Color anti-skid layer for reducing haze guided traveling traffic and preparation method thereof

A color and haze technology, applied in the field of color anti-skid layer and its preparation, to achieve the effects of reducing cracking, reducing traffic jams, and high bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The present invention also provides a method for preparing a colored anti-skid layer for reducing smog and guiding traffic described in the above technical solution, comprising the following steps:

[0034] (1) mixing bonding material, colored graded crushed stone, nano photocatalyst material and additive to obtain mixed material;

[0035] (2) Sealing and storing the mixed material obtained in the step (1) to obtain a premixed material;

[0036] (3) subpackage the premix obtained in the step (2) and the curing agent to obtain a colored anti-skid layer that reduces smog and guides traffic.

[0037] The present invention mixes the bonding material, the colored graded gravel, the nano photocatalyst material and the additive to obtain the mixed material, and the present invention does not make any difference to the order of adding the bonding material, the colored graded crushed stone, the nano photocatalyst material and the additive For any special limitation, it is suffi...

Embodiment 1

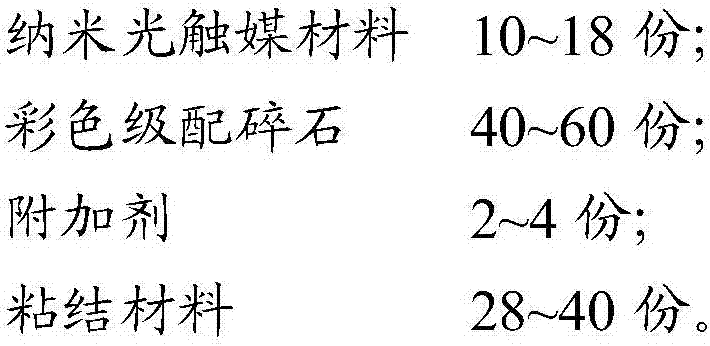

[0051] The proportioning of each raw material component by weight is as follows:

[0052] 10 parts of nano photocatalyst material;

[0053] 40 parts of colored graded gravel;

[0054] Additive 2 parts;

[0055] 28 parts of bonding material;

[0056] 2 parts curing agent;

[0057] The raw materials of additive are proportioned as follows by weight:

[0058] 1 part of toughening agent;

[0059] 0.5 parts of anti-stripping agent;

[0060] 0.5 parts of coupling agent.

[0061] Stir the bonding material and the colored graded crushed stone at 500r / min for 30min to mix evenly, then mix with the nano photocatalyst material at 1000r / min for 5min, and finally mix with the additive for 30min at 1000r / min The mixed material is obtained. When the obtained mixed material is used in the pavement anti-skid layer, it is mixed with the curing agent at 500 r / min for 30 minutes to obtain a colored anti-skid layer that reduces smog and guides traffic.

[0062] The colored anti-skid layer ...

Embodiment 2

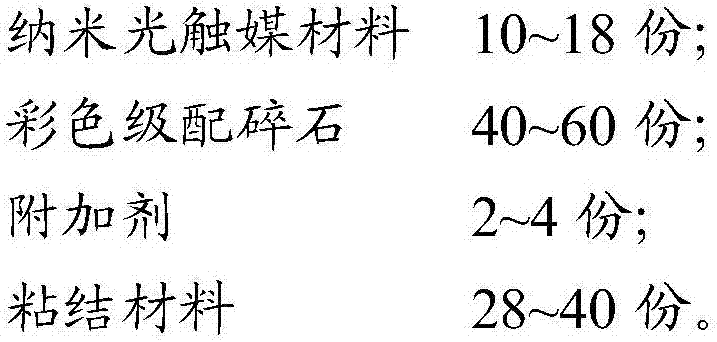

[0064] The proportioning of each raw material component by weight is as follows:

[0065] 15 parts of nano photocatalyst material;

[0066] 55 parts of colored graded gravel;

[0067] 3 parts of additives;

[0068] 32 parts of bonding material;

[0069] 3 parts curing agent;

[0070] The raw materials of additive are proportioned as follows by weight:

[0071] 1 part of toughening agent;

[0072] 1 part of anti-stripping agent;

[0073] 1 part of coupling agent.

[0074] Stir the bonding material and colored graded crushed stone at 1500r / min for 50min to mix evenly, then mix with the nano-photocatalyst material at 1500r / min for 50min, and finally mix with the additive for 60min at 1000r / min The mixed material is obtained. When the obtained mixed material is used in the pavement anti-skid layer, it is mixed with the curing agent at 600 r / min for 30 minutes to obtain a colored anti-skid layer that reduces smog and guides traffic.

[0075] The colored anti-skid layer that...

PUM

| Property | Measurement | Unit |

|---|---|---|

| coating mass | aaaaa | aaaaa |

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com