Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

60results about How to "Low surface treatment requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Heat insulating reflecting anticorrosive paint

InactiveCN101585992AAdd supportImprove performanceAnti-corrosive paintsPolyurea/polyurethane coatingsSurface oceanWeather resistance

A heat insulating reflecting anticorrosive paint, in a coordinated system composed of bottom, surface and middle layer paints coated on surface of concrete or metal, is suitable for sea climate and chemical engineering air severe atmosphere, which breaks convention of making the heat reflecting surface paint in white in prior market. Surface paints in present coordinated system is added with dye infrared transparent block powder with special function or gray, yellow and brown series made of titanium yellow powder so that the color of paints is versatile, which enlarges use scale. The whole paint system has excellent heat insulating, solar heat reflecting property by rational match and good heavy-duty anticorrosive property as well as excellent weather resistance. Thickness of total dry film does not exceed 250microns. Heat reflecting effect of surface paint in various colors is similar to that of white paint which has greater reflectivity and insulating effect. Compared with a tank coating aluminum powder chlorinated rubber solvent, the tank coating the paint has inner temperature 15 DEG.. C lower, surface temperature 23 DEG.. C.

Owner:袁泉利

High-solid surface-tolerant epoxy zinc-rich primer and preparation method and application thereof

ActiveCN110144160AIncrease crosslink densityImprove penetration resistanceAnti-corrosive paintsEpoxy resin coatingsChemical industryEpoxy

The invention relates to a high-solid surface-tolerant epoxy zinc-rich primer. The primer is prepared from a component A and a component B according to a weight ratio of (16-20):1; the component A comprises the following components in parts by weight: 5-9 parts of liquid phenolic epoxy resin, 6-15 parts of E20 solid epoxy resin, 0.5-1.5 parts of an active diluent, 0.1-0.3 part of a dispersing agent, 70-80 parts of main rust-proof pigment, 2-6 parts of chemical anti-rust pigment, 1.5-2.5 parts of an anti-settling agent and 3-4 parts of an organic mixed solvent; and the component B comprises thefollowing components in parts by weight: 1.5-2.5 parts of a polyamide curing agent, 2-3 parts of a Mannich base curing agent, 0.3-0.6 part of a silane coupling agent and 0.2-0.6 part of an organic mixed solvent. The invention also relates to a preparation method of the primer and a coating film. The primer is high in solid content and low in VOC content, is resistant to corrosion, has a long effect, has good adhesive force and salt fog resistance, and is particularly suitable for repairing and maintaining equipment in industries such as chemical industry, thermoelectricity, machinery and thelike.

Owner:江阴市大阪涂料有限公司

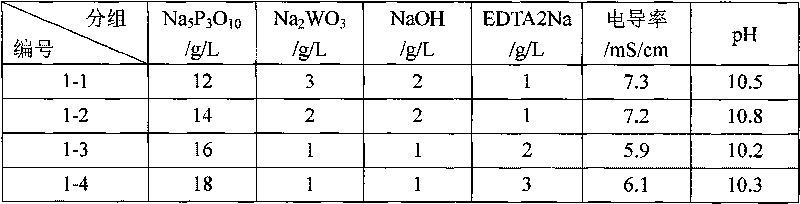

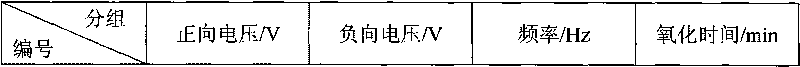

Electrolyte and technology for preparing ceramic coating formed by plasma micro-arc oxidation on zirconium alloy surface

InactiveCN101713091AExtended service lifeImprove wear resistanceSurface reaction electrolytic coatingAlkalinityMicro arc oxidation

The invention discloses an electrolyte and technology for preparing a ceramic coating formed by plasma micro-arc oxidation on a zirconium alloy surface. The technology comprises the following steps: (1) preparing the electrolyte; (2) treating the zirconium alloy surface; and (3) carrying out the micro-arc oxidation technology. The invention has the advantages that the electrolyte is water solution of various compounds, can provide a micro-arc discharge center, and has proper acidity and alkalinity, good ionic conductivity and chemical stability; the solutes of the electrolyte have wide source and low price; the treatment of the zirconium alloy surface has low requirement, and the micro-arc oxidation technology is simple and convenient in control; the ceramic coating formed by micro-arc oxidization has larger thickness, and by adjusting the formula of the electrolyte and the conditions of the micro-arc oxidation technology, the thickness of the ceramic coating can be controlled in a range of 30-80 micrometers; and the ceramic coating has good wear resistance and corrosion resistance.

Owner:INNER MONGOLIA UNIV OF TECH +1

Nano-composite PU (polyurethane) aircraft coating and preparation method thereof

ActiveCN104098996AImprove anti-corrosion performanceIncreased durabilityAnti-corrosive paintsPolyurea/polyurethane coatingsAcrylic resinSlurry

The invention relates to a nanotechnology and a corrosion prevention technology, particularly to a nano-composite PU (polyurethane) aircraft coating with high corrosion resistance and a preparation method thereof. In parts by weight, a first component comprises 60-80 parts of waterborne hydroxyl acrylic resin, 5-10 parts of nano slurry, 1-3 parts of a coloring pigment, 8-10 parts of an organic corrosion inhibitor, 10-15 parts of an anti-rust pigment and the like; a second component comprises 70-80 parts of a waterborne isocyanate curing agent and 20-30 parts of deionized water. Raw materials, such as the waterborne hydroxyl acrylic resin, the deionized water, the nano slurry, the additives and the like, are dispersed at the high speed, then ground and filtered to prepare the first component, the curing agent and the deionized water are dispersed and mixed to prepare the second component, and the two components are evenly mixed in proportion to obtain the coating. The novel composite nano slurry, the anti-rust pigment, the composite organic corrosion inhibitor, the water and the like are used for preparing the nano-composite PU aircraft coating, so that the nano-powder material is stably dispersed in the coating, and the corrosion resistance of the coating is improved.

Owner:山东中科纳米科技有限公司

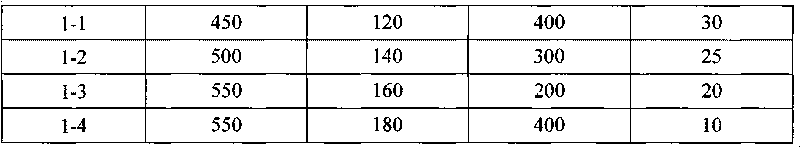

Cashew phenolic aldehyde amide epoxy hardener for four-season-general type anticorrosive paint and preparation method of cashew phenolic aldehyde amide epoxy hardener

ActiveCN102977670AComponent ratio scienceImprove reaction efficiencyOrganic compound preparationCarboxylic acid amides preparationFeeding orderDiethylenetriamine

The invention discloses a cashew phenolic aldehyde amide epoxy hardener for four-season-general type anticorrosive paint and a preparation method of the cashew phenolic aldehyde amide epoxy hardener. The cashew phenolic aldehyde amide epoxy hardener is composed of, by weight, one part of diethylenetriamine, 2.5-3 parts of dimer acids or fat single acids, 2.8-3.2 parts of anacardol, one part of the diethylenetriamine, and 0.9-1.2 parts of 96%-purity paraformaldehyde. Raw material composition, and the best matching and the feeding order of each material are optimized through a large number of experiments, and each component matching is scientific and reasonable. The method of mannich addition after amidation is utilized, the whole process is strong in operability, cost is low, production periods are short, productivity is high, the prepared cashew phenolic aldehyde amide epoxy hardener can be general in four seasons, drying is rapid, operation periods are short, anti-corrosion performance is good, and water-proof performance is excellent. The cashew phenolic aldehyde amide epoxy hardener can be widely used in the fields of pipe and storage tank storage corrosion prevention, adhesion agents, metallic top coats, chip heavy corrosion prevention and the like.

Owner:江苏三木化工股份有限公司

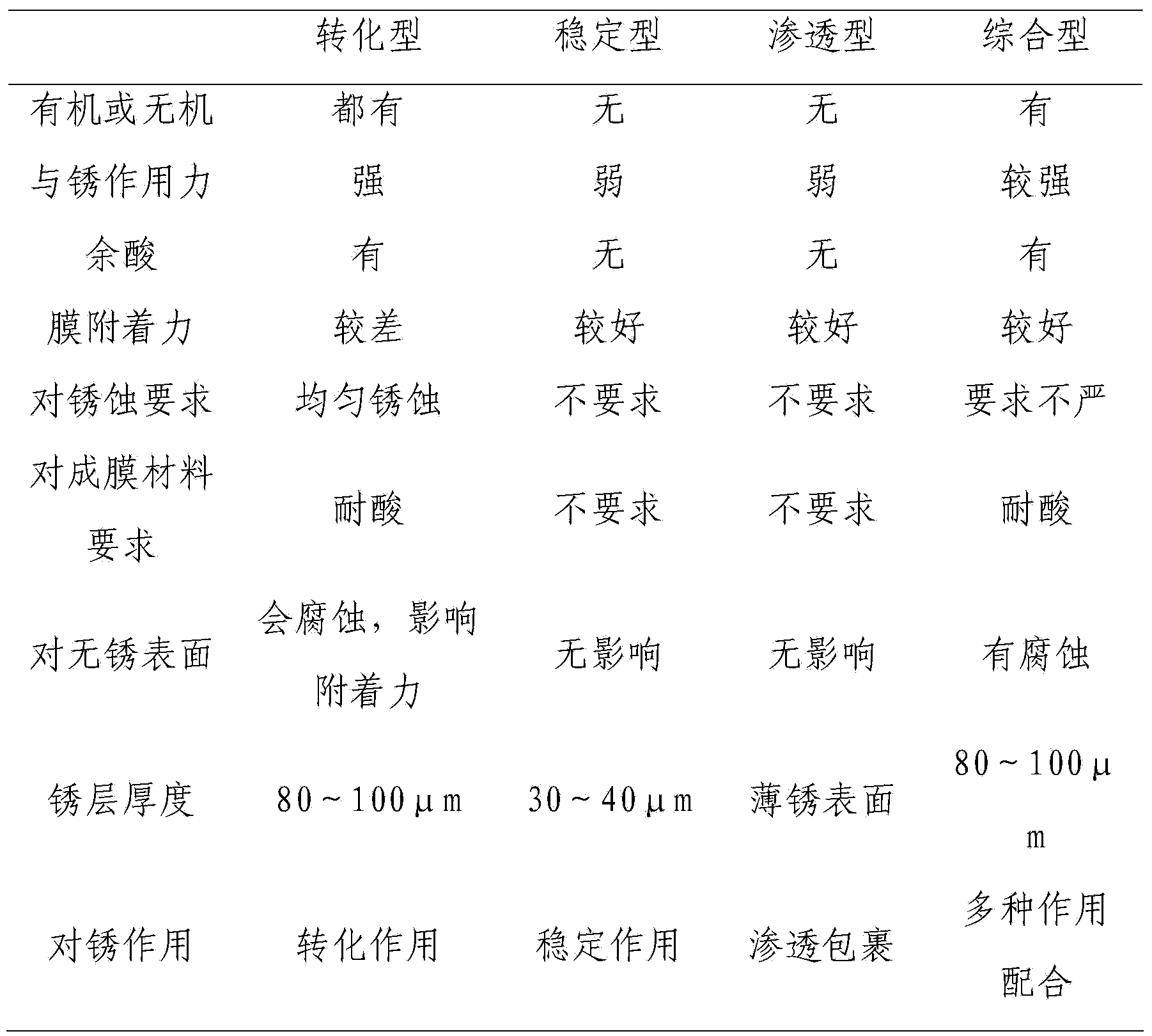

Rust transforming agent and preparation method thereof, water-based iron rust conversion coating and preparation method thereof

InactiveCN103849862AImprove water resistanceImprove stabilityAnti-corrosive paintsMetallic material coating processesWater basedGallic acid ester

The invention belongs to the technical field of a metal anti-corrosion coating, and particularly relates to a rust transforming agent and a preparation method thereof, a water-based iron rust conversion coating and a preparation method thereof. The rust transforming agent comprises a step of synthesizing 2-hydroxypropyl 3,4,5-trihydroxybenzoic acid by taking a gallic acid, 1,2-propylene glycol and a p-toluenesulfonic acid as initial raw materials, wherein the rust transforming agent contains 18.5-26.7% of gallic acid, 66.6-74% of 1,2-propylene glycol, and 6.6-7.5% of p-toluenesulfonic acid; the water-based iron rust conversion coating is prepared from a vinylidene chloride composite polymer emulsion, ethylene glycol butyl ether, filling slurry prepared in the step (1) and the rust transforming agent. The prepared rust transforming agent disclosed by the invention is good in water tolerance, strong in stability, and good in matching property with a water paint and an oil paint.

Owner:SHANDONG UNIV OF SCI & TECH

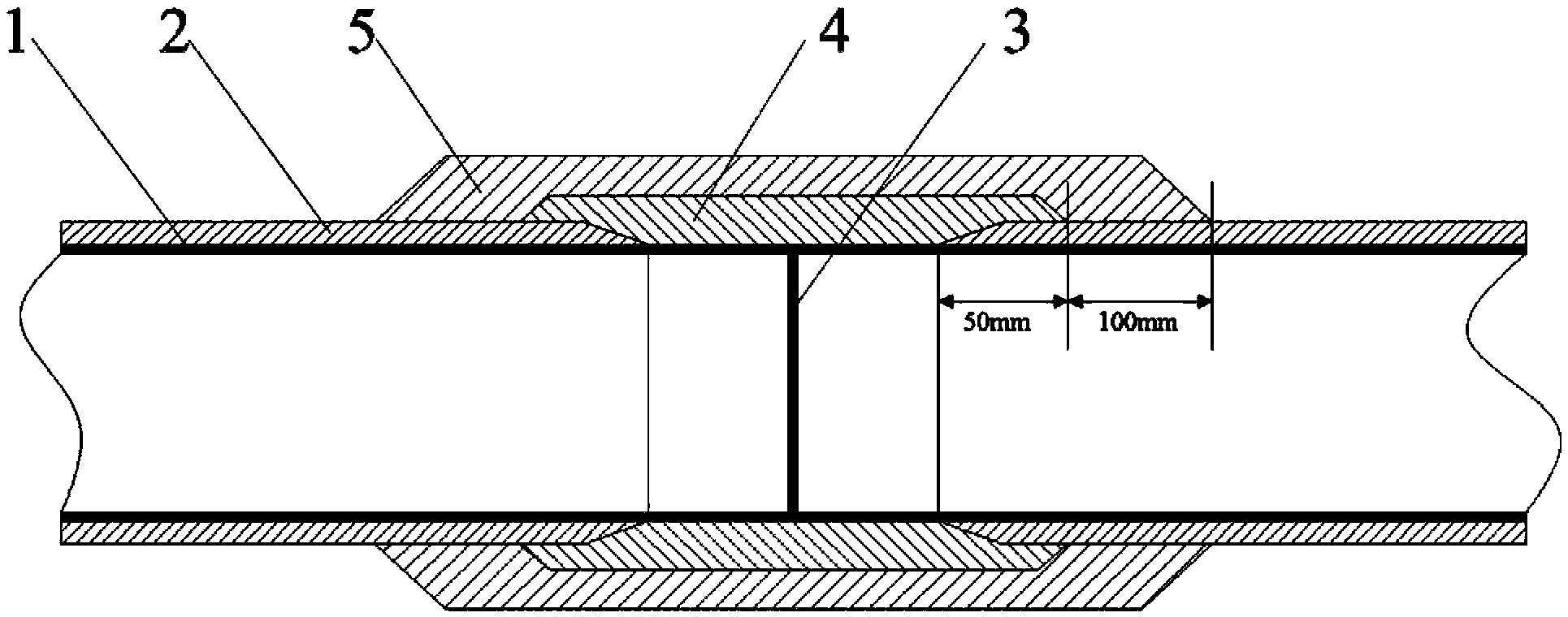

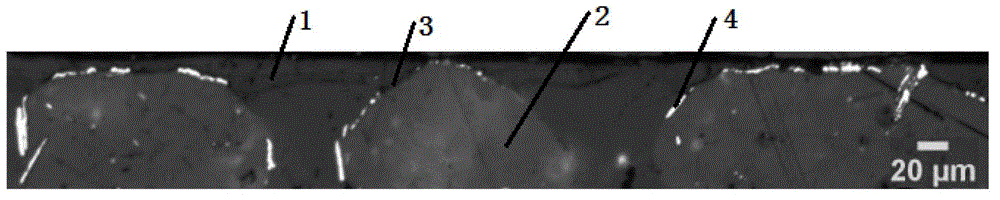

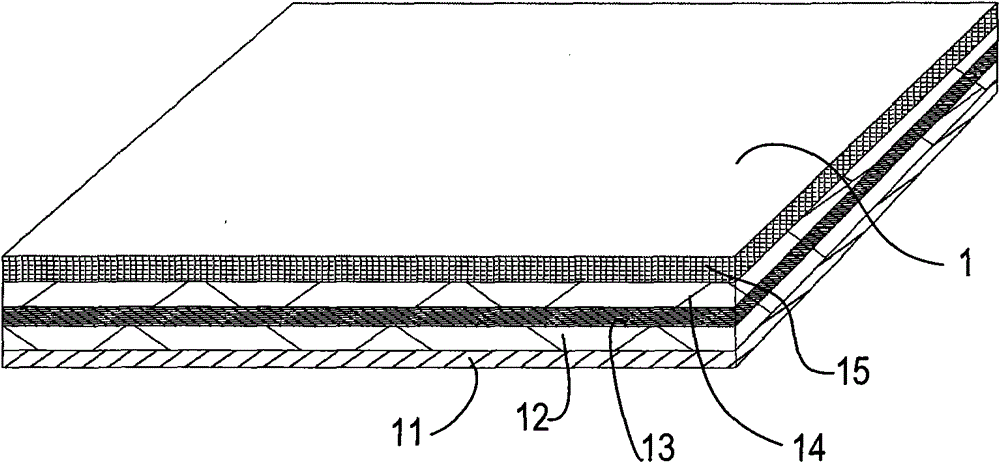

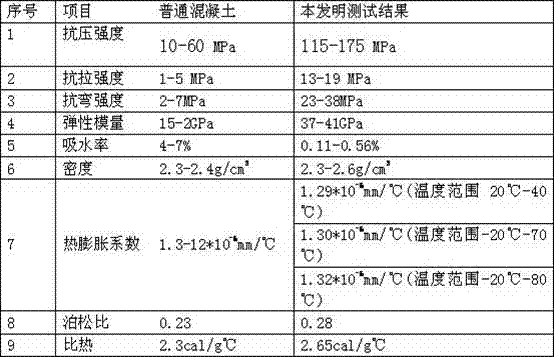

Joint coating repairing anticorrosion layer structure for in-service pipeline

ActiveCN104110556AAdhesiveImproves bond stabilityCorrosion preventionPipe protection against corrosion/incrustationLap jointCompound structure

The invention discloses a joint coating repairing anticorrosion layer structure for an in-service pipeline, and belongs to the field of oil and gas pipeline transportation technologies. The in-service pipeline comprises steel pipes (1), anticorrosion layers (2) and joint coating metal ring seams (3). The steel pipes (1) are buried in the ground, a viscoelastic rubber band (4) is arranged on the outer surface of each joint coating metal ring seam (3), a pressure-sensitive adhesive type thermal contraction band (5) covers the outer periphery of each viscoelastic rubber band (4), each viscoelastic rubber band (4) completely covers the corresponding joint coating metal ring seam (3), two ends of each viscoelastic rubber band (4) are in lap joint with the corresponding anticorrosion layers (2), each pressure-sensitive adhesive type thermal contraction band (5) completely covers the corresponding viscoelastic rubber band (4), and two ends of each pressure-sensitive adhesive type thermal contraction band (5) are in lap joint with the corresponding anticorrosion layers (2). The joint coating repairing anticorrosion layer structure has the advantages that compound structures with the viscoelastic rubber bands and the pressure-sensitive adhesive type thermal contraction bands which are combined with one another are arranged at joint coating positions of the pipeline, so that the joint coating repairing anticorrosion layer structure is excellent in anticorrosion performance and has low surface treatment requirements, and a construction process can be carried out conveniently and quickly.

Owner:PETROCHINA CO LTD

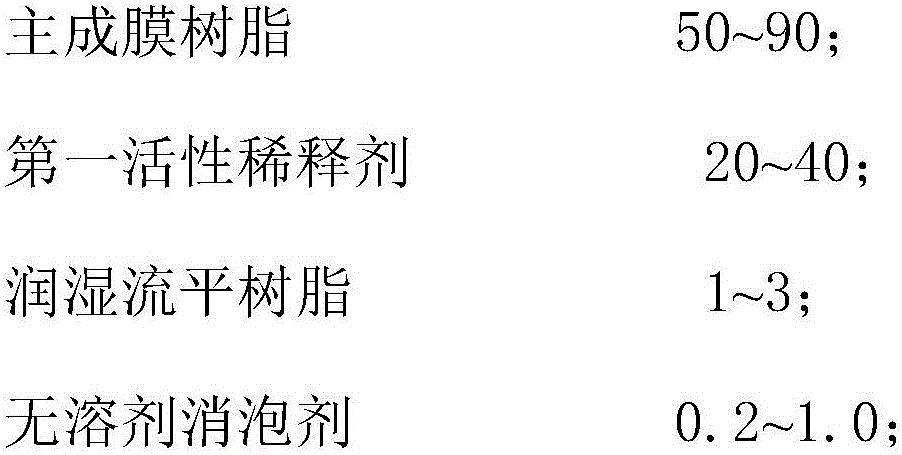

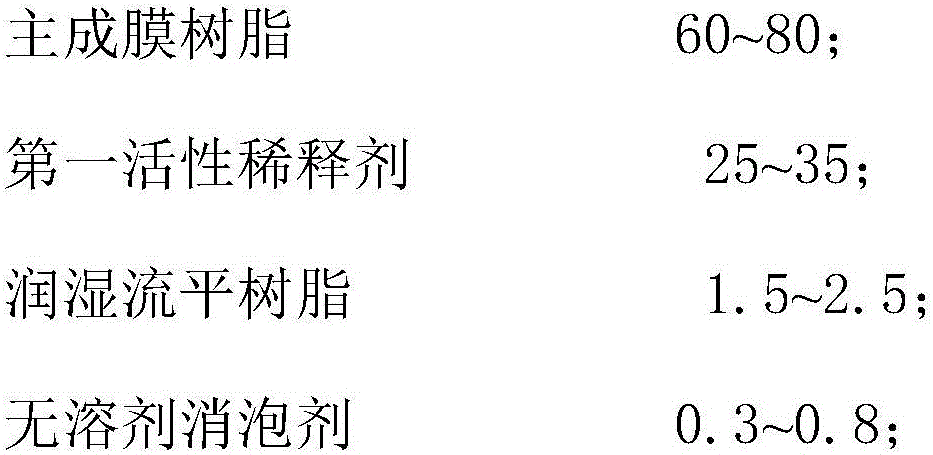

Solvent-free epoxy rust confining coating capable of coating in wet and rust environment

InactiveCN106634447AEnsure safetyImprove adhesionAnti-corrosive paintsEpoxy resin coatingsActive agentSolvent free

The invention relates to a solvent-free epoxy rust confining coating capable of coating in a wet and rust environment. The solvent-free epoxy rust confining coating consists of two components A and B; the weight of the component A is 1.5 to 2.5 times that of the component B; in percentage by weight, the component A is prepared from 50 to 90 percent of main film forming resin, 20 to 40 percent of first reactive diluent, 1 to 3 percent of wetting leveling resin and 0.2 to 1.0 percent of solvent-free defoaming agent; in percentage by weight, the component B is prepared from 60 to 90 percent of curing agent, 2 to 10 percent of modifier and 5 to 15 percent of second reactive diluent. The main film forming resin is bisphenol F-type epoxy resin, an active agent is hyperbranched polyether-polyester resin terminated by phenolic hydroxy and carboxyl, the curing agent is mannich amide, and the modifier is ketimine. The rust confining primer disclosed by the invention has a low requirement for surface processing, can be constructed on a wet surface, is high in stability of a rusted position, and is excellent in long-acting protection performance on an integral object.

Owner:GUANGZHOU RAILWAY GRP CORP

Flame-retardance-type multi-layer wrapping anticorrosion system and construction method thereof

ActiveCN107955531AGood construction toleranceImprove adaptabilityAntifouling/underwater paintsHeat resistant fibresWeather resistanceAdhesive

The invention discloses a flame-retardance-type multi-layer wrapping anticorrosion system. The system comprises anticorrosion paste, a flame-retardance-type anticorrosion band, an oil separation basecoating, a flame-retardance-type nonmetal protection cover and a dirt-adhesive-resistance surface coating along the metal structure surface towards outside in sequence. The flame-retardance-type multi-layer wrapping anticorrosion system has excellent construction tolerance and adaptability, a long-acting and lasting anticorrosion effect, flame retardance, excellent dirt-adhesive-resistance and weather resistance and is attractive in appearance, wide in application field and particularly suitable for steel structure connection parts, local severe-corrosion parts, facilities of splash areas in ocean and the like, the anticorrosion effect can last for above 20 years, maintenance is not needed within the anticorrosion validity period, and the system has remarkable economic benefits and wide popularization prospects.

Owner:青岛海弗莱安全科技有限公司

Water-based rust conversion priming paint and preparation method

InactiveCN107033686AImprove water resistanceImprove stabilityAnti-corrosive paintsWater basedEmulsion

The invention belongs to the technical field of metal anticorrosive coatings and relates to a water-based rust conversion priming paint and a preparation method. The water-based rust conversion priming paint comprises the components of, by weight, 30-60 parts of vinylidene chloride compound macromolecule emulsion, 20-40 parts of color filling slurry, 5-15 parts of 2-hydroxyl propyl-3,4,5-trihydroxybenzoic acid rust conversion agent, 0.05-0.1 part of antifoaming agent and 0.1-0.5 part of thickening agent. The rust conversion agent is good in water resistance, high in stability and excellent in matching with water-based and oil-based paints, and the workability, the conversion efficiency and the corrosion resistance are all relatively high.

Owner:SHANDONG UNIV OF SCI & TECH

Powder coating with effect of color changing along with angle and preparation method thereof

ActiveCN103131306AImprove mechanical propertiesImprove adhesionPowdery paintsEpoxy resin coatingsEpoxyColor changes

The invention belongs to the field of powder coating and particularly relates to power coating with an effect of color changing along with an angle. The powder coating with the effect of color changing along with the angle comprises epoxy resin, an epoxy resin particle system corresponding to a matched curing agent A and color changing pigments and a fluorocarbon resin particle system with fluorocarbon resin and a matched curing agent B. The parts by weight ratio of the epoxy resin particle system and the fluorocarbon resin particle system is 7-3:3-7. According to the powder coating, the color changing pigments are adhered in an epoxy resin layer successfully through bonding technology. In the process of curing, the color changing pigments are sunk into the coating bottom instead of floating to the surface of the coating along with the epoxy resin. A transparent fluorocarbon resin layer floating to the upper layer has the function of protecting the color changing pigments so that the color changing pigments are antioxidative. A structure of the color changing pigments is not damaged in the whole process and the color changing effect is thoroughly played.

Owner:NINGBO SOUTH SEA CHEM

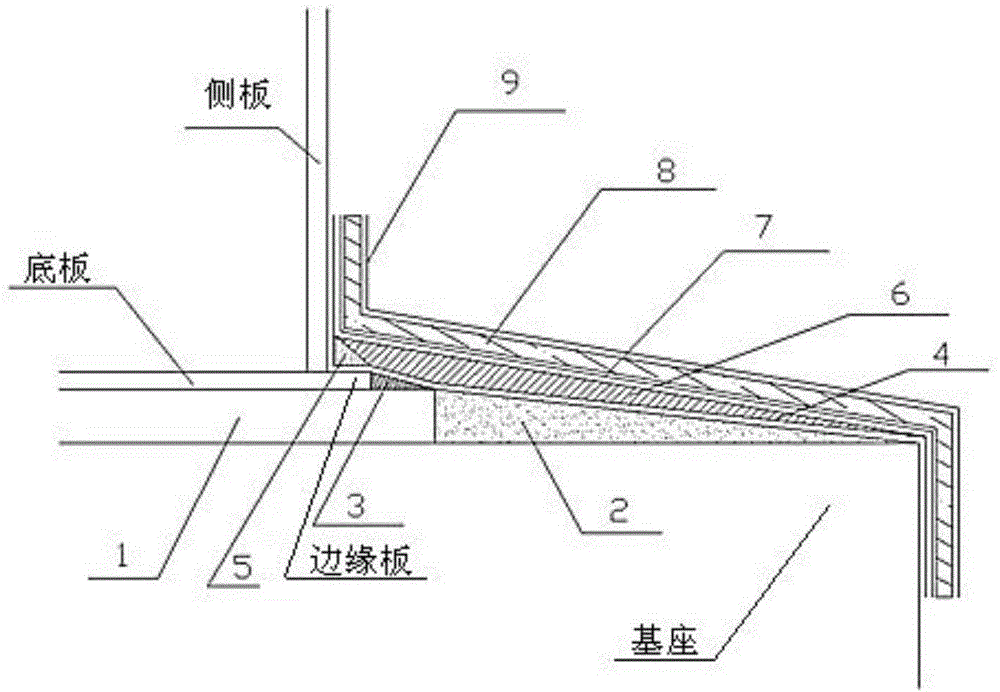

Anticorrosion structure and treatment method of outer bottom edge board of gas chamber

ActiveCN104912208ALow surface treatment requirementsLow costBuilding insulationsBulk storage containerPolymer scienceGas chamber

The invention is applicable to the technical field of anticorrosion, and provides an anticorrosion structure and a treatment method of an outer bottom edge board of a gas chamber. A multi-layer wrapping structure is formed on a gas chamber wall, the gas chamber edge board, an asphalt mortar layer and a concrete foundation, and a cement motor apron slope (2), an anticorrosion agent (3), a first elastic polymer bottom coating (4), a first elastic polymer cement gum layer (5), a second elastic polymer cement gum layer (6), a second elastic polymer bottom coating (7), a viscoelastic body anticorrosion rubber belt (8) and an elastic polymer weather-resisting finishing coating (9) are arranged from inside to outside sequentially. The surface treatment requirement is low, and the structure has the good adhesive property with concrete, steel materials and the like, after curing, a seamless waterproof layer with a complete coating is formed, the elasticity is achieved, deformation generated by weight bearing or high temperature of the gas chamber can be absorbed well, and the effects of no cracks, non pulling off and non falling off can be achieved; and the structure is simple, easy and convenient to construct, convenient to maintain and low in cost and saves time and labor; and the good sealing performance and anticorrosion property are achieved, and the service life can reach more than 10 years.

Owner:WISDRI ENG & RES INC LTD

Metal powder coating for enhancing flash effect and preparation method thereof

ActiveCN103146272AAvoid the problem of easy rub offImprove mechanical propertiesPowdery paintsEpoxy resin coatingsEpoxySurface layer

The invention belongs to the field of metal powder coatings, and in particular relates to a metal powder coating for enhancing a flash effect. The metal powder coating for enhancing the flash effect comprises an epoxy resin particle system containing epoxy resin, a correspondingly adaptive curing agent A and flash metal pigment, and a fluorocarbon resin particle system containing fluorocarbon resin and an adaptive curing agent B. The weight part ratio of the epoxy resin particle system to the fluorocarbon resin particle system is (6-4):(4-6). According to the metal powder coating for enhancing the flash effect disclosed by the invention, thick aluminium-silver powder is successively bonded into an epoxy resin layer by using a binding process, so that the thick aluminium-silver powder is deposited in the bottom layer of a coating together with the epoxy resin layer in the curing process and cannot float in the surface layer of the coating; and a transparent fluorocarbon resin layer floating to the upper layer plays a role of protecting oxidative resistance of flash metal powder.

Owner:NINGBO SOUTH SEA CHEM

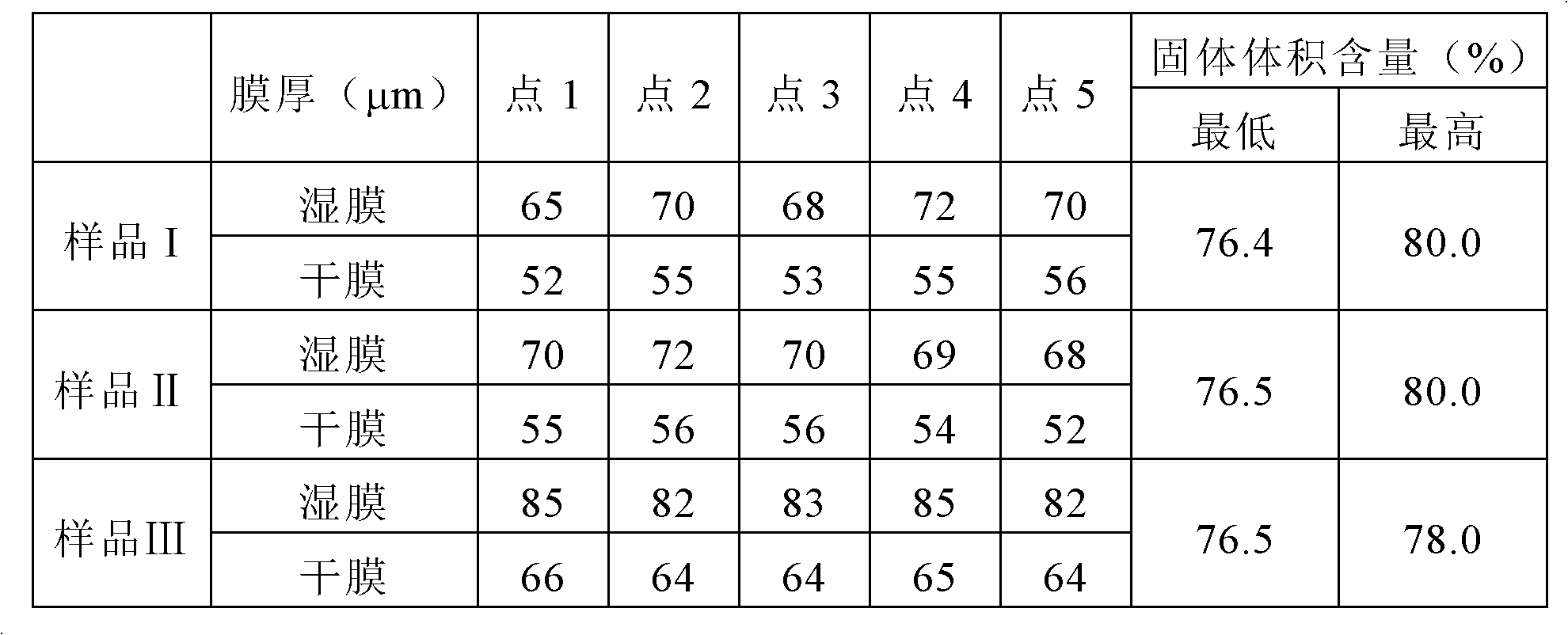

High solid labour-saving paint

InactiveCN102604511ALower requirementShorten the construction periodAnti-corrosive paintsEpoxy resin coatingsVolatile organic compoundCorrosion

The invention relates to high solid labour-saving paint which can reduce VOC (volatile organic compound) discharge and has solid volume content of being 80%, belonging to the technical field of paint. The paint is composed of base material A and curing material B, wherein the curing material B contains a curing agent, a reactive diluent and a non-ionic surfactant. The paint provided by the invention can realize the solid volume content of being higher than 80%, VOC can be effectively reduced, and green and environmental development direction of the paint industry can be met. The paint disclosed by the invention realizes construction 'with rust and moisture' in heavy-duty corrosion protection of steel, and influence of the environment to the construction can be eliminated to the utmost extent.

Owner:DALIAN UNIV OF TECH +2

Low-surface treatment heavy anti-corrosion coating as well as preparation method and application thereof

ActiveCN113045955ASolving Toxic ProblemsImprove environmental performanceAnti-corrosive paintsEpoxy resin coatingsWeather resistanceFirming agent

The invention belongs to the technical field of coatings, and discloses a low-surface treatment heavy anti-corrosion coating as well as a preparation method and an application thereof. The coating is prepared from the following raw materials: a component A: first film-forming resin, second film-forming resin, an epoxy diluent, hydrocarbon resin, titanium dioxide, mineral powder, an anti-rust pigment, inorganic matter powder, a coupling agent, a pigment and an auxiliary agent; and the component B comprises a first curing agent, a second curing agent, a modifier, an accelerant and an adhesion promoter. The coating disclosed by the invention takes the bio-based resin as a main film-forming substance, has higher environmental protection performance, is low in base surface treatment requirement, can be coated in a state with water, moisture and rust, can independently form a coating, can also be compounded with weather-resistant finish paint, and is long in anti-corrosion time and good in adhesive force and salt spray resistance.

Owner:河北涂铠新材料科技有限公司

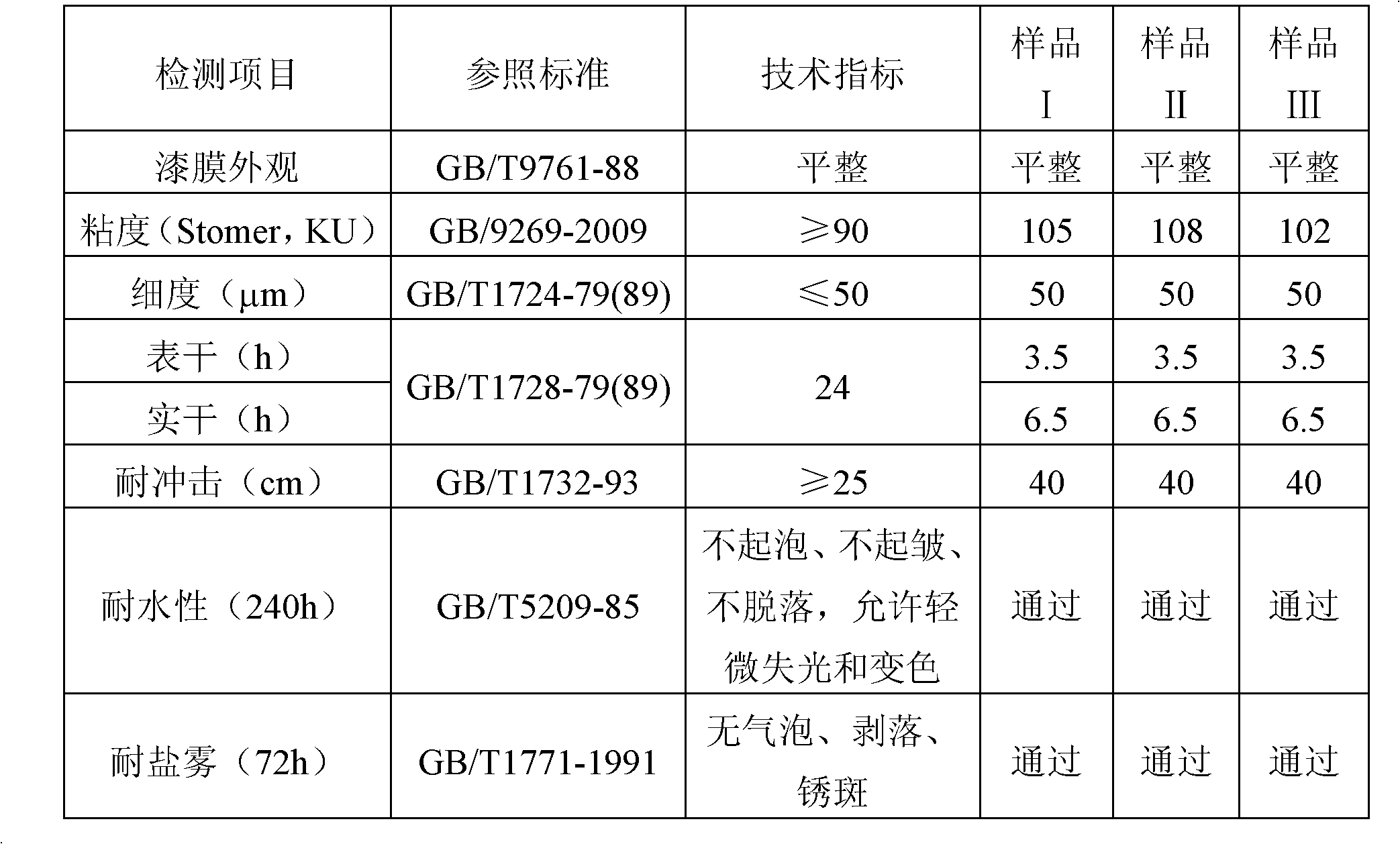

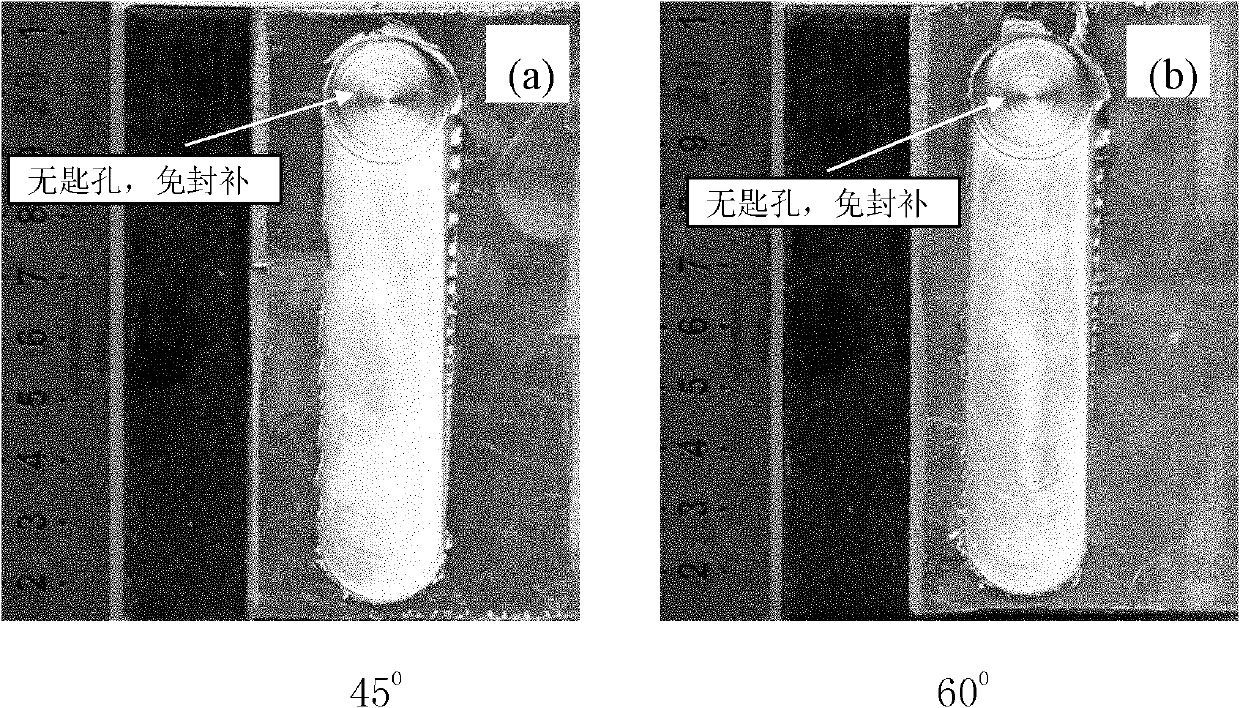

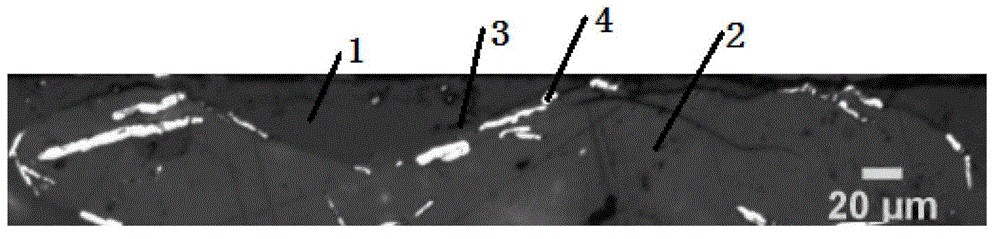

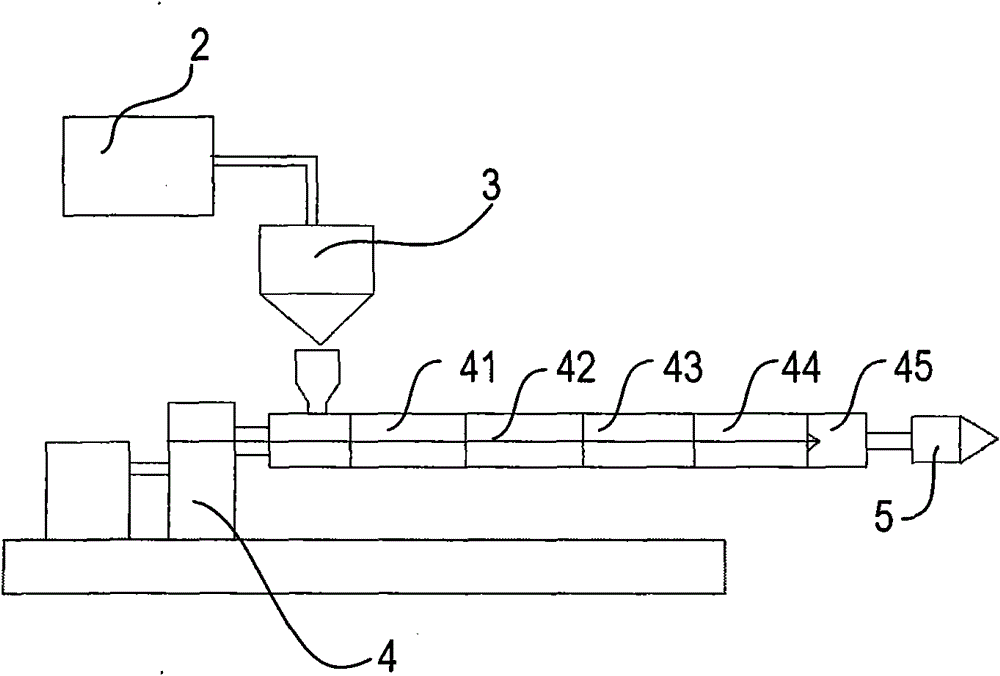

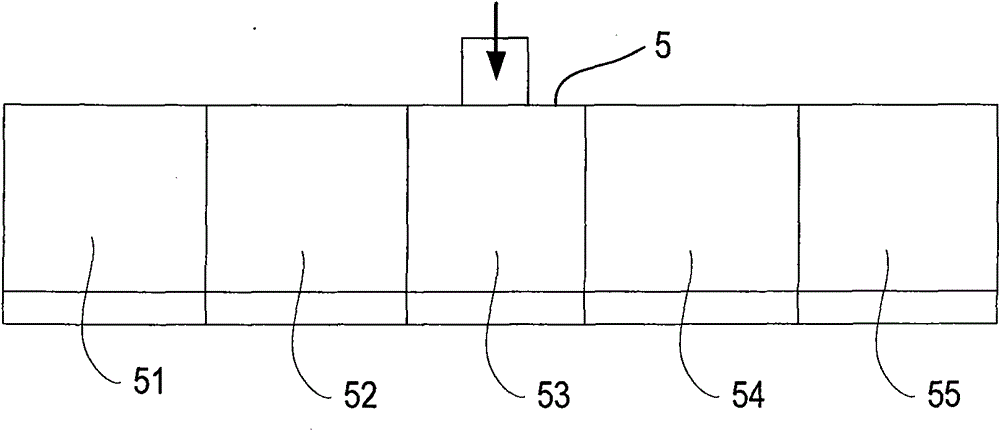

Embedded stirring and rubbing slit welding method

InactiveCN102120287BImprove bindingAvoid too thickNon-electric welding apparatusNeedle freeEngineering

The invention discloses an embedded stirring and rubbing slit welding method for dissimilar metals, which is especially suitable for large-area lap connection of aluminum or magnesium or harder metal materials. The embedded stirring and rubbing slit welding method comprises the steps of: firstly, processing one or more dovetail grooves on a second harder base material; secondly, assembling according to a lap connection form, and placing an aluminum plate on the upper sides of the dovetail grooves of the second harder base material; using a needle-free stirring head and installing in an inclining manner; starting the stirring head to rotate and enabling the stirring head to be in contact with the upper surface of the aluminum plate, wherein the pressing depth of the stirring head is limited to about between 0.1mm and 2mm and a welding interface needs not to be penetrated; after rubbing and preheating for several seconds at the starting end, moving the rotating stirring head or operating platform so that the aluminum plate is helically extruded in a groove of a lower plate and the welding or cladding is completed. Compared with the resistance slit welding, the method disclosed by the invention has remarkable energy saving advantage. Compared with the traditional stirring rubbing welding, the method disclosed by the invention has the advantages of no keyhole and no abrasion to needles by the harder base material. The method can be used for welding, and can also be used for preparing a bimetal composite plate.

Owner:西安英特金属复合材料有限公司

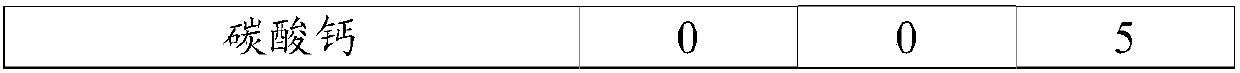

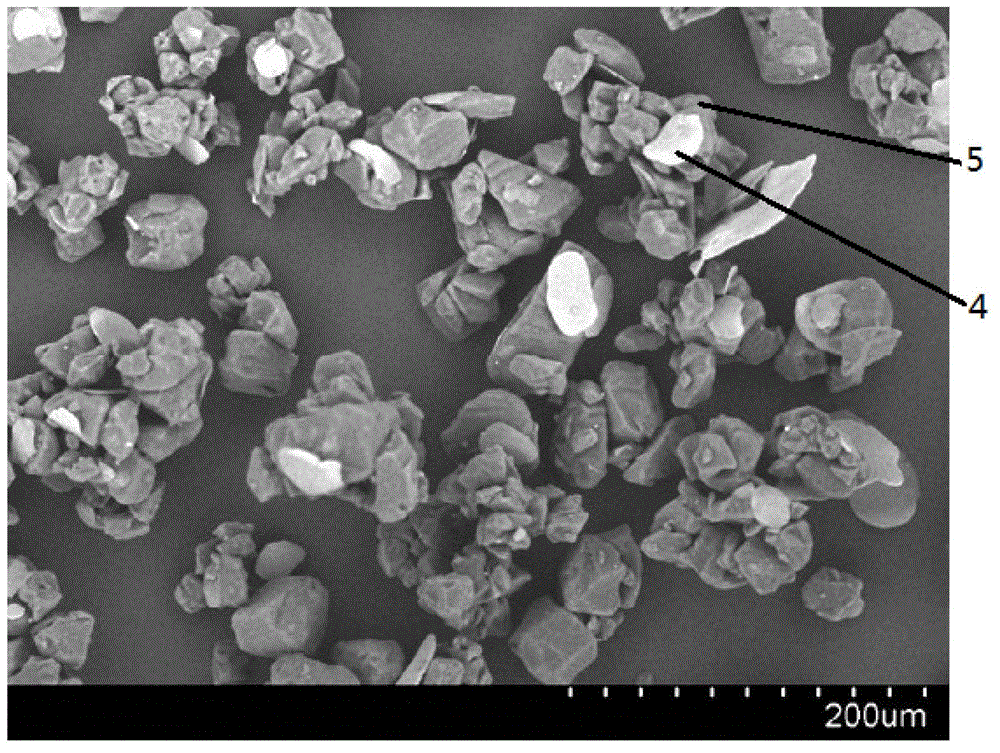

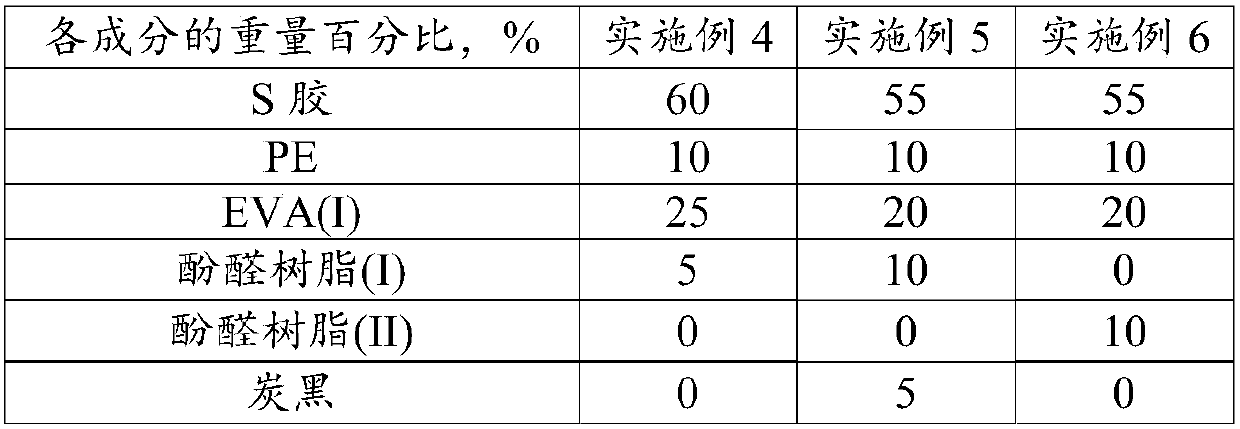

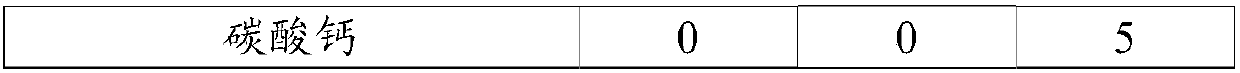

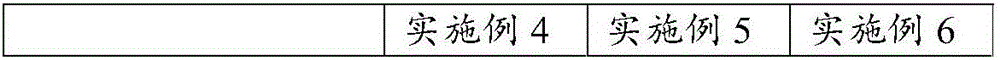

Hot melt adhesive, preparation method and application of hot melt adhesive, and heat shrinkable sleeve

InactiveCN107892887AExcellent performance indexImprove performanceNon-macromolecular adhesive additivesBituminous material adhesivesHeat-shrinkable sleevePolymer science

The invention discloses a hot melt adhesive, a preparation method and an application of the hot melt adhesive, and a heat shrinkable sleeve. The hot melt adhesive is prepared from the following main components in percentages by weight: 30 to 80% of asphalt mastic, 15 to 50% of thermoplastic resin, 5 to 40% of thickening resin, 0 to 5% of an antioxidant and 0 to 20% of a filling material. The preparation method for the hot melt adhesive comprises the following steps: weighing of raw materials in a formula proportion, mixing under heating, cooling and molding. The invention alleviates problems like poor binding properties, narrow application range and no resistance to low temperature for a conventional hot melt adhesive. The hot melt adhesive provided by the invention has excellent binding properties and high peel strength to PE, steel and epoxy primer; meanwhile, the preparation method for the hot melt adhesive provided by the invention has the advantages of convenience in operation andcontrol, low energy consumption, low cost, easy implementation of large-scale production, and facilitation of further promotion of industrial development.

Owner:NITTO QINGDAO TECH RES INST CO LTD

Improved heat resistance and corrosion resistance thermal spray coating and preparing method thereof

ActiveCN106318197ALow surface treatment requirementsReduce processing costsFireproof paintsAnti-corrosive paintsThermal sprayingPliability

The invention provides an improved heat resistance and corrosion resistance thermal spray coating. The coating comprises, by weight, 15-20 parts of polyamide-imide resin, 5-10 parts of polyethersulfone resin, 20-30 parts of ketones solvent, 15-20 parts of viscosity modifier, 15-25 parts of aluminium paste, 0. 5-1.5 parts of triethylamine, 3-6 parts of nano-alumina, 1-3 parts of inorganic filler, 0.5-1.5 parts of leveling agent. Accordingly, the invention also provides the preparing method for the coating and the product obtained features excellent comprehensive performance, good hardness, friction resistance, flexibility, impact resistance and heat resistance. It can replace thermal spraying aluminum coating as a new protection coating, meet the corrosion requirements for salt-spray corrosion, water and oil when using cookers, and has good adhesive force with iron cookers.

Owner:JIANGMEN ANNUOTE COOKING UTENSILS MFG

Two-component high zinc epoxy priming paint and preparation method thereof

InactiveCN104804609AHigh hardnessImprove adhesionAnti-corrosive paintsEpoxy resin coatingsWaxAlcohol

The invention provides a two-component high zinc epoxy priming paint and a preparation method thereof. The two-component high zinc epoxy priming paint comprises a component A and a component B; the component A is a modified polyamide curing agent; the component B comprises 6-9wt% of epoxy resin, 0.2-0.5wt% of a modified polyamide wax thickener, 5-10wt% of an alcohol and alcohol ether ester environmentally-friendly solvent, 0.3-1wt% of a silane coupling agent and 80-88wt% of zinc powder; and the two-component high zinc epoxy priming paint is prepared by mixing the component A with the component B according to a weight ratio of the component B to the component A of 100:(2-5). The priming paint adopts the curing agent to cure, and can resist various solvents, the mass fraction of solids is greater than 90%, the zinc content in non-volatile matters reaches above 96%, a film obtained by using the priming paint has high hardness and good adhesion and can provide good protection when a coating layer is damaged, and the priming paint has the advantages of no layering or precipitation after long-term storage, convenient construction, low surface treatment requirements, and easy popularization.

Owner:福建百花化学股份有限公司

Metal powder coating for enhancing flash effect and preparation method thereof

ActiveCN103146272BAvoid the problem of easy rub offImprove mechanical propertiesPowdery paintsEpoxy resin coatingsEpoxySurface layer

The invention belongs to the field of metal powder coatings, and in particular relates to a metal powder coating for enhancing a flash effect. The metal powder coating for enhancing the flash effect comprises an epoxy resin particle system containing epoxy resin, a correspondingly adaptive curing agent A and flash metal pigment, and a fluorocarbon resin particle system containing fluorocarbon resin and an adaptive curing agent B. The weight part ratio of the epoxy resin particle system to the fluorocarbon resin particle system is (6-4):(4-6). According to the metal powder coating for enhancing the flash effect disclosed by the invention, thick aluminium-silver powder is successively bonded into an epoxy resin layer by using a binding process, so that the thick aluminium-silver powder is deposited in the bottom layer of a coating together with the epoxy resin layer in the curing process and cannot float in the surface layer of the coating; and a transparent fluorocarbon resin layer floating to the upper layer plays a role of protecting oxidative resistance of flash metal powder.

Owner:NINGBO SOUTH SEA CHEM

Hot melt adhesive, thermal shrinkable sleeve, and preparation method and application of hot melt adhesive

InactiveCN107892886AImprove sealingImprove anti-corrosion performanceNon-macromolecular adhesive additivesBituminous material adhesivesThermoplasticPolymer science

Owner:NITTO QINGDAO TECH RES INST CO LTD

Hot melt adhesive used for pipeline anticorrosion, preparation method thereof, and thermal shrinkable sleeve

InactiveCN106520021AImprove performanceLow surface treatment requirementsNon-macromolecular adhesive additivesBituminous material adhesivesAsphalt masticHot-melt adhesive

The invention relates to a hot melt adhesive used for pipeline anticorrosion, a preparation method thereof, and a thermal shrinkable sleeve. The hot melt adhesive used for pipeline anticorrosion is mainly formed through mixing, by weight, 30-80% of asphalt mastic, 15-50% of thermoplastic resin, 5-40% of tackifying resin, 0-5.0% of an antioxidant and 0-20% of a filler. The problems of poor high-and-low-temperature application range and poor low-temperature performances are solved, and the hot melt adhesive has good low temperature resistance, good high temperature adhesion, good seal performance and good anticorrosion effect.

Owner:NITTO QINGDAO TECH RES INST CO LTD

Solvent-free type heavy anti-corrosion coating based on secondary doped polyaniline nanometer material

InactiveCN107474694AImprove mechanical propertiesImprove impact resistanceAnti-corrosive paintsPolyamide coatingsSolvent freePolyamide

The invention relates to a solvent-free type heavy anti-corrosion coating based on a secondary doped polyaniline nanometer material and belongs to the technical field of heavy anti-corrosion coating. The solvent-free type heavy anti-corrosion coating is characterized by comprising a component A and a component B; the weight ratio of the component A to the component B is 10:(2.6-3.2); the component A comprises the following components by weight percent: 32-40% of liquid epoxy resin, 7-18% of a nuclear shell rubber flexibilizer, 6-10% of a reactive diluent, 0.6-1.4% of a silane coupling agent, 1.2-2.5% of a dispersing agent, 0.3-0.7% of a de-foaming agent, 1.5-2.4% of a sterilizing agent, 0.6-1.2% of a thixotropic agent, 1.6-2.5% of a flatting agent, 4-12% of zinc phosphate, 4-8% of mica powder, 3.5-20% of superfine talcum powder and 7-12% of titanium dioxide, wherein the sum of the weight percent of the components is 100%; the component B comprises the following components by weight percent: 44-56% of phenolic amine, 20-44% of modified polyamide, 1.6-2.4% of a dispersing agent, 0.2-0.6% of a de-foaming agent, 2-6% of nanometer graphite powder, 7-15% of polyaniline and 0.4-0.8% of a thixotropic agent, wherein the sum of the weight percent of the components is 100%. The anti-corrosion coating provided by the invention is environmentally friendly and nontoxic and has the advantages of excellent mechanical properties, low surface processing requirement, applicability on wet and even water-containing metal substrate, excellent mold-proof and antibacterial properties, excellent corrosion protection and corrosion inhibition, high site construction operability, and the like.

Owner:QINGDAO UNIV OF SCI & TECH

Anticorrosive paint for die-cast aluminum heating radiator and preparation method of anticorrosive paint

InactiveCN107118693ALow surface treatment requirementsNo peelingFireproof paintsNatural resin coatingsPhenolphthaleinPhenol

The invention relates to anticorrosive paint for a die-cast aluminum heating radiator. The anticorrosive paint is composed of the following components in parts by weight: 35-55 parts of Ca-Zn-Se borophosphate, 15-25 parts of ceramic microbeads, 8.5-10 parts of betulin acid, 5-8 parts of modified phenolphthalein, 3-5 parts of iridium-acetylacetonate, 1.5-3.5 parts of acrylic acid, 0.6-1.2 parts of a wetting dispersant, 2.4-2.8 parts of tribenzyl phenol polyoxyethylene ether, 0.3-0.6 part of a thickening agent and 0.65-1.5 parts of an antifoaming agent. The anticorrosive paint disclosed by the invention has the advantages that 1, the production process is simple and reasonable, the input equipment is less, and the production cost is low; 2, the coating surface treatment requirement is low, the adsorption effect is excellent, the adhesive force is high, and the coating does not flake or discolor; 3, leveling and heat radiation effects are excellent, the heat transfer speed is high, and the heat efficiency is high; 4, the anticorrosive paint is resistant to acid, base and salt corrosion and seawater corrosion and excellent in anticorrosive effect; 5, the wear resistance and impact resistance are high.

Owner:ZHEJIANG YANGMING IND & TRADE CO LTD

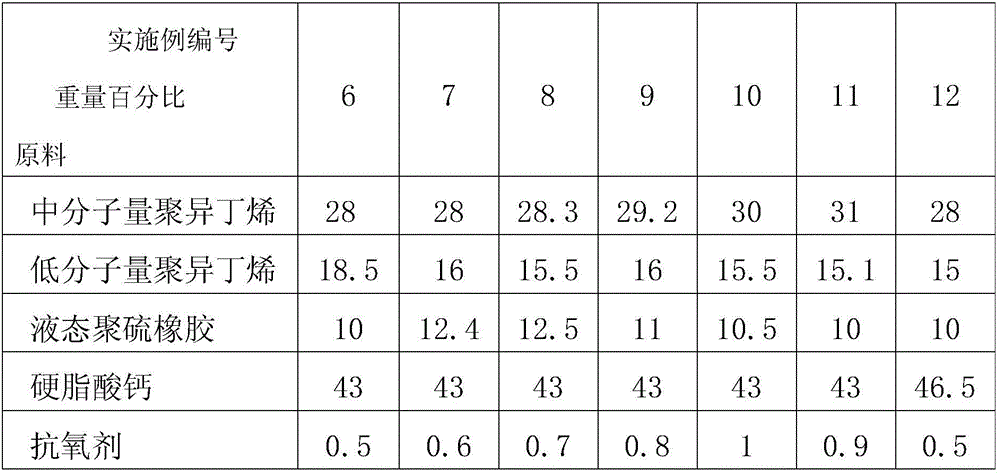

House leakage repair high-viscosity cold-flow adhesive tape and preparation method thereof

InactiveCN106590457AUnique cold fluidityRealize self-healing functionNon-macromolecular adhesive additivesFilm/foil adhesivesPolyesterPolysulfide rubber

The invention discloses a house leakage repair high-viscosity cold-flow adhesive tape, which is composed of, successively, a protective film, a house leakage repair high-viscosity cold-flow adhesive layer, and an isolation film. The protective film is a polyester film and the isolation film is a polyethylene film. The house leakage repair high-viscosity cold-flow adhesive layer is composed of, by weight, 28-31% of medium-molecular polyisobutylene, 15-18.5% of low-molecular polyisobutylene, 10-13.5% of liquid state polysulfide rubber, 43-46.5% of calcium stearate, and 0.5-1% of an antioxidant. A preparation method of the adhesive tape includes the steps of: kneading the raw materials into glue mud, feeding the glue mud into a reaction kettle to blend the glue mud, extruding the glue mud through an extruder, coating the isolation film with the glue mud, laminating the protective film, and rolling the adhesive tape through a double-roller to produce the product. The house leakage repair high-viscosity cold-flow adhesive tape has cold-flowability and auto-repairing function and can be used for seam repairing and leakage prevention for top floor of a house and leakage repairing for a fish tank and a circulating water tank.

Owner:绵阳市振华科技有限公司

Repair assembly for corrosion-resistant layer of buried pipeline and construction method

The invention discloses a repair assembly for a corrosion-resistant layer of a buried pipeline and a construction method. The repair assembly is arranged outside a pipeline body in a covering mode, isof a layered structure and sequentially comprises an oily petrolatum primer, an oily petrolatum adhesive tape, an outer protective belt and an armored outer protective belt. The construction method comprises the steps of surface treatment of the pipe body, specifically, the pipe body is derusted through a handheld angular derusting machine, and the surface of the pipe body is washed with alcoholor acetone; b, repair construction of the corrosion-resistant layer, specifically, the oily petrolatum primer is smeared on the surface of the pipe body, and the oily petrolatum adhesive tape is manually wound on the surface of the pipe body in a wrapping mode from left to right; and c, repair construction of the outer protective layer, specifically, the outer protective belt is manually wound from left to right to fix and seal the anti-corrosion layer inside, and the armored outer protective belt is spirally wound outside the outer protective belt. According to repair assembly for the corrosion-resistant layer of the buried pipeline and the construction method, multiple oily protective layers are continuously formed on the surface of the workpiece based on the hydrophobic corrosion-resisting mechanism of oily petrolatum so that corrosive media cannot permeate into the workpiece, generation and spreading of corrosion can be rapidly prevented, and the effect is remarkable.

Owner:蓝色海洋(天津)工程技术有限公司

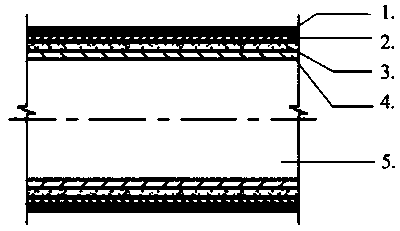

Anticorrosive viscoelastic body rubber belt and preparation method thereof

ActiveCN101935500BImprove adhesionUnique cold flow characteristicsNon-macromolecular adhesive additivesFilm/foil adhesivesCompound aAntioxidant

The invention relates to an anticorrosive viscoelastic body rubber belt, which comprises a protective film layer, a first viscoelastic body rubber belt, an enhanced network layer, a second viscoelastic body rubber layer and a release film layer arranged in turn, wherein the protective film layer is bonded with the first viscoelastic body rubber layer, the first viscoelastic body rubber layer is bonded with the enhanced network layer, and the enhanced network layer is bonded with the second viscoelastic body rubber layer to compound a whole body; and the release film layer is adhered to the second viscoelastic body rubber layer, wherein the viscoelastic body rubber is prepared from the following raw materials in percentage by weight: 3 to 10 percent of butyl rubber, 5 to 10 percent of high molecular weight polyisobutylene, 25 to 35 percent of medium molecular weight polyisobutylene, 10 to 15 percent of low molecular weight polyisobutylene, 30 to 45 percent of inorganic enhanced powder, 0.5 to 1.0 percent of antioxidant, 0.5 to 1.0 percent of anti-aging agent, and 0 to 1.0 percent of colorant. The viscoelastic body rubber belt has a self-healing function, is not brushed with a primer when used, and can be directly used for corrosion protection of irregular components. The invention also relates to a preparation method of the anticorrosive viscoelastic body rubber belt.

Owner:CYG CHANGTONG NEW MATERIAL

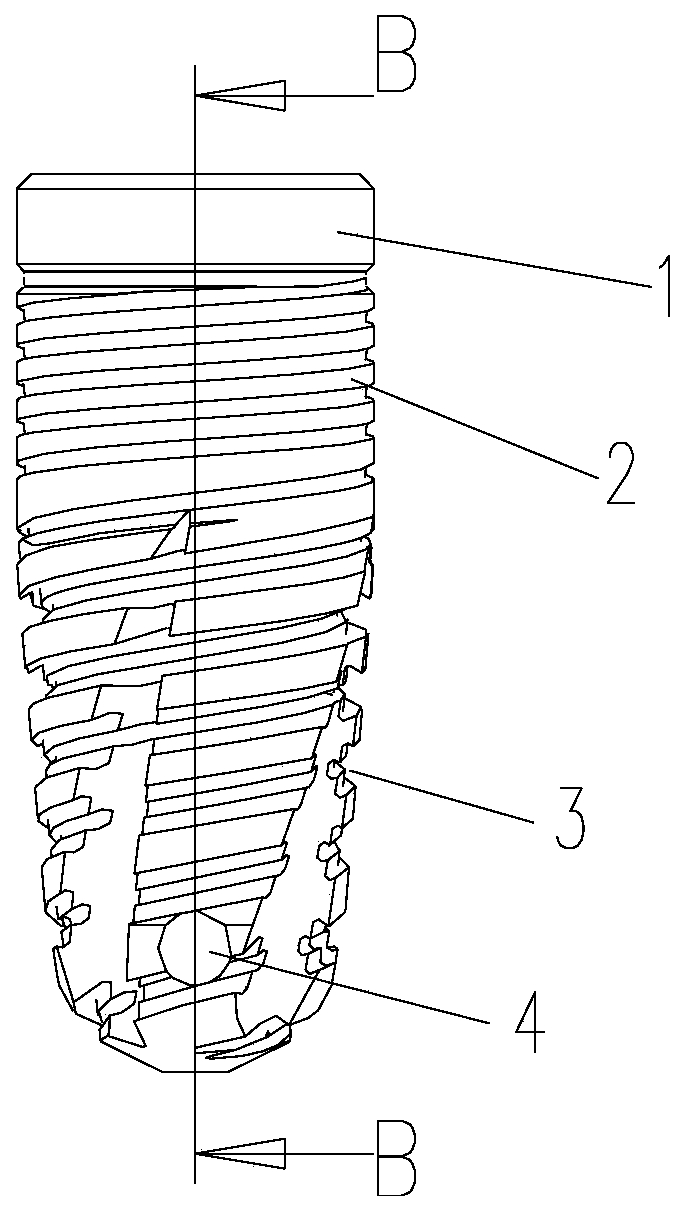

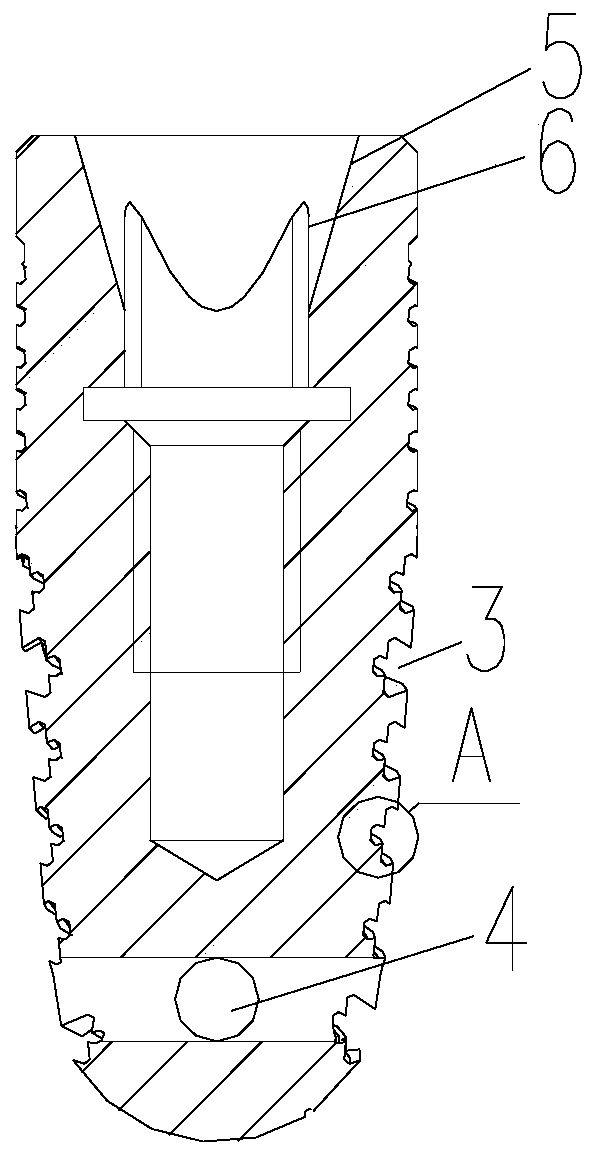

Dental implant with reducing thread

InactiveCN109938855AReduce lossIncrease success rateDental implantsOsteoblastUltimate tensile strength

The invention provides a dental implant with a reducing thread. The dental implant comprises an implant body. At least one continuous thread is arranged from the root to the periphery of the neck of the implant body. The thread pitch of the thread from the root to the neck is gradually reduced, containing grooves are formed between the two side faces of adjacent thread teeth, and the opening widths of the containing grooves are smaller than the groove bottom widths. One thread is adopted, the bone bonding strength of the implant can be improved, the adhesion rate of osteoblast is improved, proliferation and differentiation of the osteoblast implant surface in the early implantation period are obviously promoted, and the planting survival rate is greatly increased.

Owner:JIANGSU TRAUSIM MEDICAL INSTR

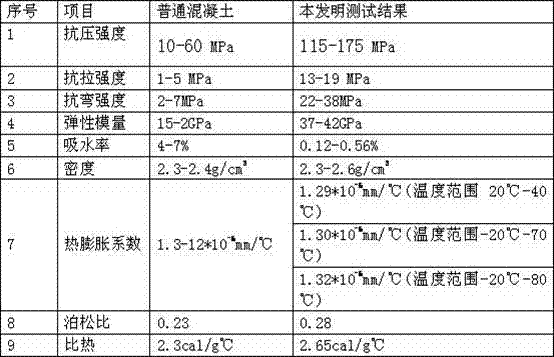

Machine tool body made from waste glass

The invention provides a machine tool body made from waste glass. The invention aims at providing a machine tool body made from waste glass, which has the advantages of being high in stability, good in anti-vibration performance, low in coefficient of thermal expansion, high in tensile strength and compressive capacity, and the like, and can utilize the waste glass as a raw material so as to realize recycling of resources and changing waste into valuable. The machine tool body is prepared from the following raw materials in parts by weight: 70-75 parts of waste glass fragments and crushed glass sand, 8-10 parts of glass powder, 7-10 parts of epoxy resin, 1.75-2.5 parts of a curing agent, 1 part of carbon fibers, 1 part of basalt fibers, 0-1 part of bismuth, 0-1 part of antimony, 8-10 parts of silica powder and 0-10 parts of alumina powder.

Owner:福建振丰矿物新材料有限公司

Latent active filler composition, solvent-free high-temperature-resistant permeation-resistant liquid polymer coating material, coating and preparation method thereof

ActiveCN112662218AHigh molecular weightHigh Tg valueAnti-corrosive paintsEpoxy resin coatingsPolymer scienceSolvent free

The invention discloses a latent active filler composition, a solvent-free high-temperature-resistant permeation-resistant liquid polymer coating material, a coating and a preparation method thereof. The latent active filler composition takes a solid epoxy resin composition EG as a main raw material and comprises the following components in percentage by mass: 60%-70% of the solid epoxy resin composition, 10%-13% of a modified phenolic curing agent, 0%-1.5% of pigments and fillers and 20.01%-26% of other aids, the latent active filler composition is added into the formula of the coating material and used as a latent active powder filler at normal temperature, and when the temperature of a coating using working condition exceeds 100 DEG C, the latent active filler begins to slowly react and crosslink and forms a multi-layer reticular three-dimensional composite structure with a liquid normal-temperature cured coating; the glass transition temperature and crosslinking density of the whole coating are greatly improved, and the purpose of high temperature resistance is achieved through latent secondary reaction. The coating material can be used for a long time in an acid-base-salt medium at the temperature of less than or equal to 130 DEG C.

Owner:大庆庆鲁朗润科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com