Preparation method of light weight panel

A kind of panel and light-weight technology, which is applied in the field of architectural decoration, can solve the problems of no effective and economically valuable methods, uneven material of finished panels, and not easy to mix evenly, so as to achieve rich colors, low cost of panels, and high strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

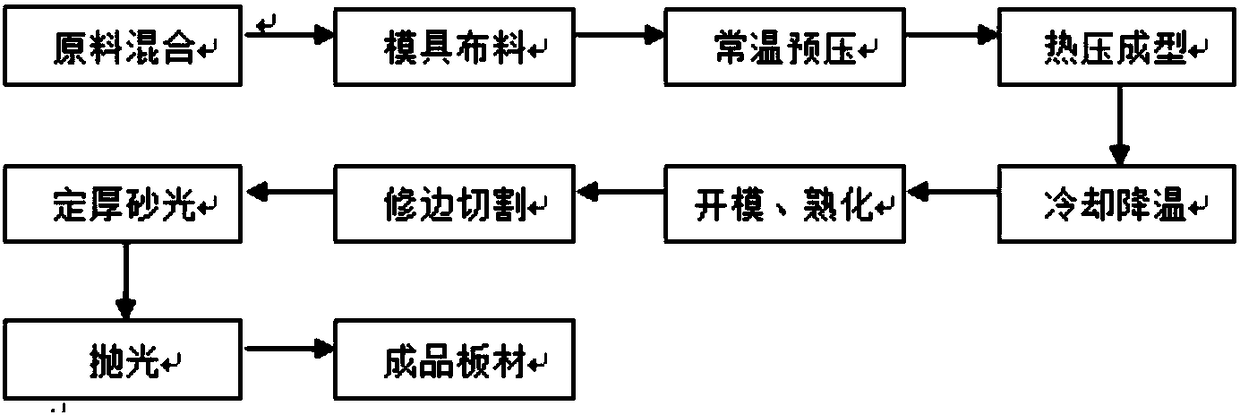

[0034] Such as figure 1 Shown, the present invention provides a kind of preparation method of light board, it comprises the following steps:

[0035] Mix 10-20 parts by mass of stone waste, 50-70 parts of microbeads, 10-20 parts of cement, and 6-8 parts of thermosetting phenolic resin powder to prepare a raw material mixture;

[0036] Lay a layer of release paper on the bottom plate of the mold, then install four removable mold frames, lay the raw material mixture and lay a layer of release paper on top of it, add a mold cover plate, and carry out pre-pressing treatment , followed by hot-pressing treatment for solidification and molding, and after cooling, the mold is opened to obtain a lightweight plate body, wherein the hot-pressing treatment includes:

[0037] In the first stage, the temperature of the hot pressing is 100-120°C, the pressure of the hot pressing is 25-30Mpa, and the time of the hot pressing is 10-30min;

[0038] In the second stage, the temperature of the ...

Embodiment 1

[0060] The invention provides a kind of preparation method of light board, it comprises the following steps:

[0061] 10 parts by mass of stone waste, 50 parts of microbeads, 10 parts of cement, and 6 parts of thermosetting phenolic resin powder are mixed to obtain a raw material mixture;

[0062] Lay a layer of release paper on the bottom plate of the mold, then install four removable mold frames, lay the raw material mixture and lay a layer of release paper on top of it, add a mold cover plate, and carry out pre-pressing treatment , followed by hot-pressing treatment for solidification and molding, and after cooling, the mold is opened to obtain a lightweight plate body, wherein the hot-pressing treatment includes:

[0063] In the first stage, the temperature of the hot pressing is 120°C, the pressure of the hot pressing is 30Mpa, and the time of the hot pressing is 20min;

[0064] In the second stage, the temperature of the hot pressing is 140°C, the pressure of the hot pr...

Embodiment 2

[0083] The invention provides a kind of preparation method of light board, it comprises the following steps:

[0084] 20 parts by mass of stone waste, 70 parts of microbeads, 20 parts of cement, and 8 parts of thermosetting phenolic resin powder are mixed to obtain a raw material mixture;

[0085] Lay a layer of release paper on the bottom plate of the mold, then install four removable mold frames, lay the raw material mixture and lay a layer of release paper on top of it, add a mold cover plate, and carry out pre-pressing treatment , followed by hot-pressing treatment for solidification and molding, and after cooling, the mold is opened to obtain a lightweight plate body, wherein the hot-pressing treatment includes:

[0086] In the first stage, the temperature of the hot pressing is 110°C, the pressure of the hot pressing is 25Mpa, and the time of the hot pressing is 10min;

[0087] In the second stage, the temperature of the hot pressing is 130°C, the pressure of the hot pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com