Method for manufacturing artificial colorized quartz composite stone with colorized quartz sand

A technology of colored quartz sand and synthetic stone, applied in the field of formulation and preparation of artificial synthetic stone, can solve the problem that bright color, purity, depth and layering cannot be expressed or insufficiently expressed, and color, luster, pattern, texture and texture cannot be achieved. Problems such as performance level, natural pattern texture, fidelity, texture and diversity can not be expressed, to achieve the effect of eliminating pigment waste water, low cost and short curing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] The invention provides a method for making artificial colored quartz synthetic stone from colored quartz sand, comprising the following steps:

[0059] Prepare artificial colored quartz sand. Artificial colored quartz sand is made by wrapping natural quartz sand with inorganic color paste, drying and sintering at high temperature.

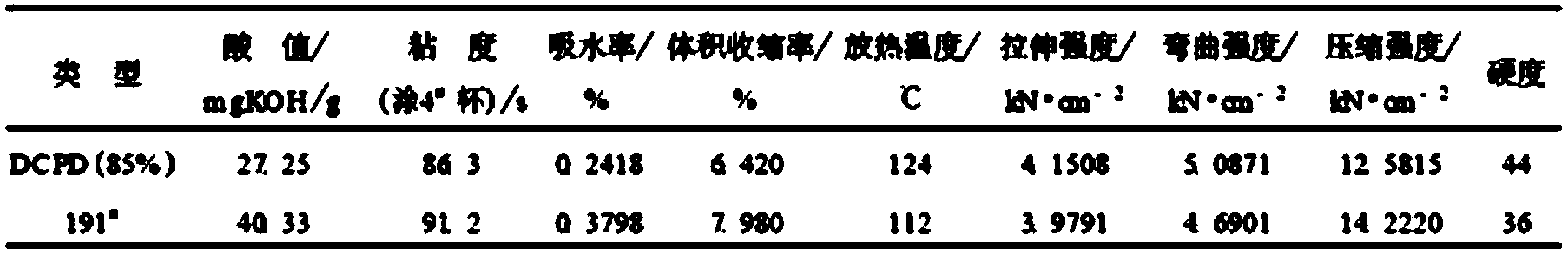

[0060] Add natural quartz powder into the binder and stir evenly; the binder is DCPD modified air-drying unsaturated polyester resin. The binder also includes a reactive dissolving agent with a weight fraction of 30%, and the reactive dissolving agent is styrene (St).

[0061] Add artificial colored quartz sand to the mixture of natural quartz powder and binder, and stir evenly; the particle size of natural quartz powder is above 325 mesh.

[0062] Add the accelerator and stir evenly; the accelerator is cobalt naphthenate; the dosage is 0.2% of the weight of the binder.

[0063] Add a coupling agent and stir evenly; the coupling agent is a...

Embodiment 2

[0090] The binder in Example 1 is replaced by a reactive dissolving agent that also includes a weight fraction of 20%, and the reactive dissolving agent is styrene (St);

[0091] In addition, 30% of the weight of the artificial colored quartz sand is added as an auxiliary material, the auxiliary material is a mixture of transparent quartz sand and metal flakes, and the particle size of the auxiliary material is 5-40 mesh.

[0092] The accelerator is cobalt isooctanoate; the dosage is 0.01% of the weight of the binder.

[0093] The organic silane coupling agent is used in an amount of 0.01% by weight of the binder.

[0094] The curing agent is cyclohexanone peroxide (CHP), and its dosage is 0.02% of the weight of the binder.

[0095] Curing is to spread the mixture of artificial colored quartz sand, accelerator, coupling agent and curing agent evenly through the uniform material equipment, then press it into shape after vacuuming with a vacuum machine, and then put it in a cur...

Embodiment 3

[0103] The binder in Example 1 is replaced by a reactive dissolving agent that also includes a weight fraction of 35%, and the reactive dissolving agent is styrene (St);

[0104] In addition, 30% of the weight of the artificial colored quartz sand is added as an auxiliary material, the auxiliary material is a mixture of transparent quartz sand and metal flakes, and the particle size of the auxiliary material is 5-40 mesh.

[0105] The accelerator is cobalt isooctanoate; the dosage is 0.5% of the weight of the binder.

[0106] Organosilane coupling agent, the dosage is 0.4% of the binder weight.

[0107] The curing agent is tert-butyl peroxide 2-ethylhexanoate (TBPO), and its dosage is 0.6% of the weight of the binder.

[0108] Curing is to spread the mixture of artificial colored quartz sand, accelerator, coupling agent and curing agent evenly through the uniform material equipment, then press it into shape after vacuuming by a vacuum machine, and then put it in a curing furn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com