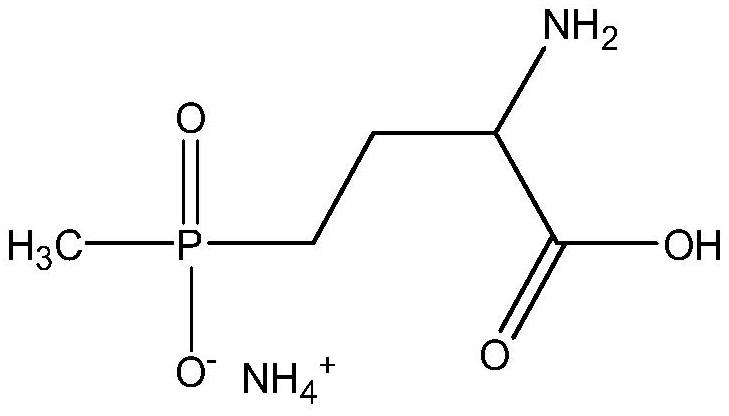

Synthesis method of glufosinate-ammonium

A synthesis method and technology of glufosinate-ammonium, applied in the field of pesticides, can solve the problems of high resin price, low-value inorganic waste salt, difficult separation, etc., and achieve the effects of serious loss, large amount of three wastes, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

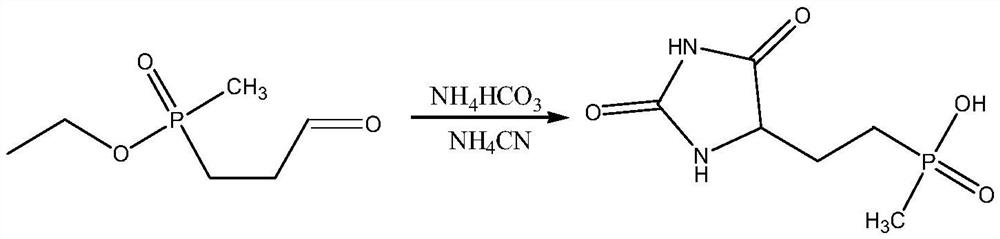

Method used

Image

Examples

Embodiment 1

[0039] The present embodiment provides a kind of preparation method of glufosinate-ammonium, comprising the steps:

[0040] In the 2L autoclave, add 5-[2 (hydroxyl (methyl) phosphono) ethyl] hydantoin 210g (1mol), 20wt% ammoniacal liquor 85g (1mol), water 900g (50mol), catalyst MTBD7.6g ( 0.05mol), heated to 160°C and controlled the pressure at 2.0MPa to react for 2h. After the reaction finished, the reaction solution was concentrated under reduced pressure to reclaim ammonia and catalyst, and the resulting concentrated solution was added with 350g methanol to reflux for 2h, then naturally dropped to room temperature, filtered and dried to obtain glufosinate-ammonium 195.3g after crystallization, detected by HPLC, its content was 97.1%, the yield is 95.8%.

Embodiment 2

[0042] The present embodiment provides a kind of preparation method of glufosinate-ammonium, comprises the steps:

[0043] In the 2L autoclave, add 5-[2 (hydroxyl (methyl) phosphono) ethyl] hydantoin 210g (1mol), 25wt% ammoniacal liquor 136g (2mol), water 900g (50mol), catalyst MTBD3.1g ( 0.02mol), heated to 160°C and controlled the pressure at 2.5MPa to react for 2h. After the reaction was finished, the reaction solution was concentrated under reduced pressure to recover ammonia water and catalyst. The resulting concentrated solution was added with 350 g of methanol and refluxed for 2 hours, then naturally lowered to room temperature, filtered and dried to obtain 197.1 g of glufosinate-ammonium, which was detected by HPLC with a content of 97.0%. , yield 96.6%.

Embodiment 3

[0045] The present embodiment provides a kind of preparation method of glufosinate-ammonium, comprises the steps:

[0046]In the 2L autoclave, add 5-[2 (hydroxyl (methyl) phosphono) ethyl] hydantoin 210g (1mol), 20wt% ammoniacal liquor 170g (2mol), water 900g (50mol), catalyst MTBD1.5g ( 0.01mol), heated to 160°C and controlled the pressure at 1.0MPa for 3h. After the reaction was finished, the reaction solution was concentrated under reduced pressure to recover ammonia water and the catalyst. The resulting concentrated solution was added with 350 g of methanol and refluxed for 2 hours, then naturally lowered to room temperature, filtered and dried to obtain 192.7 g of glufosinate-ammonium, which was detected by HPLC with a content of 96.9%. , yield 94.3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com