Organic garbage treatment method and organic garbage disposal tank

A technology of organic waste and treatment method, applied in the direction of biological organic part treatment, organic fertilizer, organic fertilizer equipment, etc., can solve the problems of low calorific value, difficult to handle properly, perishable, etc. The effect of process safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Specific embodiments of the present invention will be further described in detail below.

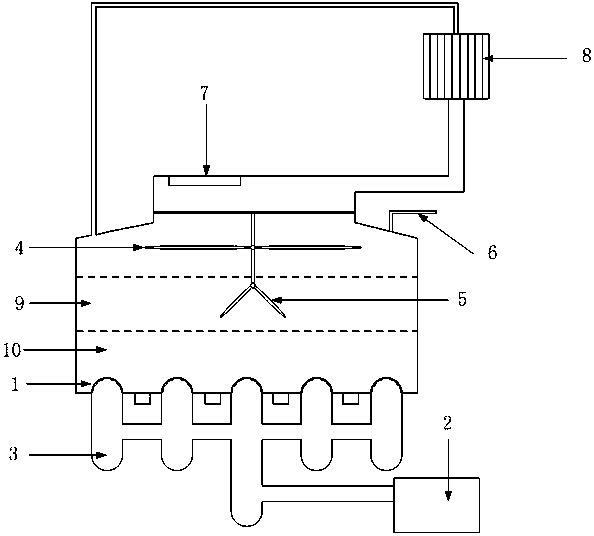

[0015] The organic waste treatment method of the present invention comprises the steps of mixing 55-65 parts by weight of water and 35-45 parts of organic waste so that the water surface is completely covered with organic waste; aerating upward from the bottom of the solid-liquid mixture, and heating the solid-liquid mixture To 70-80 degrees Celsius, closed fermentation in the fermentation tank and keep the temperature constant within 70-80 degrees Celsius; adjust the pH value of the liquid in it to keep it at 6.0-8.0; the generated steam is led to the heating device for heat exchange and circulation after completion Back to the fermentation tank; the organic waste includes but not limited to manure, straw, distiller's grains, leaves and organic kitchen waste.

[0016] Adopting the organic waste treatment method and the organic waste treatment pool of the present invention has the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com