Wear-resistance and heat-resistance functional ceramic pot and preparing technology thereof

A technology of functional ceramics and ceramic pots, which is applied in the production of ceramic materials, clay products, and other household utensils, etc. It can solve the problems of ceramic pot damage, glaze layer thinning, cracking, etc., to increase stability, increase density, improve The effect of stickiness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

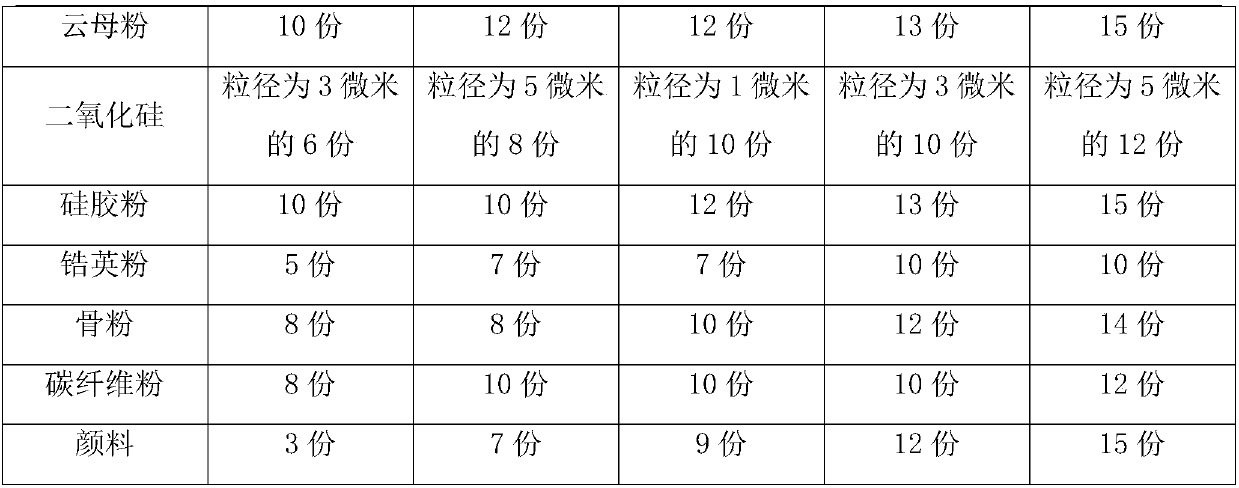

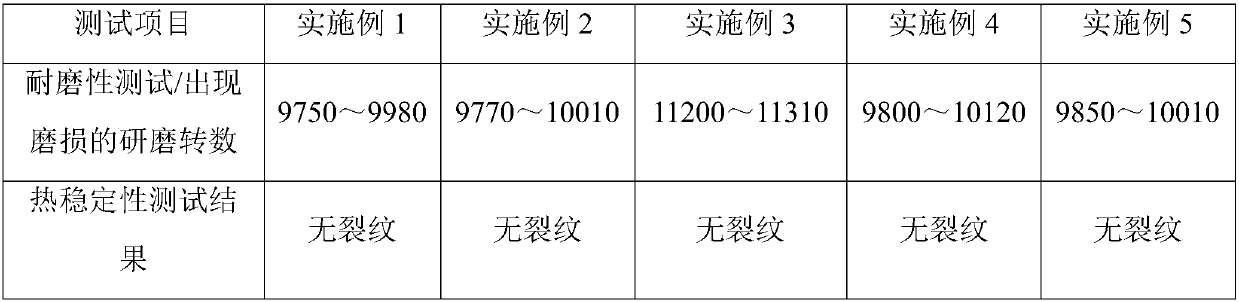

[0026] This embodiment provides a wear-resistant and heat-resistant functional ceramic pot, including a green body and a glaze layer applied on the green body. The green body is made of the following raw materials in parts by weight: 35 parts of kaolin, 35 parts of waste ceramics, 25 parts of zircon powder, 10 parts of sepiolite powder, 20 parts of activated alumina with a particle size of 200 microns, and 8 parts of silica gel powder; the glaze layer is made of the following raw materials in parts by weight: 10 parts of kaolin, 10 parts of mica powder , 6 parts of silicon dioxide with a particle size of 3 microns, 10 parts of silica gel powder, 5 parts of zircon powder, 8 parts of bone meal, 8 parts of carbon fiber powder, and 3 parts of iron oxide red pigment.

[0027] This embodiment also provides a preparation process for this kind of wear-resistant and heat-resistant functional ceramic pot, including the following steps:

[0028] (1), take each raw material respectively a...

Embodiment 2

[0036] This embodiment provides a wear-resistant and heat-resistant functional ceramic pot, including a green body and a glaze layer applied on the green body. The green body is made of the following raw materials in parts by weight: 40 parts of kaolin, 37 parts of waste ceramics, 27 parts of zircon powder, 10 parts of sepiolite powder, 22 parts of activated alumina with a particle size of 300 microns, and 10 parts of silica gel powder; the glaze layer is made of the following raw materials in parts by weight: 15 parts of kaolin, 12 parts of mica powder , 8 parts of silicon dioxide with a particle size of 5 microns, 10 parts of silica gel powder, 7 parts of zircon powder, 8 parts of bone meal, 10 parts of carbon fiber powder, and 7 parts of wrapped red pigment for glaze.

[0037] This embodiment also provides a preparation process for this kind of wear-resistant and heat-resistant functional ceramic pot, including the following steps:

[0038] (1), take each raw material respe...

Embodiment 3

[0046] This embodiment provides a wear-resistant and heat-resistant functional ceramic pot, including a green body and a glaze layer applied on the green body. The green body is made of the following raw materials in parts by weight: 45 parts of kaolin, 40 parts of waste ceramics, 30 parts of zircon powder, 12 parts of sepiolite powder, 25 parts of activated alumina, and 10 parts of silica gel powder; the glaze layer is made of the following raw materials in parts by weight: 17 parts of kaolin, 12 parts of mica powder, and a particle size of 1 micron 10 parts of silicon dioxide, 12 parts of silica gel powder, 7 parts of zircon powder, 10 parts of bone meal, 10 parts of carbon fiber powder, and 9 parts of white ceramic pigment.

[0047] This embodiment also provides a preparation process for this kind of wear-resistant and heat-resistant functional ceramic pot, including the following steps:

[0048] (1), take each raw material respectively according to parts by weight, for sub...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com