Environment-friendly siloxane-terminated polyurethane sealant and preparation method thereof

The technology of siloxane-terminated polyurethane and siloxane-terminated polyurethane is applied in the field of siloxane-terminated polyurethane sealant and its preparation, and can solve the problems of low tensile strength, surface pollution of substrate, high viscosity of prepolymer, etc. problems, to achieve the effect of excellent tensile strength and elongation at break, good storage stability, and good oil stain resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) Preparation of NCO-terminated polyurethane prepolymer

[0038] Composition mass (g)

[0039]

[0040] According to the above proportion, the mixture of 30 g of polytetrahydrofuran ether diol 2000 and 60 g of polyglycerol 5000 and 15 g of diphenylmethane diisocyanate were sequentially added to a 250 mL four-neck round bottom flask, and the water bath was heated to 60 °C for 1 h. Then the temperature was raised to 75°C, 0.08 g of stannous octoate was added dropwise to the round-bottomed flask, and nitrogen gas was introduced into the flask to isolate the air. The reaction was carried out at 75°C for 2 hours. Measure the NCO content every 30min, when the NCO content reaches or is less than the theoretical capping value. Cooling and cooling to obtain terminal NCO polyurethane prepolymer.

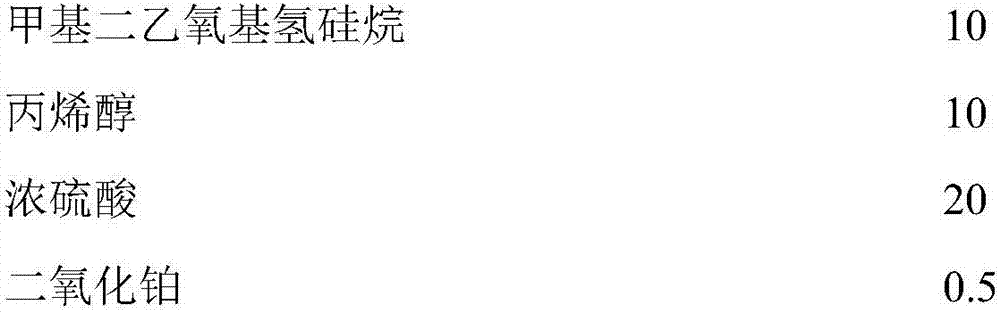

[0041] (2) Synthesis of a hydroxyl-containing siloxane

[0042] Composition mass (g)

[0043]

[0044] Add 10g methyldiethoxyhydrosilane, 10g allyl alcohol, 20g concentrate...

Embodiment 2

[0054] (1) Preparation of NCO-terminated polyurethane prepolymer

[0055] Composition mass (g)

[0056]

[0057] According to the above ratio, the mixture of 30 polytetrahydrofuran ether diol 1000 and 60 g polyglycerol 6000 and 17 g diphenylmethane diisocyanate were sequentially added to a 250 mL four-neck round bottom flask, and the water bath was heated to 70 °C for 1 h. Subsequently, the temperature was raised to 75° C., 0.08 g of dibutyltin dilaurate was added dropwise to the round-bottomed flask, and nitrogen was introduced into the flask to isolate the air. The reaction was carried out at 75°C for 2 hours. Measure the NCO content every 30min, when the NCO content reaches or is less than the theoretical capping value. Cooling and cooling to obtain terminal NCO polyurethane prepolymer.

[0058] (2) Synthesis of a hydroxyl-containing siloxane

[0059] Composition mass (g)

[0060]

[0061] Add 10g methyldiethoxyhydrosilane, 10g allyl alcohol, 20g concentrated sul...

Embodiment 3

[0071] (1) Preparation of NCO-terminated polyurethane prepolymer

[0072] Composition mass (g)

[0073]

[0074]According to the above ratio, the mixture of 30 g of polytetrahydrofuran ether diol 2000 and 60 g of polyglycerol 6000 and 16 g of toluene diisocyanate were sequentially added to a 250 mL four-neck round bottom flask, and the water bath was heated to 70 °C for 1 h. Subsequently, the temperature was raised to 75°C, 0.1 g of dimorpholine diethyl ether was added dropwise to the round bottom flask, and nitrogen gas was introduced into the flask to isolate the air. The reaction was carried out at 75°C for 2 hours. Measure the NCO content every 30min, when the NCO content reaches or is less than the theoretical capping value. Cooling and cooling to obtain terminal NCO polyurethane prepolymer.

[0075] (2) Synthesis of a hydroxyl-containing siloxane

[0076] Composition mass (g)

[0077]

[0078] Add 10g methyldiethoxyhydrosilane, 10g allyl alcohol, 20g concentra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com