Purging device and technology of blast furnace charging bucket weighing system

A material tank and blast furnace technology, which is applied in the field of blast furnace top material tank weighing system, can solve problems such as narrow working space and short ash deposition period, and achieve the effects of ensuring external force interference, increasing iron output, and reducing coke ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

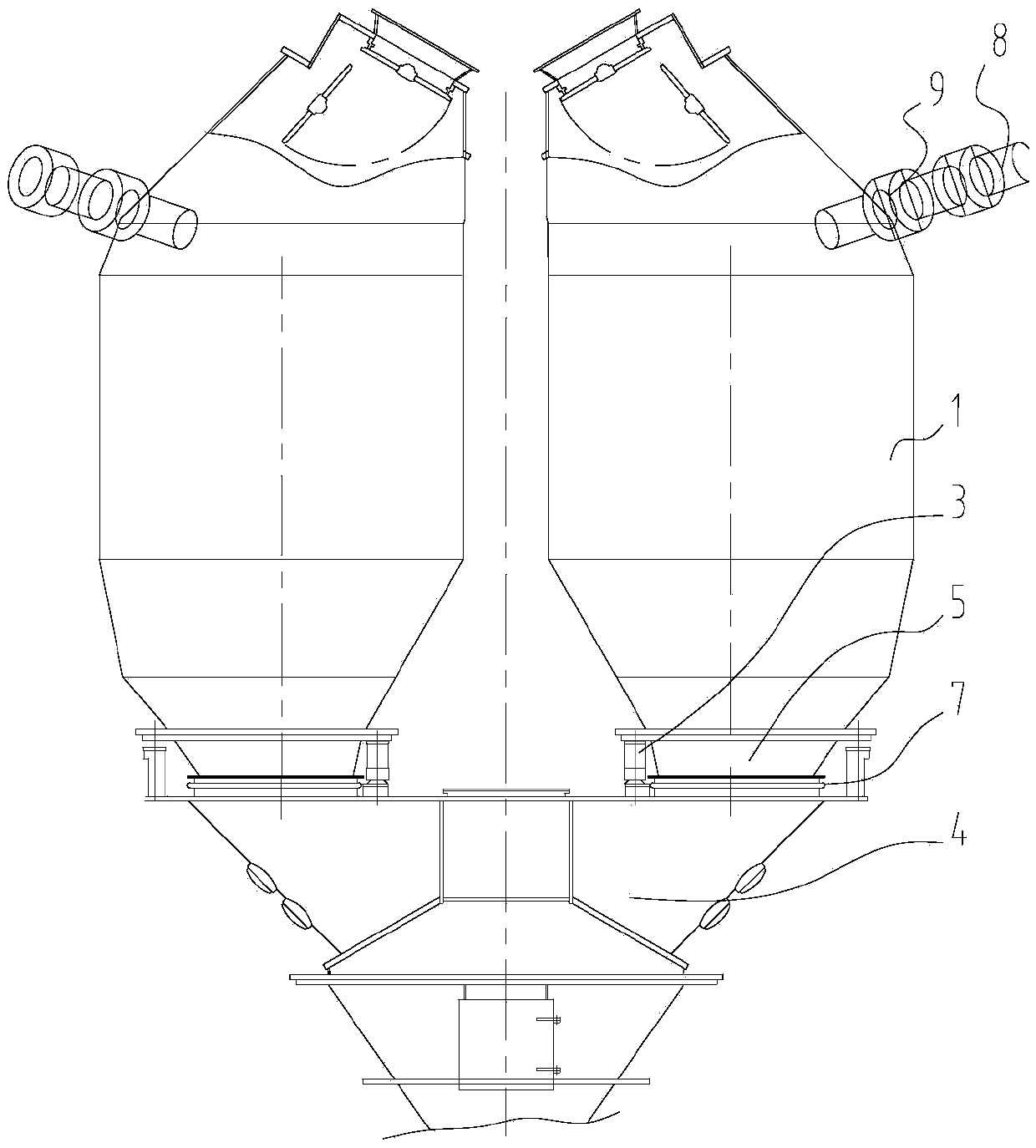

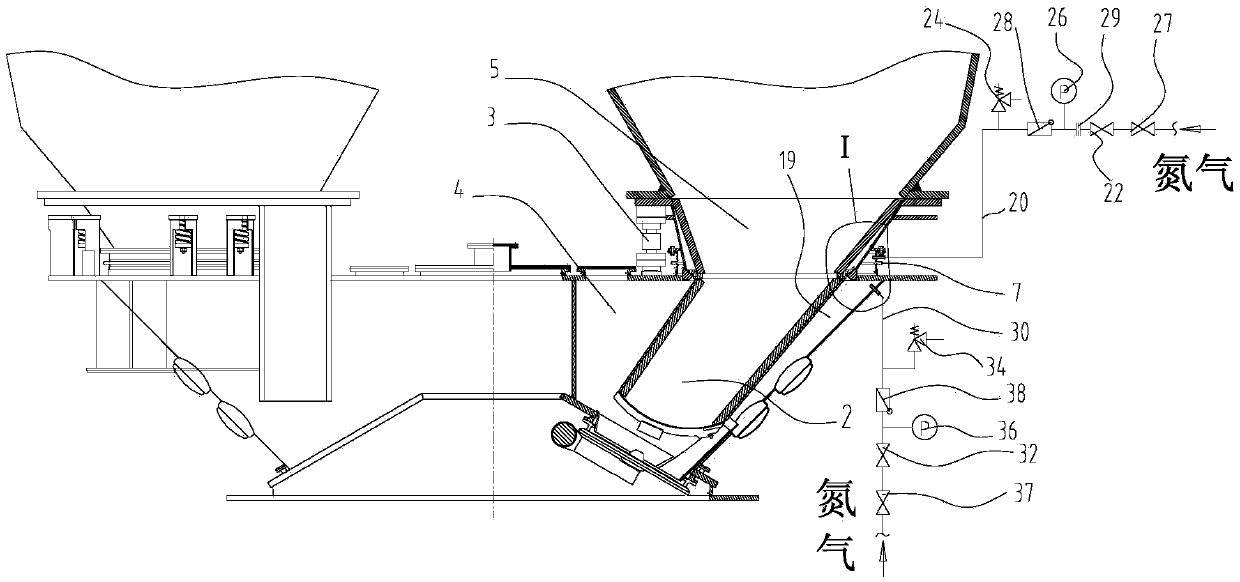

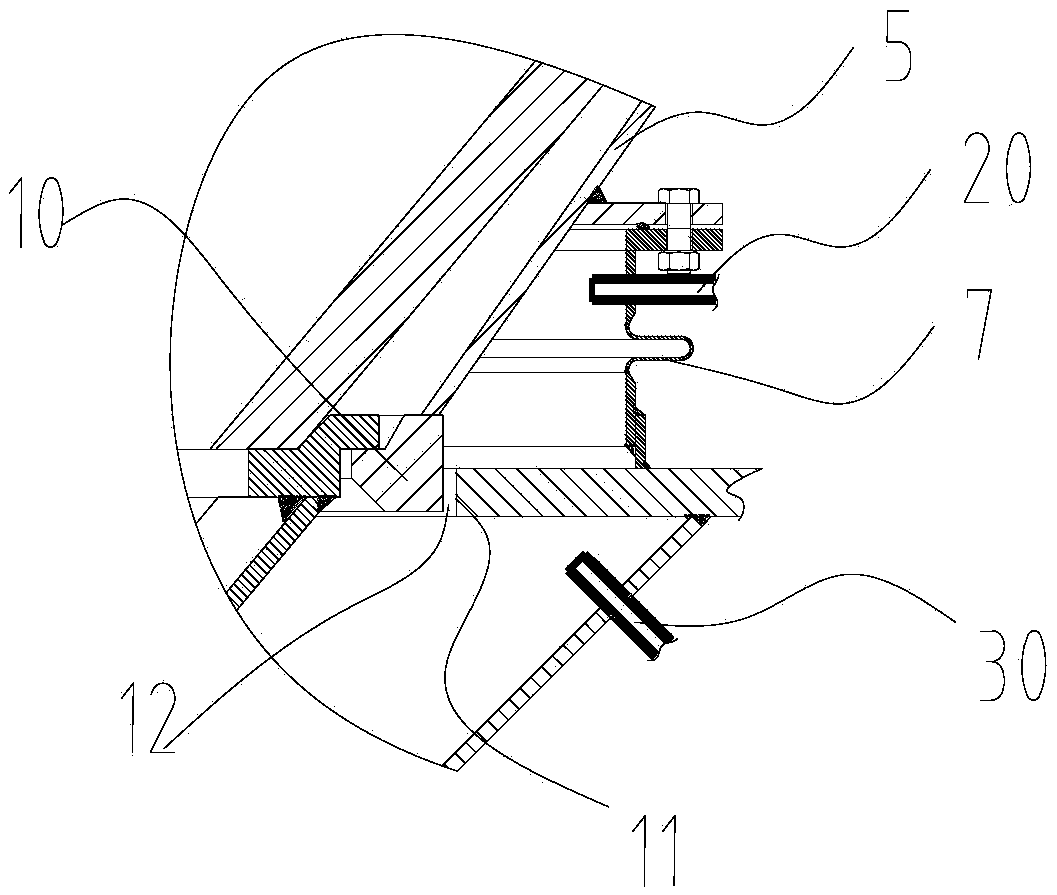

[0027] Such as Figure 1-Figure 3 As shown, a blast furnace material tank weighing system purging device, the weighing system includes: including a material tank 1, a material flow regulating valve 2, three weighing sensors 3 and a lower valve box 4, the inlet cone of the material flow regulating valve 5 is connected to the bottom of the material tank 2, the whole formed by the material tank 2 and the material flow regulating valve 2 is located on the three load cells 3, the lower valve box 4 is arranged outside the material flow regulating valve 2, and is connected with the material flow regulatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com