Slurry transportation pipeline system for high viscosity coating device

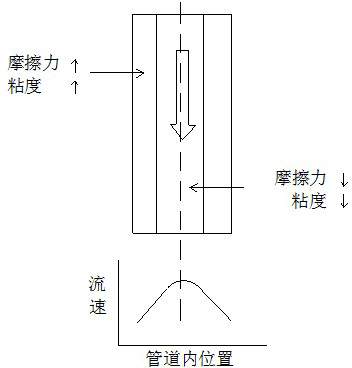

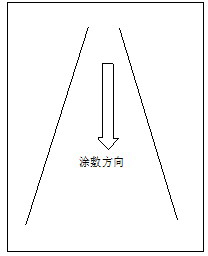

A piping system, high-viscosity technology, applied in coatings, devices for coating liquids on surfaces, etc., can solve the problems of inconsistent film uniformity, streaks during the coating process, and poor V-shaped streaks, etc. Save electricity and eliminate the effect of coating streaks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

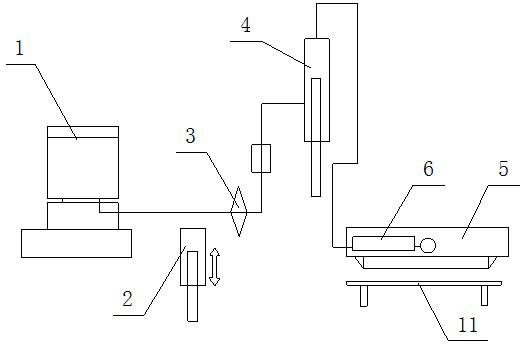

[0028] Such as Figures 3 to 6 As shown, a slurry transport pipeline system for high-viscosity coating equipment includes a supply tank 1, a booster pump 2, a filter 3, a syringe pump 4 connected in sequence, and a coating machine nozzle 5. A static agitator 6 is also connected before the machine nozzle 5, and the syringe pump 4 is connected with the static agitator 6. The static stirrer 6 includes a tubular shell 7 and a stationary spiral stirring member 8 arranged in the shell 7, and the spiral stirring member 8 forms a spiral channel in the shell 7 for generating a spiral motion of the high-viscosity fluid inside. As a preferred manner, as shown in this embodiment, the helical stirring member 8 and the shell 7 are detachably assembled. Both the shell 7 and the spiral stirring member 8 are smooth parts made of stainless steel. As shown in the figure, the spiral stirring member 8 is composed of 6 stationary spiral stirring units, and each spiral stirring unit is connected e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com