Wet garbage disposal device and technology

A disposal device and garbage technology, applied in transportation and packaging, chemical instruments and methods, solid waste removal, etc., can solve the problem that the temperature is not easy to meet high temperature requirements, so as to improve the quality of living environment, realize the utilization of garbage resources, reduce waste The effect of waste disposal volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

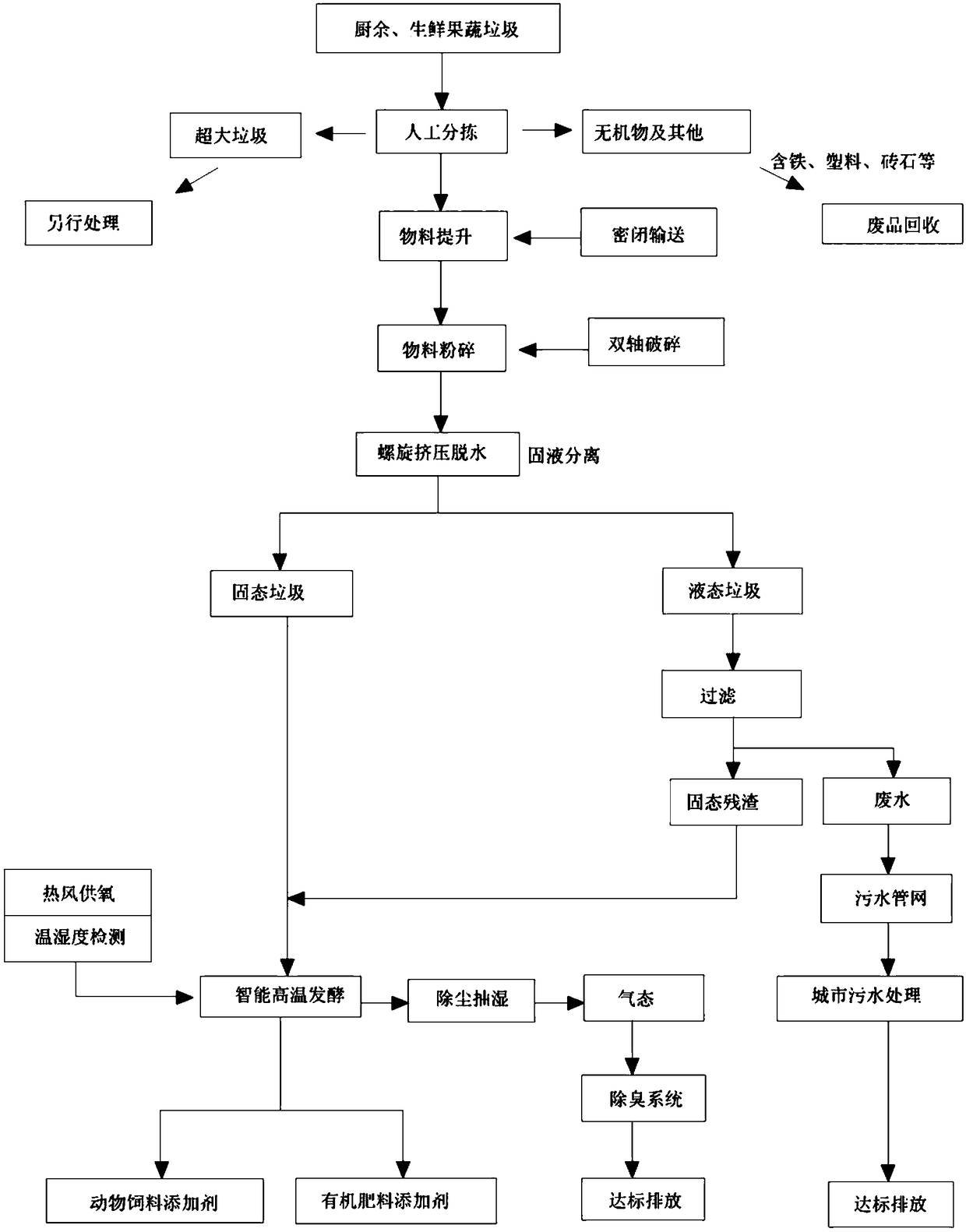

[0051] Embodiment 1: A wet garbage disposal process, which is a process of mechanical crushing and dehydration plus microbial harmless fermentation, and the process technology is mature. First, the organic waste is crushed and squeezed and dehydrated to a moisture content of about 60%. The crushed and dehydrated material enters the microbial decomposition and drying device. Biodegradable.

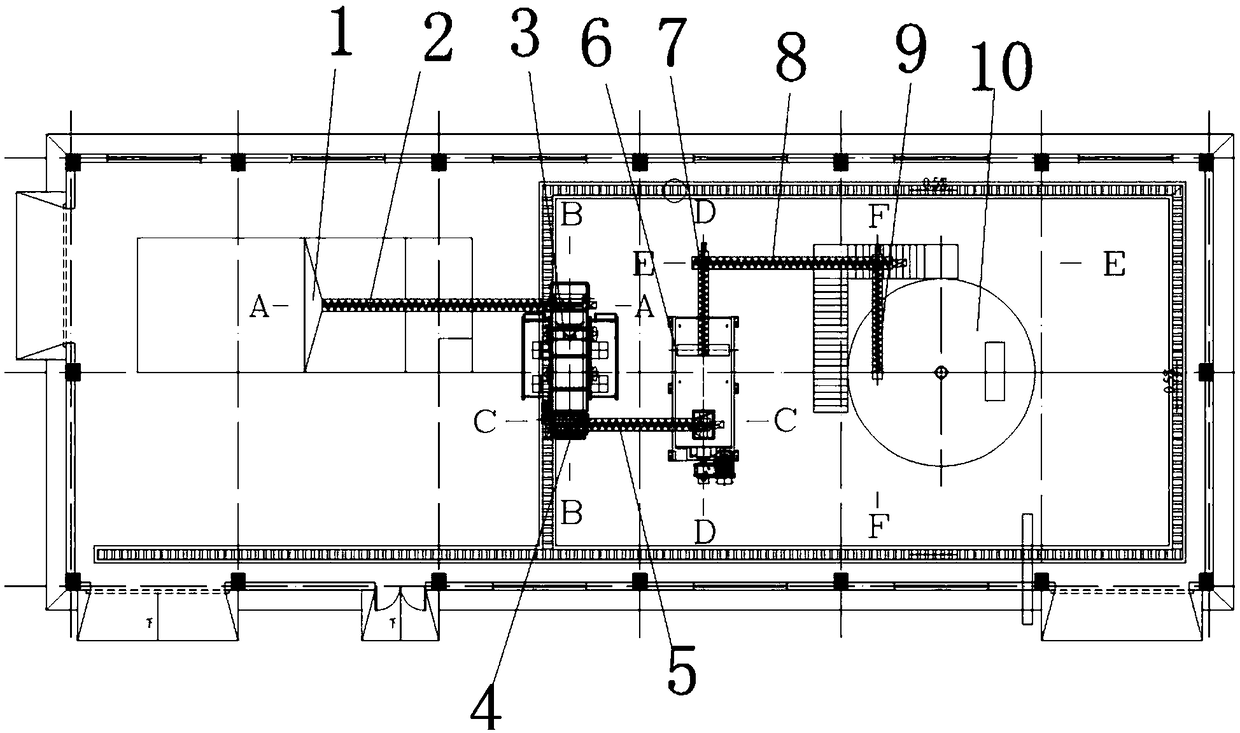

[0052] see figure 1, the process includes sorting, material lifting, crushing, solid-liquid separation, and garbage disposal.

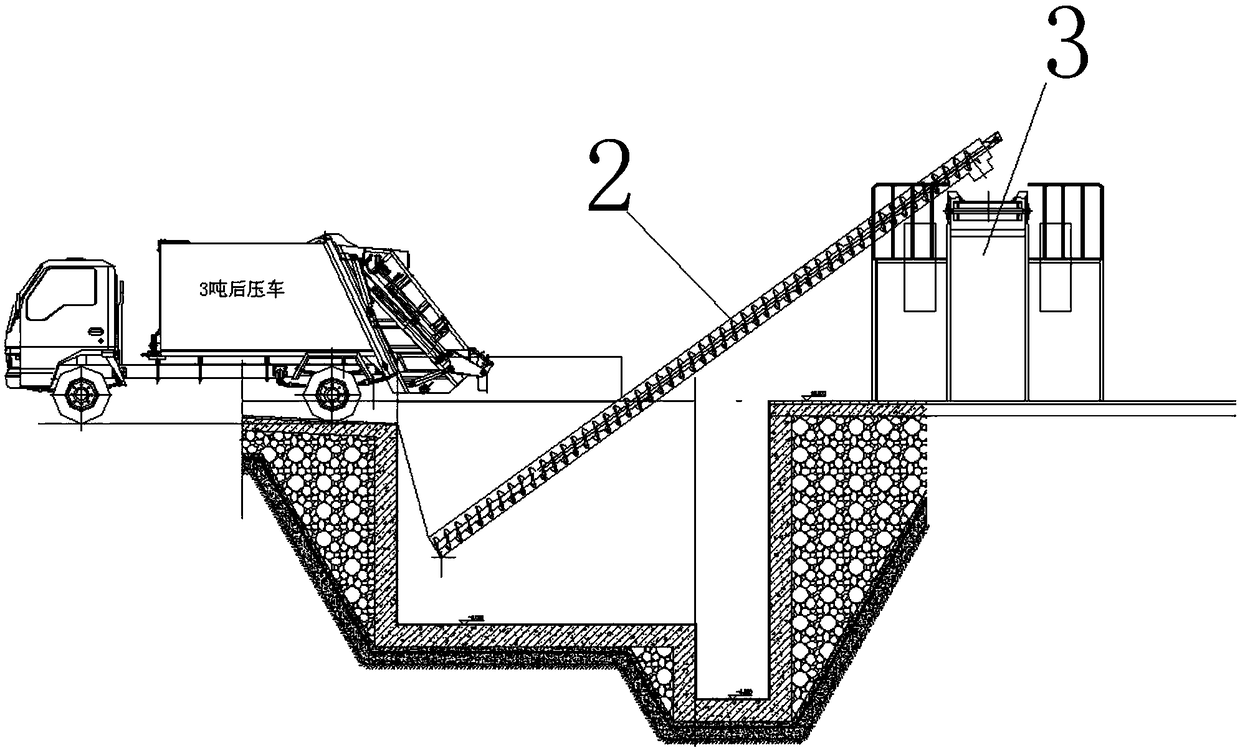

[0053] In the sorting step, for example, garbage transport vehicles are used to transport kitchen waste, fresh fruit and vegetable waste to the treatment workshop. In the treatment workshop, the garbage sent by the garbage transport vehicle is received by using storage pits, etc., and the garbage is transported to the sorting workshop by using a bolt conveyor. After the conveyor is selected, it is used for manual sorting, and the oversized garbage is treated sepa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com