Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

75results about How to "No seepage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

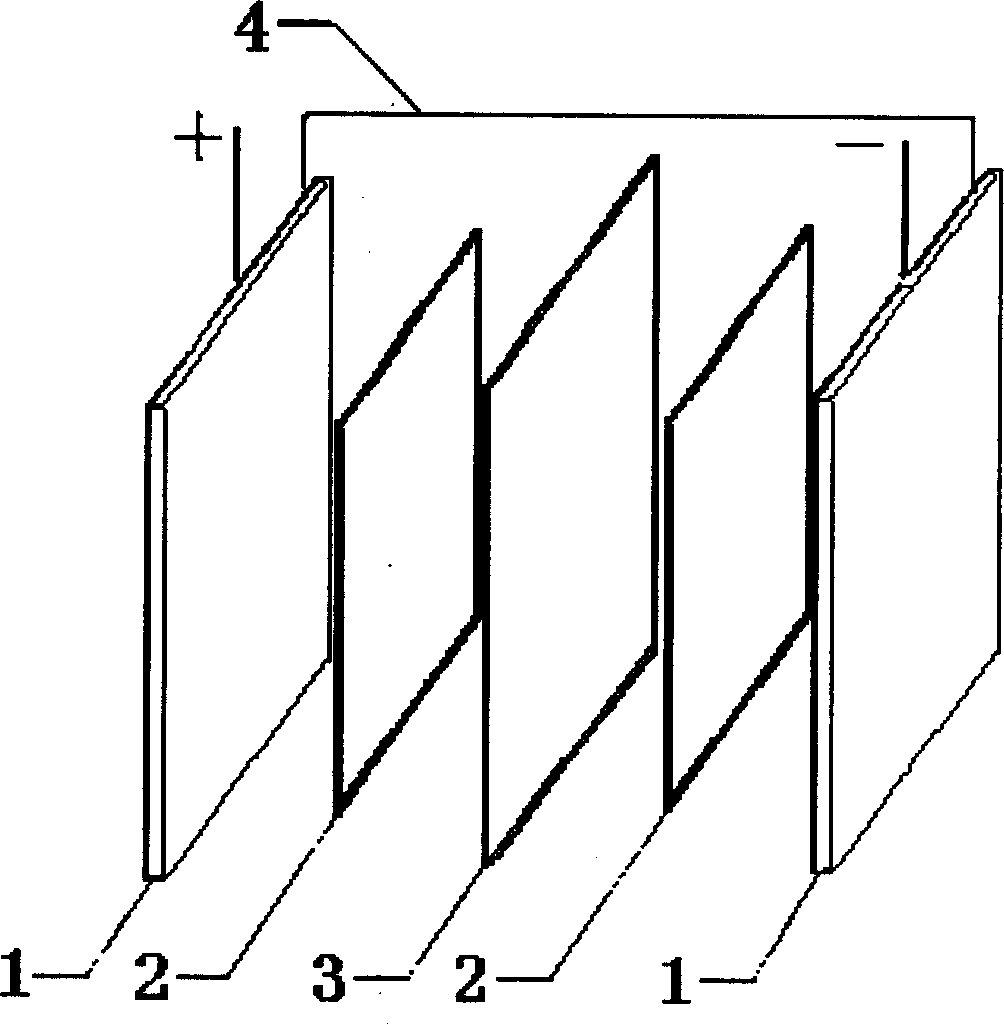

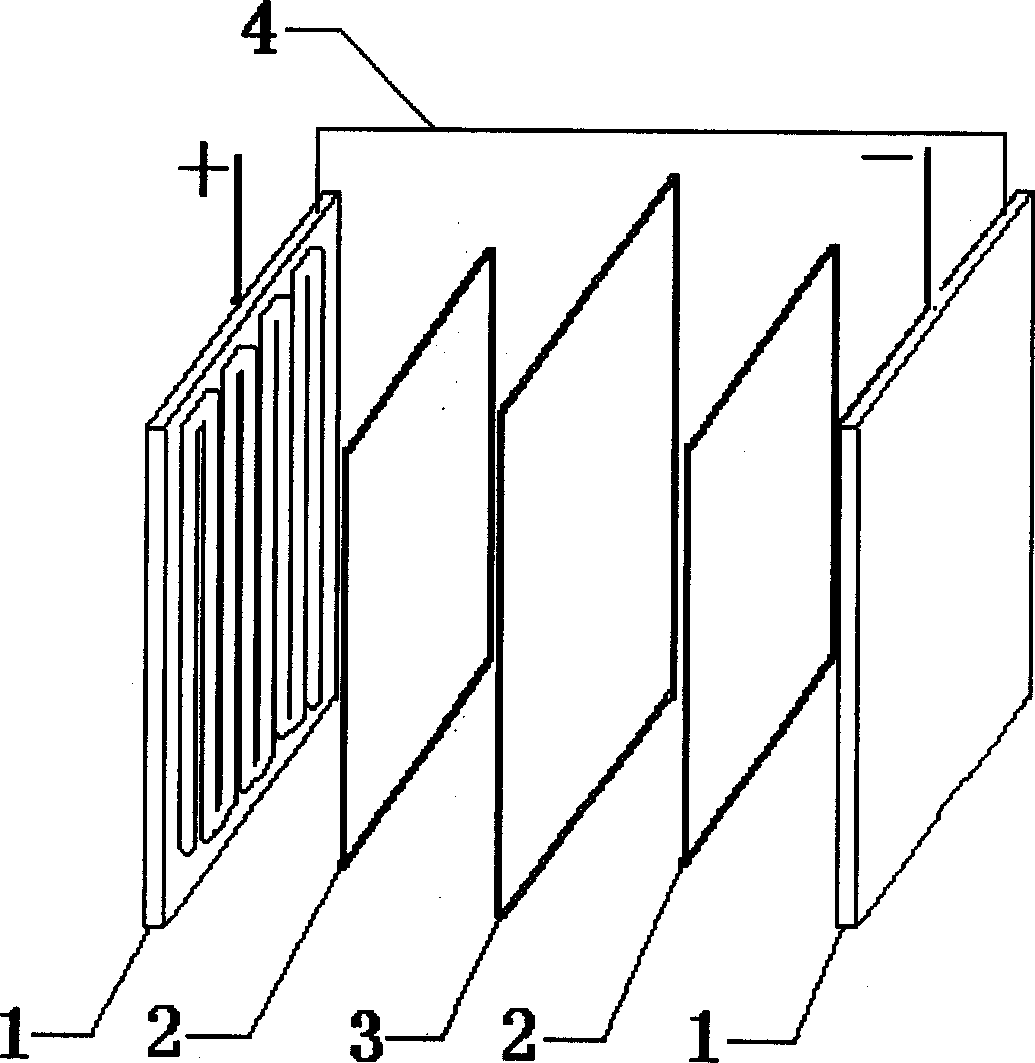

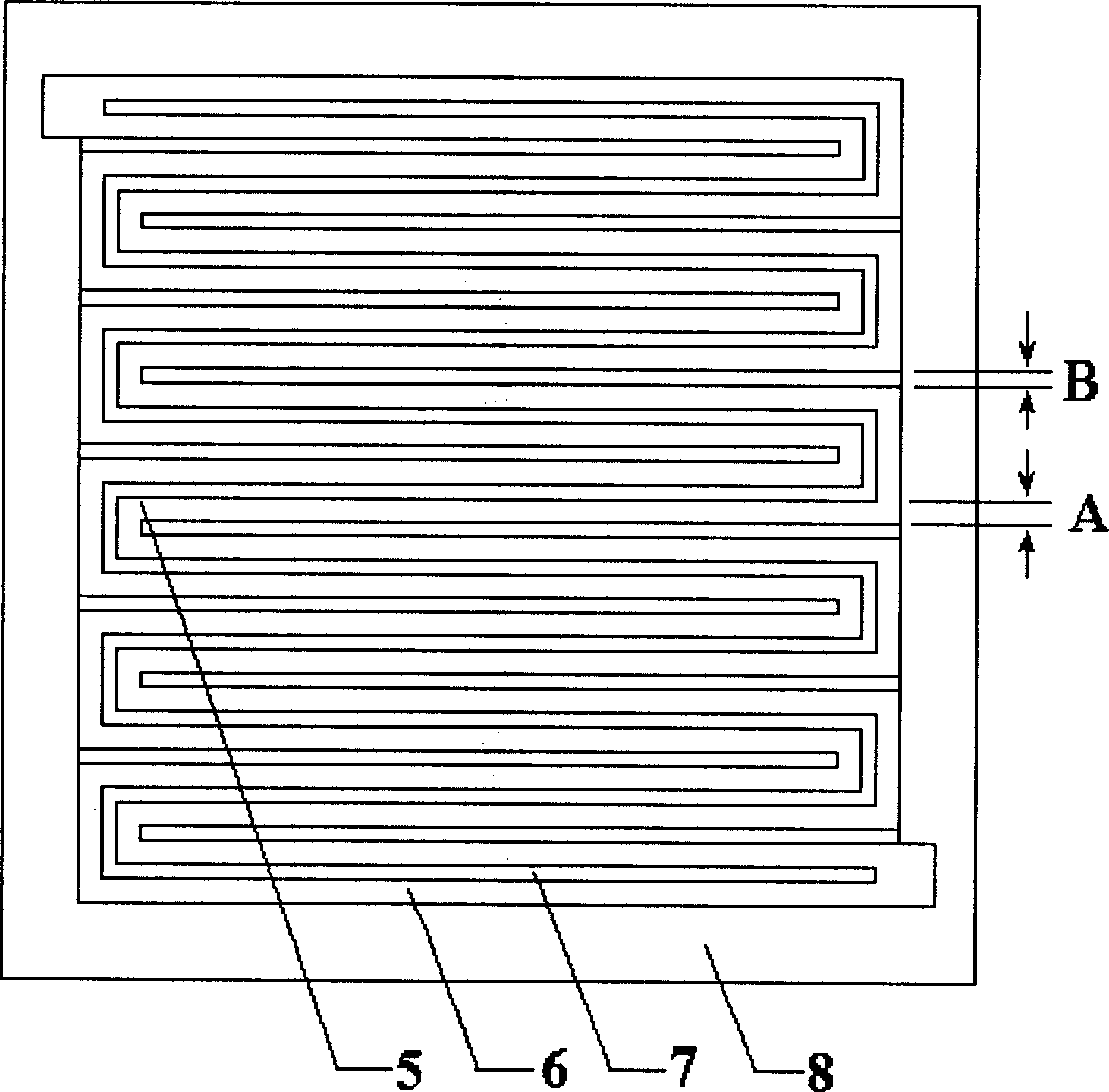

Current collection plate for all vanadium redox flow battery

InactiveCN1845368AAvoid deformationReduce polarizationElectrode carriers/collectorsFuel cellsEpoxyVanadium redox battery

The structure of a collecting board for full-vanadium redox fluid cell comprises: the high-density graphite plate dipped by epoxy resin or phenol resin, and a S-shaped flow field with width rate of ridge and channel as 1:0.5~6 and the rate between the channel depth to channel width as 1:1~5. The advantages of this invention include: 1) small resistance, stable chemical property, and strong ability to bear large current charge / discharge; 2) strong rigidity and intensity; 3) smooth flow of the electrolyte, and little polarization on cell.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

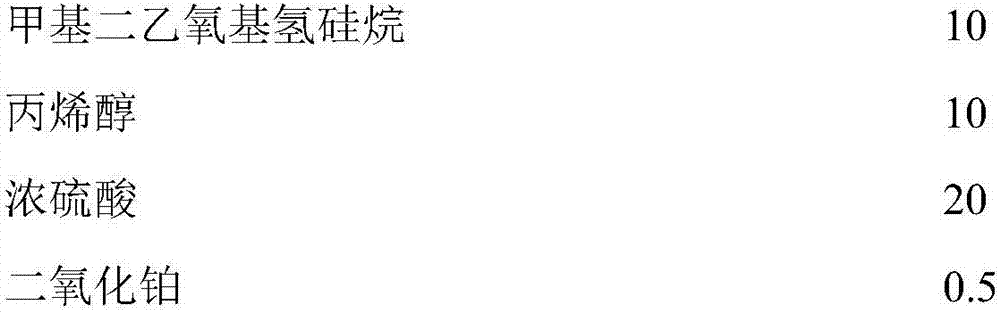

Environment-friendly siloxane-terminated polyurethane sealant and preparation method thereof

ActiveCN107216845ANo seepageNo pollutionNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesSealantMechanical property

The invention discloses an environment-friendly siloxane-terminated polyurethane sealant and a preparation method thereof. First, a NCO-terminated polyurethane prepolymer is prepared, hydroxypropyl siloxane is synthesized, the NCO-terminated polyurethane prepolymer is put in a reaction kettle, a silane coupling agent and the obtained hydroxypropyl methyldiethoxysilane are added into the reaction kettle for heating to 50 to 70 DEG C for reacting for 2-3H; NCO content is tested, and when the NCO content is close to zero, a small molecule volatile capping agent is added, and stirring is performed; triethyl orthoformate is added and stirred after cooling to room temperature, and a siloxane-terminated polyurethane prepolymer is discharged; a plasticizer and an inorganic filler are added, mixed and cooled to room temperature, and an additive and a catalyst are added, and mixed under vacuum conditions; and the obtained environment-friendly siloxane-terminated polyurethane sealant has good stability, can be fast cured at room temperature to obtain an elastic sealant with good mechanical properties, has a very good adhesion effect on glass, metal and other matrixes without a primer.

Owner:SOUTH CHINA UNIV OF TECH

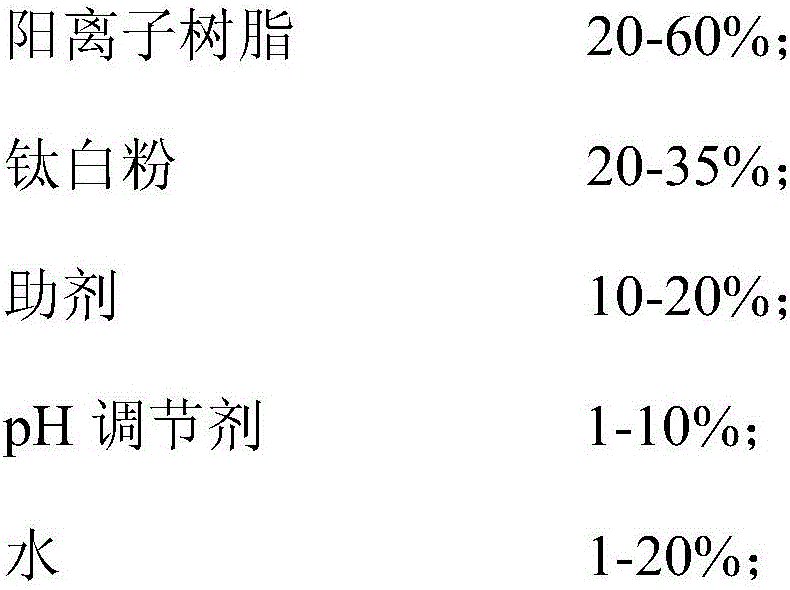

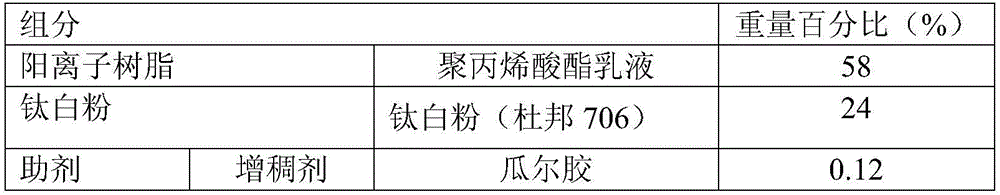

White glue for paint ink digital printing and preparation process of white glue

The invention discloses white glue for paint ink digital printing. The white glue is prepared from, by weight, 20-60% of cation resin, 20-35% of titanium dioxide, 10-20% of auxiliaries, 1-10% of a pH regulating agent and 1-20% of water, wherein the sum of weight percentages is 100%. The white glue has advantages of simple formulation, easiness in raw material acquisition and environment friendliness. The invention further discloses a preparation process of the white glue. The preparation process of the white glue has advantages of simplicity, convenience in operation and short process.

Owner:东莞市竤穗实业投资有限公司

Degradable disposable medical nursing article and mfg. method thereof

InactiveCN100999883AReduce infectionAntibacterialSpecial paperWater-repelling agents additionFiberSlurry

The present invention relates to one kind of degradable disposable medical nursing material and its production process. The degradable disposable medical nursing material consists of dry fiber 100 weight portions, water repellent 5-9.3 weight portions and antiseptic 0.01-10 weight portions. Its production process includes the steps of: pulping fiber to obtain 1-6 wt% concentration slurry, adding other components, forming to obtain product with water content of 55-80 %, drying to water content of 10-16 %, hot pressing to shape, trimming and packing.

Owner:宁波海基包装制品有限公司

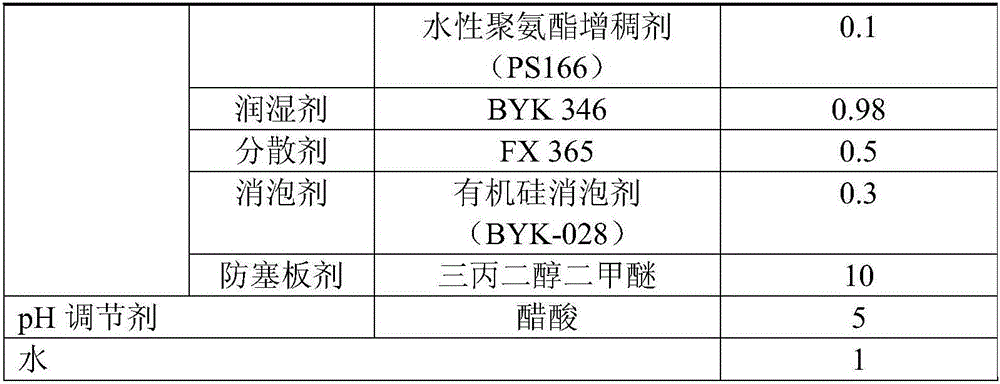

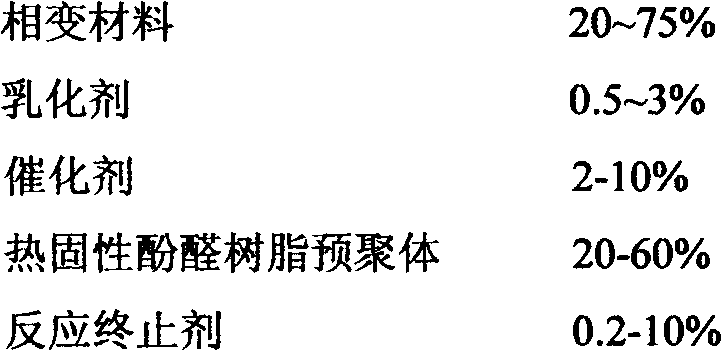

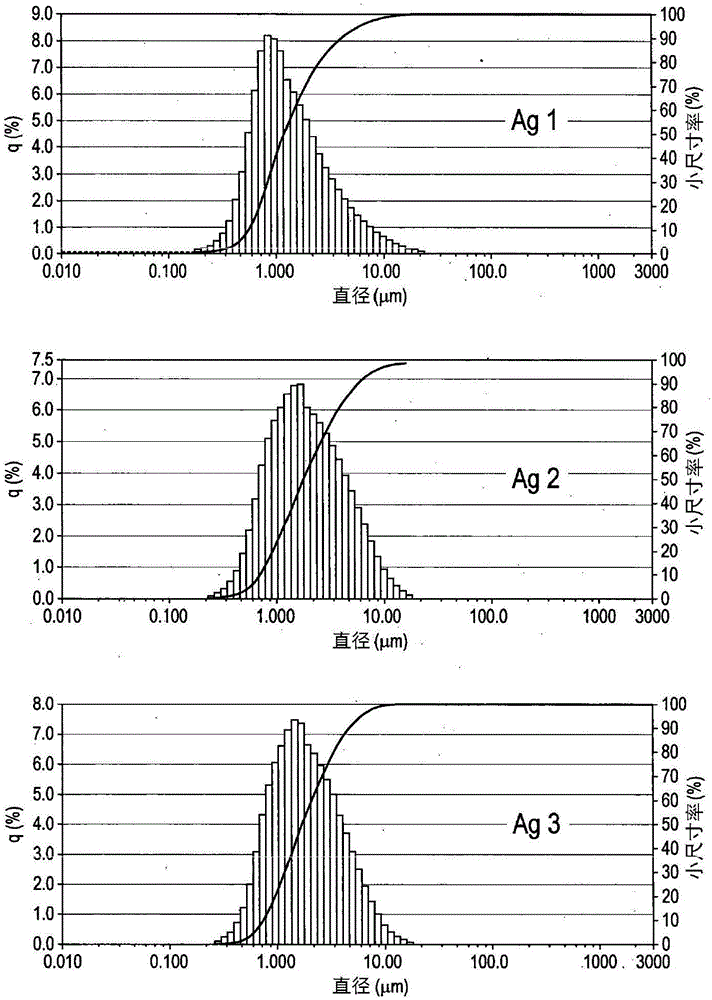

Phase change material microcapsule coated by thermoset phenolic resin and preparation method thereof

InactiveCN102618223AImprove quality scoreIncrease coverageHeat-exchange elementsMicroballoon preparationMass ratioMoisture

The invention discloses a phase change material microcapsule coated by thermoset phenolic resin and a preparation method thereof. The capsule uses a phase change material as a capsule core and the thermoset phenolic resin as the capsule wall. The mass ratio of materials of the microcapsule is that 20-75% of the phase change material, 0.5-3% of an emulsifying agent, 2-10% of a catalyst, 20-60% of thermoset phenolic resin prepolymer and 0.2-10% of a reaction terminating agent. The preparation method comprises heating and melting the phase change material, mixing the phase change material with the emulsifying agent, distilled water and the catalyst to form emulsion, heating the emulsion to 40 DEG C to 80 DEG C, dropwise adding the thermoset phenolic resin prepolymer, keeping constant temperature for 20-100minutes after finishing dropwise adding, adding the reaction terminating agent, adjusting the potential of hydrogen (pH) to about 7.0 with organic acid or inorganic acid, vacuumizing to evaporate moisture, and obtaining the phase change material microcapsule coated with the thermoset phenolic resin. The particle diameter of the phase change material microcapsule ranges from 0.5mum to 4mum. The phase change material microcapsule can be used for manufacturing building materials, thermal storage thermoregulation textiles, crop growth protection agents and the like.

Owner:李雨杉

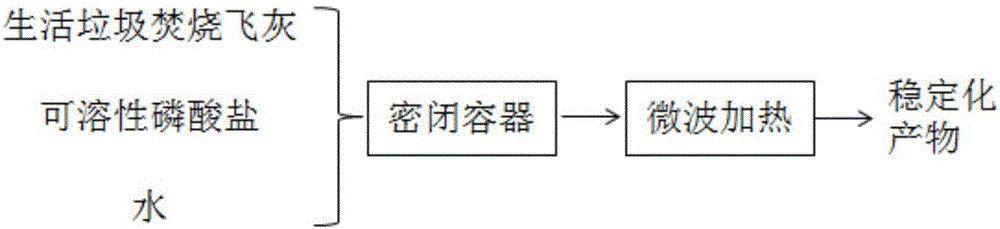

Disposition method for municipal solid waste incineration fly ash with microwave hydrothermal method applied

InactiveCN106077031AImprove adsorption capacityLow costSolid waste disposalTransportation and packagingMicrowaveResource utilization

The invention discloses a stabilizing method for municipal solid waste incineration fly ash with microwave applied. The stabilized products can be obtained by adding fly ash to be processed, a certain concentration of additive agent and water into a polytetrafluoroethylene container directly and then performing heating by the microwave to solidify heavy metal in the fly ash. After disposed by the method, the leaching concentration of the heavy metal in the fly ash can be far below the limiting value of national standard 16889-2008. By means of the stabilizing method, hazardous wastes such as the municipal solid waste incineration fly ash can be processed efficiently and rapidly to meet the requirements of secure landfill and post resource utilization. The method is simple in technology, convenient to operate, high in heavy metal solidified rate, capable of making up for deficiencies that the conventional hydrothermal disposition is high in energy consumption, long in computing time and the like, and high in practical application potential of large-scale disposition of the municipal solid waste incineration fly ash.

Owner:ZHEJIANG UNIV

Air electrode and manufacturing method thereof

The invention relates to an air electrode and a manufacturing method thereof. The air electrode comprises a current collector; a ventilating protection layer is arranged at the lower end of the current collector; and a hydrophobic layer, a reaction layer and a catalysis layer are arranged at the upper end of the current collector from the bottom up in sequence. According to the air electrode disclosed in the invention, the formed A surface is high in hydrophily and weak in hydrophobicity, and a liquid can permeate into the air electrode through the hole channels in the medium to form B surfacepermeation in a fingering manner; along with prolonging of the permeation distance, the medium hydrophobicity is gradually improved, and the holes are smaller and smaller; as a result, the permeationflow resistance is improved, and liquid permeation speed is lower and lower, and finally, the liquid stops permeation in a certain position in the middle of the A and B surfaces to form a stable air,liquid and solid three-phase interface; and by virtue of the interface, a large number of occasions can be provided for the positive electrode reaction, submerging of the electrode by the liquid canbe prevented, and finally, the air electrode can satisfy the standards of high performance and long service life.

Owner:莱尔(深圳)新能源有限公司

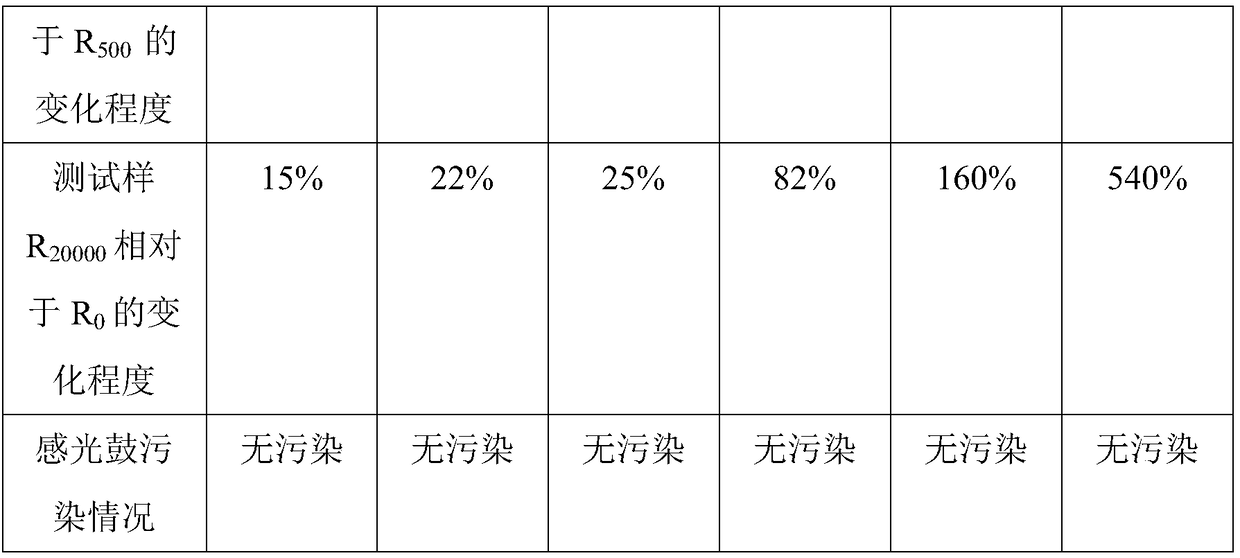

Semi-conductive silicone rubber roller material with highly repeated charge and discharge properties and preparation method thereof

InactiveCN109280394AEasy to crossLower volume resistivityElectrical resistance and conductanceEthylene-propylene-diene-monomer

The invention relates to the technical field of preparation of semi-conductive composite materials, and particularly discloses a semi-conductive silicone rubber roller material with highly repeated charge and discharge properties and a preparation method thereof. The semi-conductive silicone rubber roller material with highly repeated charge and discharge properties is made of the following raw materials in parts by weight: 50-90 parts of methyl vinyl silicone rubber, 10-50 parts of ethylene propylene diene monomer, 8-15 parts of conductive masterbatch A, 5-12 parts of conductive masterbatch B, and 1-5 parts of cross-linking agent. The volume resistivity of the semi-conductive silicone rubber roller material is in a range of 0.42*10<4>-0.88*10<4> [omega]*cm in a semi-conductive region (ie,about 105-109 [omega]*cm), and the resistance of the material is extremely stable, and in a high-temperature high-moisture environment, no chemical substance that oozes a photosensitive drum seeps; and in addition, the material has good printing durability, can ensure stable image output, and has a long service life.

Owner:广州德润橡胶制品有限公司

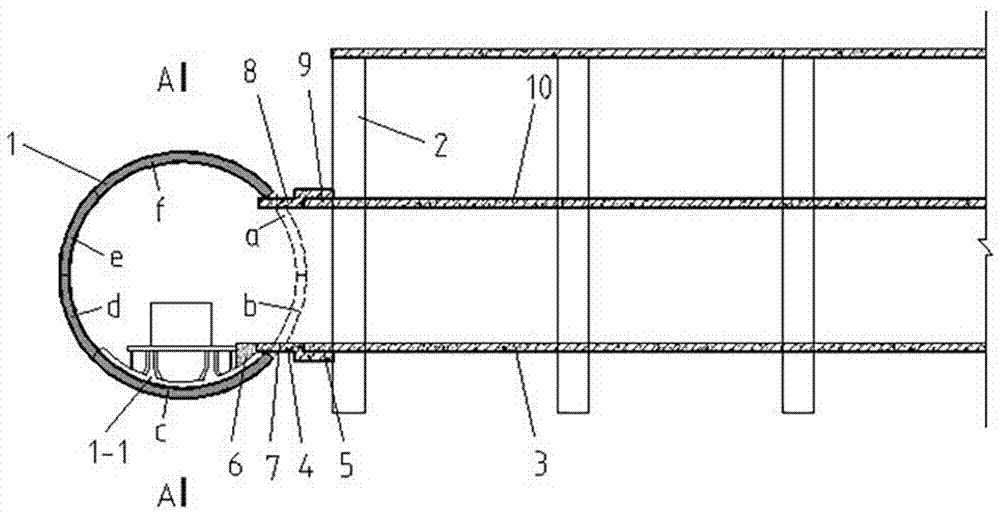

Novel connecting structure for subway tunnel and extended station and construction method of novel connecting structure

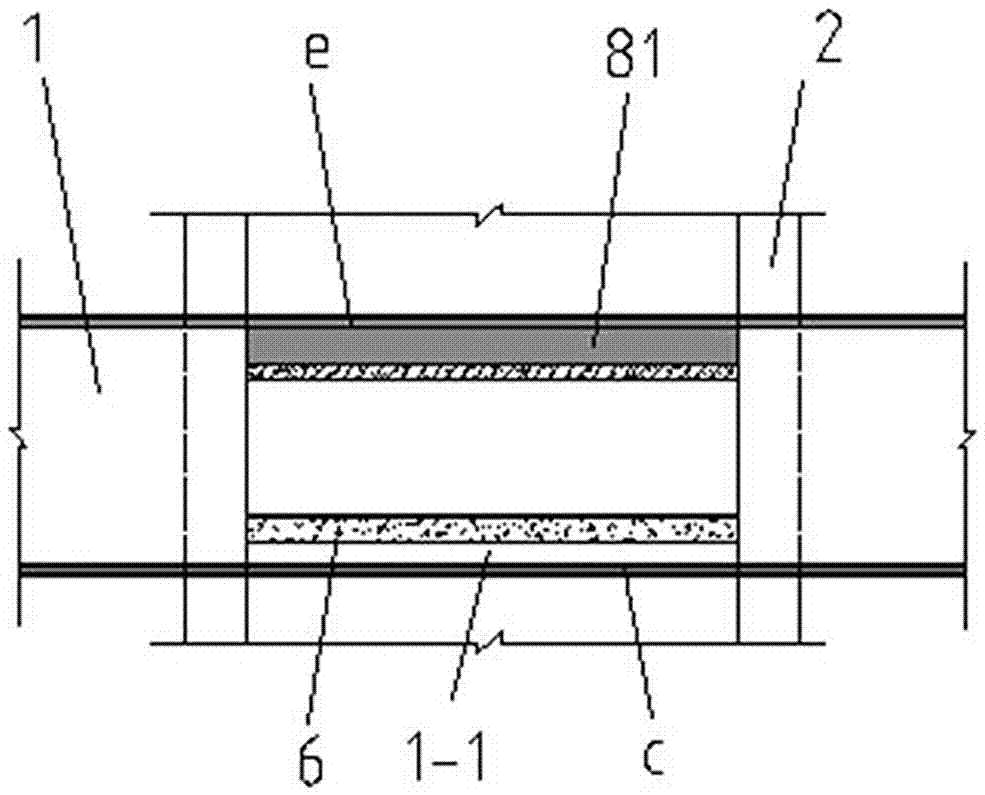

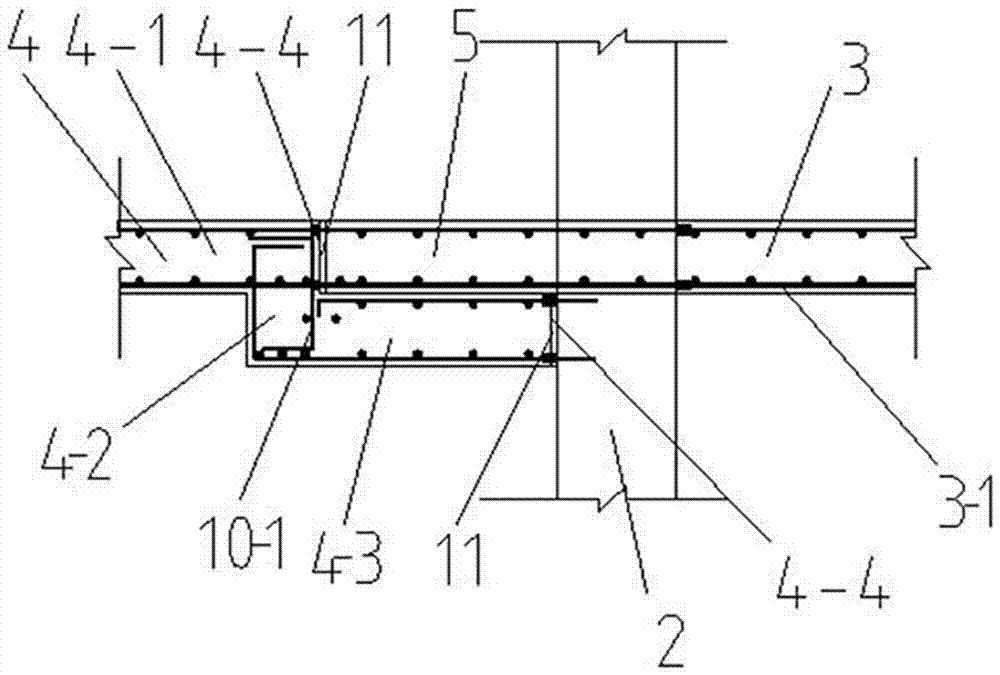

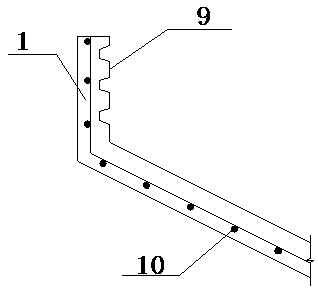

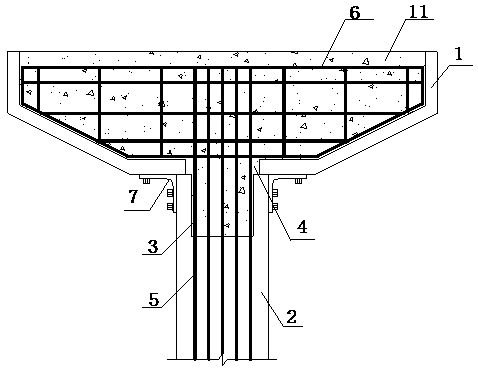

InactiveCN107476340AEnsure safetyImprove the phenomenon of uneven stress on the structureArtificial islandsUnderwater structuresInternal forcesSegment structure

The invention relates to a novel connecting structure for a subway tunnel and an extended station and a construction method of the novel connecting structure, and belongs to the technical field of underground buildings. The novel connecting structure comprises a tunnel pipe rack segment, a bearing column, a top face connecting block, a bottom face connecting block, a concrete trowelling layer and a waterproof layer. Through strengthened ribs, it can be guaranteed that the shield tunnel pipe sheet in the transfer station extending process can bear large internal force, and accordingly pipe segment safety is guaranteed; by adoption of the top face connecting block and the bottom face connecting block, connecting joints have enough rigidity, and joint deformation is reduced; a third bottom plate is arranged on a bent support of a second bottom plate, differential settlement between the second bottom plate and the first bottom plate is eliminated, a connecting structure between the second bottom plate and the first bottom plate and stress are well balanced, and the problem about connection between the rigid transfer station body structure and the flexible pipe segment structure is solved. The special tunnel shield pipe segment and an ordinary subway interval tunnel shield tunnel pipe segment are consistent in appearance, and a die the same as a die of the ordinary subway interval tunnel shield tunnel pipe segment can be utilized for production.

Owner:SHENYANG JIANZHU UNIVERSITY

Manufacturing method for PCB for charging pile

ActiveCN110678004AShort processNormal thicknessHigh current circuit adaptationsElectric vehicle charging technologyGum printingCopper

The invention discloses a manufacturing method for a PCB for a charging pile. The manufacturing method comprises the following steps: S1, earlier-stage processing is carried out; S2, copper depositionis carried out; S3, blue glue pasting is carried out: a gold-plated area and a non-gold-plated area are preset on the PCB, a to-be-gold-plated bonding pad to be gold-plated is arranged on the presetgold-plated area, blue glue is pasted on the non-gold-plated area, and a copper layer is exposed in the gold-plated area; S4, first micro-etching and blue glue tearing off are carried out: the copperlayer in the gold-plated area is subjected to micro-etching, and the blue glue in the non-gold-plated area is torn off: S5, ink printing is carried out: the preset gold-plated area is covered by the ink and is then baked, and after exposure and development, the bonding pad to be gold-plated is exposed; S6, a dried film is selected and gold plating is carried out: the two sides of the PCB are covered with the dried film, the bonding pad to be gold-plated is exposed and developed, and gold plating is carried out after nickel plating is carried out on the bonding pad to be gold-plated; S7, film stripping and ink stripping are carried out; S8, second micro-etching is carried out; and S9, post-processing is carried out. According to the method, the conditions of gold infiltration and circuit infiltration and corrosion are avoided, the product quality is ensured, the production efficiency is improved, and the prepared PCB can bear large current.

Owner:VICTORY GIANT TECH HUIZHOU CO LTD

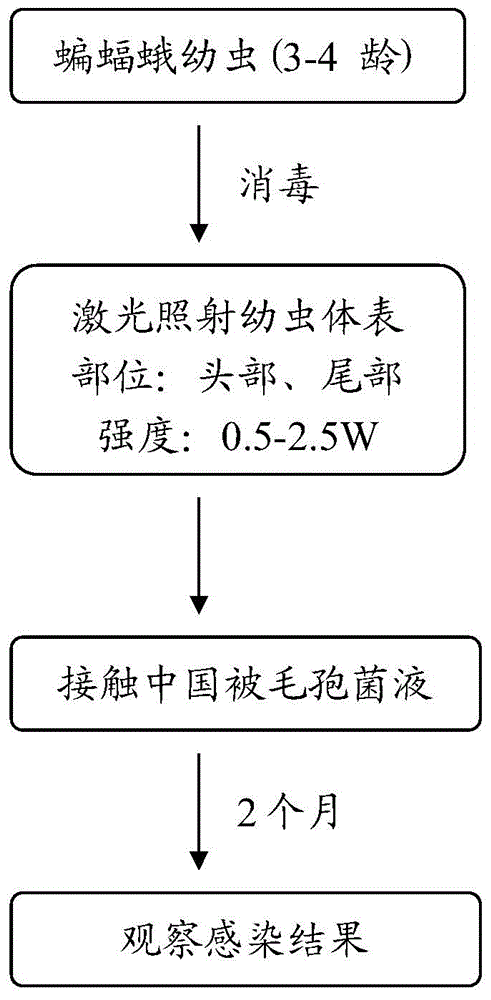

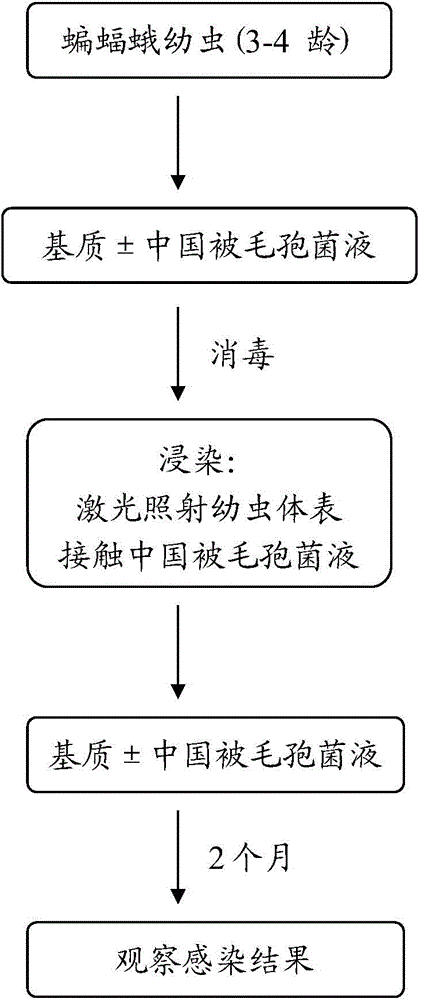

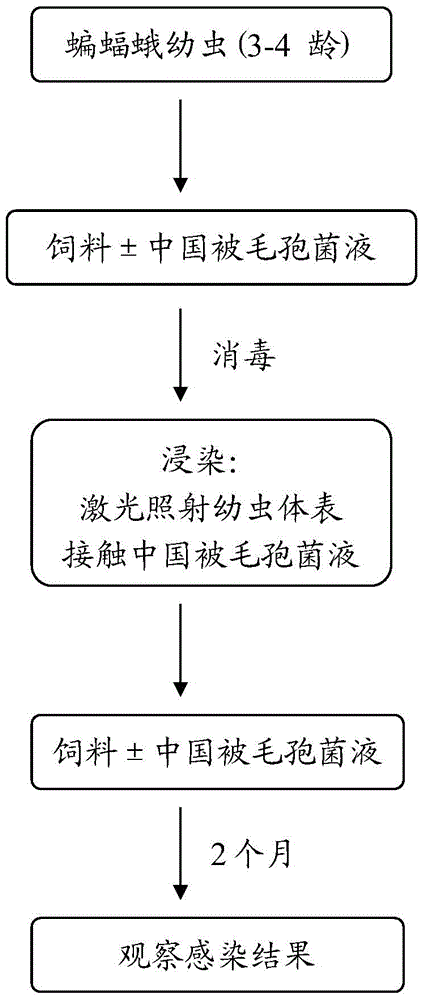

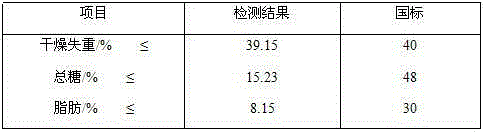

Method for improving infection rate of hosts of parasites of cordyceps sinensis

ActiveCN104920066AHigh speedNo seepageCultivating equipmentsMushroom cultivationInfection rateObserved Survival

The invention relates to a method for improving infection rate of hosts of parasites of cordyceps sinensis. By the method, body surfaces of larvas of the hosts of the parasites of the cordyceps sinensis are illuminated by laser light, tiny wounds are generated, hirsutella sinensis bacteria can enter body cavities of the larvas of the hosts of the parasites easily, and fruiting bodies of the cordyceps sinensis can be generated. The index components of the fruiting bodies, which are obtained by the artificial culture method, of the cordyceps sinensis are the same with those of fruiting bodies of wild cordyceps sinensis. By the method, the infection rate and the survival rate of the larvas can be improved greatly and are not limited by degree of proficiency of operators, the larvas of the hosts of the parasites of the cordyceps sinensis can be infected quickly and widely, the problem that the infection rate and the survival rate of the larvas, which are infected artificially in the prior art, of the hosts of the parasites of the cordyceps sinensis are low is solved, and the method can be used for artificial large-scale breeding and production of the cordyceps sinensis and has an important popularization role in artificial cultivation of the cordyceps sinensis.

Owner:SYNGEN BIOTECH

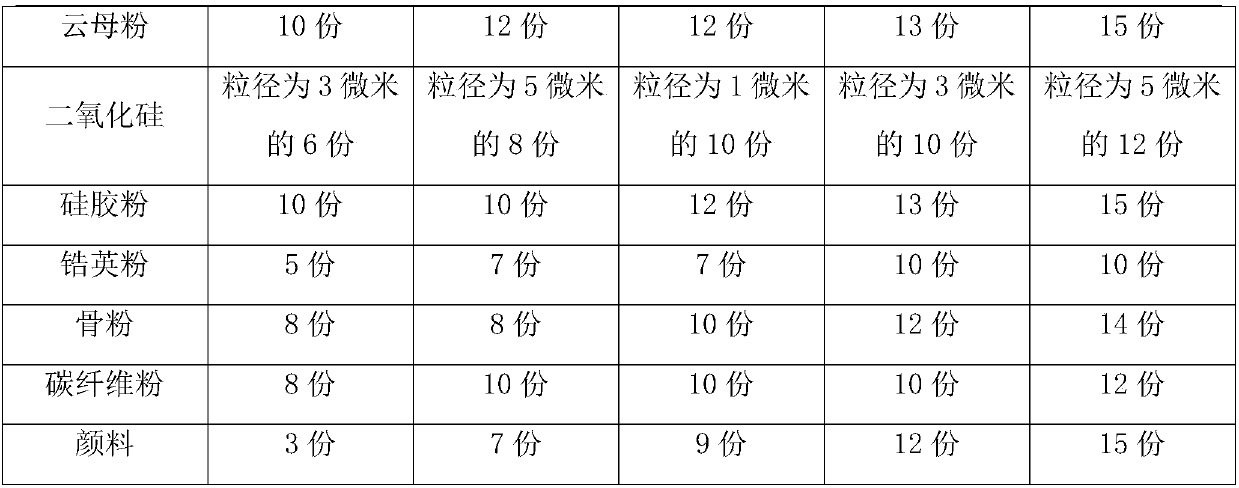

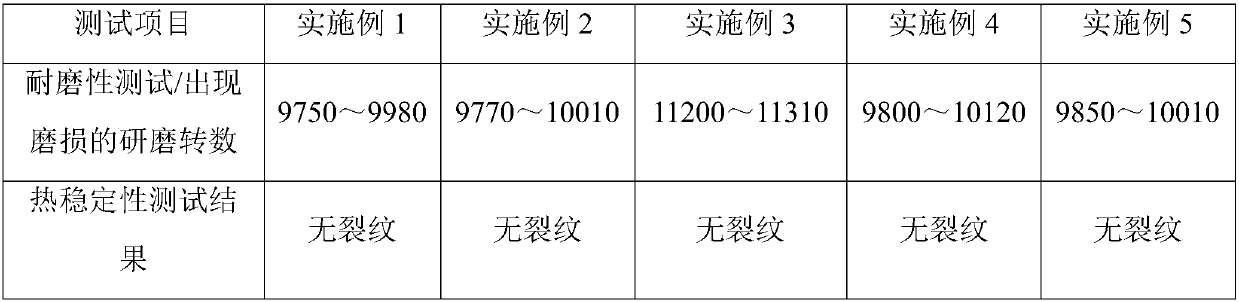

Wear-resistance and heat-resistance functional ceramic pot and preparing technology thereof

InactiveCN109608166ALow costHigh hardnessCeramic materials productionClaywaresFiberThermal insulation

The invention provides a wear-resistance and heat-resistance functional ceramic pot. The wear-resistance and heat-resistance functional ceramic pot comprises a blank and an enamel layer applied to theblank; the blank is prepared from, by weight, 35-50 parts of kaolin, 35-50 parts of waste ceramic, 25-35 parts of zircon powder, 10-15 parts of sepiolite powder, 20-30 parts of activated aluminum oxide and 8-12 parts of silica gel powder; the enamel layer is prepared from, by weight, 10-20 parts of kaolin, 10-15 parts of mica powder, 6-12 parts of silicon dioxide, 10-15 parts of silica gel powder, 5-10 parts of zircon powder, 8-14 parts of bone meal, 8-12 parts of carbon fiber powder and 3-15 parts of pigment. The ceramic pot is smooth and bright in appearance, quick in heat conduction, goodin thermal insulation, resistant to wear and corrosion, and free of toxicity or pollution.

Owner:FUJIAN HUAXIA VAJRA TECH CO LTD

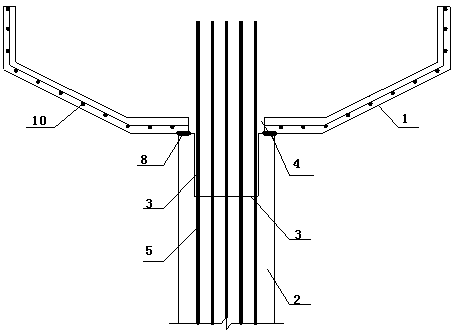

Semi-prefabricated UHPC shell overlap cover beam and prefabricated pier stud connecting structure and construction method thereof

PendingCN110258302ASimple equipment requirementsLight weightBridge structural detailsBridge erection/assemblyStructural engineering

The invention relates to a semi-prefabricated UHPC shell overlap cover beam and prefabricated pier stud connecting structure and a construction method thereof. The semi-prefabricated UHPC shell overlap cover beam and prefabricated pier stud connecting structure comprises a semi-prefabricated UHPC cover beam shell and a prefabricated pier stud located under the semi-prefabricated UHPC cover beam shell; the semi-prefabricated UHPC cover beam shell is of an uncovered shell-shaped structure with the hollow interior; a pier stud after-pouring groove is vertically formed in the top of the prefabricated pier stud from top to bottom; a through hole which is coaxial with and is matched with the pier stud after-pouring groove is formed in the bottom of the semi-prefabricated UHPC cover beam shell in a penetrating manner, and the through hole is located at the center of the bottom of the semi-prefabricated UHPC cover beam shell; a plurality of pier stud longitudinal ribs are embedded into the prefabricated pier stud, and the upper ends of the pier stud longitudinal ribs all vertically and upwards extend to penetrate through the through hole and go into the semi-prefabricated UHPC cover beam shell; and a cover beam steel reinforcement cage is arranged in the semi-prefabricated UHPC cover beam shell. The semi-prefabricated UHPC shell overlap cover beam and prefabricated pier stud connecting structure is simple and reasonable in structure and good in durability.

Owner:FUZHOU UNIV

Convenient-to-clean sputum suction device for pneumology department

InactiveCN112023154AContent monitoringNo splashHollow article cleaningMedical devicesMedicineMechanical engineering

The invention discloses a convenient-to-clean sputum suction device for a pneumology department, and relates to the technical field of sputum suction devices for the pneumology department, and aims tofully clean sputum adhered to a sputum suction collection box. The sputum suction device specifically comprises a box body, two cover plates are connected to the outer wall of one side of the box body through hinges, the sputum aspiration collection box is arranged on the outer wall of the top of the box body, a graduated scale is arranged on the inner wall of one side of the sputum aspiration collection box, three connectors are fixed to the outer wall of one side of the sputum aspiration collection box through bolts, a liquid outlet pipe is fixed to the outer wall of one side of the sputumsuction collection box through screws, a sealing cover plate is slidably connected to the outer wall of the top of the sputum suction collection box, a water disc is welded to the outer wall of the bottom of the sealing cover plate, and two or more flushing heads are fixed to the outer wall of the bottom of the water disc through bolts. Water in the water tank can be pressurized through a pressurepump, meanwhile, an insertion hole is formed in the outer wall of the top of the sealing cover plate, and the water in the water tank can be rapidly guided into the water disc through a flushing pipe.

Owner:李瑞

Water pump dedicated motor

InactiveCN108712003ANo seepageGuaranteed tightnessPumpsPositive-displacement liquid enginesMechanical engineeringEngineering

Owner:海宁梅尔环境科技有限公司

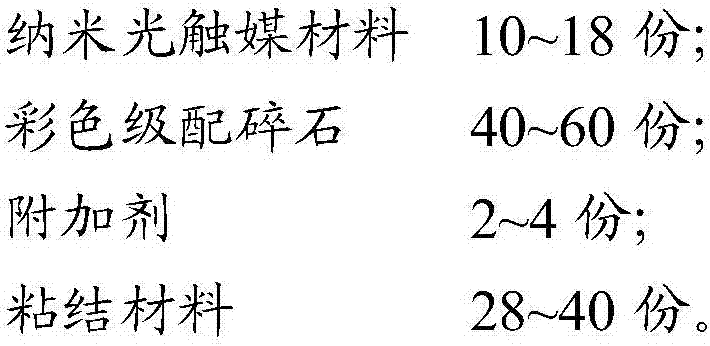

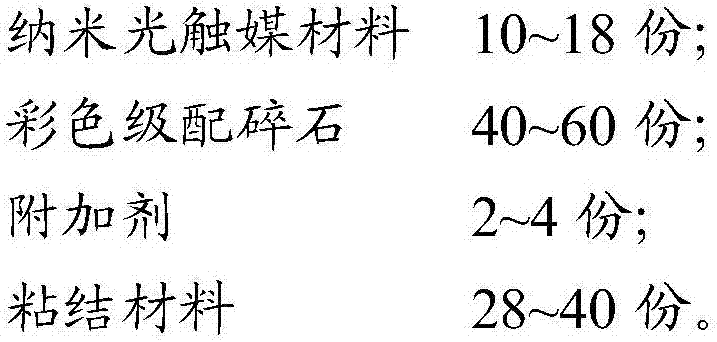

Color anti-skid layer for reducing haze guided traveling traffic and preparation method thereof

The invention provides a color anti-skid layer for reducing haze guided traveling traffic, which belongs to the technical field of pavement maintenance. The color anti-skid layer comprises a premix and a curing agent with weight ratio of 14: 1-5: 1, the premix comprises the following components in parts by mass: 10-18 parts of a nano photocatalyst material; 40-60 parts of color-graded broken stone, 2-4 parts of an additive, 28-40 parts of a bonding material, and 2-8 parts of a curing agent, the bonding material is capable of coating the color-graded broken stone and other auxiliary agents; the color-graded broken stone provides intensity, hardness and wear resistance, the bright color can effectively guide the traffic, traffic flow is induced, and the passing capability is increased; the photocatalyst material is mainly used for decomposing a harmful substance in haze; the effect of the components in the additive can better present the performance of the color anti-skid layer, the friction coefficient of the color anti-skid layer for haze guided traveling traffic is reduced by about 50% by comparing with the newly built pavement, and the PM2.5 in a product-used area is reduced by 20-30%.

Owner:BEIJING MUNICIPAL ENG RES INST

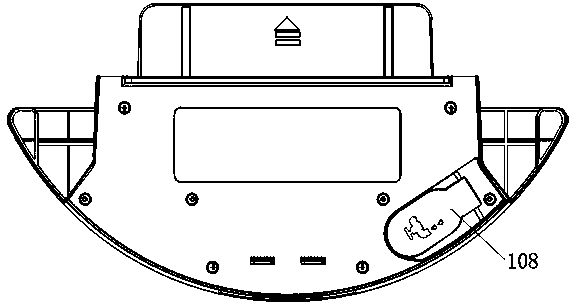

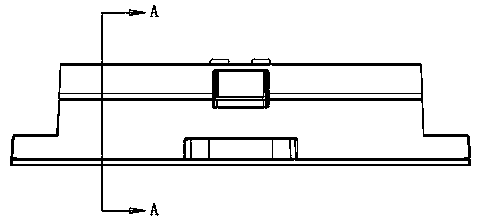

Water tank and cleaning robot

PendingCN109730591ASolve the problem of uneven water seepageImprove mopping efficiencyMachine detailsFloor sweeping machinesEnvironmental engineeringConsumptive water use

The invention discloses a water tank and a cleaning robot. The water tank comprises a water tank body and cleaning cloth, wherein water seepage cloth and fixed parts thereof are not arranged in the water tank body; water seepage holes in arc distribution are formed in the bottom of the water tank body; any water seepage cloth does not cover the upper surfaces of the water seepage holes; the cleaning cloth crimps with the bottom surfaces of the water seepage holes; air holes communicated with the water seepage holes are formed in the cover surface of the water tank body; and the communicating space of the air holes and the water seepage holes is isolated by cleaning water inside the water tank body. Compared with the prior art, the water tank in the technical scheme has the advantages thatthe water outlet structure of the water tank is simplified, the working efficiency of the water tank body is improved, and the water seepage holes are avoided from being blocked by the water seepage cloth.

Owner:DONGGUAN XINSU TECH CO LTD

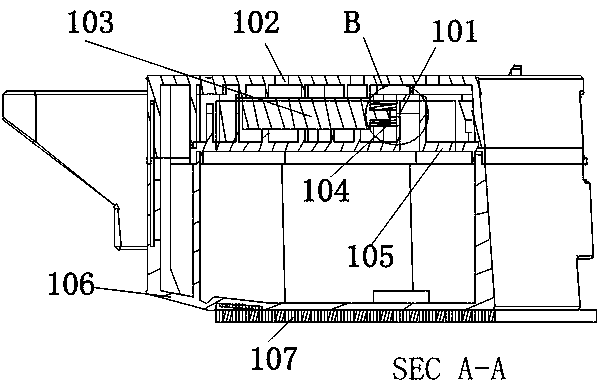

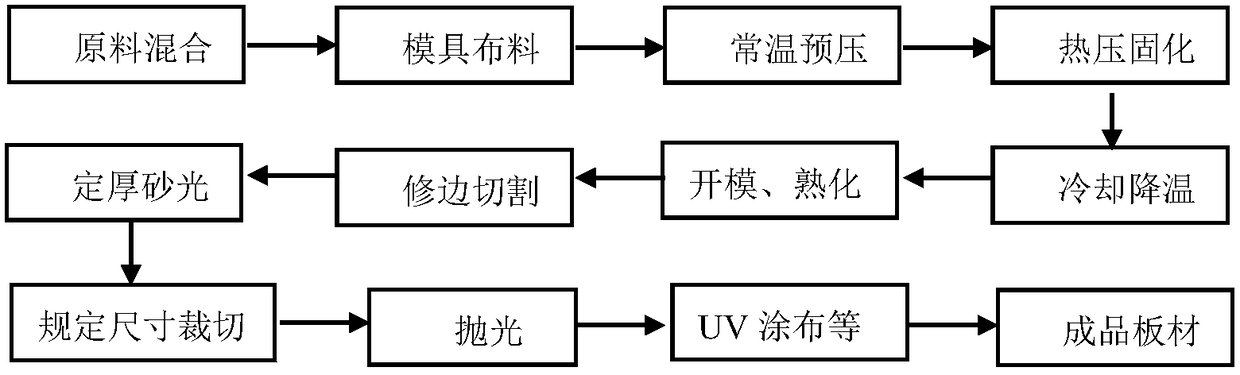

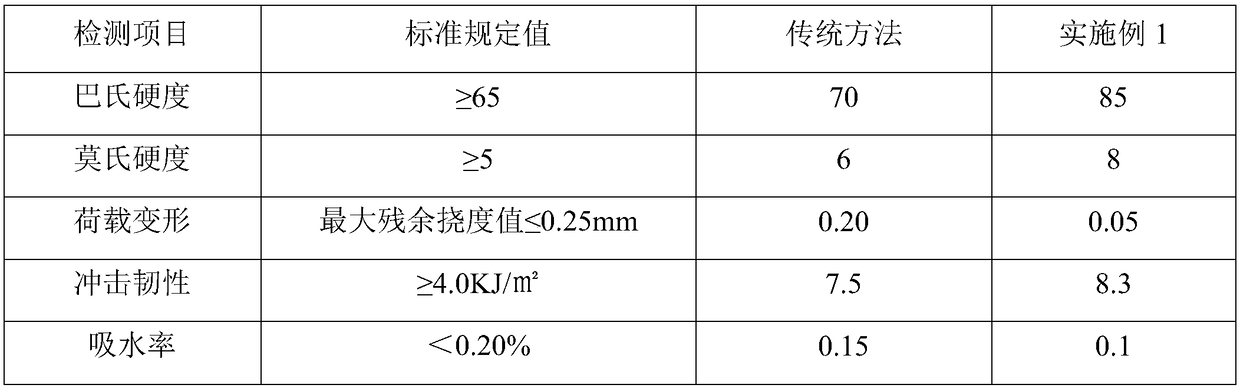

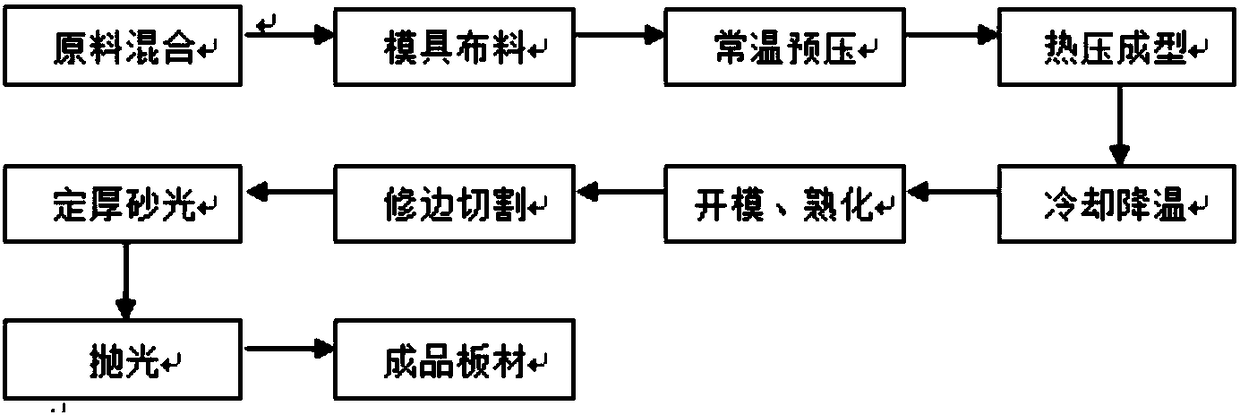

Preparation method of lightweight composite board

InactiveCN108911780ANo toxicityNo radioactivityCeramic shaping apparatusCeramicwareRoom temperatureHardness

The invention discloses a preparation method of a lightweight composite board. The preparation method comprises following steps: raw material mixing, die material distribution, normal temperature pre-compressing, hot pressing solidification, cooling, die-opening, aging, trimming and cutting, thickness fixing and sanding, standard size cutting, polishing, and board surface composite treatment. Theobtained lightweight composite board is nontoxic, possesses no radioactivity, reaches flame resistance A2 grade, possesses oil resistance, stain resistance, mildew resistance, antibacterial performance, wear resistance, impact resistance, is abundant in color, uniform in color, high and uniform in texture density, extremely high in natural texture performance, strength, and hardness, and can be used for UV coating or other surface composite processing based on different application requirements; maintenance is convenient; seamless splicing can be realized; and the moulding can be changed.

Owner:北京禾木之家科技发展有限公司

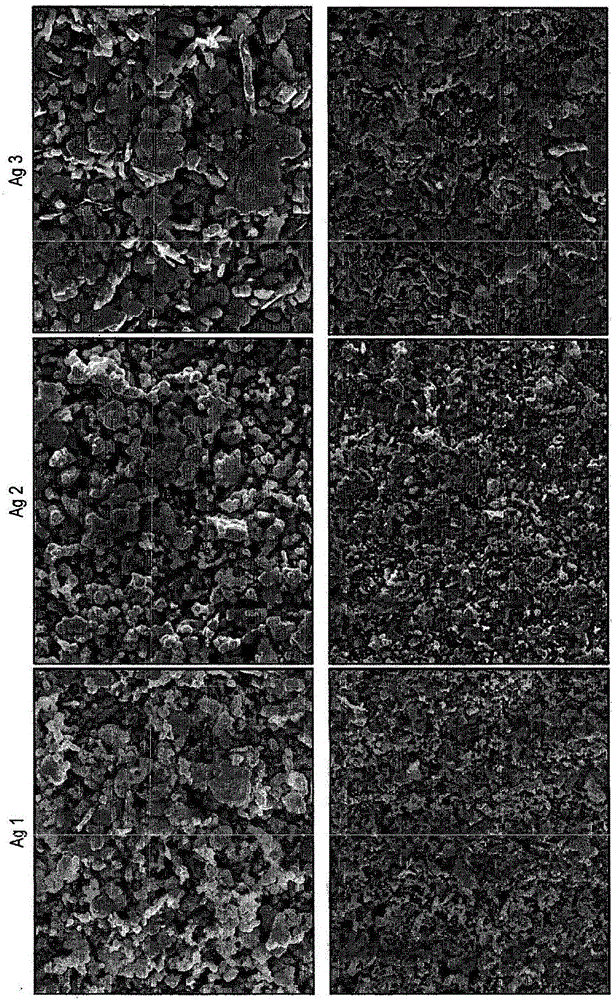

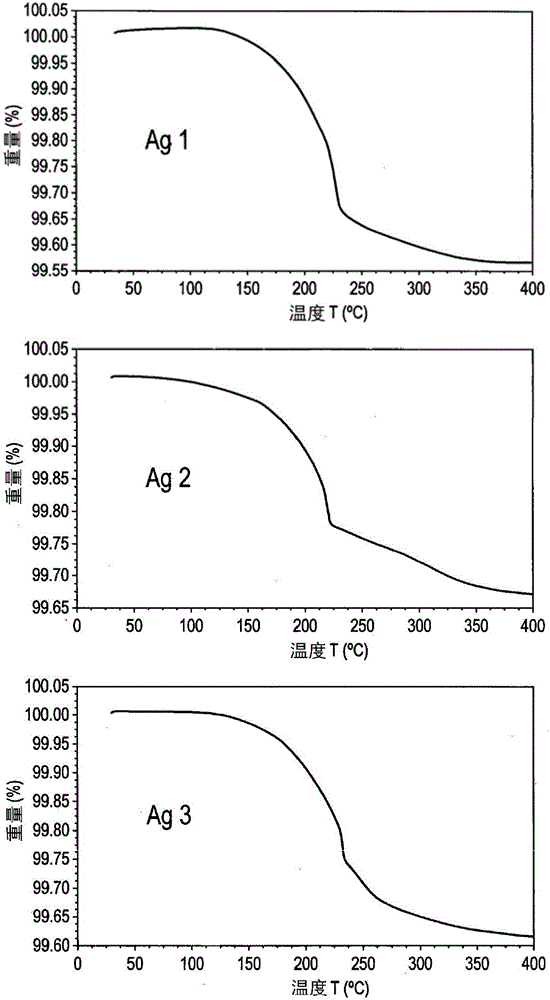

Method for manufacturing metal powder

ActiveCN106457404AIncrease powerGood thermal cycle performancePigmenting treatmentNon-macromolecular adhesive additivesSolventMetal powder

A method for manufacturing metal powder comprising: providing a basic metal salt solution; contacting the basic metal salt solution with a reducing agent to precipitate metal powder therefrom; and recovering precipitated metal powder from the solvent.

Owner:ALPHA METALS

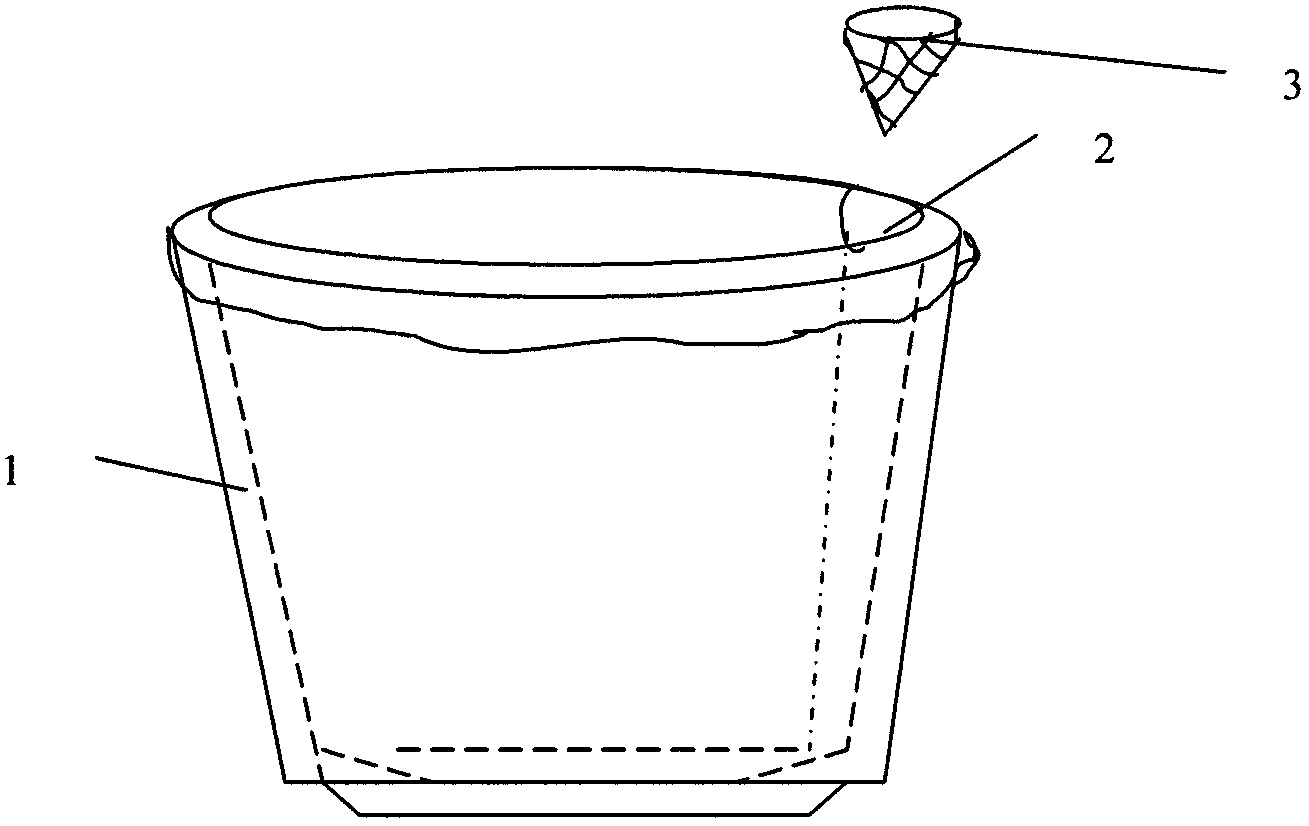

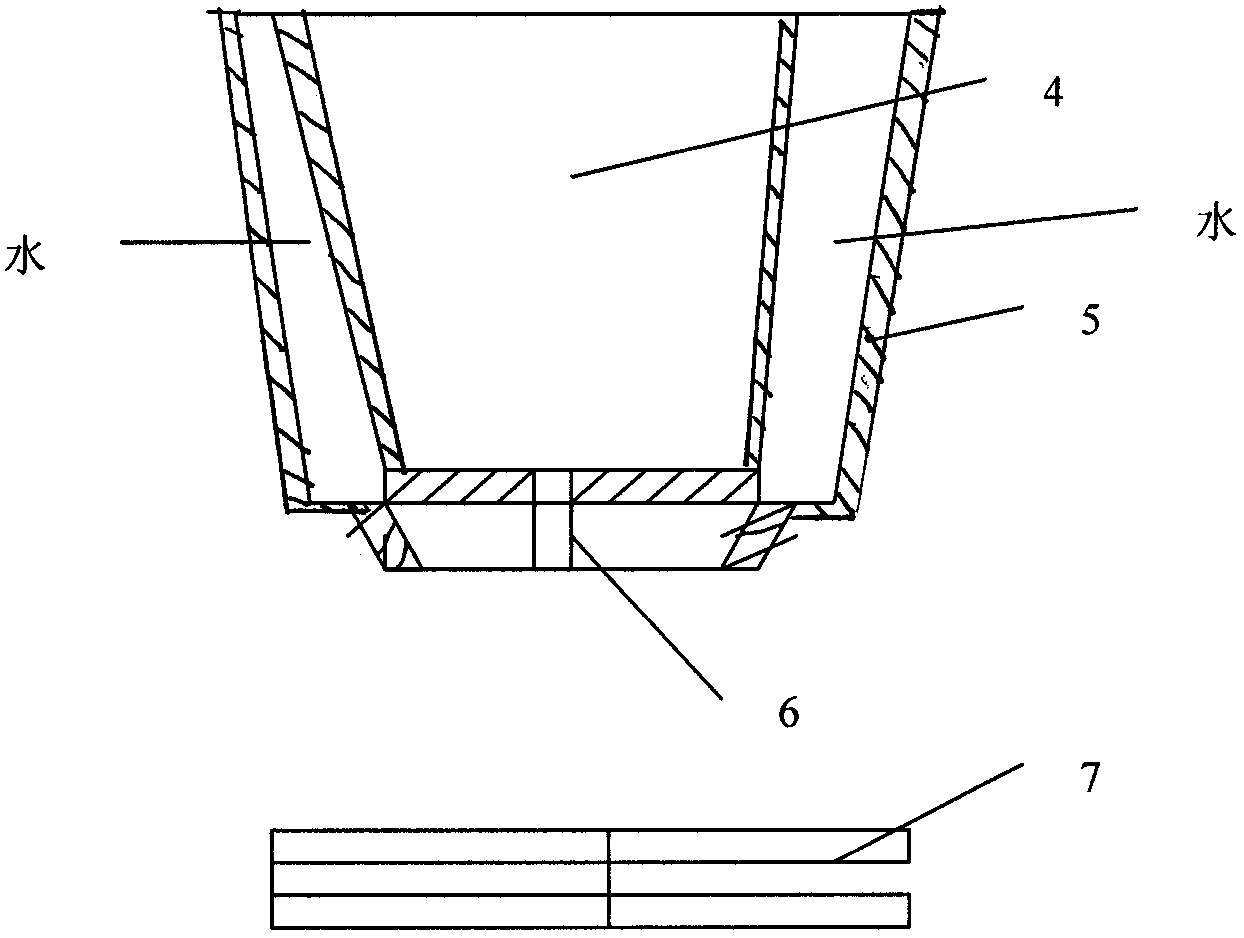

Water storage automatic permeation flower moistening double-layer hollow flower pot

InactiveCN103503716AAvoid churnAvoid complainingSelf-acting watering devicesReceptacle cultivationWater storageSiphon

The invention discloses a water storage automatic permeation flower moistening double-layer hollow flower pot. The bottom of a multi-cotton-sliver water absorption assembly device (7) is inserted in a water adding and cotton sliver outlet (2), and the upper portion of the multi-cotton-sliver water absorption assembly device (7) is placed on soil on the surface of an inner flower pot. The water adding and cotton sliver outlet (2) is sleeved with a mosquito prevention net 3, and the double-layer flower pot (1) is filled with water. By the utilization of the capillary siphon effect of bar type fibers, water is gradually sucked and permeates into the flower pot for flower moistening (watering). The number of cotton slivers which are placed in the inner flower pot is increased or decreased to control and adjust the soil humidity. By the utilization of the flower pot, water and fertilizers can be saved, environment-friendly flower watering is achieved, and labor time and labor amount of users are reduced.

Owner:陈建贤

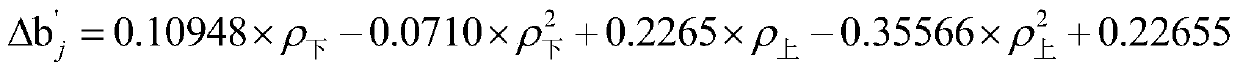

Method for determining control index of double-layer continuous reinforced concrete pavement reinforcement ratio

ActiveCN109930456ASolve the problem of control index of reinforcement ratioSolve the problem that there is no control index for the reinforcement ratio of double-layer CRCPRoads maintainenceReinforced concreteEconomic benefits

The invention discloses a method for determining the control index of a double-layer continuous reinforced concrete pavement reinforcement ratio. The method is characterized in that the method comprises the following steps of step one, initializing the reinforcement ratio of the upper and lower layers of steel bars and the positions of the reinforcement; step two, according to the calculation formula of a transverse crack width variation value delta bj under different reinforcement positions, calculating the transverse crack width variation value delta bj under different reinforcement positions; step three, according to the calculation formula of the transverse crack width variation value delta b'j under different reinforcement ratios, calculating the transverse crack width variation valuedelta b'j under the different reinforcement ratios; step four, according to the delta bj and delta b'j values, determining a double-layer CRCP transverse crack width control value bj, wherein the double-layer CRCP transverse crack width control value bj is the double-layer CRCP reinforcement ratio control index. According to the method, the reinforcement ratio control index can be used for the reinforcement ratio design, which has important significance for scientifically and rationally designing the double-layer CRCP reinforcement ratio, the reinforcement ratio is an important index for determining the performance and economy of the double-layer CRCP, and the method has significant social and economic benefits.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

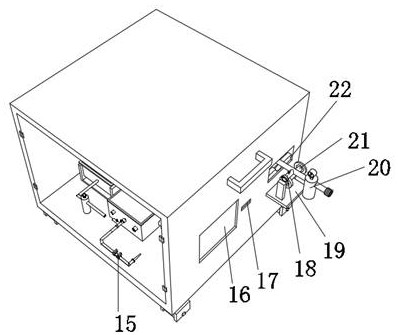

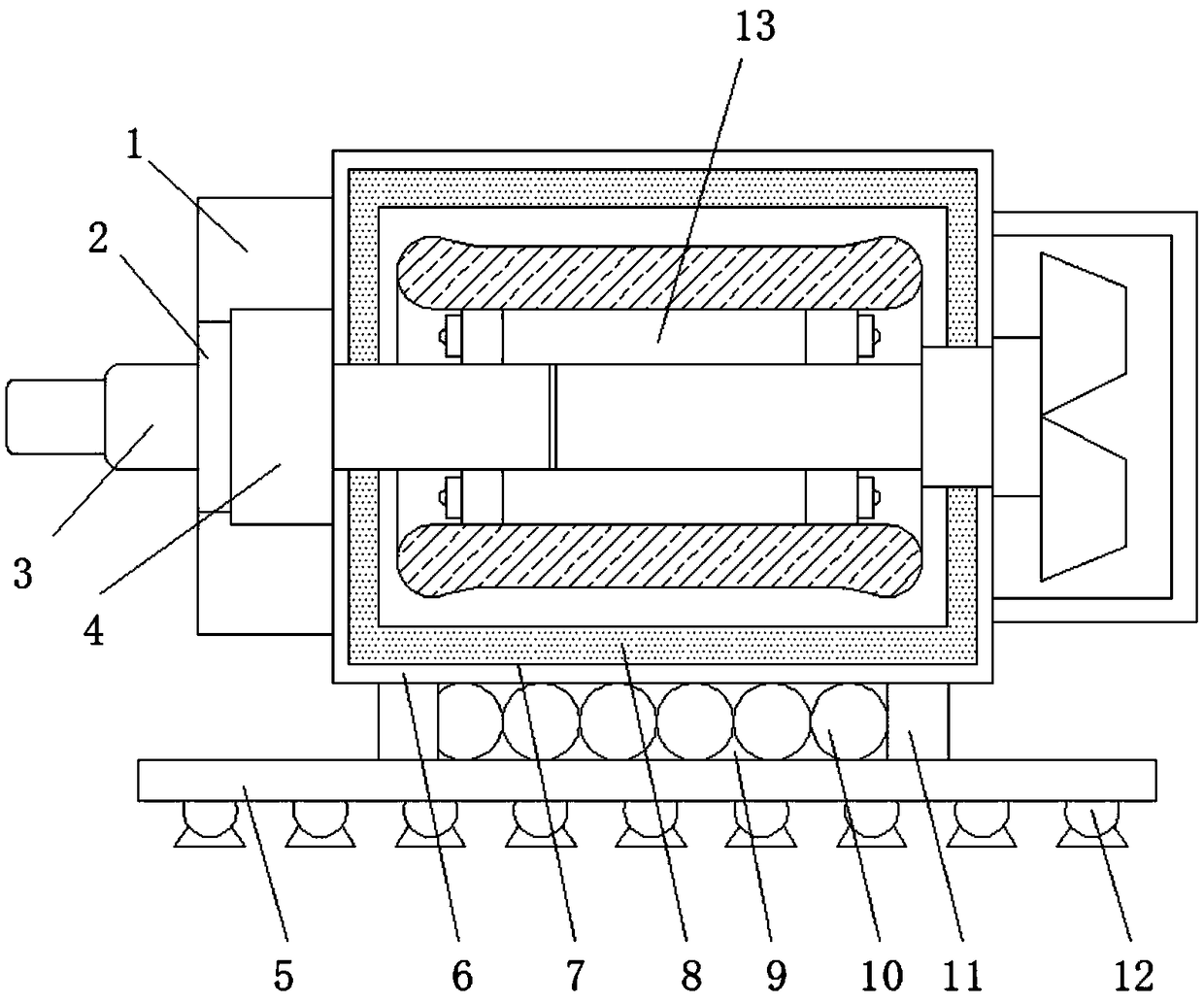

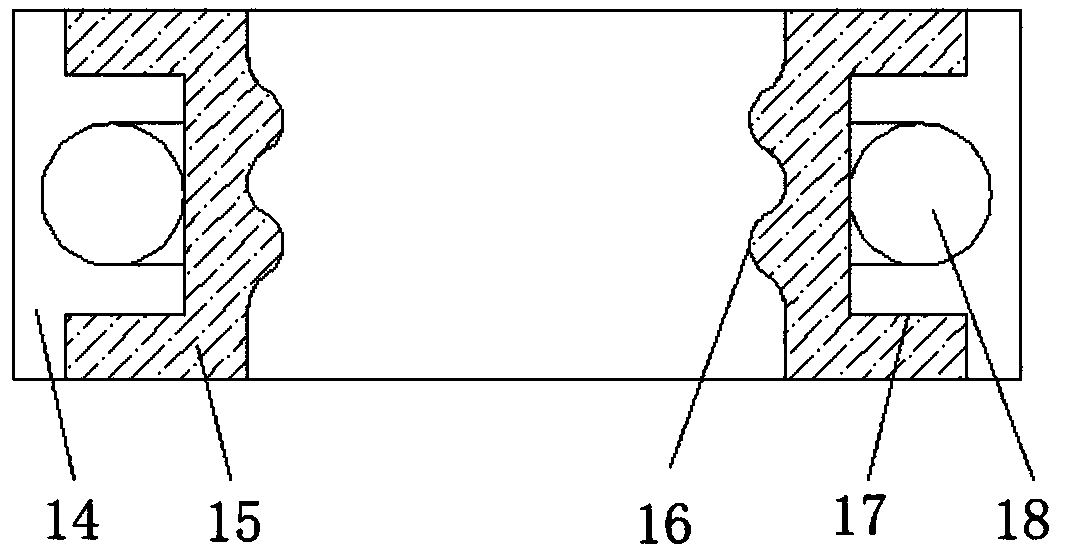

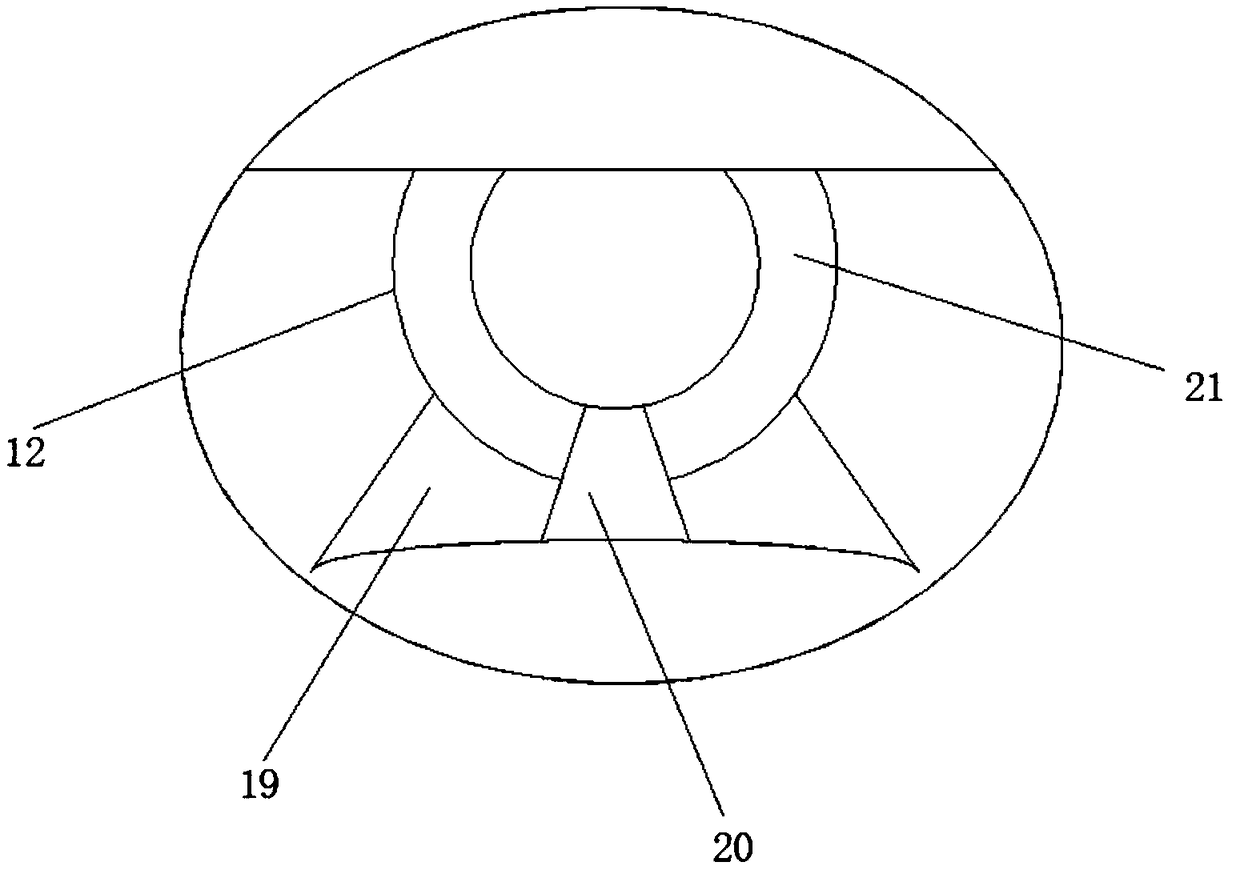

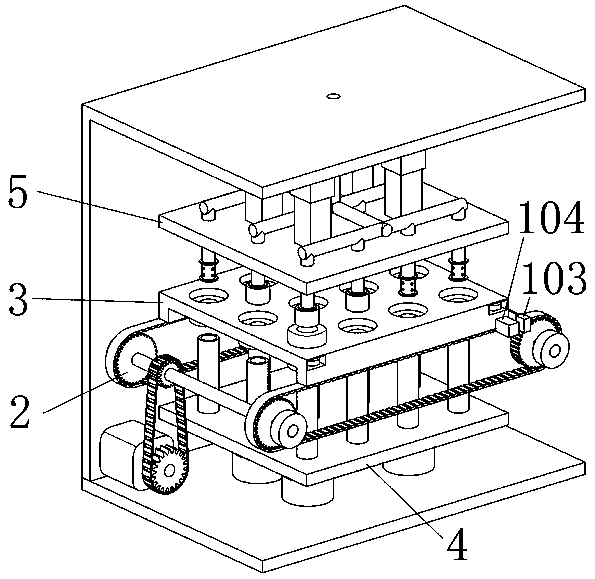

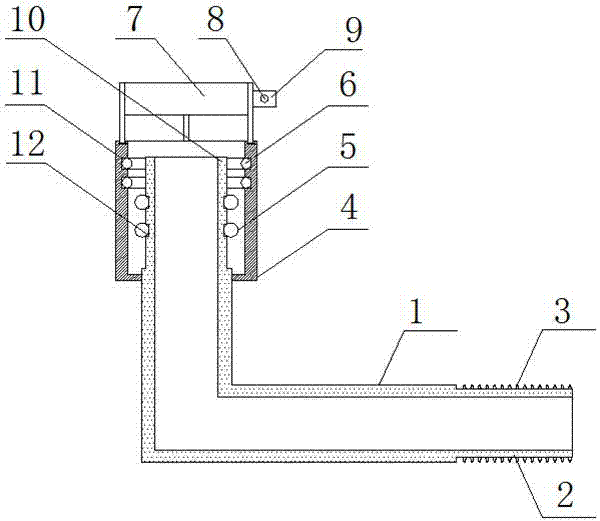

Plastic package stator rust-proof treatment device and using method thereof

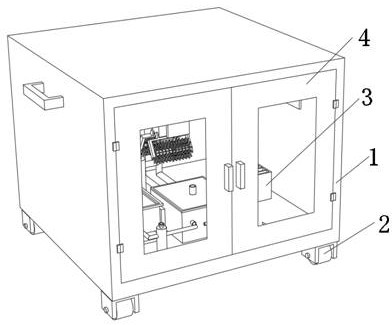

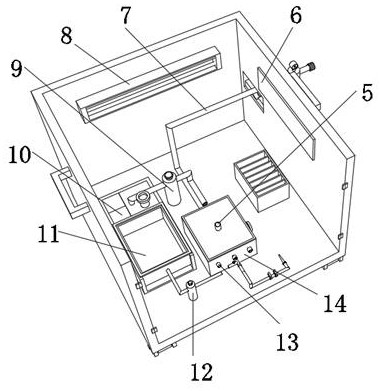

InactiveCN111010000AIncrease productivityAvoid bad noiseManufacturing stator/rotor bodiesMechanical engineeringPhysics

The invention relates to the technical field of intelligent processing equipment, and especially relates to a plastic package stator rust-proof treatment device and a using method thereof. The plasticpackage stator rust-proof treatment device comprises a shell, a conveying mechanism, a tray, a dust blowing seepage prevention mechanism and a coating mechanism and is characterized in that the shellis a rectangular hollow box body; the conveying mechanism is arranged in a lower area in the shell and is composed of a synchronous belt mechanism driven by a servo motor, and the tray is arranged onthe synchronous belt mechanism; the tray is a rectangular flat plate, and a plurality of countersunk head through holes are uniformly distributed in the rectangular flat plate to serve as plastic package stator placement grooves; the dust blowing seepage prevention mechanism is arranged below the conveying mechanism; and the coating mechanism is located above the conveying mechanism and right faces the dust blowing seepage prevention mechanism. The device and the method have the beneficial effects that rust-proof treatment can be performed under a condition that an inner cavity of the plasticpackage stator is kept clean all the time, and meanwhile a rust-proof liquid can be prevented from permeating into a bearing chamber of an end cover.

Owner:蔡国政

Preparation method of light weight panel

InactiveCN108069727ADensity dense and uniformNo toxicityCeramic shaping plantsCeramicwareHigh humidityMicrosphere

The invention provides a preparation method of a light weight panel. The preparation method of the light weight panel comprises the following steps of mixing the following raw materials in parts by weight: 10 to 20 parts of waste stone materials, 50 to 70 parts of microsphere particles, 10 to 20 parts of cement, and 6 to 8 parts of thermosetting phenolic resin powder so as to obtain a raw materialmixture; paving the raw material mixture, pre-pressing, hot-pressing, curing molding, cooling, and opening a mould to obtain a light weight panel blank body. The panel prepared by adopting the preparation method provided by the invention is dense and uniform in material, rich in color, uniform in color, higher strength and hardness, better in secondary processability without containing water, extra low in water absorption, and free of shrinkage and buckling deformation in a high-temperature high-humidity environment.

Owner:北京禾木之家科技发展有限公司

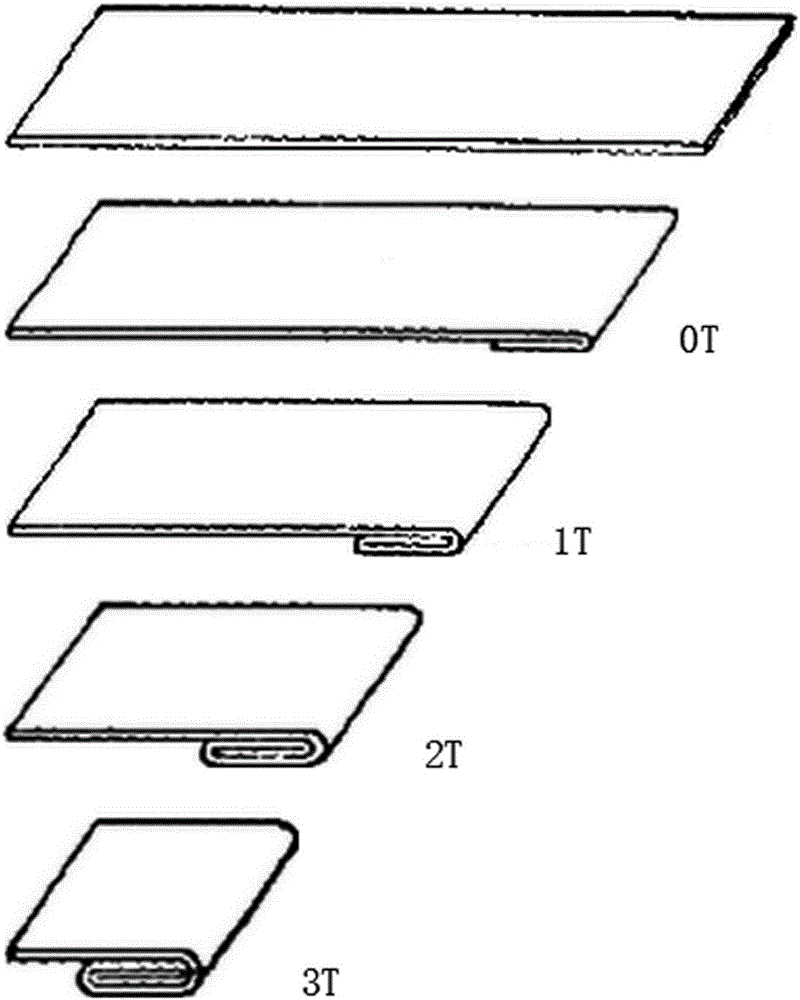

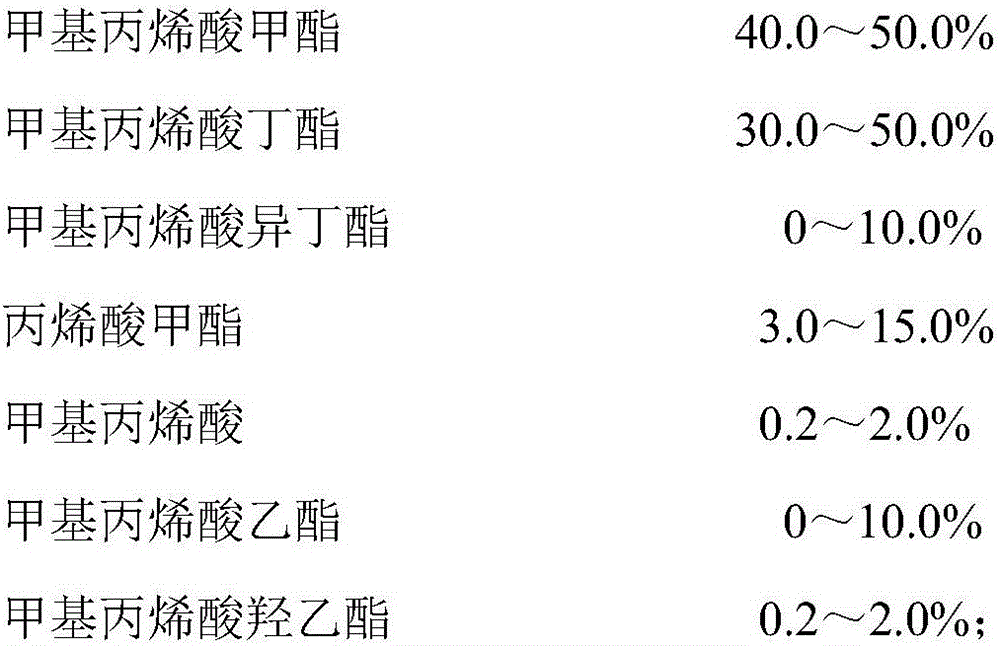

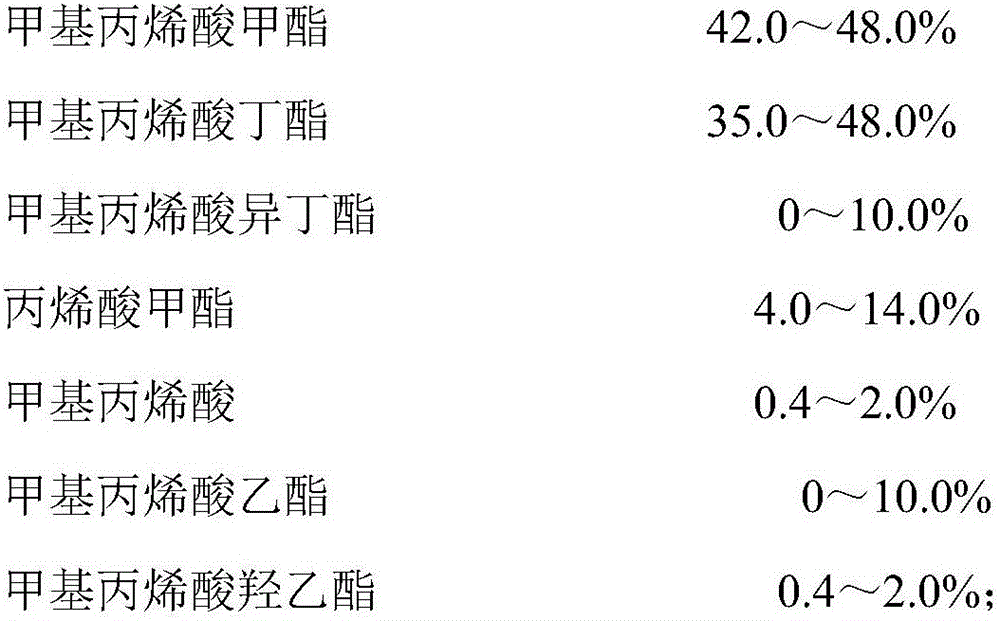

Acrylic resin having excellent compatibility with environment-friendly plasticizers

The invention discloses acrylic resin having an excellent compatibility with environment-friendly plasticizers. The acrylic resin is prepared by polymerizing the following monomers by weight percent: 40.0%-50.0% of methyl methacrylate, 30.0-50.0% of butyl methacrylate, 0-10.0% of isobutyl methacrylate, 3.0-15.0% of methyl acrylate, 0.2-2.0% of methacrylic acid, 0-10.0% of ethyl methacrylate and 0.2-2.0% of hydroxyethyl methylacrylate, wherein the sum of the weight percent of the monomers is 100%. The acrylic resin provided by the invention has the excellent compatibility with non-phthalate esters environment-friendly plasticizers and can be completely miscible with the environment-friendly plasticizers so as to form a transparent liquid and form a film; the film toughness reaches up to level 0T; the acrylic resin has the advantages of high stability, environmental protection, safety, no toxicity, and the like and can be used for replacing PVC.

Owner:BOLIER CHEM YANGZHOU

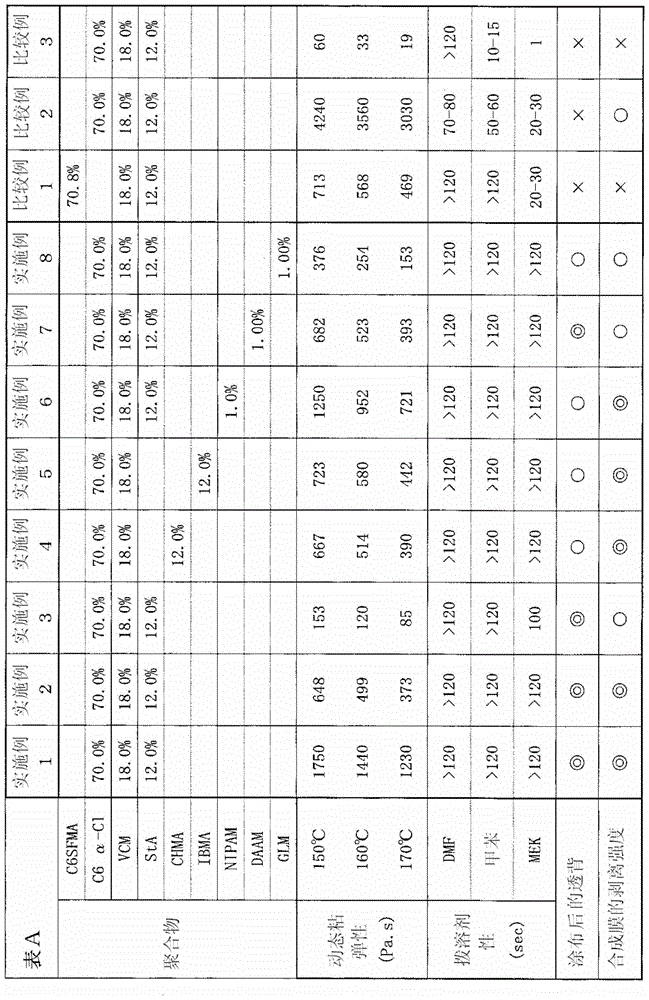

Moisture-permeable waterproof fabric and method for manufacturing same

ActiveCN104379831AGood moisture permeabilityImprove water resistanceLiquid repellent fibresDynamic viscoelasticityHalogen

The present invention is a treatment agent for a moisture-permeable fabric having excellent moisture permeability, water resistance and launderability. The treatment agent comprises a fluorine-containing polymer having repeating units derived from: (a) a fluorine-containing monomer represented by the formula, CH2=C(-X)-C(=O)-Y-Z-Rf [wherein, X is a monovalent organic group excluding methyl groups, or a halogen atom, Y is -O- or -NH-, Z is a directly-bonded or divalent organic group, and Rf is a fluoroalkyl group with 1 to 6 carbons]; (b) a halogenated olefin monomer; and (c) a fluorine-free monomer that is used as necessary, does not have a fluorine atom, and has at least one carbon-carbon double bond. The dynamic viscoelasticity of the fluorine-containing polymer at 160°C is at least 100 Pa.s.

Owner:DAIKIN IND LTD

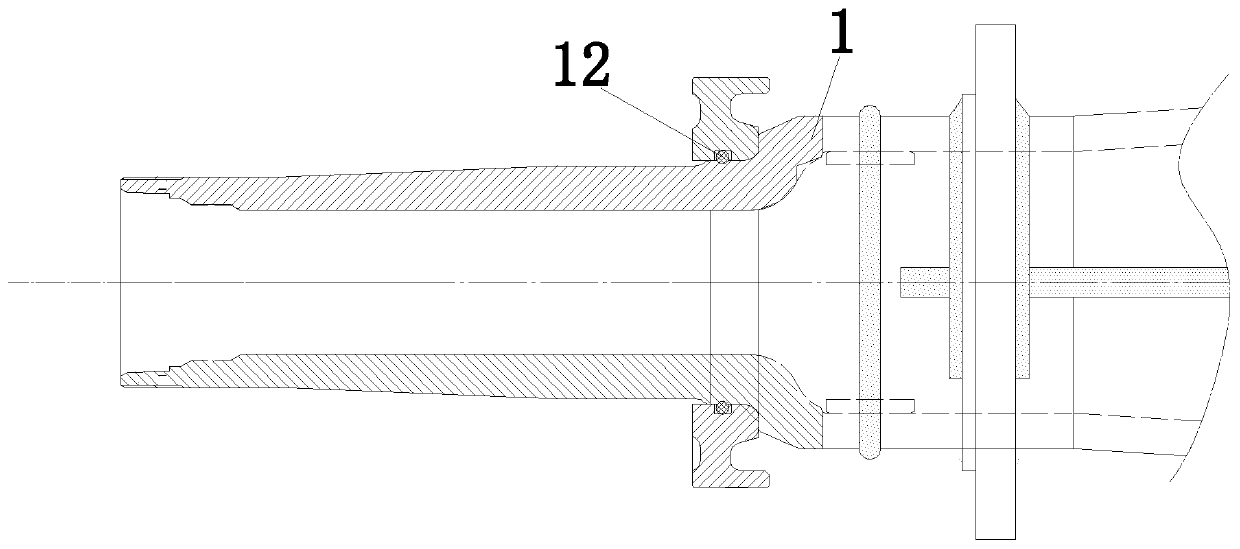

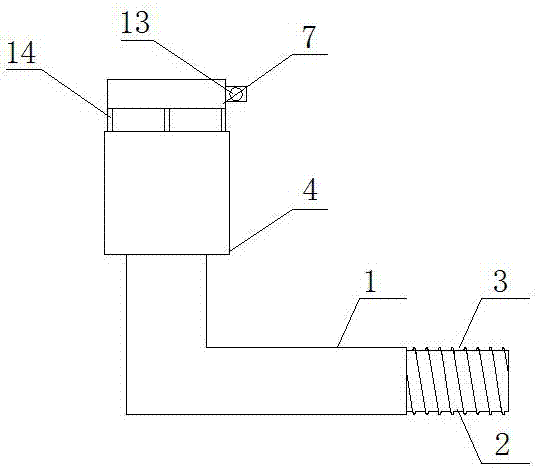

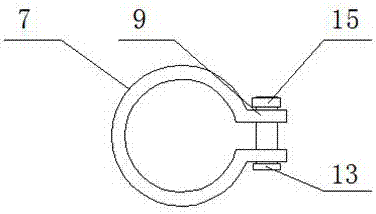

Waterproof wheel edge system for engineering mixer truck

InactiveCN110561970AProne to water leakageReduce the waterproof effectHubsAxle unitsWater leakageButt joint

The invention relates to a waterproof wheel edge system for an engineering mixer truck. The system comprises an axle housing body, wherein the left end of the axle housing body is provided with a hub;the hub is sheathed with a brake drum; the outer wall of the right end of the axle housing body is connected with a space ring assembly; and the space ring assembly and the axle housing body are sealed through an O ring. The system can solve the following problems of an existing mixer truck waterproof wheel edge in a practical use process: 1) in an existing waterproof wheel edge, an independent hub oil seal is adopted to carry out a waterproof operation, dynamic lubrication sealing can not be realized in a use process, a situation of water leakage is liable to happen, and a waterproof effectis lowered; 2) after the hub and the axle housing body are simply isolated by the space ring, installation and connection are carried out, and a gap between the hub and the axle housing body needs tobe subjected to additional sealing processing; 3) a connection position between a half shaft and the hub is not subjected to the sealing processing; and 4) the brake drum and the hub are connected through a butt joint way, so that a stabilization effect is poor, and daily protection and maintenance is troublesome.

Owner:TAIZHOU SHENZHOU TRANSMISSION TECH

Quick-frozen oil and quick-frozen smallanthus sonchifolius filling using same

InactiveCN105230812AState delicate and lubricatedNo stratificationEdible oils/fats ingredientsSucroseEngineering

The invention relates to quick-frozen oil. The quick-frozen oil is prepared from soybean oil, peanut oil, glyceryl monostearate, sucrose fatty acid ester and water through the processes of rapid cooling and kneading; the quick-frozen oil is fine, smooth and lubricating in tissue state, and does not have the phenomena of layering and water seepage substantially. The quick-frozen smallanthus sonchifolius filling using the quick-frozen oil is prepared from smallanthus sonchifolius, the quick-frozen oil, white granulated sugar, water, citric acid, agar and pectin. The quick-frozen smallanthus sonchifolius filling is light yellow in color and presents a plastic solid state at a normal atmospheric temperature, and fruit granules are uniform in distribution and are clear in sight, so that the quick-frozen smallanthus sonchifolius filling is convenient to form, wrap and process; after being heated, the quick-frozen smallanthus sonchifolius filling presents a viscous flow state, is clean, sweet and sourish in mouth feel and good in palatability, has delicate fragrance, and is free from peculiar smell.

Owner:UNIV FOR SCI & TECH ZHENGZHOU

Water valve joint of automobile air conditioner radiator

PendingCN106885086AEasy to cleanReduce spendingAir-treating devicesVehicle heating/cooling devicesRubber ringAutomobile air conditioning

The invention discloses a water valve joint of an automobile air conditioner radiator. The water valve joint comprises a pipe body, a water tank joint and a tightening button; one end of the pipe body is fixedly connected with a water valve connection pipe; the other end of the pipe body is fixedly connected with a joint inner pipe; two pipe body grooves are formed in the periphery of the joint inner pipe; a small rubber ring is connected in each pipe body groove in a sleeving manner; the pipe body, at one end of the joint inner pipe, is fixedly connected with a water tank connection; two joint grooves are formed in the inner side of the water tank connection, close to the end point; a large rubber ring is adhered in each joint groove; one end of the water tank joint is fixedly connected with three steel strips; and one end of each steel strip is fixedly connected with the tightening button. According to the water valve joint, one end of the pipe body is fixedly connected with the joint inner pipe and the water tank connection, and the outer side of the joint inner pipe and the inner side of the water tank connection are connected with the small rubber rings and the large rubber rings in the sleeving manner respectively, so that water cannot leak due to strong sealing performance when passing through the part, mounting and disassembly are also convenient, scales cannot be retained when the water valve joint is disassembled for cleaning during maintenance, and a great amount of expenses are saved for an automobile owner.

Owner:诺贝特空调(盐城)有限公司

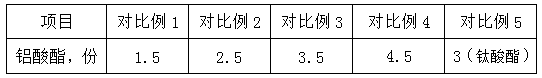

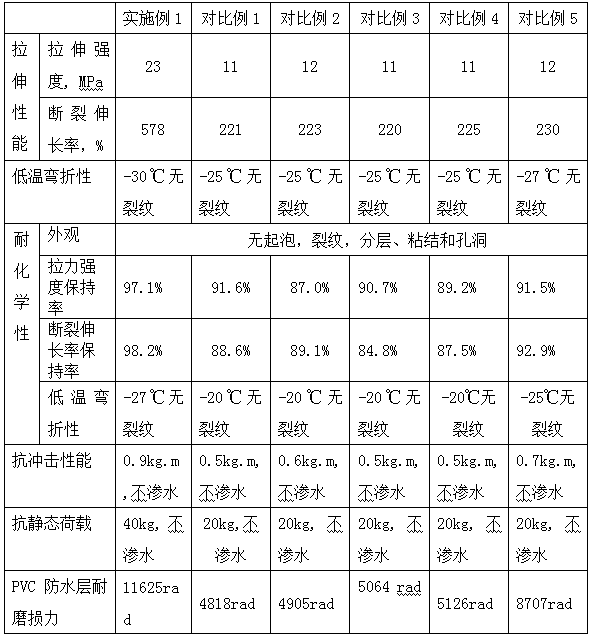

Super-weather-resistant composite waterproof roll and preparation method thereof

InactiveCN110540715AGood flame retardant performanceHigh tensile strengthRoof covering using flexible materialsSynthetic resin layered productsPliabilityDiisodecyl phthalate

The invention provides a super-weather-resistant composite waterproof roll. The super-weather-resistant composite waterproof roll is prepared from diisodecyl phthalate, epoxypropane glyceryl polyether, a tackifier, castor oil alkyd resin and zinc stearate. A preparation method disclosed by the invention comprises the following steps: carrying out plastifying at a temperature of 78 DEG C for 10 minat first, then performing mixing at a temperature of 85 DEG C for 30 min, and then carrying out cooling to 65 DEG C at a speed of 2 DEG C / min. According to the waterproof roll in the invention, lithium-based bentonite is used as an inorganic wear-resistant material, and then a certain amount of aluminate is added to improve the compatibility among components; and with the preparation method, obtained pellets are smooth, low in roughness coefficient, small in fluid resistance and high in uniformity, and the super-weather-resistant composite waterproof roll with integrated wear resistance, compression resistance, tensile properties and flexibility is obtained.

Owner:郑月友

Novel mortar additive and preparation method thereof

The invention relates to a novel mortar additive and a preparation method thereof. The additive is prepared from the following raw materials (by weight): 0.2 to 0.8 part of a penetrating agent, 3 to 7parts of a dispersing agent, 3 to 7 parts of cellulose, 3 to 6 parts of a powdery defoaming agent and 0.2 to 0.8 part of a viscosity regulator. The preparation method is simple, low in cost and suitable for being popularized and used in large-area terrace projects such as supermarkets and shopping malls.

Owner:海南瑞宸新型建材有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com