Multi-accessory high-precision automatic positioning and adhering equipment

An automatic positioning, high-precision technology, applied in the direction of mechanical equipment, connecting components, material gluing, etc., can solve the problems of poor positioning accuracy, low production efficiency, weak bonding, etc., to achieve clear division of labor, ensure accuracy, and structural layout compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

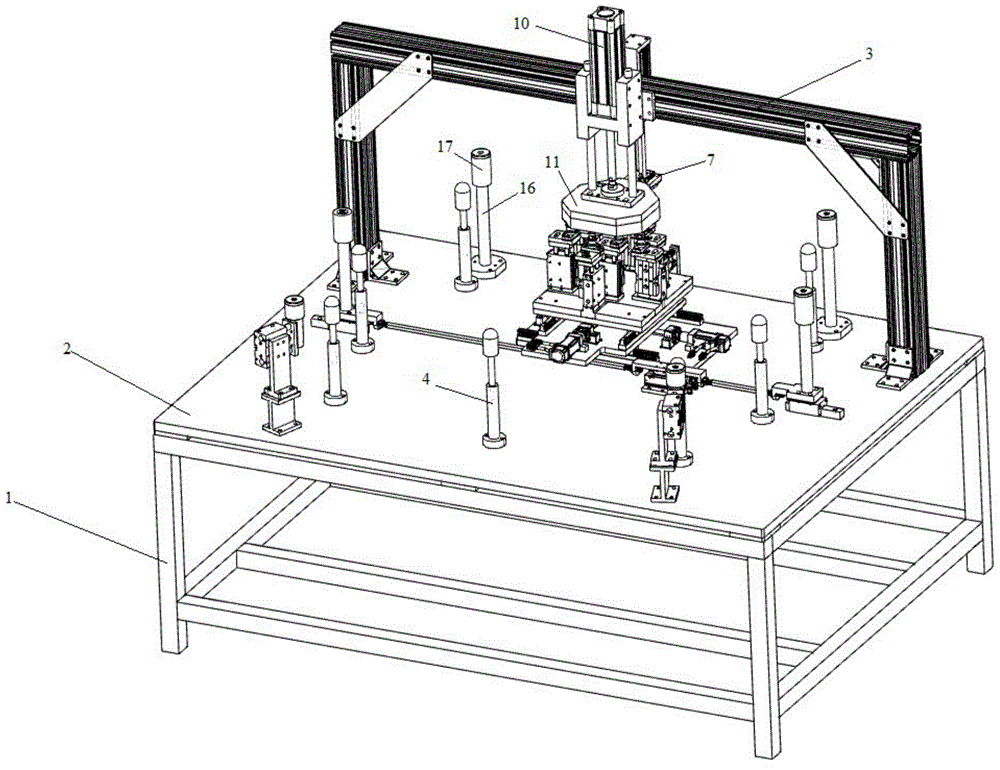

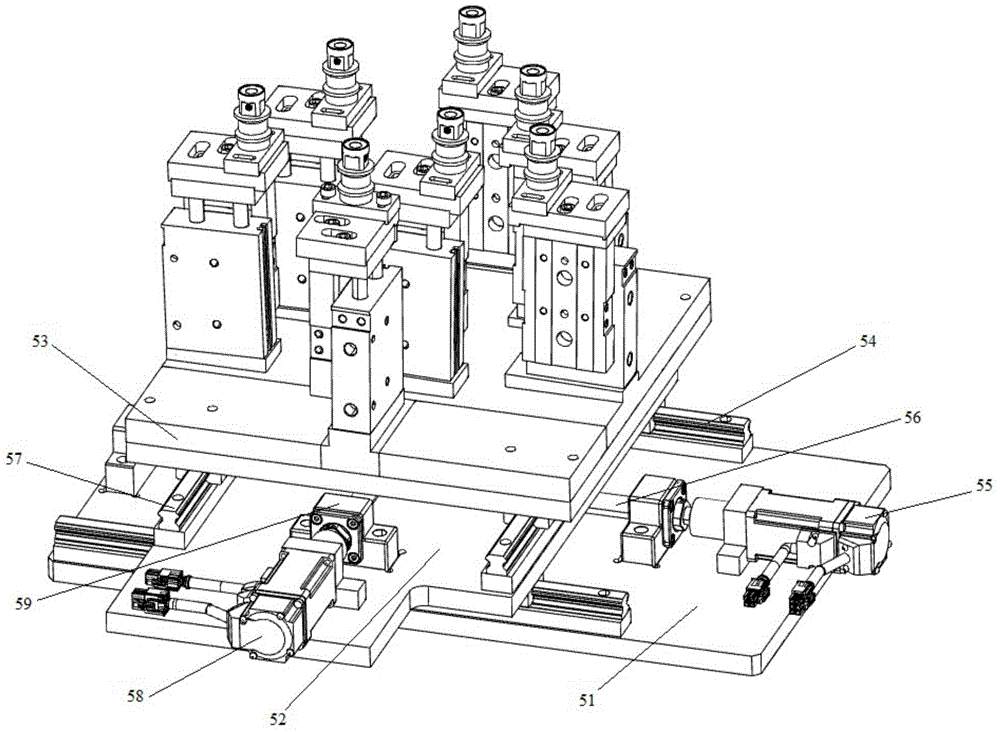

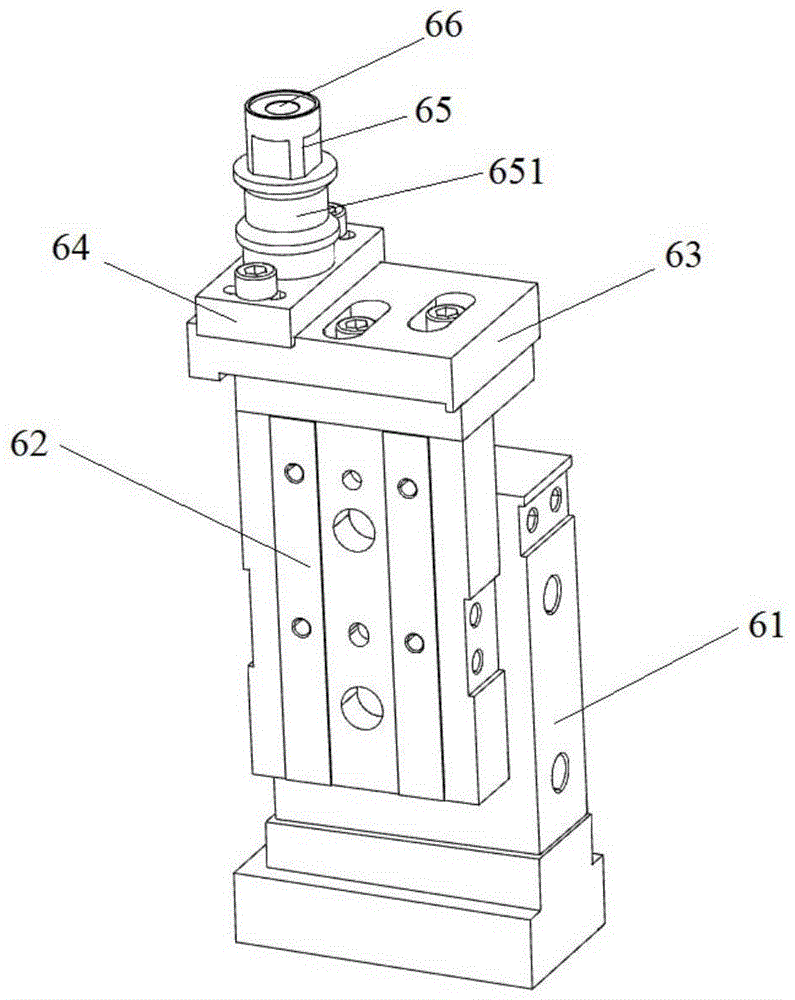

[0056] Such as figure 1 As shown, a multi-attachment high-precision automatic positioning and bonding equipment includes a frame 1, a workbench 2 arranged on the top of the frame 1, a fixing mechanism arranged at the front end of the workbench 2, and a The clamping mechanism and the limit mechanism arranged at the rear end of the workbench 2, the workbench 2 is provided with a gantry bracket 3 and a plurality of support columns 4 for supporting the windshield, and the frame 1 is also provided with an electrical box and a computer , the computer is connected to the electrical box through a circuit, and the equipment also includes a pressing mechanism arranged on the gantry support 3, a positioning servo mechanism and a photographing mechanism arranged on the workbench 2, and the pressing mechanism, the positioning servo mechanism and the photographing mechanism are all passed through The circuit is connected with the electrical box, and the positioning servo mechanism is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com