tundish and extends into the inner portion of the tundish. The liquid discharge pipe is hollow. One end portion of the liquid discharge pipe, extending into the tundish, is fixedly connected with the liquid inlet plate. The top and the side faces of the liquid inlet plate are respectively sealed. One or more flow guide holes are formed in the bottom face of the liquid inlet plate. An opening of each flow guide hole is downward. Each flow guide hole is communicated with a hollow portion in the liquid discharge pipe. The flow control stopper rod is arranged right below the flow guide holes. The outer diameter of the flow control stopper rod is matched with the inner diameter of the corresponding flow guide hole. The flow control stopper rod is vertically arranged and fixed on the bottom of the tundish. The lift mechanism is arranged at one end, located outside the tundish, of the liquid discharge pipe and controls lift of the liquid discharge pipe and the liquid inlet plate. The pouring gate flow control device for preventing the rotational flow from generating in the continuous casting tundish can effectively prevent the rotational flow from generating and improve purity of liquid steel.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

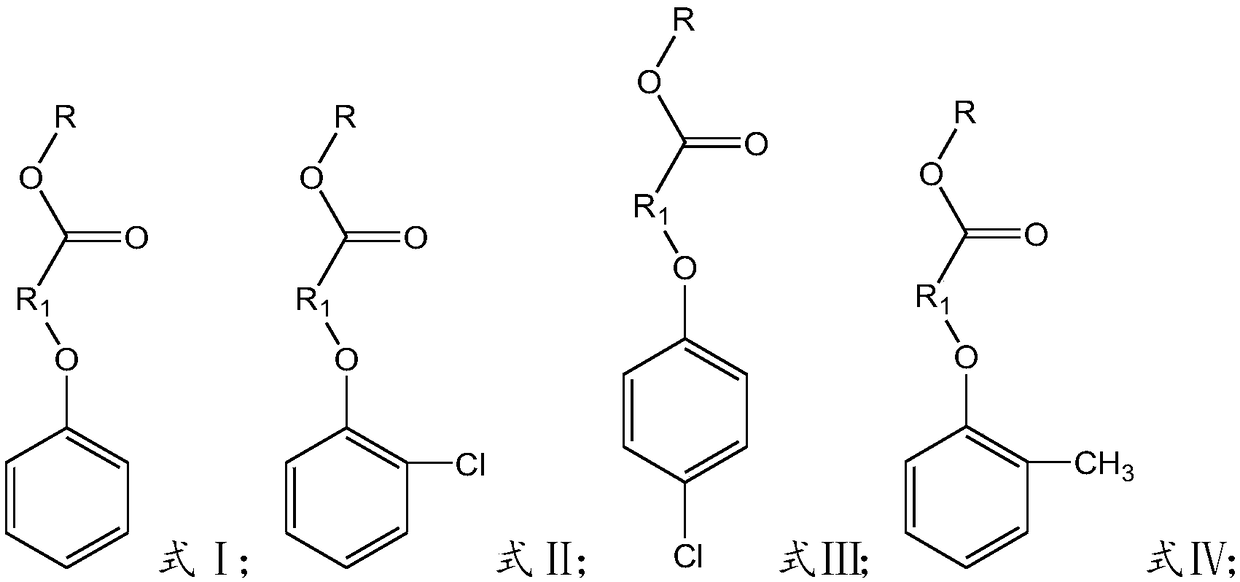

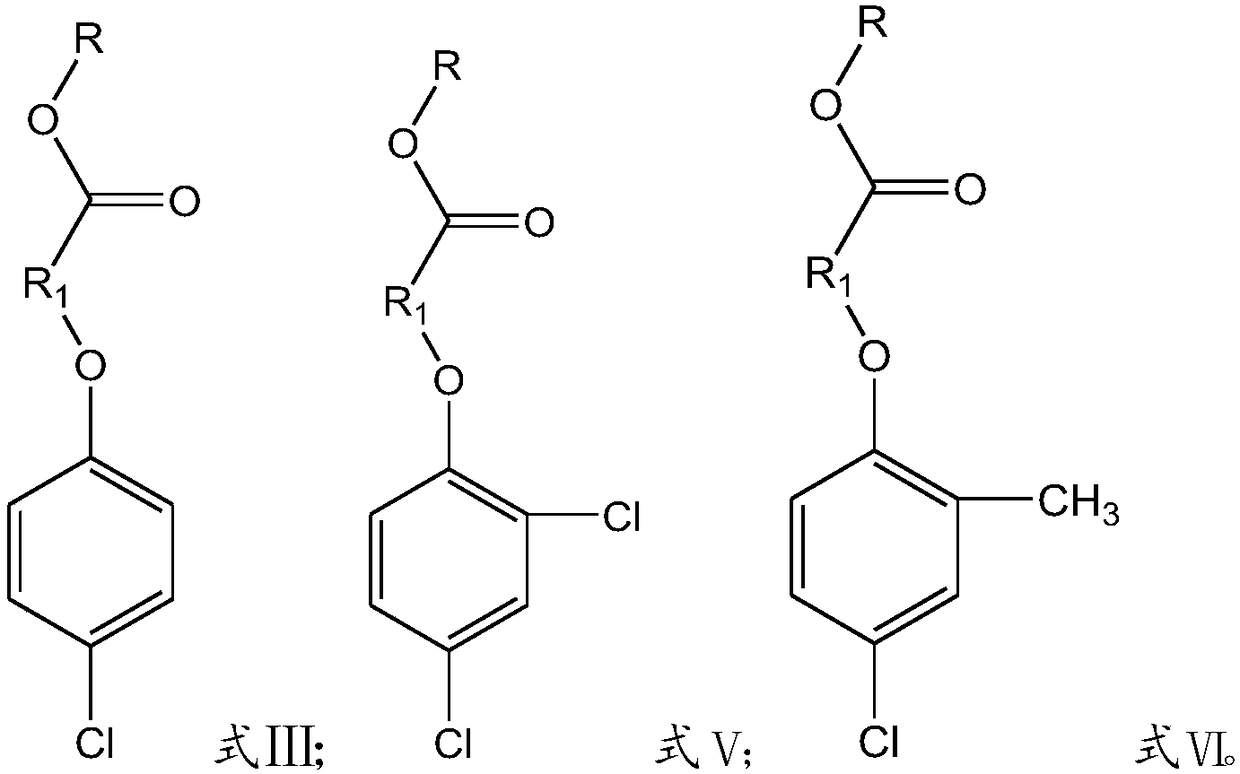

Preparation method of chlorophenoxycarboxamide salt

InactiveCN108947806AEasy to separateImprove utilization efficiencyOrganic compound preparationCarboxylic acid salt preparationChemistrySite selective

The invention provides a preparation method of chlorophenoxycarboxamide salt, wherein the preparation method includes the following steps: S1) carrying out 2-site and / or 4-site selective chlorinationreaction of phenoxycarboxylic ester with a chlorinating agent under the action of a catalyst A and a catalyst B to obtain chlorophenoxycarboxylic ester, wherein the catalyst A is Lewis acid, and the catalyst B has the following structural formula of R1'-S-R2'; and S2) carrying out ammonolysis reaction of chlorophenoxycarboxylic ester and amine to obtain chlorophenoxycarboxamide salt. By redesigning of the process route and fine screening of the catalysts and the chlorinating agent, the method reduces energy consumption, improves chlorination selectivity and avoids loss of effective components.The yield of the obtained chlorophenoxycarboxamide salt can reach 98.5% or more. At the same time, the production of high-salt wastewater is completely eradicated, the dust hazard caused by drying and use of chlorophenoxycarboxylic acid is avoided, energy is saved and equipment investment is reduced.

Owner:SHANDONG RUNBO BIOTECH CO LTD

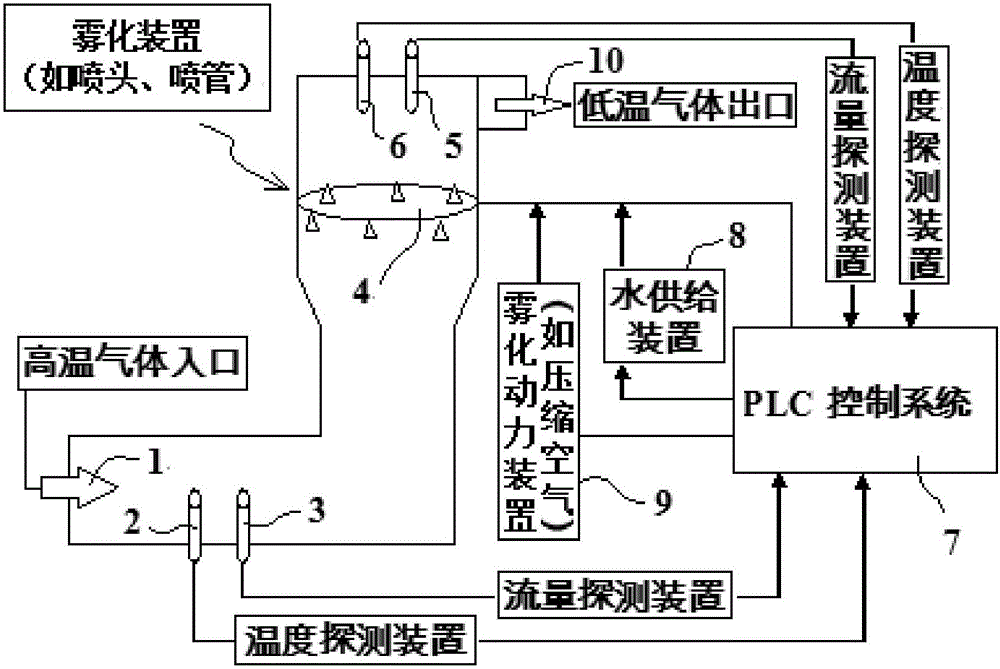

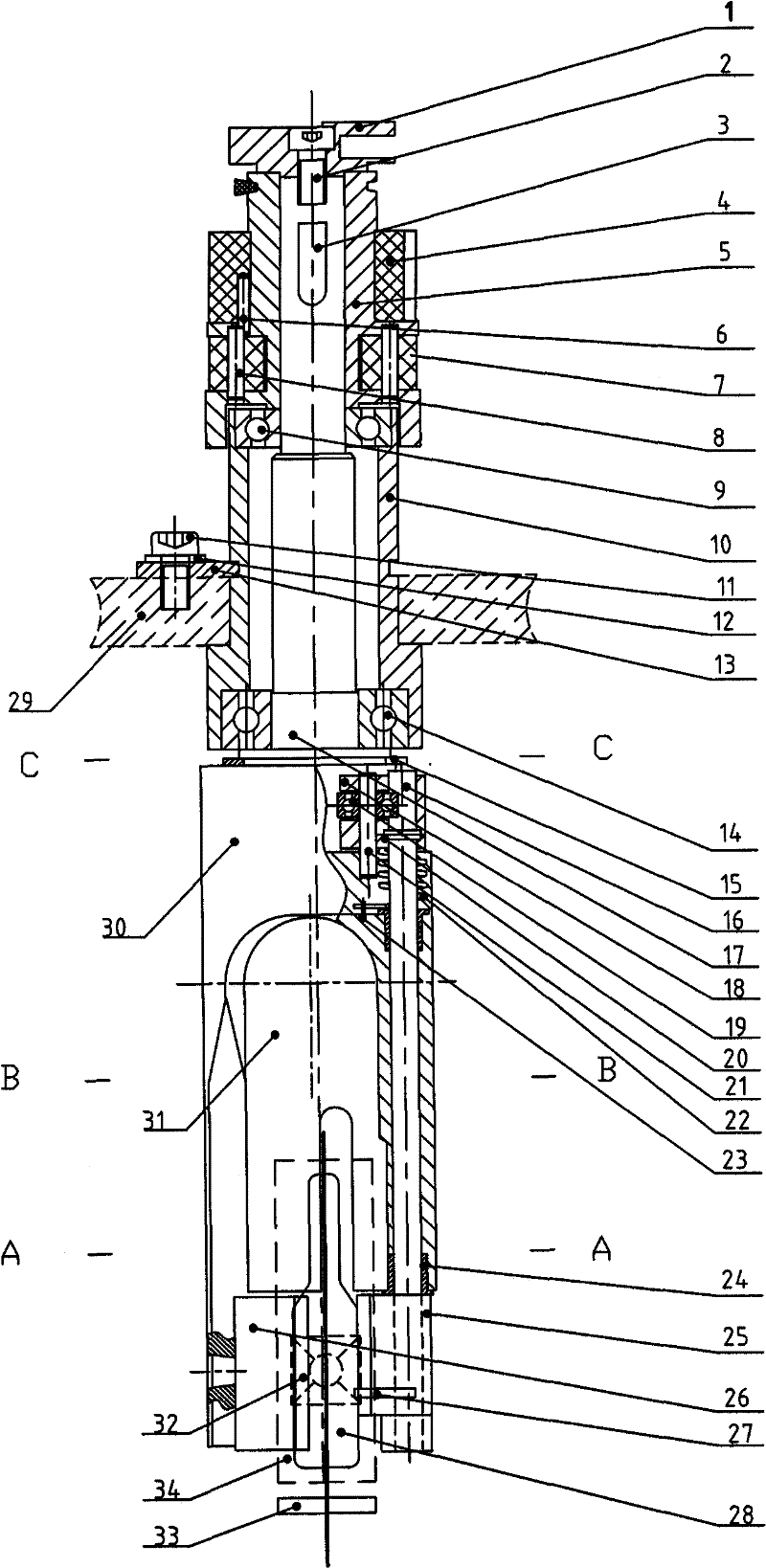

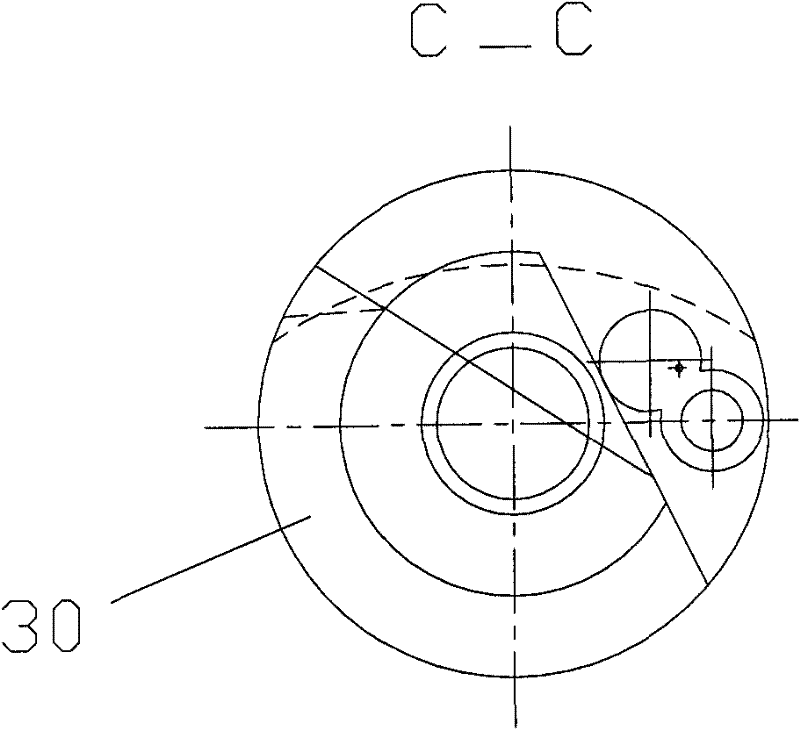

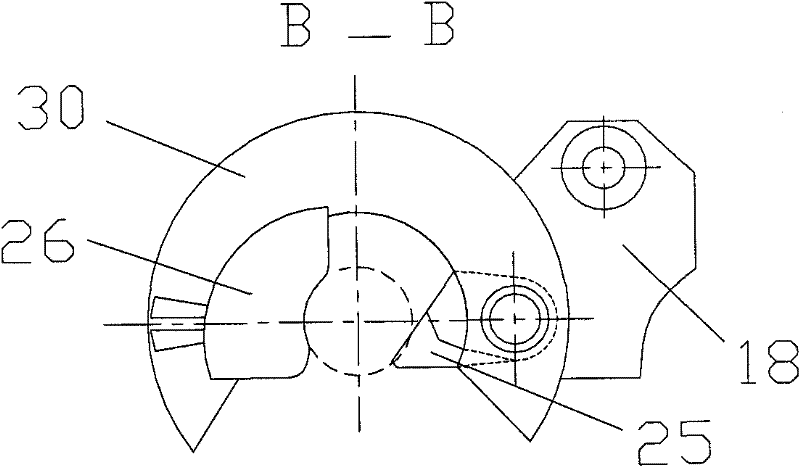

A high-temperature gas atomization rapid cooling system and method

InactiveCN103557719BRapid coolingJump quicklyIncreasing energy efficiencyHeat exchange apparatusCooling towerControl system

The invention discloses a high-temperature air atomization and shock cooling system and a method. High-temperature air flows to the top of a cooling tower from the bottom of the cooling tower by an air guide device; a temperature detection device and a flow detection device are arranged at the bottom of the cooling tower; cooling water is sprayed in from the periphery of the upper part in the cooling tower, the atomization is performed for absorbing heat, and the high-temperature air is cooled; the amount of the cooling water required by the atomization for cooling is calculated by using a PLC (Programmable Logic Controller) control system; the high-temperature air is subjected to shock cooling to a preset temperature, the sprayed water is changed to steam which is pumped out from the top end after cooling; another temperature detection device and another flow detection device are arranged at the top of the cooling tower and can be used for feeding back to the PLC control system so as to realize the automatic fine water amount adjusting. The system has the characteristics that the high-temperature air can be subjected to the shock cooling, and the fast cooling aim can be realized by water atomization for the cooling, so that a certain temperature region can be fast crossed, the cooling can be realized with a short flow, the occupying area is small, the secondary pollution is avoided and the like.

Owner:GANZHOU JIANGWU NEW TYPE ALLOY MATERIAL

Method and equipment for visual detection of visible foreign matters in bottled liquid medicine

InactiveCN101806752BGuaranteed stabilitySimple structureOptically investigating flaws/contaminationForeign matterVisual perception

The invention discloses a method and equipment for the visual detection of visible foreign matters in a bottled liquid medicine. The method comprises the following steps of: (1) obtaining a multi-frame continuous image from a current liquid medicine which is to be detected and is filled in a medicine bottle by using an industrial camera; (2) preprocessing the image: carrying out top-hat morphologic filtering on the obtained image by adopting a 7*7 circular template as a structural element; (3) extracting a moving object; (4) tracking the moving object; and (5) identifying and judging the image. The device comprises a bottle grabbing manipulator used for grabbing the medicine bottle and an image collecting and processing device arranged close to the bottle grabbing manipulator. The method and the device are suitable for detecting the visible foreign matters of a traditional small-capacity bottled liquid medicine and have the advantages of simple realization, good detection effect, highsafety and reliability, extensive application range and the like.

Owner:长沙图创机电科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com